Floating arch cofferdam and construction method

A construction method and cofferdam technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as difficult engineering, unrelated underwater foundation treatment problems, easy rollover of cofferdams, etc., to reduce pollution and avoid economic and loss of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

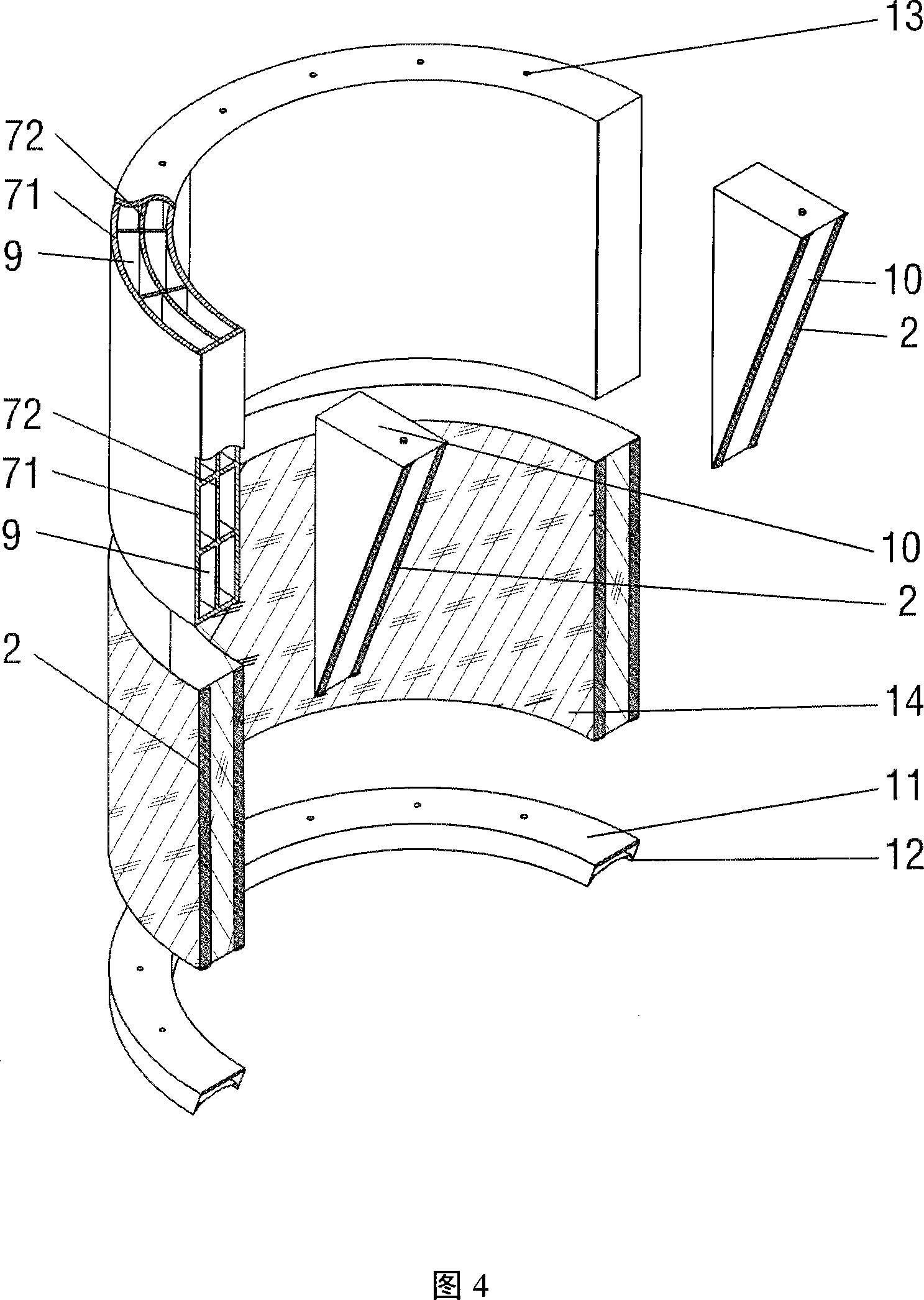

[0035] As shown in Fig. 3 and Fig. 4, the floating arch cofferdam 7 of the present invention is made of steel plates and reinforced concrete materials, the main body can adopt ordinary concrete, and the outer layer is an outer formwork steel plate made of thin steel plates; The water pressure varies with the water depth, so from a structural point of view, the width and thickness of the arch cofferdam can vary with the water depth. Generally, it can gradually become smaller from deep to shallow. As shown in Figure 5a and Figure 5b, the thickness of the upstream surface of the arch cofferdam remains constant with the water depth, and the thickness of the downstream surface of the arch cofferdam is gradually thickened, constant or stepped with the water depth. The surface can also gradually thicken with water depth like the downstream surface. However, considering the construction process and the use of the internal cabin 9, the vertical section should be selected to have the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com