Patents

Literature

37results about How to "Easy chamfering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

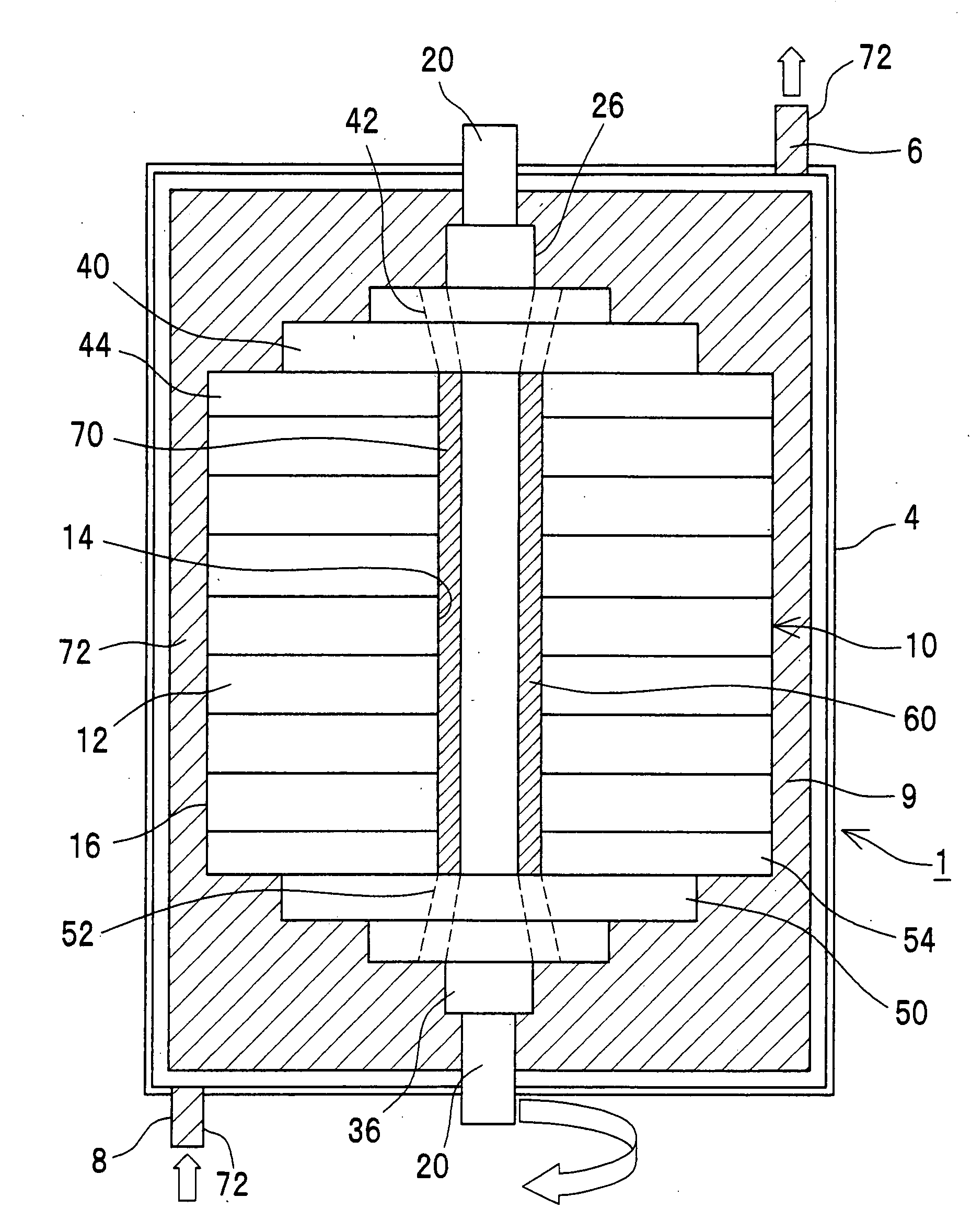

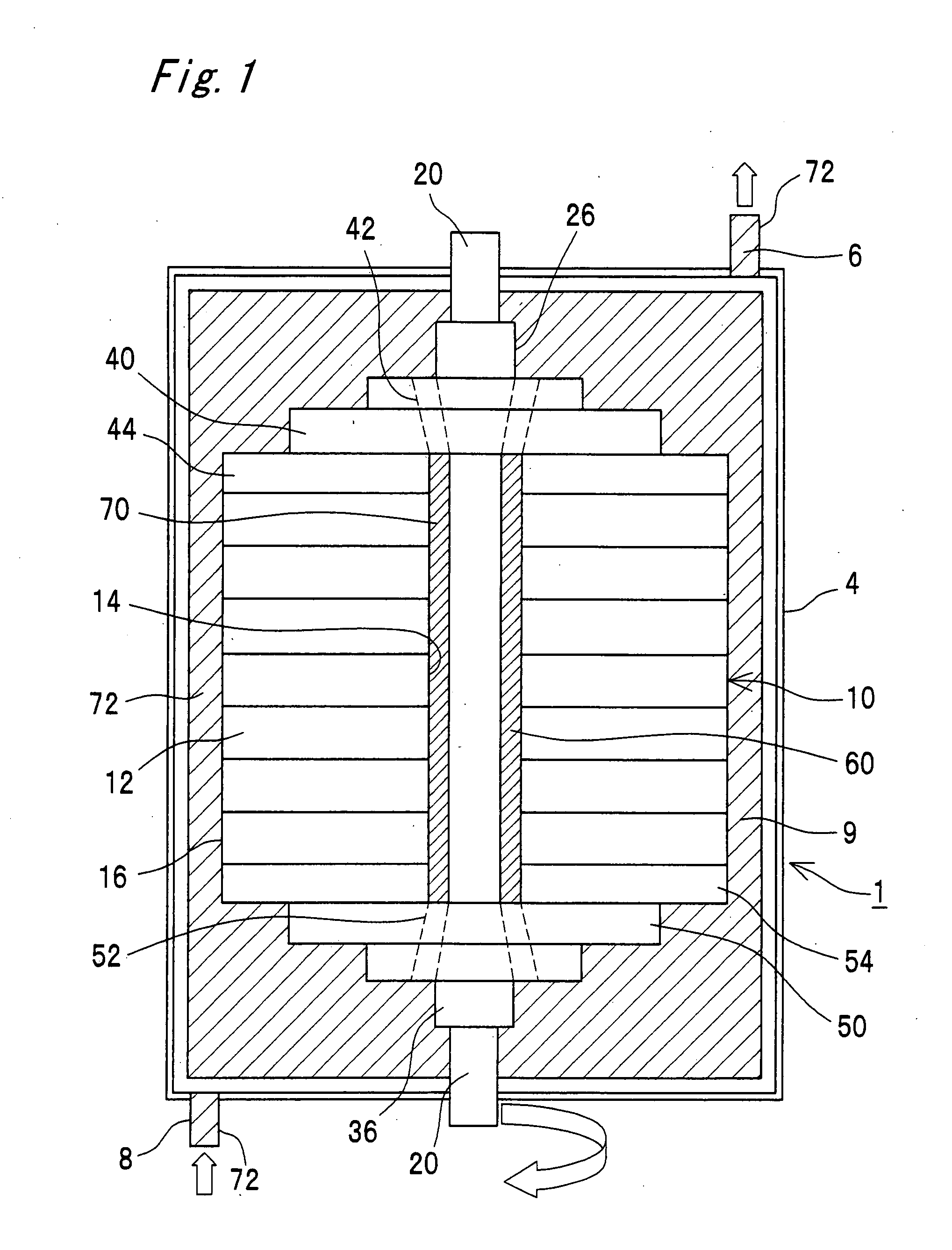

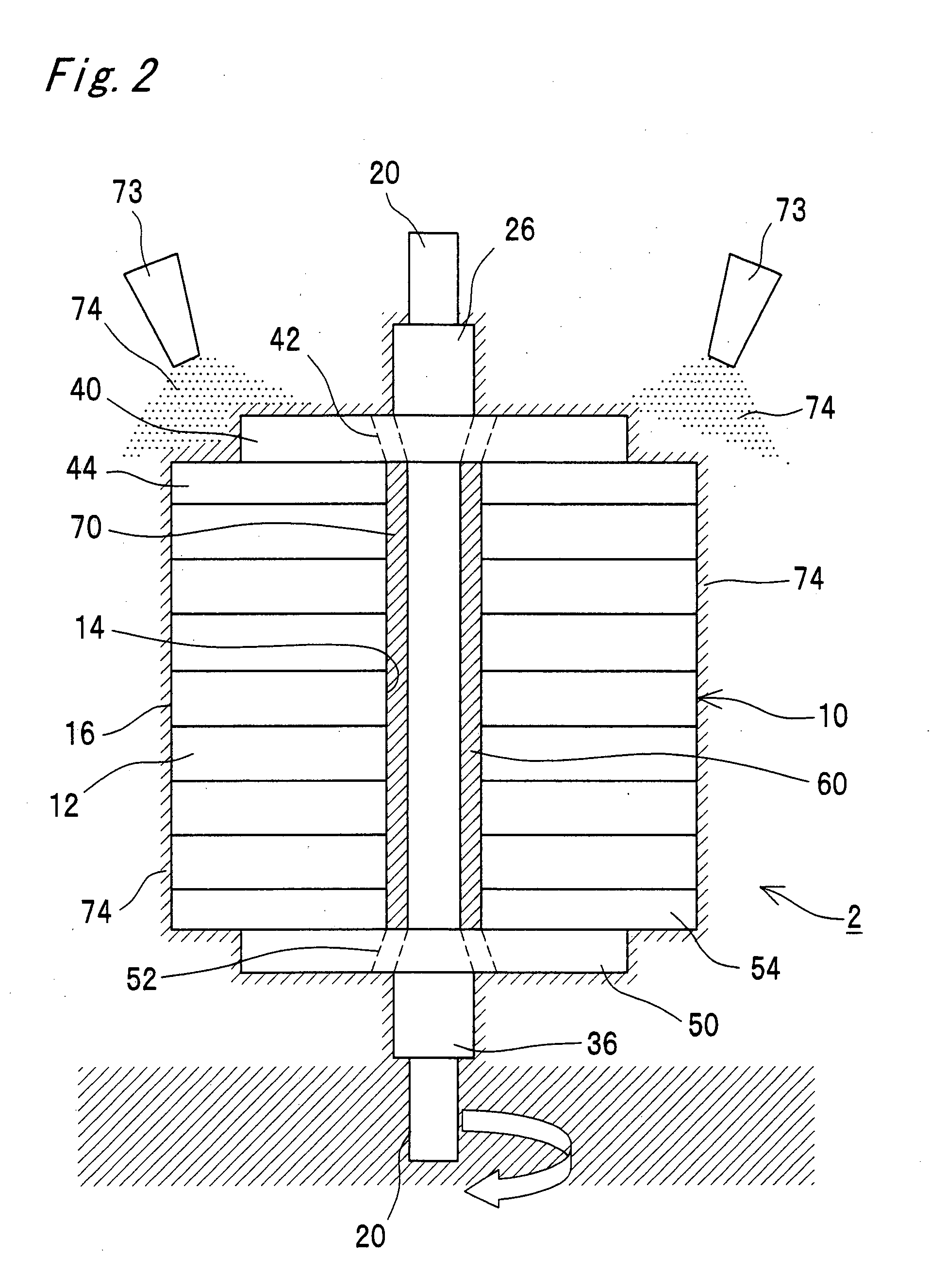

Glass disk processing method

The present invention provides a method of easily chamfering and polishing an inner peripheral face and an outer peripheral face of a glass disk at low cost. By continuously supplying fresh etchants to an inner peripheral face and an outer peripheral face of a glass disk stacked body in which a plurality of glass disks are stacked, the inner and outer peripheral faces are polished.

