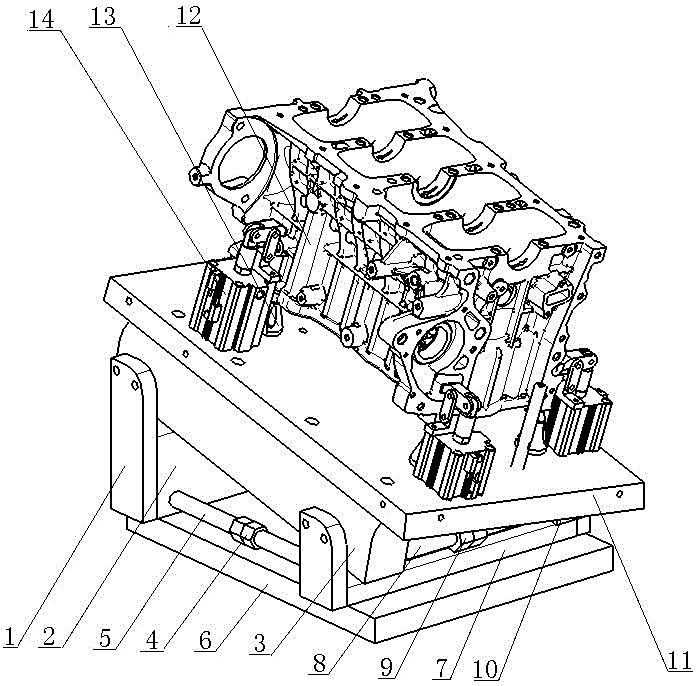

Engine cylinder oblique-hole processing clamp and aligning method thereof

A technology for engine cylinder blocks and fixtures, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of huge fixtures, angle errors that cannot be adjusted, and unusable, etc., to achieve accurate alignment, ensure accuracy, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

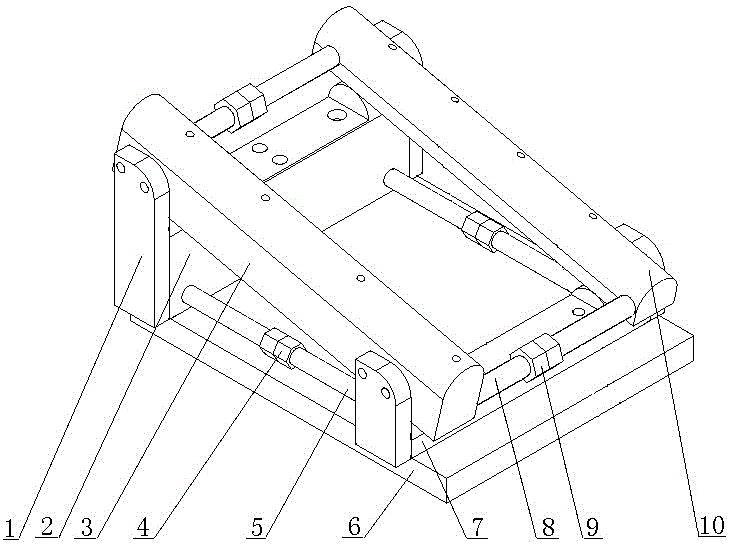

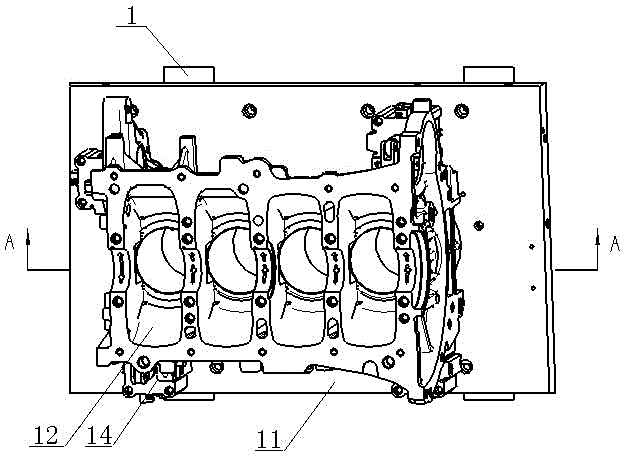

[0027] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described: figure 1 , figure 2 , image 3 , Figure 4 As shown, a jig for drilling inclined holes in an engine block includes a jig plate 11 on which a positioning device 13 and a clamping device 14 are arranged. The inclined hole axis 15 on the top is parallel to the main shaft of the machine tool; the left side of the fixture plate 11 is parallel to the YZ plane of the machine tool coordinate system, and the rear side of the fixture plate 11 is parallel to the XZ plane of the machine tool coordinate system; on the fixture plate 11 The bottom is connected with the first vertical support block 3 and the second vertical support block 10, the heights of the first vertical support block 3 and the second vertical support block 10 are not equal, and the first vertical support block 3 and the second vertical support block 10 are unequal in height. The top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com