Patents

Literature

111 results about "Chalk line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chalk line or chalk box is a tool for marking long, straight lines on relatively flat surfaces, much farther than is practical by hand or with a straightedge. They may be used to lay out straight lines between two points, or vertical lines by using the weight of the line reel as a plumb line.

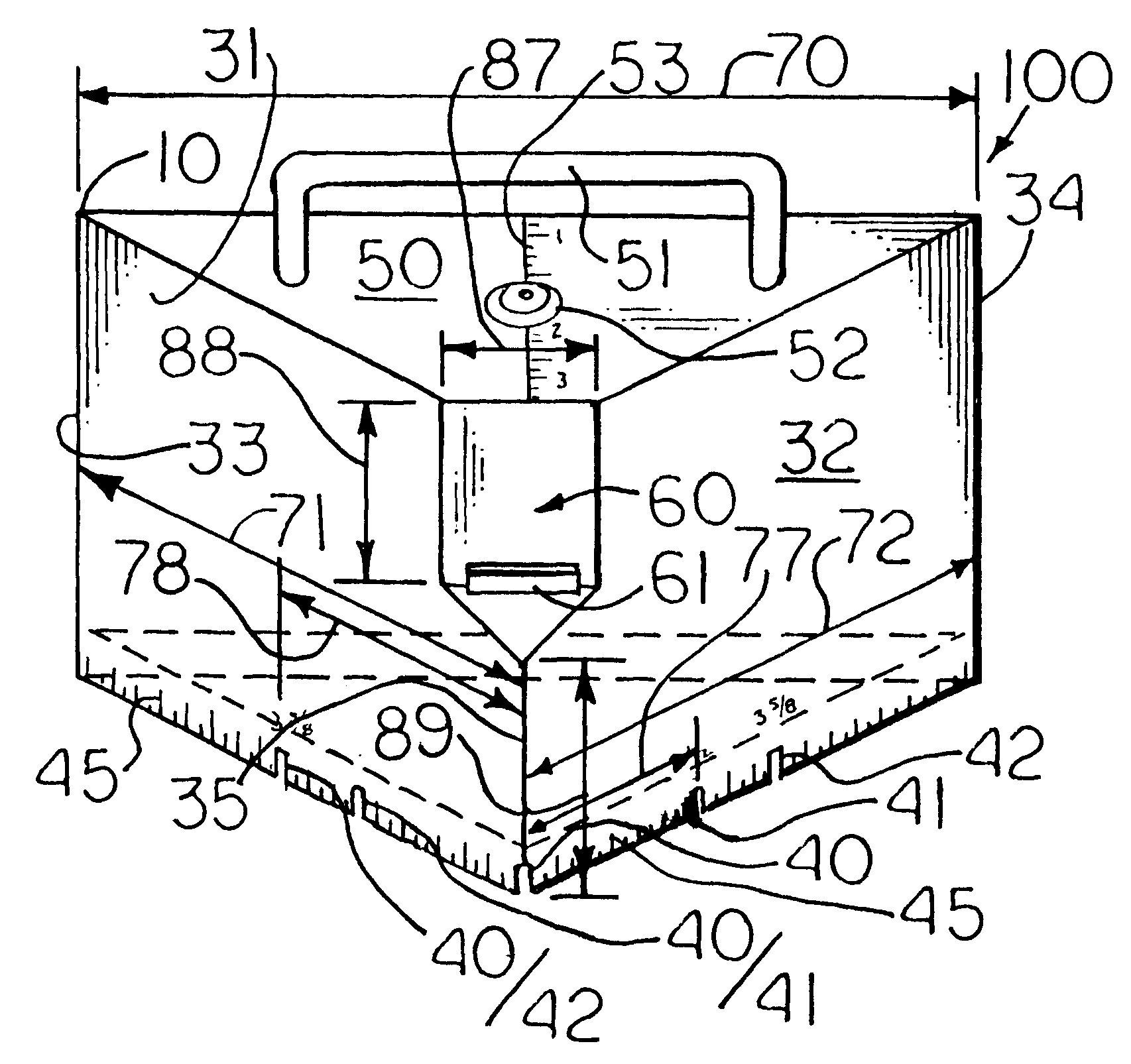

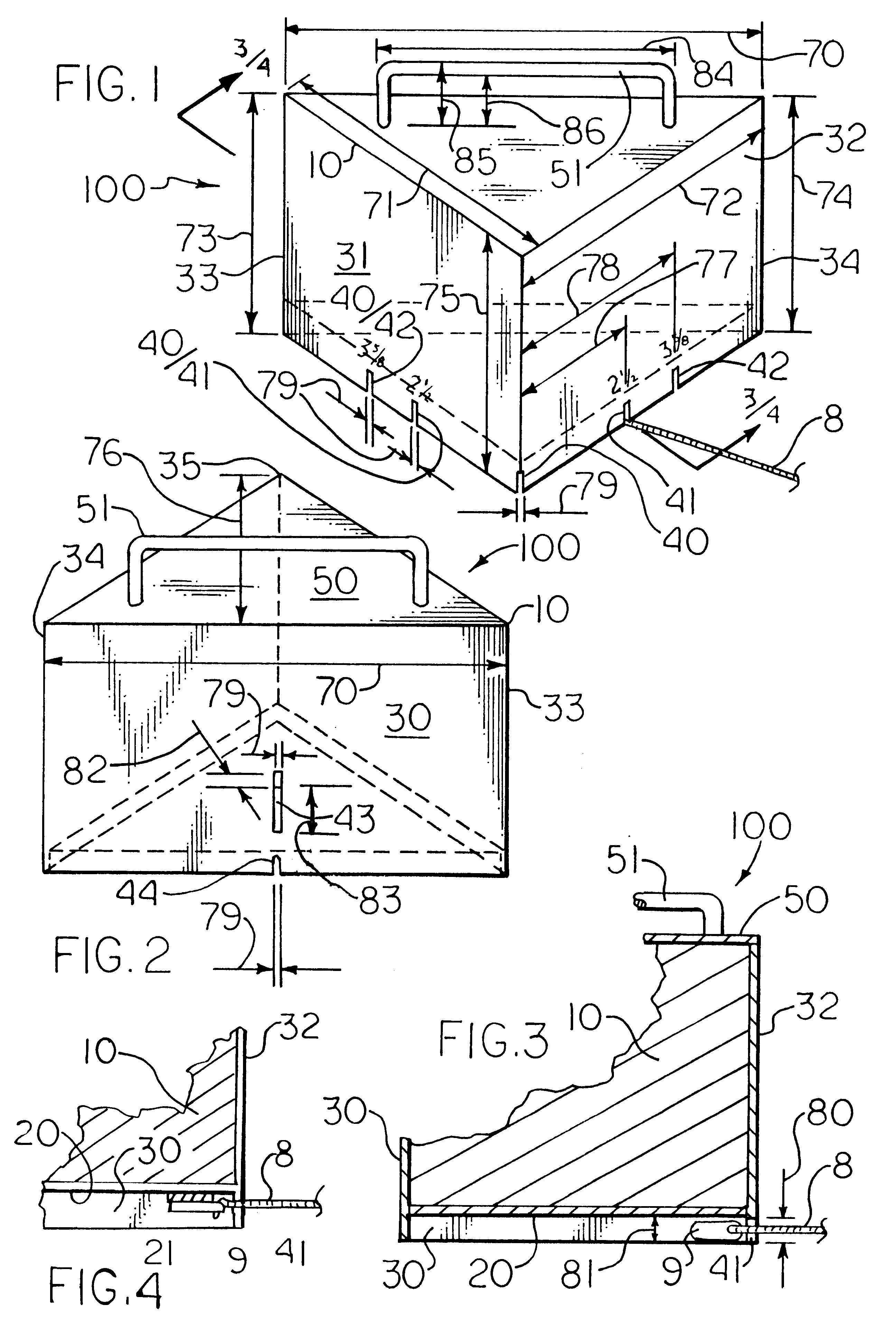

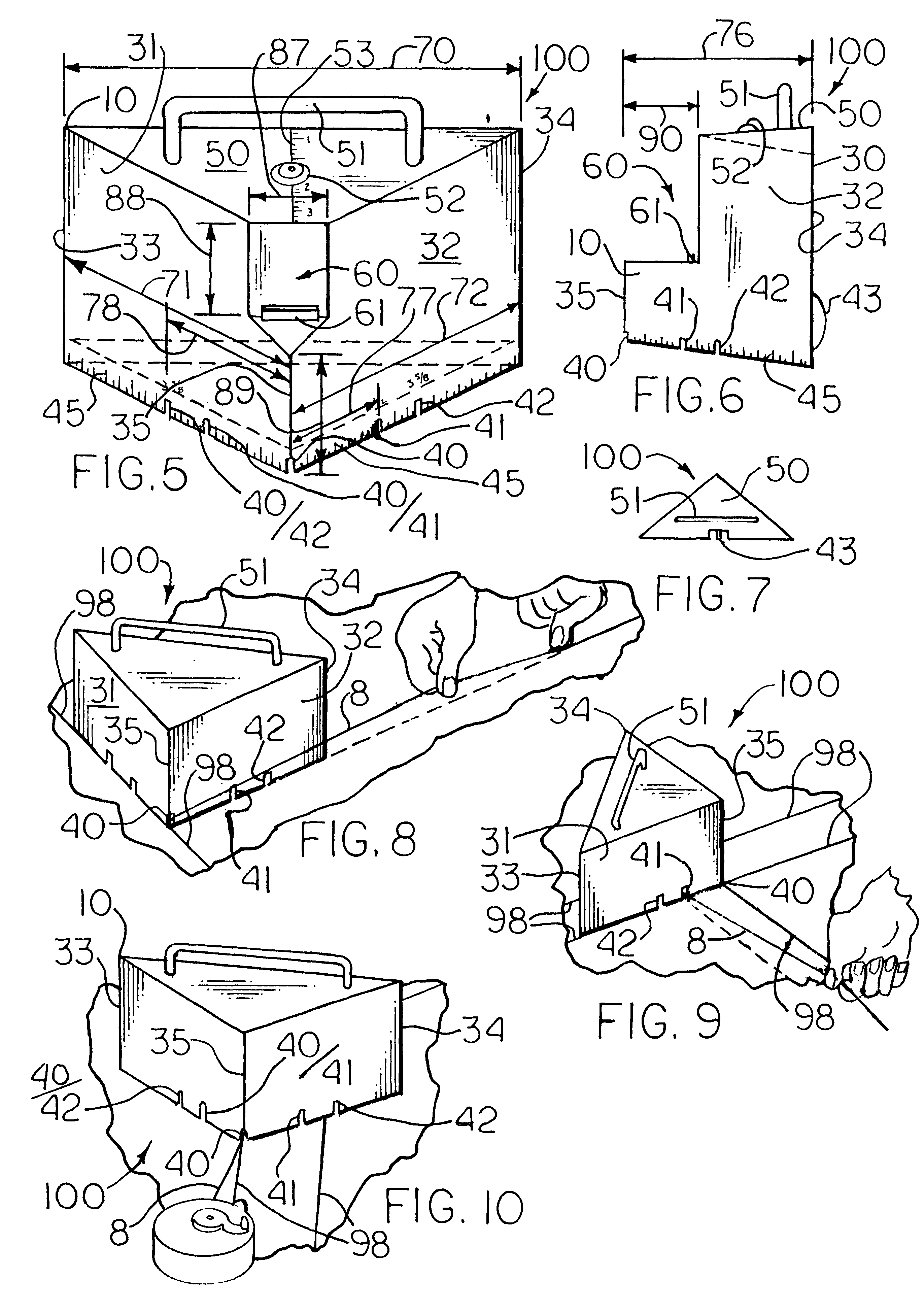

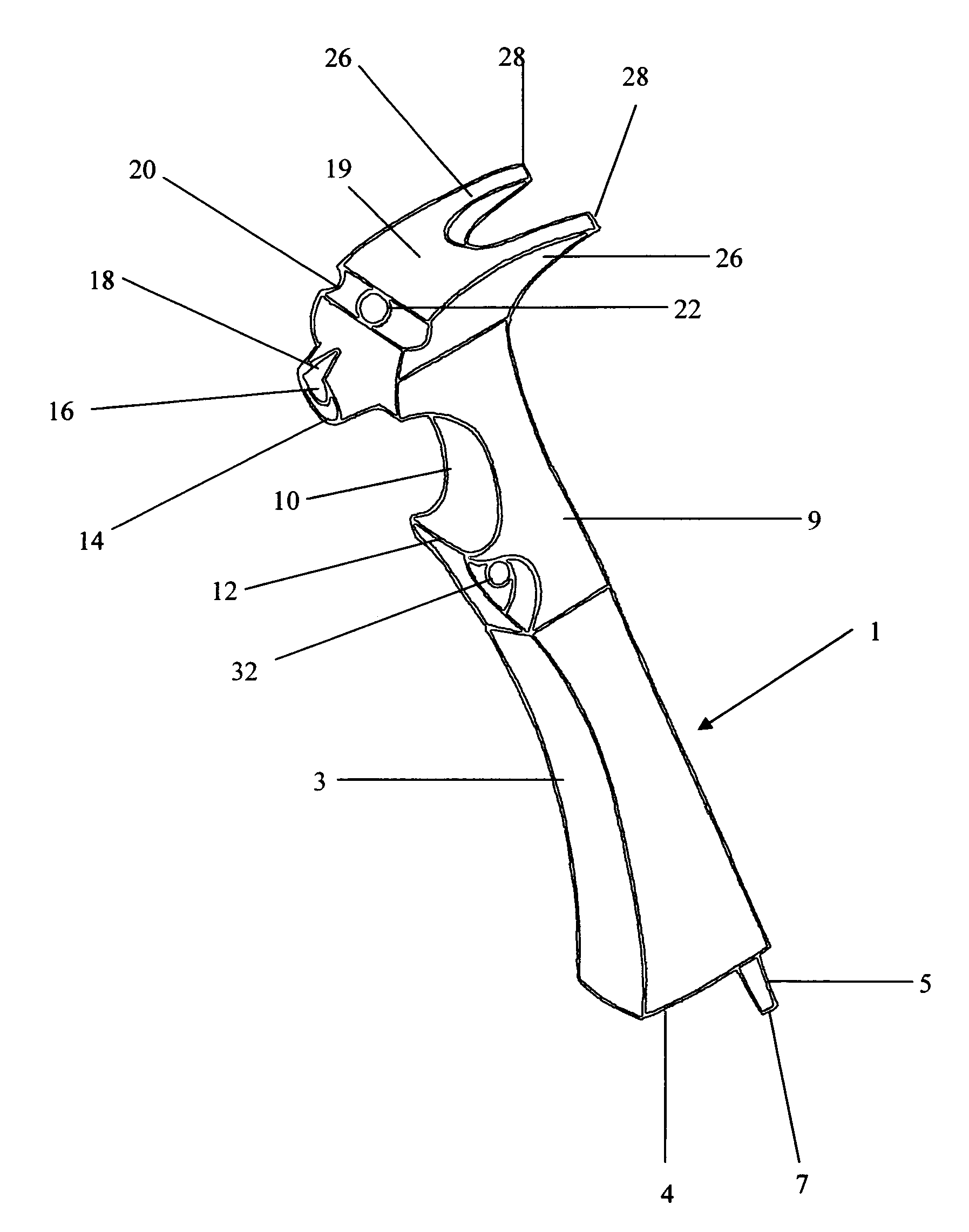

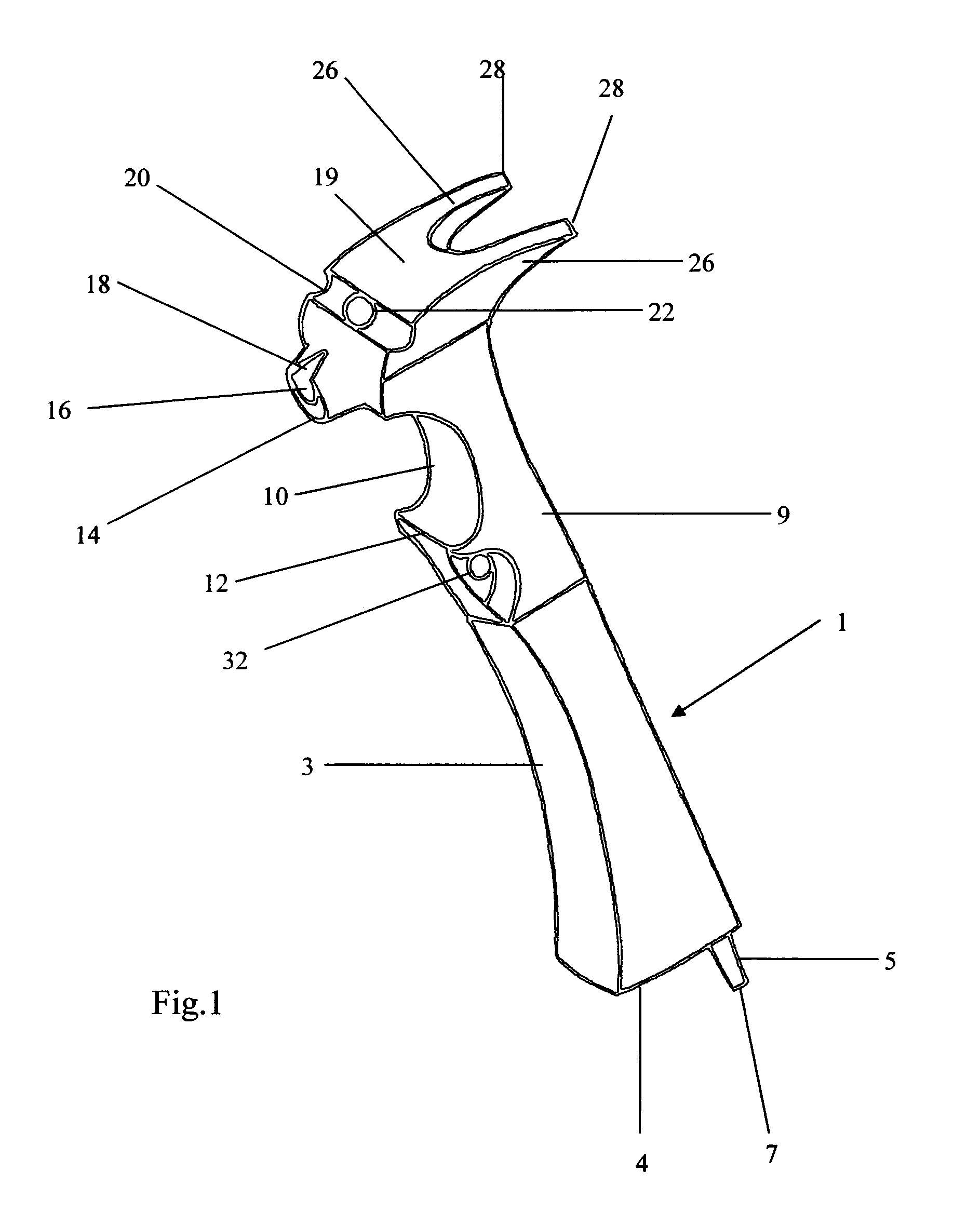

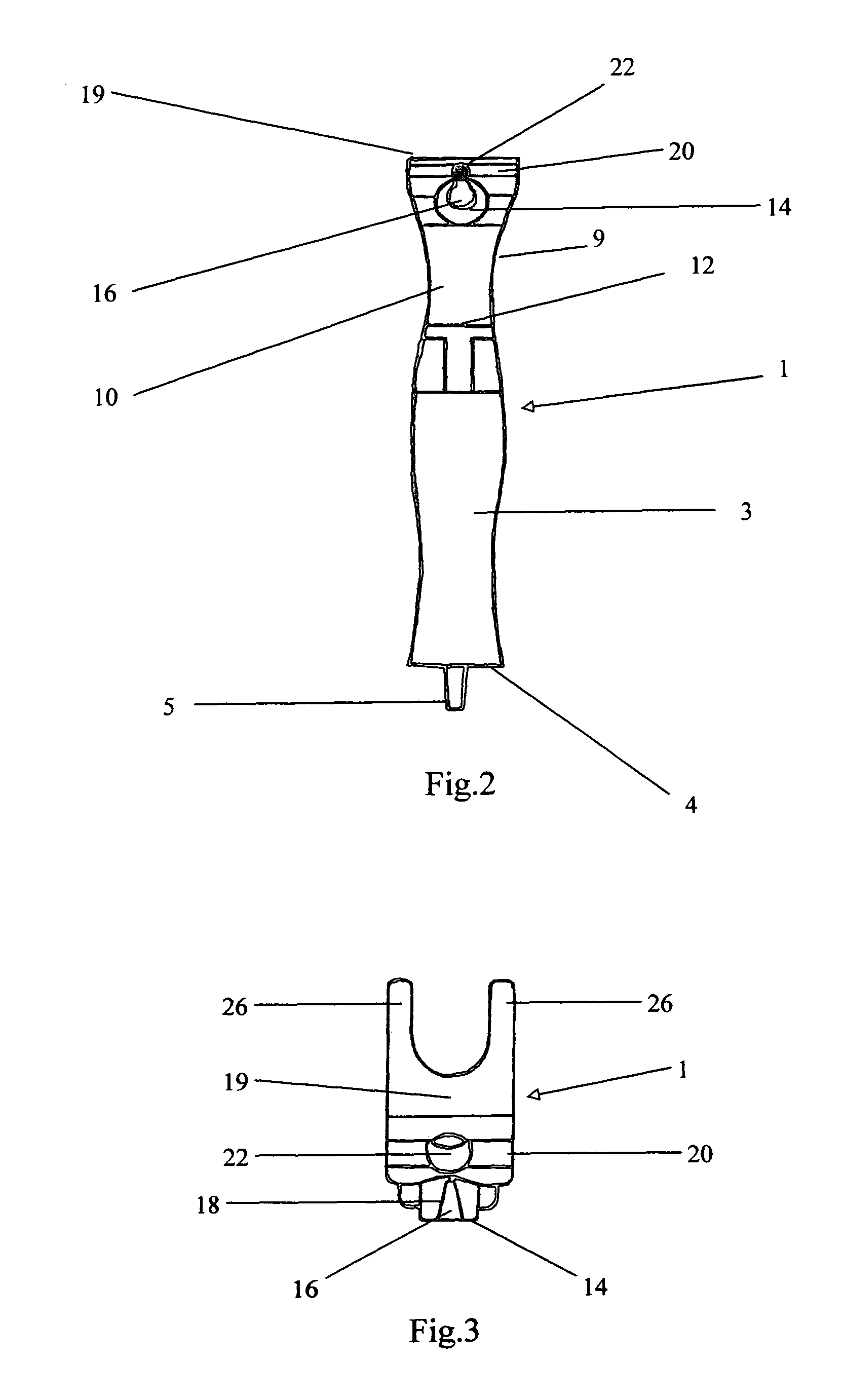

Construction layout block

InactiveUS6578274B1Facilitate measurement of distances from layout linesHigh degreeLiquid surface applicatorsWriting aidsLaser targetEngineering

Construction layout block can be provided with a triangularly shaped body with a triangular bottom; a base wall and two side walls extending up from the bottom; base wall junctures formed about intersections of the base wall and the side walls, and an apex juncture formed about intersections of the side walls. It may have one or more of an artifice capable of holding a chalk line; top, with a top carrying handle; a laser target notch; a rear reference system; a top alignment system; a ruler scale; an intrinsic level; and a contrivance for holding a tape measure by its distal end. The block has relative immovability, in general, to resist the force of pulling on a chalk line with the same attached to the block during layout. A construction layout block of any shape may be plastic-coated.