Owner:HOYA CORP

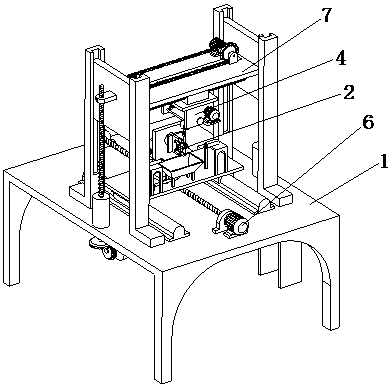

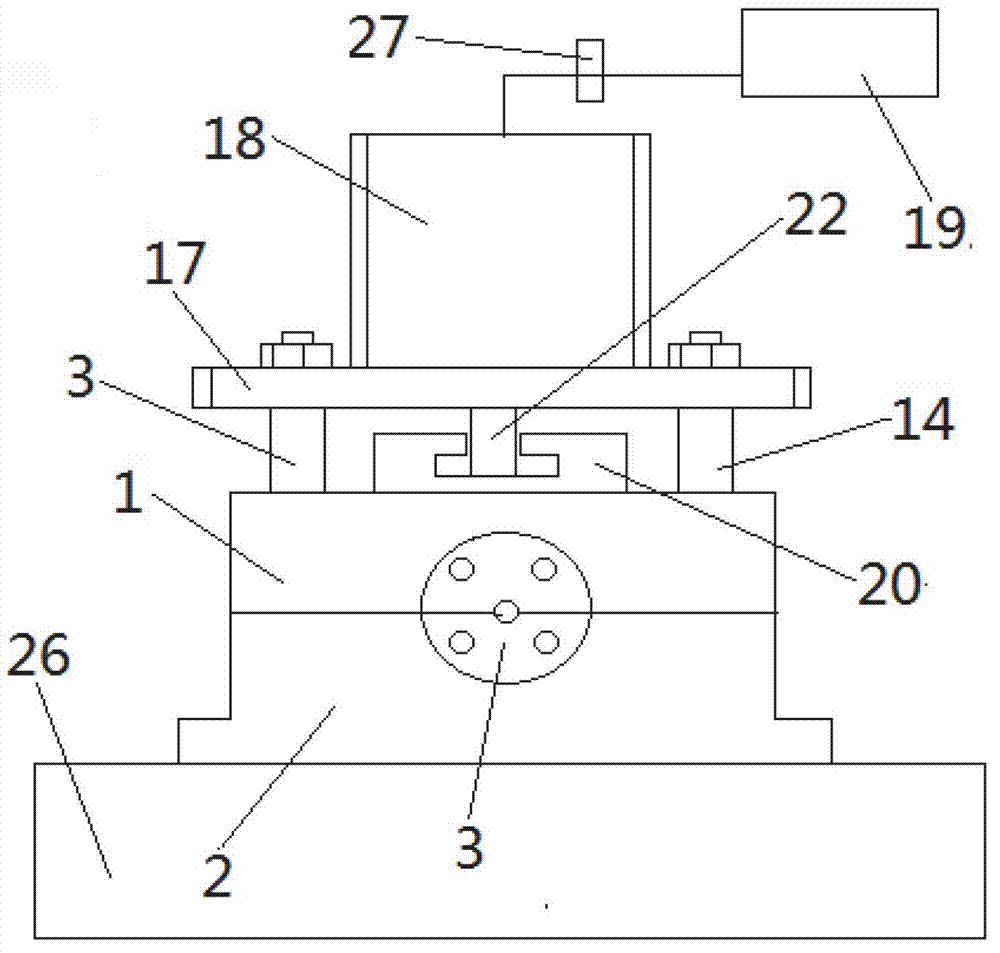

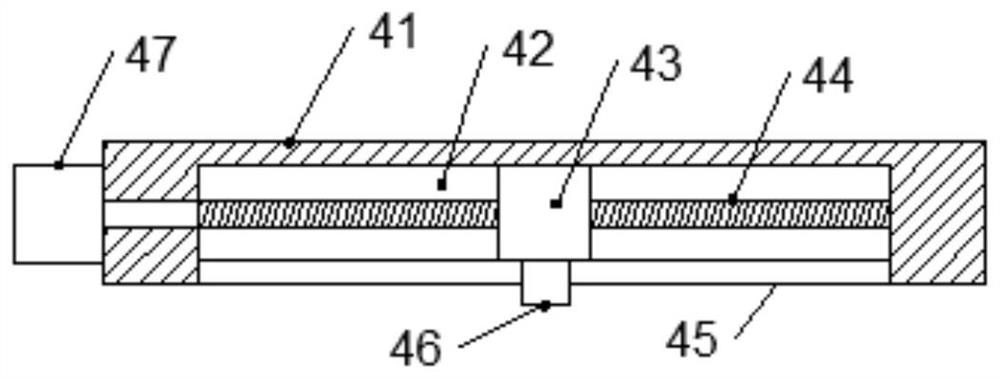

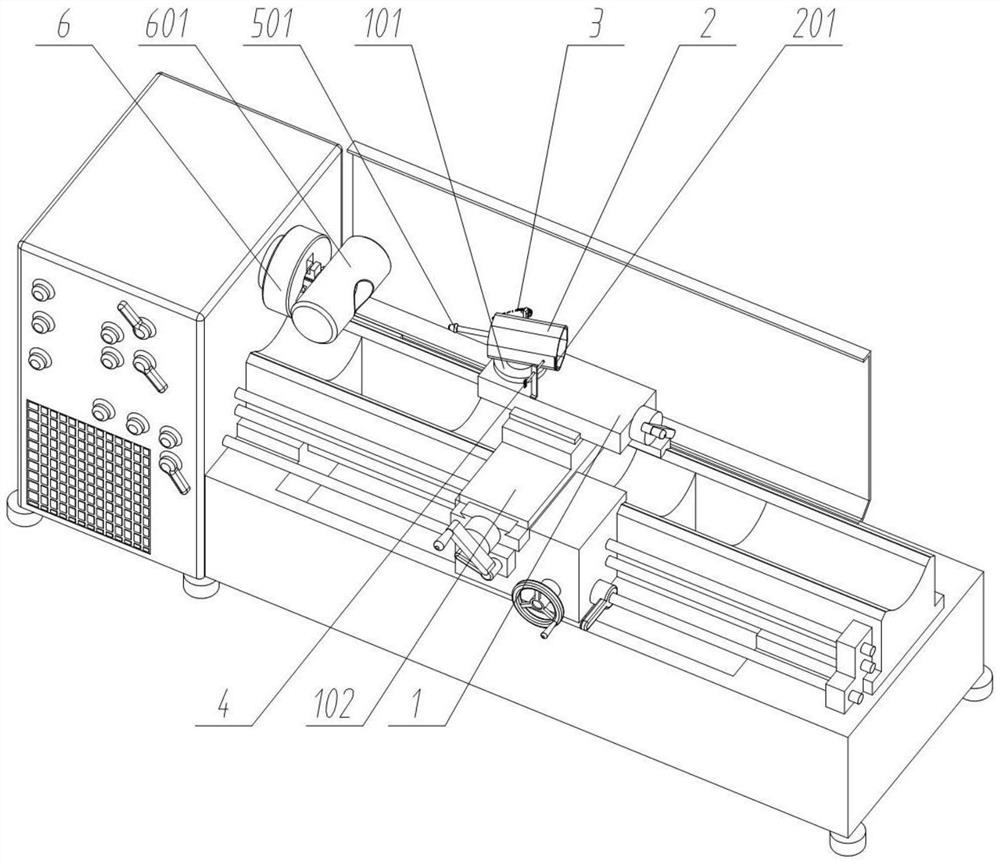

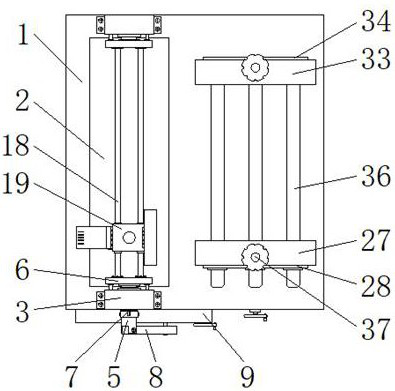

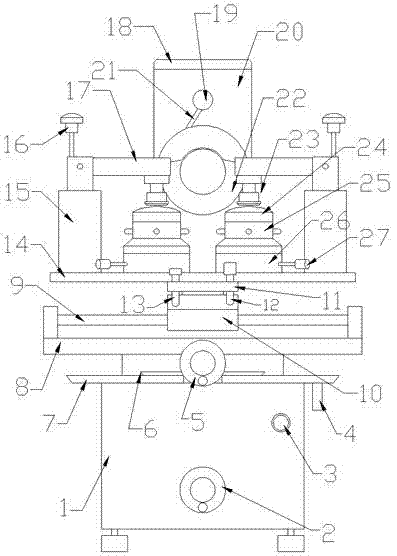

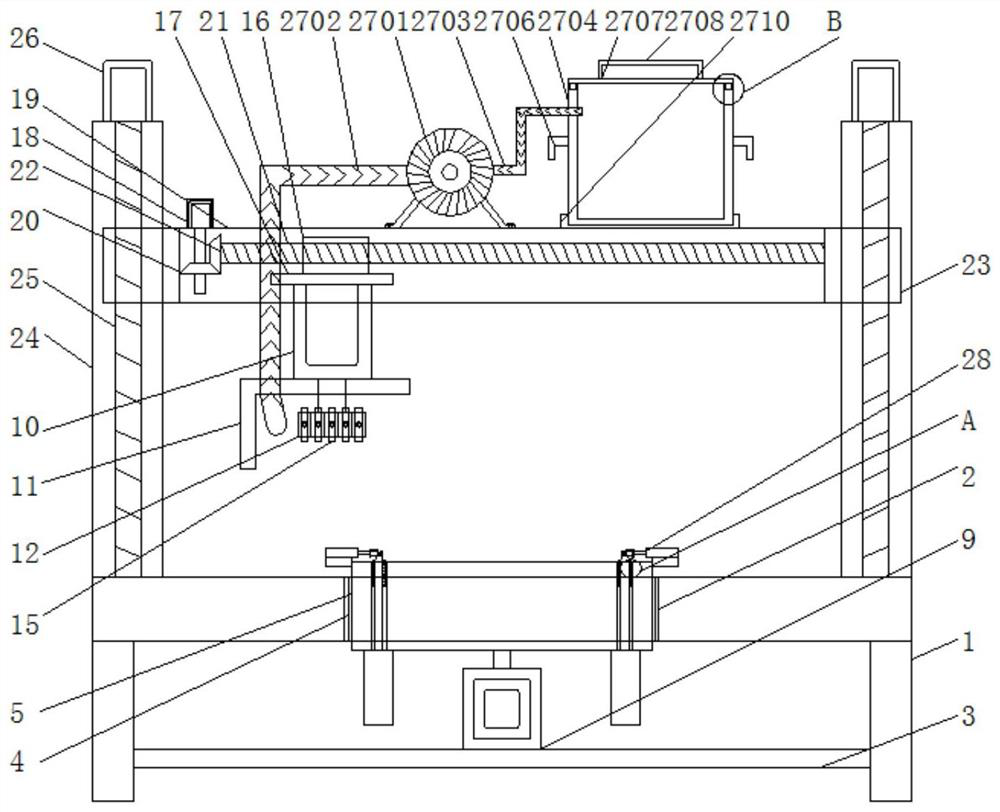

Clock hand grinding equipment

InactiveCN110524381AAutomatically realize limit operationRealize limit operationGrinding carriagesGrinding drivesEngineeringGrinding wheel

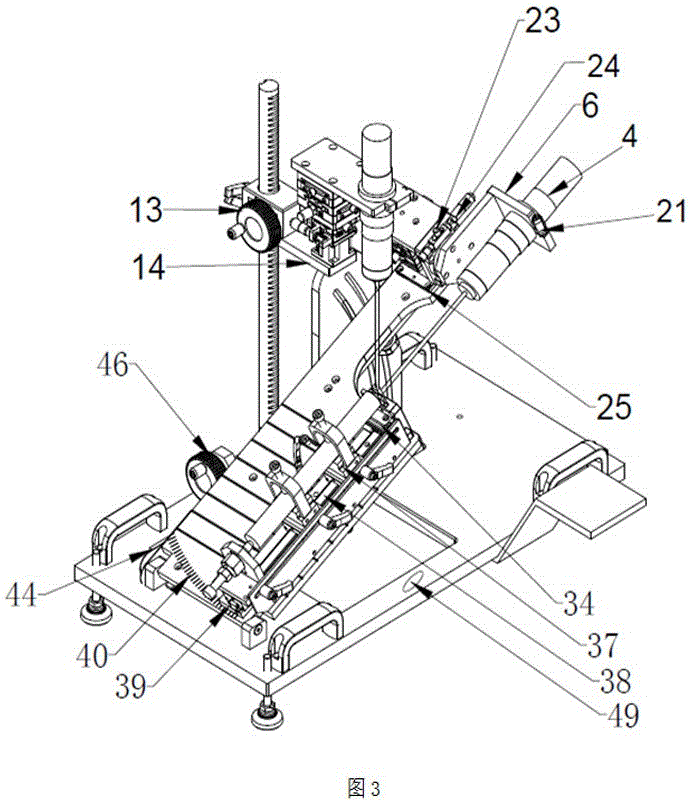

The invention discloses clock hand grinding equipment. The invention belongs to the technical field of clock processing equipment. The grinding equipment comprises a workbench, a hand fixing and rotating mechanism, a grinding machine, an angle adjusting mechanism, a scrap collecting mechanism, a transverse moving mechanism and a position adjusting mechanism. The hand fixing and rotating mechanismand the scrap collecting mechanism are both arranged at the moving end of the transverse moving mechanism. The output end of the grinding machine is sleeved with a grinding wheel, the hand fixing androtating mechanism comprises a rotating assembly, a supporting vertical plate, a limiting plate and a fixing assembly; a positioning groove is formed in the limiting plate, a rotating cylinder rotationally connected with the supporting vertical plate is arranged on the supporting vertical plate, and a mounting table is fixed to the end of the rotating cylinder. The grinding equipment has the beneficial effects that generated waste chips can be collected through the scrap collecting mechanism; dust falling operation can be conducted on generated scrap flying dusts, the angle adjusting mechanismcan enable the grinding machine to be at a proper inclination angle, and therefore the grinding wheel can conduct chamfering operation on the top face of the hand conveniently.

Owner:王伟

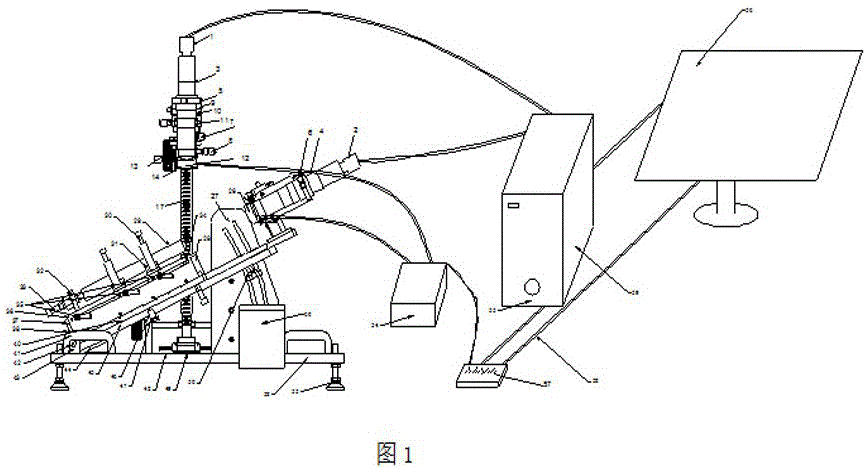

Dual-lens cutting edge image measuring chamfering machine

The invention discloses a dual-lens cutting edge image measuring chamfering machine comprising a vertical camera, a side camera, a vertical lens, a side lens, a cutting tool, and a slide block. The cutting tool is localized axially by a front positioning block assembly; and positioning and supporting are realized by a V-shaped block assembly, a rear limiting block assembly, an axial positioning screw rod, and a liftable cutter front-end support platform assembly. A positioning block of the front positioning block rotates inwardly at an angle of 90 degrees in a pedestal. A guide rail pedestal rotates at an angle from 0 to 90 degrees in a high-precision arc groove of an inclined plate by using a focal point overlapped point of the vertical lens and the side lens as a rotating axis; and the arc groove uses a cutting cuspidal point localized by the front positioning assembly as a center of circle. A special positioning mechanism is used for positioning at an angle of 0 degree and an angle of 90 degrees; and at any position by rotation, a guide rail pedestal quick-tightening wrench assembly arranged at the lower side of the inclined plate is used for realizing tight locking. With the vertical lens, accurate alignment is realized; and a horizontal lens is used for magnifying the cutting tool to realize cutting tool chamfering, wherein the cutting tool can be magnified by 800 times maximally.

Owner:上海旌锐精密机械有限公司

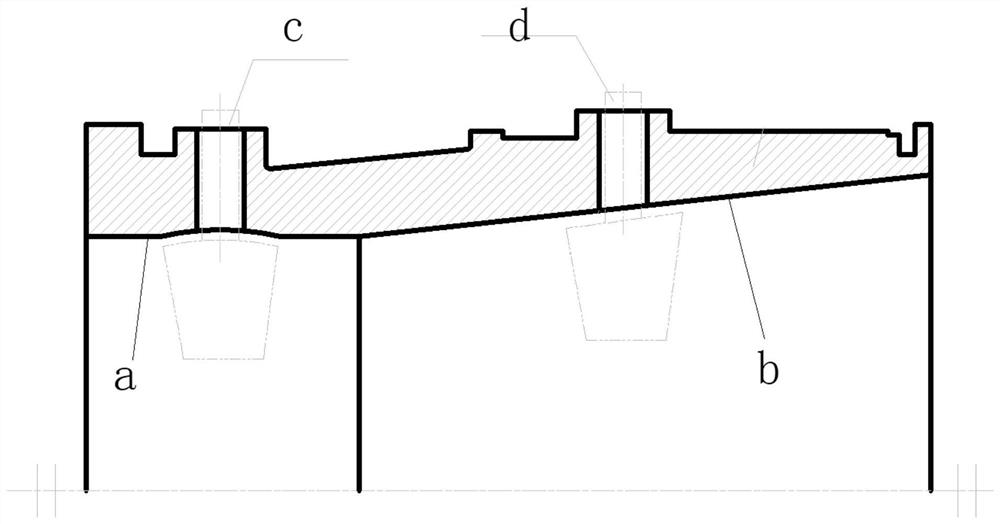

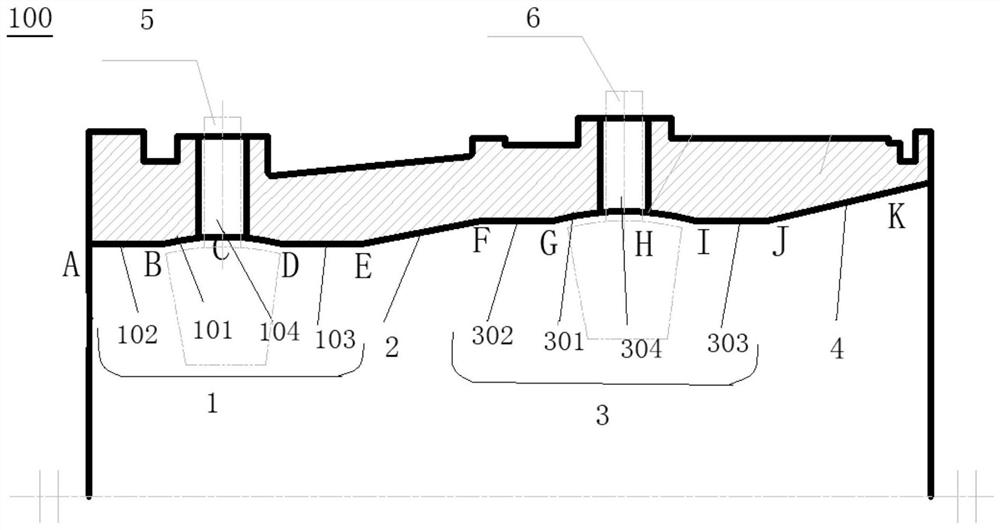

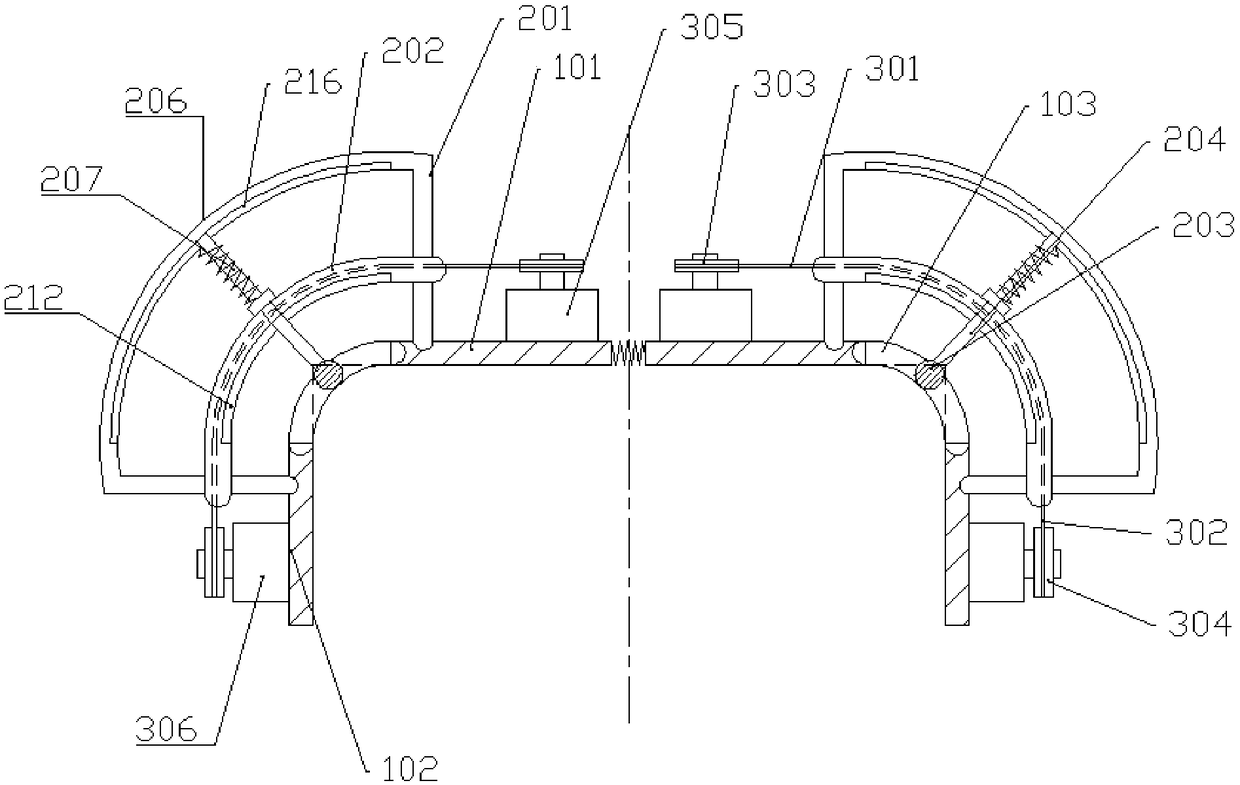

Multi-section TRT stationary blade inner shell

PendingCN112049691ASolve the problem of excessive radial clearanceEasy chamferingStatorsMachines/enginesEngineeringMechanical engineering

The invention relates to a multi-section TRT stationary blade inner shell. The multi-section TRT stationary blade inner shell comprises a first-stage air inlet section, a first-stage expanding section, a second-stage air inlet section and a second-stage expanding section which are coaxially arranged and sequentially connected. A first arc section capable of being matched with the spherical surfaceof a first-stage stationary blade is arranged in the circumferential direction of the first-stage air inlet section. A second arc section capable of being matched with the spherical surface of z second-stage stationary blade is arranged in the circumferential direction of the second-stage air inlet section. The stationary blade inner shell adopts a multi-section structural design, so that each stage of stationary blade of the TRT has an expansion angle matched with the stationary blade. The first arc section of the first-stage air inlet section is matched with the spherical surface of the first-stage stationary blade, and the second arc section of the second-stage air inlet section is matched with the spherical surface of the second-stage stationary blade, so that on one hand, the problemthat a radial gap between a TRT stationary blade body and an inner shell is too large is solved, the overall efficiency is improved, and on the other hand, chamfering machining of stationary blade mounting holes is facilitated, and machining efficiency is effectively improved.

