Crankshaft eccentric segment external diameter cylindricity detection device

A detection equipment and eccentric section technology, which is applied in the field of outer diameter cylindricity detection equipment of the eccentric section of a crankshaft, can solve the problems such as the inability to ensure that the rotation center of the cylindricity meter is concentric with the workpiece center, the entry of unqualified products into the market, and the slow alignment speed. , to achieve the effect of simple and trouble-free alignment process, overcoming slow measurement speed and avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

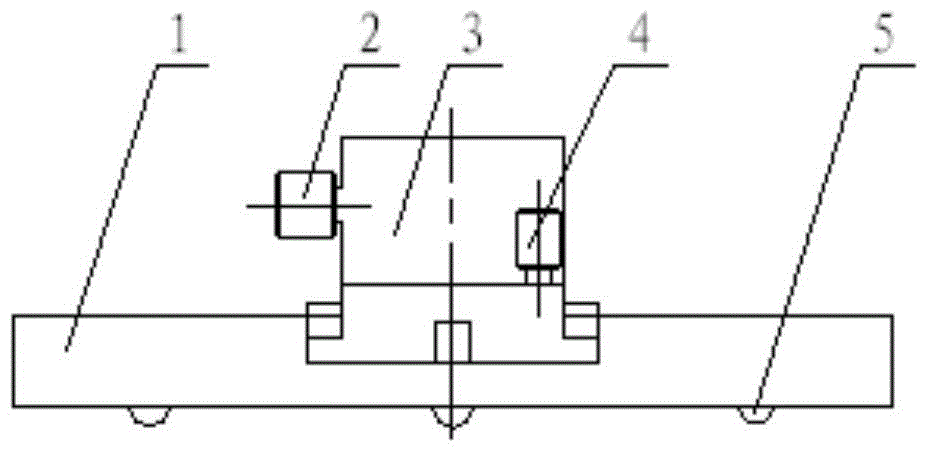

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

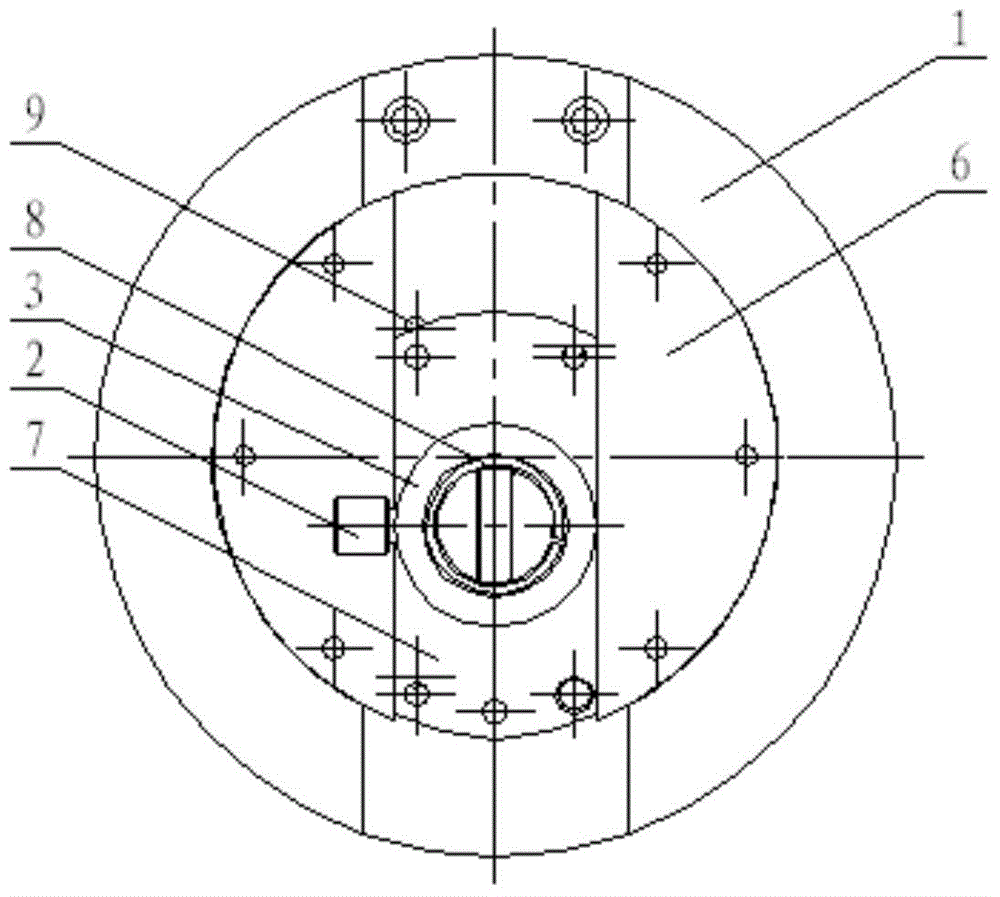

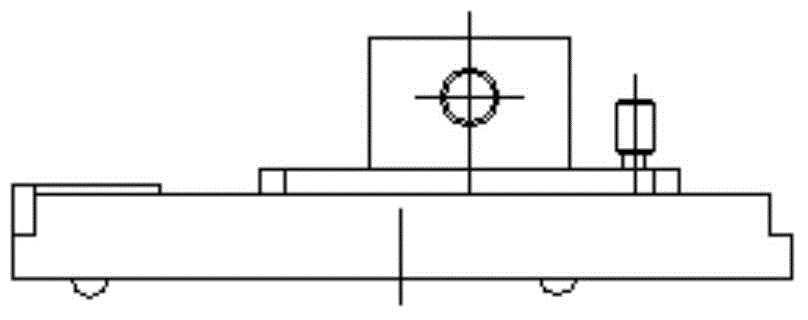

[0018] A cylindricity detection device for the outer diameter of the eccentric section of a crankshaft, comprising a chassis 1, a sleeve 3 and self-centering balls 5, a plurality of self-centering balls are embedded in the lower surface of the chassis, and all self-centering balls are arranged on the same circumference , self-centering balls are usually three concentrically arranged.

[0019] A guide rail disc 6 is coaxially installed on the upper surface of the chassis, and an adjustable eccentric slider 7 is slidably installed on the guide rail disc. One or more adjustment holes 9 are made on the guide rail disc, and an eccentric adjustment positioning is installed on the adjustable eccentric slider. Pin 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com