Owner:TANGO JR RONALD M +1

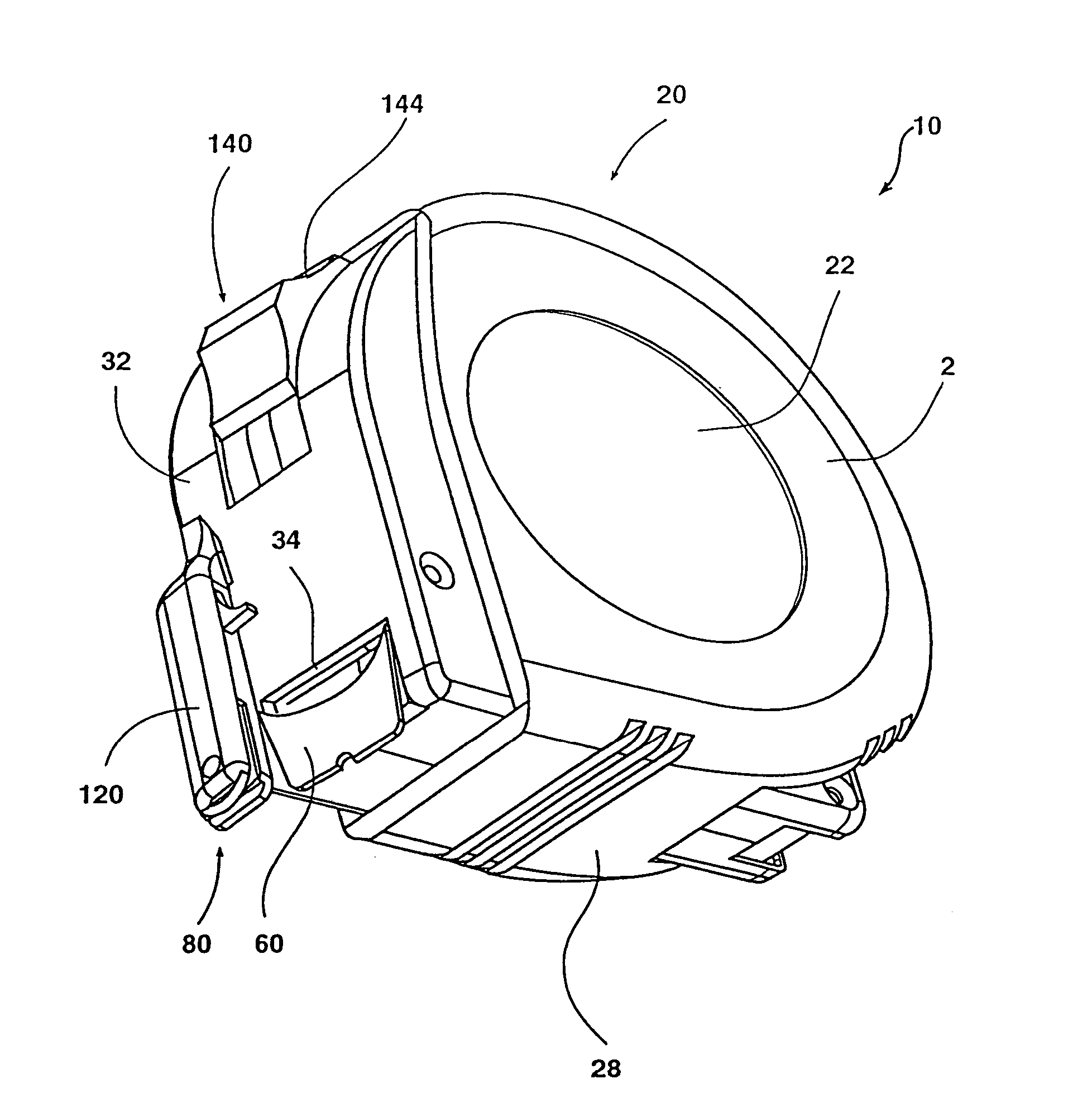

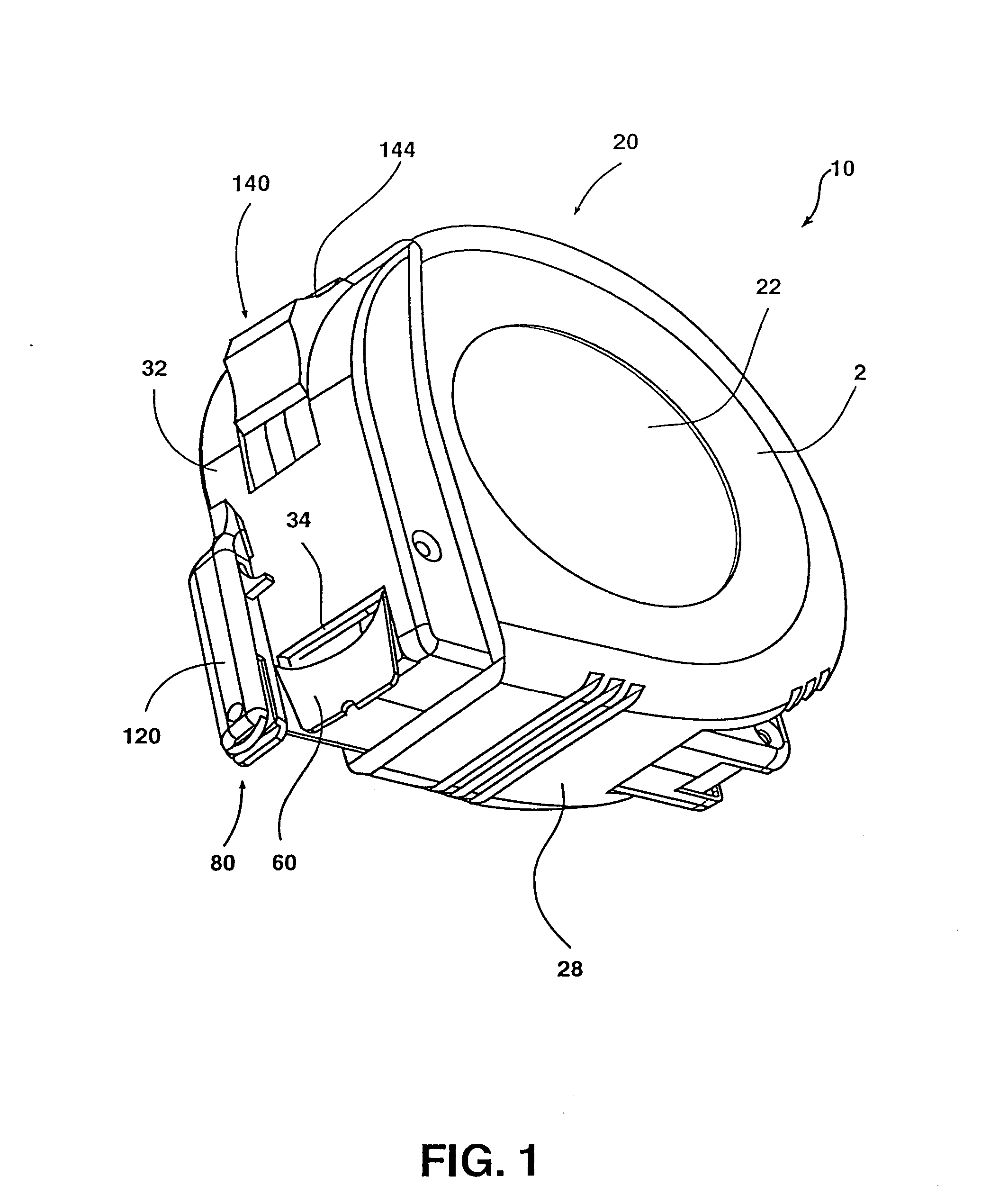

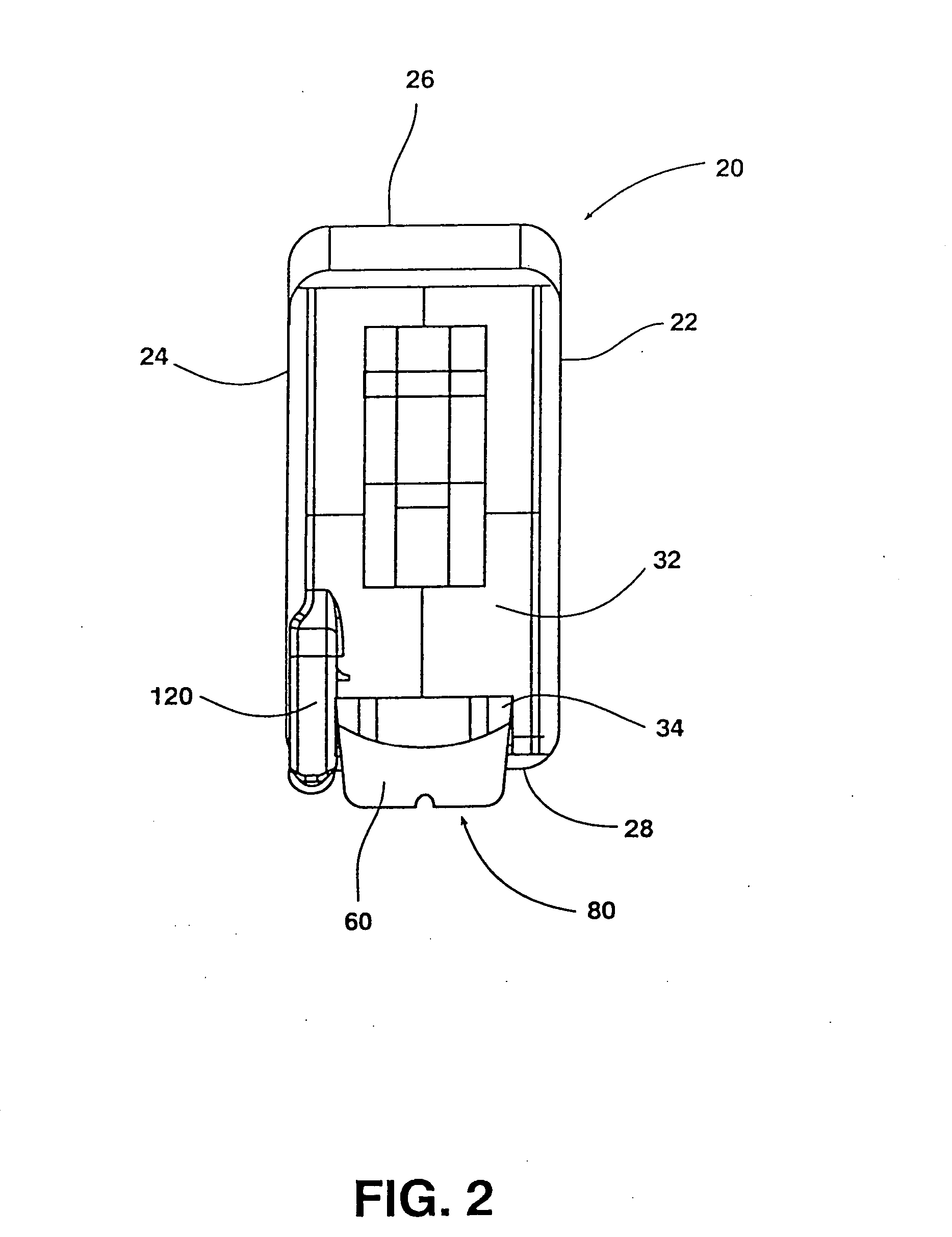

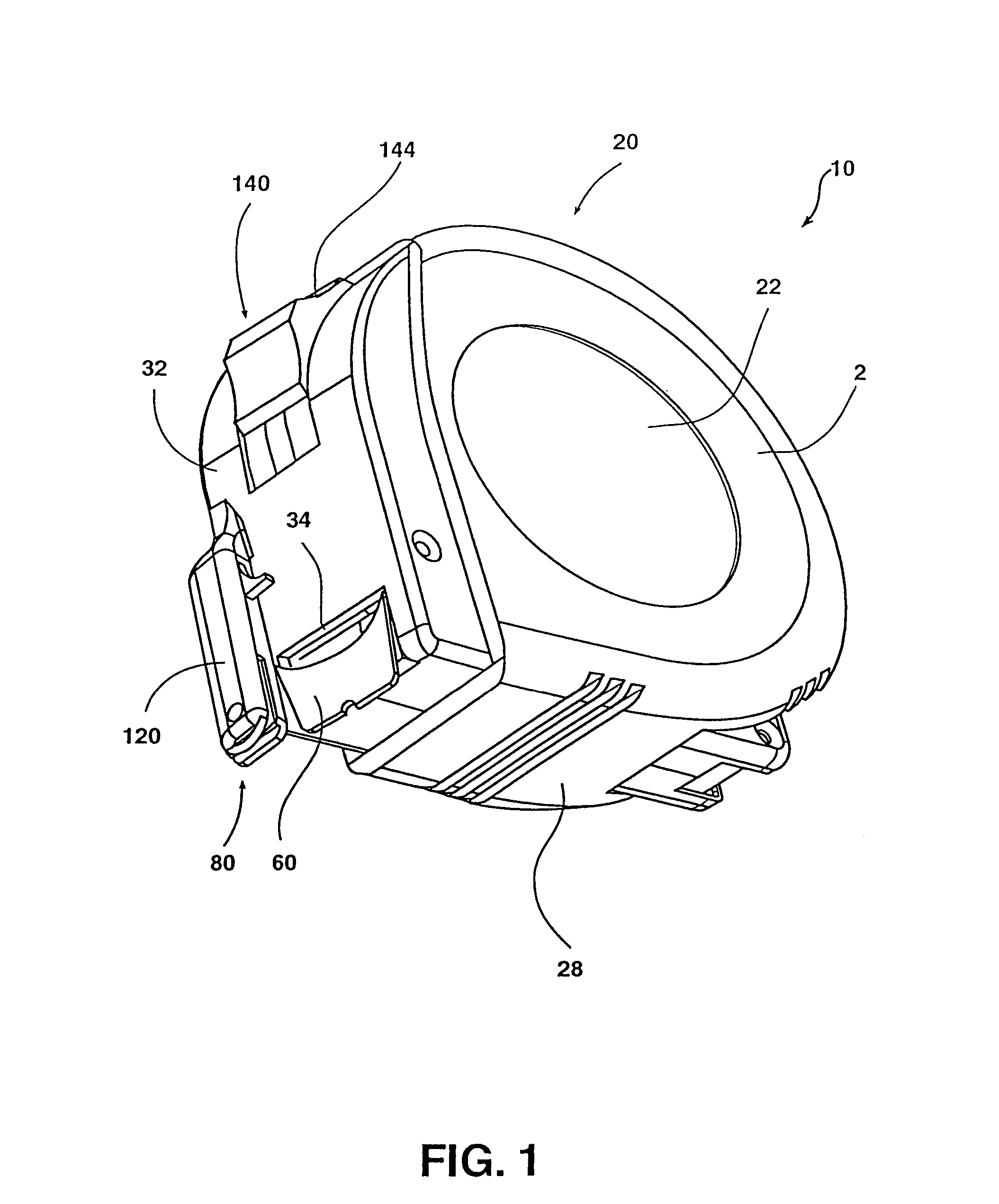

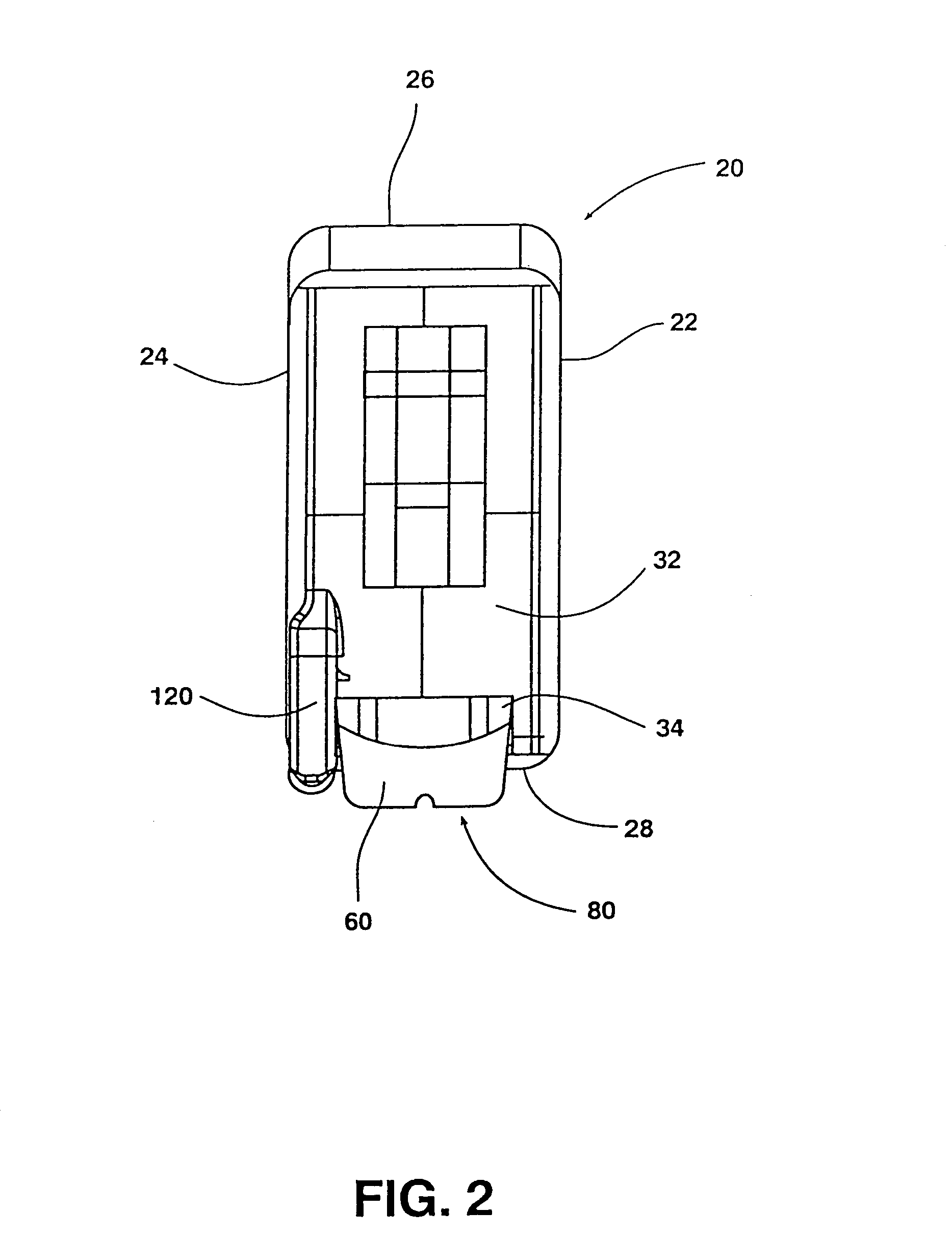

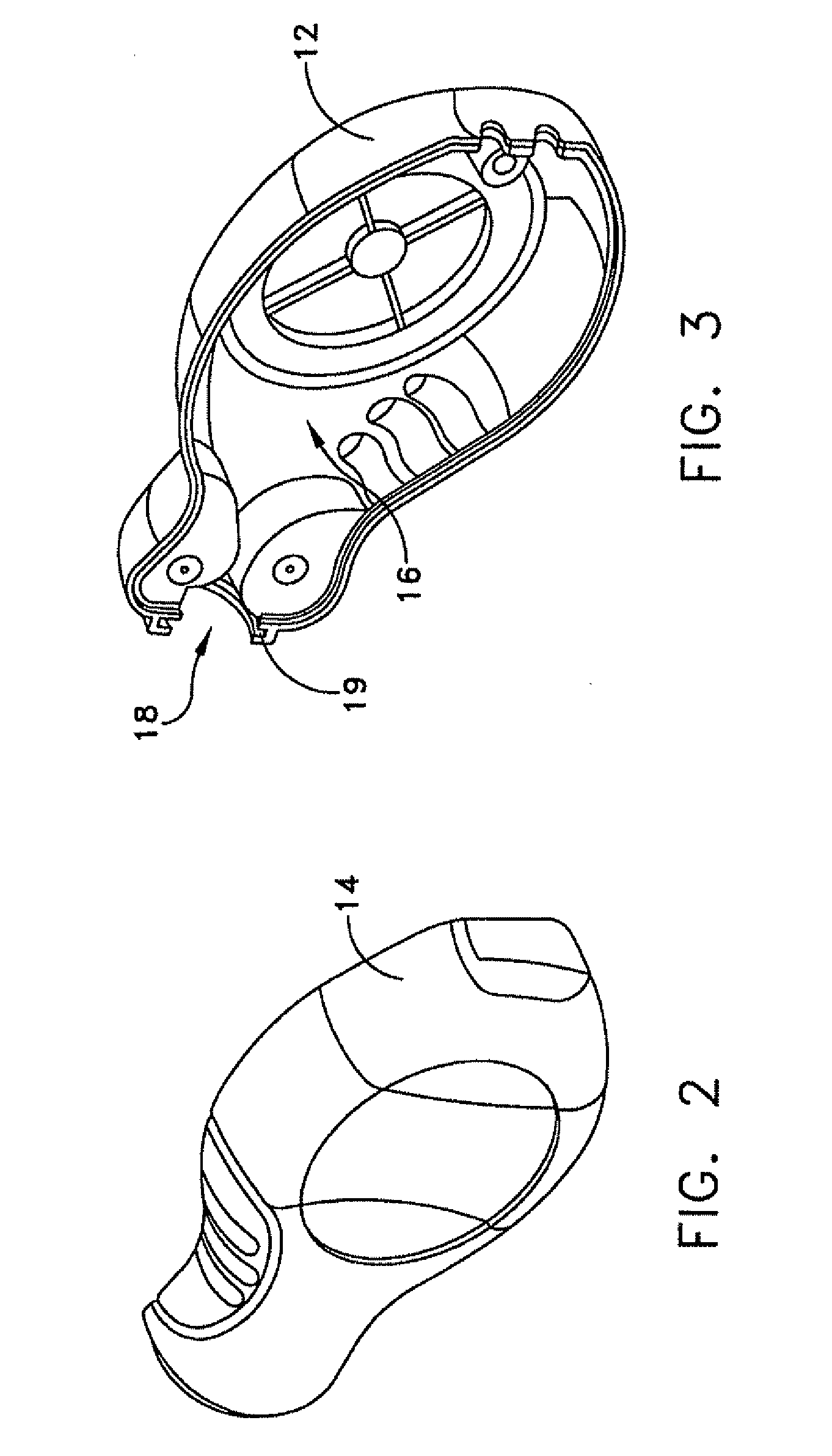

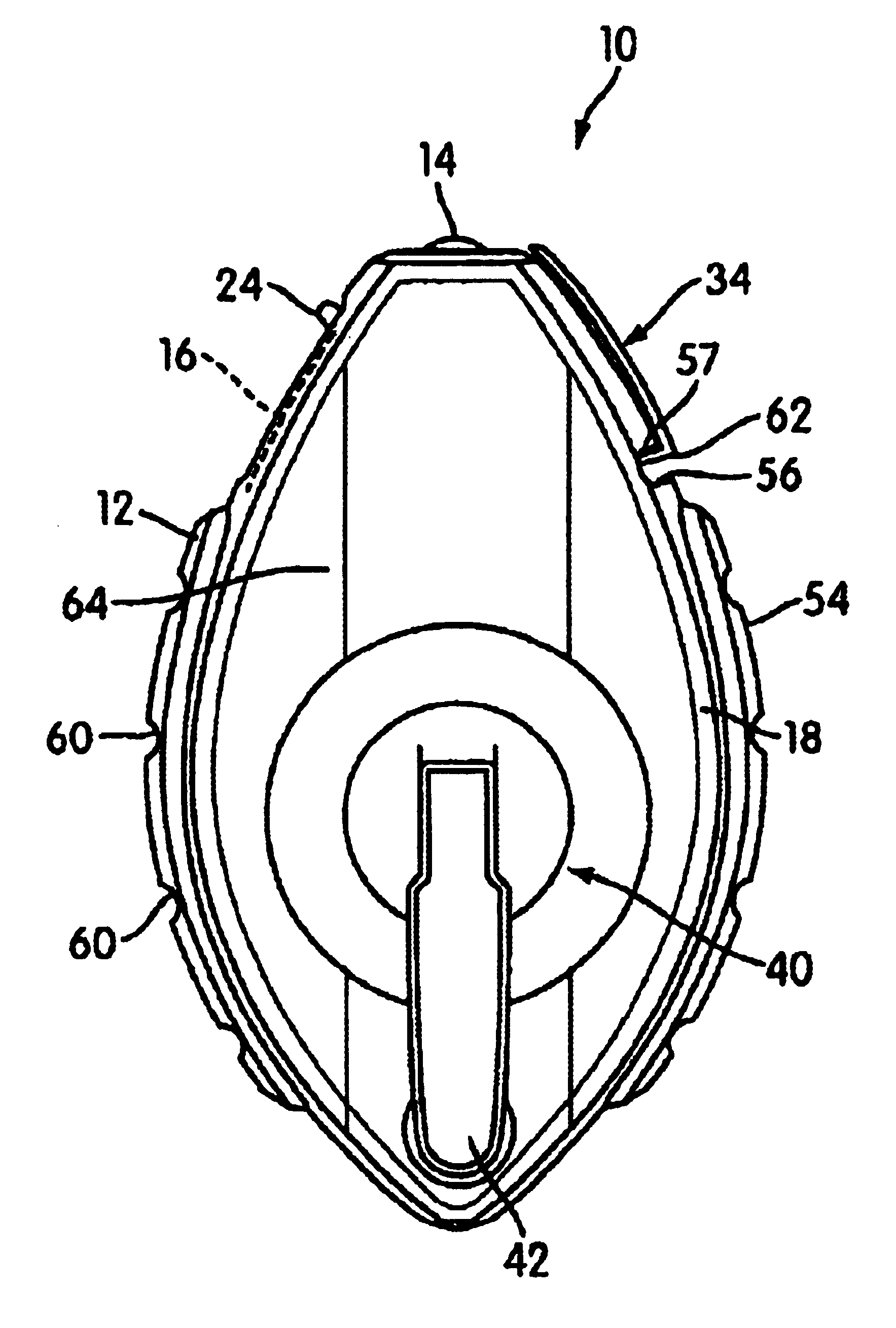

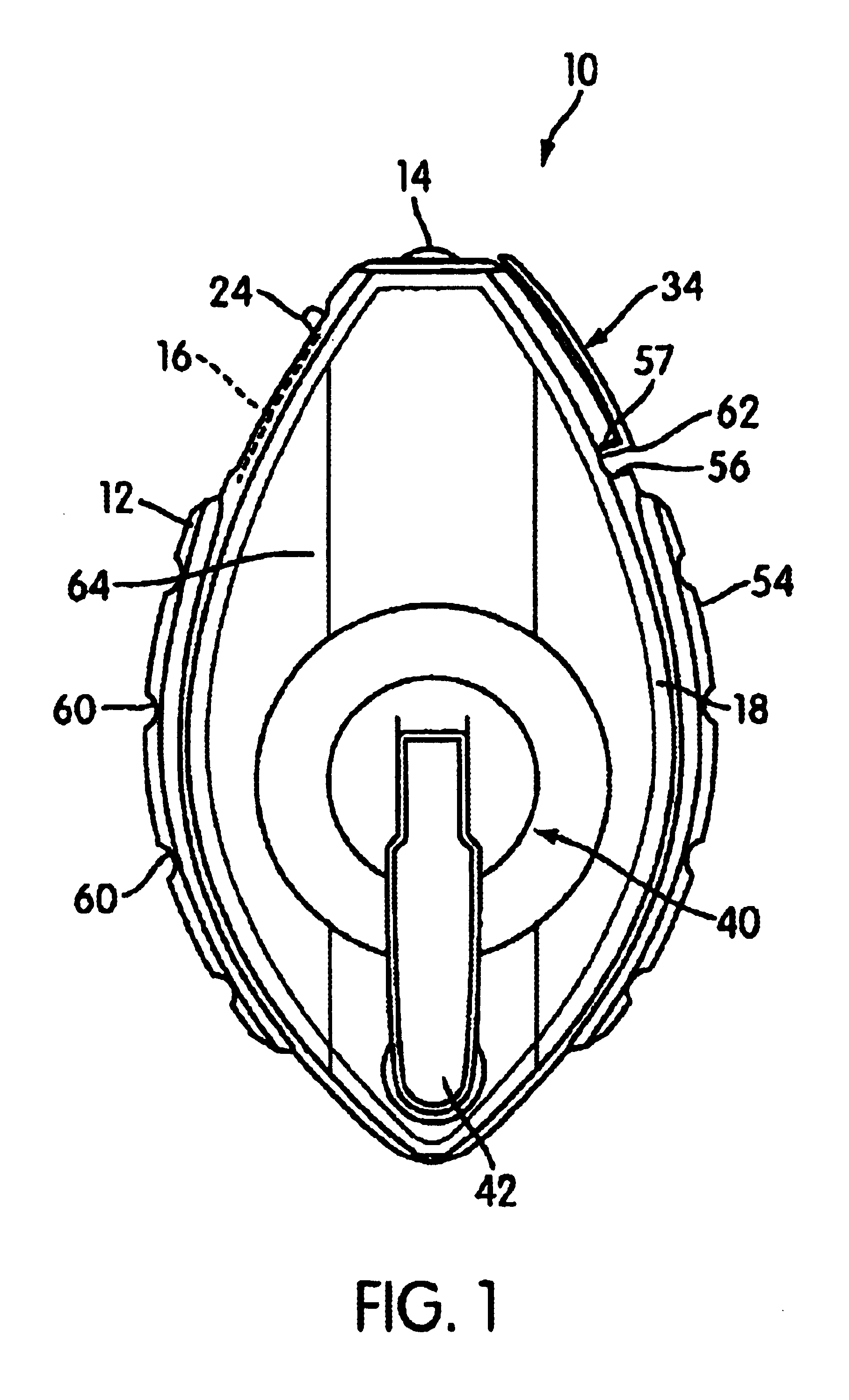

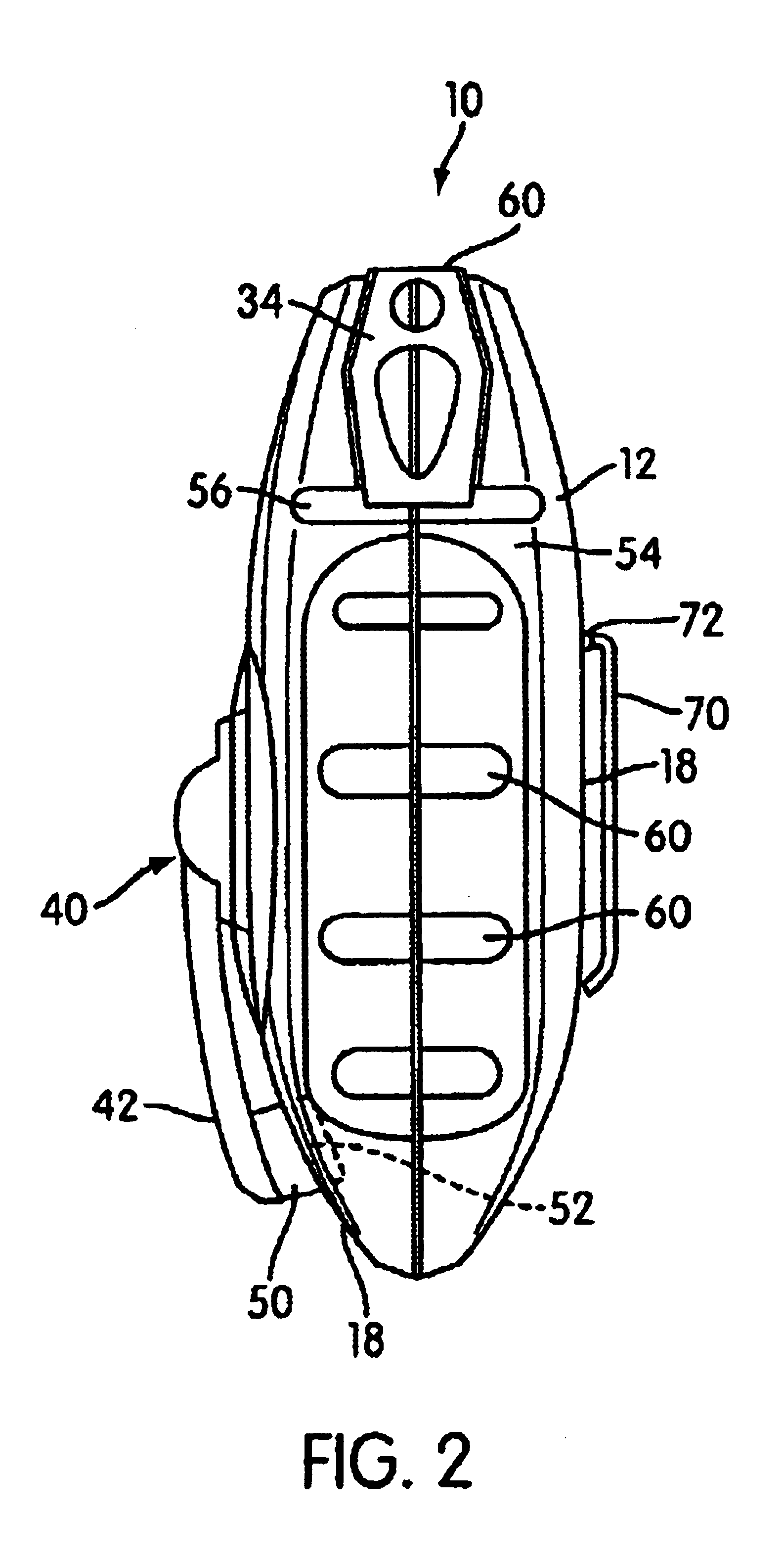

Chalk line with viewing window

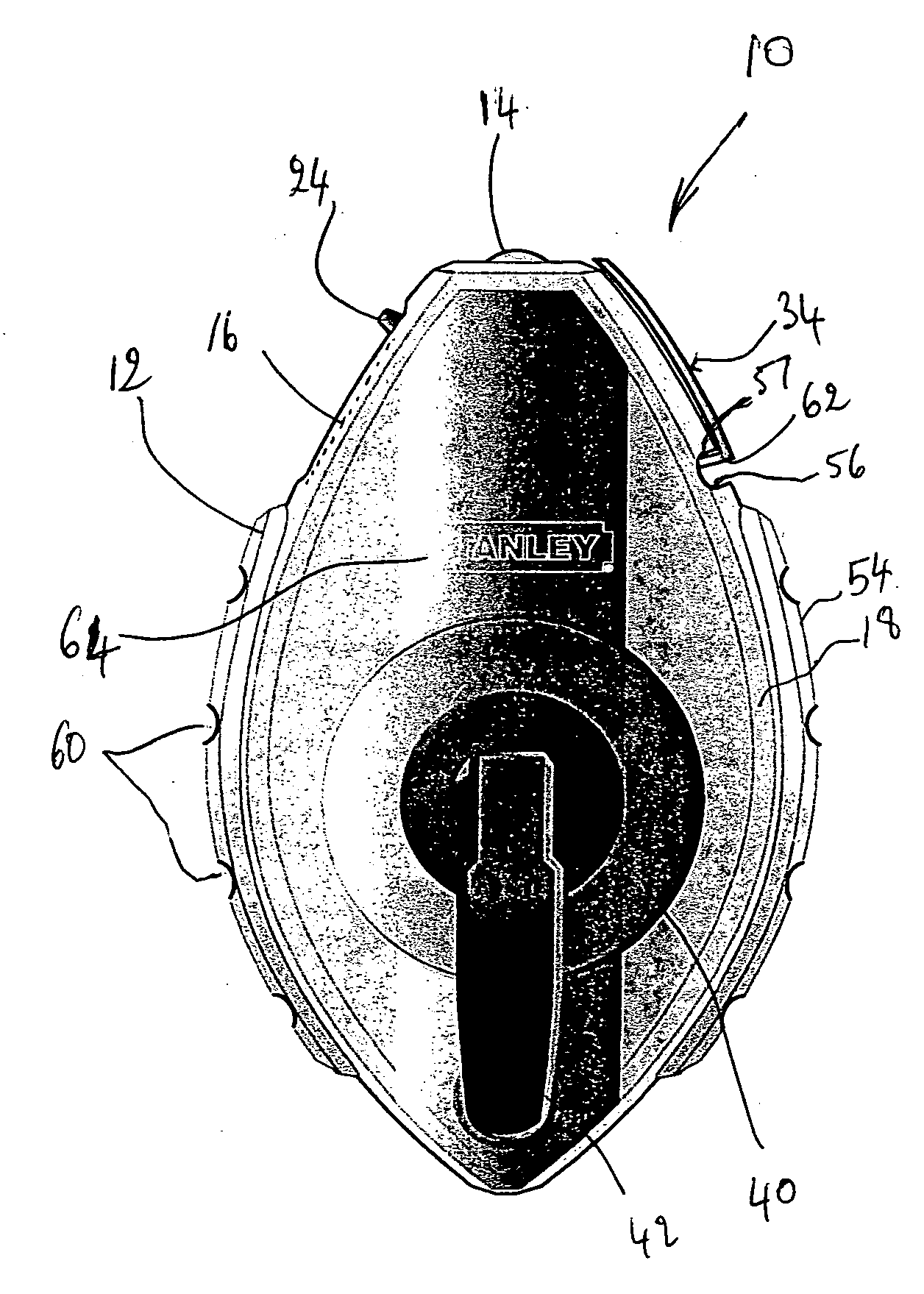

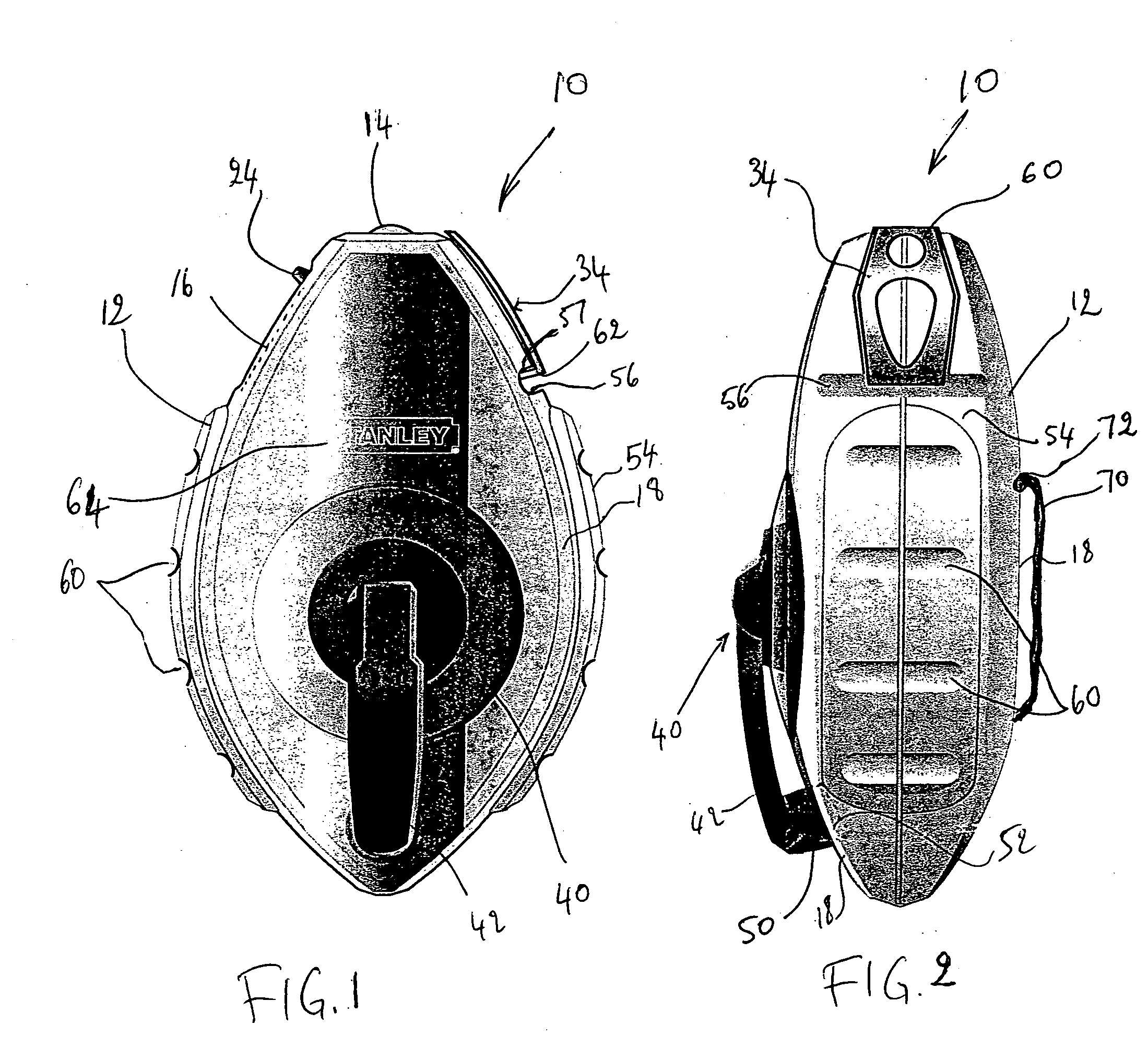

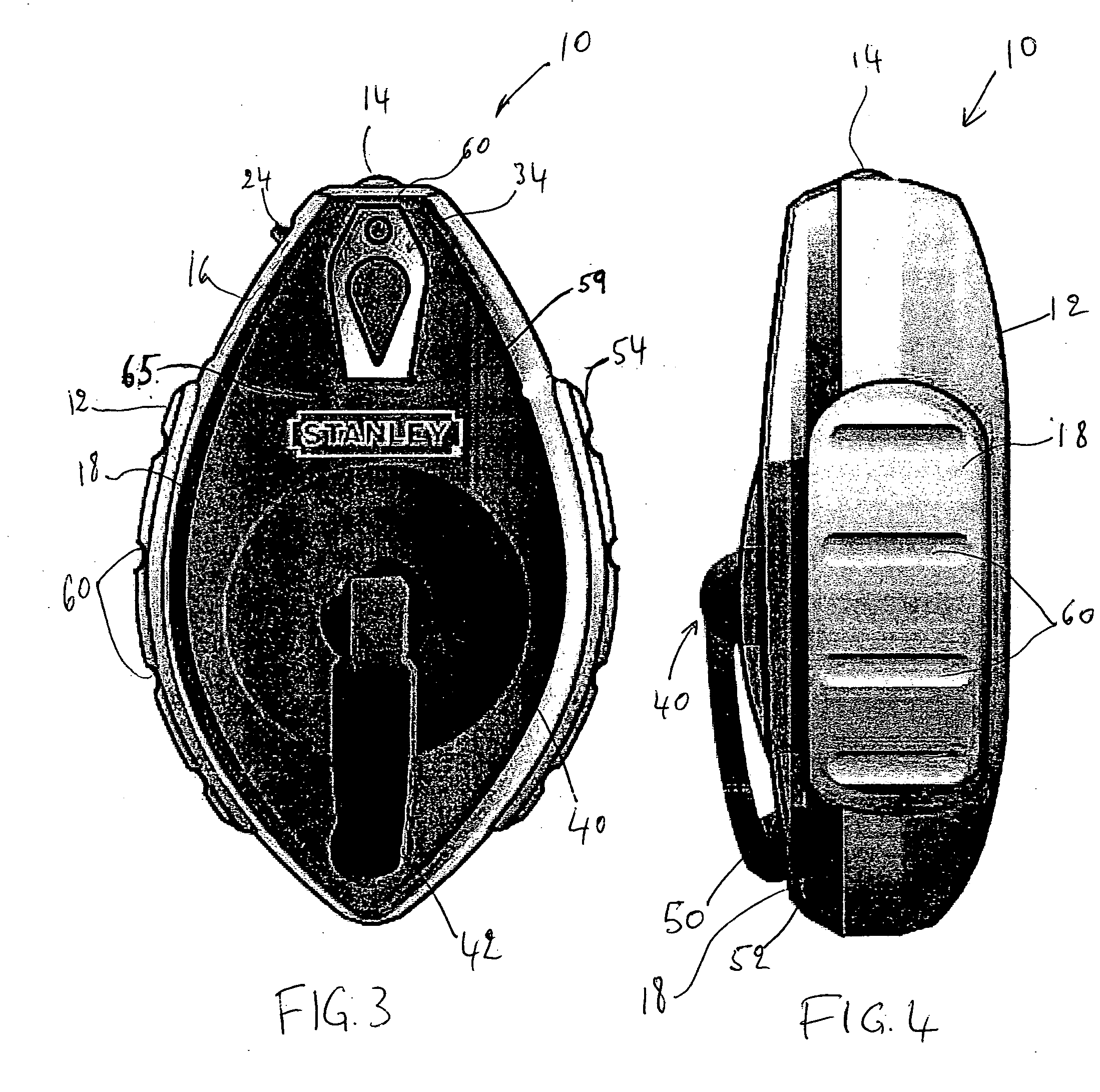

A chalk line device includes a housing and a chalk line stored in the housing. The chalk line terminates in a hook at one end and the hook is disposed outside of the housing. The housing may include a side wall with a depression formed therein that is shaped to receive the hook for storage. The depression has an edge that allows the hook to securely engage. The housing may also include a translucent window for allowing the user to check the level of chalk in the chalk line device. The translucent window forms at least a portion of a wall of the housing. The translucent window can be made, for example, of a plastic and can be integrally formed with the housing.

Owner:STANLEY WORKS THE

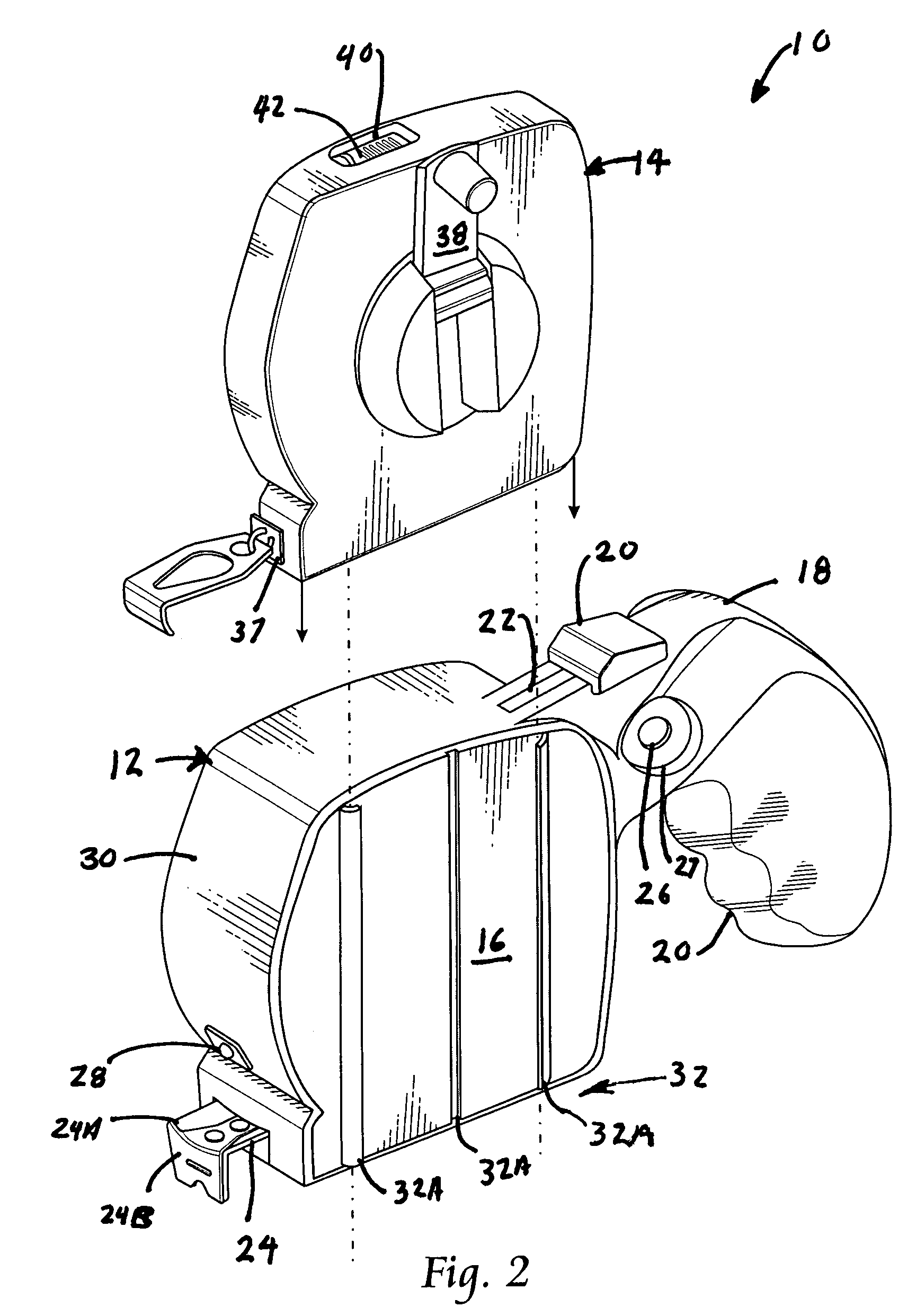

Tape measure having a handle and a removable chalk line marker and method therefor

InactiveUS7260899B2Save spaceEasy to useOther artistic work equipmentsMeasuring tapesElectrical and Electronics engineeringTape measure

A construction tool has a tape measure. A handle is coupled to the tape measure. The handle allows a user of any size or shape hand to comfortably and easily use the tape measure.

Owner:JONES JOHNNY T

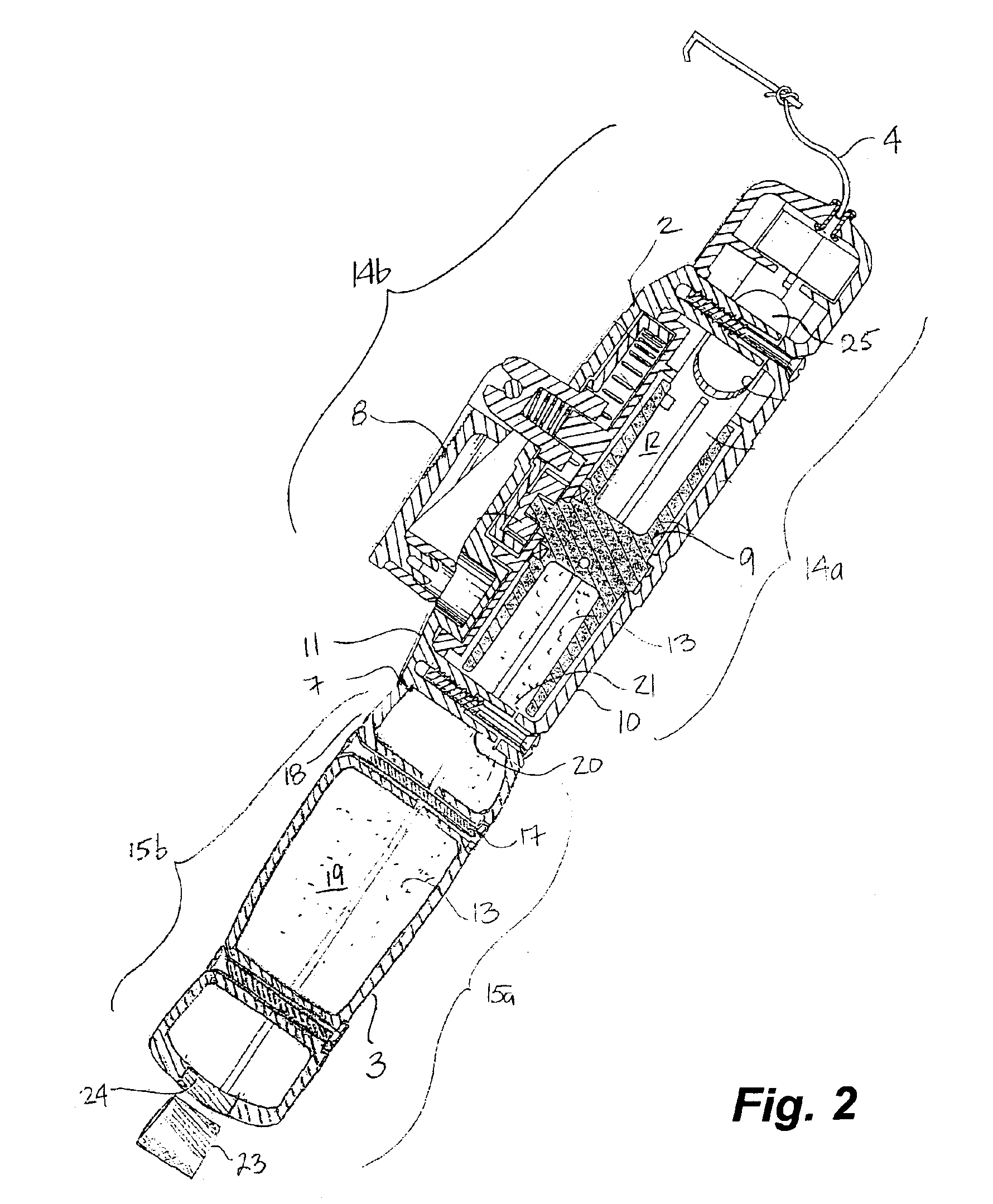

Spring lock spring line chalk box

InactiveUS6957495B1Effective brakingOther artistic work equipmentsStraightedgesCoil springEngineering

An automatically retracting chalk line dispenser having a first and second casing elements, chalk line, reel, coil spring, and thumb-lever. The thumb-lever operates as a brake thereby allowing for either controlled retraction or an effective lock on the chalk line.

Owner:SCHMILLEN LUKE

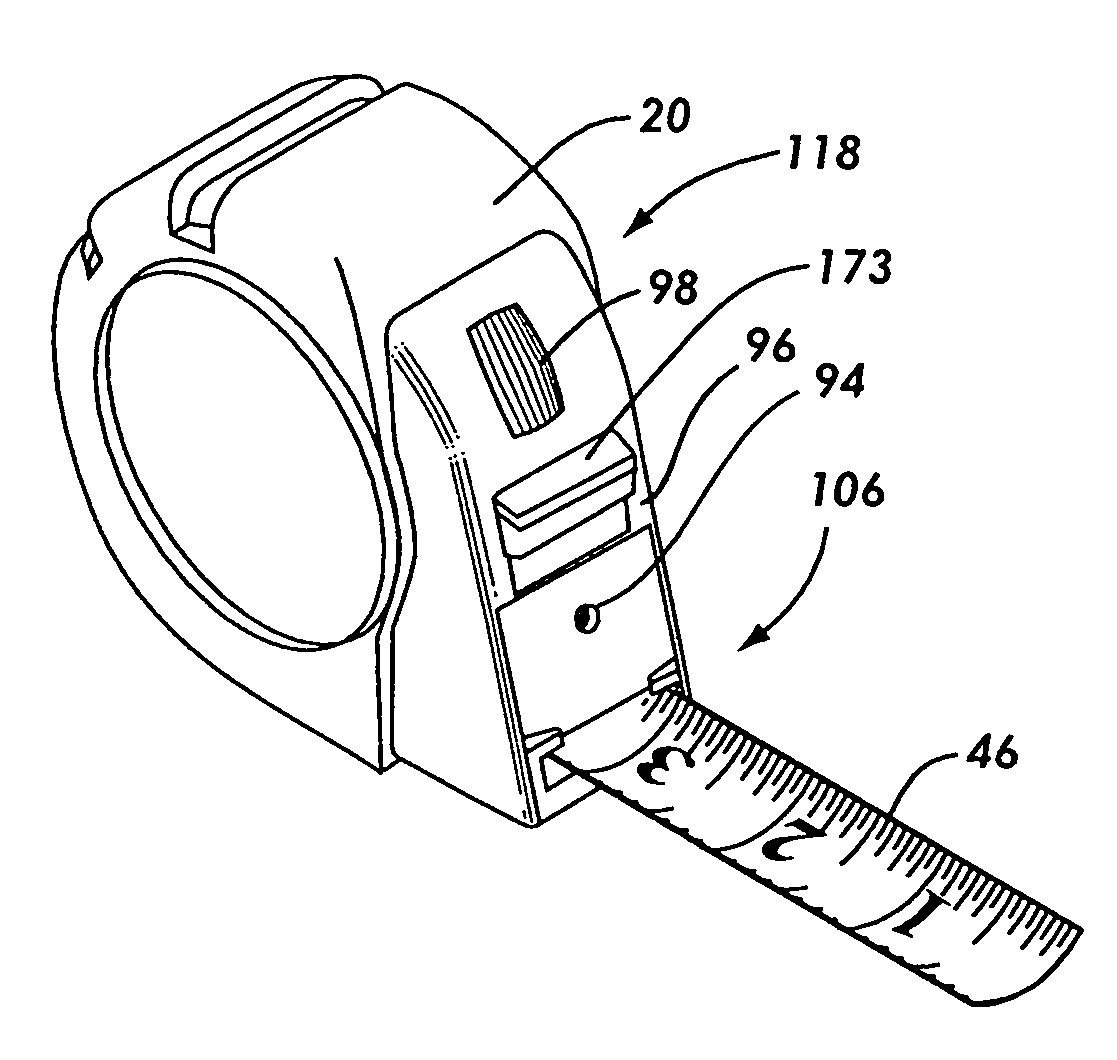

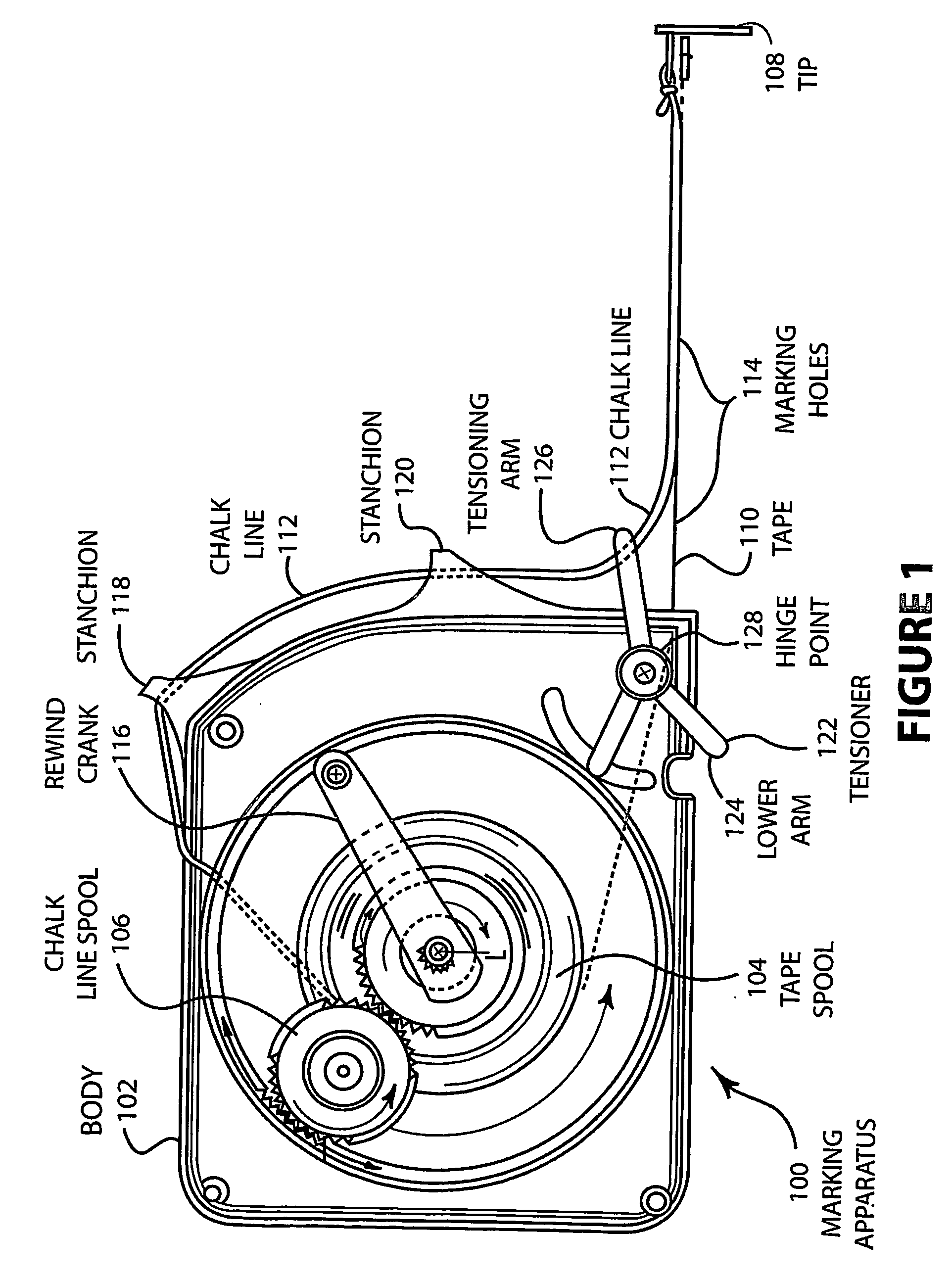

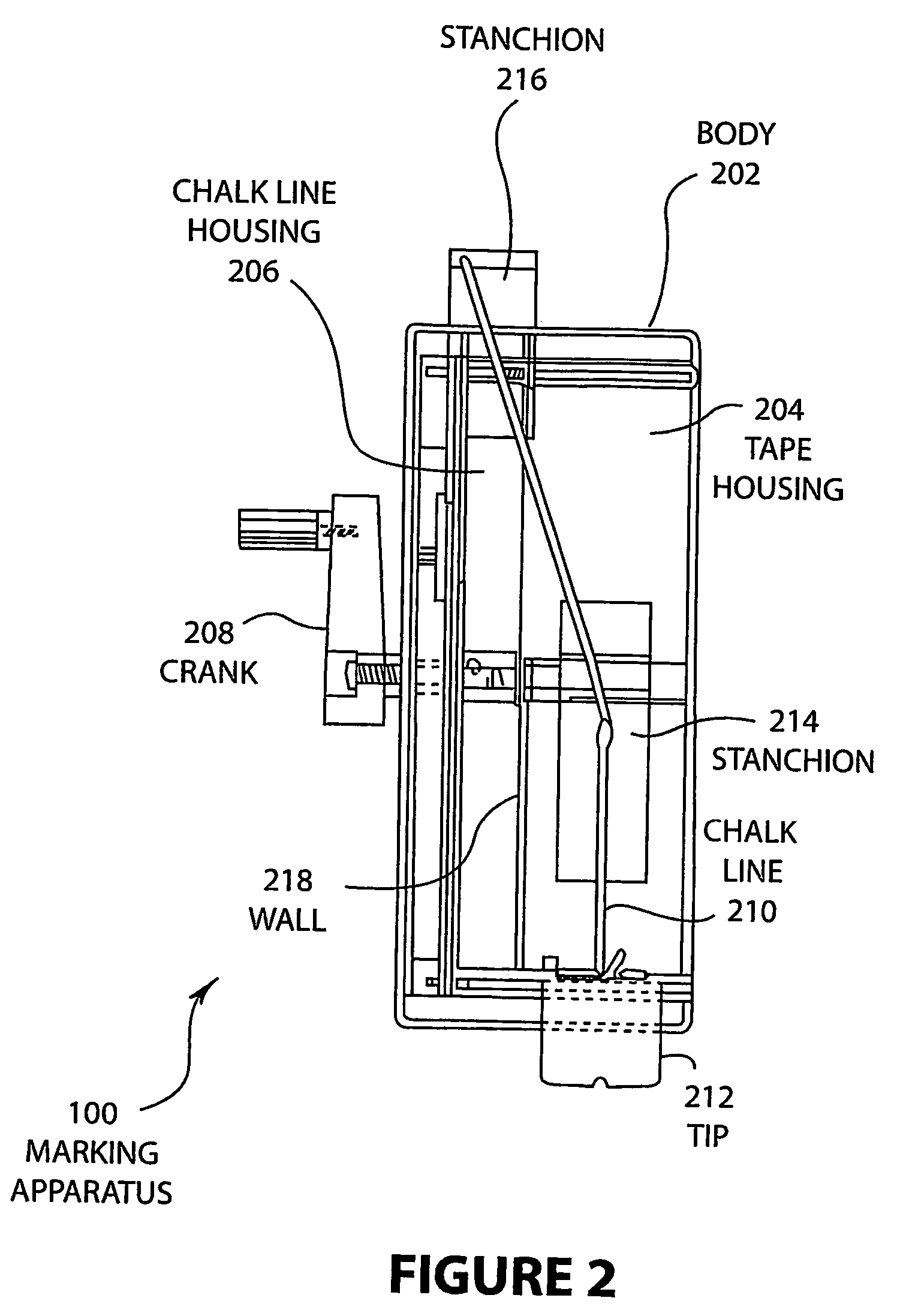

Tape measure that incorporates a chalk line style marking device

InactiveUS20060185185A1Efficient and economicalEasily advancedMeasuring tapesTape measureElectrical and Electronics engineering

A tape measure that incorporates a marking device for allowing an individual to measure and mark a wide variety of materials in a more efficient and economical manner, and for measuring and marking the beginning point of reference and the measured position point simultaneously. The tape measure has a housing, a coiled measuring tape, a tape tip, a chalk line, a chalk receptacle, a chalk line recharger, an activator, and an advancer. The chalk line is easily advanced and retracted for making marks at varying distances. The chalk is stored in a chalk storage receptacle that allows the chalk line to be re-chalked and is refillable for multiple uses. The activator allows the retractable chalk line to transfer a chalk substance from the chalk line to the surface to be measured and marked.