Owner:CHENGDU CHENGFA SCI & TECH POWER ENG

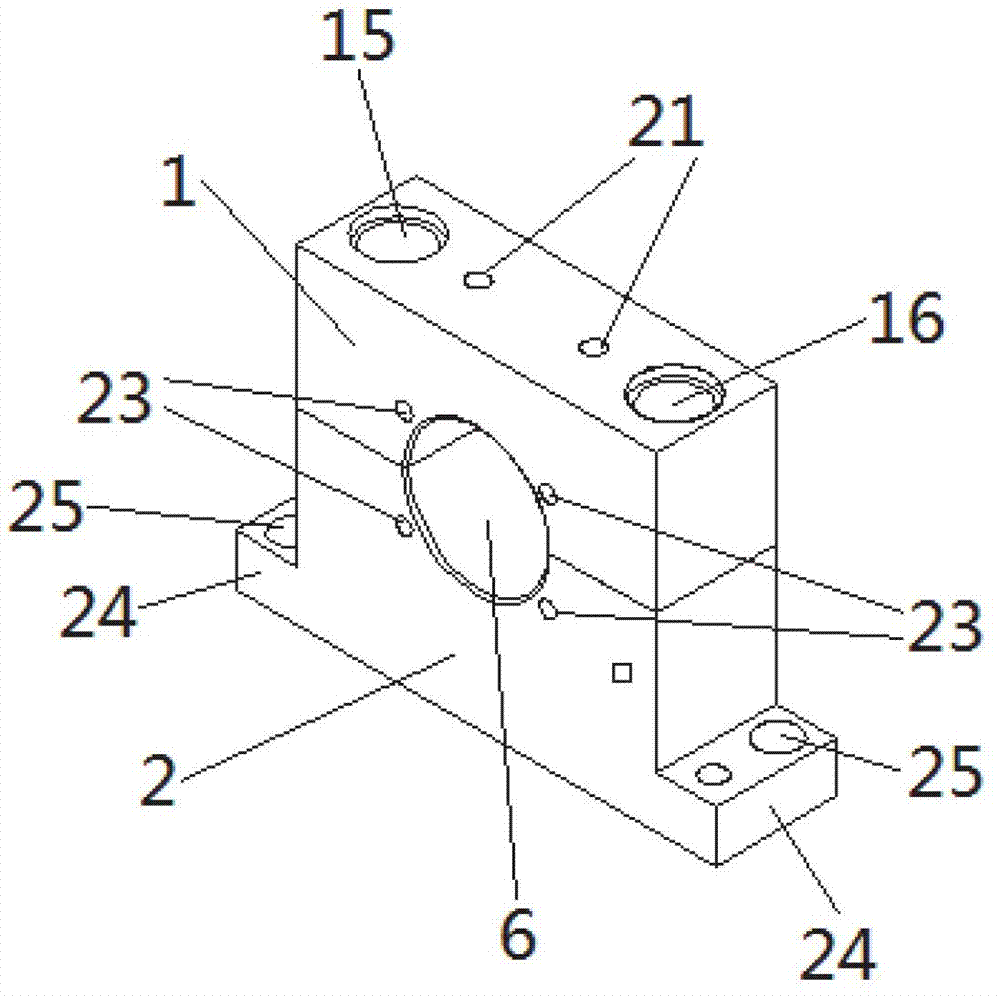

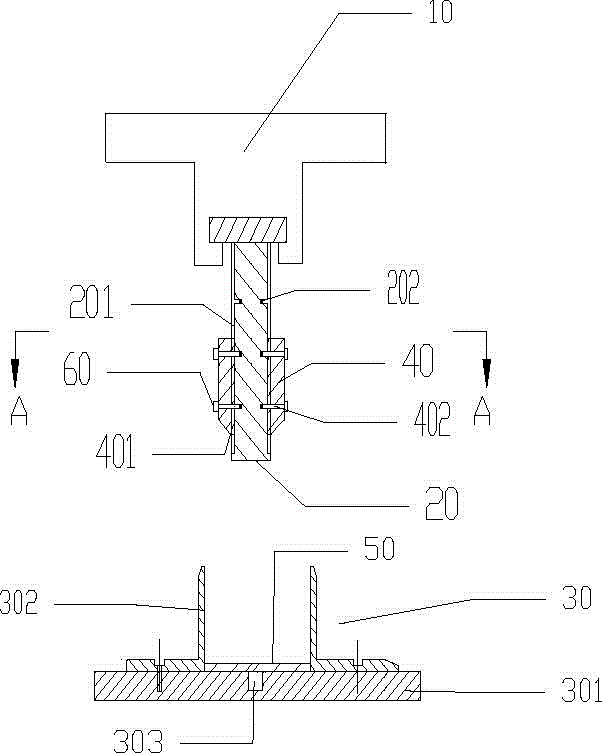

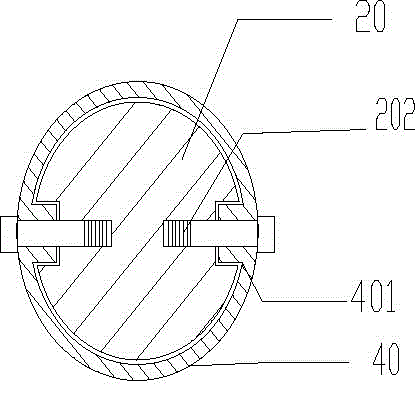

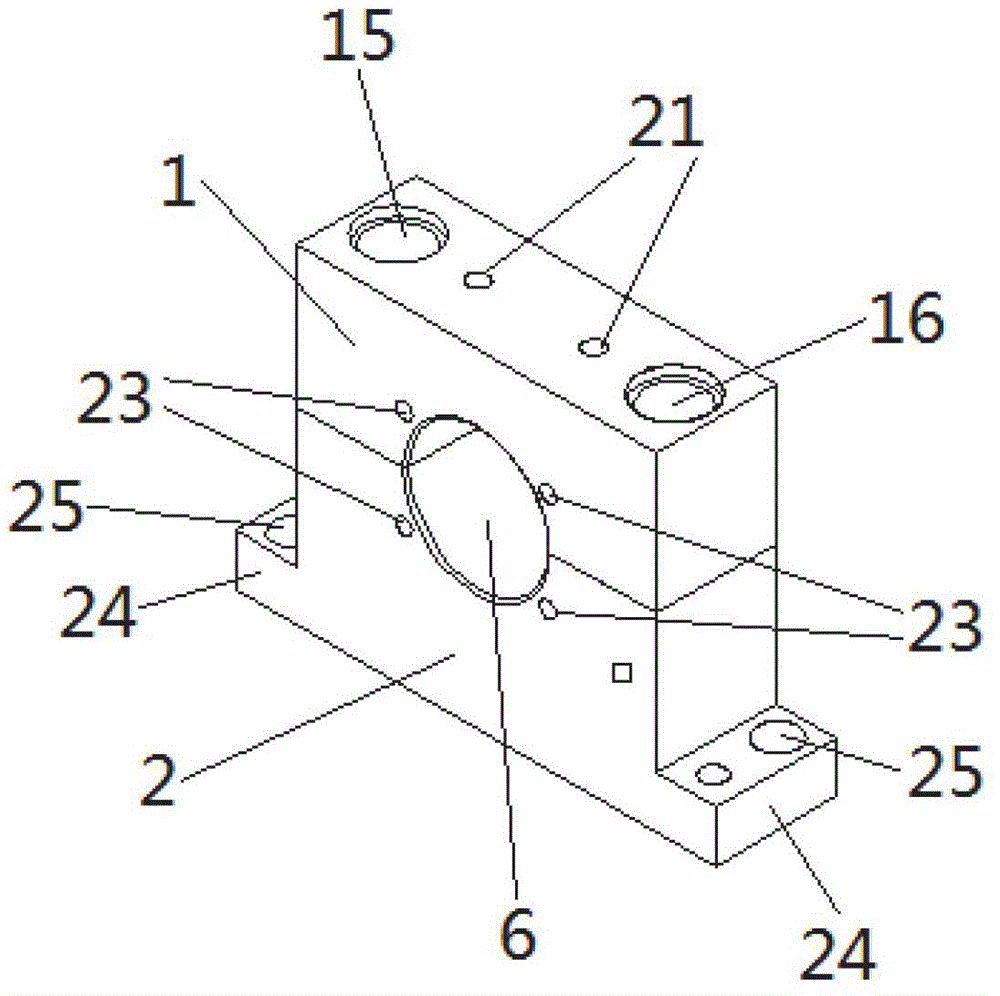

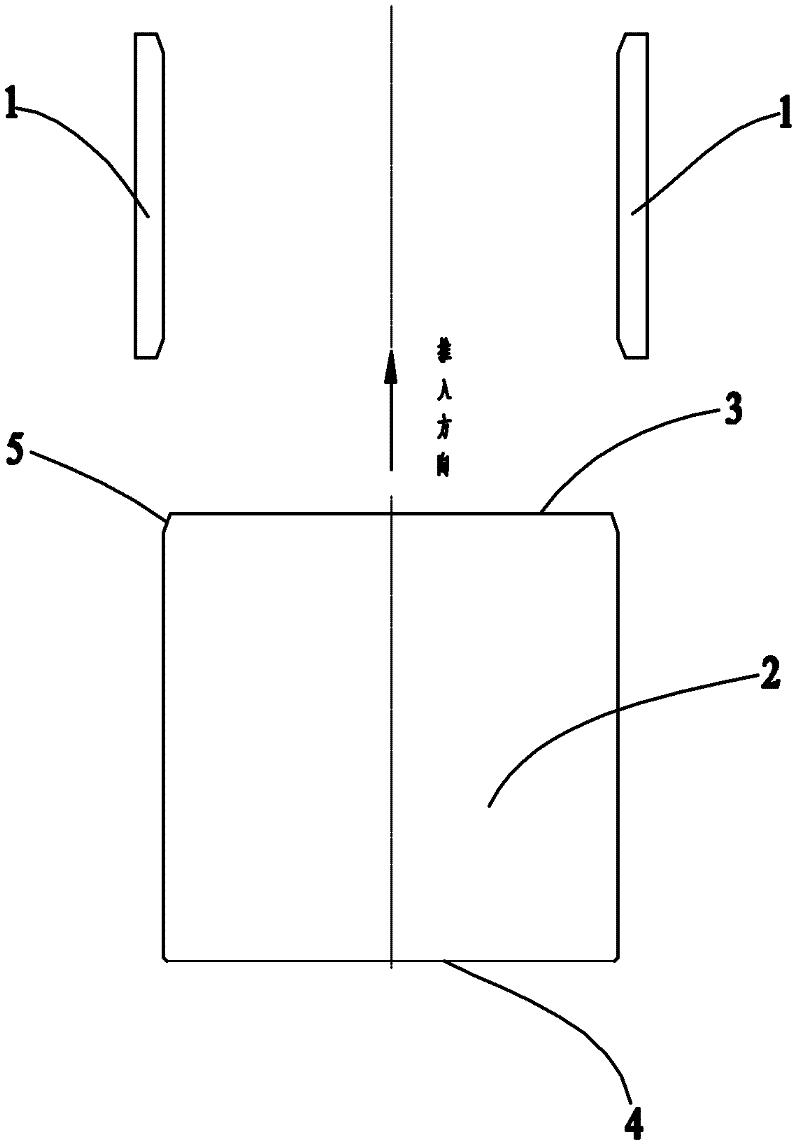

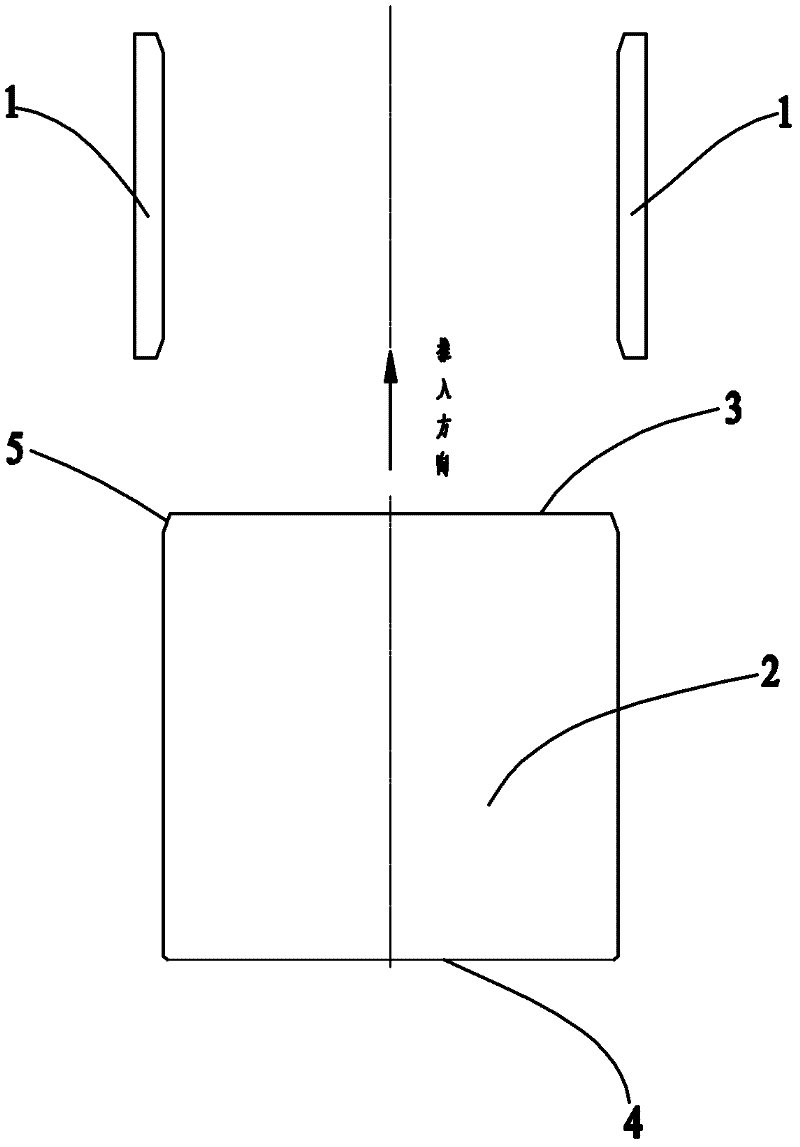

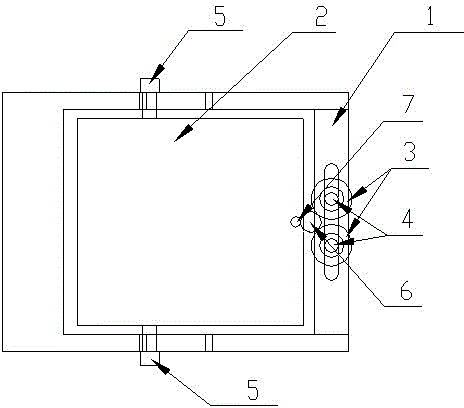

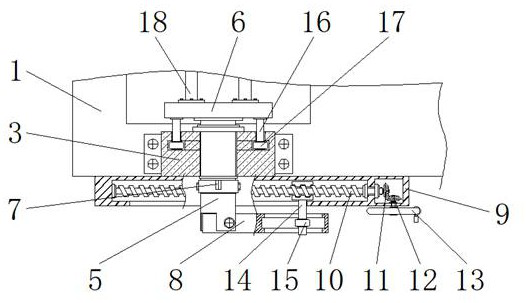

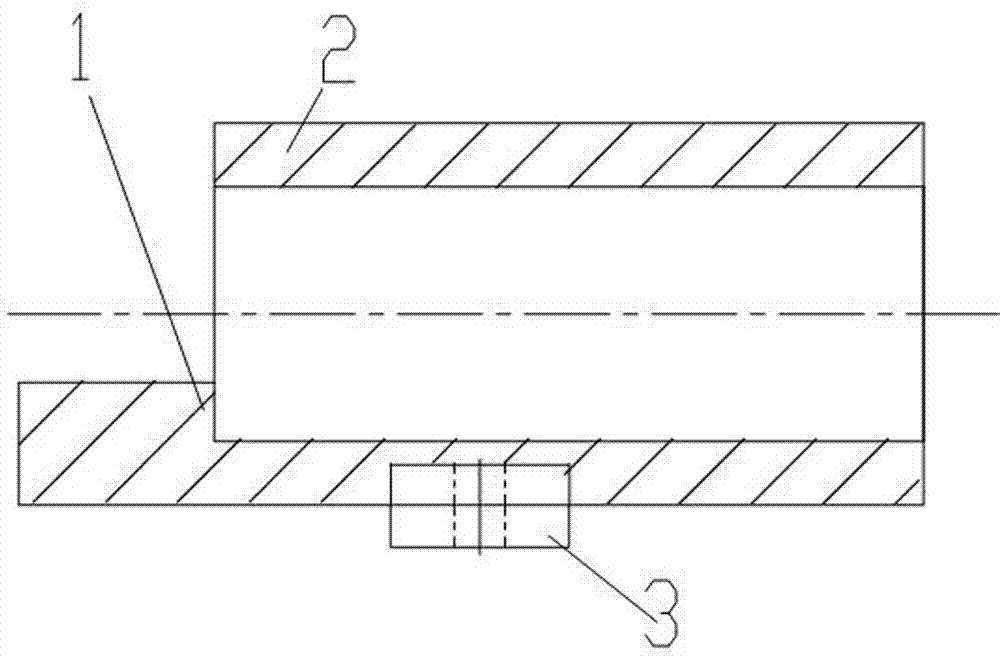

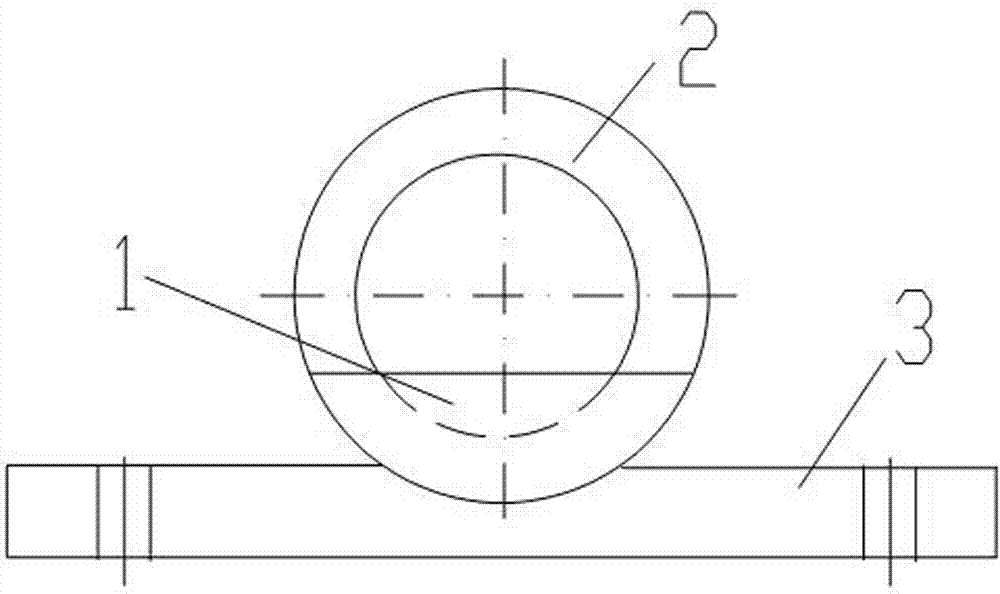

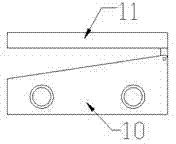

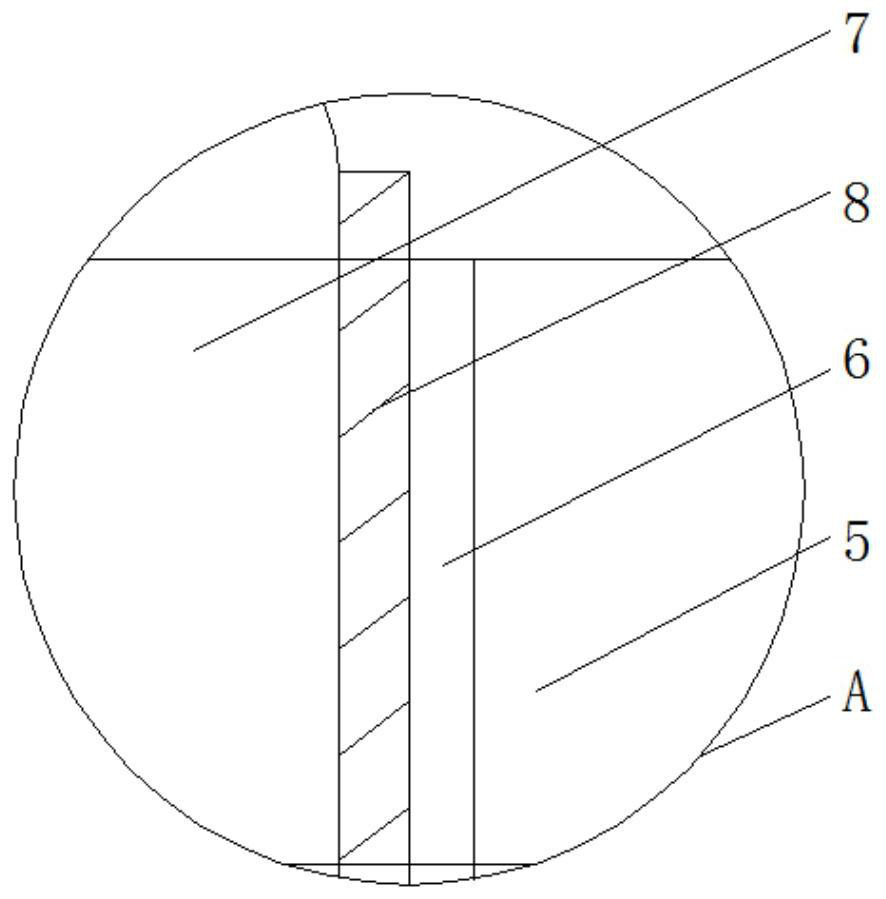

Fixture for chamfering ends of steel pipes

InactiveCN102806478AEasy chamferingSimple structurePositioning apparatusMetal-working holdersEngineeringMachining

