Method for calibrating concrete prefabricated wallboard installation construction datum and calibrating device

A prefabricated wall panel and calibration device technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of low work efficiency, low efficiency, unstable construction quality, etc., to ensure flatness, improve installation work efficiency, The effect of ensuring bond quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

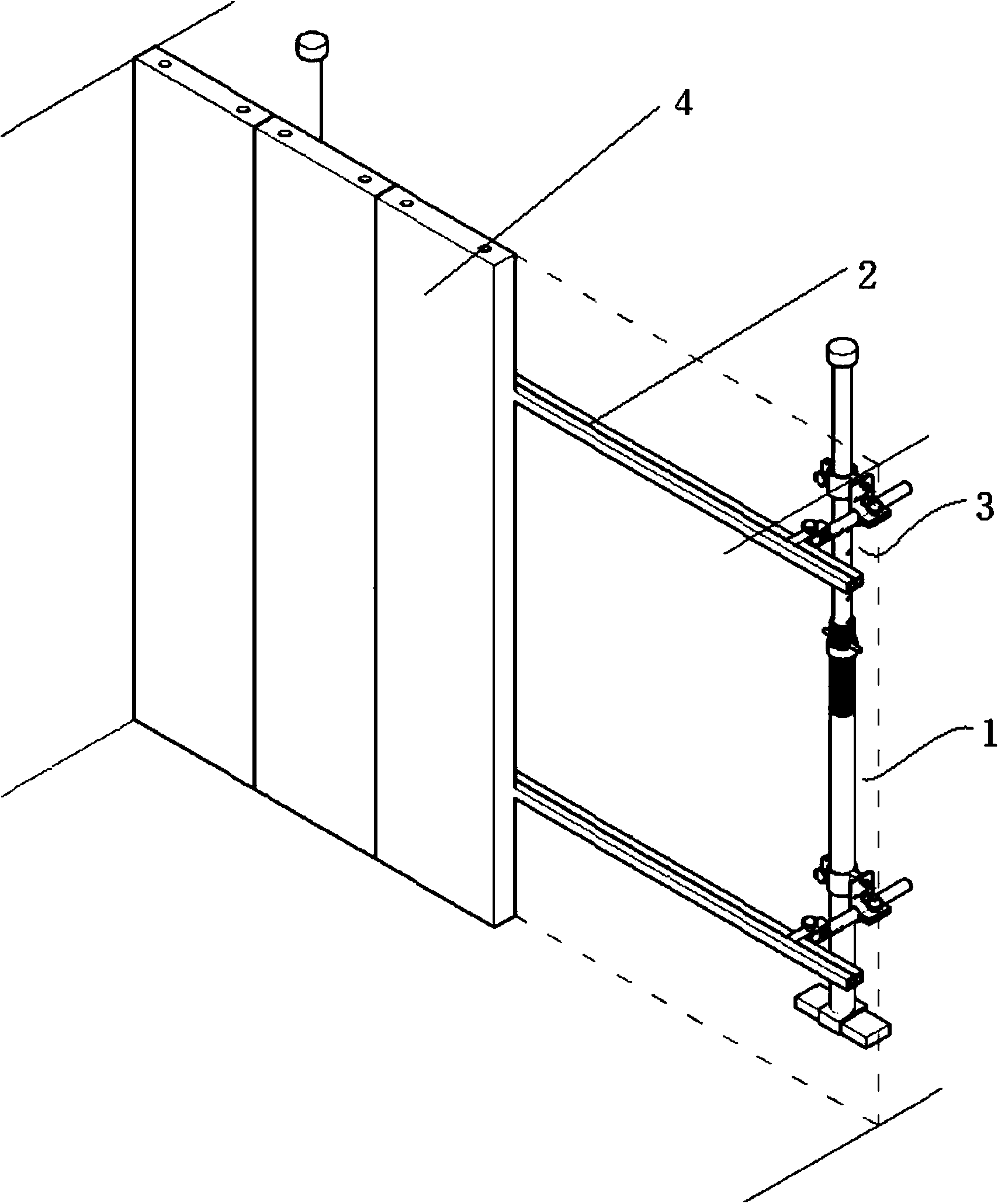

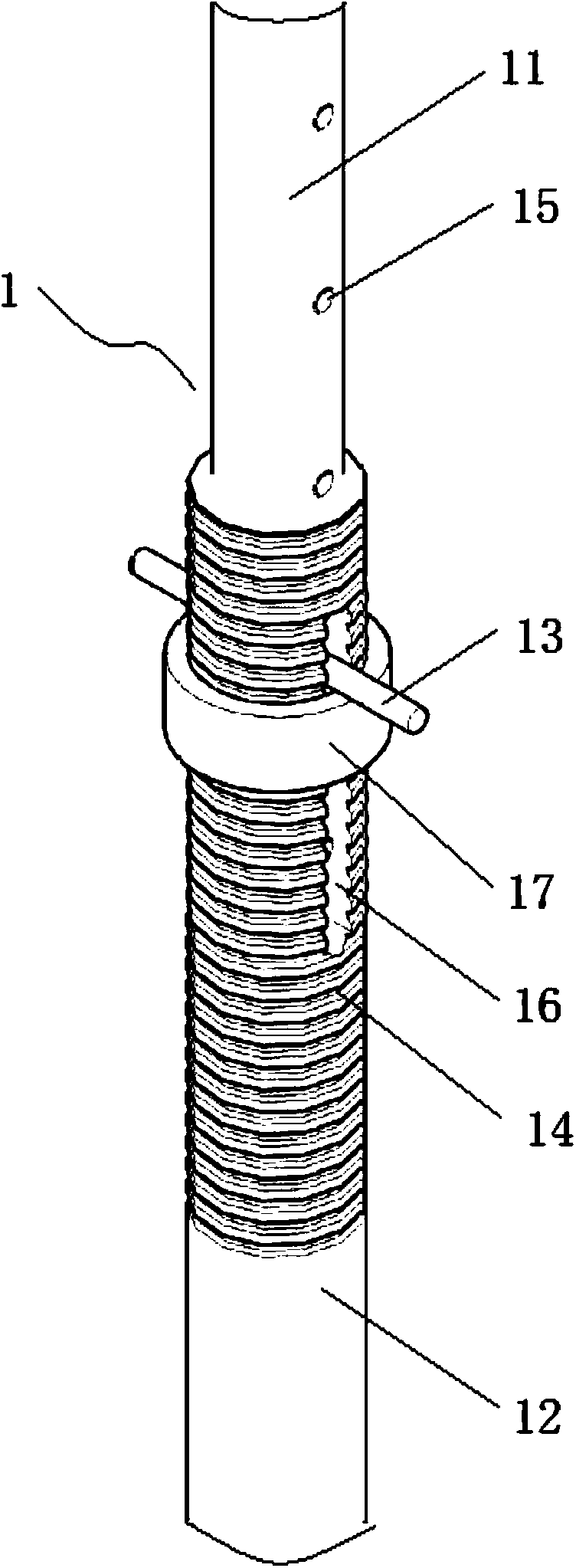