Owner:BLACK & DECKER INC

Tape measure that incorporates a chalk line style marking device

Owner:BLACK & DECKER INC

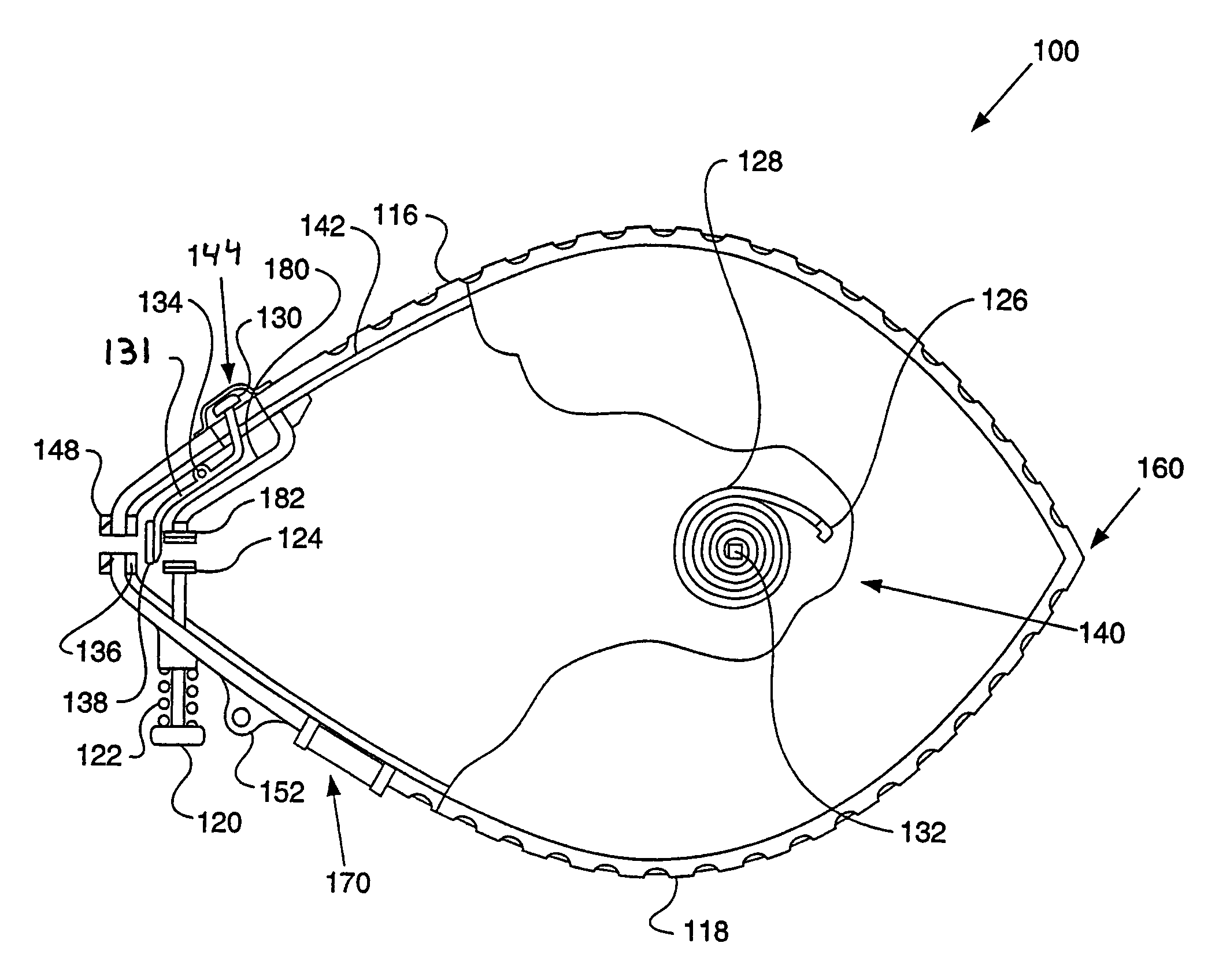

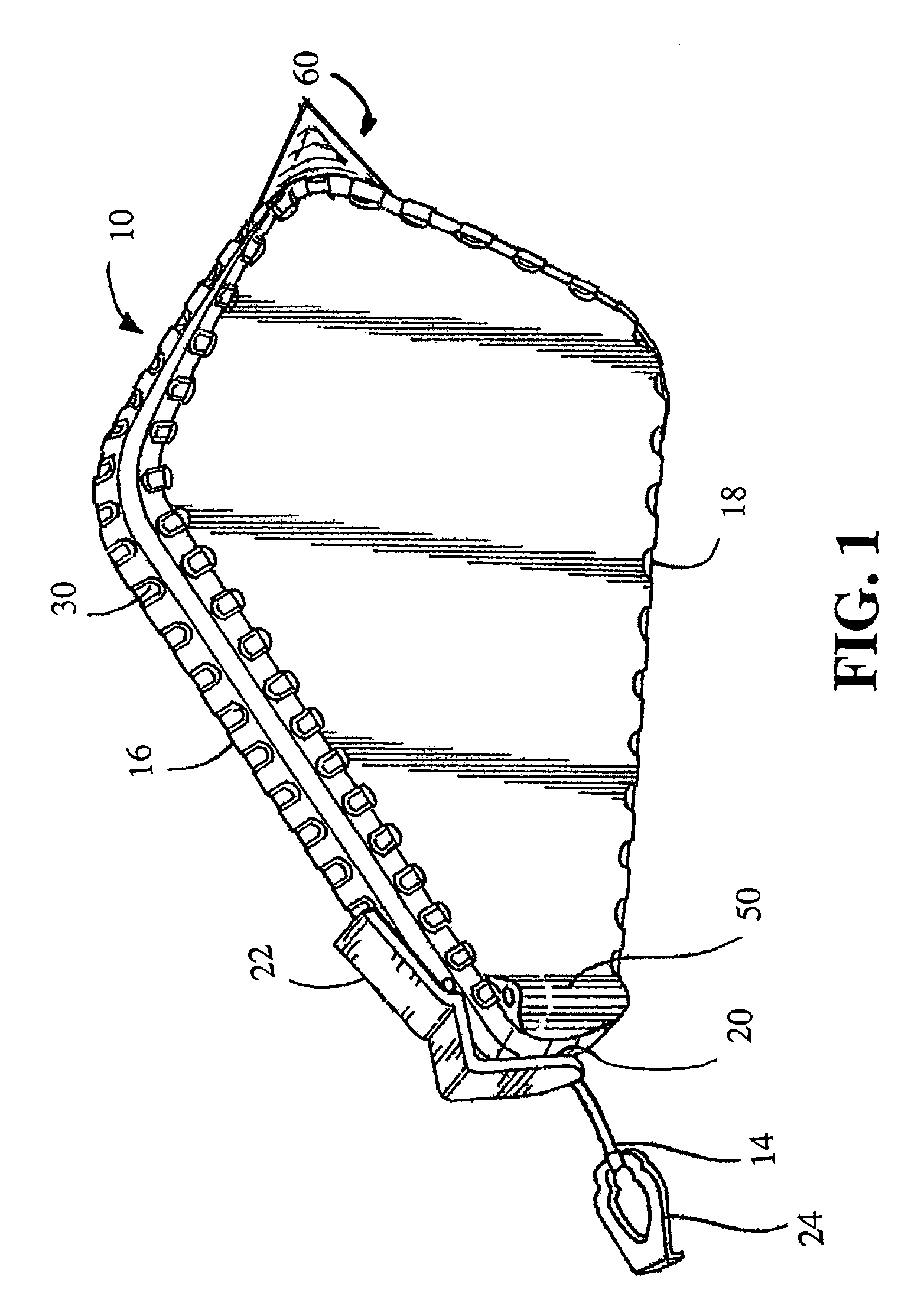

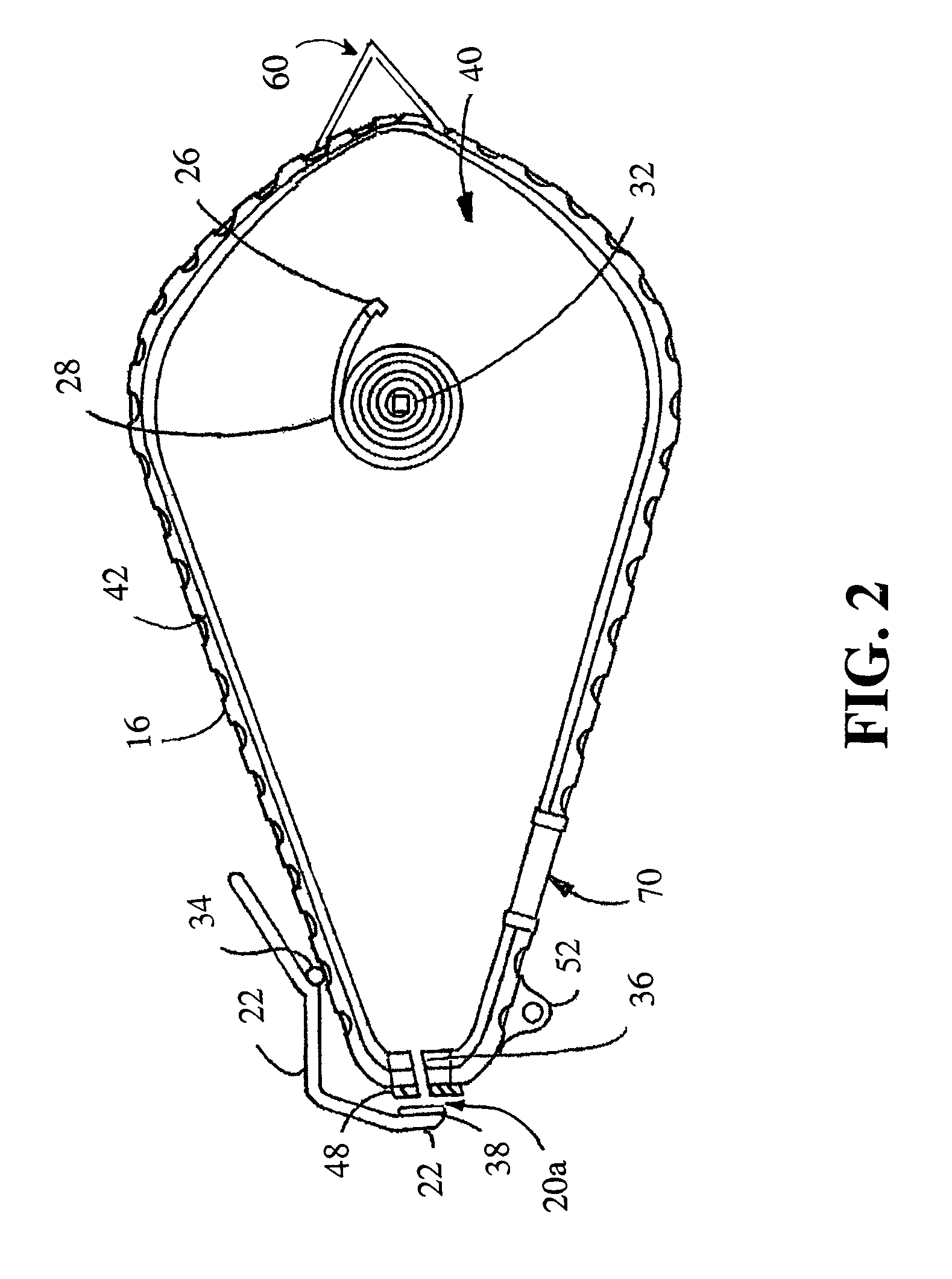

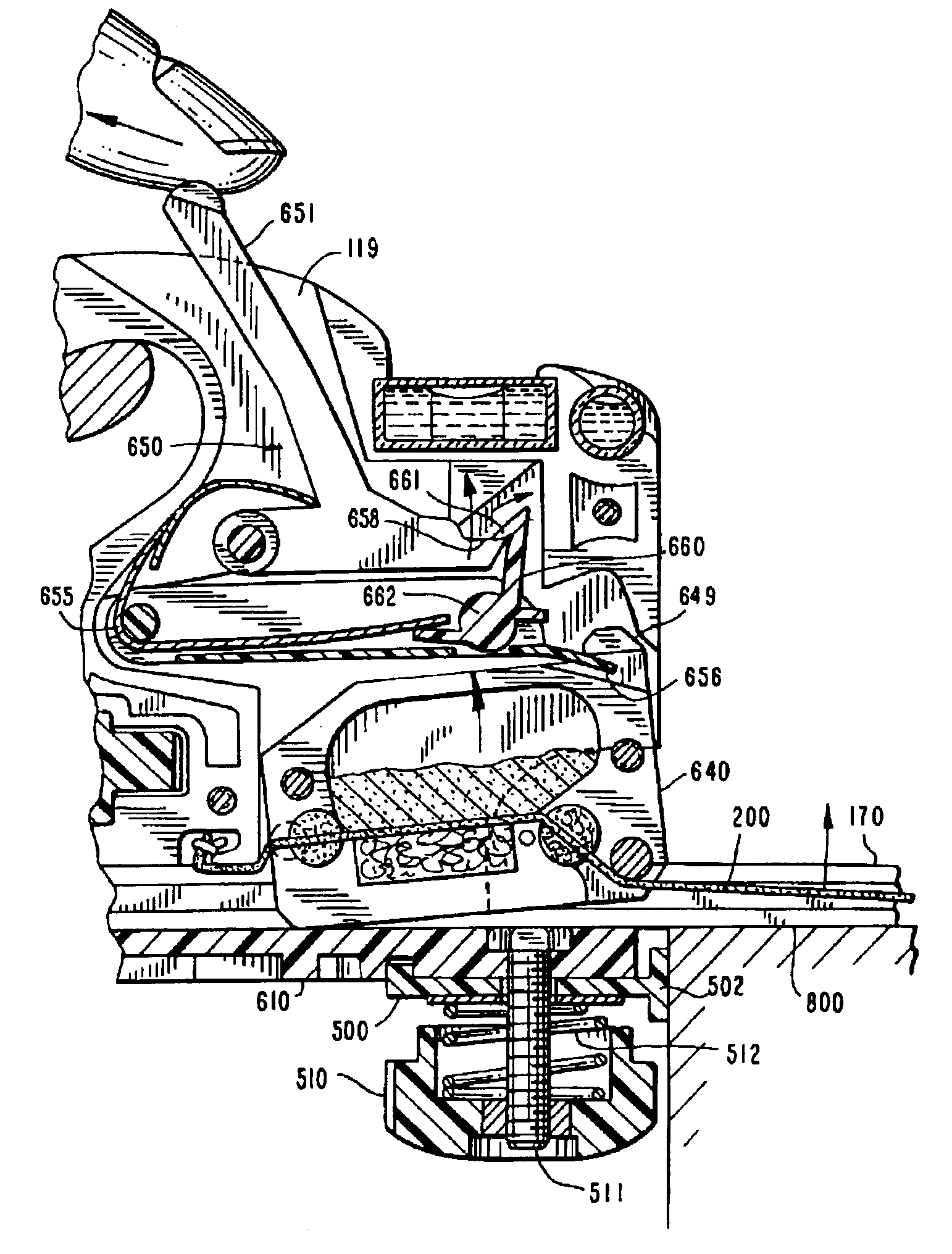

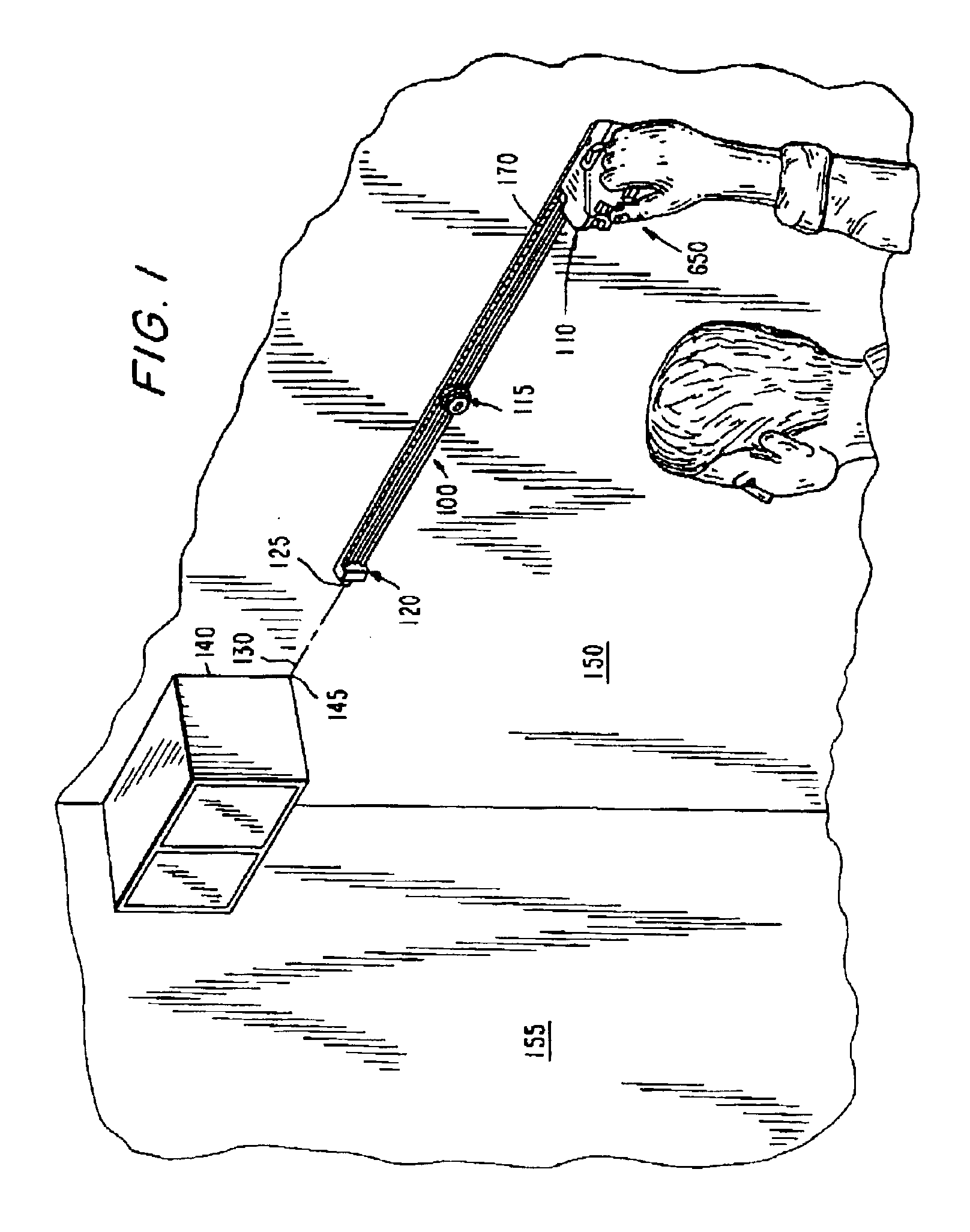

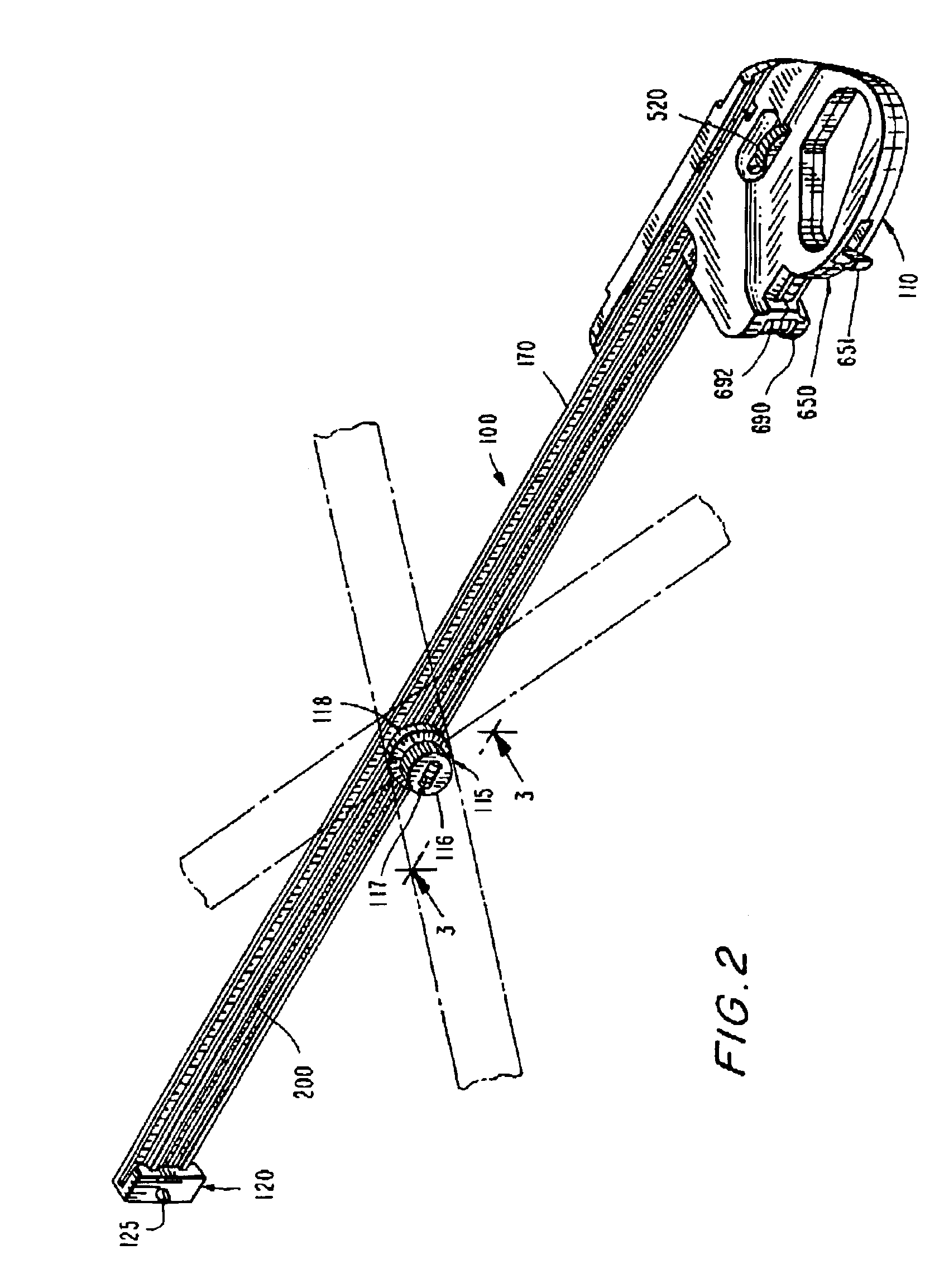

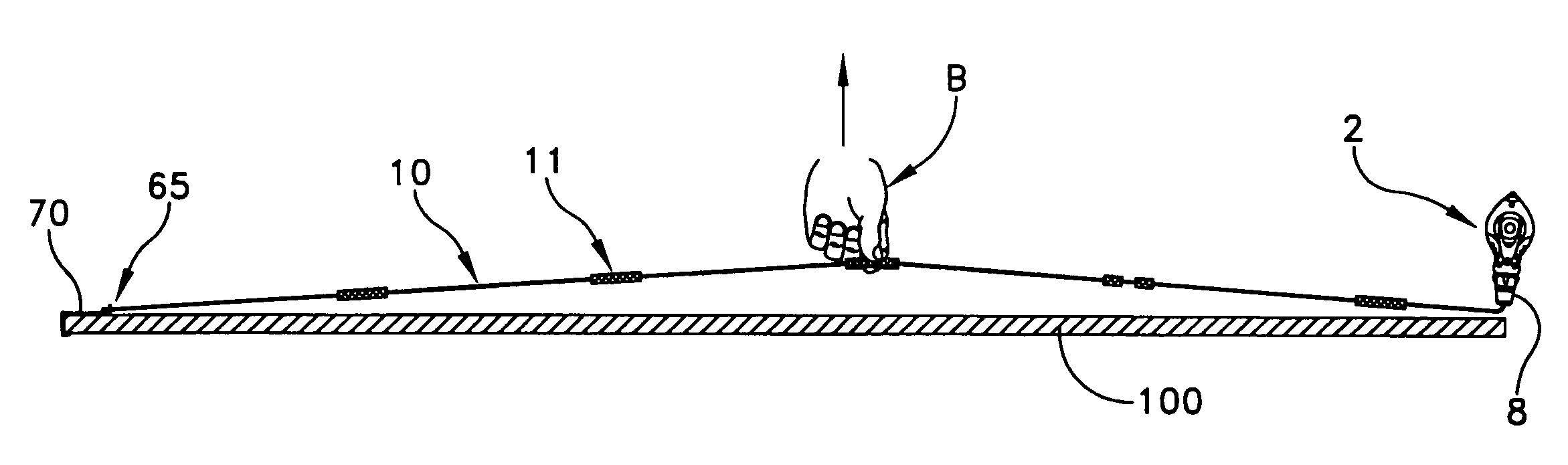

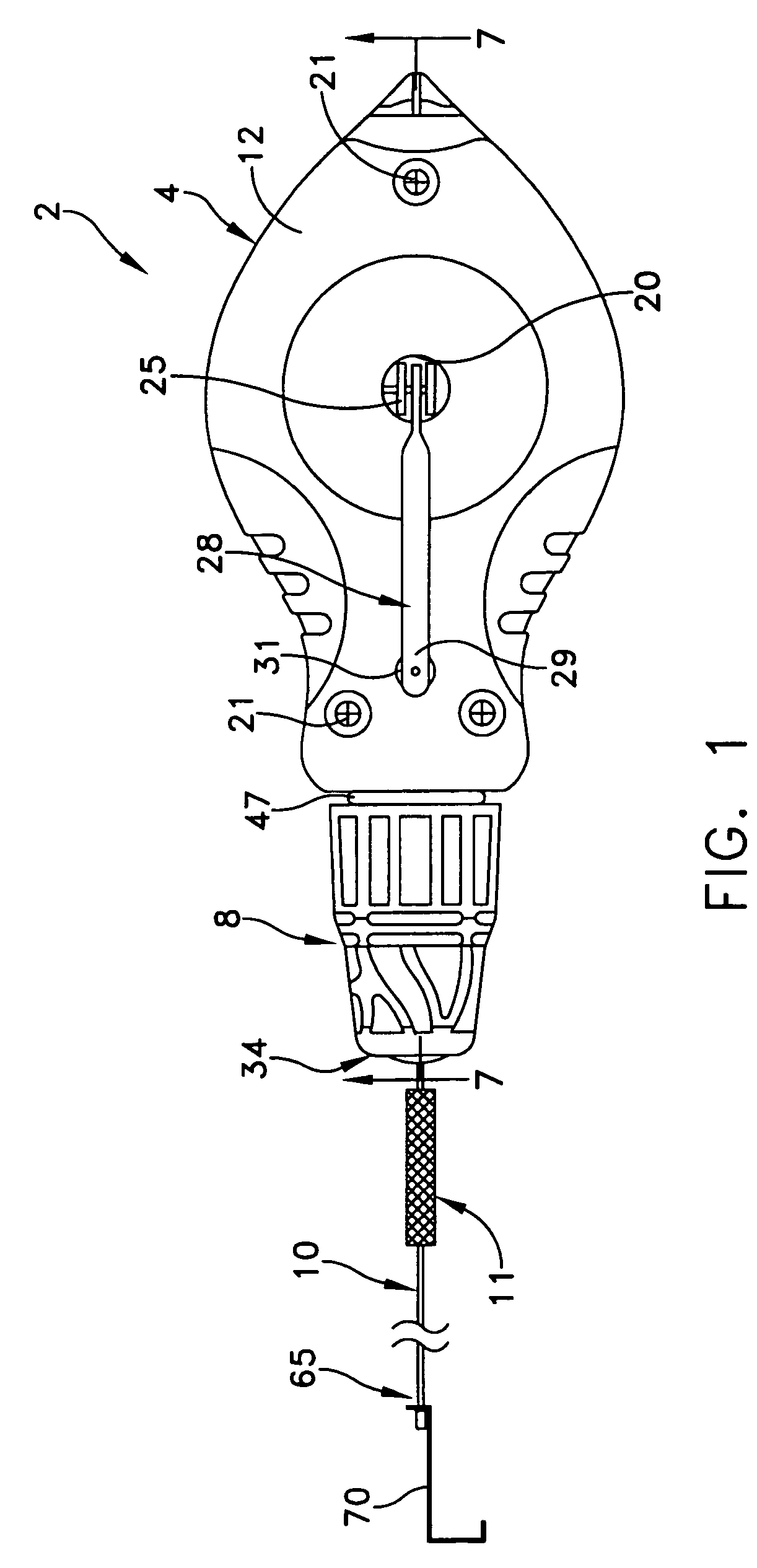

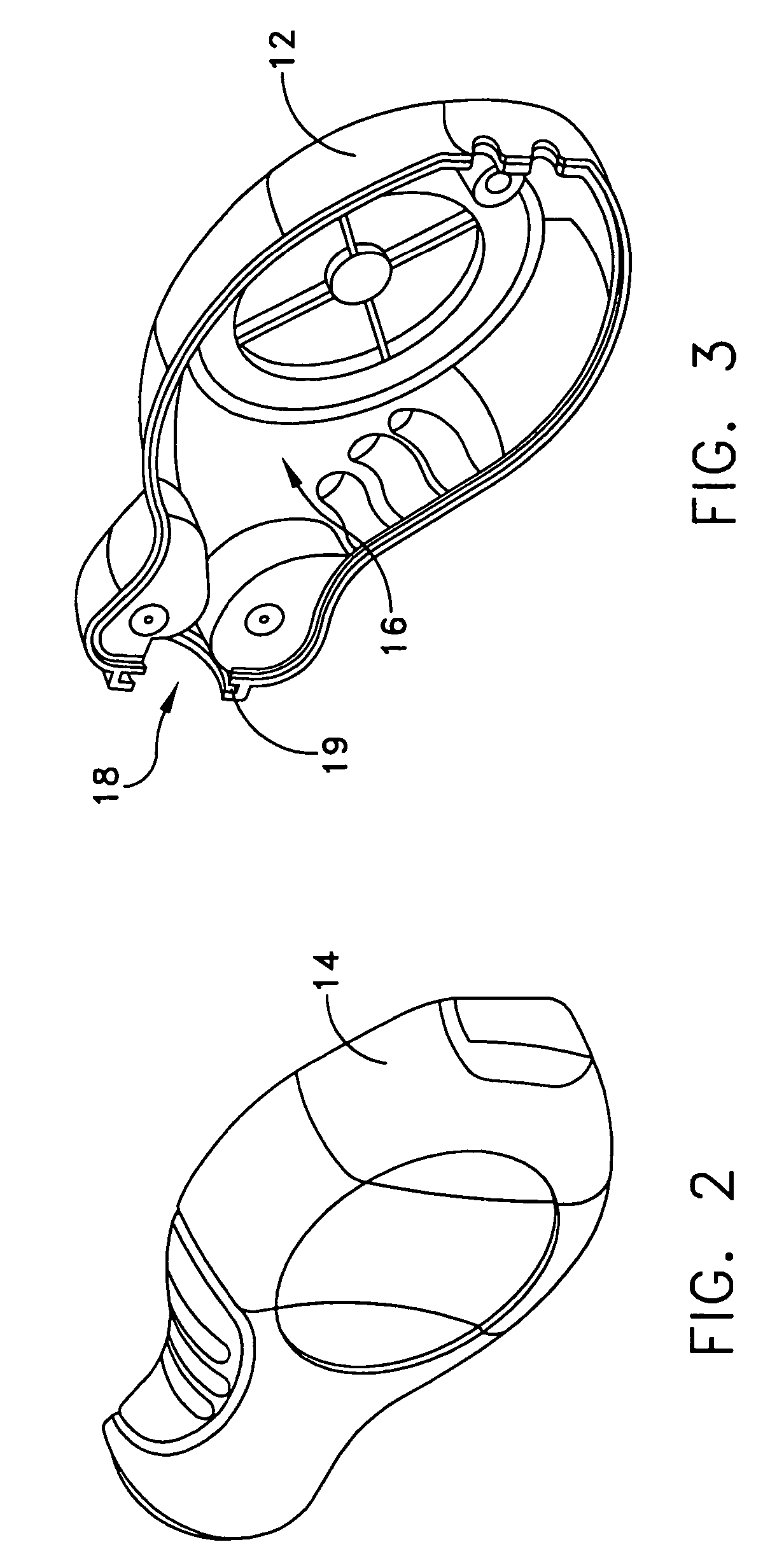

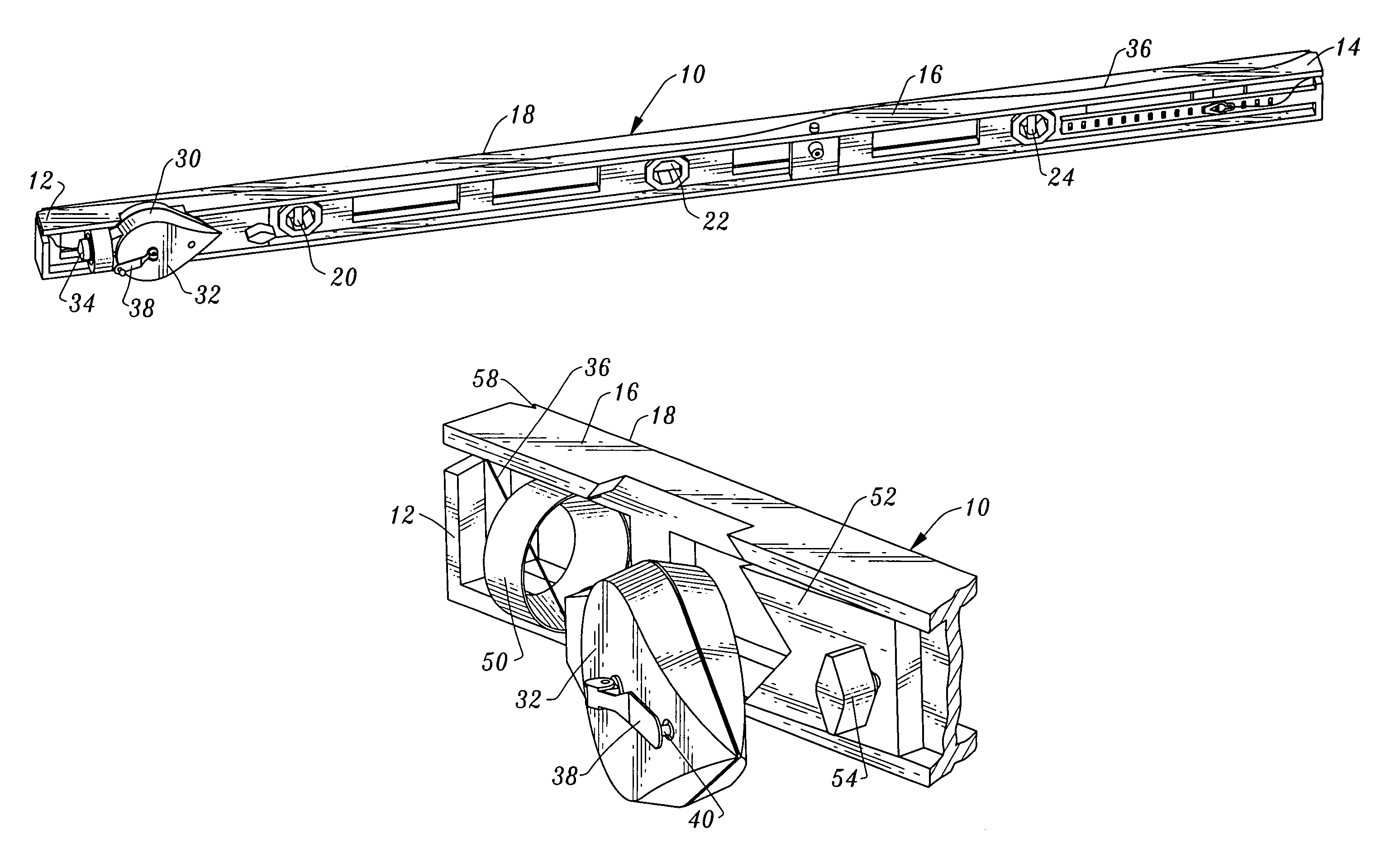

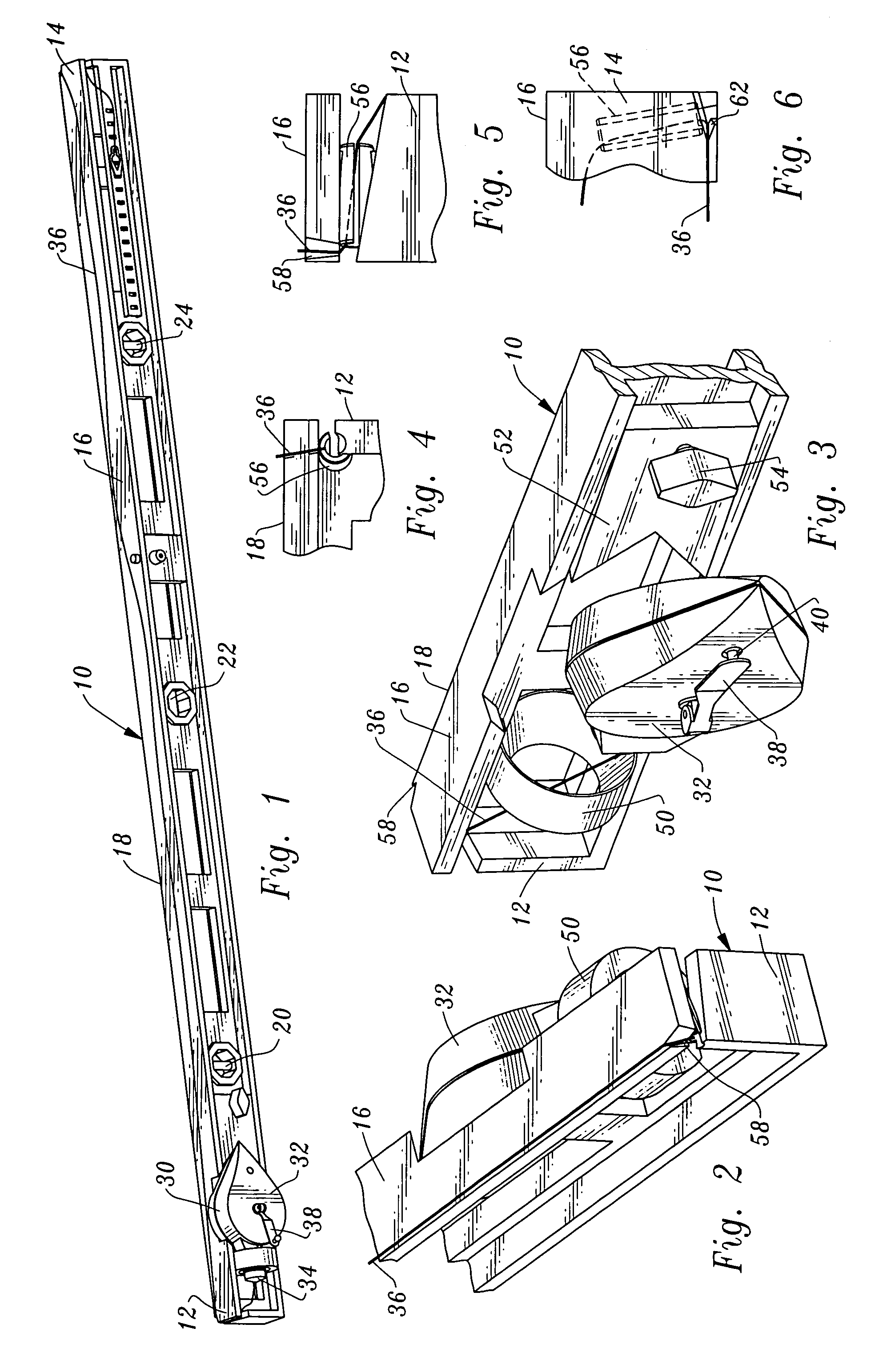

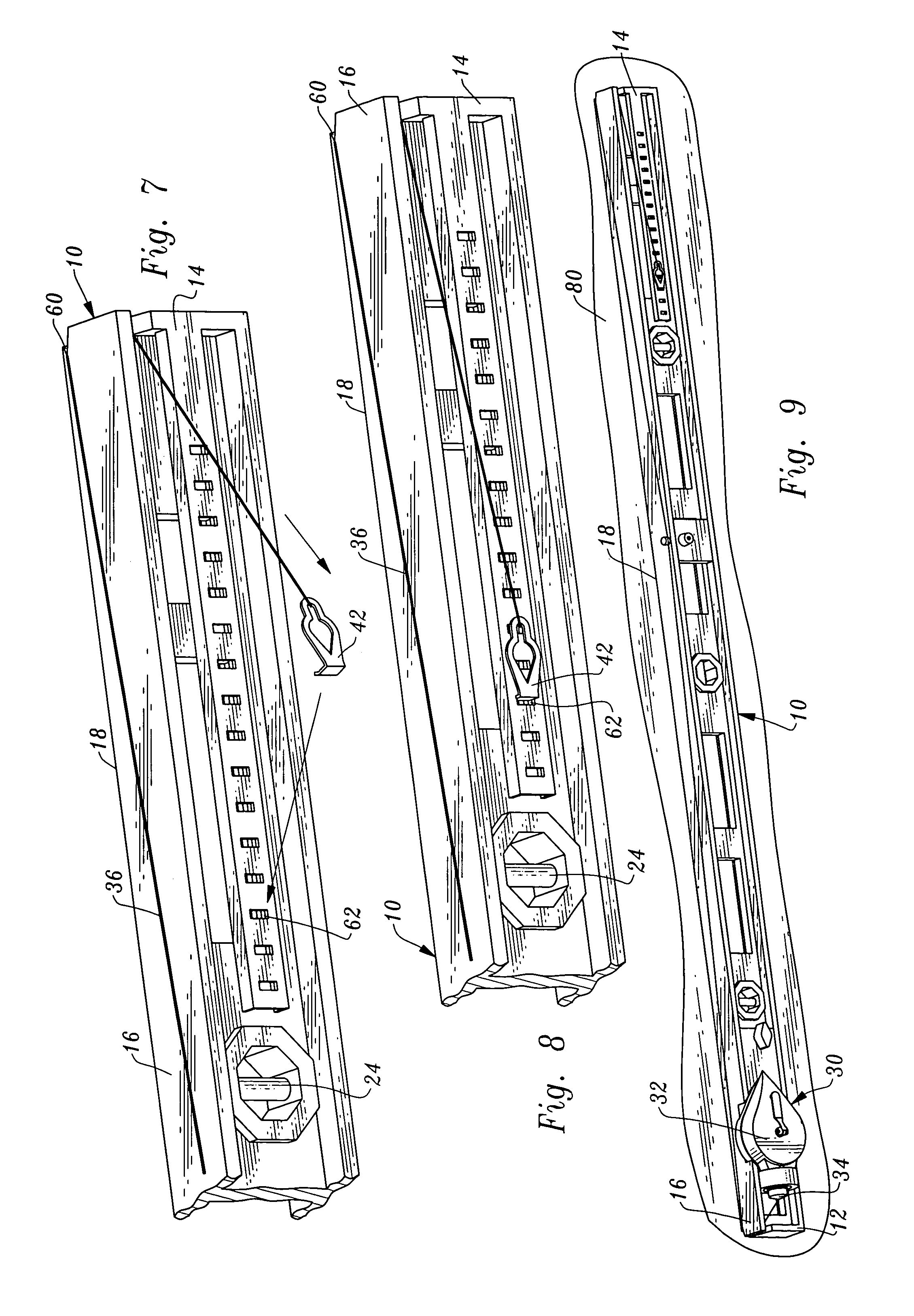

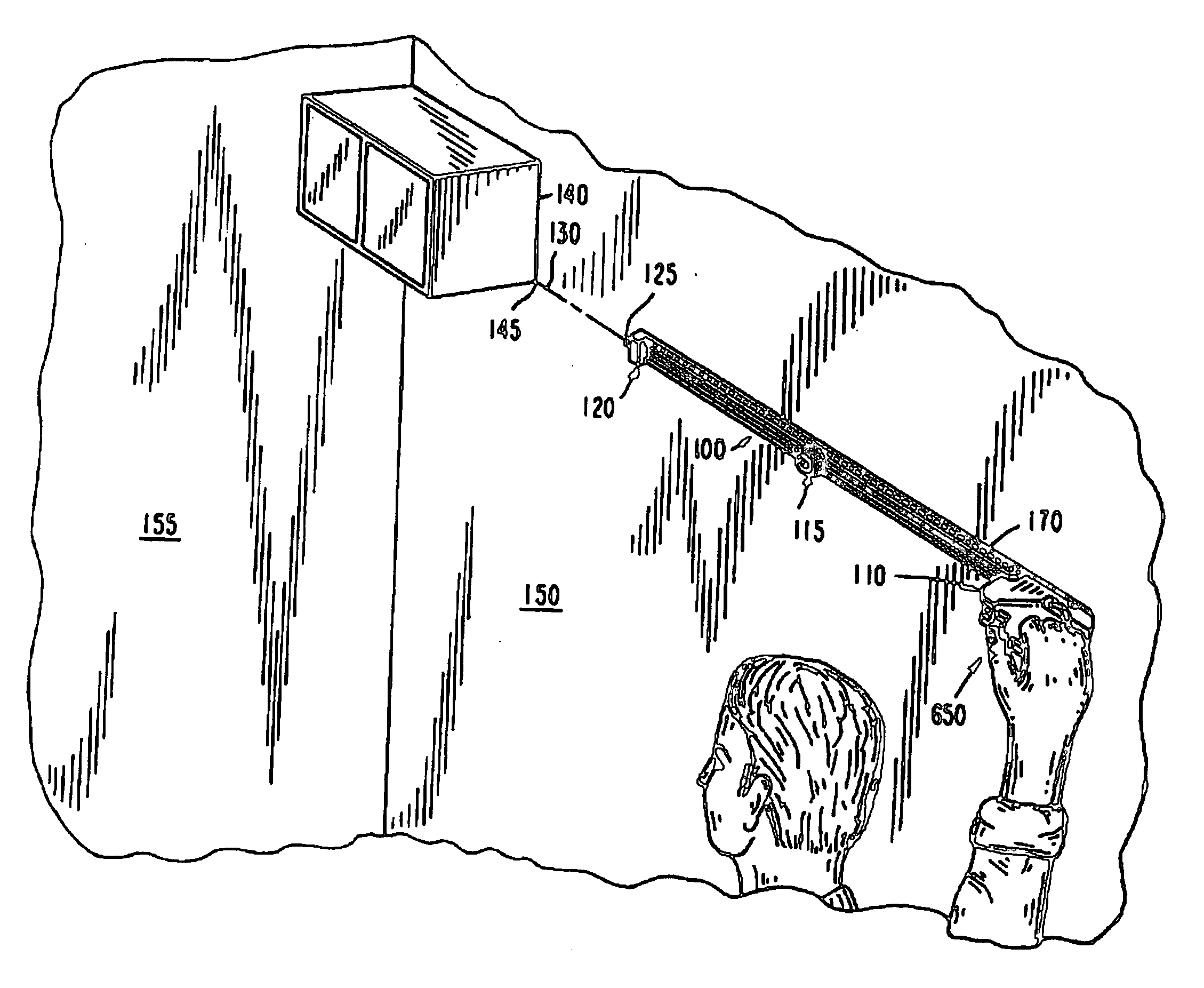

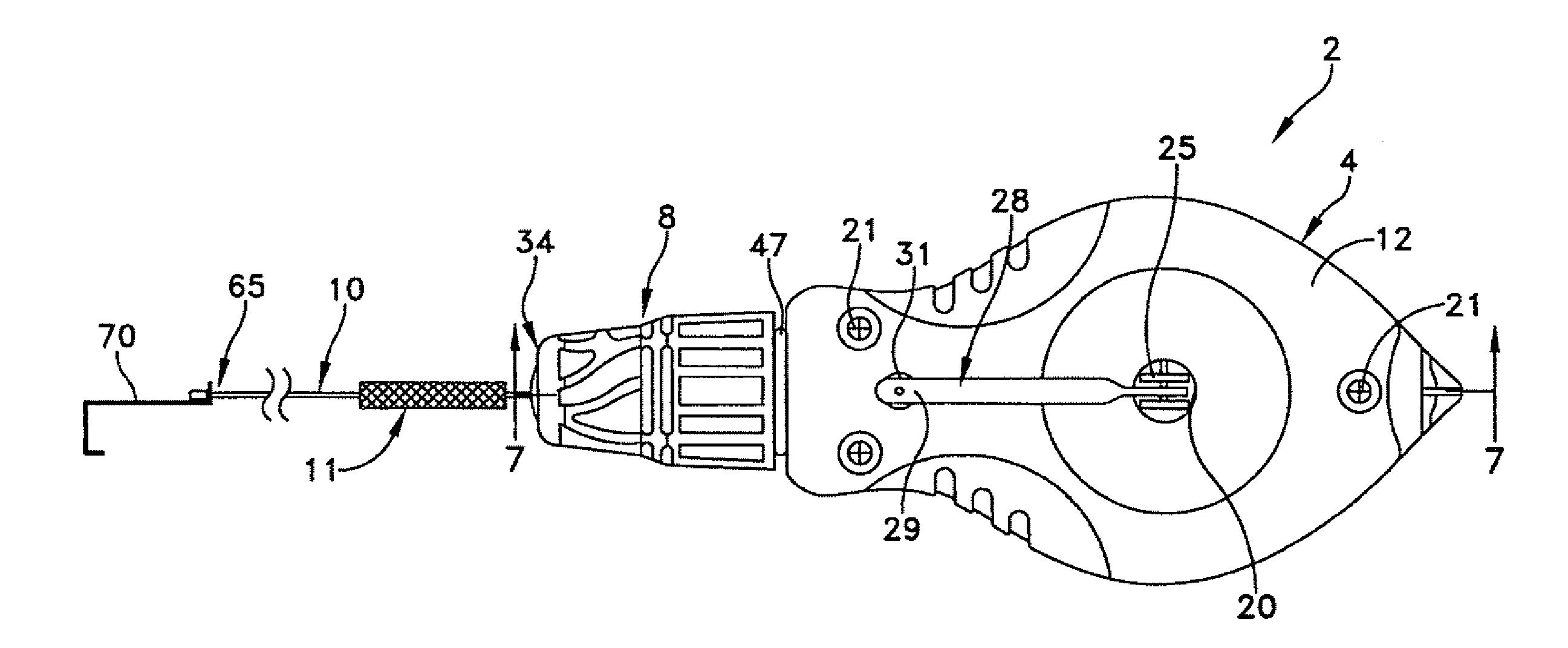

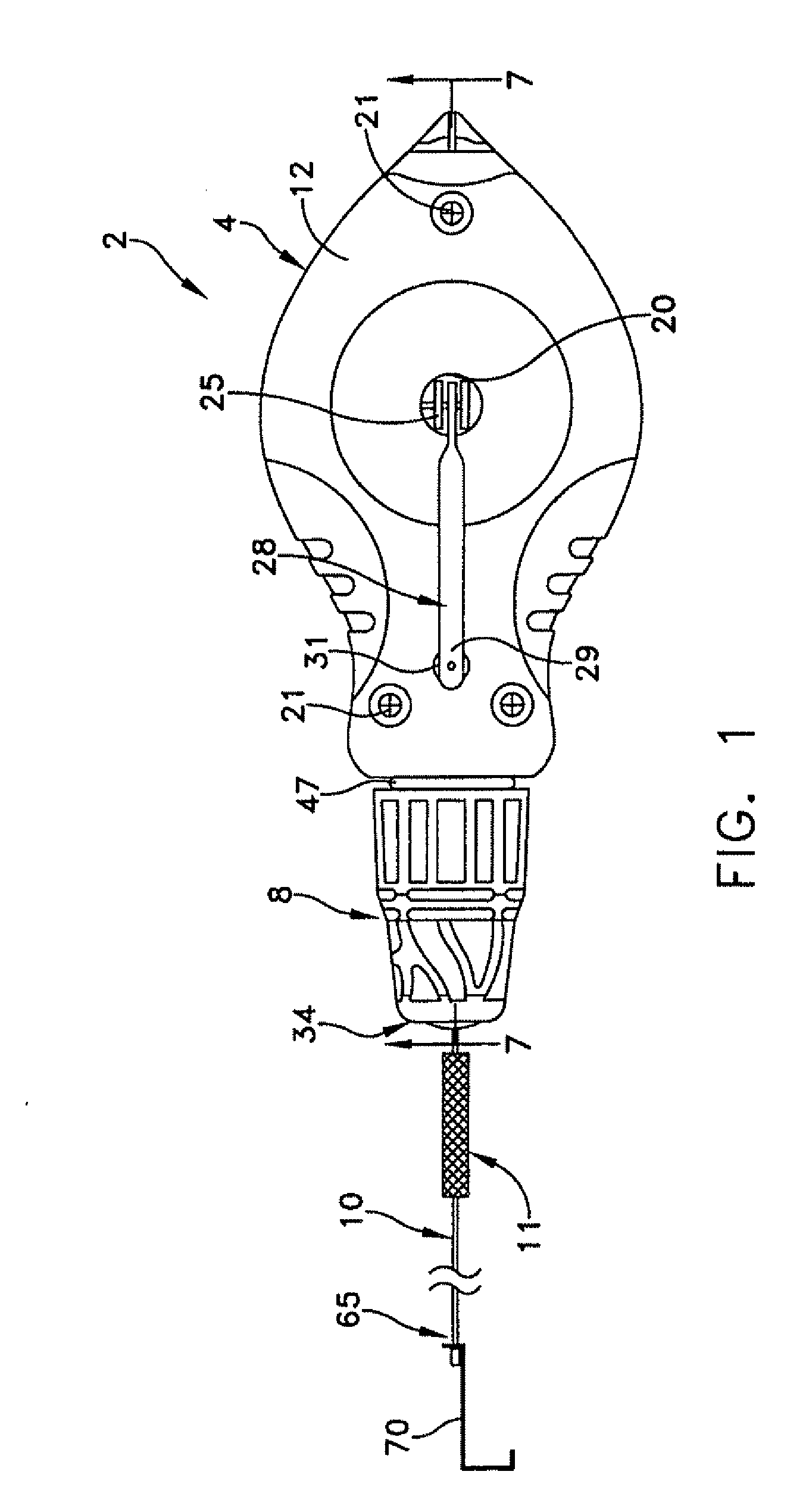

Line-marking device with positioning devices and trigger activator

InactiveUS6944962B2Easily and accurately positionEasily and accurately and markOther artistic work equipmentsProtractorEngineering

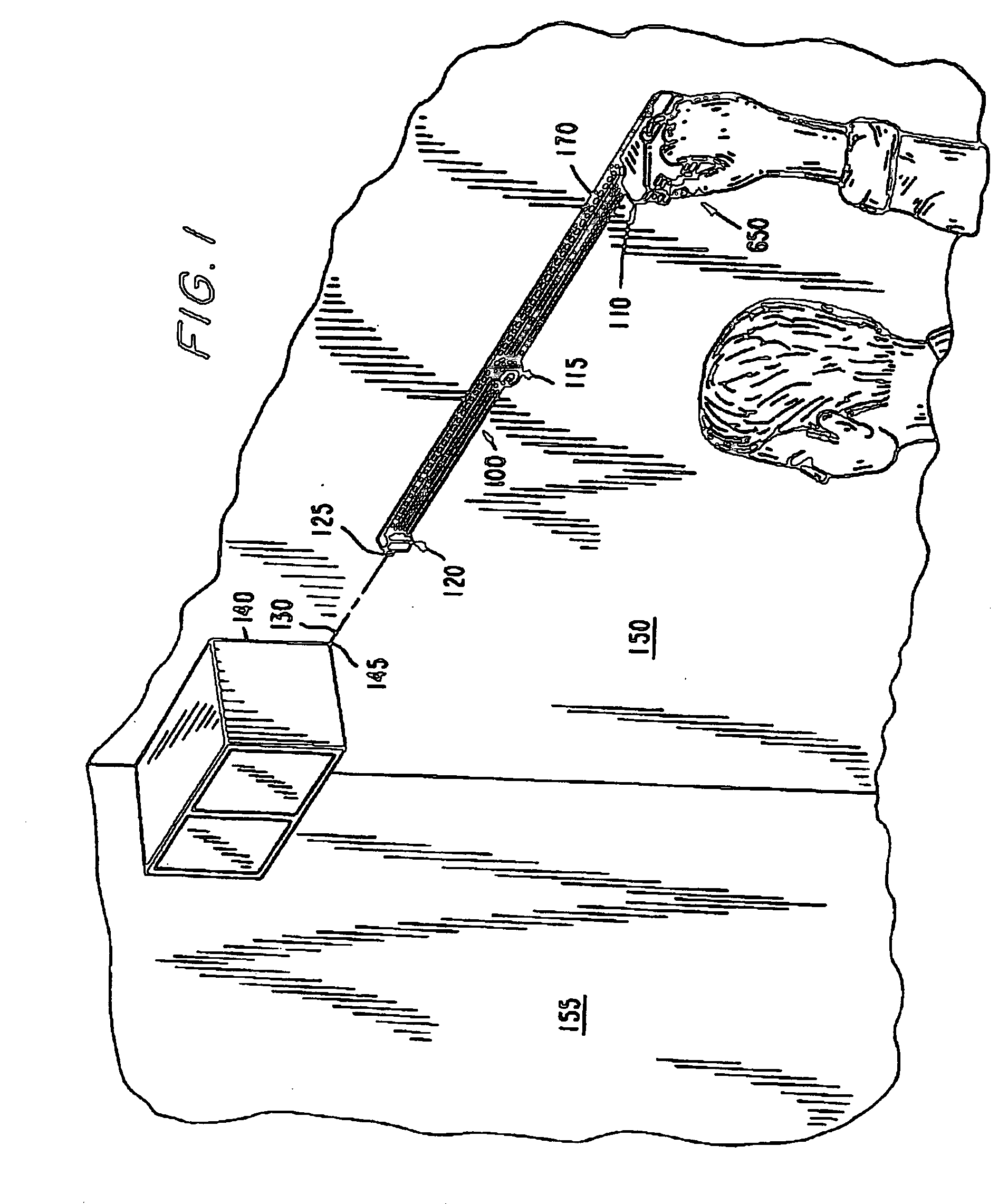

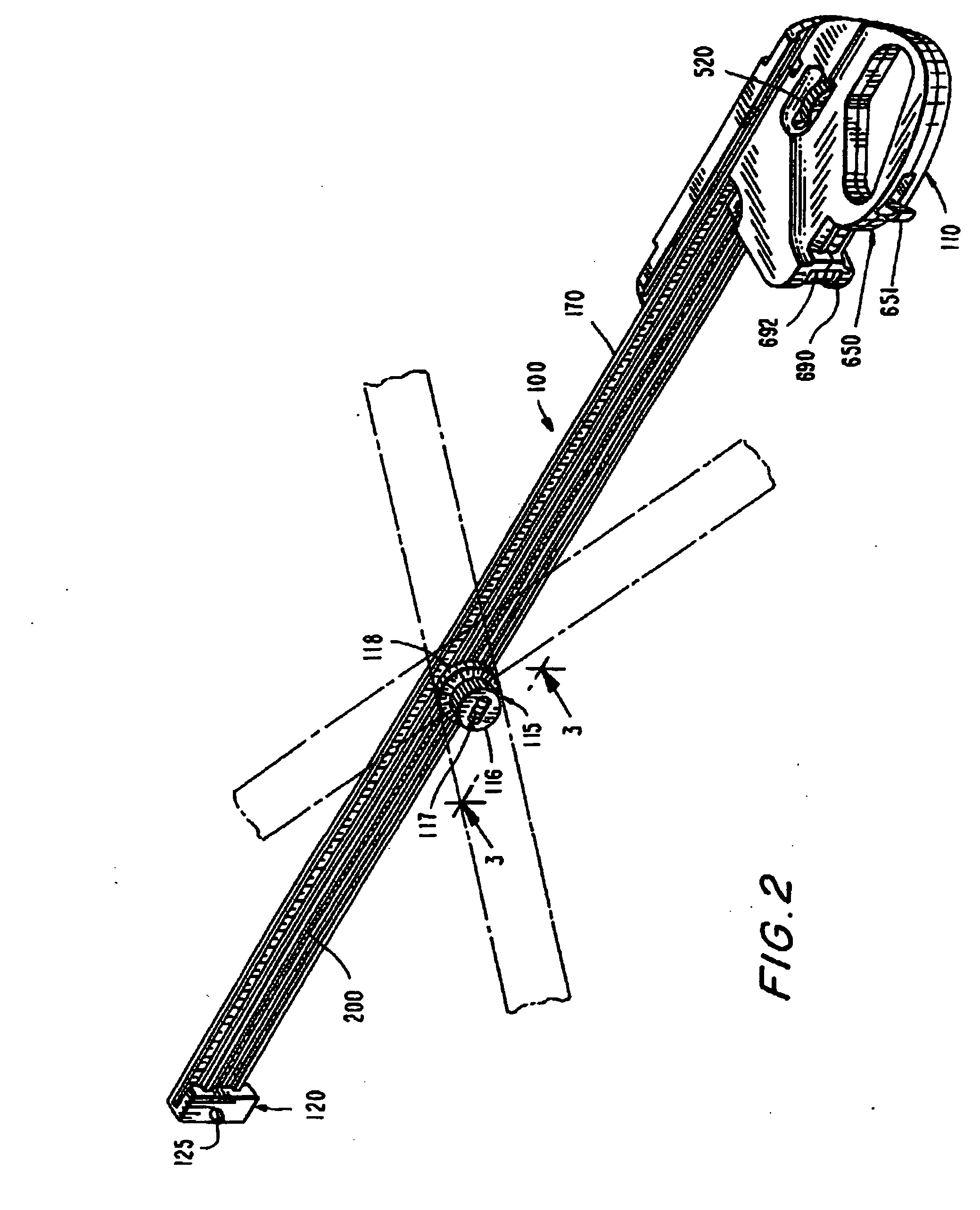

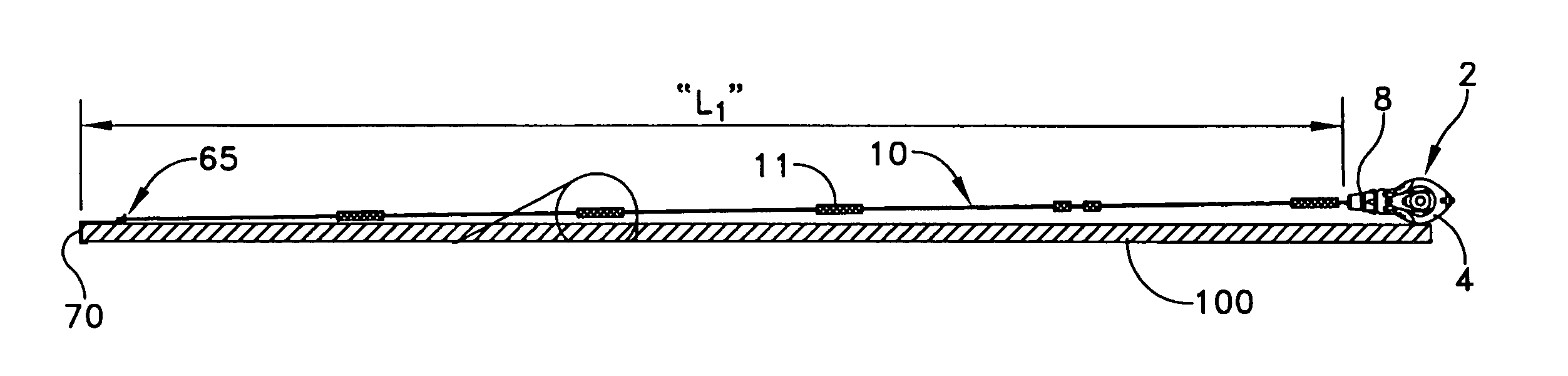

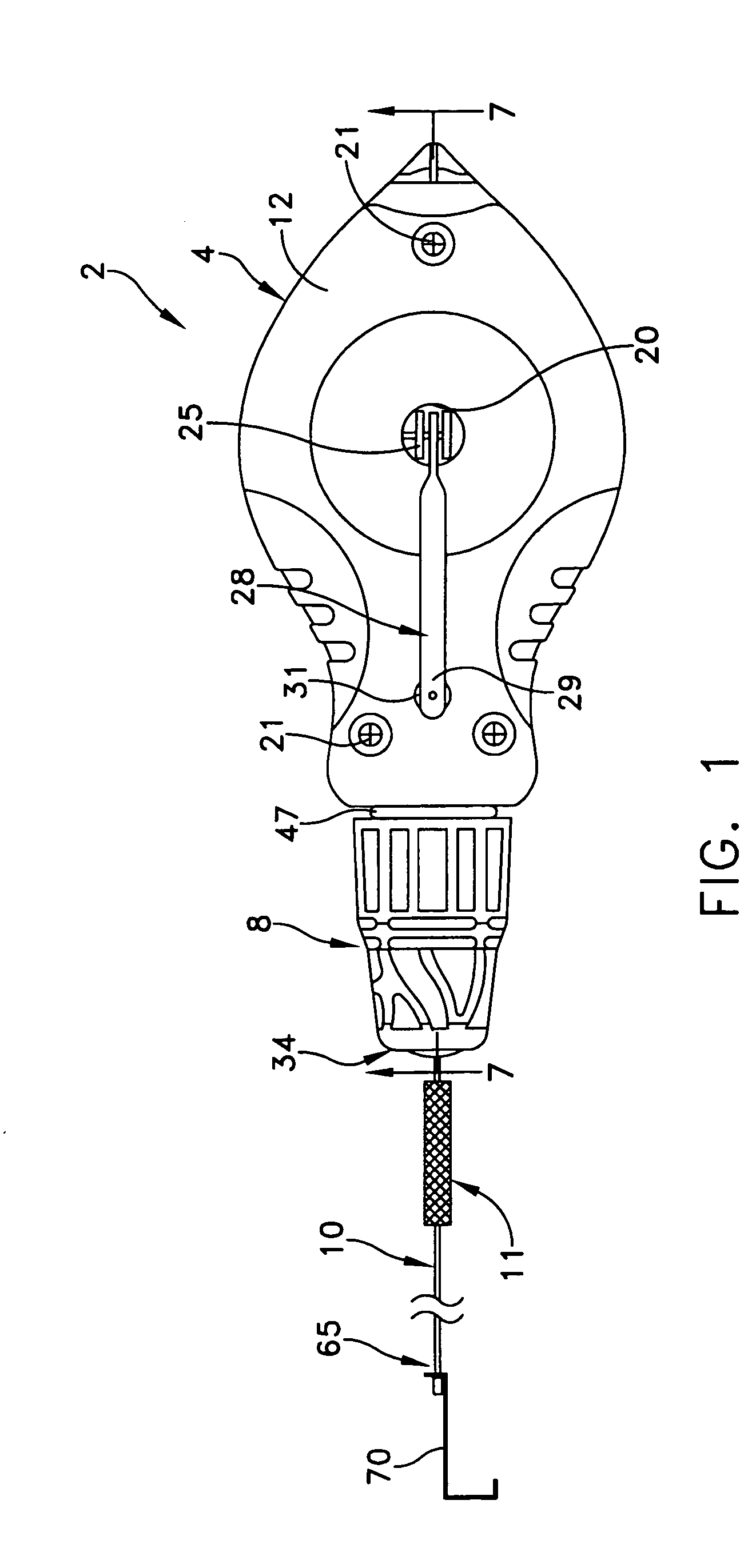

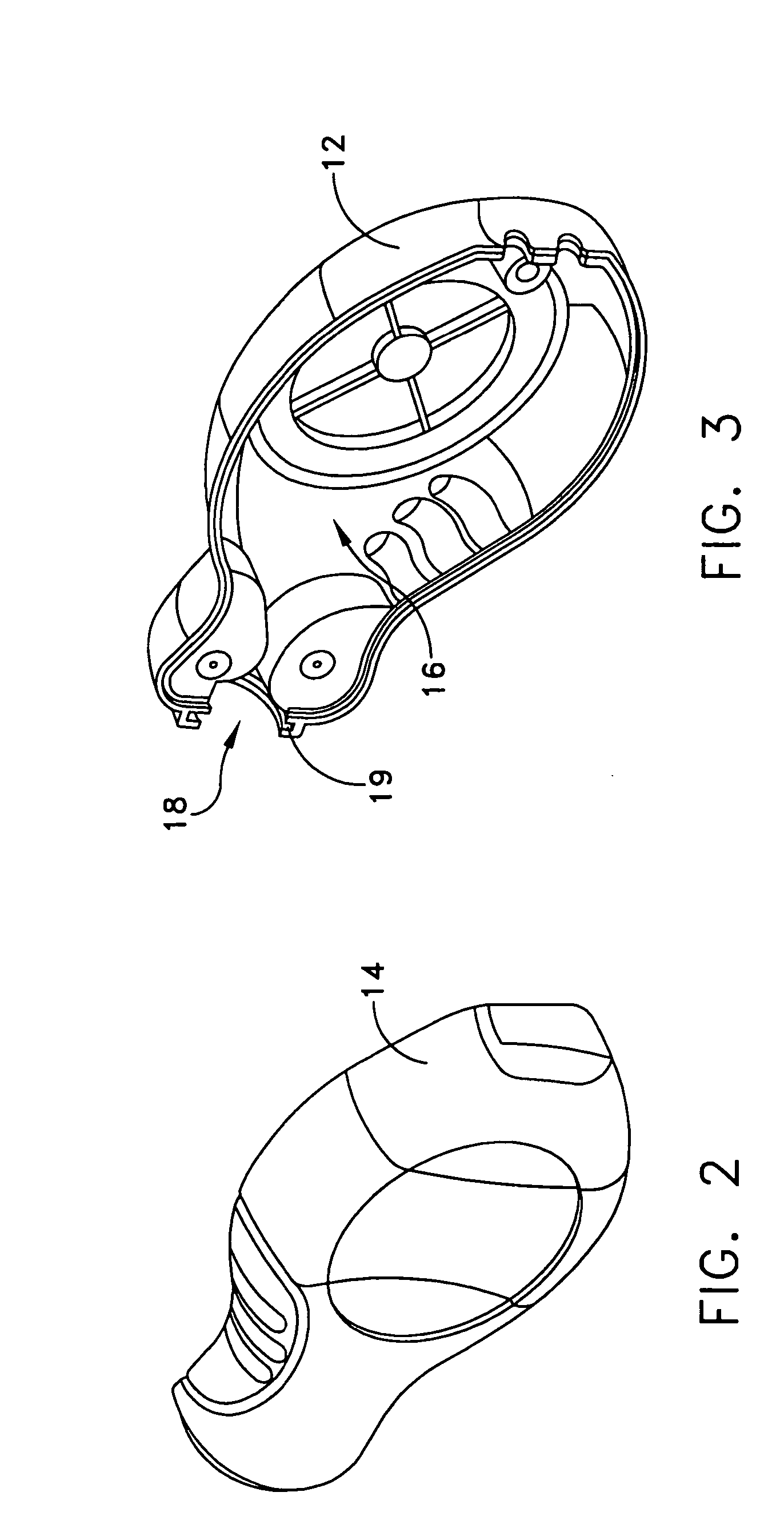

A line-marking device (100) includes a chalk line (200) that is held in an elongated frame (170). A worker can position and align the device, then snap the line (200) using a manually operated trigger (650) to leave a mark on a surface (530), such as a wall or floor. An adjustable level device (115) on the frame (170) can be rotated to dial a desired angle for the line. The adjustable level device (115) may be provided in an angle setting device independently of the line-marking device. A laser device (125) may be carried at the tip (120) of (or elsewhere on) the frame (170) to allow the chalk line to be aligned with a reference mark (145). Respective markings (176, 177) on edge regions of rails (171, 174) of the frame (170) may indicate an angular