The invention provides a fixture for chamfering ends of steel pipes, and is applied to the technical field of machining of steel pipes. A concave portion I (4) of an upper die holder (1) and a concave portion II (5) on a lower die holder (2) of the fixture for chamfering the ends of the steel pipes form a die hole (6), an upper body (7) and a lower body (8) of a clamp die (3) are respectively connected with the upper die holder (1) and the lower die holder (2), an upper pipe diameter portion (9) of the upper body (7) and a lower pipe diameter portion (10) of the lower body (8) are fastened to form a cylindrical pipe diameter portion (11), and the pipe diameter portion (11) penetrates through the die hole (6) and is of a structure capable of accommodating a steel pipe (12) in a sleeved manner. The fixture can clamp the steel pipes, so that the ends of the steel pipes can be chamfered conveniently. In addition, the fixture is simple in structure, and only clamp dies comprising pipe diameter portions with different sizes need to be changed before the steel pipes with different pipe diameters are machined.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

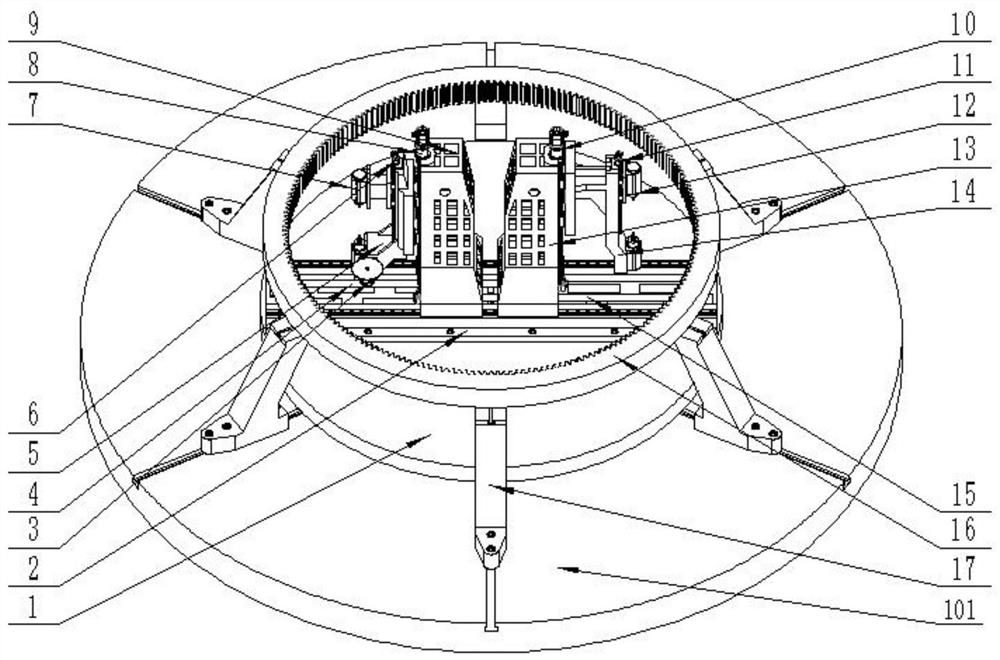

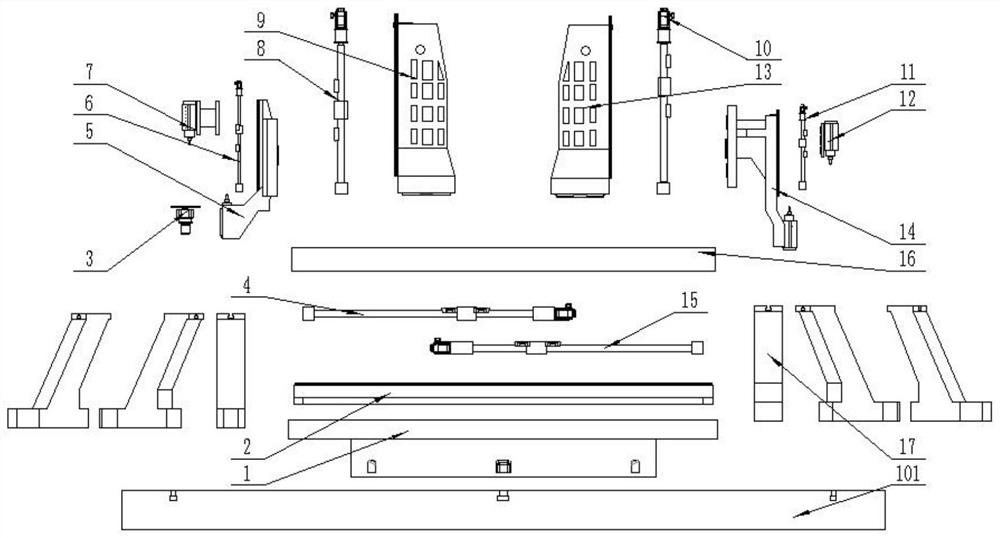

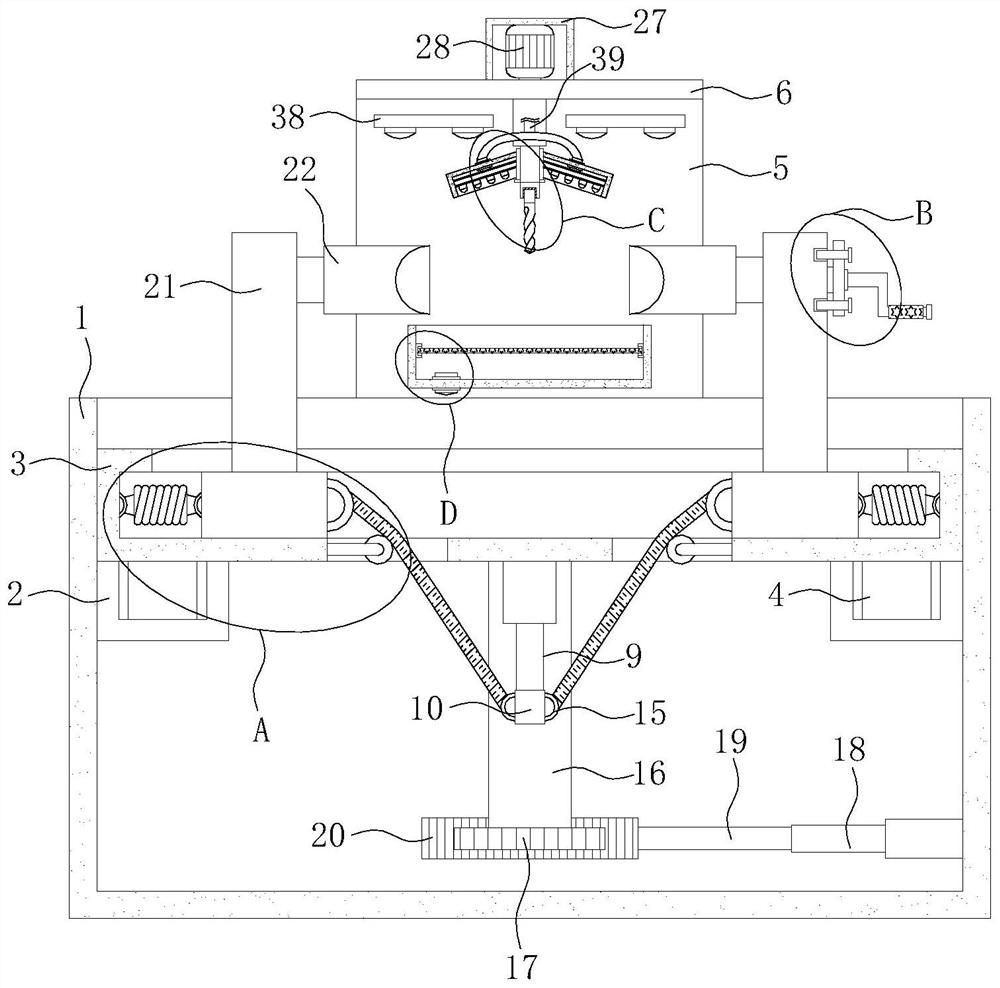

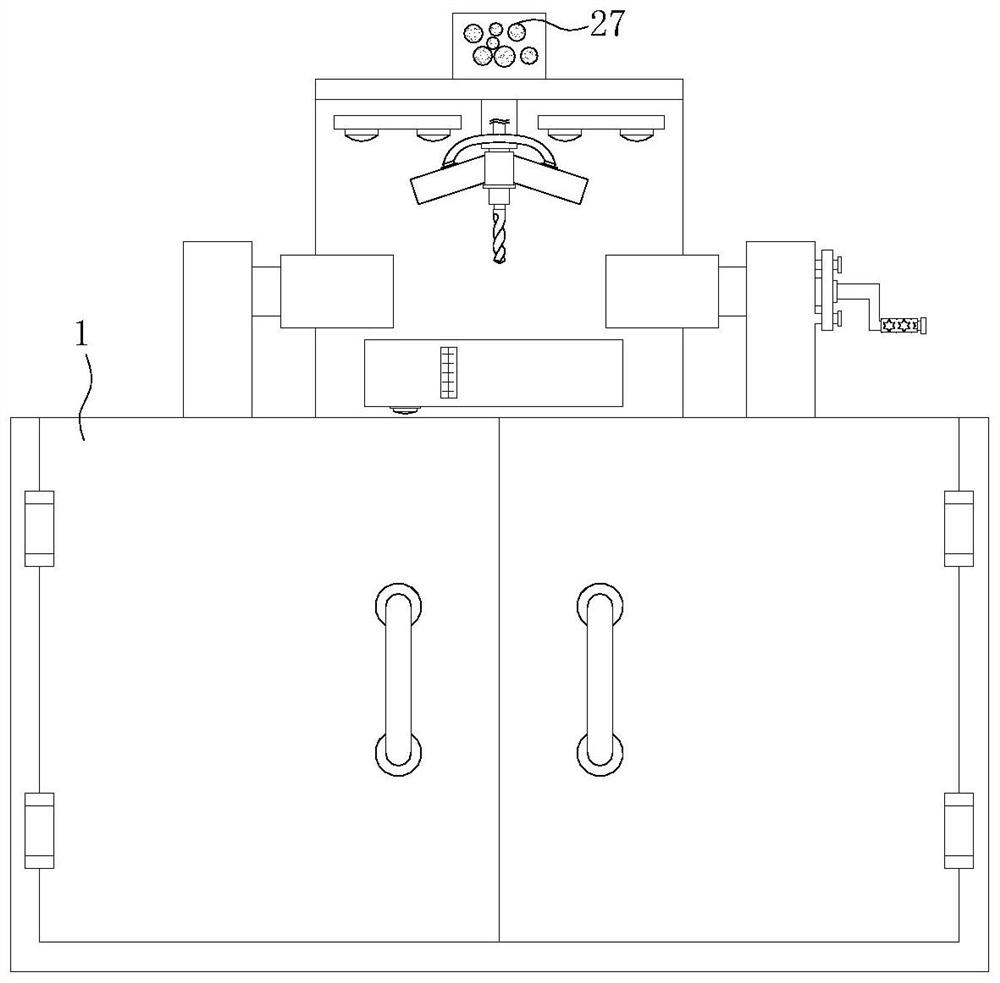

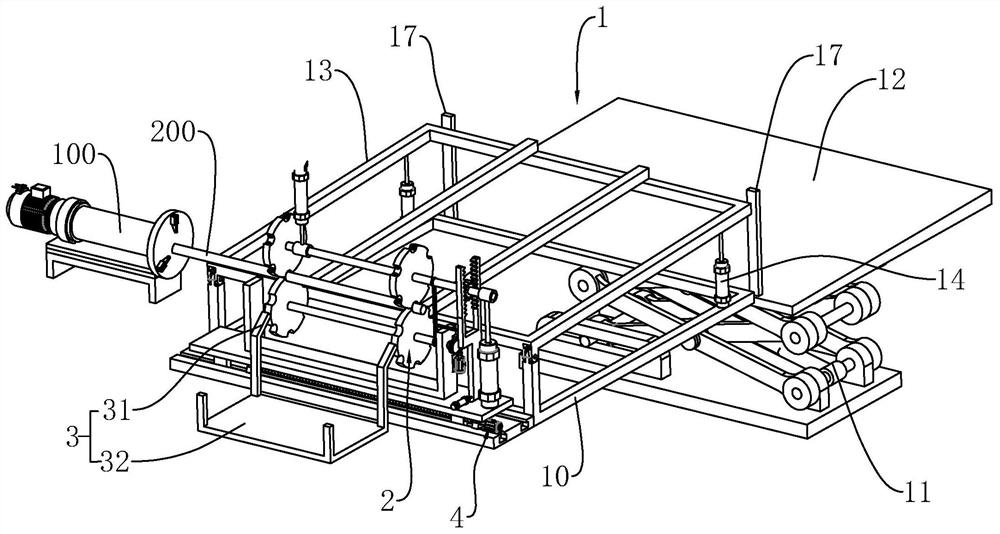

Double-end-face numerical control chamfering machine tool and method for ultra-large internal tooth gear

PendingCN112404606ASmall footprintSolve the problem that workers can only use manual chamferingGear-cutting machinesGear teethNumerical controlMilling cutter

The invention discloses a double-end-face numerical control chamfering machine tool and method for an ultra-large internal tooth gear. The machine tool comprises a numerical control rotary table, a horizontal radial sliding table, a first stand column, a second stand column, a Y1 tool rest assembly, a Y2 tool assembly, a Y3 tool rest assembly, a Y4 tool assembly, an X1-axis radial feeding system,an X2-axis radial feeding system, a Y1-axis vertical feeding system, a Y2-axis vertical feeding system, a Y3-axis vertical feeding system, a Y4-axis vertical feeding system, a steel brush deburring system and workpiece supports. According to the double-end-face numerical control chamfering machine tool, the motion mode that a workpiece is fixed and the machine tool does rotary motion is adopted, the occupied area of the numerical control machine tool for chamfering an ultra-large gear is greatly reduced, simultaneous chamfering of the end faces of the two sides of the ultra-large internal tooth gear is achieved through a hard alloy milling tool rotating at a high speed, chamfers are adjustable in size and shape, the sizes of the chamfers are consistent, tooth grooves are automatically centered, and deburring and polishing work can be carried out on tooth roots, tooth tops and other parts. The machine tool is innovative in structure, low in manufacturing cost and high in automation degree.

