Board splicing machine

A technology of a jigsaw and base plate, which is applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of high labor cost and material cost, slow processing speed, etc., and achieve uniform and stable quality and production speed. Faster, improved processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

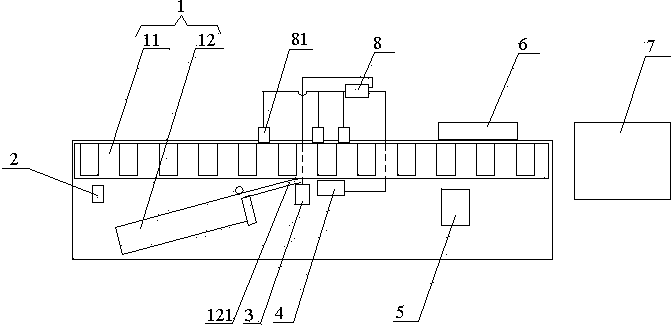

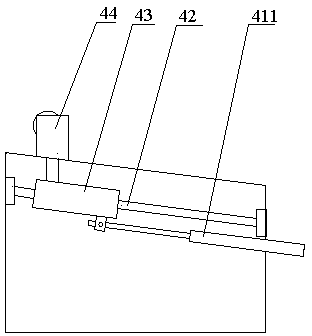

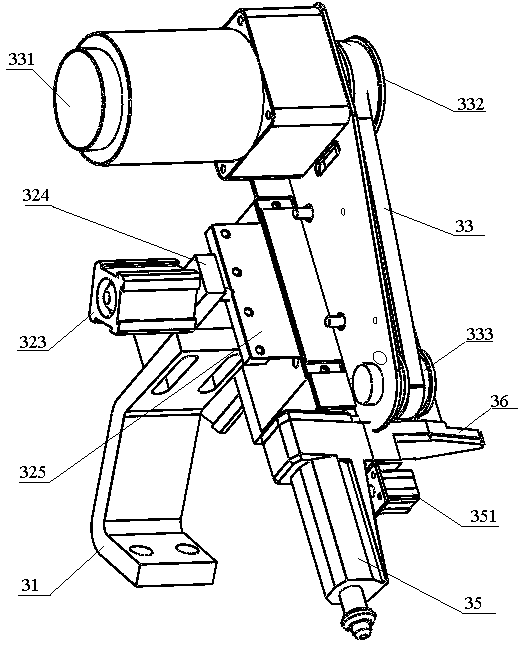

[0036] A jigsaw machine, such as figure 1 As shown, it includes a frame on which a board feeding device 1 , a gluing device 2 , a nail gun 3 , an alignment device 4 , a hot air device 5 and an auxiliary pushing device 6 are fixedly installed. The plate feeding device 1 includes a bottom plate conveyor belt 11 for transporting the bottom plate from right to rear and forward, and a side plate conveying trough 12 for transporting side plates to the side of the bottom plate conveyor belt. A glue applicator 2 is installed on the side of the inlet end of the bottom plate conveyor belt, and the glue applicator 2 is used to smear a layer of adhesive glue on the side of the bottom plate, so that the bottom plate and the side plate are closely bonded. A crimping device 7 is also provided outside the bottom conveyor belt in front of the outlet end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com