setting of a guide bar (500), or, a protractor (810, 810a) may indicate the angular setting. The guide bar (500) may be relocated facing away from the filament (200) and used as an angle finding device. A retractable tape measure (1500) carried by the device enables a worker to measure distances from the chalk line.

Owner:UMBRO LLC

Moisture resistant chalk line composition for use with chalk line devices

The present invention is moisture resistant chalk line composition comprising an effective amount of calcium carbonate, an effective amount of one or more dyes, and an effective amount of one or more hydrophobes, said effective amount of calcium carbonate comprises at least about 50% by weight of the composition, said effective amount of one or more dyes is selected from a range of about 0% to about 49% by weight of the composition, and said effective amount of one or more hydrophobes does not exceed about 30% by weight of the composition. The chalk line composition is useful for repeatedly marking guide lines with the same chalk line device on wet surfaces or moist environments. Also claimed is a method for repeatedly forming guide lines on surfaces utilizing a moisture resistant chalk line composition with a snap line from a chalk line device.

Owner:BRAHAM ERIC BARKLEY

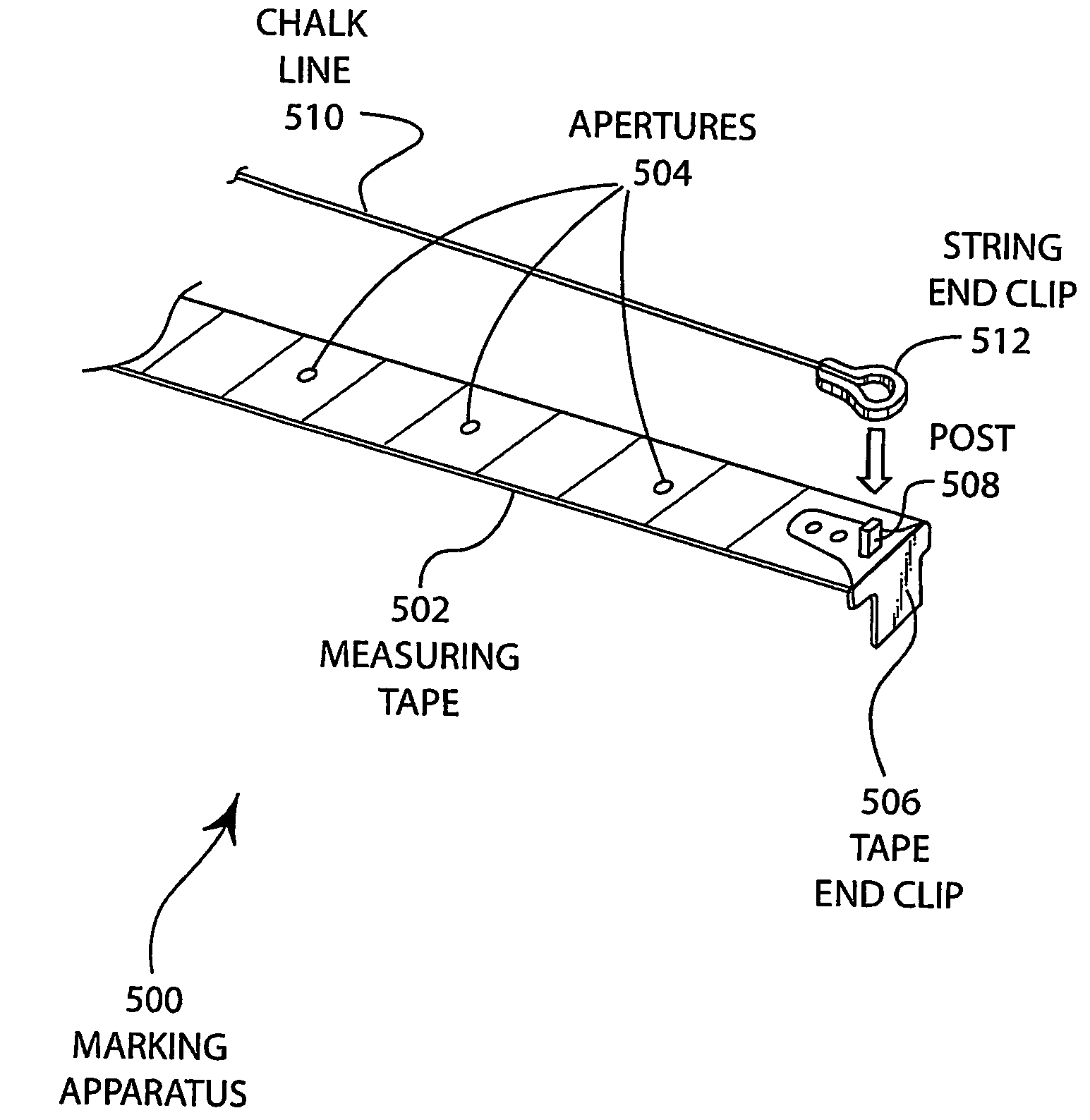

Marking tape measure

InactiveUS20060107546A1Other artistic work equipmentsMeasuring tapesEngineeringElectrical and Electronics engineering

A marking device for making layout marks an surfaces such as boards, panels, or walls including a tape measure with a plurality of holes disposed along its length is disclosed. The device also contains a reel for dispensing a chalk line wherein the chalk line is positioned over the tape measure. The chalk line may be tensioned and snapped to transfer chalk through the holes, thereby providing marks at predetermined intervals.