Owner:NANJING UNIV OF TECH +1

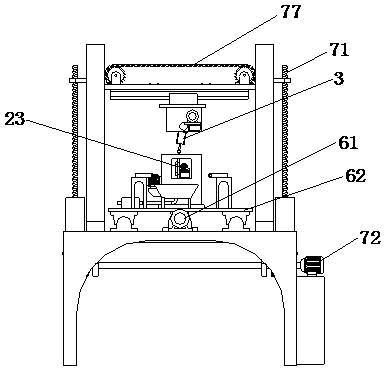

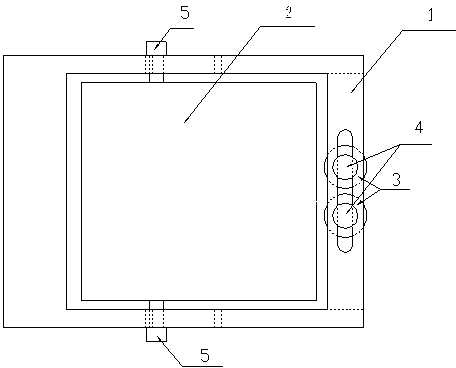

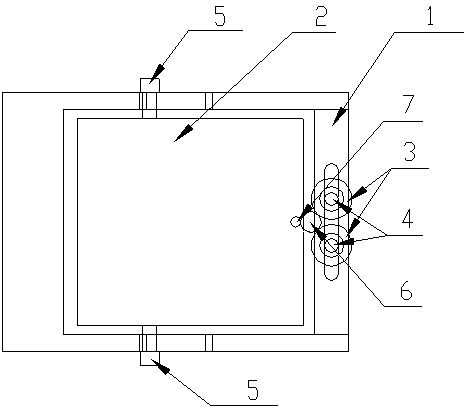

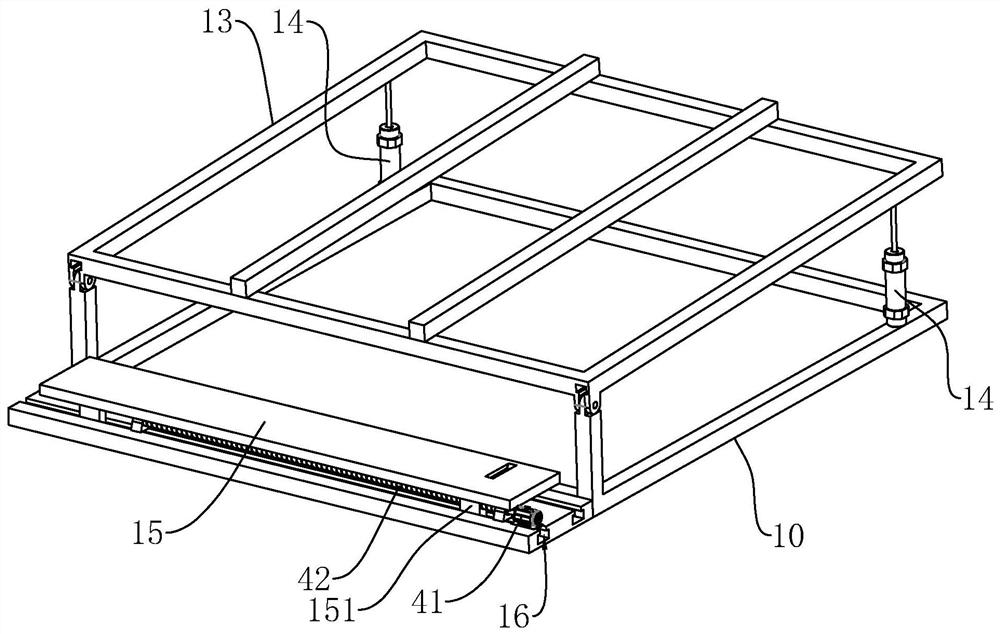

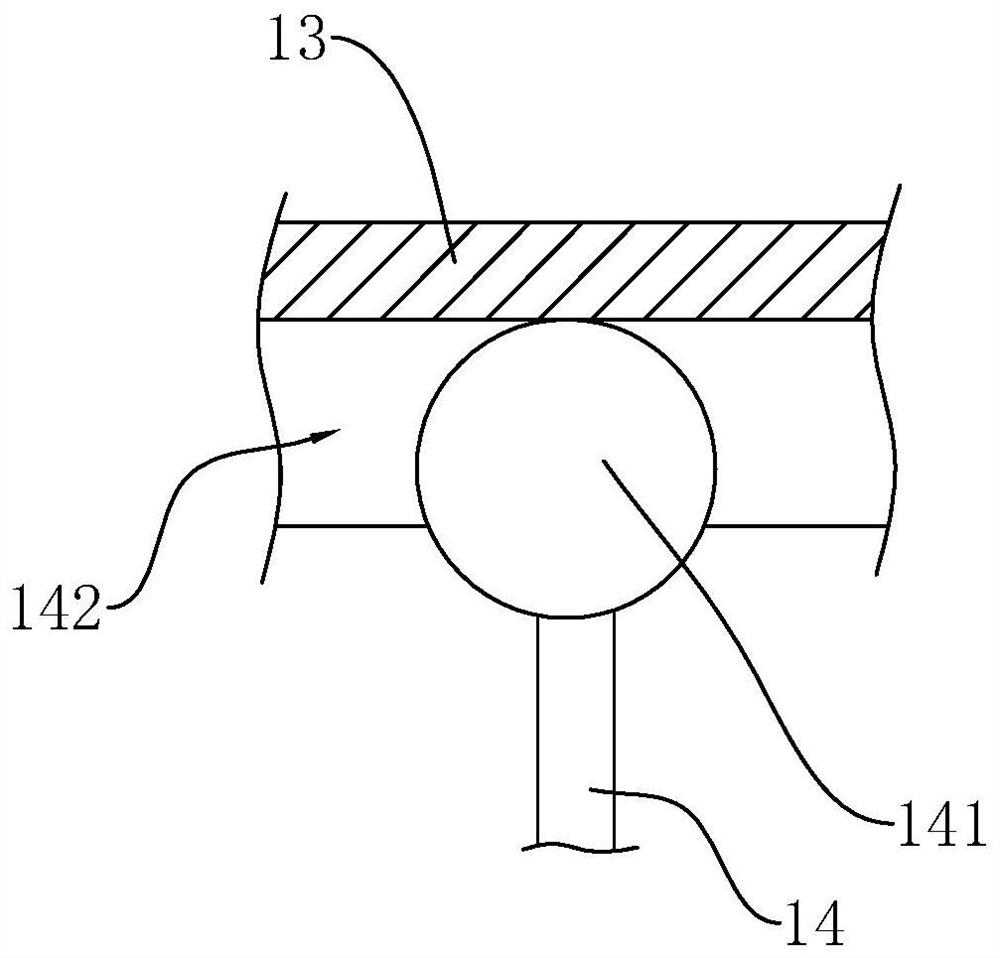

Automatic chamfering device for photovoltaic glass

InactiveCN113635174AEasy chamferingEasy to achieve chamfer grindingEdge grinding machinesGrinding drivesDust controlElectric machinery

The invention discloses an automatic chamfering device for photovoltaic glass. The automatic chamfering device comprises a base, supporting rods are fixedly connected to the four corners of the top of the base, a longitudinal adjusting assembly is arranged at the top ends of the supporting rods, a transverse adjusting assembly is connected to the top of the longitudinal adjusting assembly, an electric telescopic rod is connected to the bottom of the transverse adjusting assembly, a mounting plate is connected to the bottom end of the electric telescopic rod, a grinding motor is arranged at the bottom of the mounting plate, a grinding wheel is connected to the output end of the grinding motor, a clamping and fixing assembly is arranged on the top of the base, and a dust removal assembly is arranged on the rear side of the top of the base; and the longitudinal position of the grinding wheel can be adjusted through the longitudinal adjusting assembly, the transverse position of the grinding wheel can be adjusted through the transverse adjusting assembly, chamfering grinding of different positions of photovoltaic glass is conveniently achieved, the glass is fixed through the clamping and fixing assembly, the grinding wheel is driven to rotate through the grinding motor, chamfering of the photovoltaic glass is achieved, and dust generated during glass chamfering is treated through the dust removal assembly.

