Processing method of small radius centring rectangular splined shaft

A processing method and technology for spline shafts are applied in the processing field of small diameter centering spline shafts, which can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of the present invention: carry out according to the following steps:

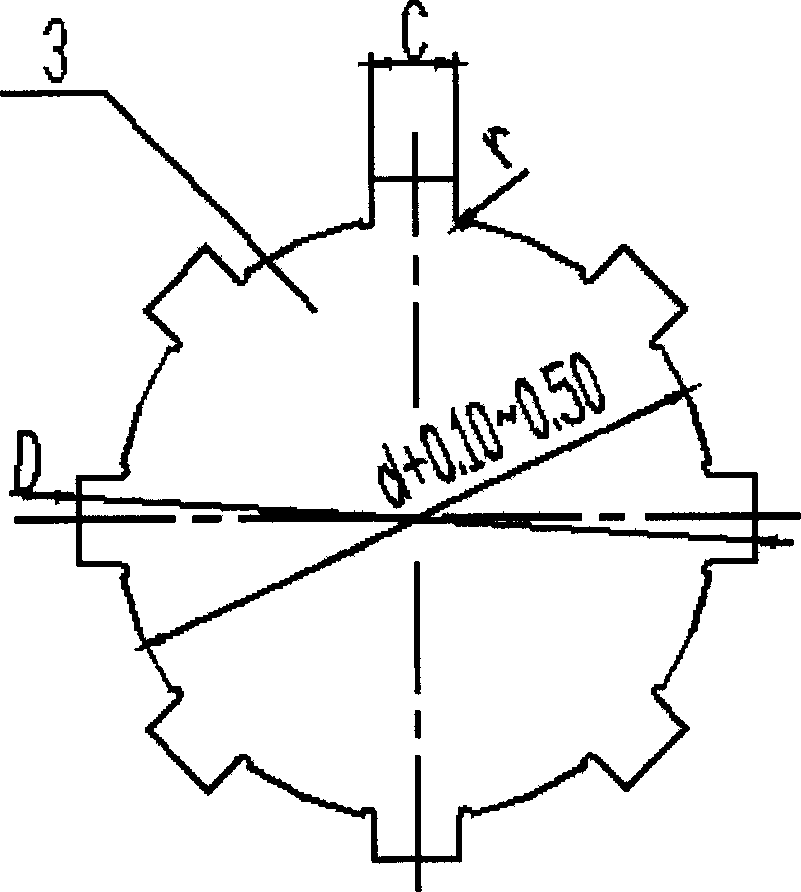

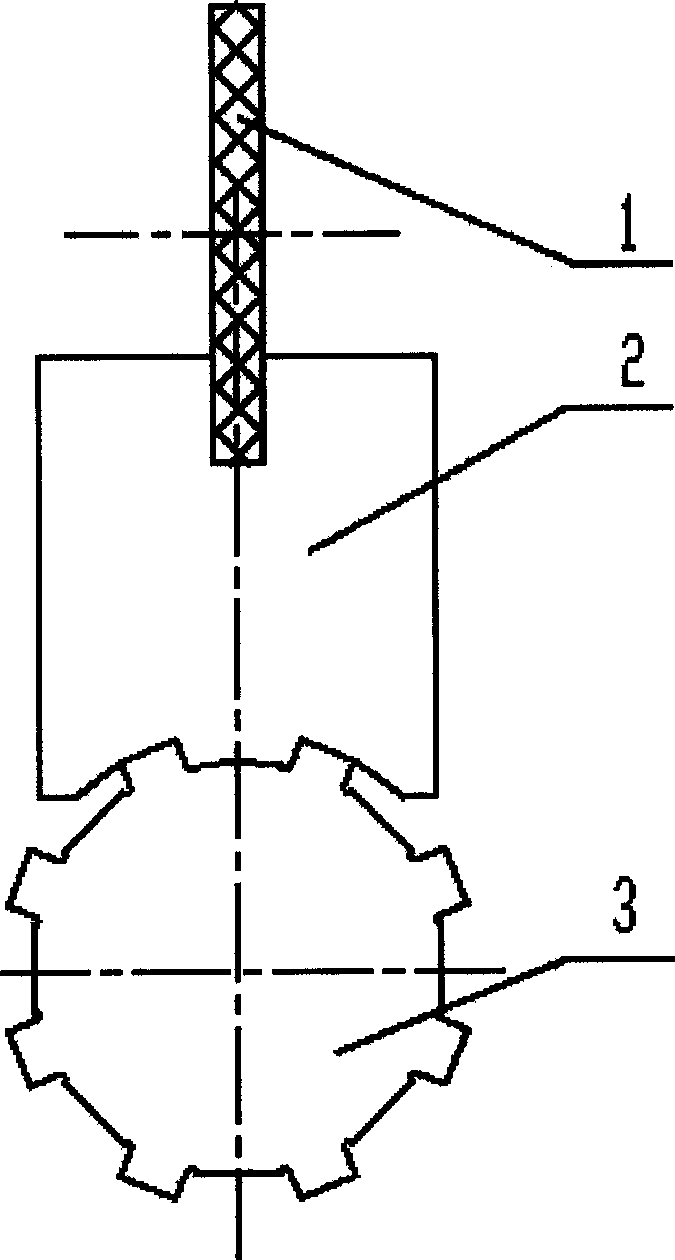

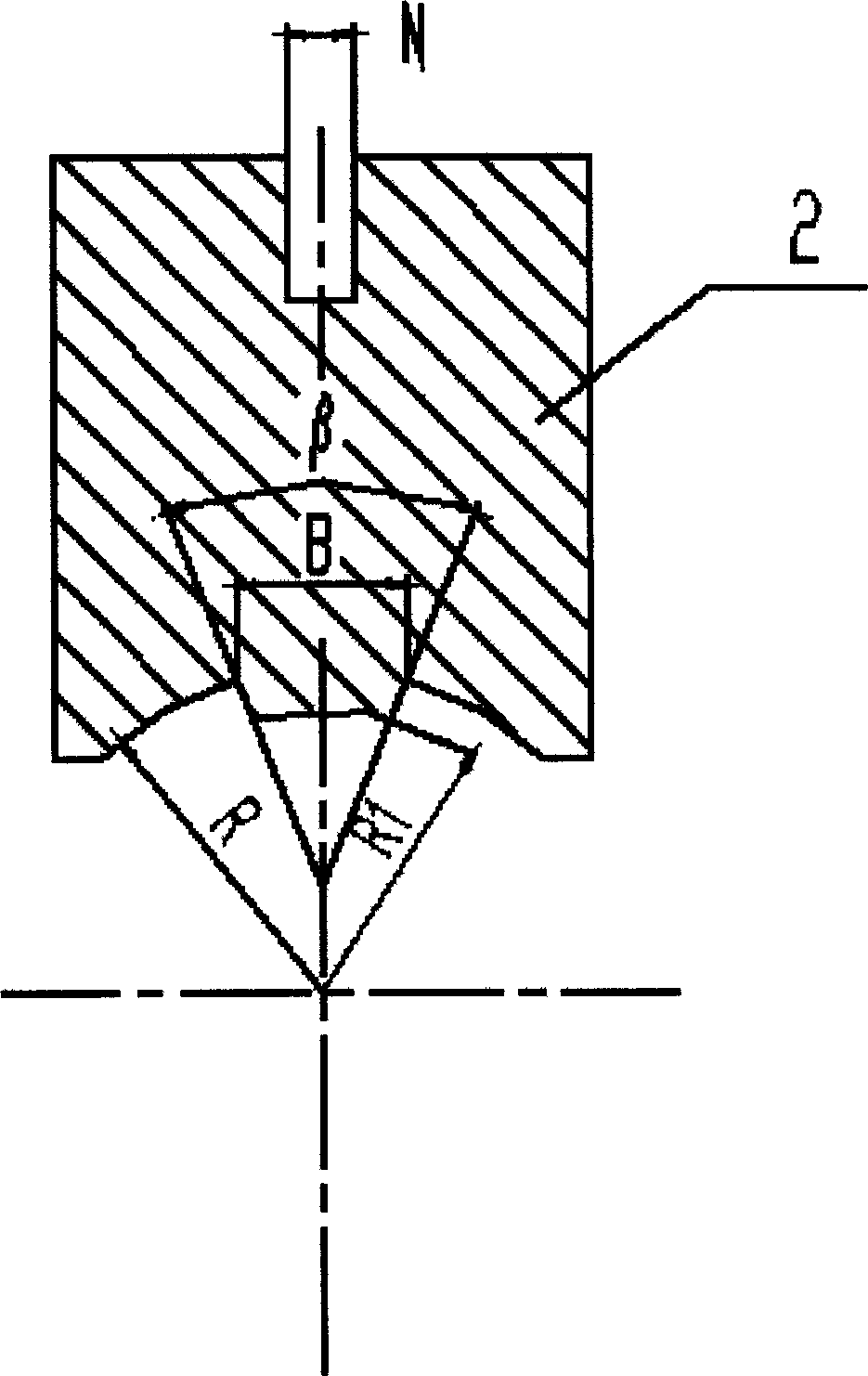

[0027] First: The processing status of spline shaft 3 before small diameter grinding is as attached figure 1 shown. Before grinding the small diameter of the spline shaft 3, use a spline hob (or milling cutter) to hob (or mill) the spline key width C to the size, and leave a certain grinding allowance for the spline minor diameter d. The size of the spline shaft is determined according to the size of the minor diameter d of the spline shaft, the length of the spline shaft, and the state of the heat treatment of the spline shaft. Generally, 0.10-0.5 mm can be selected. When hobbing or milling splines, in addition to leaving a certain grinding allowance for the spline key width C to size and the spline minor diameter d, it is also required to process the standard circular arc undercut groove r of the spline teeth. The groove is conducive to root cleaning when grinding the small diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com