Owner:PRITCHARD GARY

Chalk line with selectively adjustable tip

InactiveUS6931743B1Other artistic work equipmentsRulers for direct readingEngineeringCircular segment

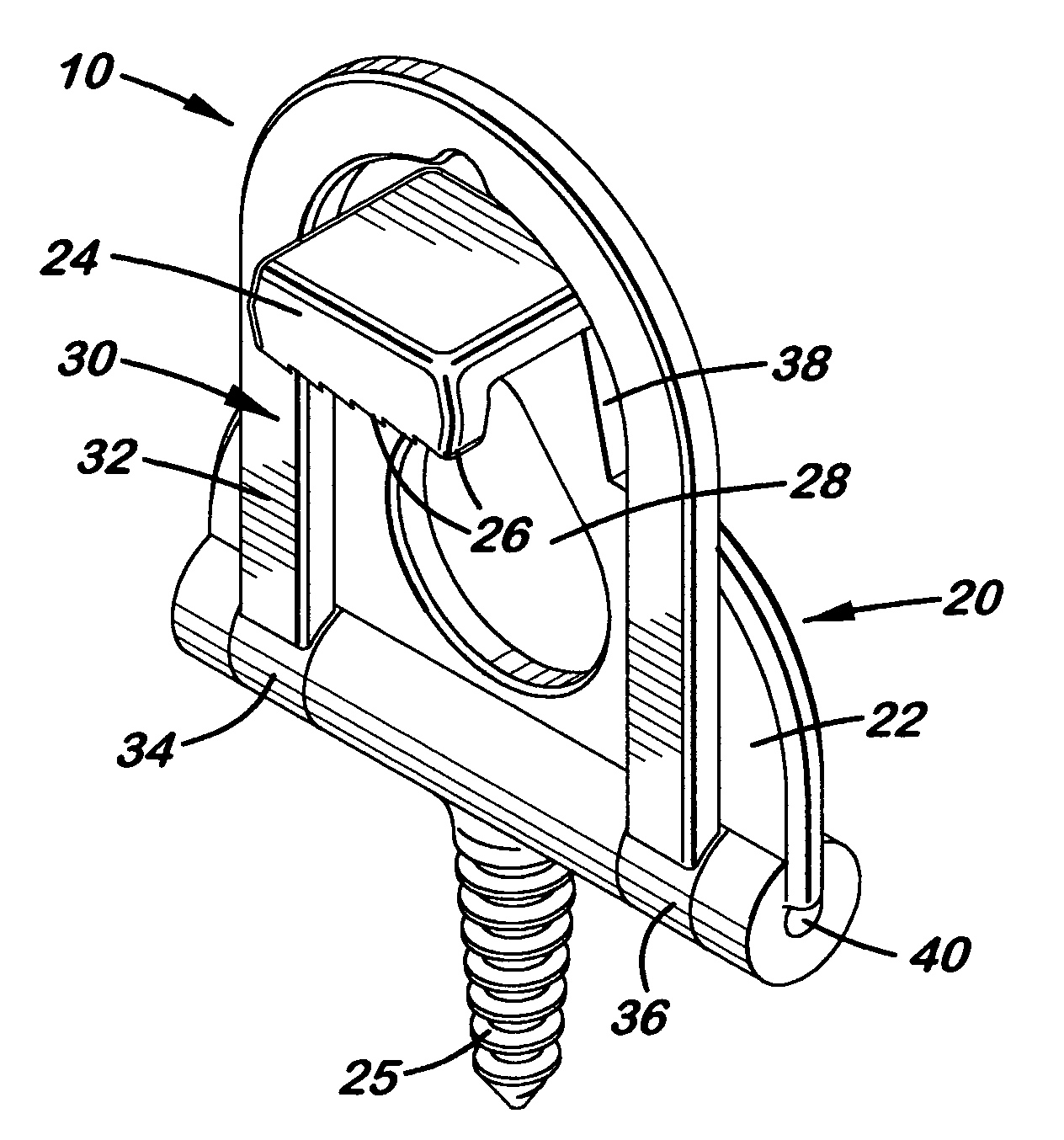

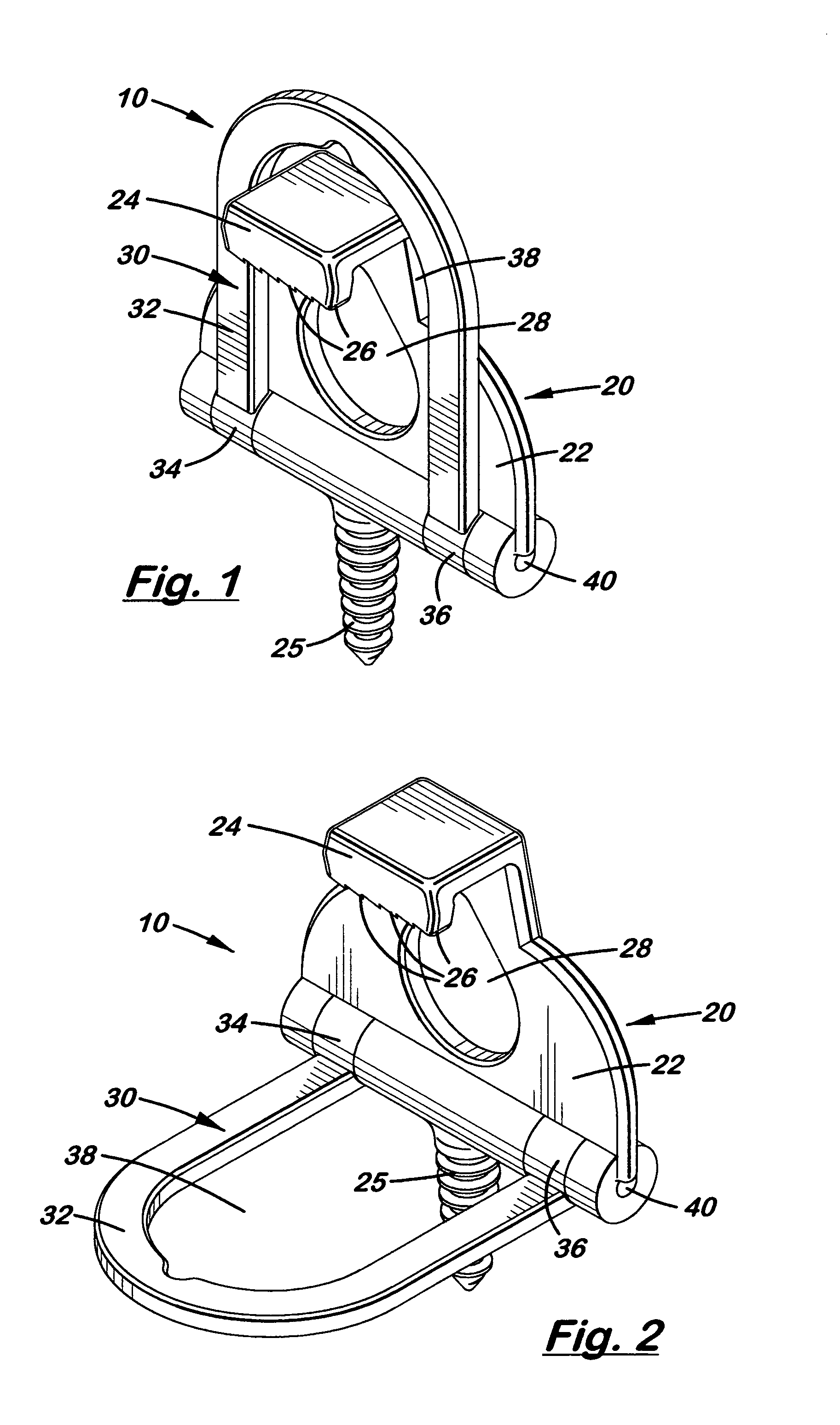

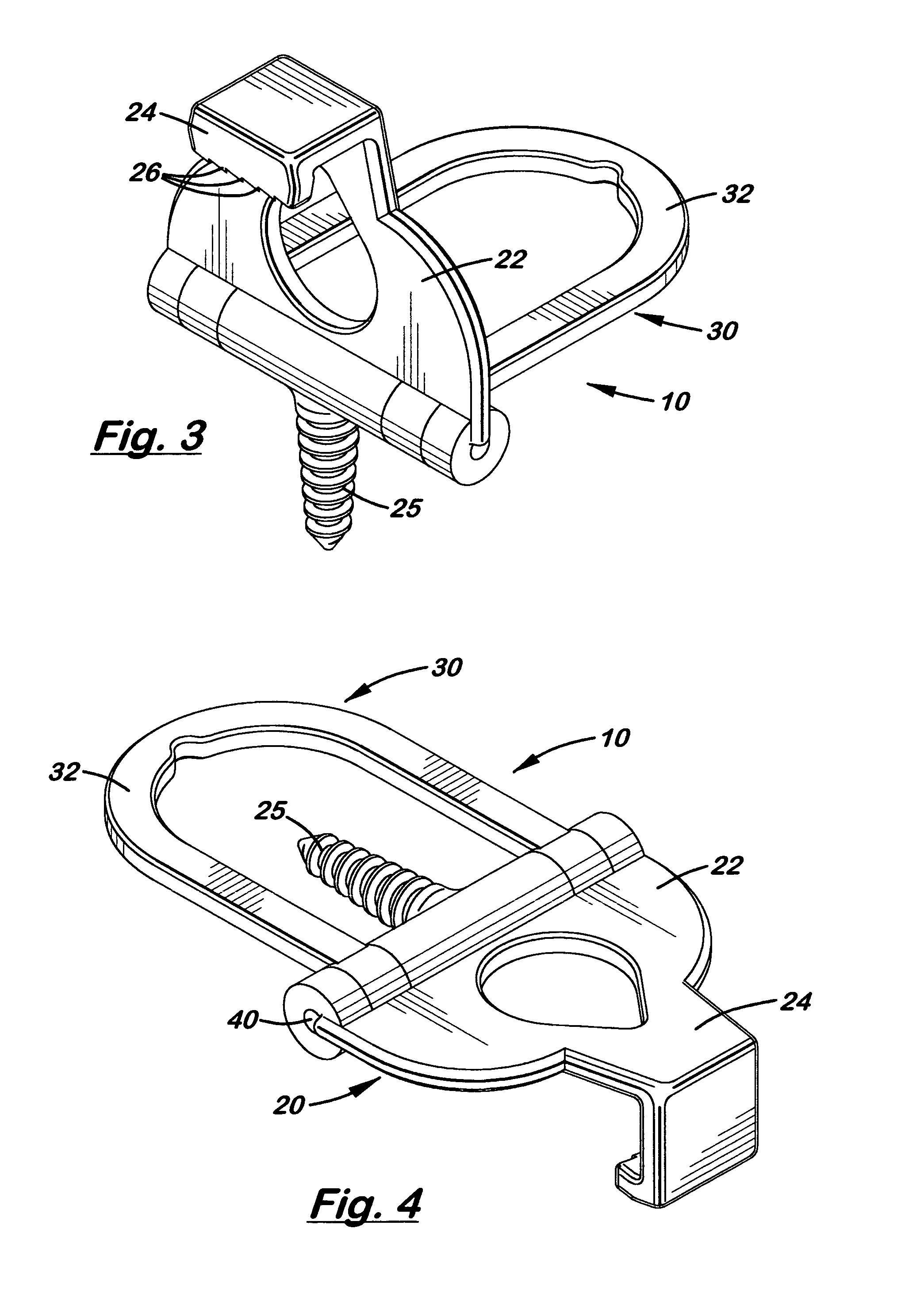

An improved chalk line tip for a chalk-line. The tip having a string attachment portion, having a first end configured to receive a pivot pin therein and extending in a generally arcuately shaped configuration toward a second end, which is also configured to receive a pivot pin therein. The string connection body defining an aperture dimensioned to allow passage of a portion of the attachment portion therethrough. A surface attachment portion having various devices for attaching the surface attachment portion to a surface to be marked. The tip is configured to allow various configurations of the attachment device to be presented and attached to a surface to be marked thus allowing for increased applicability and utility upon a variety of surfaces.

Owner:IRWIN IND TOOL CO

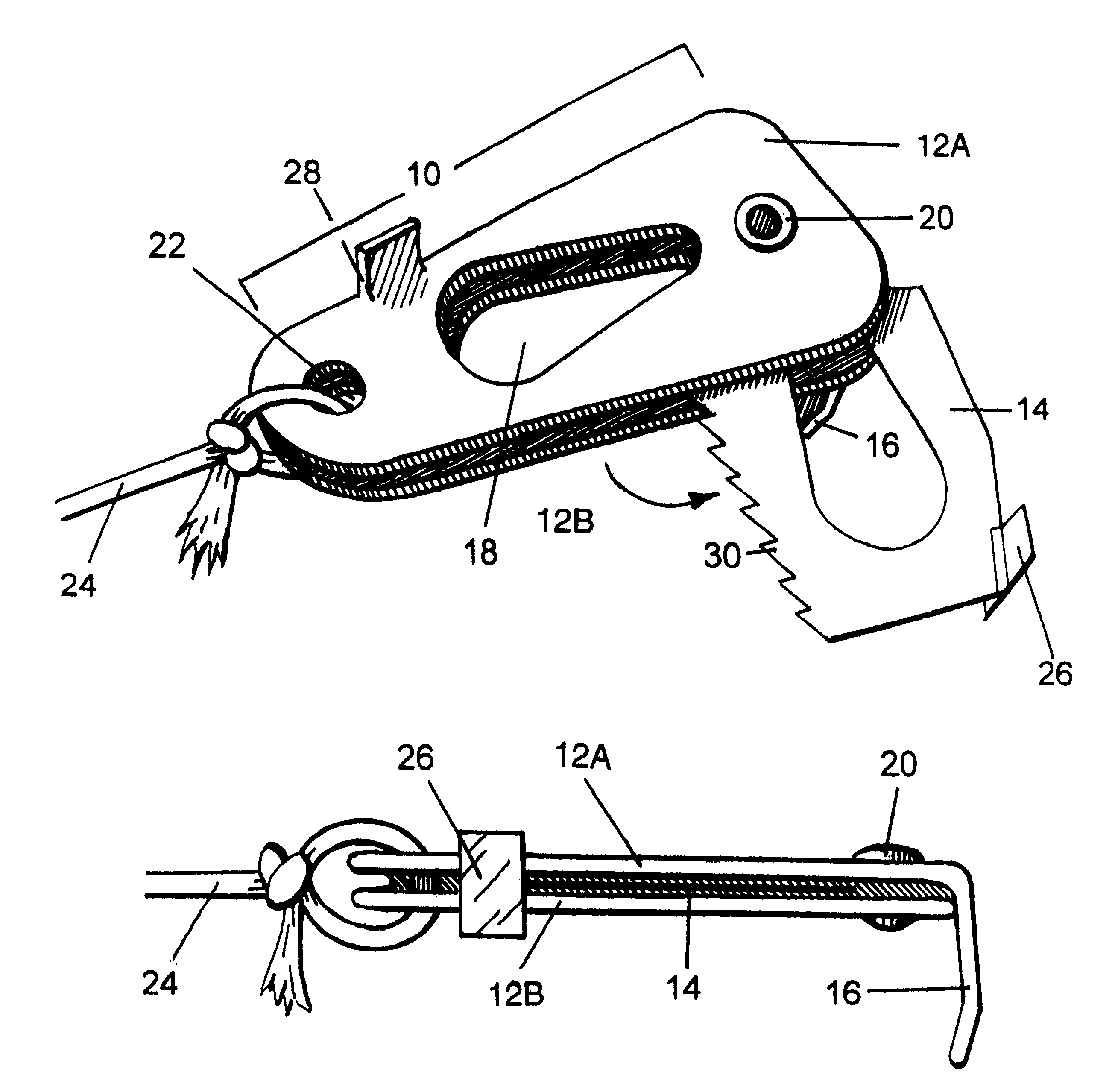

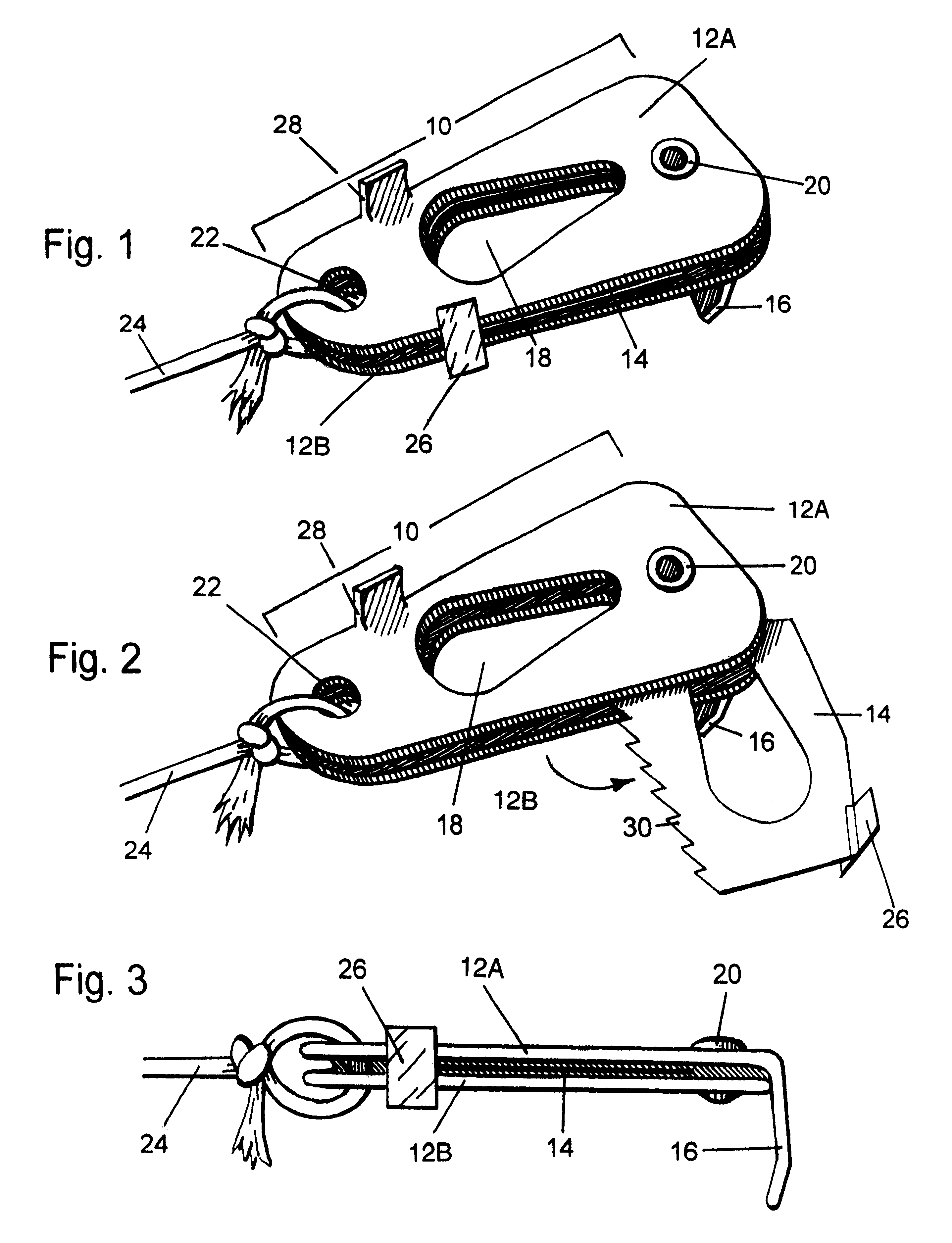

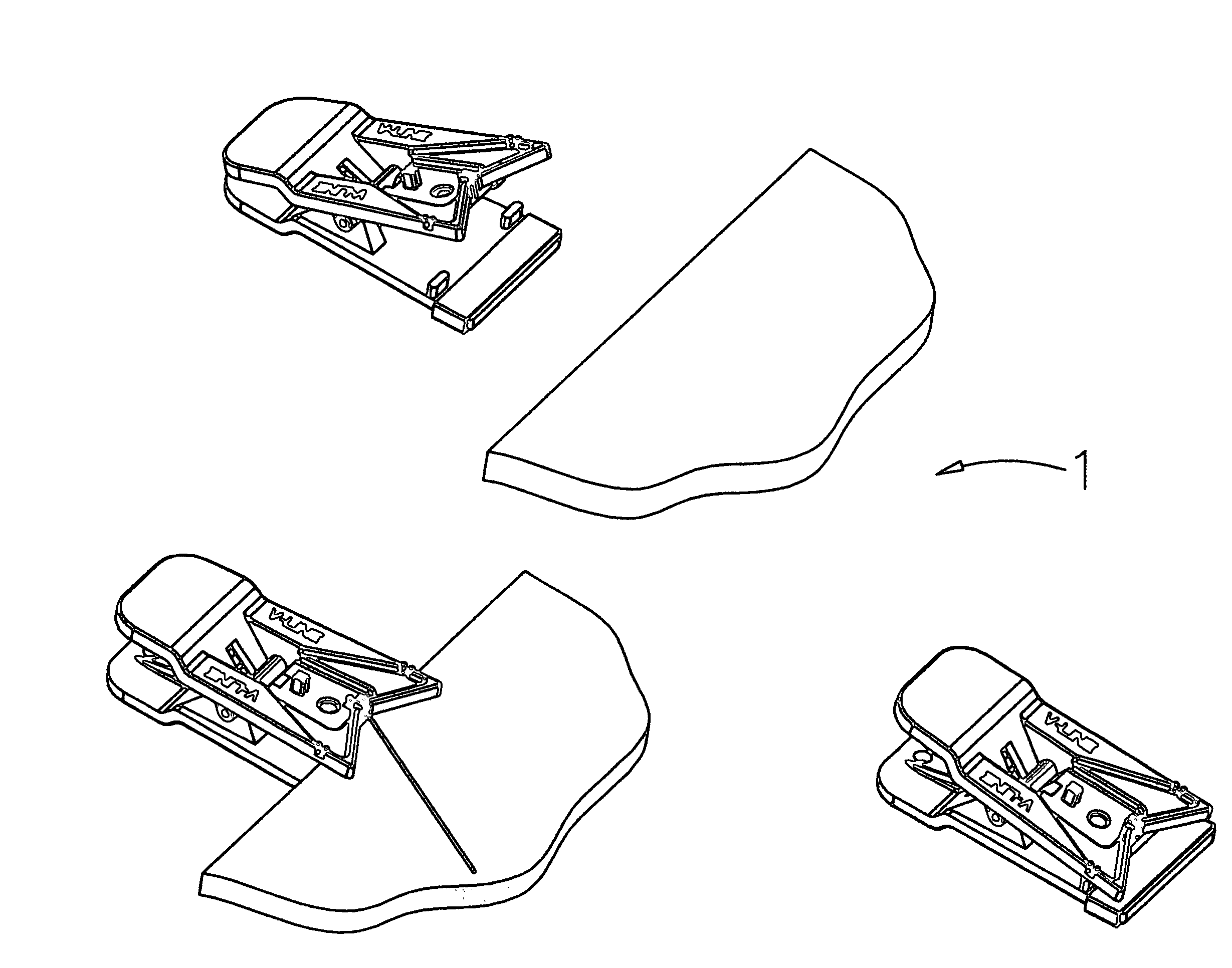

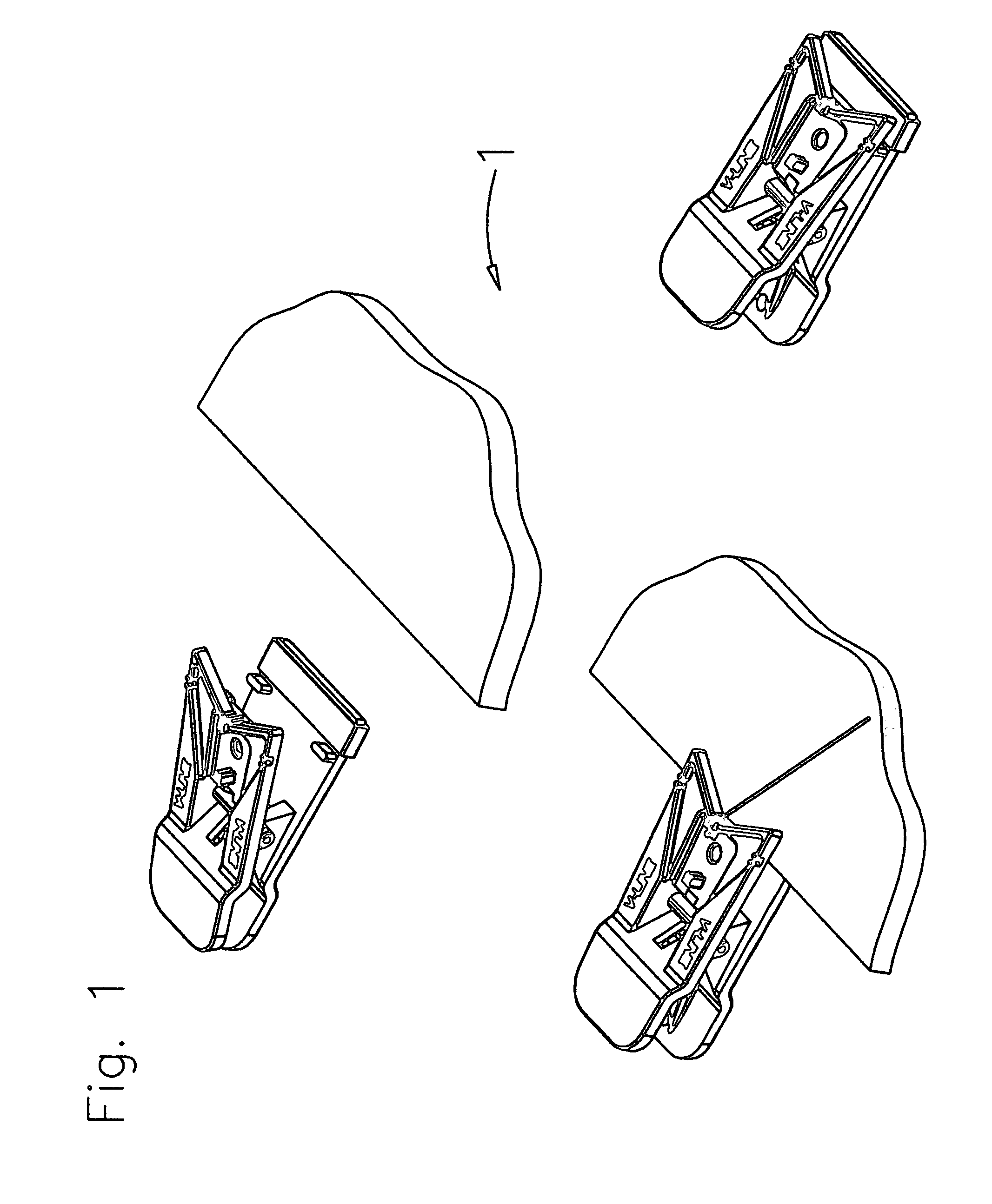

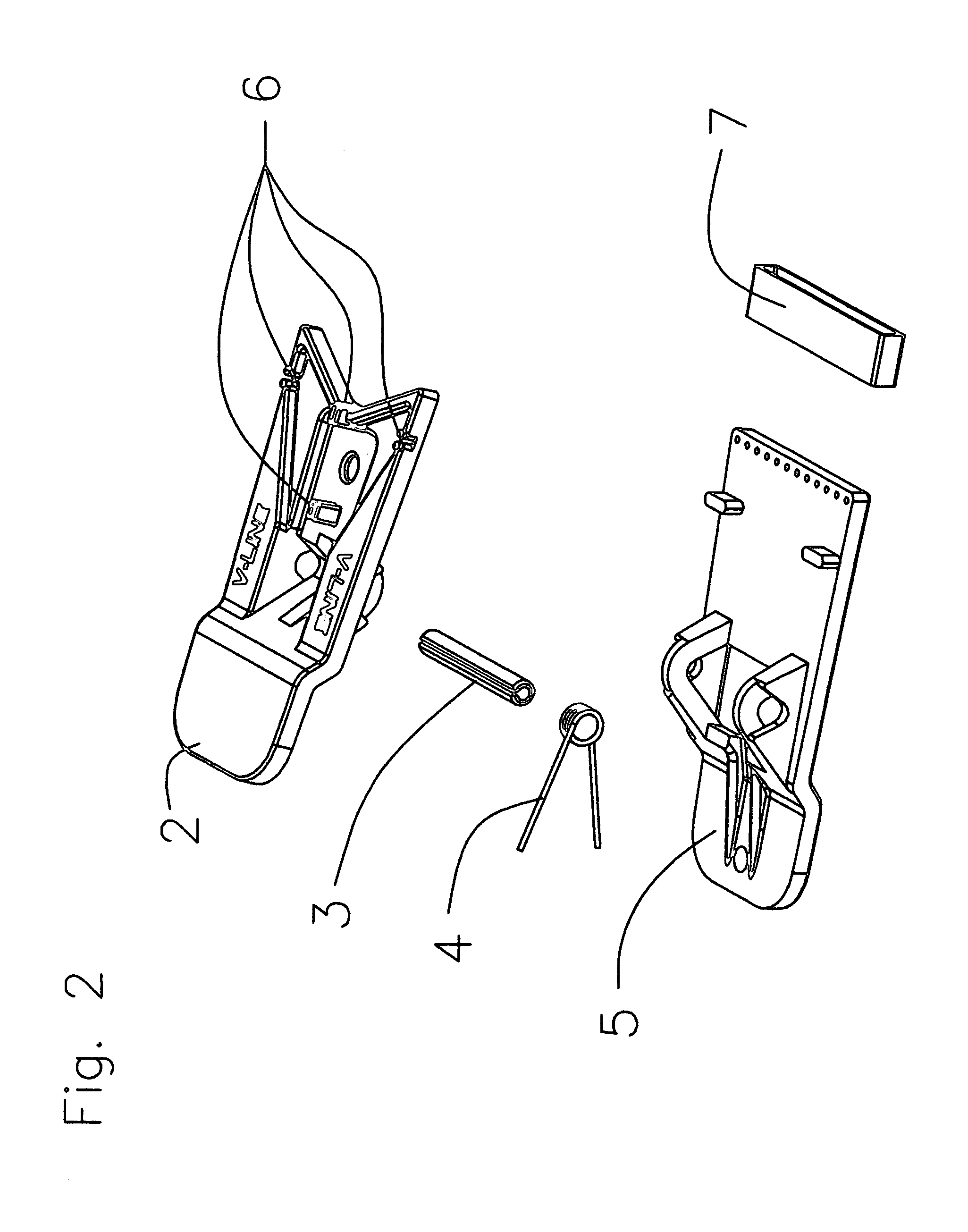

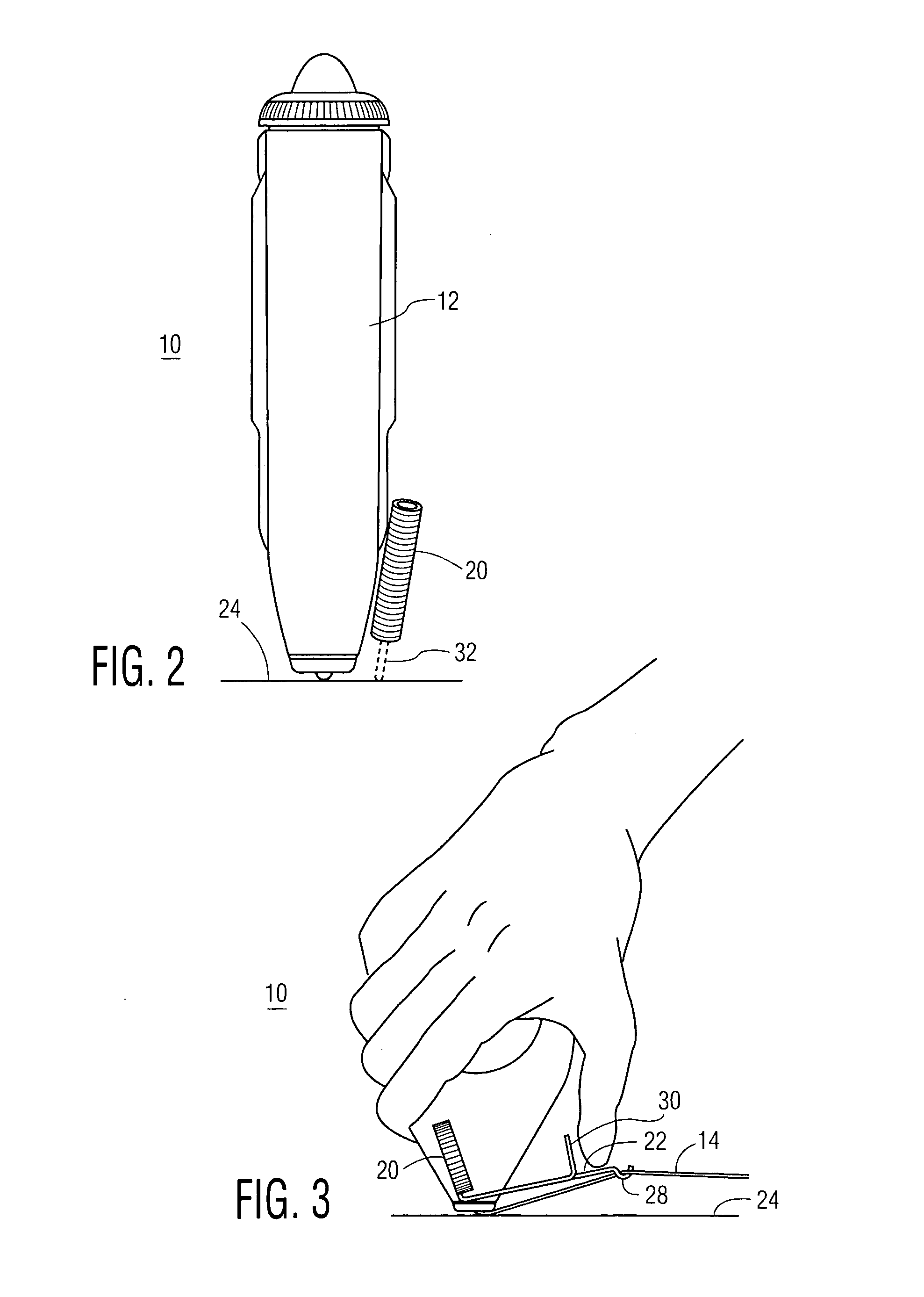

Modified chalk line end with retractable blade

A chalk line end being comprised of two flat members (12a and 12b) set parallel at a slight distance from one another and bent and fused together along at least one shared edge to form a main body (10), containing a tear-shaped aperture (18) and towards one end a smaller aperture (22) which the chalk line (24) is tied through. A main tab formed by a section of at least one of said flat members bent essentially perpendicular to said main body. A blade (14), containing a similar tear-shaped aperture (18), is sandwiched between said two flat members of said main body, and pivotally attached (20) to said main body towards one end. A means for grasping (26) on said blade at the opposite end from the pivotal connection allows the user to grasp said blade between thumb and finger and rotate it out through a long open edge of said main body, until a fused section of said flat members stops it when the blade edge (30) is at an approximate ninety-degree angle to said main body. The user can then rotate the invention on the axis of said chalk line from its position in normal use, and hook it securely on a rounded or tapered edge engaging. A chalk line end of this type also allows the user to pop a line at an angle other than ninety-degrees off the edge of a sheet of material without the aid of a helper, nail or additional tools. The present invention, therefore, represents a significant and novel improvement over prior art chalk line ends.