Owner:赫冉新能源科技扬州有限公司

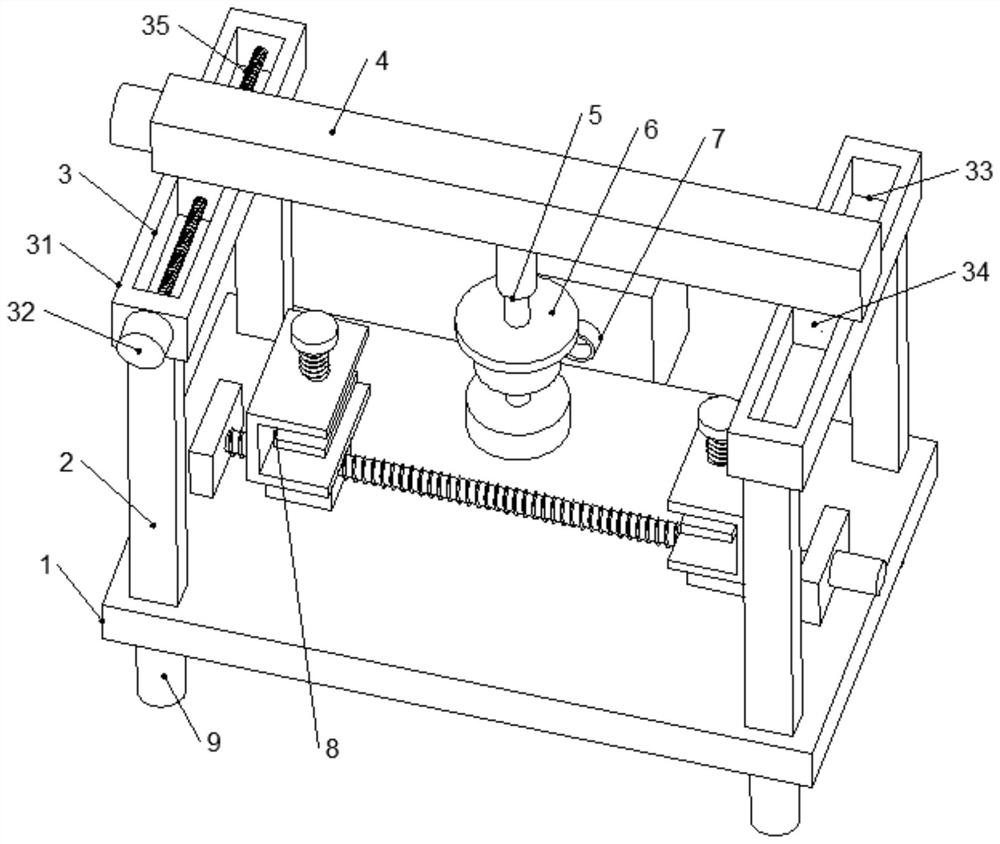

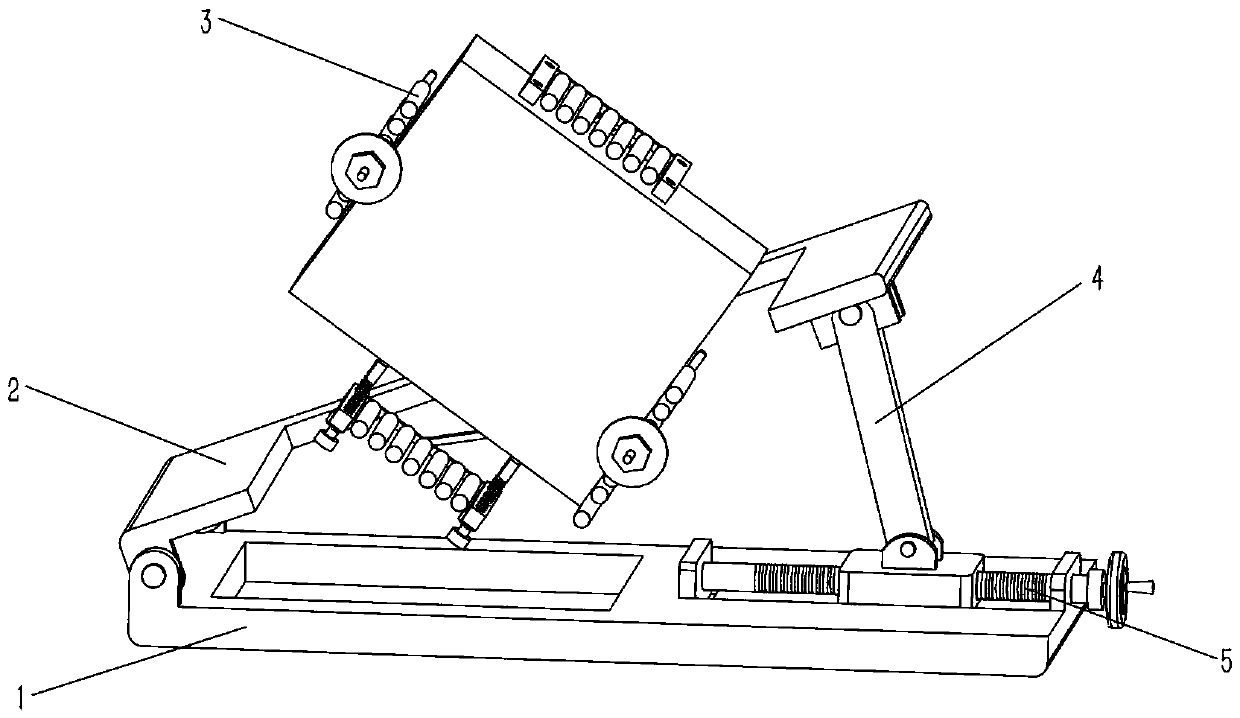

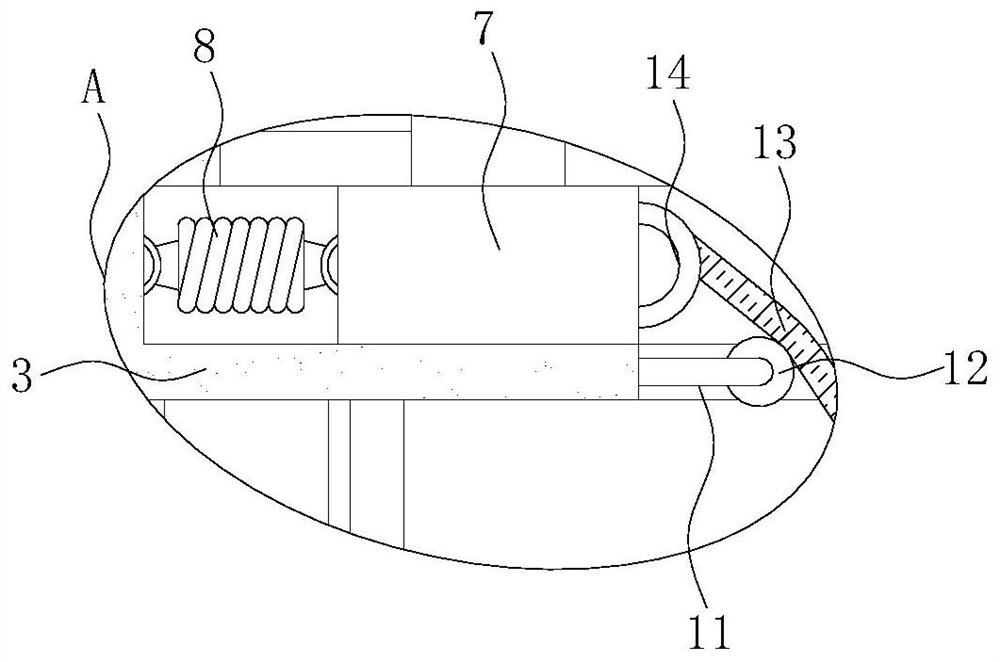

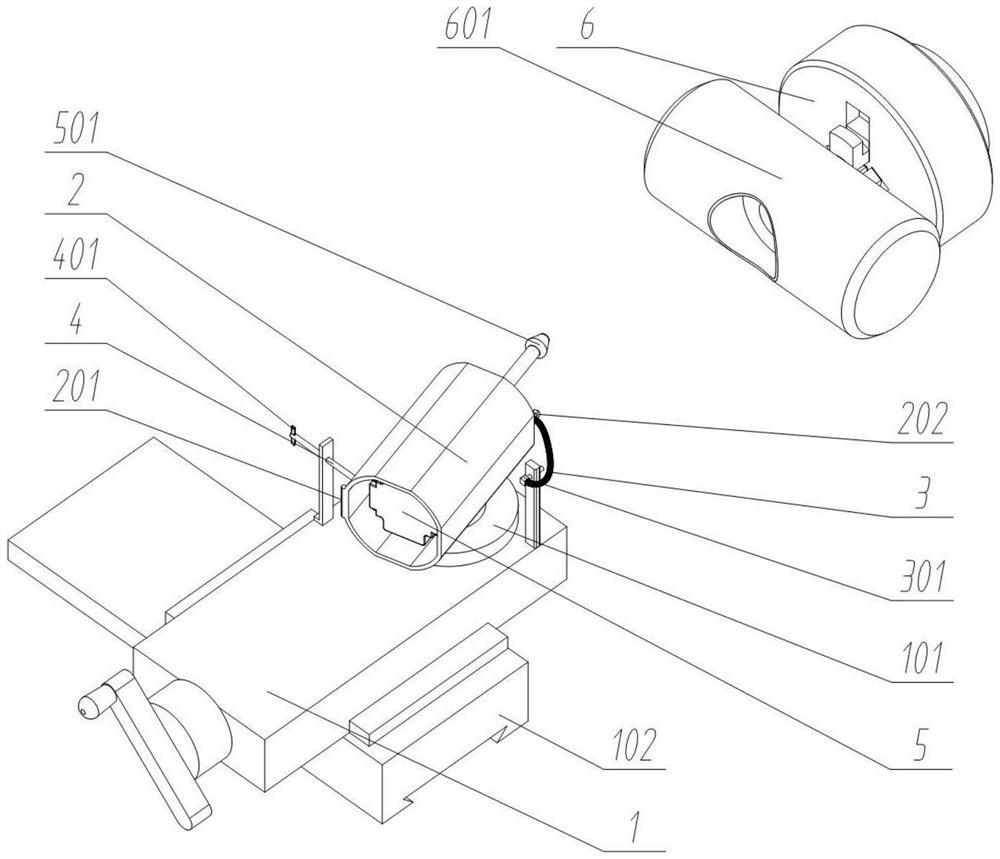

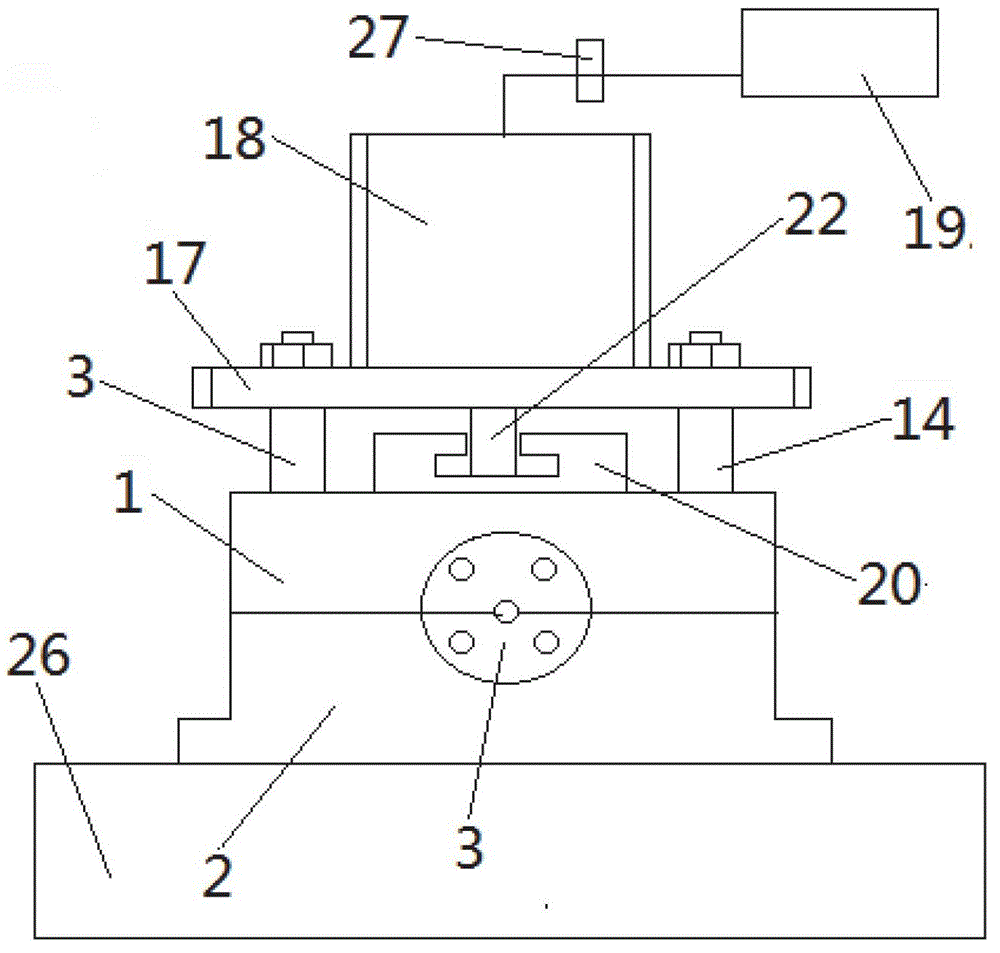

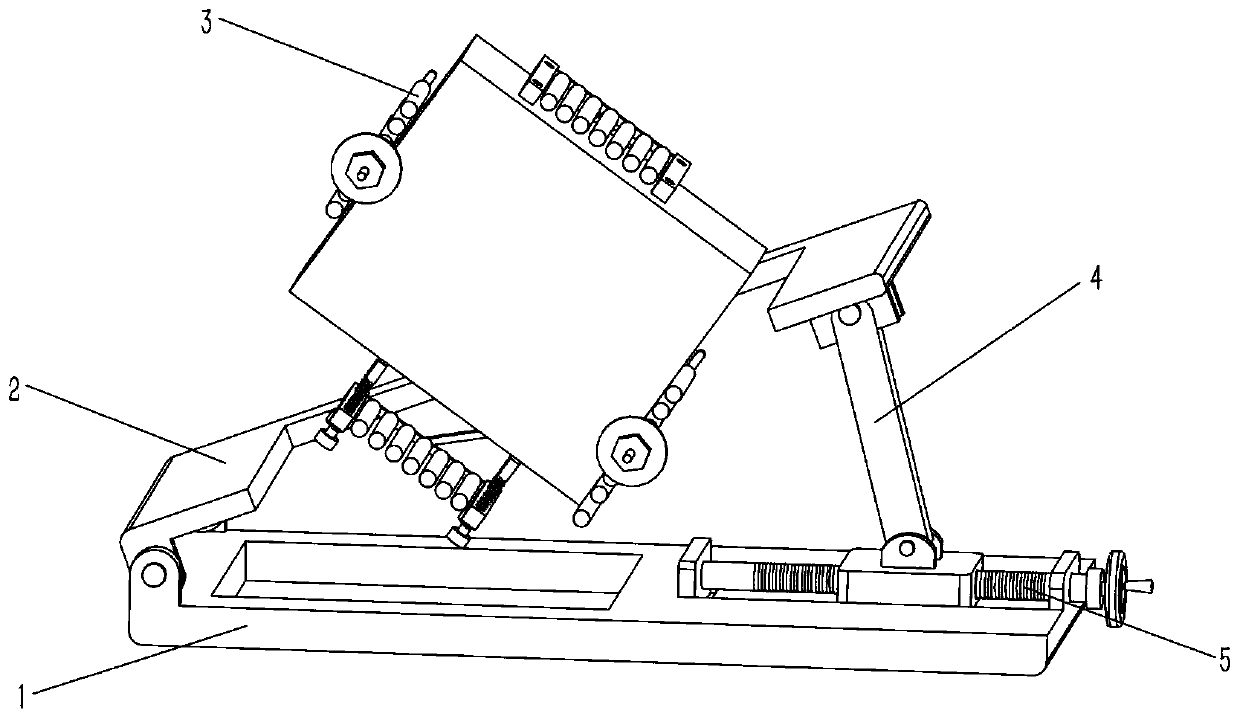

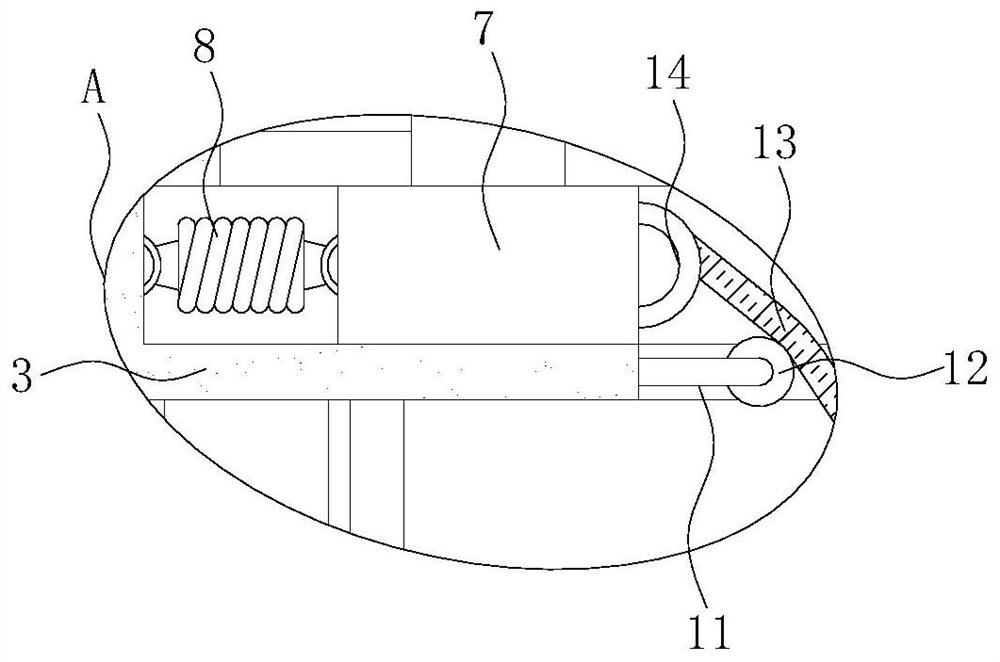

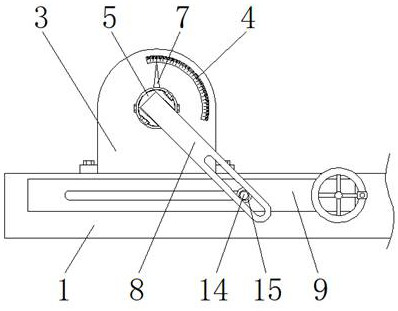

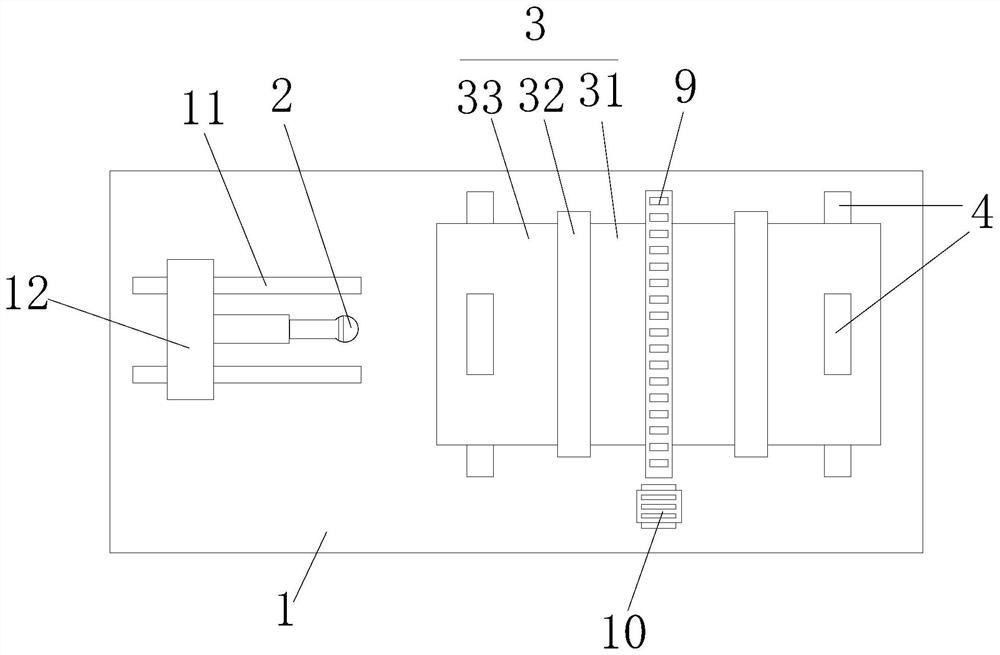

Chamfering tool for grooving machine frame sliding block

ActiveCN111152089AConvenient and stable positioningEasy chamferingEdge grinding machinesGrinding carriagesStructural engineeringMachine

The invention discloses a chamfering tool for a grooving machine frame sliding block. The tool comprises a bottom plate, a positioning plate is hinged to one end of the bottom plate, a supporting rodis hinged to the bottom of the end, away from the bottom plate, of the positioning plate, an angle adjusting mechanism is connected to the bottom of the supporting rod, a supporting plate is fixed toone side of the top of the positioning plate, a rotating shaft is rotationally connected to the center of the supporting plate, the two ends of the rotating shaft penetrate through the two sides of the supporting plate correspondingly, and a center positioning device and a rotating mechanism are fixed to the two ends of the rotating shaft; and the center positioning device comprises a U-shaped base, the rotating shaft is fixed to the center of the U-shaped base, a first sliding rail is fixed to the U-shaped base, a first adjusting screw rod is rotationally connected to the inner walls of the upper side and the lower side of the U-shaped base, and one end of the first adjusting screw rod penetrate through the outer wall of the U-shaped base to be provided with an adjusting knob. The tool has the characteristics that positioning is convenient, chamferings of the corner angles of the sliding block can be conveniently controlled be to be the same, and the machining angle can be conveniently adjusted.

Owner:JIANGSU HAIRUI CNC MACHINE TOOL CO LTD

Marble corner processing device

ActiveCN108177043AGuaranteed accuracyImprove eligibilityEdge grinding machinesGrinding work supportsEngineering

The invention relates to the field of stone processing, and particularly discloses a marble corner processing device. The marble corner processing device is provided with a limiting mechanism and a chamfering mechanism, a first limiting plate and a second limiting plate in the limiting mechanism can limit marble, a part, to be chamfered, of the marble can be conveniently located at the position ofthe chamfering mechanism, chamfering on the part to be chamfered is facilitated, and polishing balls can conduct quick and stable chamfering on the part to be chamfered in the chamfering process; andthe polished marble can be detected through an arc-shaped strip, and the chamfering accuracy of the marble can be detected conveniently.

Owner:苏州市振渭城镇建设发展有限公司

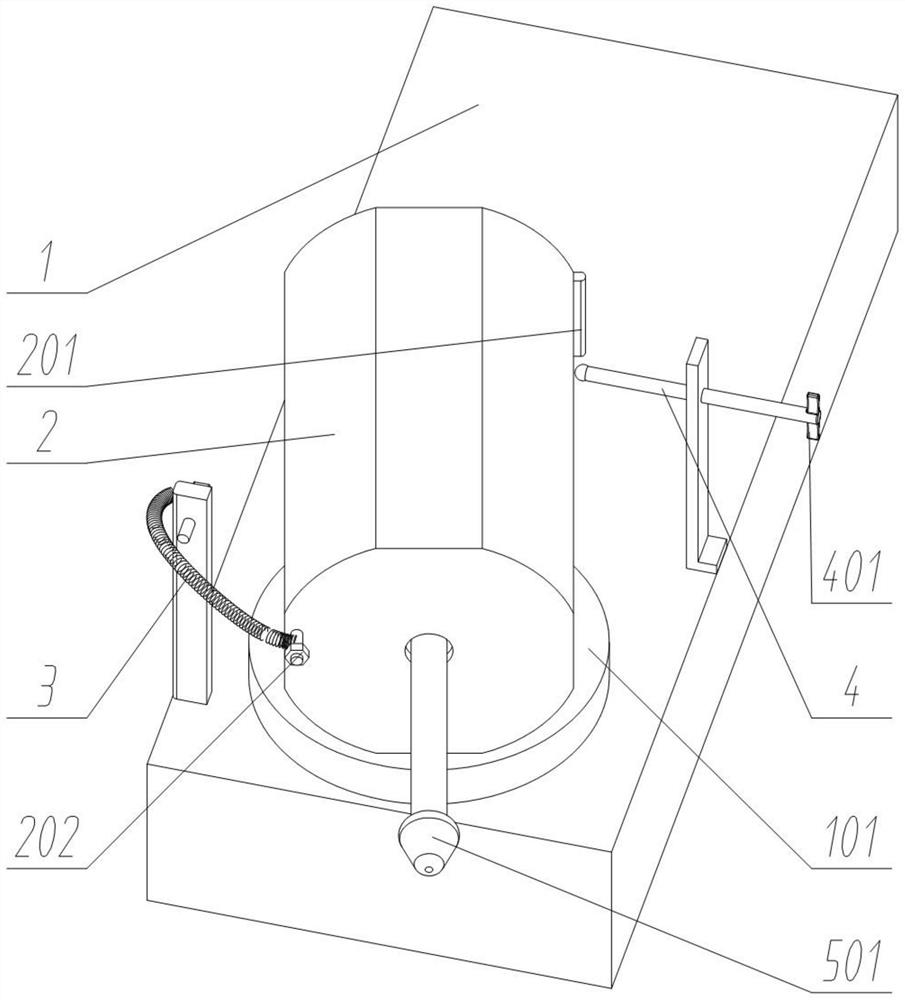

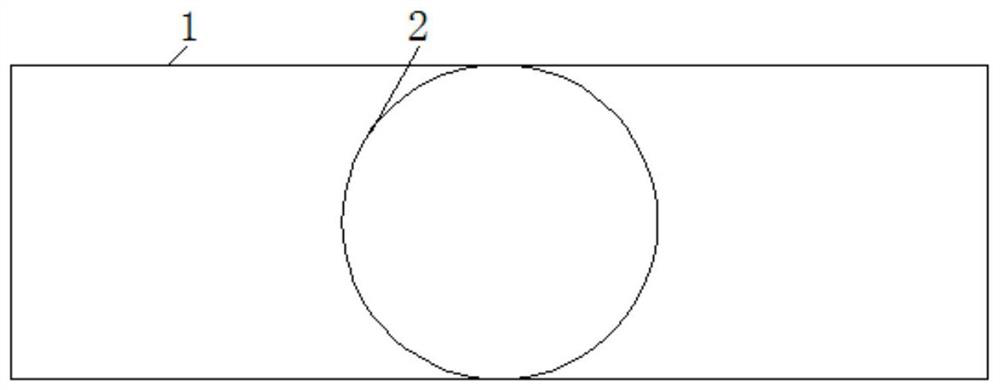

Fixing device for motor end cover machining

ActiveCN112091679AAvoid troubleEasy to drillMetal working apparatusPositioning apparatusStructural engineeringMachining

The invention discloses a fixing device for motor end cover machining, and relates to the technical field of motor machining. The fixing device for motor end cover machining comprises a mounting box,wherein an annular plate is welded and mounted in the mounting box; a mounting plate is arranged at the top of the annular plate; an annular sliding groove is formed in the annular plate; an annular sliding block is slidably mounted in the annular sliding groove; the bottom of the mounting plate and the top of the annular sliding block are fixedly mounted; the mounting plate and the annular sliding block are slidably mounted; and a fixing plate is welded to the top of the mounting box. According to the fixing device for motor end cover machining provided by the invention, a motor end cover canbe clamped and fixed, so that the next tapping operation is facilitated; and the motor end cover can still rotate after being fixed, so that the situation that the position needs to be repeatedly clamped and adjusted during transposition tapping is avoided, the problem that the machining efficiency is affected due to repeated clamping is avoided, on the other hand, troubles brought to an operatordue to repeated clamping are avoided, and the practicability and the convenience of the device are effectively enhanced.

Owner:浙江德易精密机械有限公司

Angle iron punching machine added with chamfering function

InactiveCN104550443AGuaranteed normal vertical operationImprove rigidityShaping toolsPerforating toolsPunchingEngineering

The invention relates to an angle iron punching machine, in particular to an angle iron punching machine added with a chamfering function. The angle iron punching machine comprises a punching power device, a punching head and a base, wherein the base is located below the punching head; the punching head is located below the punching power device; the punching power device drives the movement direction of the punching head to be vertical to the base; the angle iron punching machine is characterized in that the outer wall of the punching head is sleeved by a chambering head; the inner wall of the chambering head is in attached contact with the outer wall of the punching head; the center lines of the chambering head and the punching head are located on the same axis. The invention provides a chamfering machine capable of simultaneously punching and chambering to overcome the problem that an existing angle iron punching machine does not have the chambering function, so that the processing efficiency is improved; the processing cost is reduced; the occupied space is reduced.