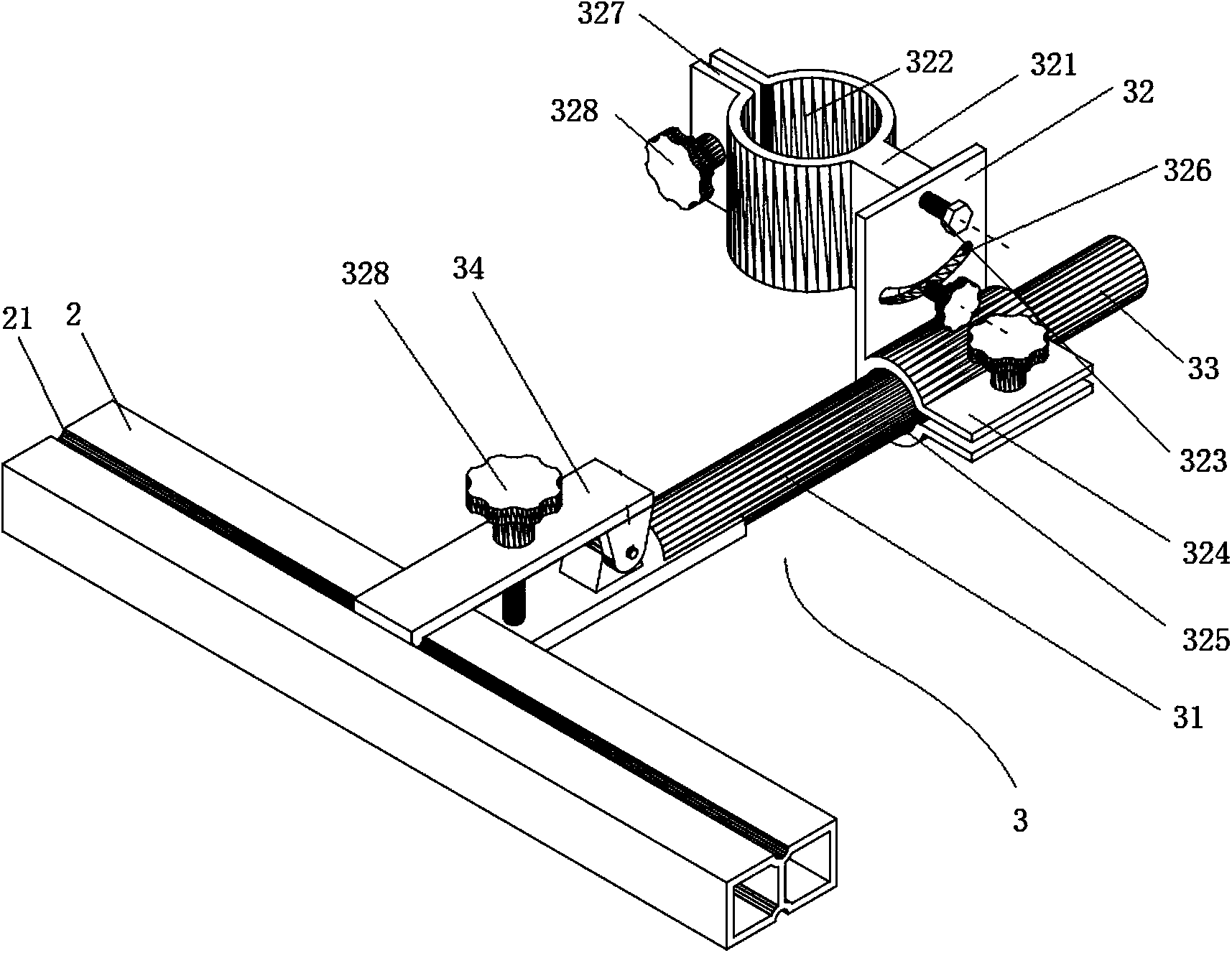

[0029] Examples, see Figure 1-Figure 3 , the method for demarcating the installation and construction reference of concrete prefabricated wallboard provided by the present invention, it comprises the following steps:

[0030](1) Preparation of calibration construction reference device, which includes 2 sets of support components 1, 2 scale rods 2 and more than 2 sets of connecting locking components 3, the support component 1 is equipped with a scale rod 2 locked into the support component 1 The connecting locking assembly 3; the connecting locking assembly 3 is composed of a connecting rod 31 and a cross member 32, one end of the connecting rod 31 is a cylindrical structure 33, and the other end is equipped with a clip that can fasten the scale rod 2 Fastener 34, the clamping piece 34 is a clamping piece arranged symmetrically up and down. The clamping piece is L-shaped, and one of the clamping pieces is fixed on the cylindrical structure 33 on the connecting rod 31, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com