American type water heater inner container alignment mechanism and alignment method

A water heater liner, American-style technology, used in metal processing and other directions, can solve the problems of inaccurate alignment, many parts, and heavy workload, and achieve the effect of being conducive to correct clamping, fewer parts, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

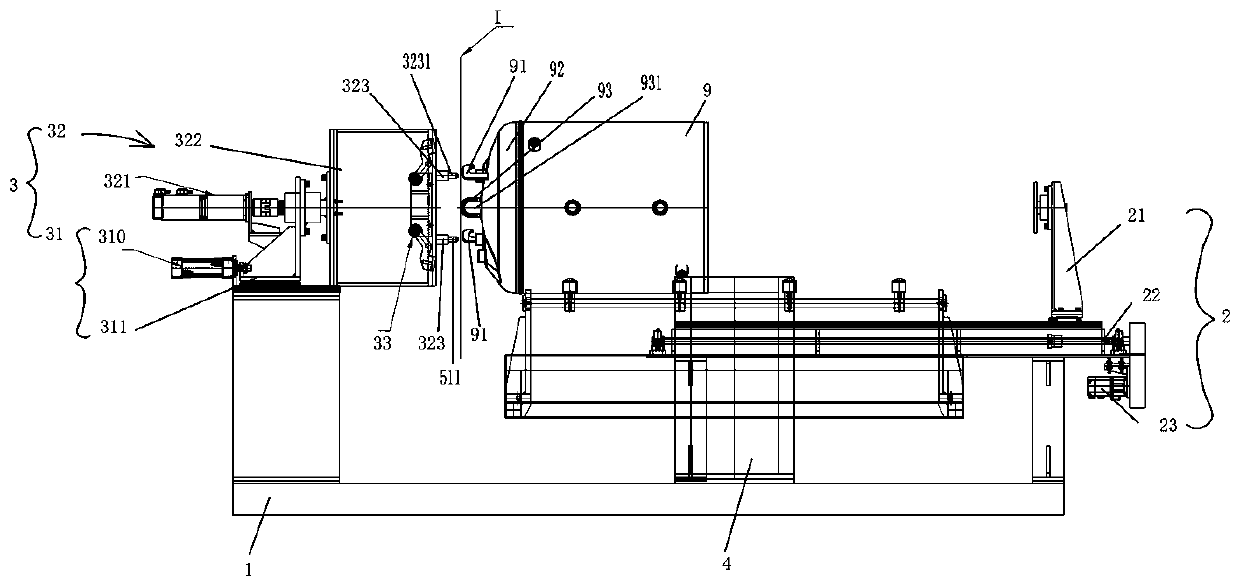

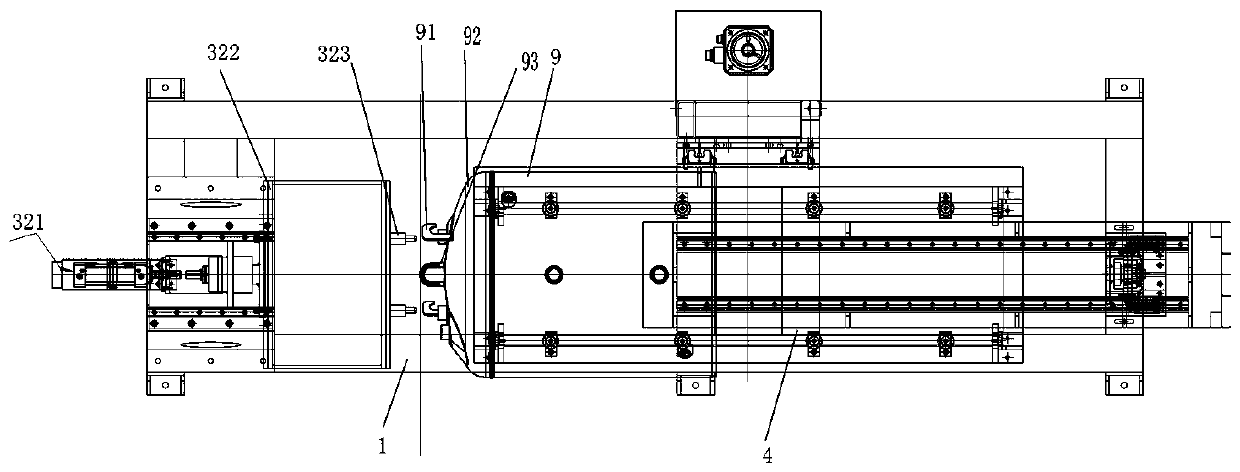

[0020] See Figure 1 to Figure 2 , Figure 1 to Figure 2 What is disclosed is an implementation of the alignment mechanism for the inner tank of an American water heater. An alignment mechanism for an inner tank of an American water heater includes a frame 1 for placing the inner tank of the water heater 9 and a control mechanism (not visible in the figure). , the control mechanism is a single-chip microcomputer or PLC, and the water heater liner alignment mechanism 2, the rotation mechanism 3 and the lifting mechanism 4 that are located on the frame 1 and rotate and position the water heater liner 9, the lifting mechanism 4 is arranged on the The water heater liner alignment mechanism 2 can move synchronously with the water heater liner alignment mechanism 2. In this embodiment, the water heater liner alignment mechanism 2 moves back and forth, and the rotation mechanism 3 is arranged on the frame 1, the rotation mechanism 3 includes a telescopic unit 31, a rotation servo un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com