Apparatus and method for assembling shelving units

a technology of apparatus and shelving unit, which is applied in the field of apparatus and a method for assembling or putting together shelving units, can solve the problems of deformation of supplied shelves, no longer fitting into the frame, twisted or bent, etc., and achieves the effect of increasing process speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

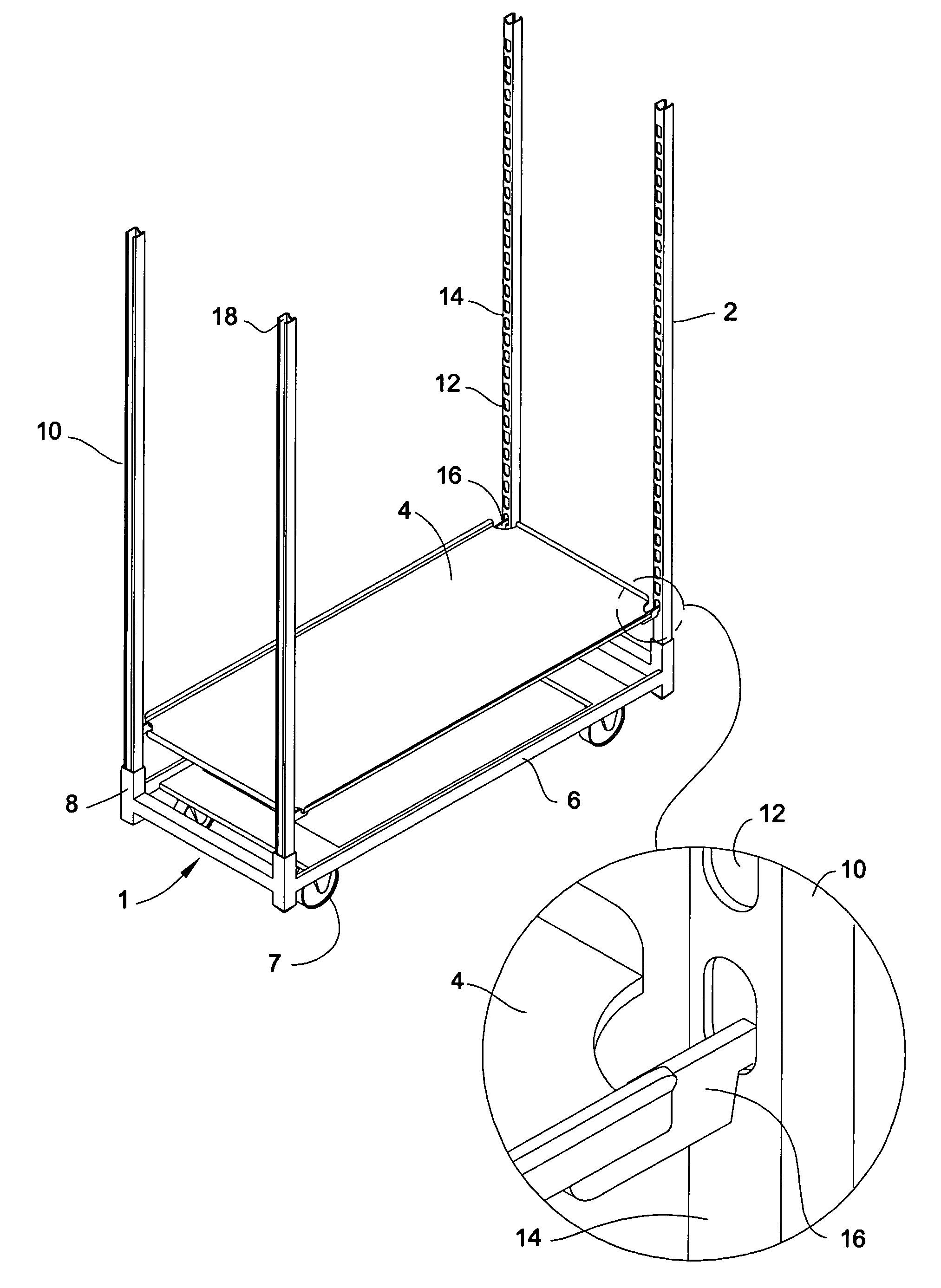

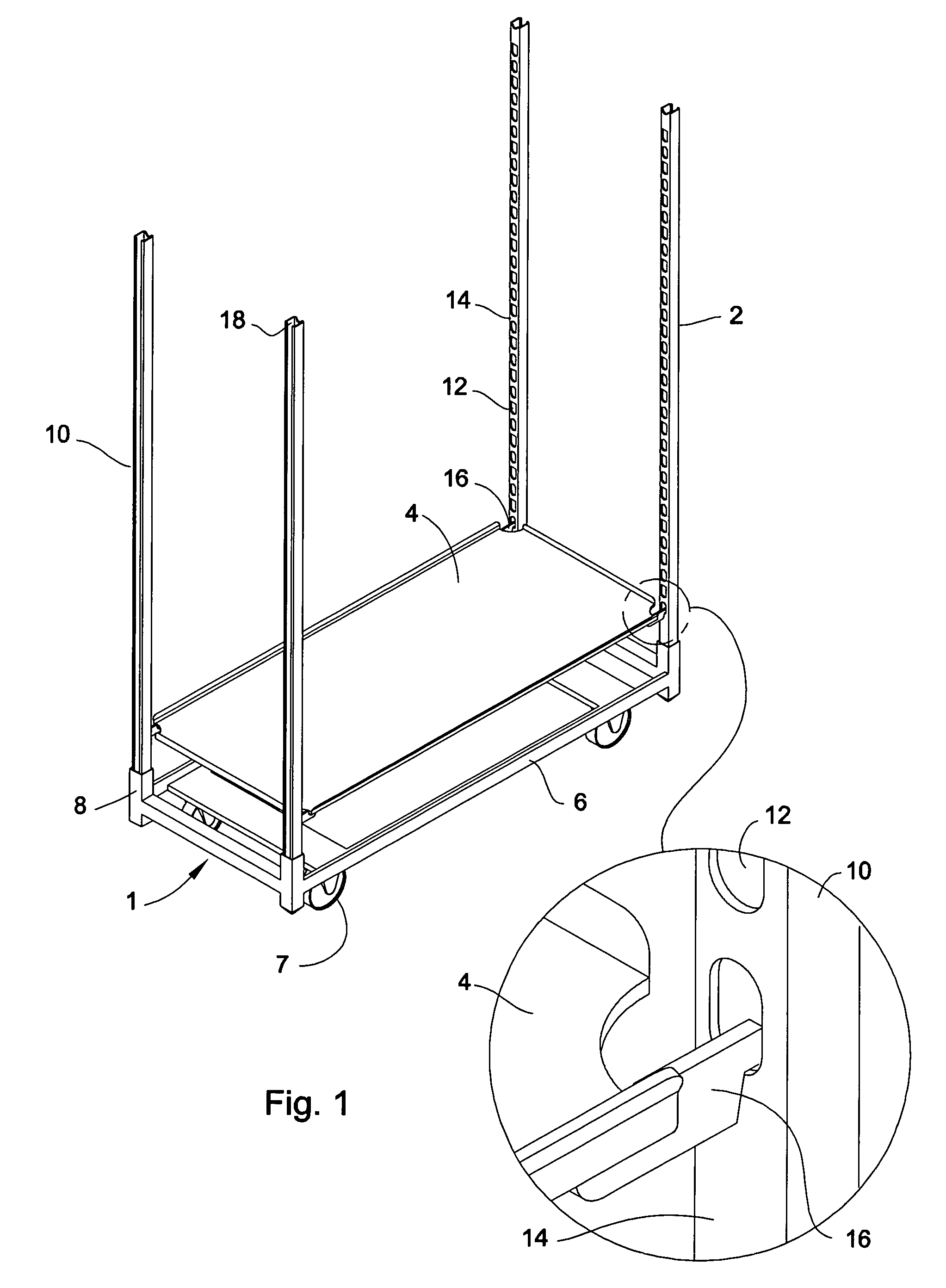

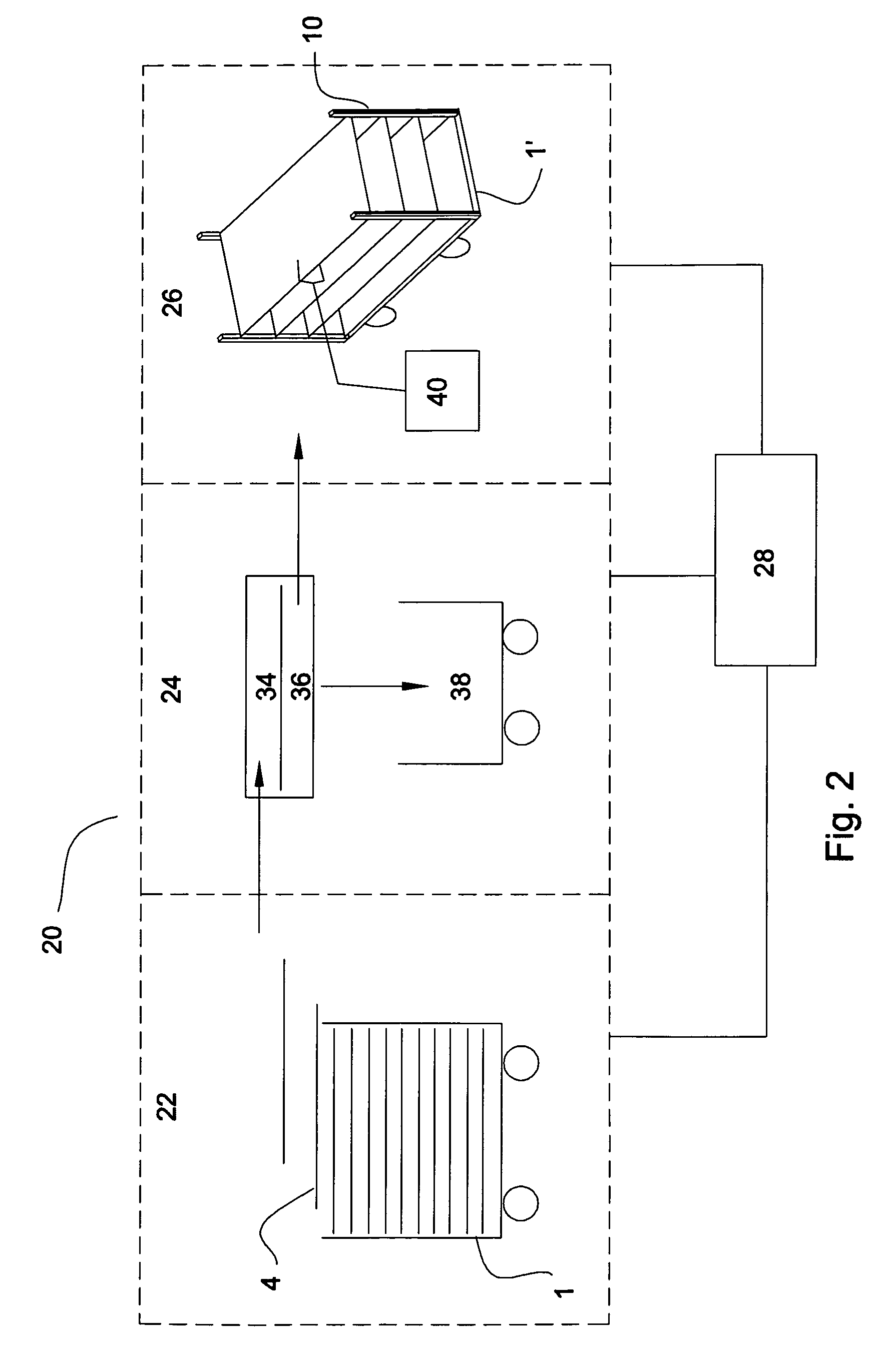

[0033]FIG. 1 shows a perspective view of a cart 1 of the type intensively used in the flower industry. The cart 1 comprises a frame 2 and a plurality of substantially planar shelves 4 mounted on the frame (for reasons of clarity only one shelf is depicted). In the current example the frame comprises a base 6 mounted on wheels 7. Each corner of the base has been provided with a socket 8 for receiving an upright 10. Although the invention will further be described in relation to such a cart for flowers, it will be immediately apparent for the person skilled in the art that the invention is also applicable to other forms of trolleys or shelving units. In this respect, it is assumed that the term shelf is not restricted to simple planar shelves or plates. The term shelf also comprises: shelving units; planks; baskets; cross elements and other supporting parts that may be utilized in a shelving system.

[0034]As is shown in detail in FIG. 1, each upright 10 comprises an essentially U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com