Owner:GUHSE SCOTT DAVID

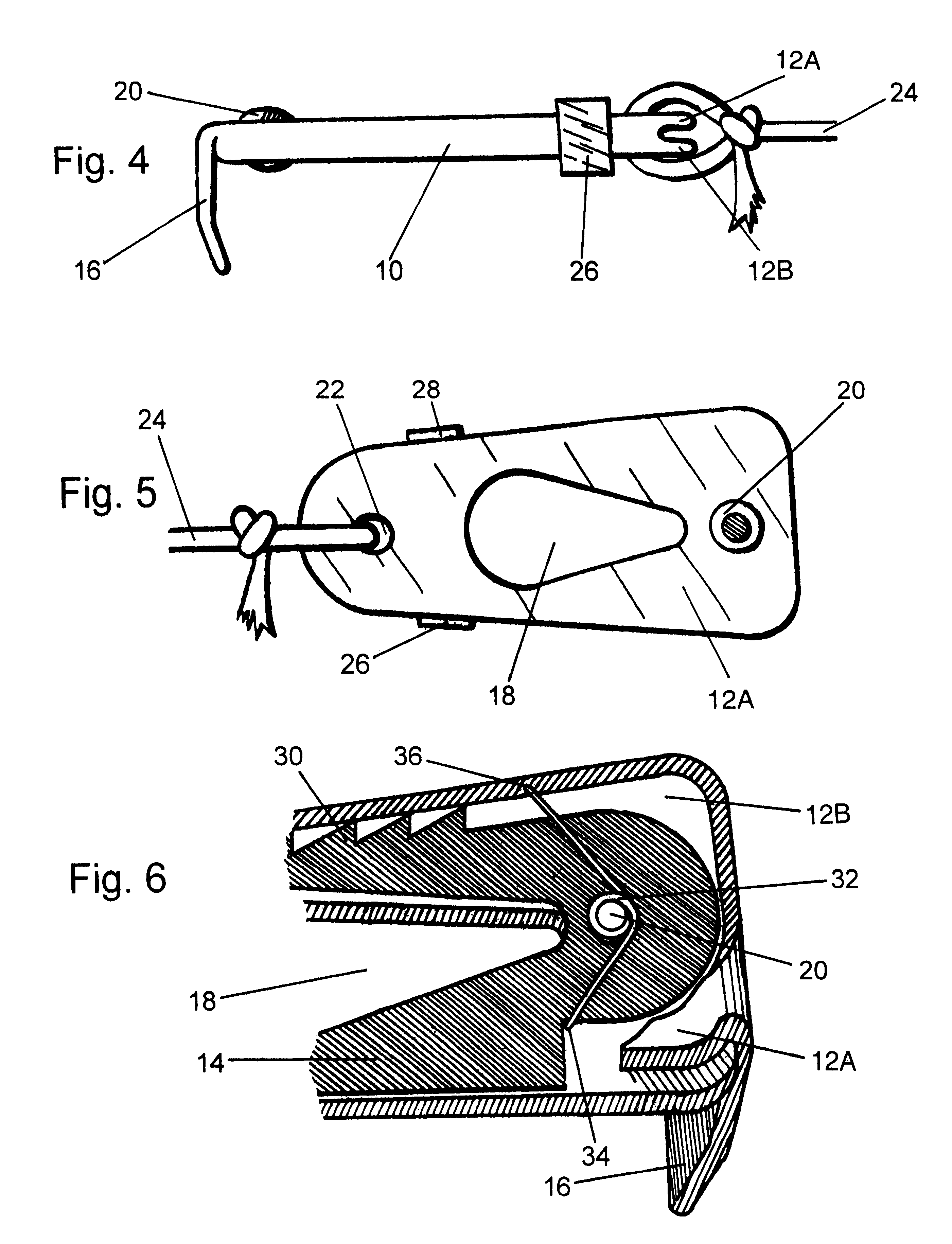

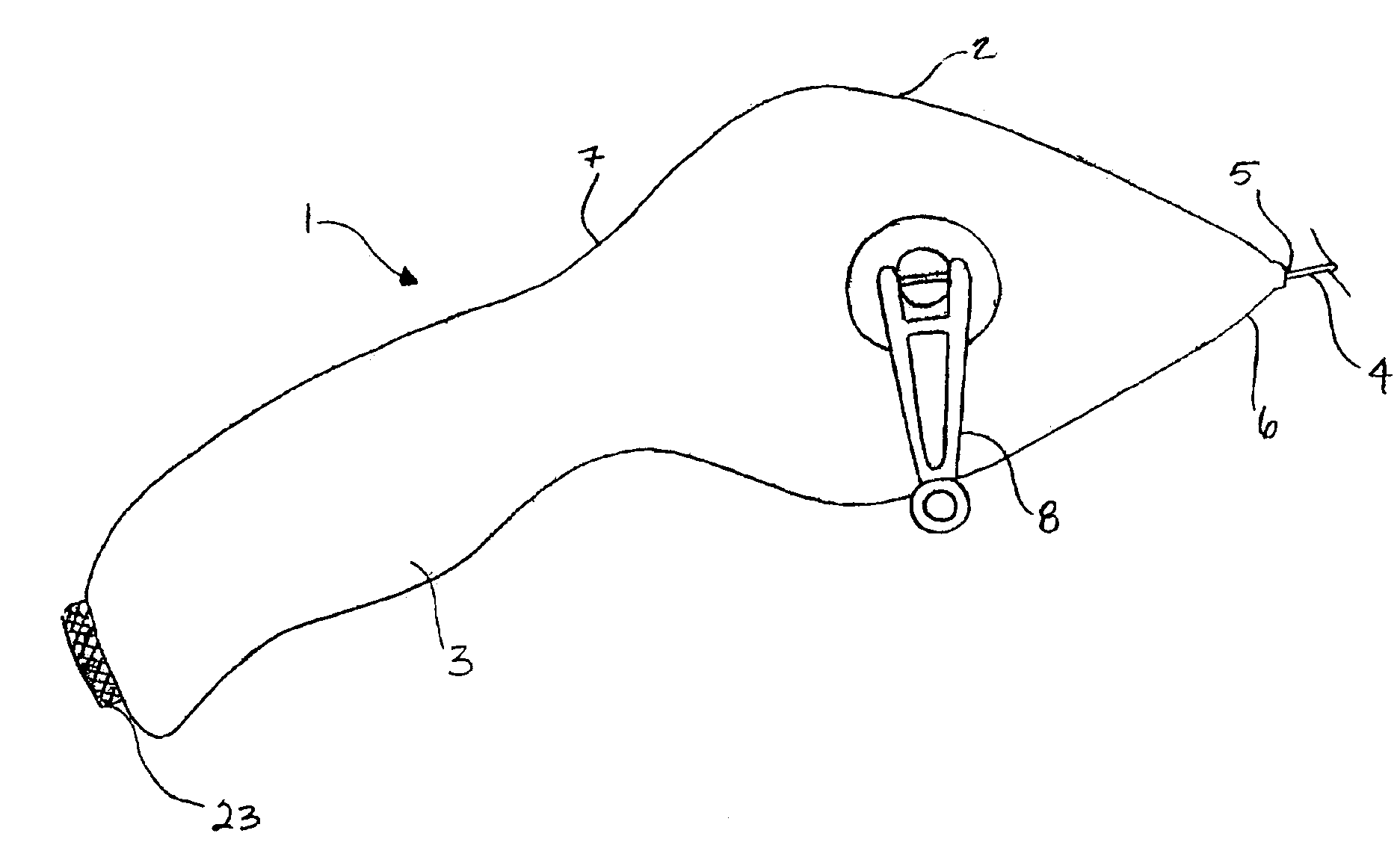

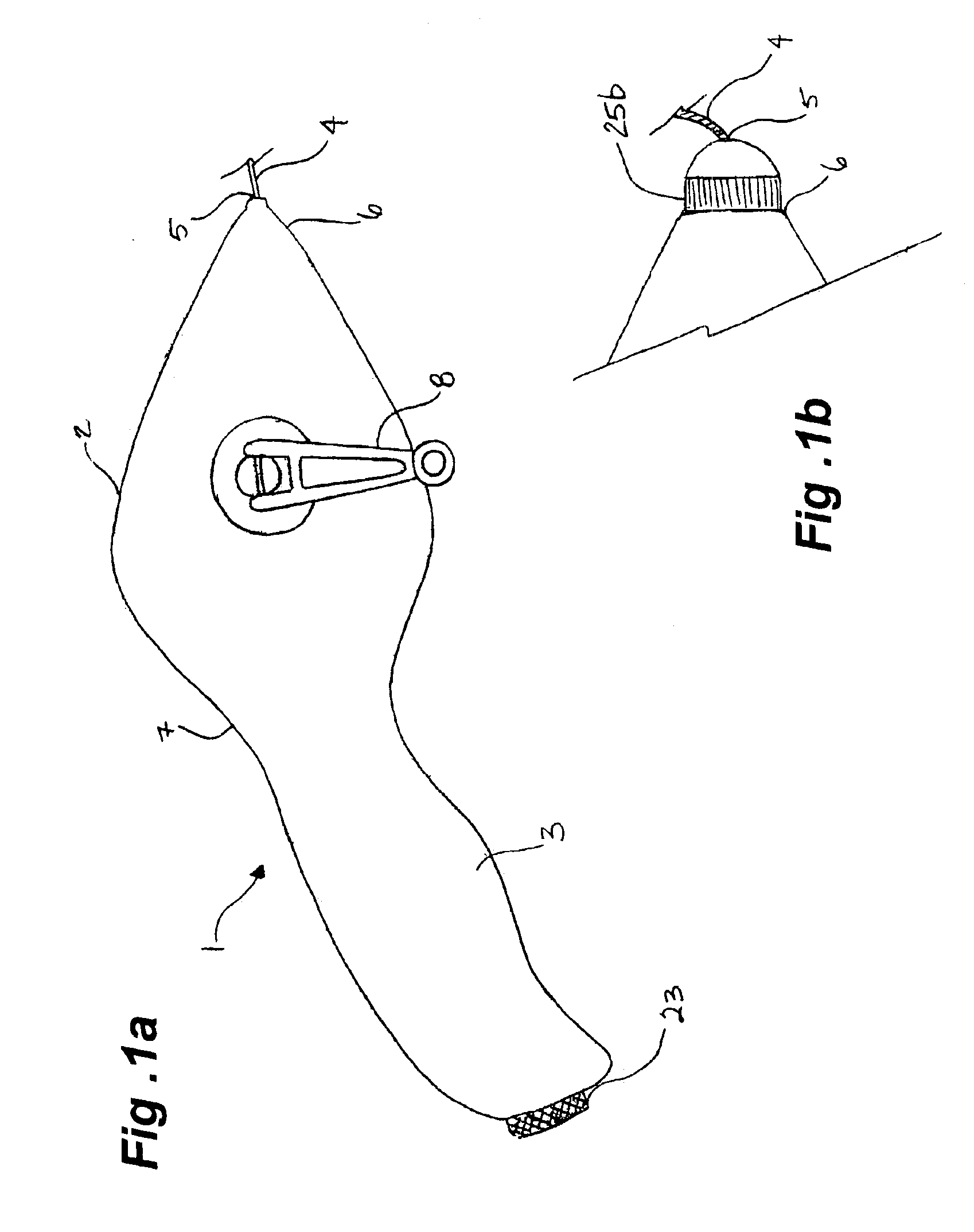

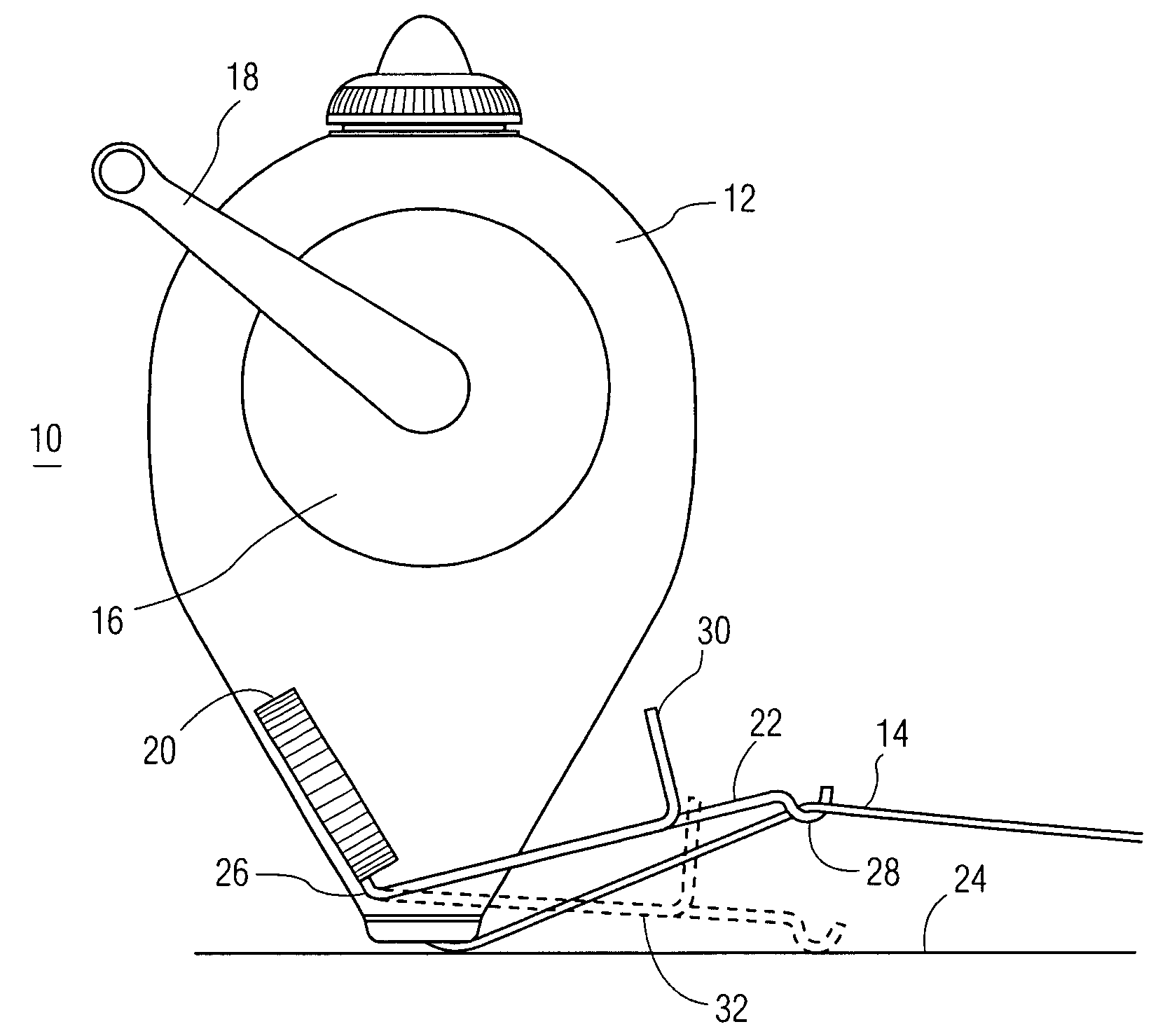

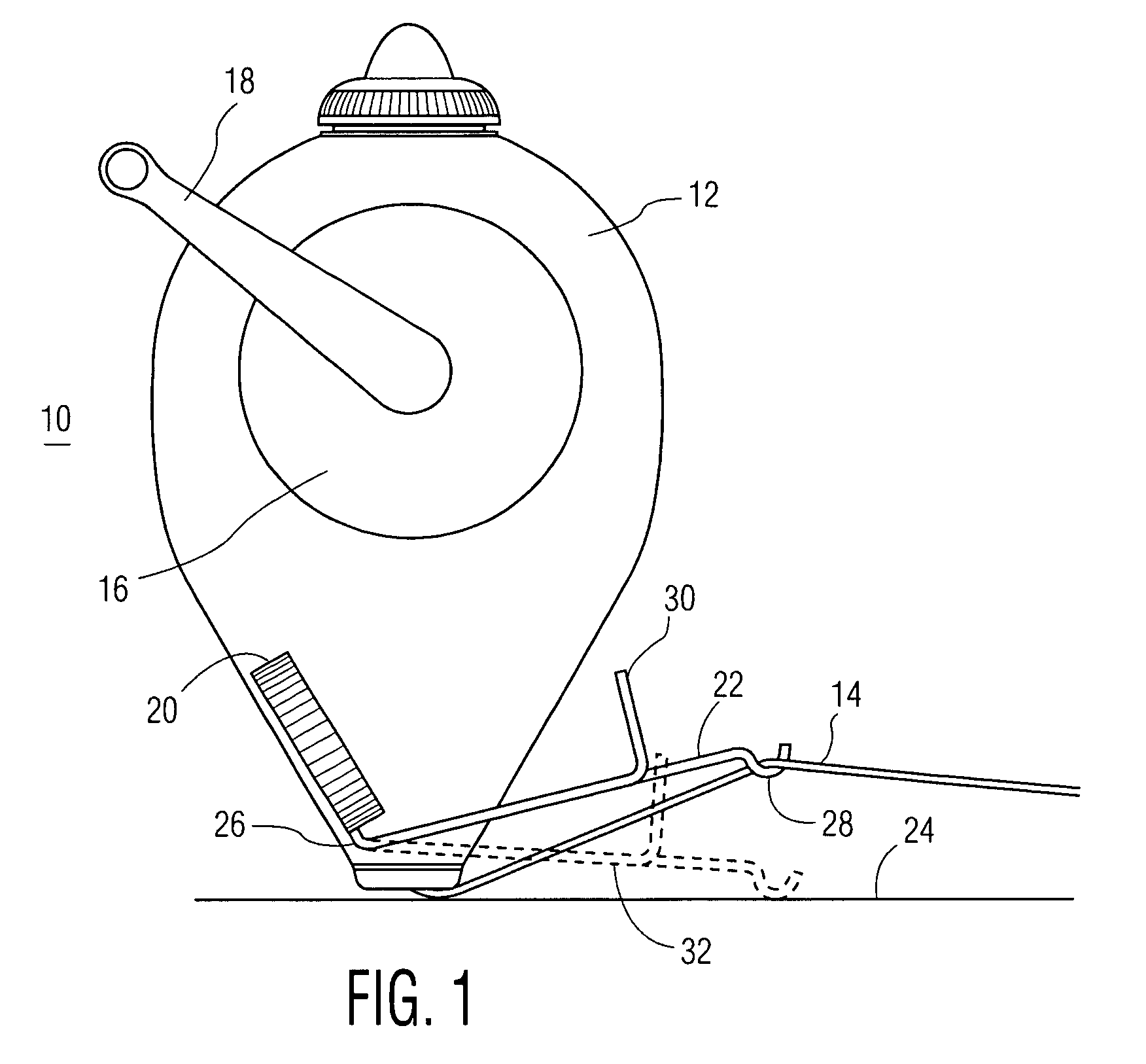

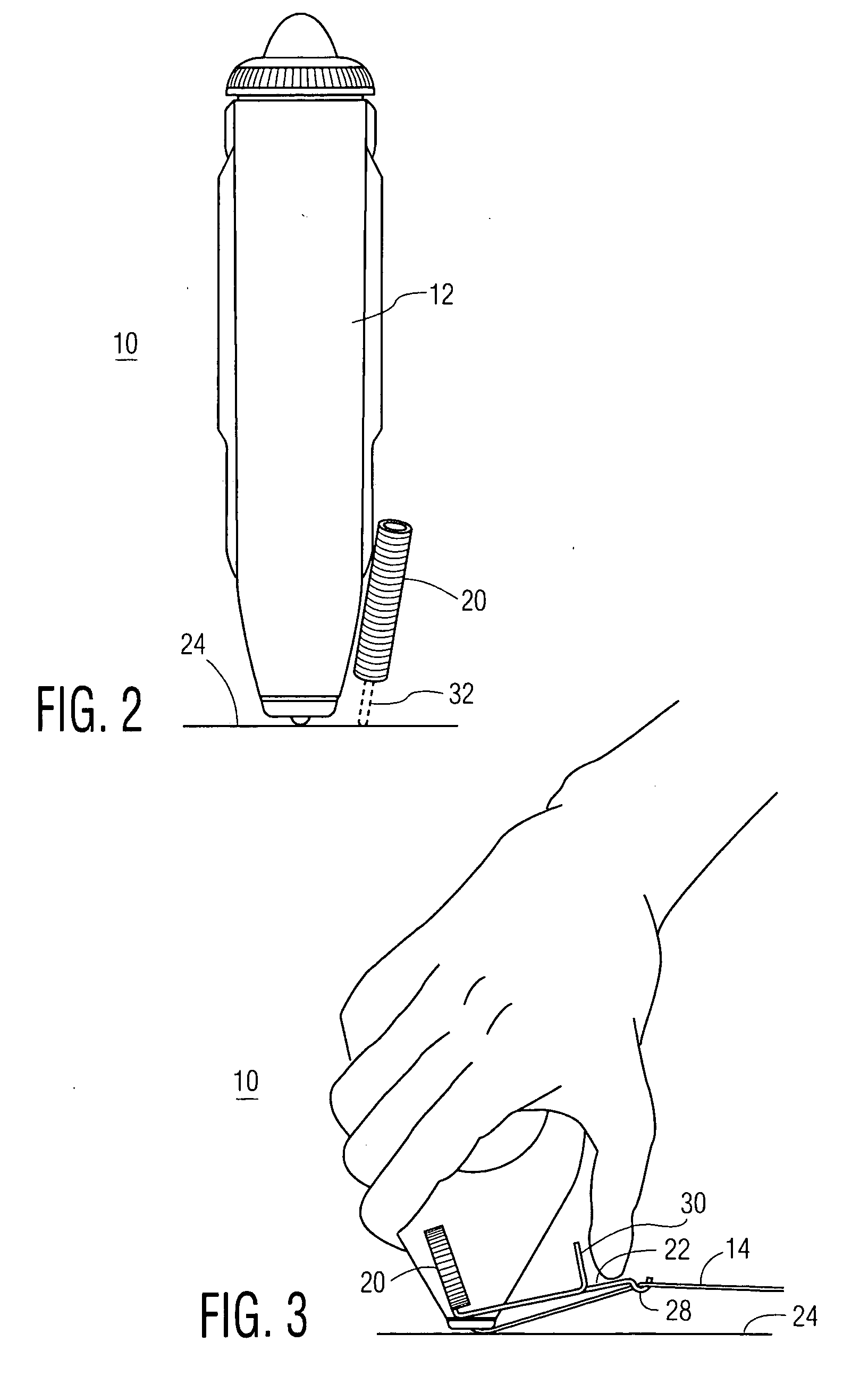

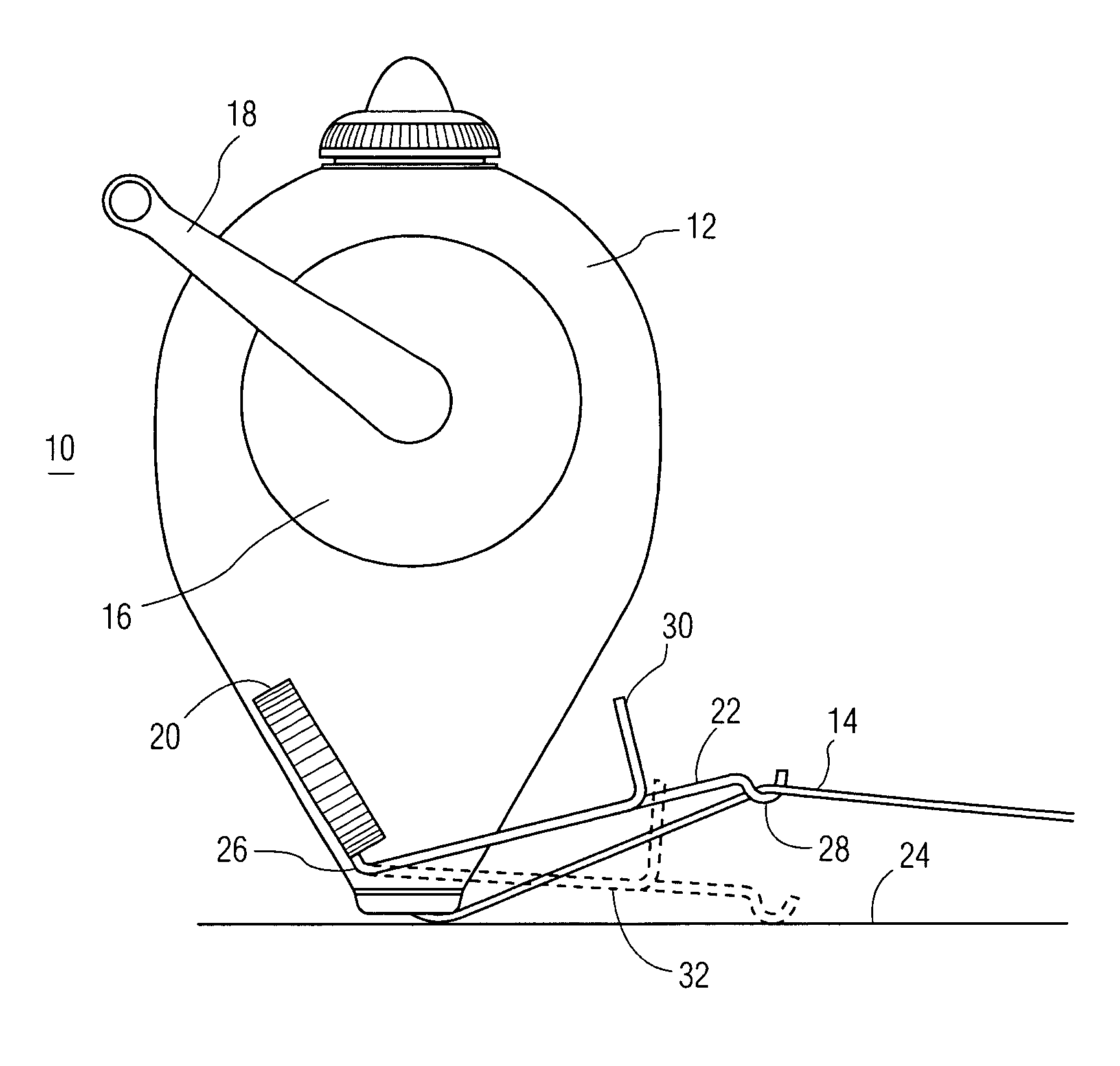

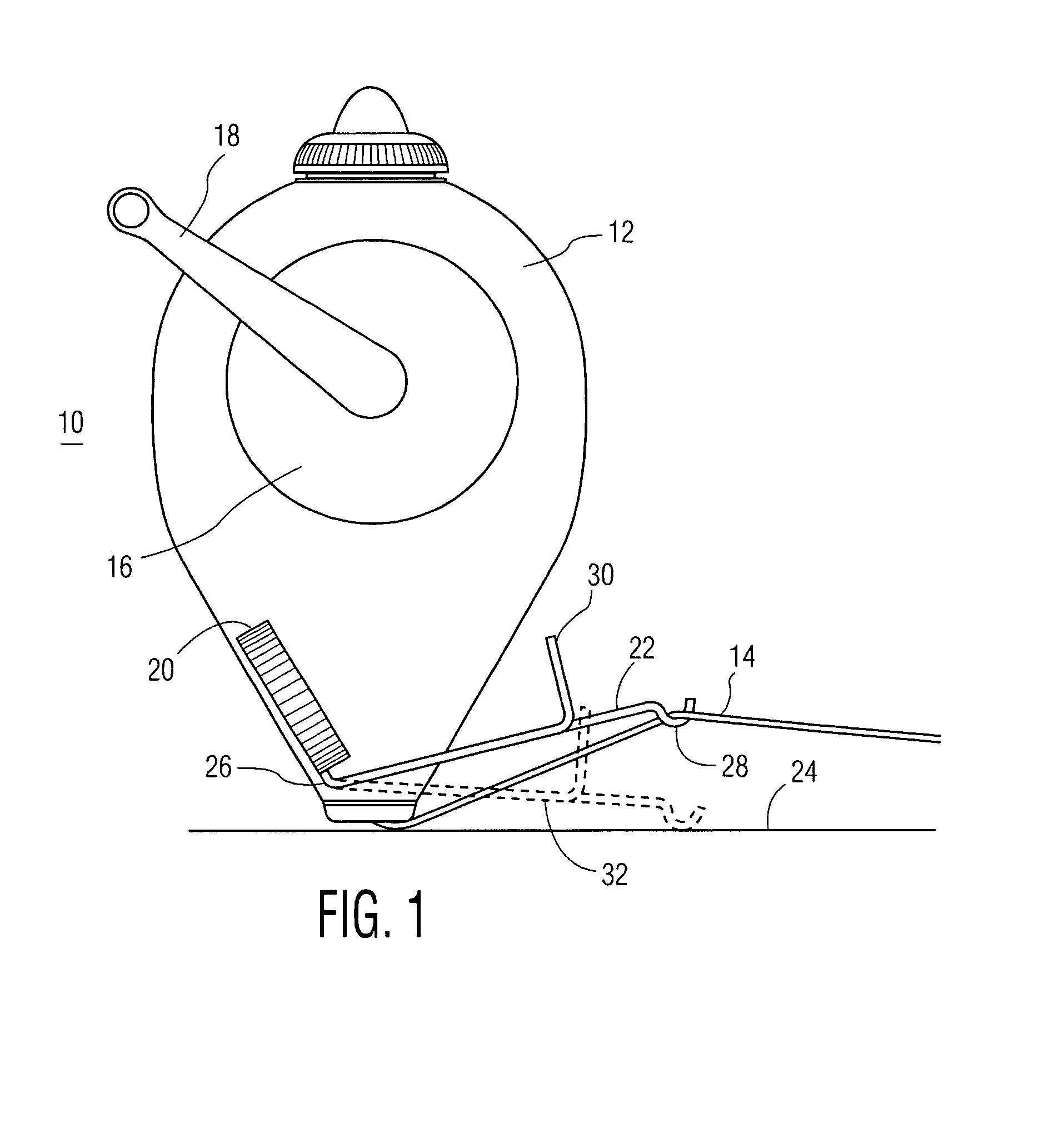

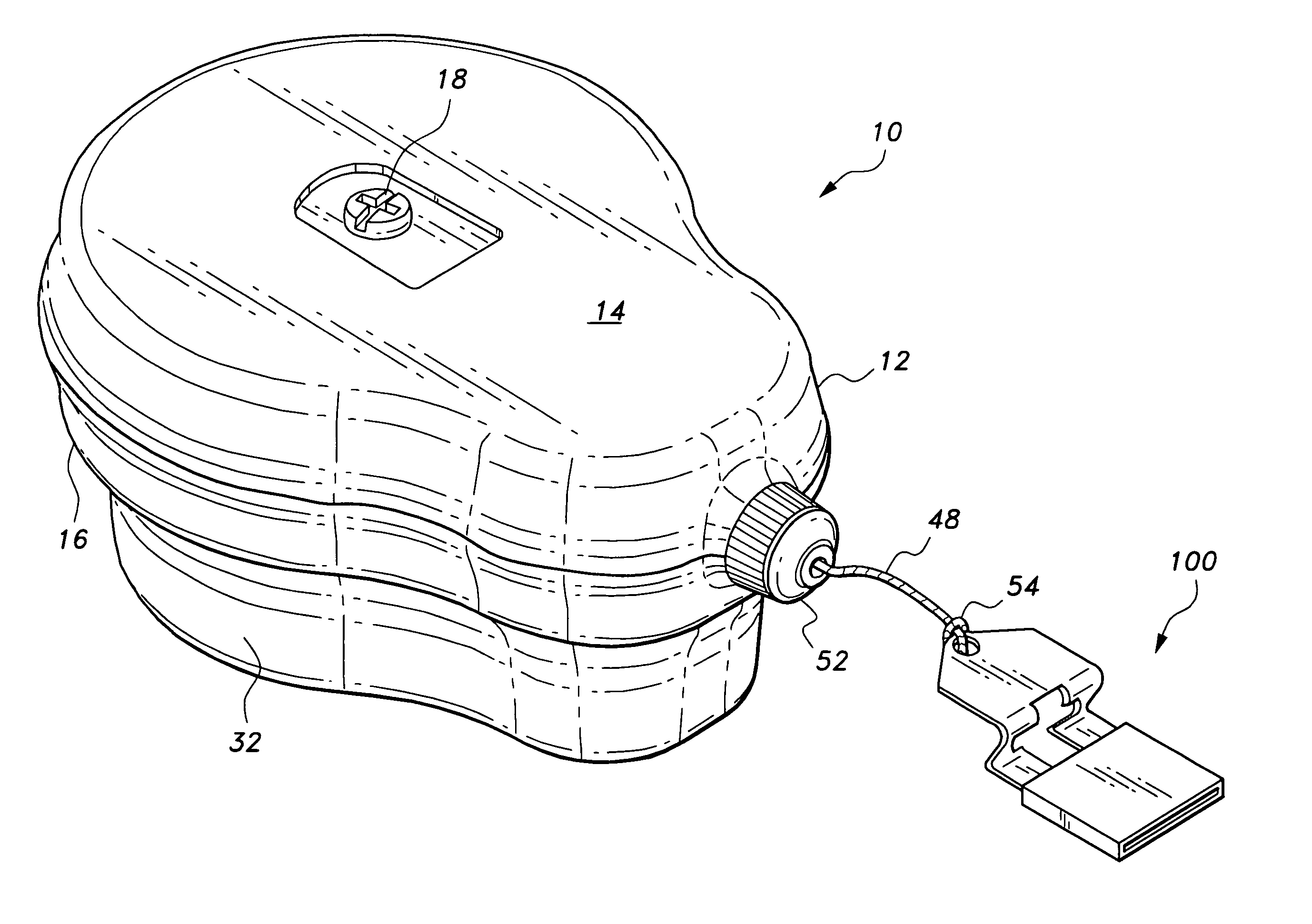

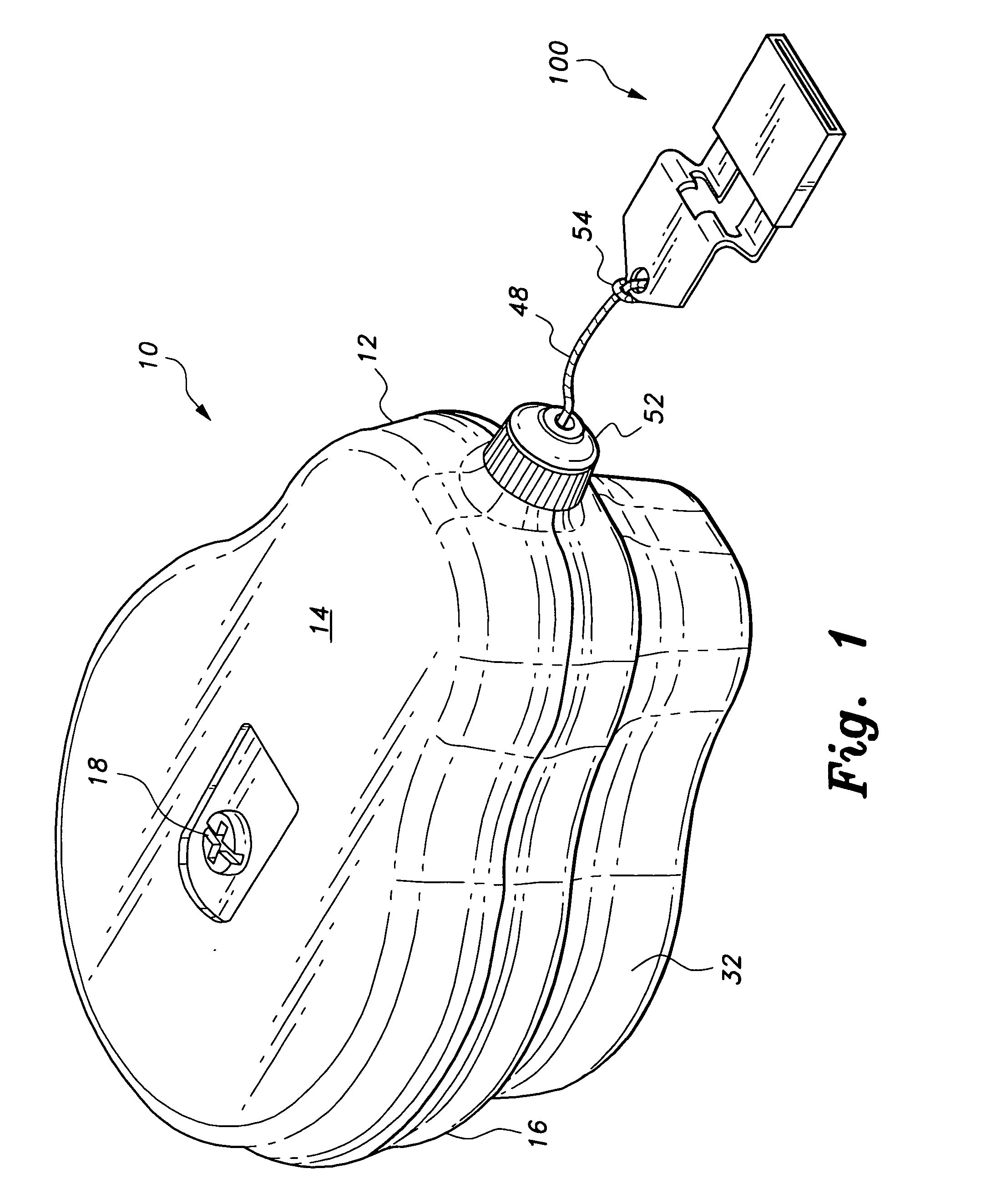

Chalk line with handle reservoir

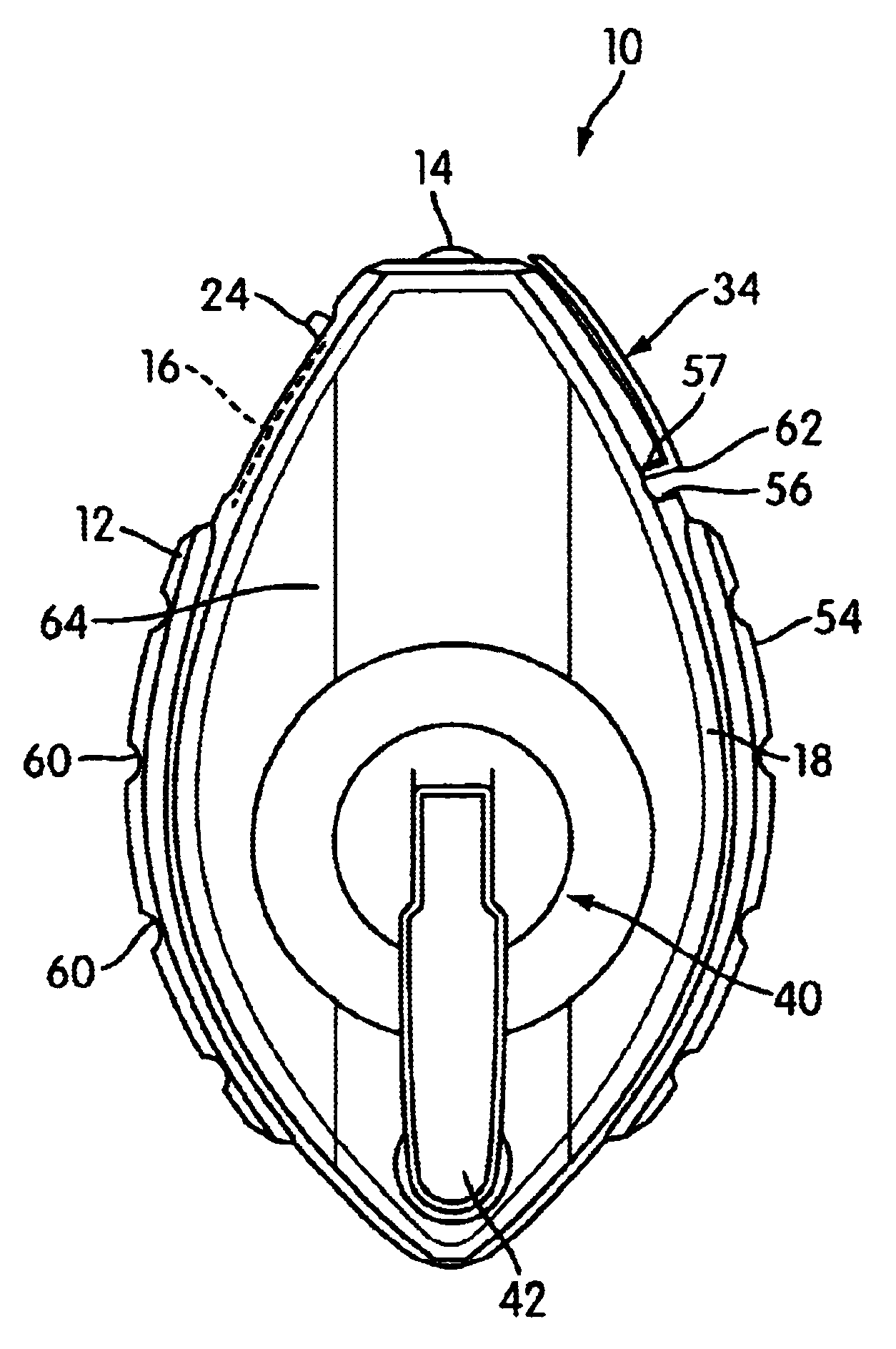

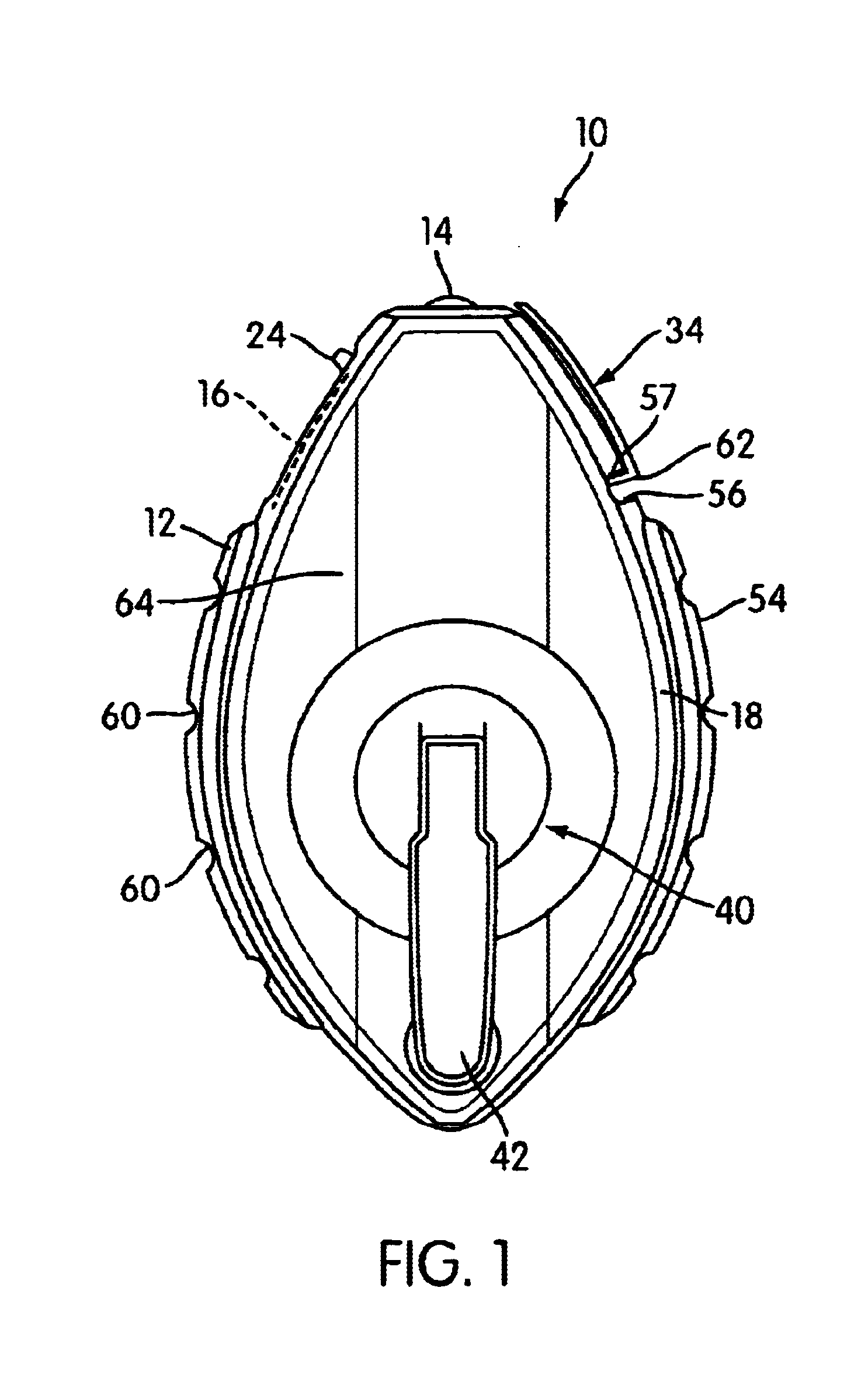

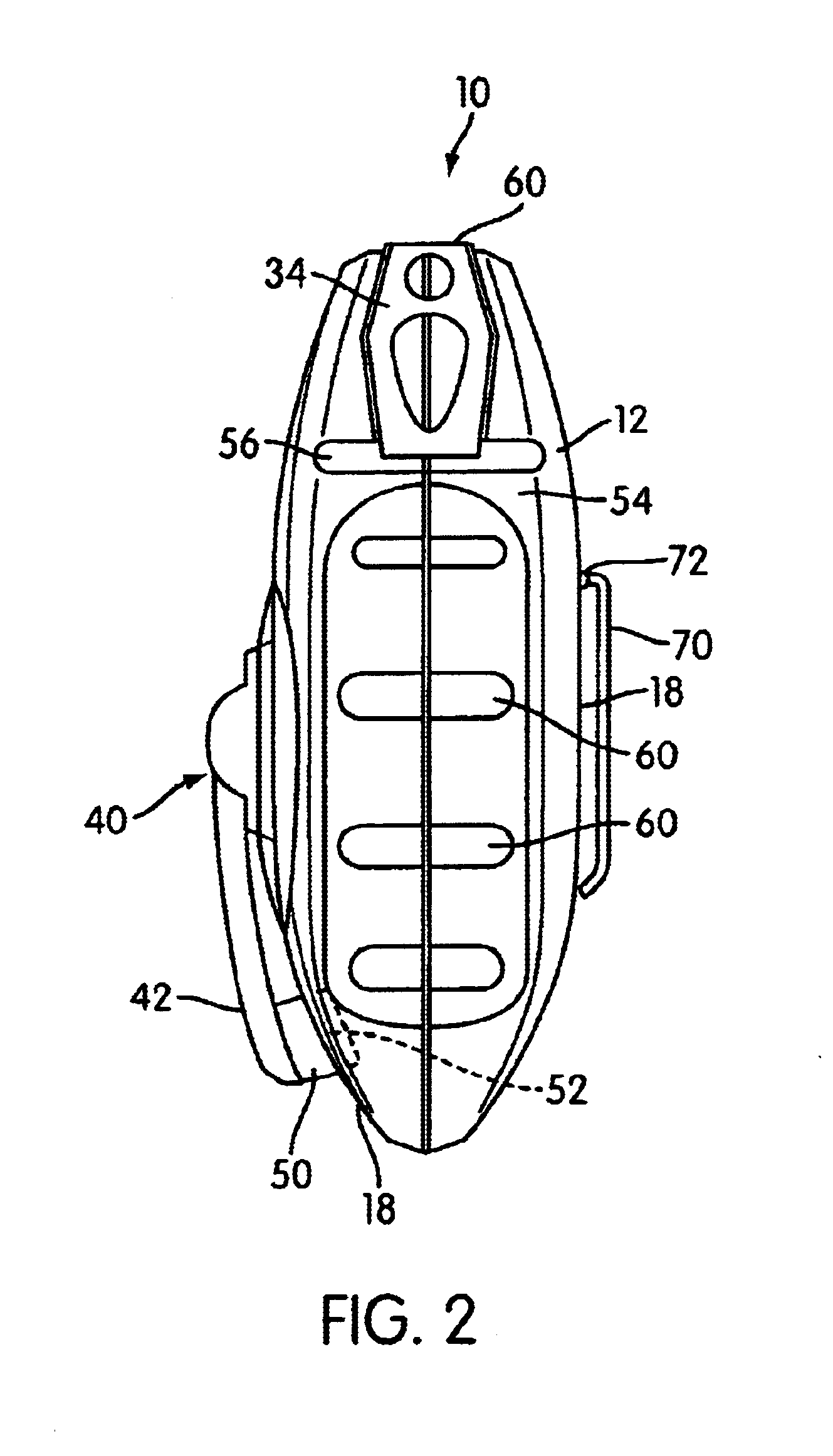

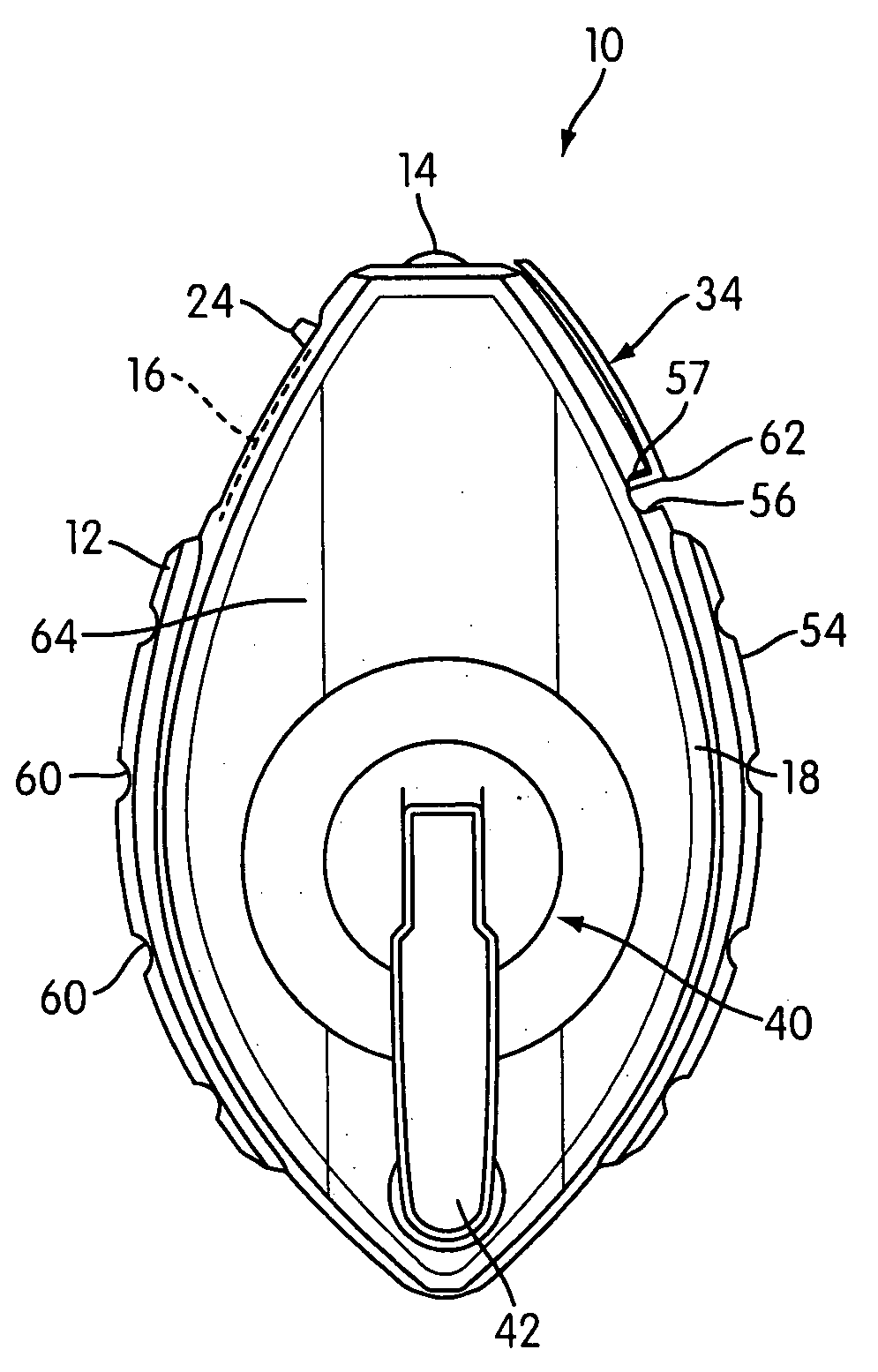

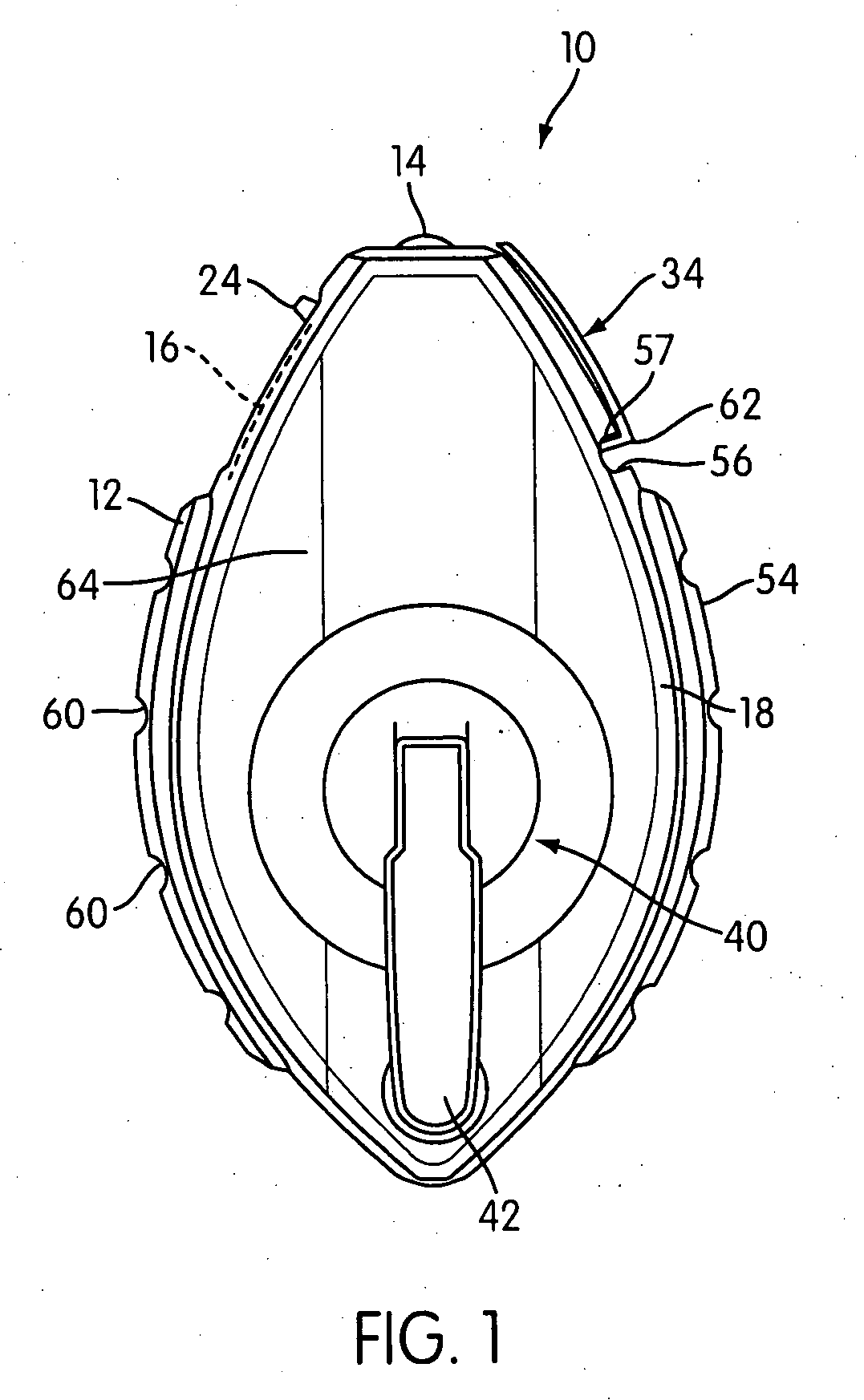

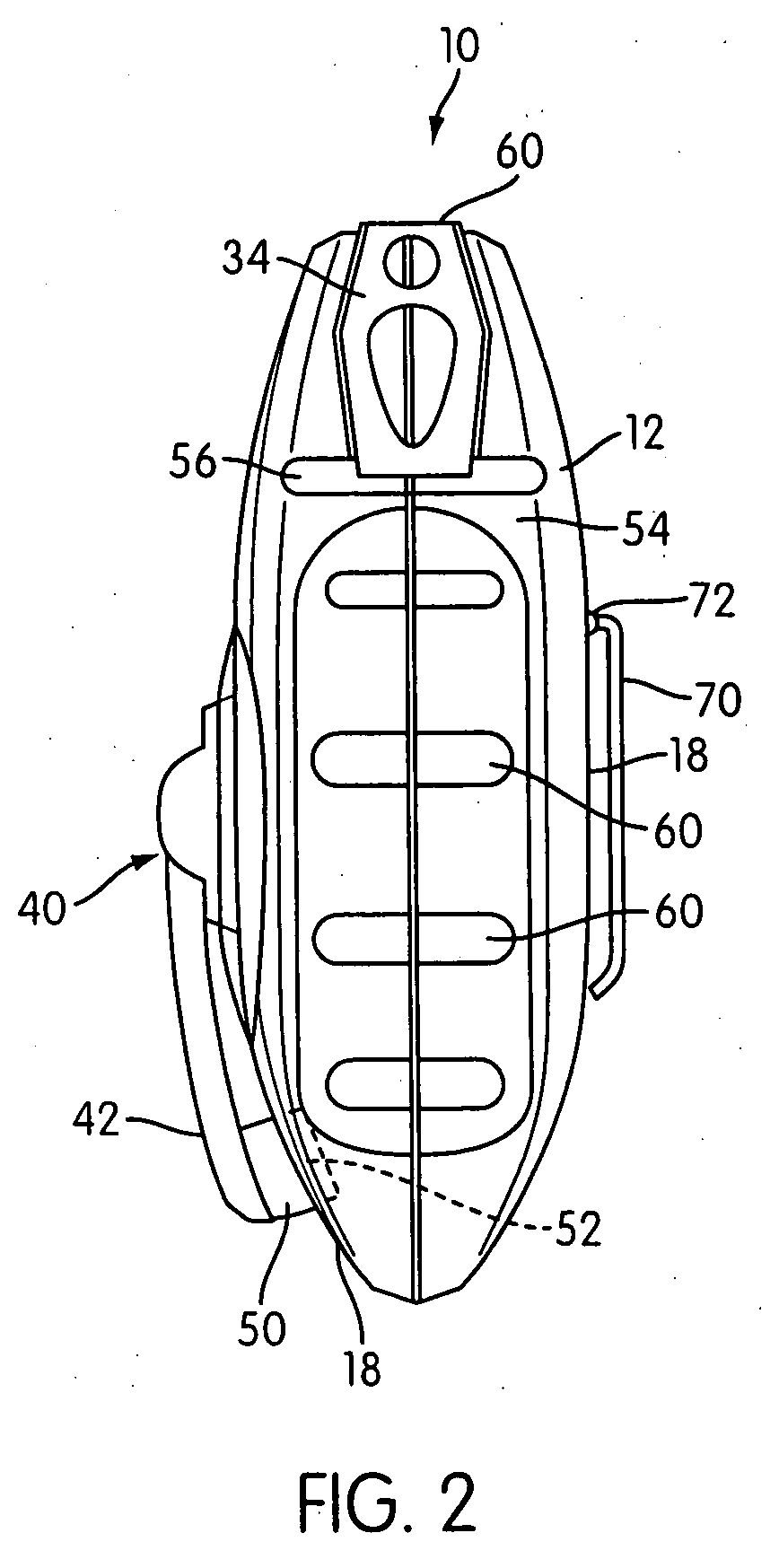

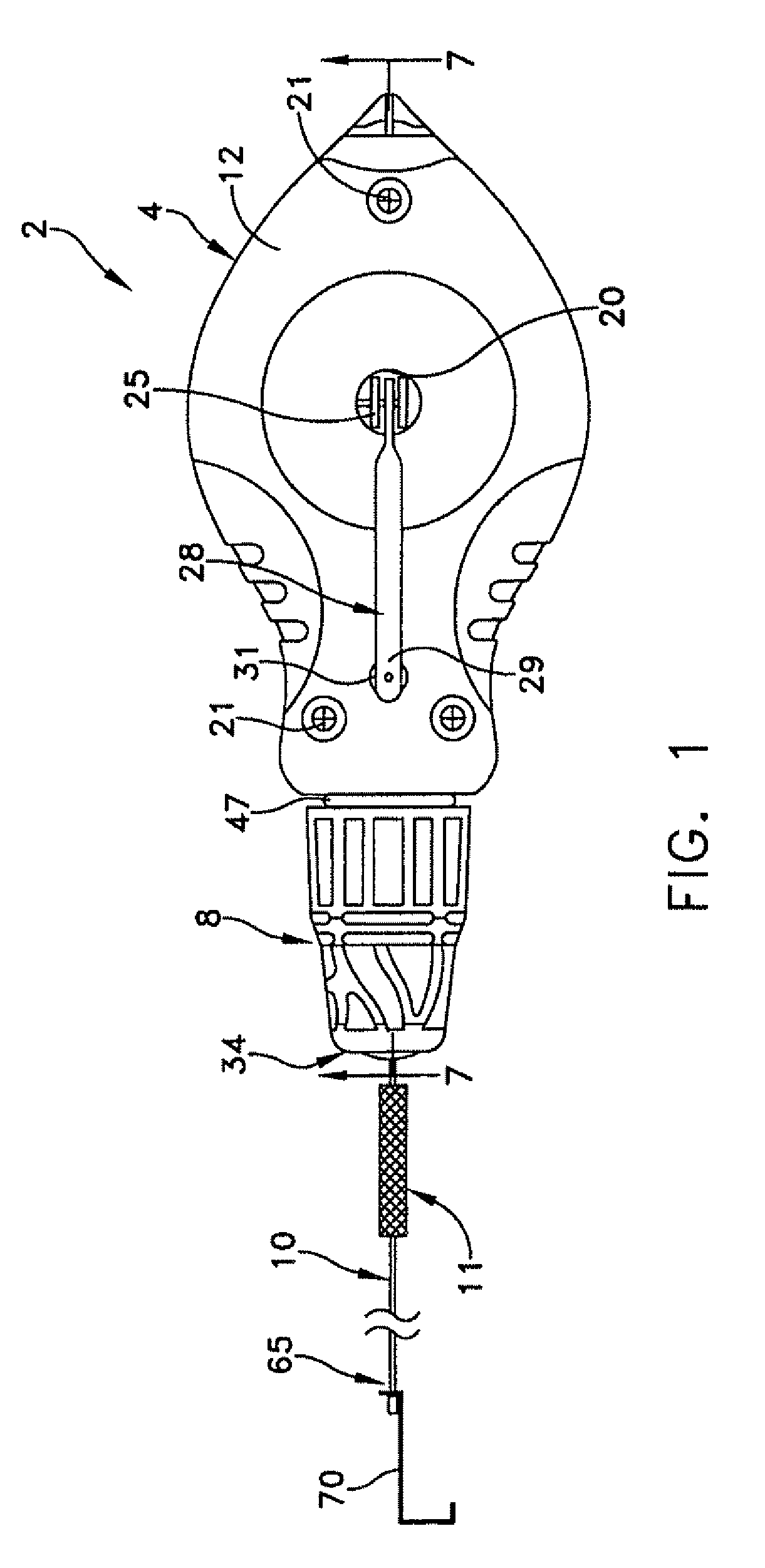

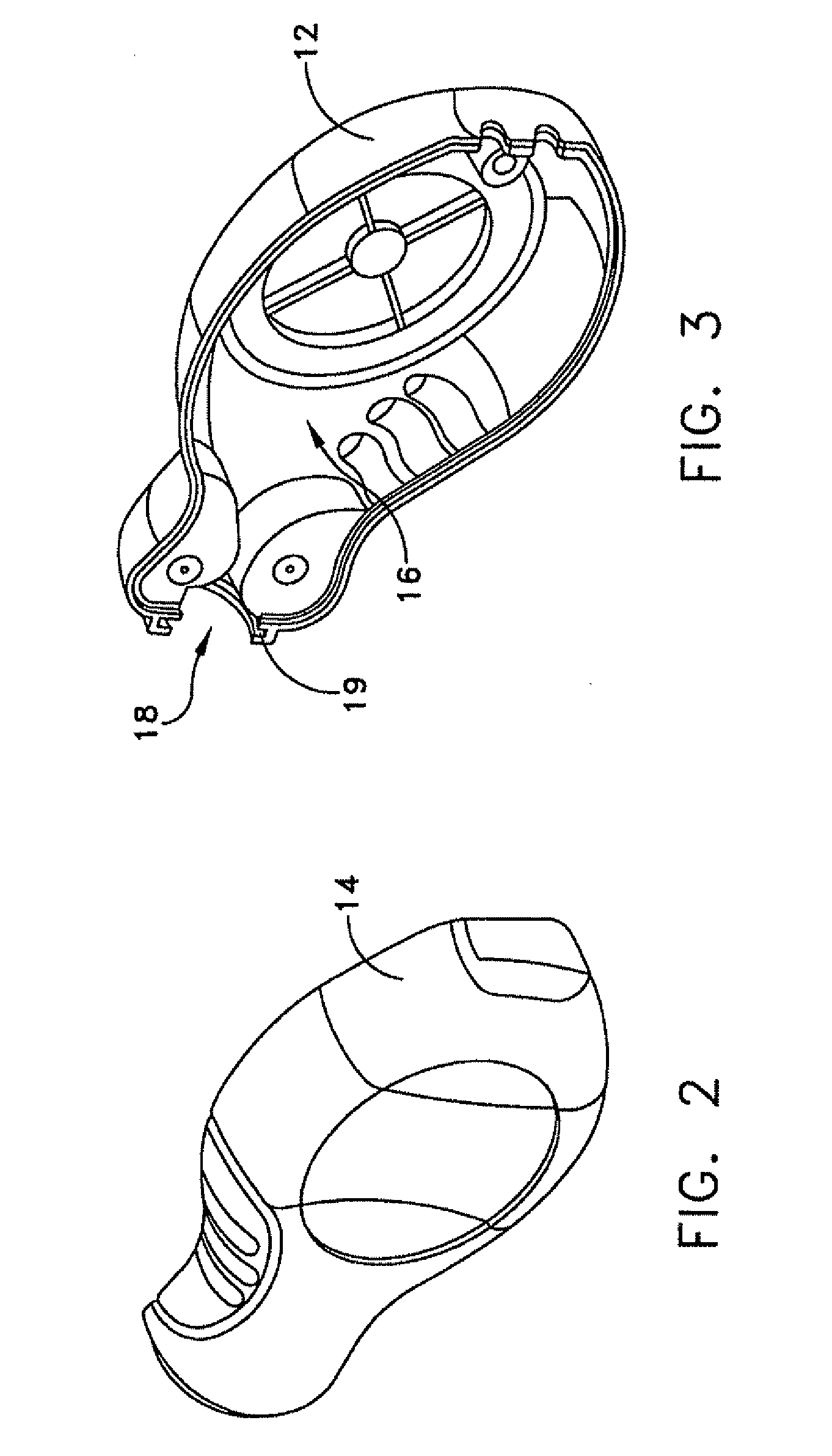

InactiveUS6895679B2Improve ergonomicsConvenient meanOther artistic work equipmentsMeasuring tapesEngineeringDrop-shaped

A chalk line tool is provided having a tear-drop shaped body which houses a chalk line spool and chalk for coating the chalk line and a handle connected to the body and acting as a reservoir for additional chalk. The reservoir feeds the cavity in the body. The flow of chalk is controlled between the reservoir and the cavity. The handle advantageously acts to maintain the operator's hands away from the hand crank used to retract the chalk line and provides an extended reach with the tool for improved ergonomics when using the tool. The chalk line tool can be manufactured with the handle or can be retrofit with parts which are supplied as a kit.

Owner:DEKORT HENRY

Lay out line

A chalk line apparatus for marking regularly spaced locations. The apparatus comprises a casing for powdered chalk containing a rotatable reel, a wire rope wound on said reel, and an exit opening for the wire rope at one end of the holder. The wire rope is coated with a material that resists retention of chalk, and has evenly spaced short chalk-retaining segments disposed thereon so that when the wire rope is tensioned to about 10 lbs, the segments reside at precisely placed predetermined intervals. When the line is snapped, the chalk-covered short segments leave evenly spaced chalk marks that correspond to the locations of underlying wall studs.

Owner:STUD LINE TOOL

Chalk line device, waterproof chalk composition, and method

A waterproof chalk composition including silicone oil, powdered chalk, and optional colorants, suitable for applying to a chalk line of a chalk line device, is provided. Methods of making and using the waterproof chalk composition using silicone oil, powdered chalk, and colorants, are provided. The waterproof chalk composition provided herein can be used or packaged immediately after preparation, and does not require a drying step to evaporate solvents. The waterproof chalk composition provided herein does not contain environmentally unfriendly components such as solvents.

Owner:STANLEY WORKS THE

Chalk line device

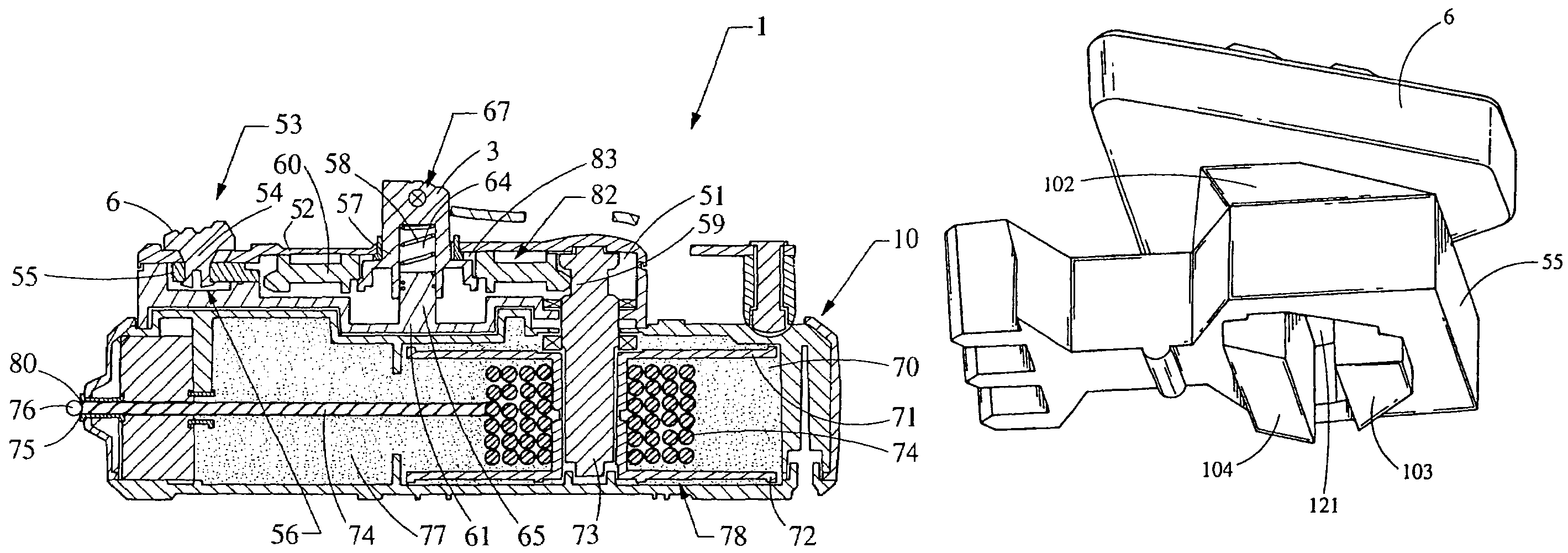

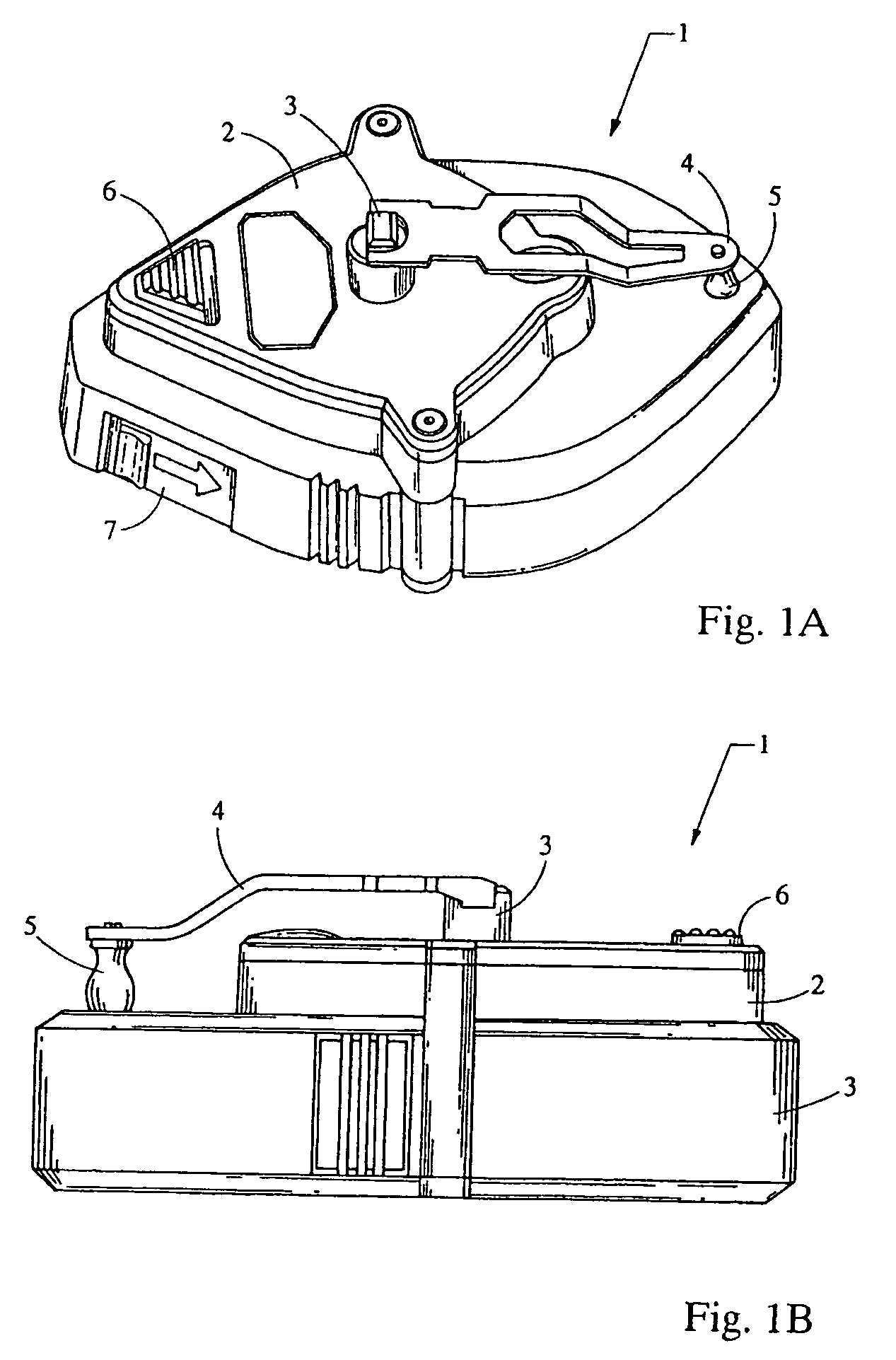

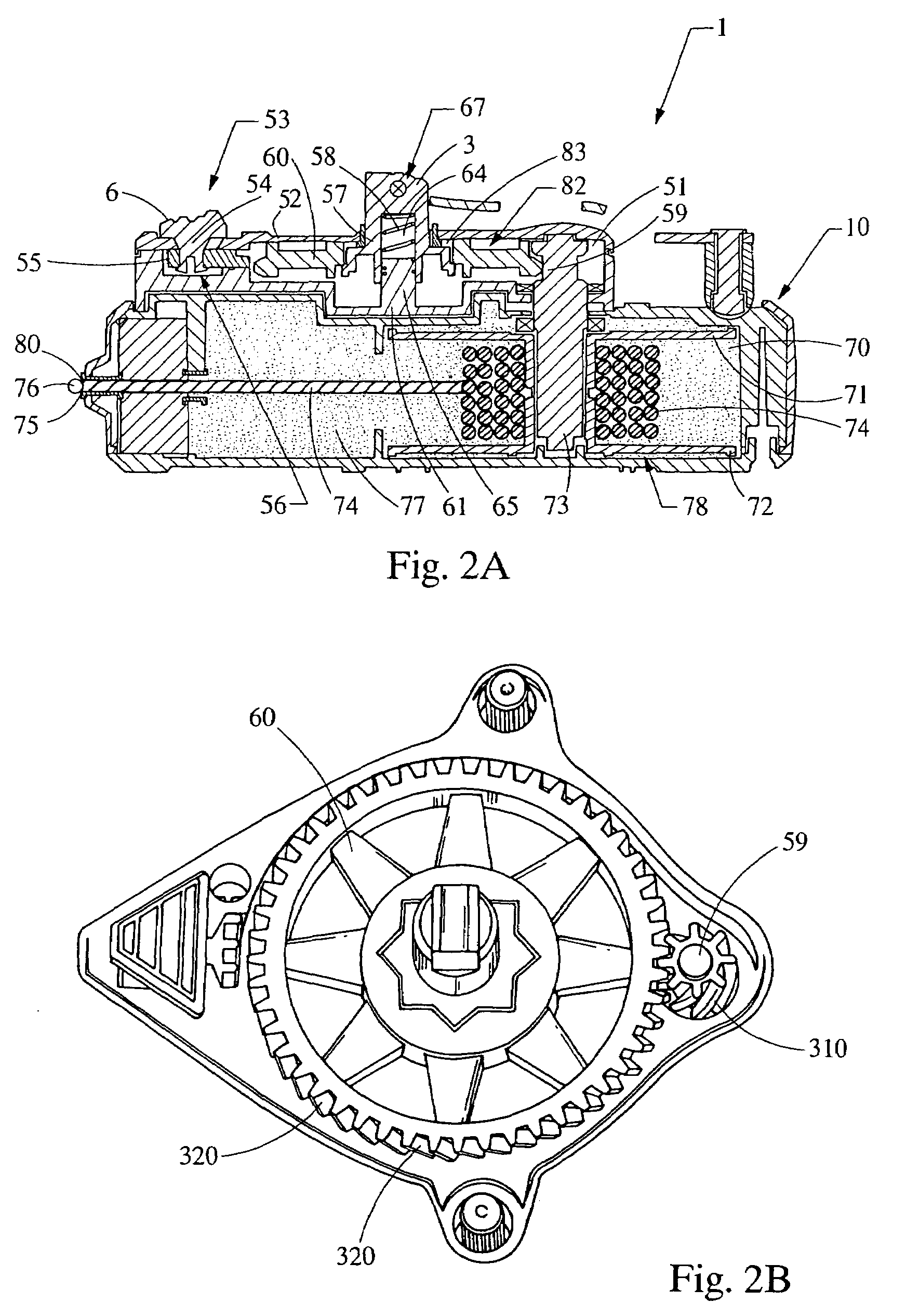

InactiveUS7311283B2MiniaturizationGuaranteed uptimeOther artistic work equipmentsGear wheelEngineering