Owner:CHONGQING XINZHUOHUI AUTOMOBILE PURIFIER

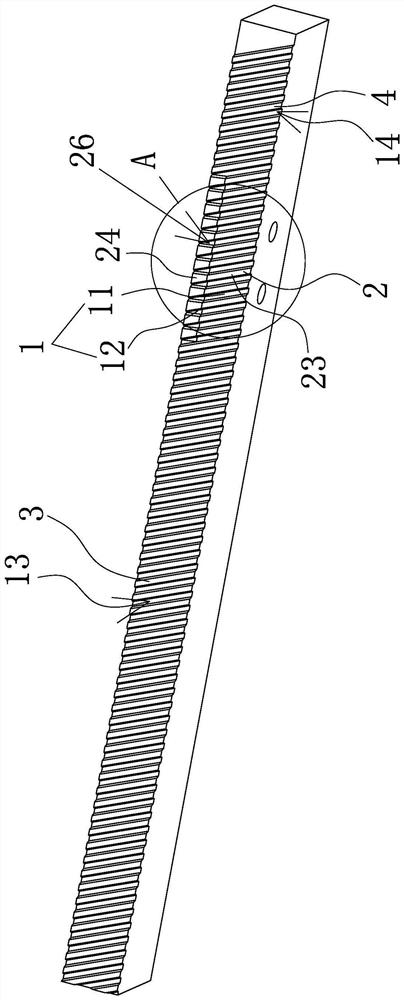

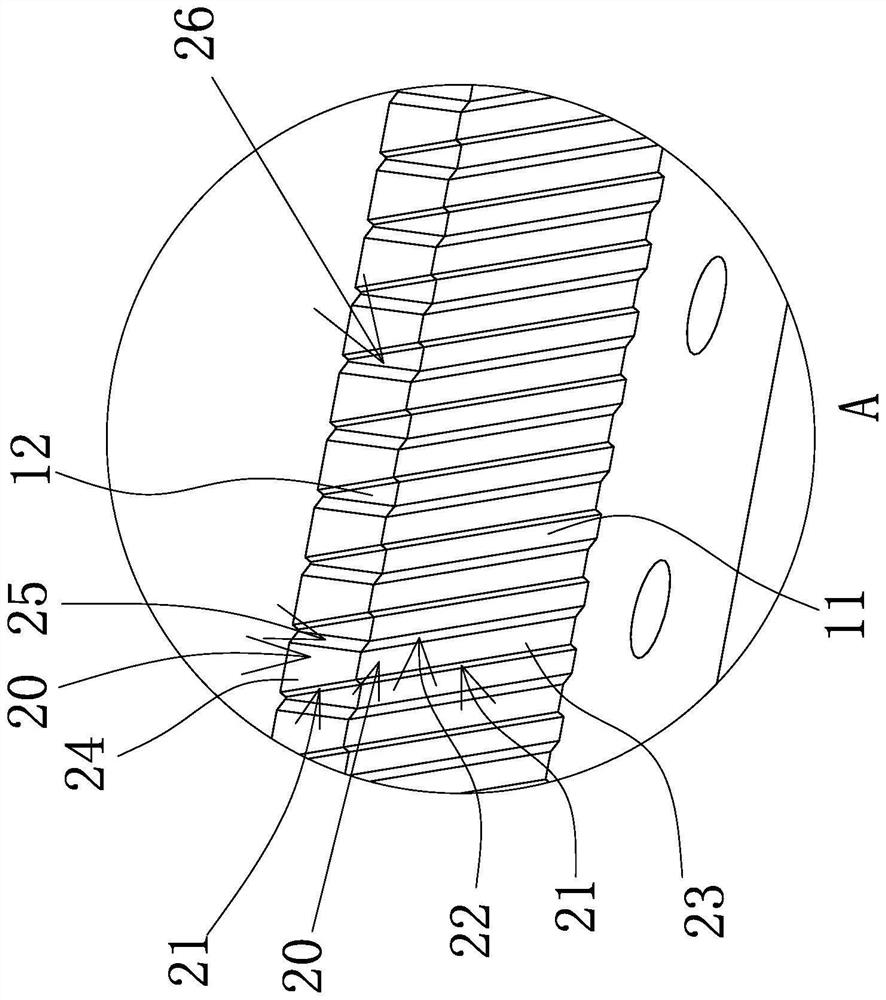

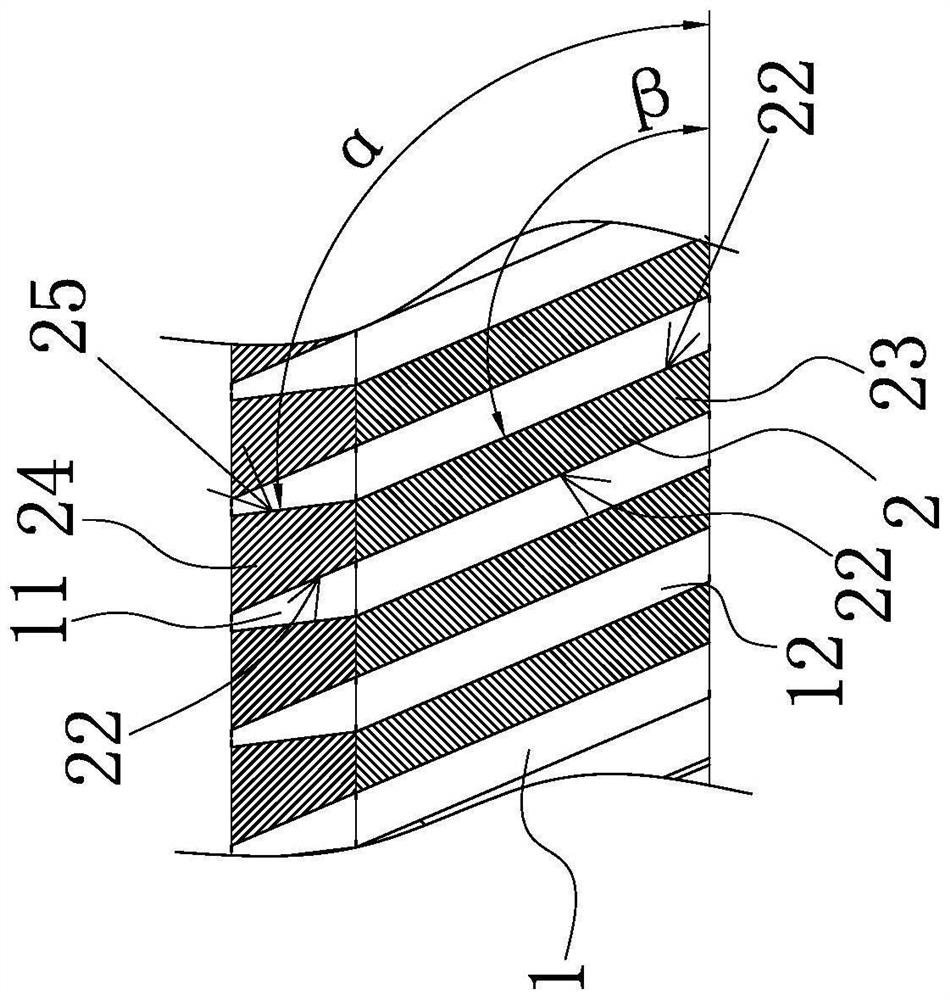

Planet wheel thread rolling plate and thread rolling process thereof

The invention provides a planet wheel thread rolling plate and a thread rolling process thereof, and belongs to the technical field of cold stamping machining. The problem that chamfering is very difficult to machine on a rack on an existing planet wheel is solved. The thread rolling plate comprises a body, a plurality of thread rolling racks which are obliquely arranged at uniform intervals are arranged on the body, each thread rolling rack is provided with a top face, a forward rack face and a reverse rack face, an inclined face intersecting with the reverse rack face is arranged on the side, located on the reverse rack face, of each thread rolling rack, the inclined direction of the inclined faces is the same as that of the reverse rack faces, and the included angles alpha between the inclined faces and the side surfaces where the long edges of the body are located are less than the included angles beta between the reverse rack faces and the side surfaces where the long edges of the body is located, after thread rolling, uniform rack grooves are formed in the periphery of a blank planet wheel of the thread rolling racks, and the inclined surface forms an arc-shaped chamfer surface on the groove wall on one side of each rack groove. By means of the design, chamfering machining on the planet gear rack is very convenient.

Owner:YUHUAN PUTIAN UNIDIRECTIONAL DEVICE CO LTD

Special-shaped hole chamfering deburring device

InactiveCN111673563ACut evenlyEasy to deburrEdge grinding machinesGrinding drivesGrindingManual handling

The invention provides a special-shaped hole chamfering deburring device, and belongs to the technical field of machining. The device aims to solve the problems that grinding of an existing electric grinder cannot be flexibly adapted to complex parts, the manual grinding flush precision is low, the working efficiency is low, and the unnecessary waste and the loss are caused in a manual operation mode. The device comprises that the top of a tail seat is rotationally connected with a group of electric grinder mounting seats; the front end of the tail seat is fixedly connected with a group of tension springs; the rear end of the tail seat is fixedly connected with a group of electric grinder limit rods; and a group of floating electric grinders is fixedly connected inside the electric grindermounting seats. The floating electric grinders rotate on the tail seat, so that floating electric grinder heads can grind the more complex parts; the tension springs enable the floating electric grinding heads to rotate along with the parts during grinding, so that the cutting effect is more natural; deburring is convenient and rapid, the work which is difficult to complete by manual and common equipment is replaced; and the production quality of the parts is improved, customer complaints are reduced, and the obvious effects on defective products of repairing burr problems are achieved.

