Positioning, alignment and forming method for lower portion of formwork of vertical structure

A vertical structure and positive forming technology, which is applied to the connection parts of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of high labor intensity, poor construction quality, and cumbersome construction, etc. problems, and achieve the effects of low labor intensity, improved construction quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

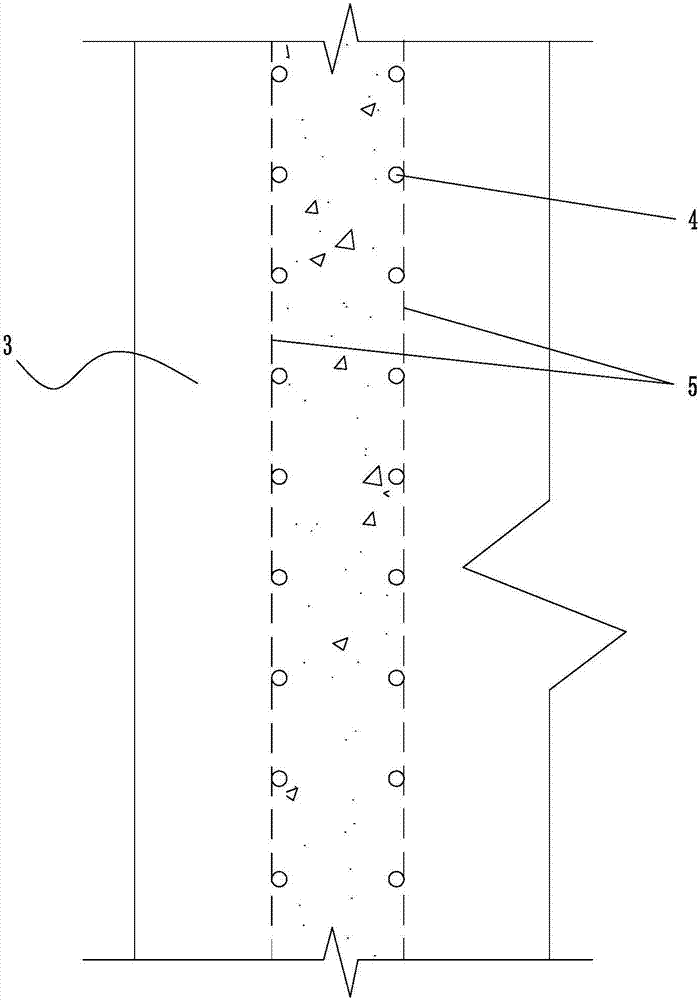

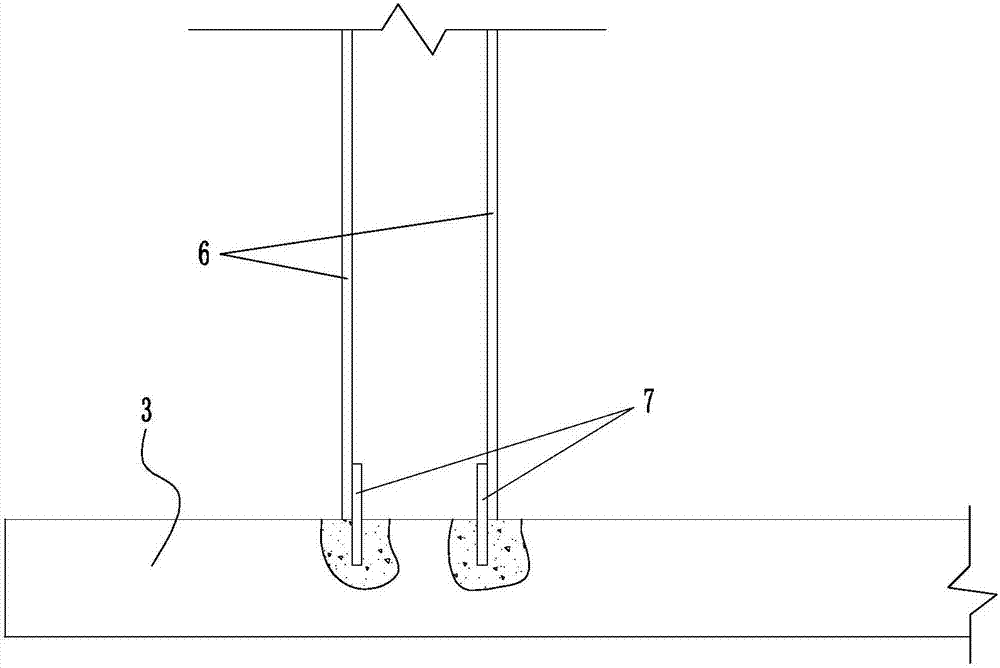

[0017] Such as figure 1 with figure 2 As shown, in this specific embodiment, a method for positioning and aligning the lower part of a vertical structure formwork according to the present invention includes the following steps:

[0018] (1) First, the surveyor performs measurement and positioning on each surface of the bottom 3 of the vertical structure, and pops the ink line 5 for formwork installation on each surface;

[0019] (2) Use a concrete impact drill to drill holes along the ink line 5. The diameter of each hole is 14mm. The distance between adjacent holes on the same ink line 5 is 500mm. At least two holes 4 are punched on each surface. The two ends of each surface Each part must have a hole 4, and the depth of each hole is 65mm;

[0020] (3) Knock in Φ12mm reinforcement pile 7 in hole 4, reinforcement pile 7 is positioned at ink line 5 inner side, and outer wall and ink line 5 are tangent, and each reinforcement pile 7 all exposes 70mm;

[0021] (4) Install the...

Embodiment 2

[0023] Different from Example 1, the diameter of each hole in step (2) is 13 mm, the distance between adjacent holes on the same ink line 5 is 450 mm, and the depth of each hole is 50 mm. In step (3), a Φ11mm reinforcement pile 7 is driven into the hole 4, the reinforcement pile 7 is located inside the ink line 5, and the outer wall is tangent to the ink line 5, and each reinforcement pile 7 is exposed 60mm.

Embodiment 3

[0025] Different from Example 1, the diameter of each hole in step (2) is 12 mm, the distance between adjacent holes on the same ink line 5 is 550 mm, and the depth of each hole is 80 mm. In step (3), a Φ10mm reinforcement pile 7 is knocked into the hole 4, the reinforcement pile 7 is located inside the ink line 5, and the outer wall is tangent to the ink line 5, and each reinforcement pile 7 is exposed 50mm.

[0026] Compared with manual alignment and multiple positioning and alignment, the present invention is easy and quick to operate during construction, can reduce labor intensity, save time and effort, and ensure accurate positioning of the lower part of the vertical structure formwork, easy and quick alignment, and improve the Production efficiency and forming quality of formwork construction (that is, the positioning axis is accurate, the formwork surface is straight, the formwork structure is square, and the structure is correctly formed).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com