A machine tool faceplate-type centering device for a tooling fixture and a centering method thereof

A technology of tooling fixtures and centering devices, which is applied to positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problem that it cannot be accurately placed at a position that roughly coincides with the center of the machine tool, sometimes with a difference of tens of millimeters. Reduce the accuracy of the table spindle, scratches on the machine table, etc., to save manpower, improve alignment efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] see Figure 1-5 , the present invention provides a kind of technical scheme:

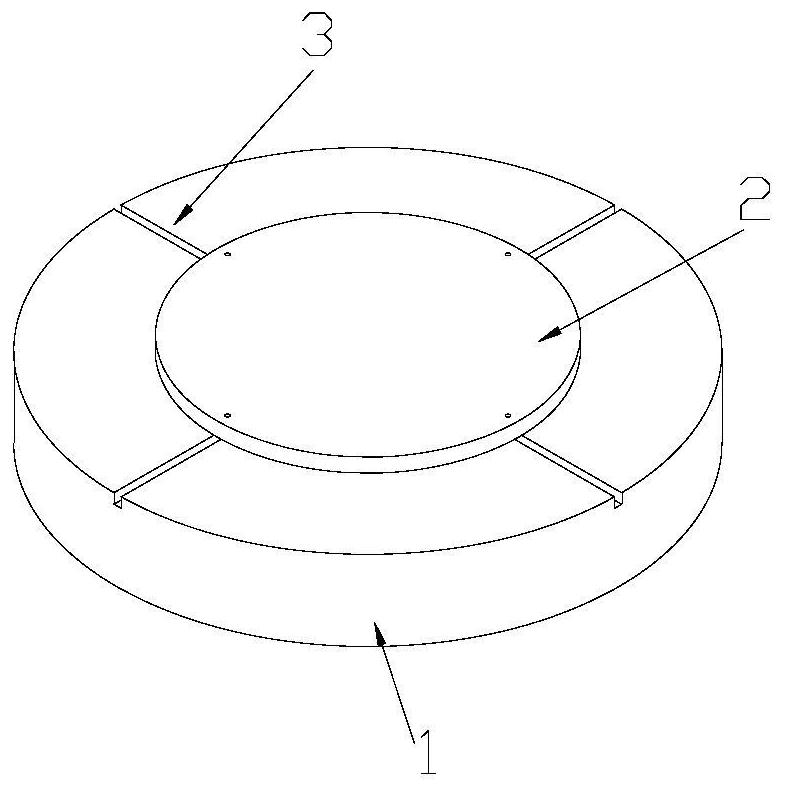

[0039] Please refer to Figure 1-4 , a centering device of the machine tool faceplate 1 type of a tooling fixture 2, comprising:

[0040] Machine tool faceplate 1;

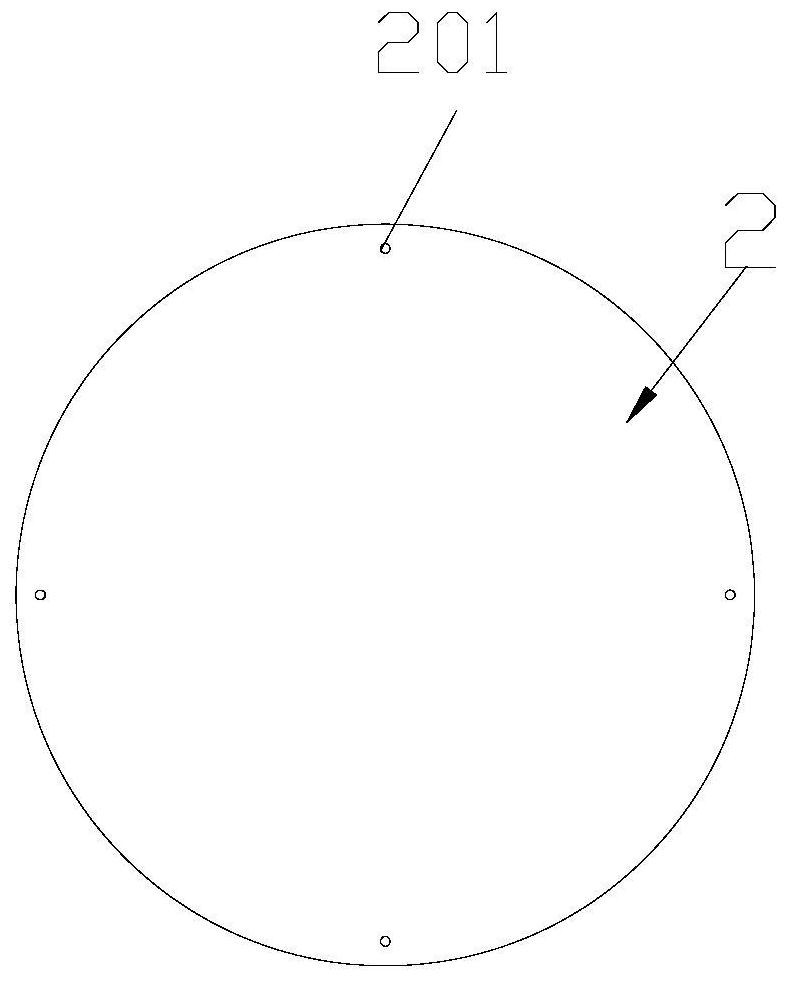

[0041] The tooling fixture 2 carried on the machine tool faceplate 1 and a number of positioning grooves 3 opened on the machine tool faceplate 1, and a number of the positioning grooves 3 are evenly arranged along the center of the machine tool faceplate 1; And,

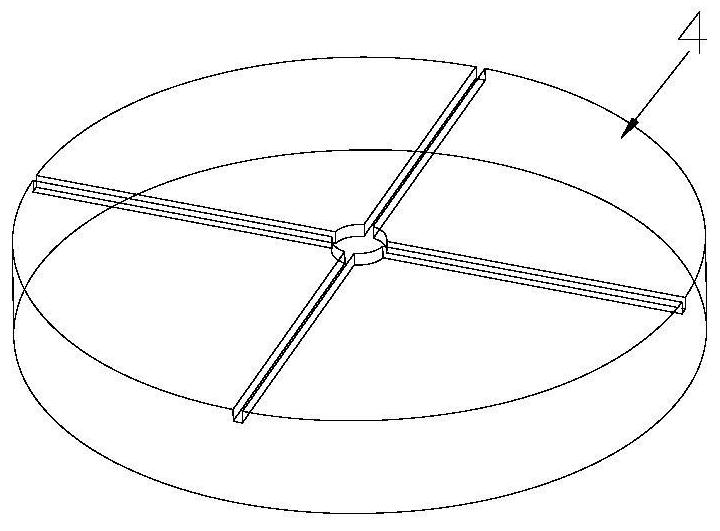

[0042] Several positioning blocks 4 are installed on the fixture 2 , one end of the positioning blocks 4 is threadedly connected with the fixture 2 , and the other end of the positioning blocks 4 is installed in sliding fit with the positioning groove 3 .

[0043] One end of the positioning block 4 of the present invention is installed on the fixture 2, and one end of the positioning block 4 can be slidably installed in the positioning groove 3 of the machine tool f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com