Aligning protection device for large-volume center roller flange

A protection device and center roller technology, which is applied in winding strips, transportation and packaging, thin material processing, etc., can solve the problems of air roller damage, central axis not rotating directly above, etc., to achieve accurate detection and simple structure , the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

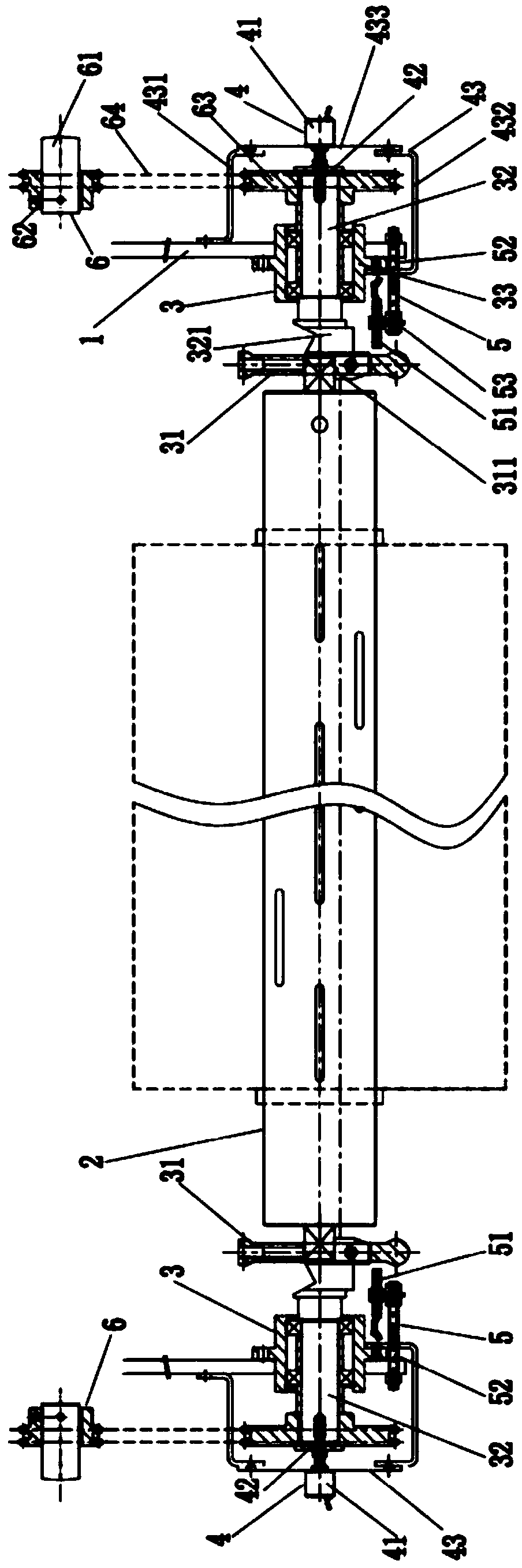

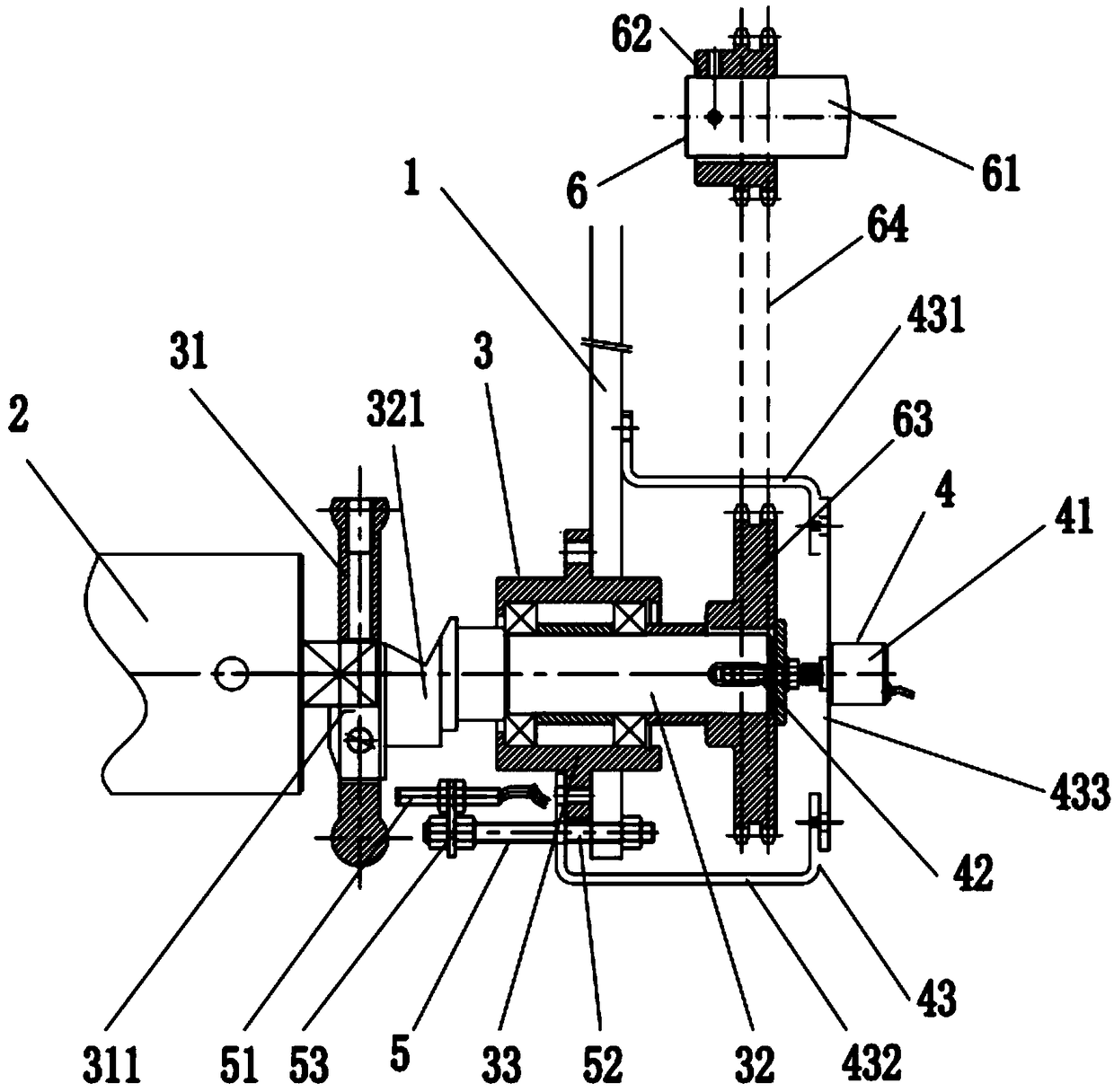

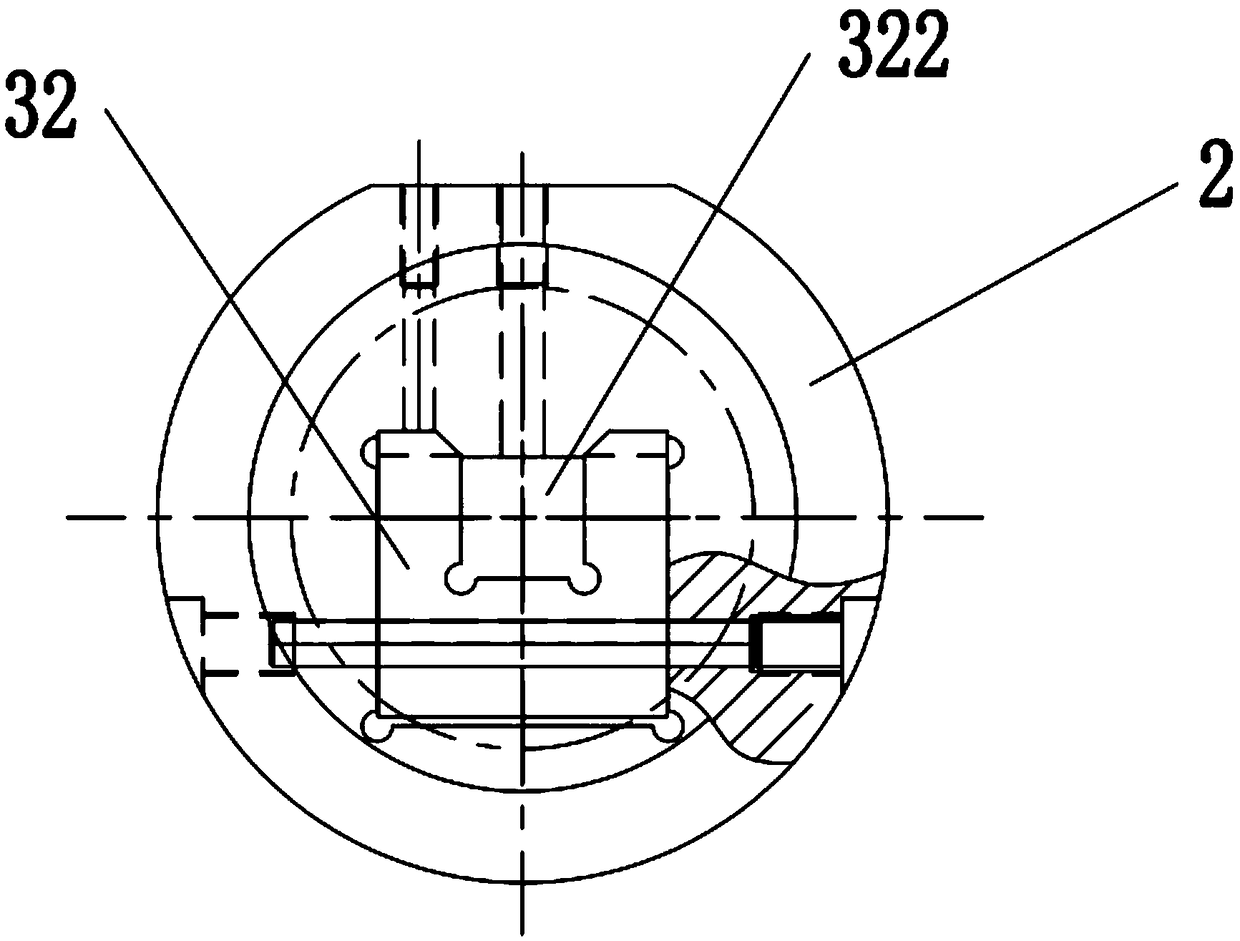

[0017] like figure 1 , 2 , 3, and 4, a kind of alignment protection device for the flange of the center roller of a large roll, including a frame 1, an air-expanding roller 2 and an air-expanding roller transmission assembly 3, and the two ends of the air-expanding roller 2 are respectively arranged There is an air expansion roller transmission assembly 3, the air expansion roller transmission assembly 3 includes a safety chuck 31, a central shaft 32 and a bearing seat 33, the bearing seat 33 is arranged on the frame 1, and the central shaft 32 is rotatably supported on the bearing On the seat 33, one end of the inflatable roller 2 is detachably connected to the safety chuck 31, and the safety chuck 31 is hingedly connected to one end of the central shaft 32, and the other end of the central shaft 32 extends out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com