One embodiment of the invention provides a chalk line device having a helical gear and an improved locking assembly. The locking assembly comprises a first lock member having a lock button. The locking assembly also comprises a second lock member including an opening to lockingly engage the first lock member and having a plurality of teeth at one end disposed adjacent one of the helical gears used in this embodiment. The second lock member engages with the helical gear in response to a movement of the lock button member.

Owner:IRWIN IND TOOL CO

Level and chalk line marker

A chalk line marker is releasably connectable to a level. When connected to the level, the chalk line marker is employed to provide chalk marks in orientations established by the level. When the chalk line marker is removed from the level, the level and chalk line marker can be used independently in conventional fashion.

Owner:KASCHE MARK

Chalk line or string attachment clamp for marking lines (straight angled or radius) on flat surfaces

Owner:CRUZ ALBERT PETER +1

Hand-operated multi-function tool

A multi-function hand-operated tool that is compact in size and of light weight so as to be carried and used to perform a variety of different jobs by carpenters, painters, do-it-yourselfers, and the like. The tool includes a nail set to transmit a driving force to the head of a nail to cause the nail to be countersunk in a work surface. An open mouth which is sized to receive the cap on a bottle cooperates with a lip that applies a rotational force to remove the cap from the bottle. A nail extractor having a cavity in which to surround and capture the head of a nail transmits a pulling force to the nail head to cause the nail to be removed from a work surface. A channel having a flush-mounted magnet carries a nail to be positioned in upstanding alignment against a work surface so that the nail can be driven therein. A pair of spaced, outwardly projecting teeth are located between a lid and a can to pry the lid off the can. A chalk line is tied to the tool, and the teeth can be either staked in a work surface or located over and against an edge of the work surface so that a chalk mark can be made along the work surface. The teeth are spaced from one another so as to engage and lift a hinge pin from a hinge to which the pin is coupled.

Owner:JONES GRANT

Line-marking device with positioning devices and trigger activator

InactiveUS20060000099A1Easy to useUsing mechanical meansOther artistic work equipmentsProtractorEngineering

A line-marking device (100) includes a chalk line (200) that is held in an elongated frame (170). A worker can position and align the device, then snap the line (200) using a manually operated trigger (650) to leave a mark on a surface (530), such as a wall or floor. An adjustable level device (115) on the frame (170) can be rotated to dial a desired angle for the line. The adjustable level device (115) may be provided in an angle setting device independently of the line-marking device. A laser device (125) may be carried at the tip (120) of (or elsewhere on) the frame (170) to allow the chalk line to be aligned with a reference mark (145). Respective markings (176, 177) on edge regions of rails (171, 174) of the frame (170) may indicate an angular setting of a guide bar (500), or, a protractor (810, 810a) may indicate-the angular setting. The guide bar (500) may be relocated facing away from the filament (200) and used as an angle finding device. A retractable tape measure (1500) carried by the device enables a worker to measure distances from the chalk line.

