Wall hole opening construction method adopting encased angle iron method

A technology of outsourcing angle steel and construction method, which is applied in building maintenance, construction, building construction, etc., and can solve problems such as research on the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

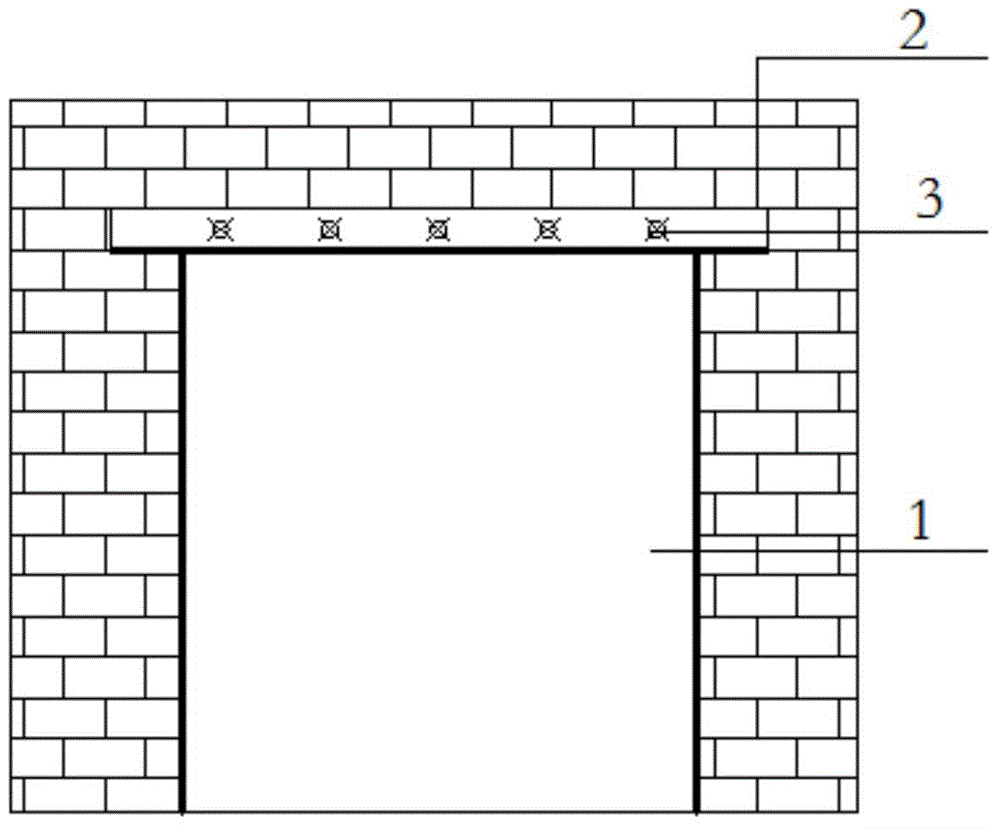

[0044] In a brick-concrete structure building, the user wants to open a door with a width of 1.5 meters and a height of 2 meters on the load-bearing wall of the first floor. It is known that the floor height is 2.8 meters, the wall thickness is 240mm, and the wall weight is 5.24kN / m 2 , using MU10 bricks and M5 mortar. The load value transmitted from the plate at a height away from the window epithelium is 60KN / m.

[0045] Solution: Clear span L=1.5m

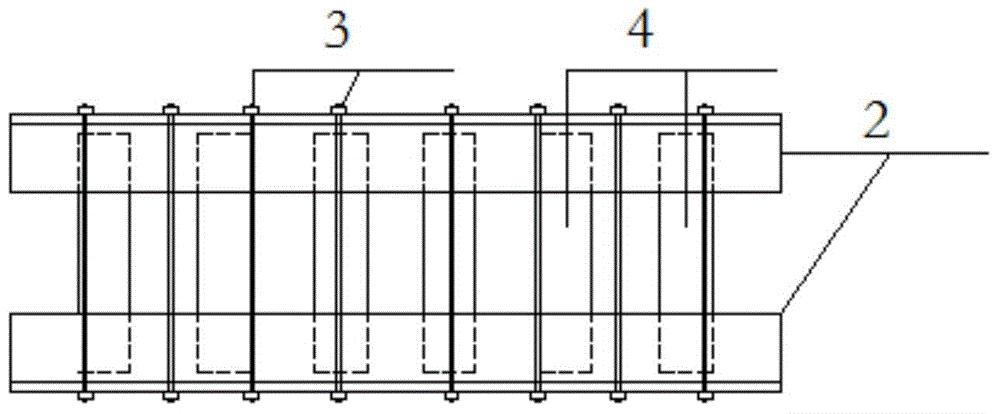

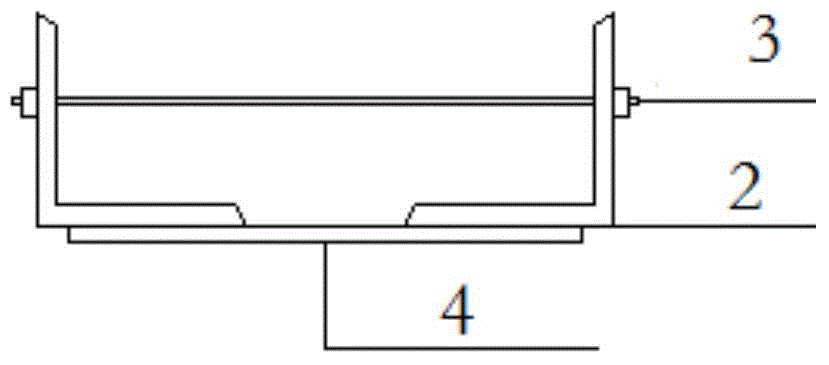

[0046] The supporting length of each side of the "lintel" to be added = 0.250m

[0047] Effective span L e =1.5+0.250=1.750m

[0048] If there is an arch effect, the minimum wall height required above the "lintel" is to be added:

[0049] h=1.75 / 2+0.203=1.078m

[0050] Masonry thickness from the upper part of the opening to the top of the wall = 3.5-2 = 1.5m > 1.078m

[0051] Assuming that there is an arch effect, the model of reinforced bricks with arched rods is used for calculation

[0052] Check the table according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com