Owner:TESSEL DAVID +1

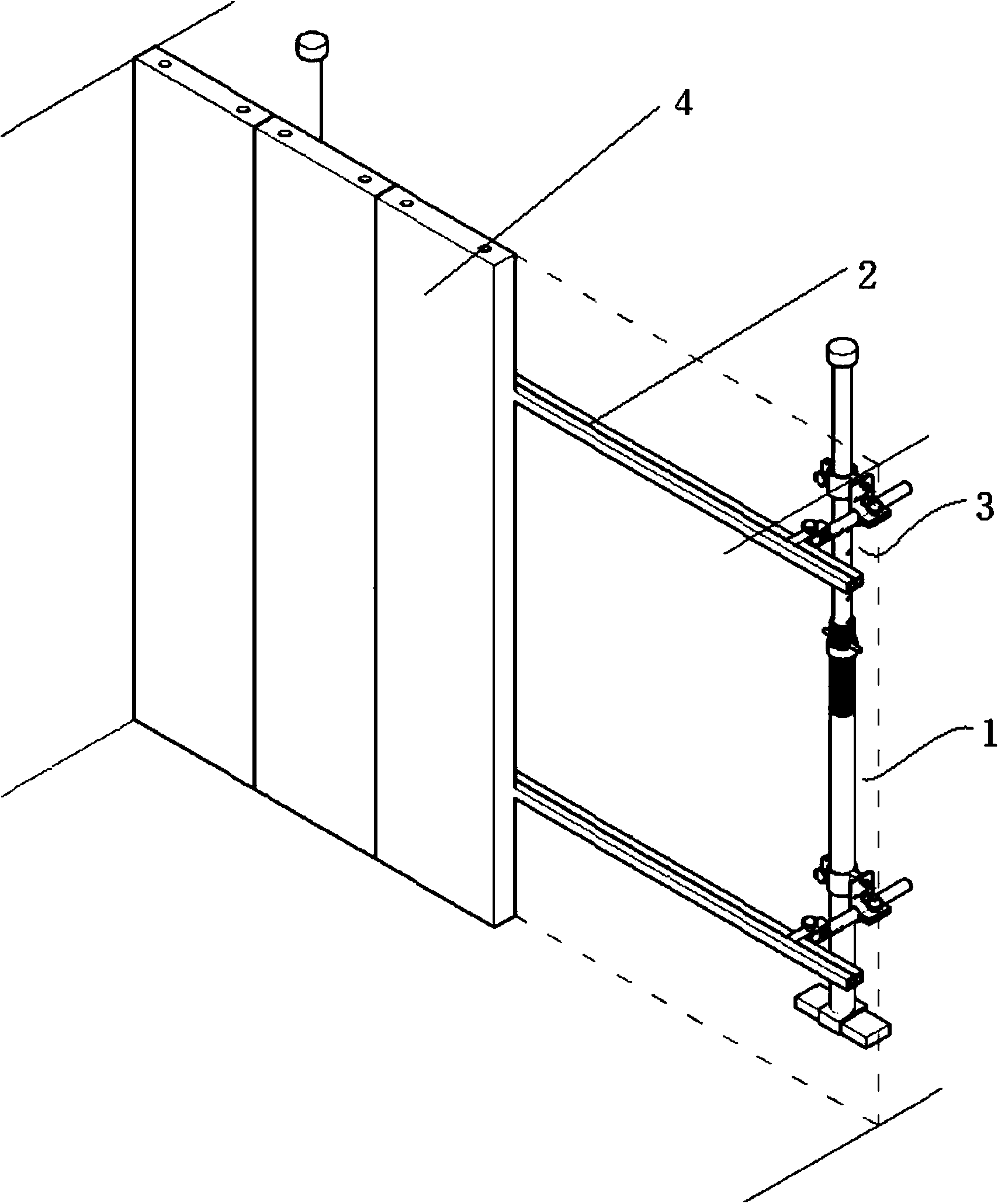

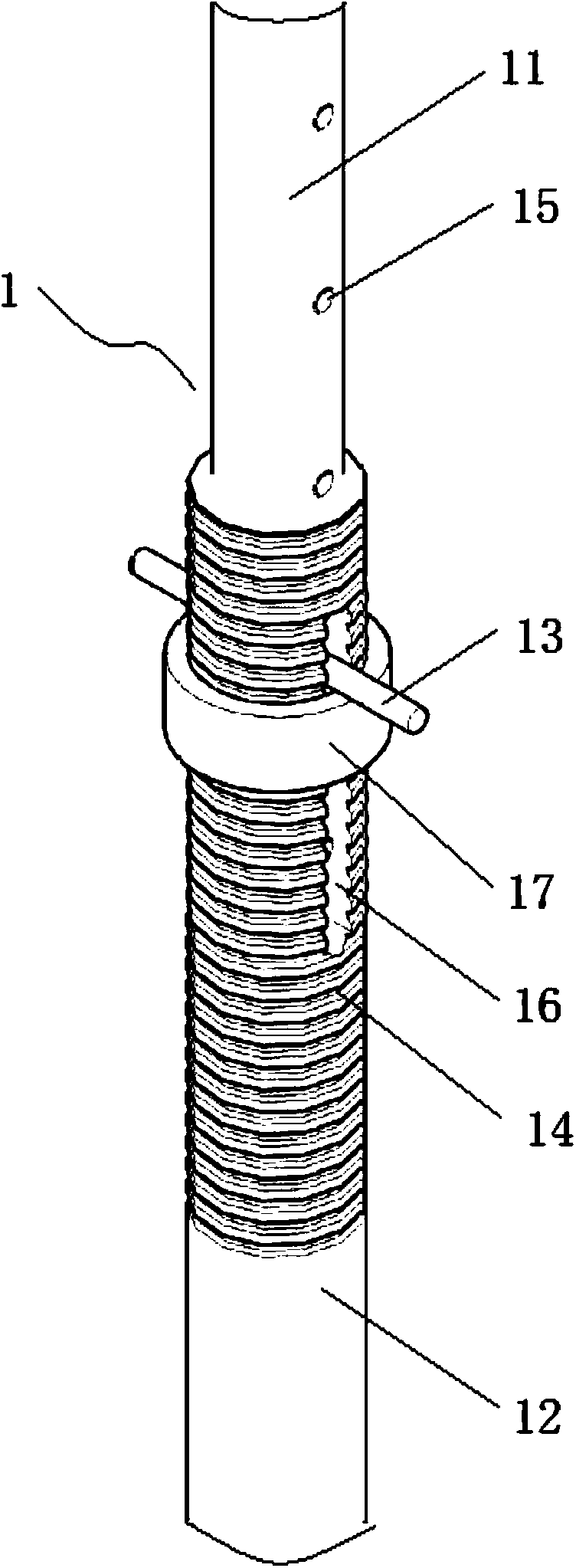

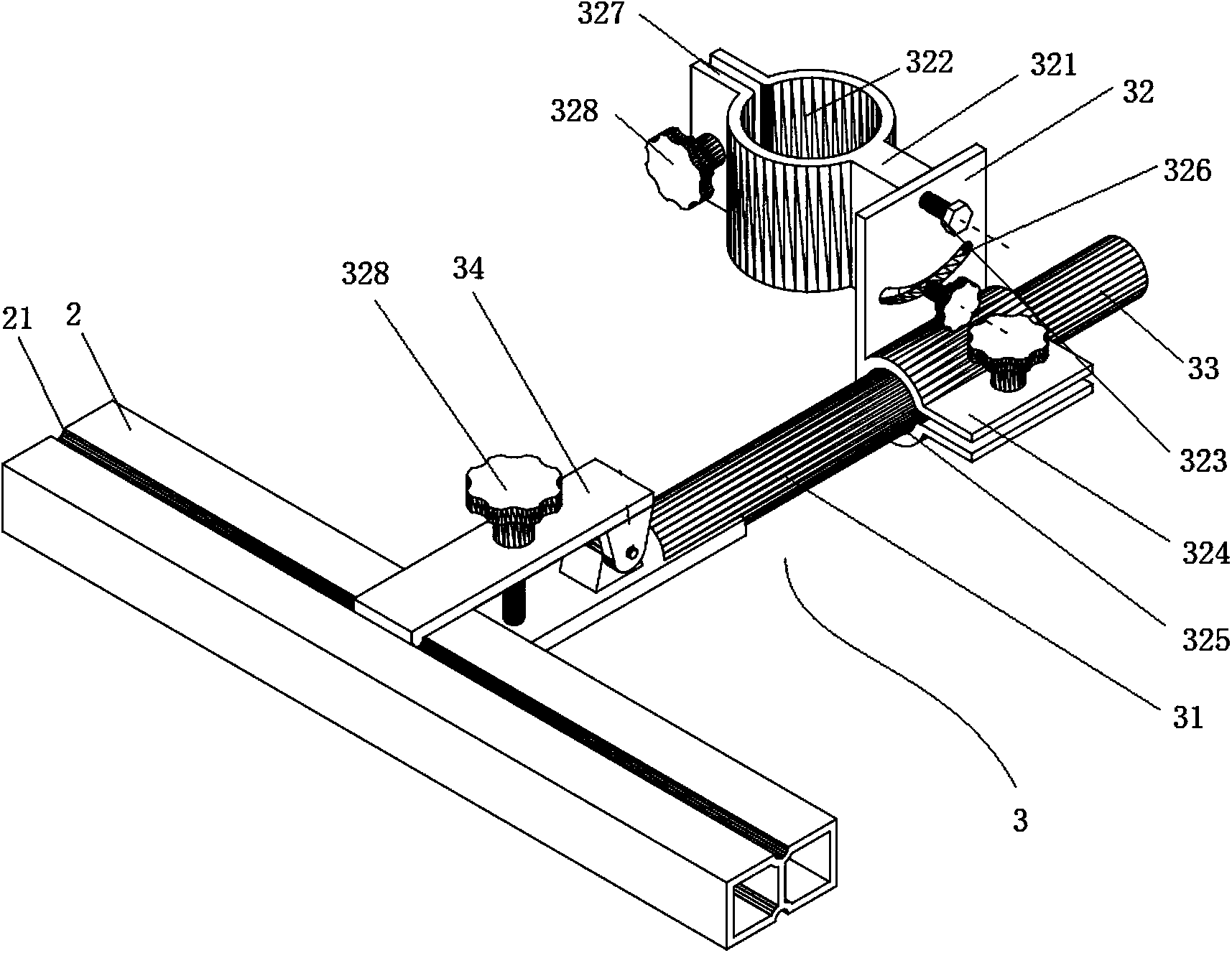

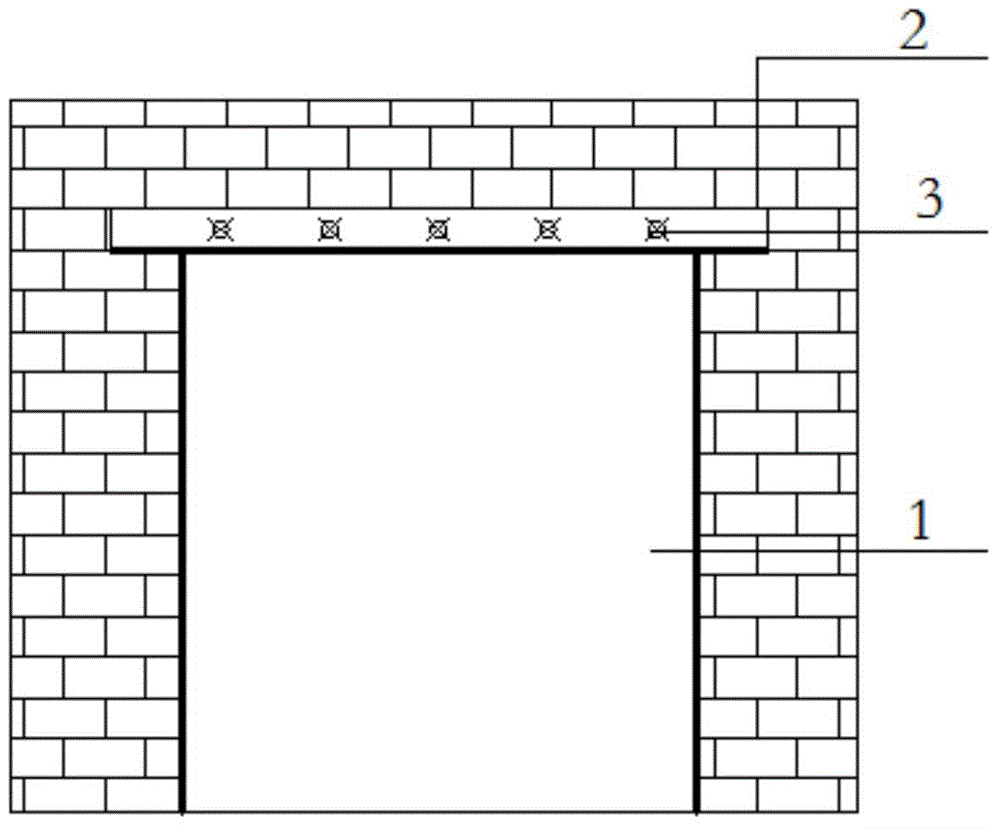

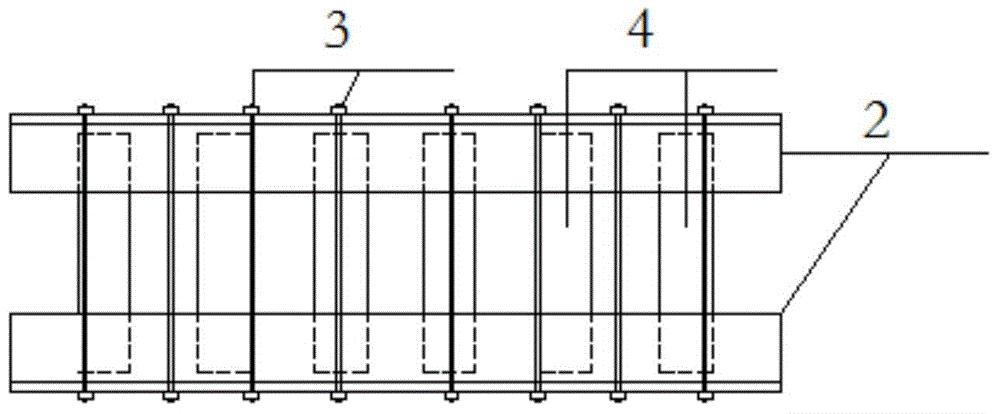

Method for calibrating concrete prefabricated wallboard installation construction datum and calibrating device

ActiveCN103510715AReliable construction basisAccurate construction standardsBuilding material handlingConstruction engineeringLaser

The invention discloses a method for calibrating a concrete prefabricated wallboard installation construction datum. The method includes the following steps that (1), a construction datum calibrating device is manufactured and comprises a supporting assembly, a ruler rod and a connecting and locking assembly; (2), chalk lines are marked at the corresponding positions where concrete prefabricated wallboards are to be installed; (3), the supporting assembly is propped; (4), a laser paying-off instrument is placed above the chalk line portion and emits rays; (5), the ruler rod is connected, the side surface of the ruler rod faces toward the direction in which the wallboards are to be installed, the side surface of the ruler rod coincides with the rays, and then the side surface of the ruler rod forms the construction datum for installing the concrete prefabricated wallboards. The invention further discloses the construction datum calibrating suite device. The concrete prefabricated wallboard installation construction datum not only improves the working efficiency of installing the concrete prefabricated wallboards, but also is beneficial to ensuring the flatness of a siding wall under construction, and is more beneficial to ensuring bond quality between the wallboards or between the wallboards and corresponding vertical faces under construction.

Owner:DONGGUAN CAILI BUILDING MAINTAIN TECH

Lay out line

A chalk line apparatus for marking regularly spaced locations. The apparatus comprises a casing for powdered chalk containing a rotatable reel, line wound on said reel, and an exit opening for the line at one end of the holder. The line has evenly spaced short segments disposed thereon so that when the line is tensioned to a predetermined level of about 10-15 lbs, the segments reside at precisely placed predetermined intervals. When the line is snapped, chalk marks are placed on the wall surface in a pattern that identifies the appropriate locations of underlying wall studs.

Owner:STUDLINE TOOL

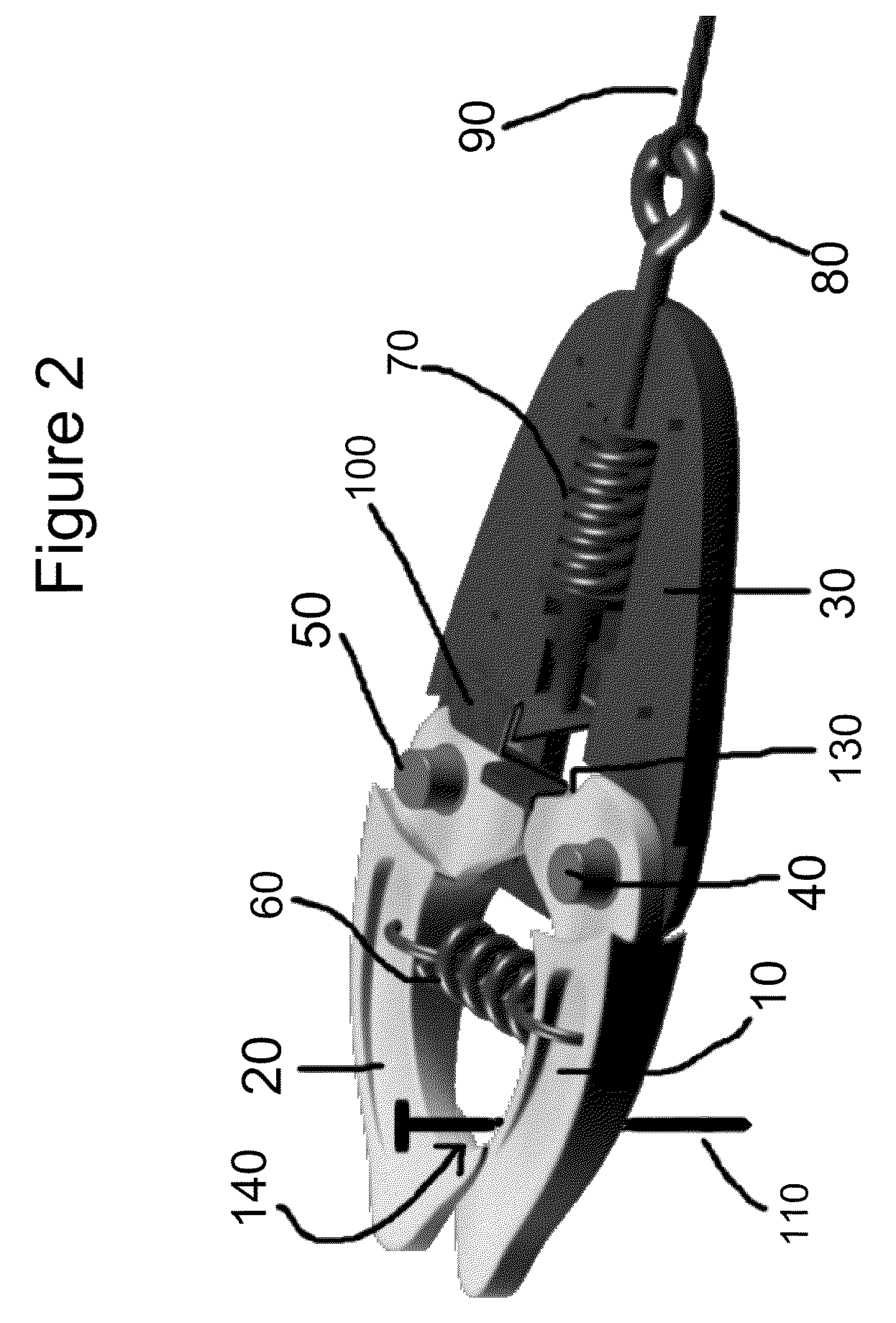

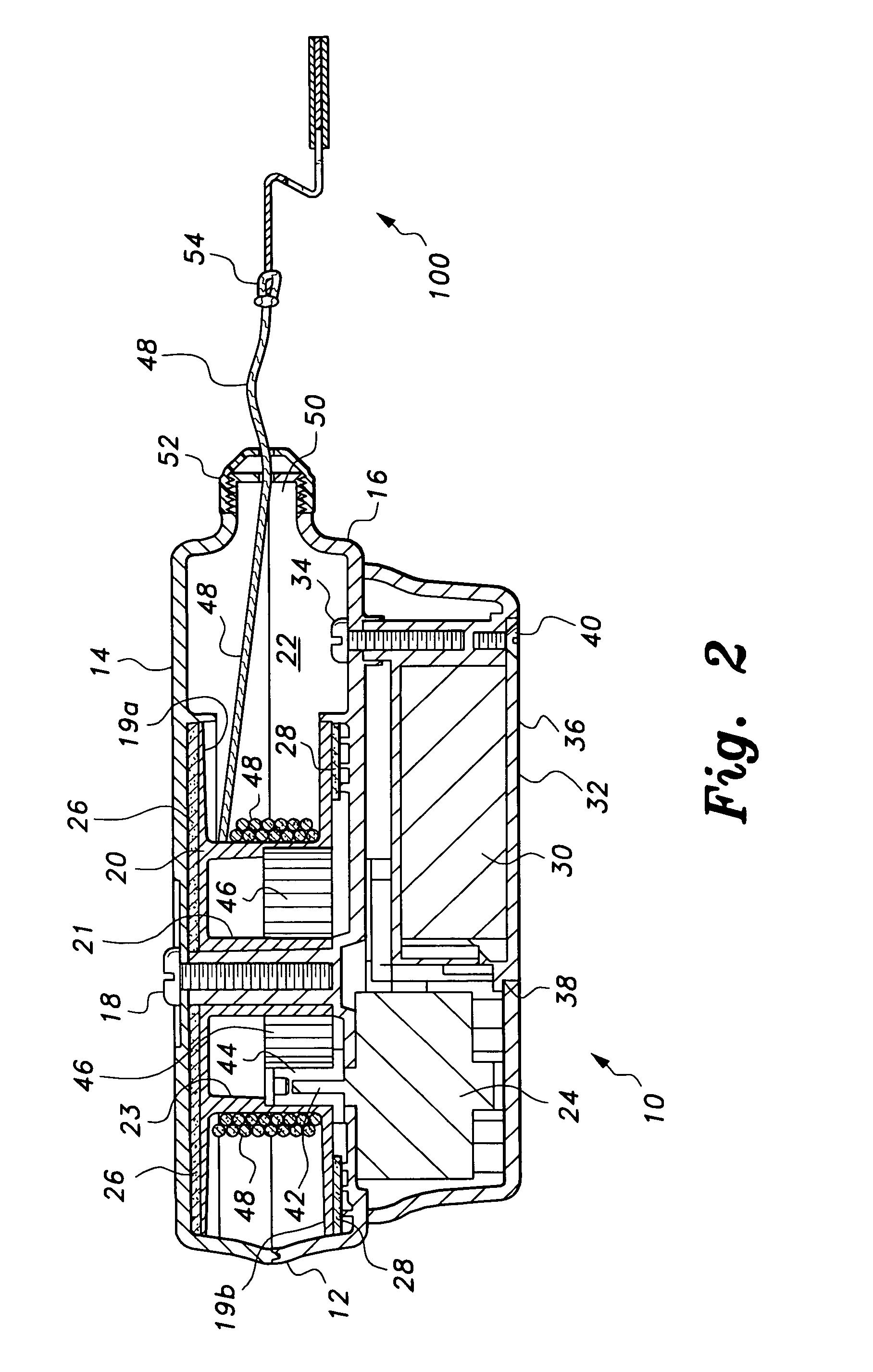

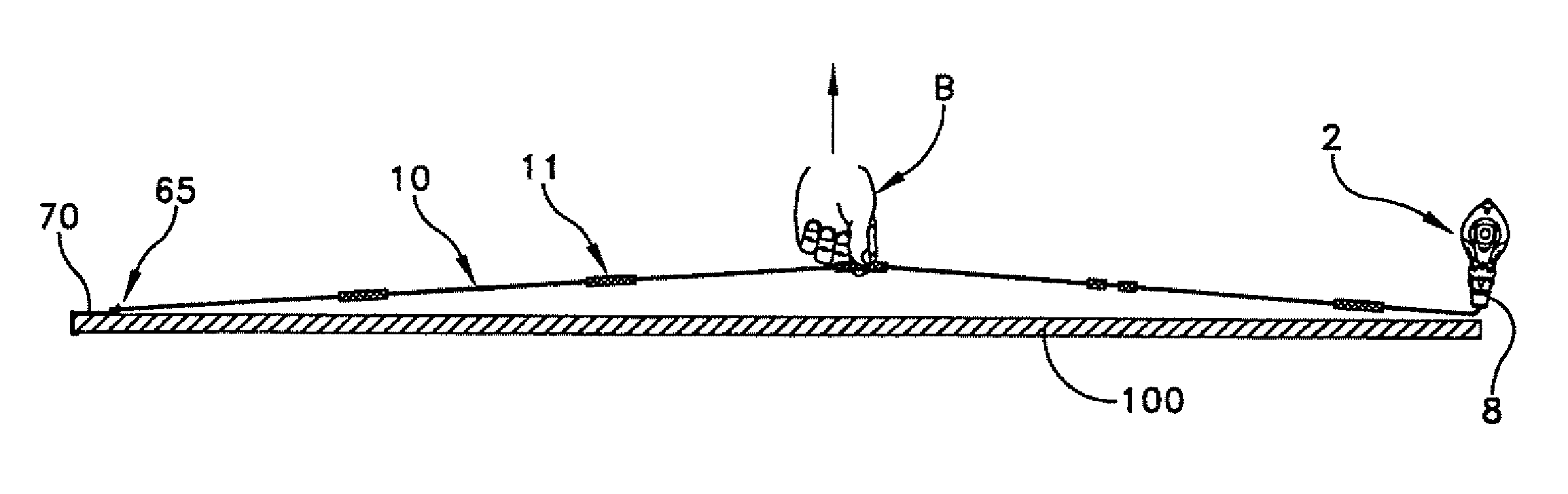

Hands free chalk line snapper

A chalk line marking device includes a chalk line that is held in a storing, dispensing and retracting device. The device comprises a housing and an element for gripping the chalk line when it is extended from the dispensing device and lifting it from the workpiece surface at a point remote from the device. A spring mechanism causes the gripping element to suddenly snap back to its original position, when released, thereby causing the chalk line to leave a linear chalk mark on the workpiece surface. The device may also comprise a gripping element arranged within the housing that includes a plunger responsive to movement of the housing, for lifting and suddenly releasing the gripping element. A worker can extend the chalk line with one hand while holding the dispensing device in the other hand. The hand holding the dispensing device can actuate the gripping element with the thumb, for example, of that same hand while the other hand holds the extended end of the chalk line in position, thereby not requiring a third hand to snap the chalk line.

Owner:ALEXANDER RICHARD

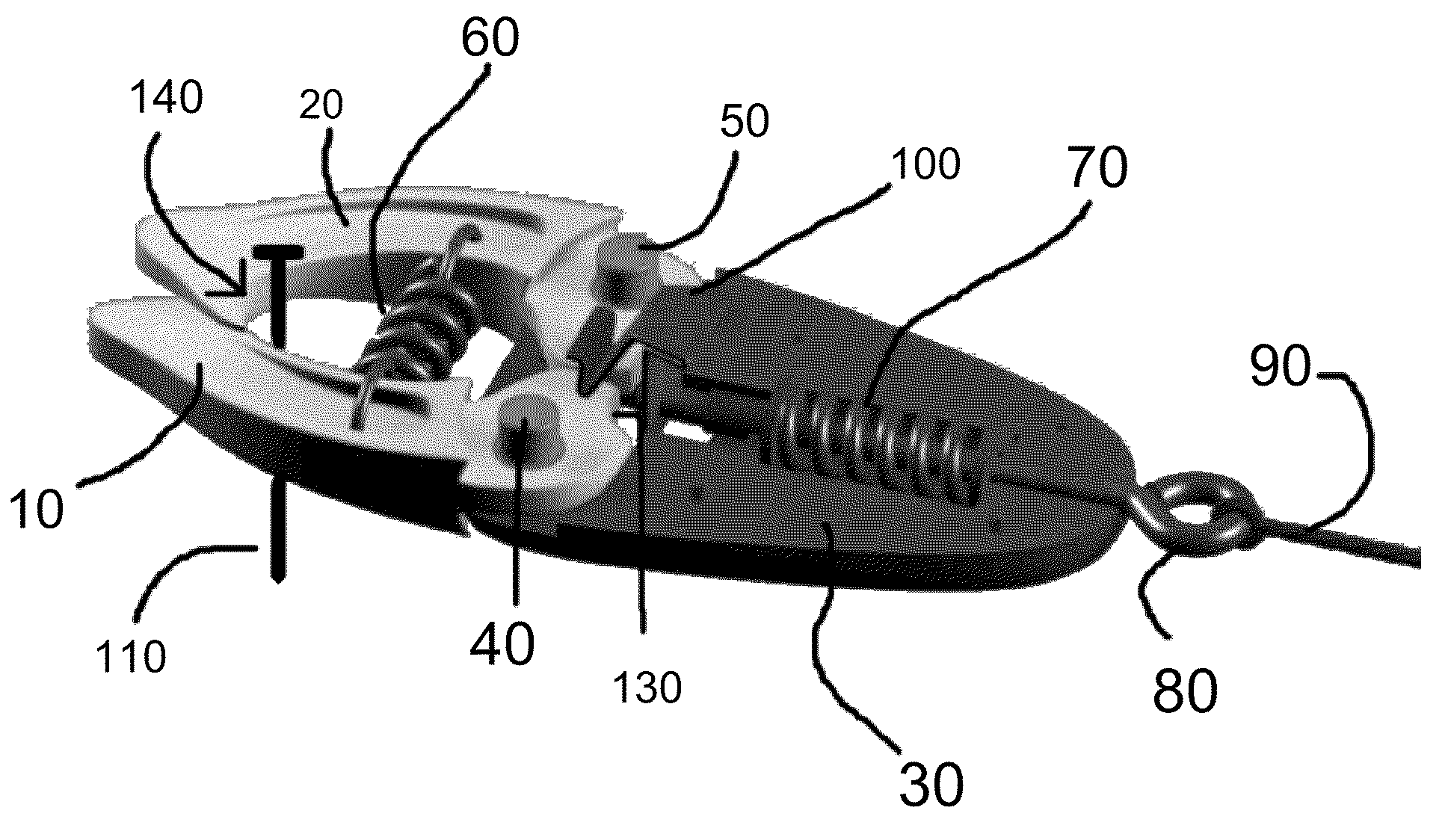

Chalk line marking system

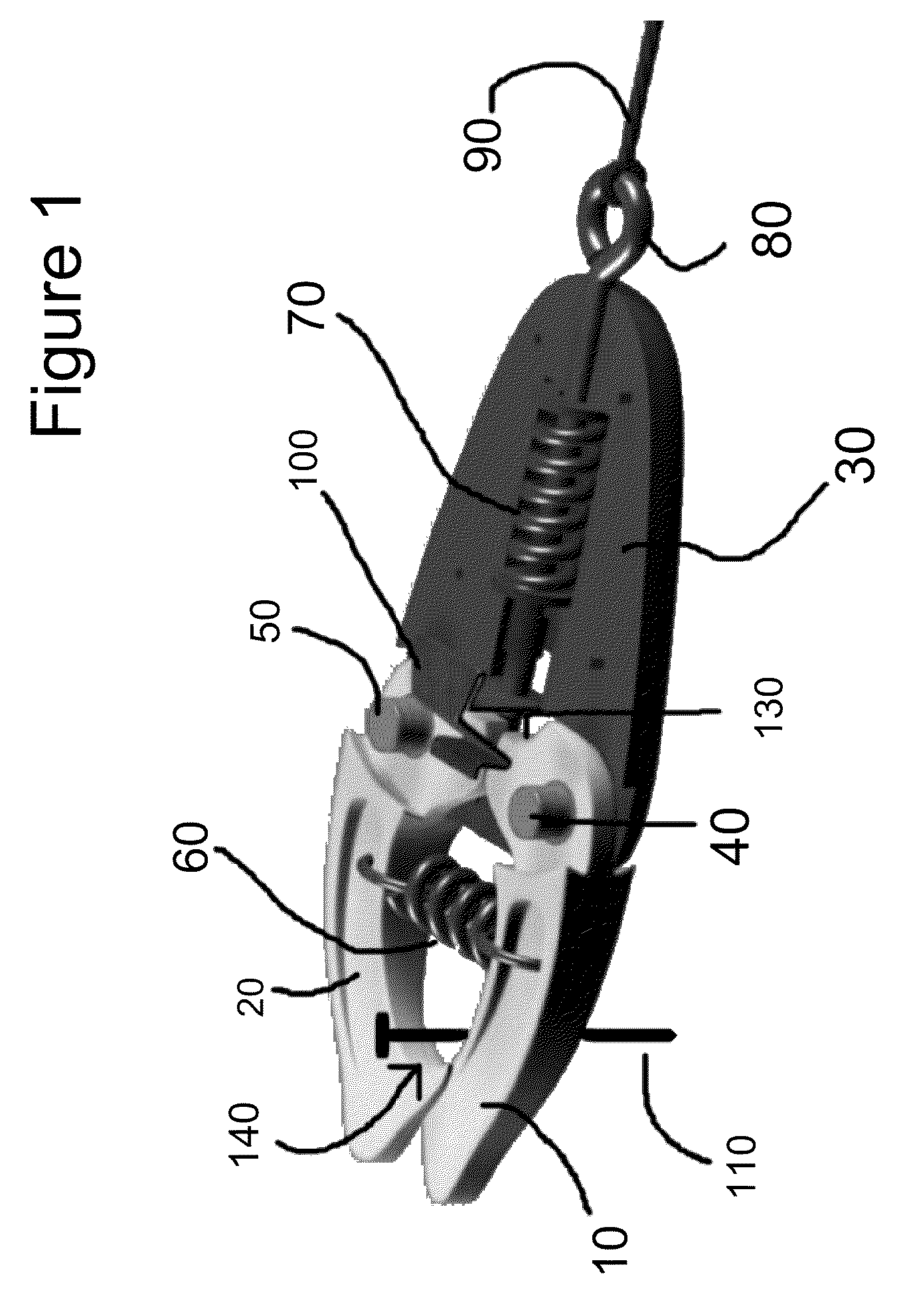

InactiveUS7913409B2Shorten the timeSurveying instrumentsOther artistic work equipmentsEmbedded systemChalk line

A chalk line is marked by attaching two hooks to a nail, and then extending a string a length from the nail. The hooks are attached to an apparatus that has multiple springs, such that there is a string attached to the rear of the apparatus while the hooks are attached to the front of the apparatus. When the string has been extended the desired length, the user then snaps the line to make a chalk line. Then, the pull on the string is released by the user, causing the two hooks to separate. When the two hooks separate, their connection to the nail is broken. The hooks and the apparatus associated with the hooks then is free to be reeled back to the user. The user does not have to return to the nail to remove the hooks and the associated apparatus.

Owner:WILSON TIMOTHY J

Hands free chalk line snapper

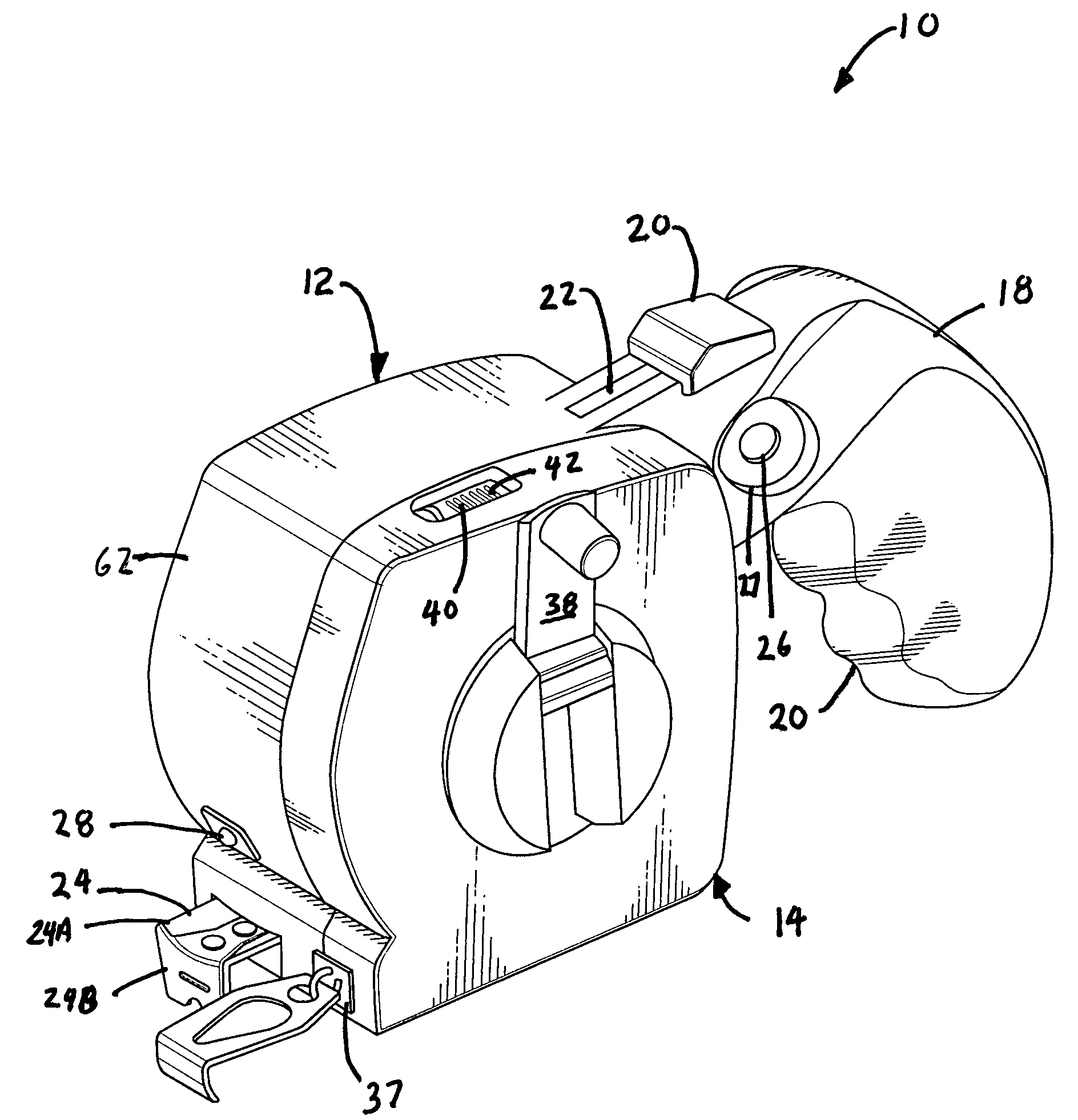

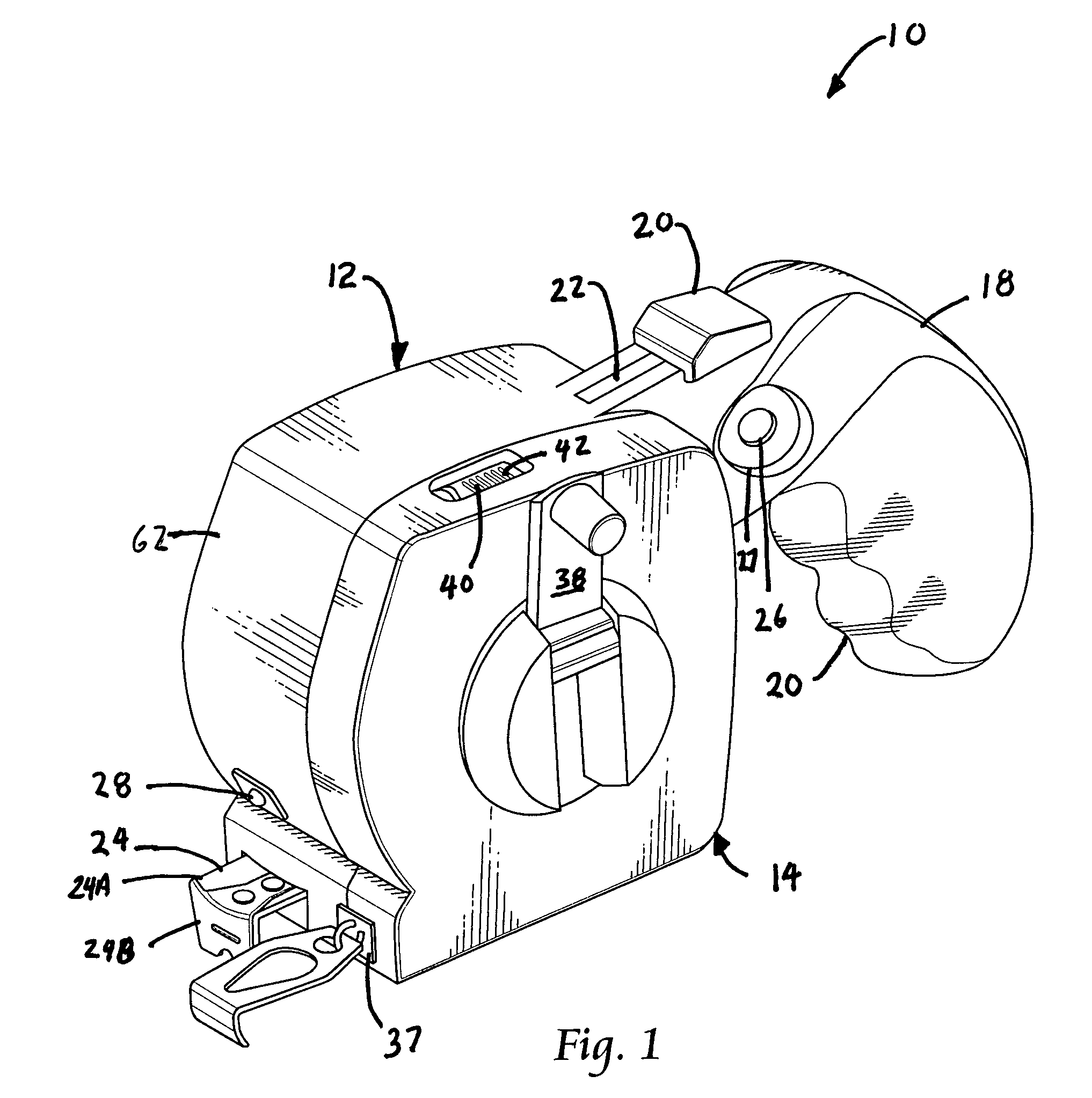

ActiveUS7707734B2Easily mark a lineSurveying instrumentsOther artistic work equipmentsHand heldEngineering

A chalk line marking device includes a chalk line that is held in a storing, dispensing and retracting device. The device comprises a housing and an element for gripping the chalk line when it is extended from the dispensing device and lifting it from the workpiece surface at a point remote from the device. A spring mechanism causes the gripping element to suddenly snap back to its original position, when released, thereby causing the chalk line to leave a linear chalk mark on the workpiece surface. The device may also comprise a gripping element arranged within the housing that includes a plunger responsive to movement of the housing, for lifting and suddenly releasing the gripping element. A worker can extend the chalk line with one hand while holding the dispensing device in the other hand. The hand holding the dispensing device can actuate the gripping element with the thumb, for example, of that same hand while the other hand holds the extended end of the chalk line in position, thereby not requiring a third hand to snap the chalk line.

Owner:ALEXANDER RICHARD

Motorized chalk box

InactiveUS7200949B2Solution to short lifeEasy maintenanceOther artistic work equipmentsMeasuring tapesEngineeringPinion

The motorized chalk box includes a chalk line reel having an internal ring gear. An electric motor drives a pinion gear, which engages the ring gear, thus resulting in a very compact assembly. The motor and gearing are sealed from the chalk dust reservoir, through which the chalk line passes. The housing comprises two components secured by a single screw to facilitate minor maintenance. A spring loaded, automatically releasing line clip extends from the distal end of the chalk line. The line clip includes a spring-loaded sleeve, which is biased against the anchor (screw, nail, etc.) when in place. Releasing the tension on the chalk line causes the sleeve to spring against the anchor, thus kicking the line clip away from the anchor. The chalk box may thus be operated using only one hand, greatly improving safety for workers in elevated environments.

Owner:LESLIE TROY A +1

Chalk line with viewing window

InactiveUS20050132590A1Other artistic work equipmentsElectrical and Electronics engineeringChalk line

A chalk line device includes a housing and a chalk line stored in the housing. The chalk line terminates in a hook at one end and the hook is disposed outside of the housing. The housing may include a side wall with a depression formed therein that is shaped to receive the hook for storage. The depression has an edge that allows the hook to securely engage. The housing may also include a translucent window for allowing the user to check the level of chalk in the chalk line device. The translucent window forms at least a portion of a wall of the housing. The translucent window can be made, for example, of a plastic and can be integrally formed with the housing.

Owner:STANLEY WORKS THE

Lay out line

A chalk line apparatus for marking regularly spaced locations. The apparatus comprises a casing for powdered chalk containing a rotatable reel, line wound on said reel, and an exit opening for the line at one end of the holder. The line has evenly spaced short segments disposed thereon so that when the line is tensioned to a predetermined level of about 10-15 lbs, the segments reside at precisely placed predetermined intervals. When the line is snapped, chalk marks are placed on the wall surface in a pattern that identifies the appropriate locations of underlying wall studs.

Owner:STUDLINE TOOL

Wall hole opening construction method adopting encased angle iron method

InactiveCN104790684ASimple construction processShort construction periodBuilding repairsSheet steelSupport point

The invention discloses a wall hole opening construction method adopting an encased angle iron method. The wall hole opening construction method includes the steps of firstly, designing angle iron; secondly, determining the size and the position of a hole by flicking a chalk line on a wall where the hole is to be opened; thirdly, scraping away a mortar painting layer at the position, nearby the position of the chalk line, of the top of the hole, and selecting a mortar joint closest to the chalk line as a horizontal mortar joint embedded in the angle iron, wherein the depth of the horizontal mortar joint is 80 mm, the length of the horizontal mortar joint is equal to the width of the hole after the hole extends leftwards by 500 mm and extends rightwards by 500 mm, the hole extends leftwards by 500 mm and extends rightwards by 500 mm to serve as supporting points of the angle iron, and a 160 mm mortar joint is formed in the other side of the wall if the wall thickness is 240 mm; fourthly, after the mortar joins are cleaned, structural cement gum is smeared into the mortar joints, horizontal limbs of the angle iron are inserted into the horizontal mortar joint to enter the wall till perpendicular limbs of the angle iron are flush with the wall; fifthly, filling supporting positions of the angle iron through a thin steel plate; sixthly, conducting construction in the same way on the other side of the wall according to the first step to the fifth step; seventhly, scraping away mortar face layers on the two sides of the portion, inside the chalk line, of the inner wall face, detaching bricks to open the hole from top to bottom till reaching a floor; eighthly, adding batten plates or lacing and batten elements to the manufacture angle iron.

Owner:SHANDONG JIANZHU UNIV

Lay out line

A chalk line apparatus for marking regularly spaced locations. The apparatus comprises a casing for powdered chalk containing a rotatable reel, a wire rope wound on said reel, and an exit opening for the wire rope at one end of the holder. The wire rope is coated with a material that resists retention of chalk, and has evenly spaced short chalk-retaining segments disposed thereon so that when the wire rope is tensioned to about 10 lbs, the segments reside at precisely placed predetermined intervals. When the line is snapped, the chalk-covered short segments leave evenly spaced chalk marks that correspond to the locations of underlying wall studs.

Owner:STUD LINE TOOL

Chalk line with viewing window

A chalk line device includes a housing and a chalk line stored in the housing. The chalk line terminates in a hook at one end and the hook is disposed outside of the housing. The housing may include a side wall with a depression formed therein that is shaped to receive the hook for storage. The depression has an edge that allows the hook to securely engage. The housing may also include a translucent window for allowing the user to check the level of chalk in the chalk line device. The translucent window forms at least a portion of a wall of the housing. The translucent window can be made, for example, of a plastic and can be integrally formed with the housing.

Owner:STANLEY WORKS THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com