Owner:湖北豪凯汽车零部件有限公司

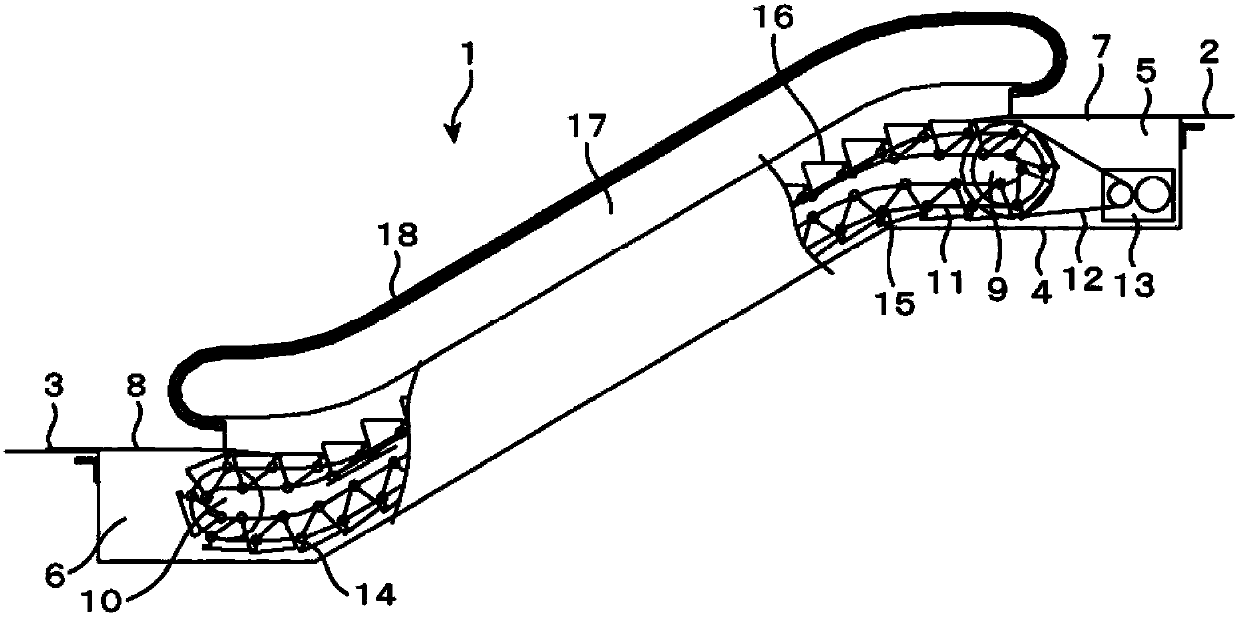

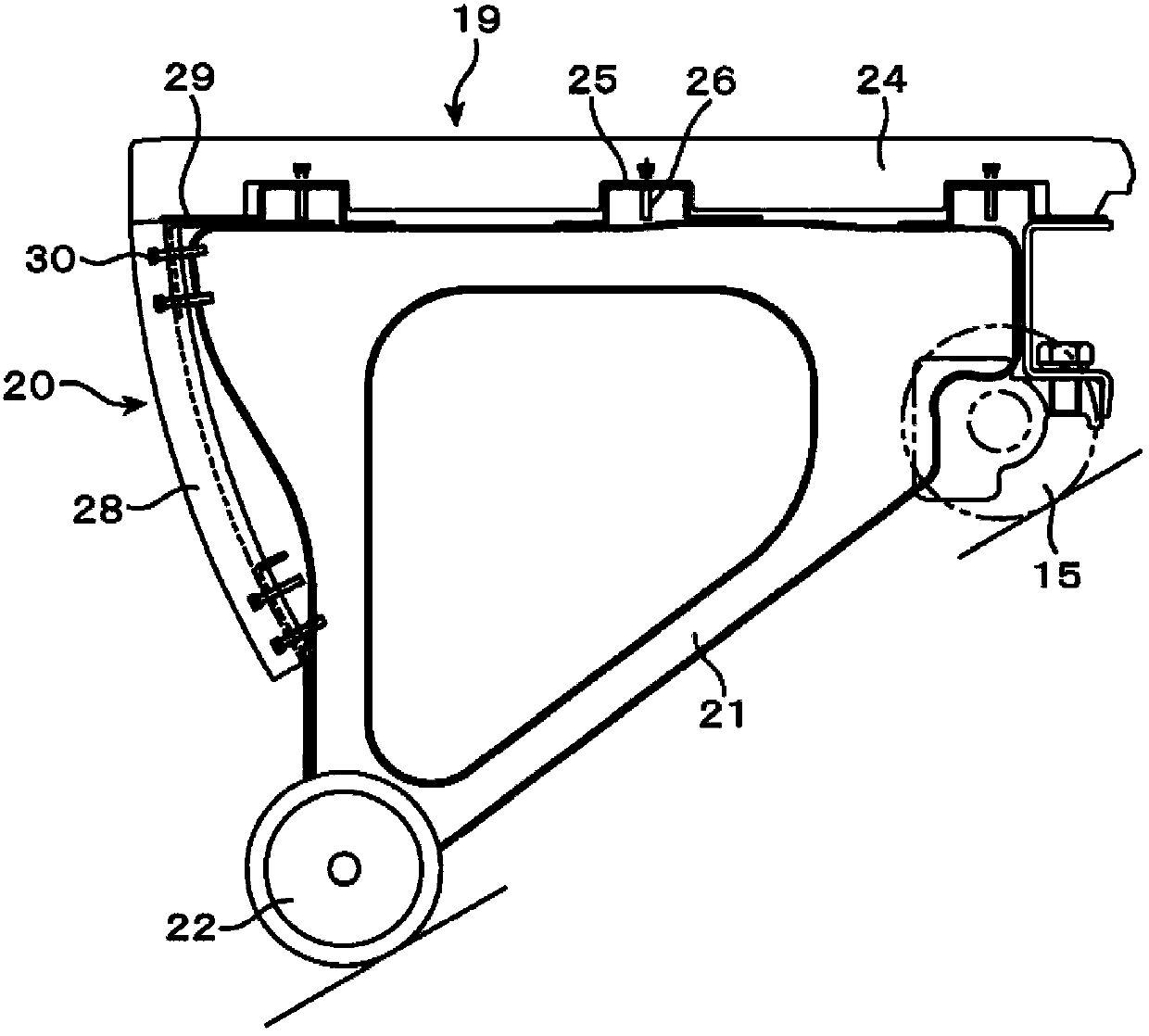

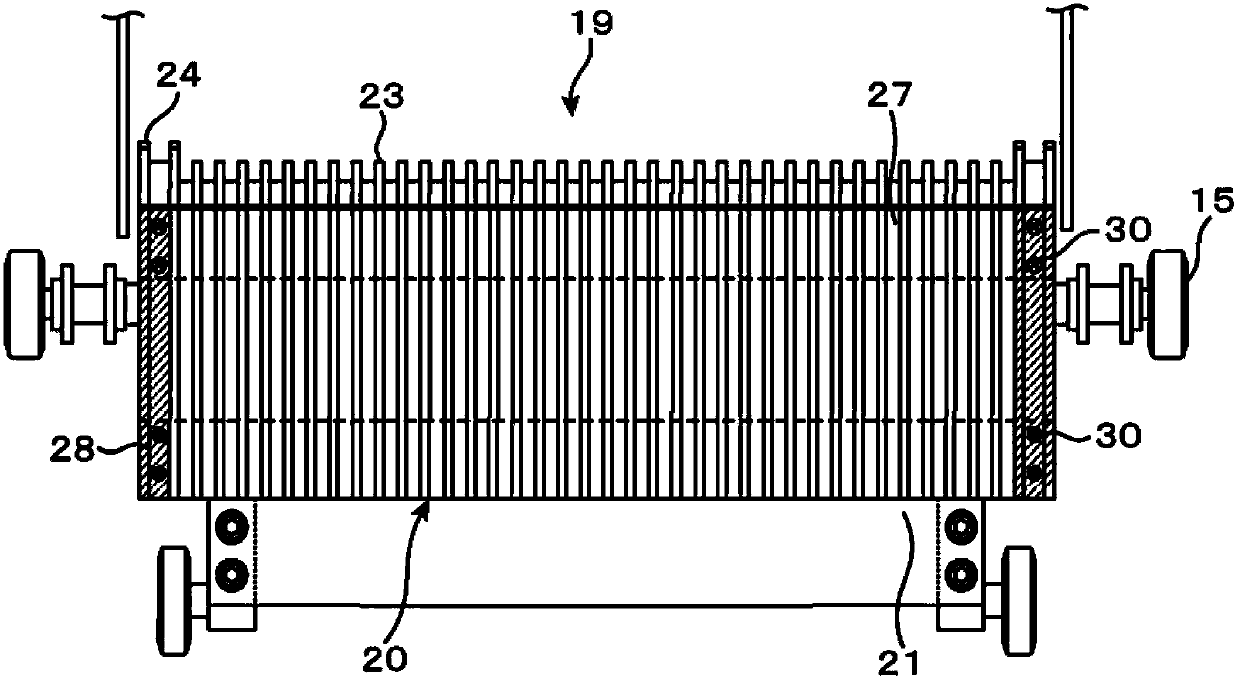

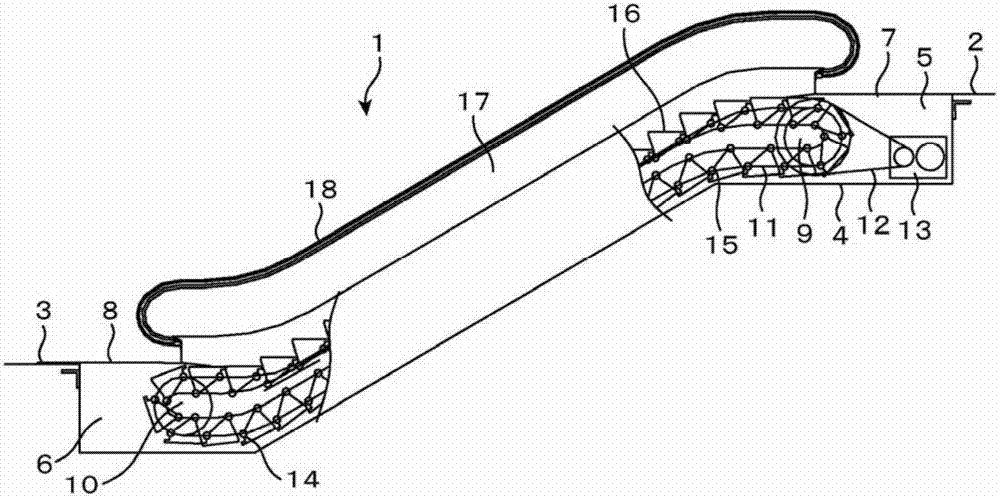

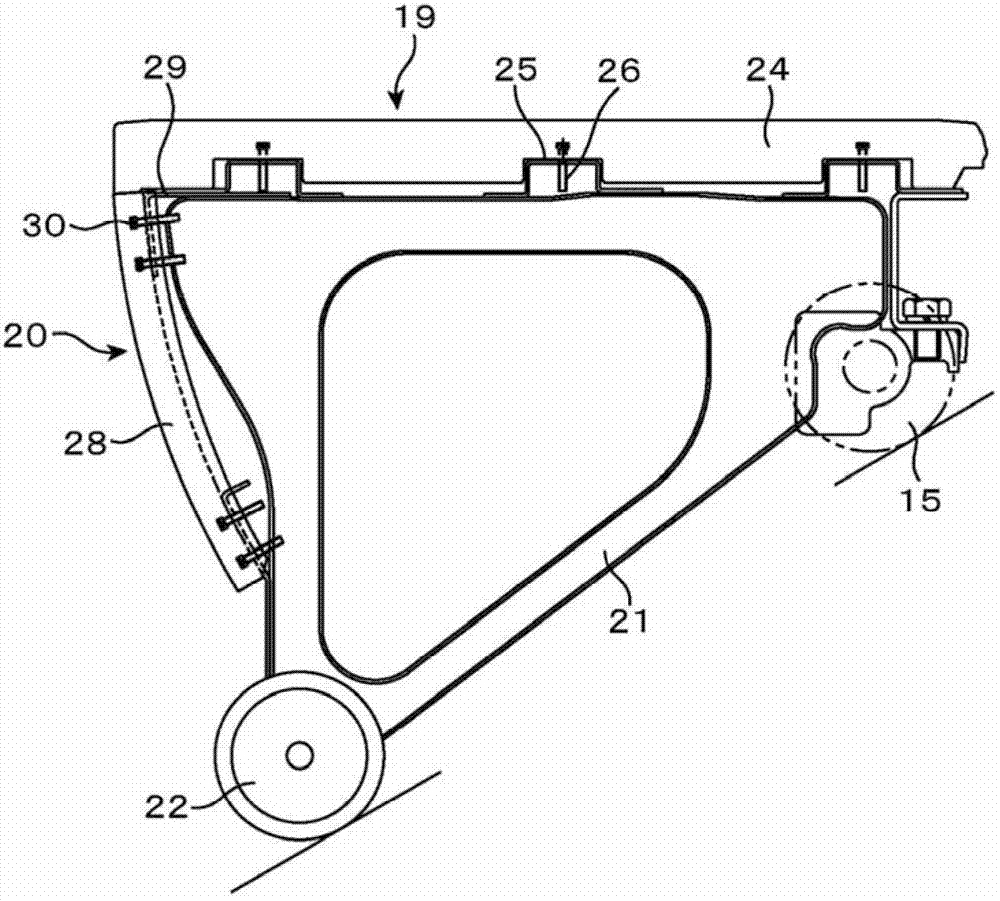

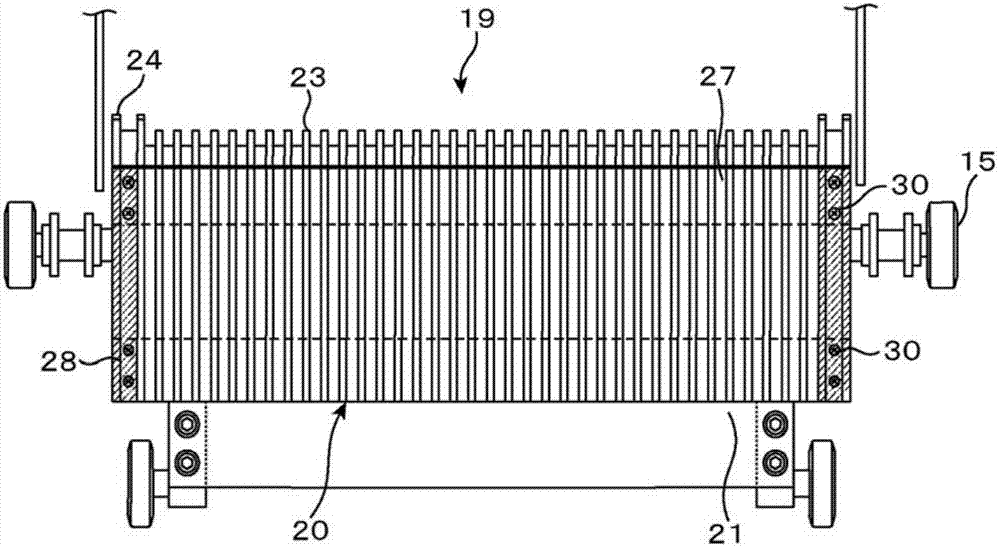

Passenger delivery apparatus and steps of passenger delivery apparatus

The invention provides a passenger delivery apparatus and steps of the passenger delivery apparatus, which enable the connection part of the side end boundary member of an anti-slip plate and the side end boundary member of a kickplate to be substantially smooth. Provided are the passenger delivery apparatus or the steps used therein. The passage delivery apparatus includes a frame body (4) spanning the upper floors and the lower floors of a building, and a plurality of steps (16) in circular connection in the frame body to perform circulated movement, each step is provided with a pedal (19) and a kickplate (20), the end of the pedal in the width direction is provided with the side end boundary member (24) of the anti-slip plate, each kickplate covers between the pedals of two adjacent steps to generate step difference, and the end of the pedal in the width direction is further provided with the side end boundary member (28) of the kickplate, and at least one connection part of the connection part of the side end boundary member of the anti-slip plate and the side end boundary member of the kickplate and the connection part of the side end boundary member of the kickplate and the side end boundary member of the anti-slip plate is subjected to chamfering or fillet machining.

Owner:HITACHI LTD

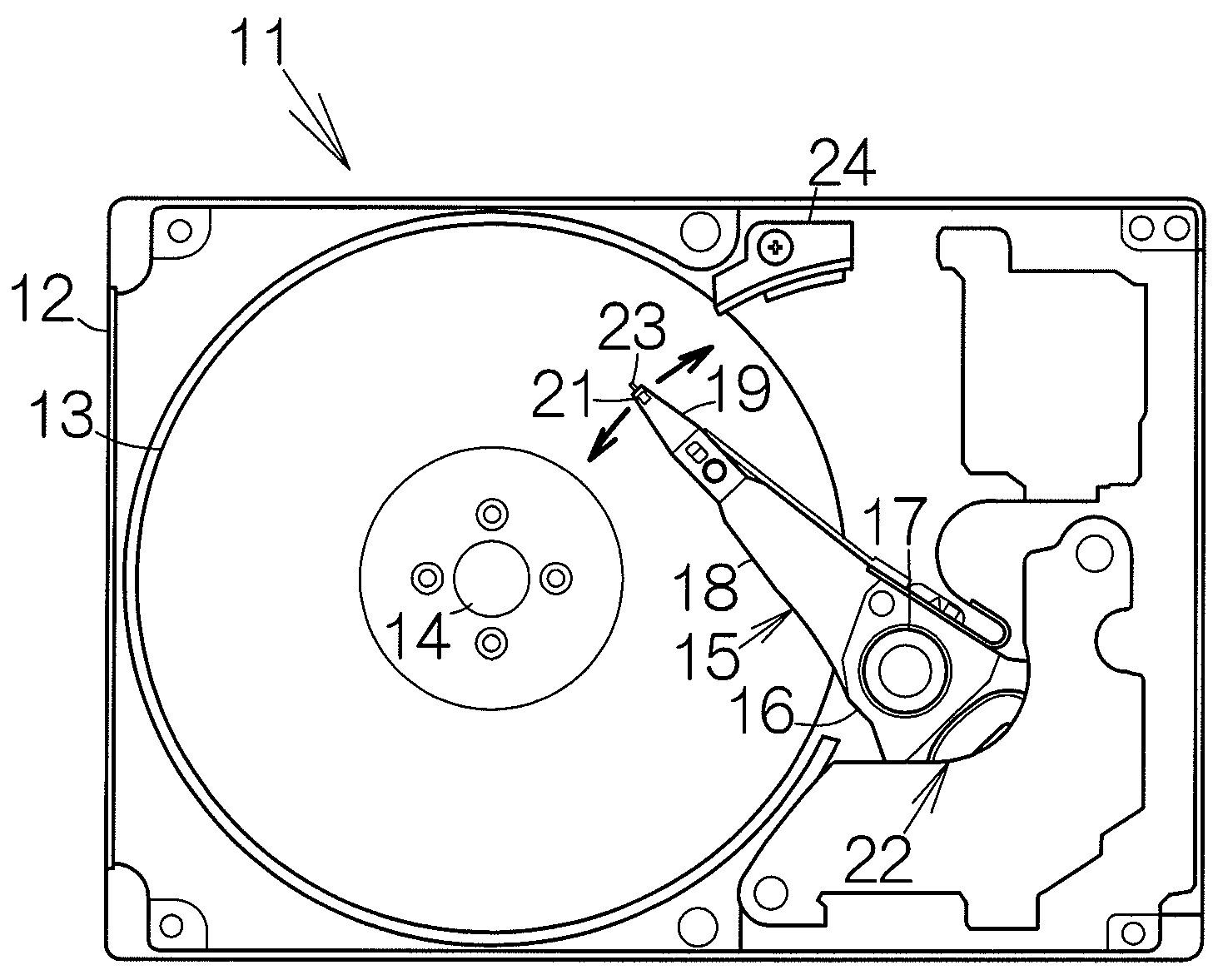

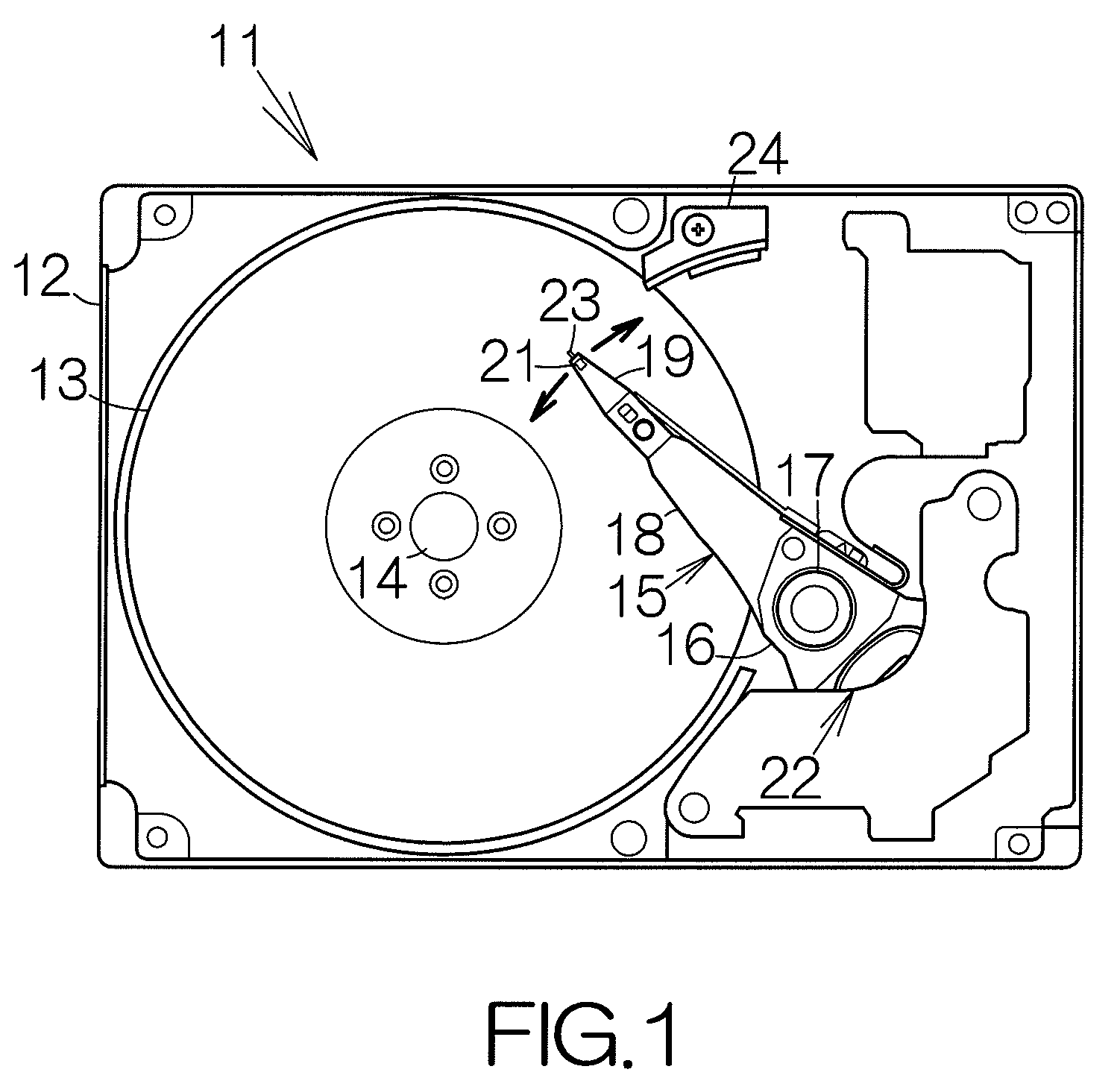

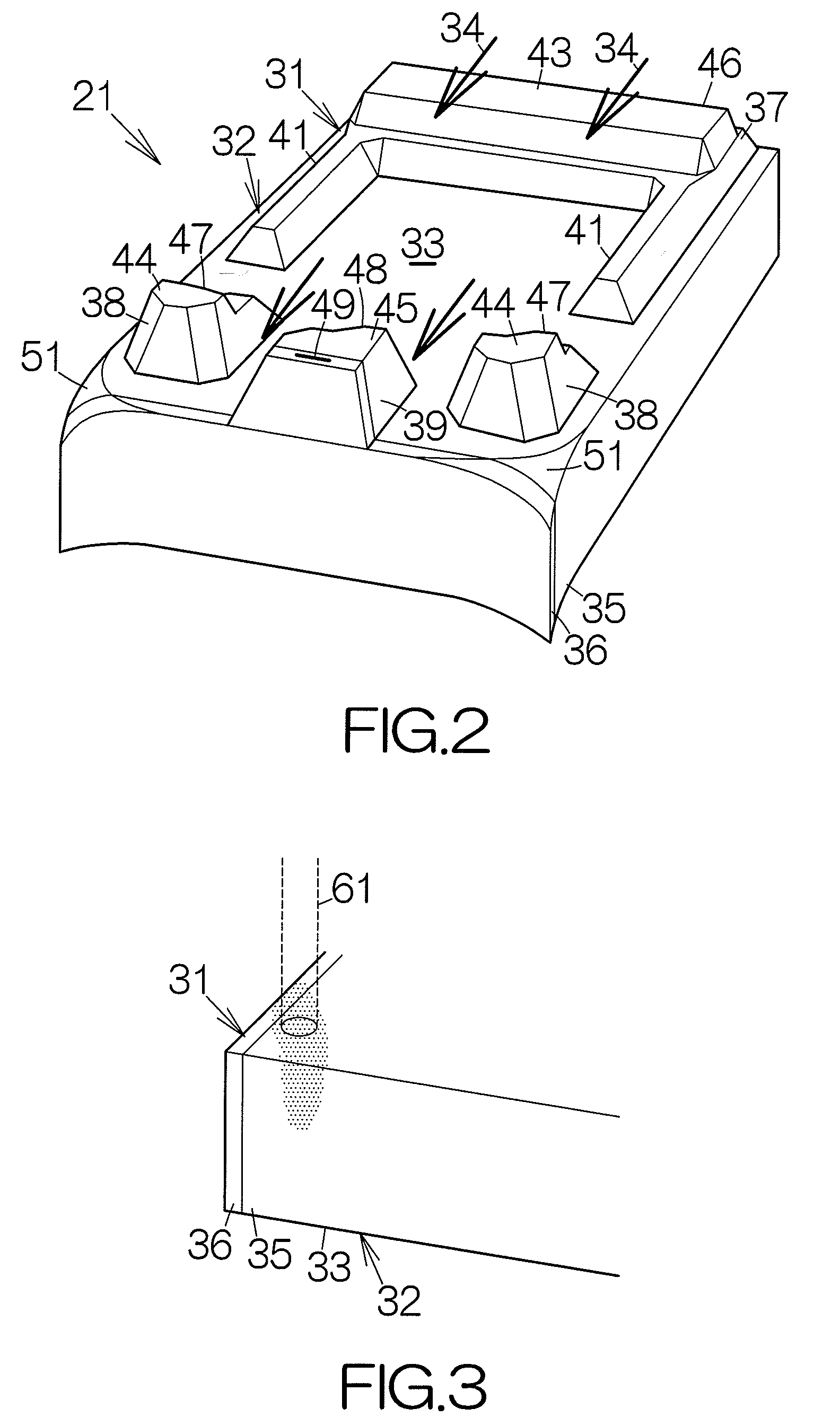

Method of making head slider and resultant head slider

InactiveUS20090052086A1Easy chamferingImprove accuracyRecord information storageFluid-dynamic spacing of headsEngineeringLaser beams

A laser beam is radiated to the corner of the back surface of the head slider having the front surface defining a medium-opposed surface. This method employs a laser beam radiated to the corner of the back surface of the head slider. The material thus gets molten at least partly at the corner of the head slider. The molten material then gets cured or hardened. The corner of the head slider warps back. The corner of the medium-opposed surface is in this manner chamfered. The shape of the chamfer can clearly be observed. Such chamfering process can be repeated until a desired shape is obtained. In this manner, the head slider can readily be chamfered with a high accuracy.

Owner:TOSHIBA STORAGE DEVICE CORP

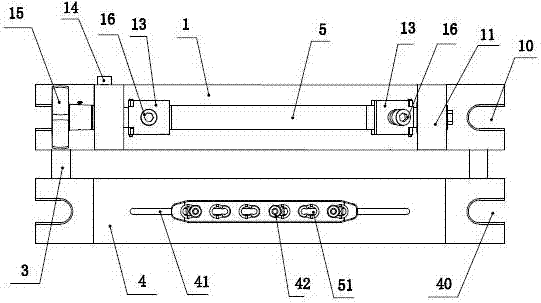

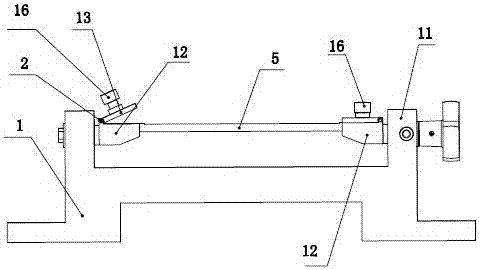

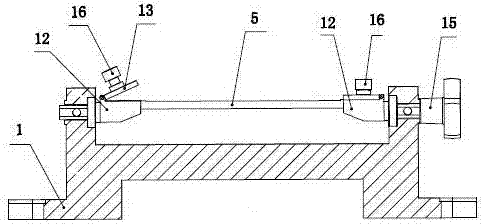

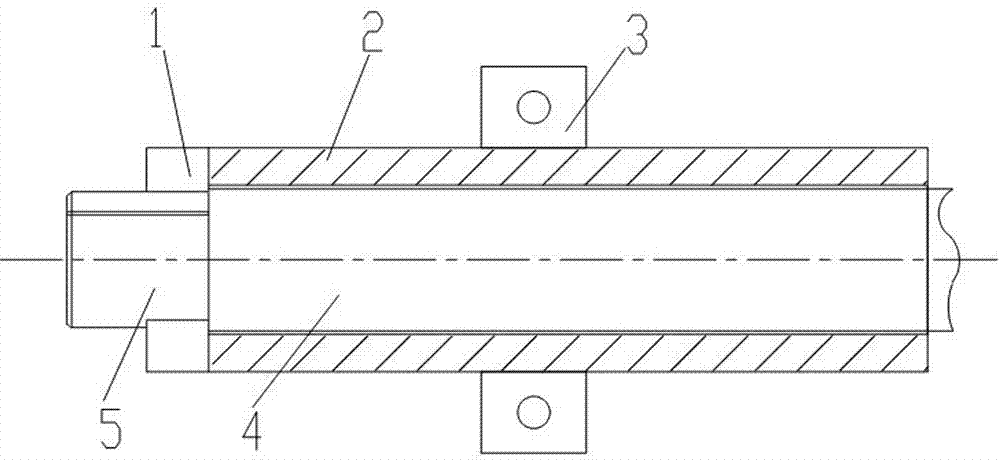

A straight bone plate processing jig

InactiveCN105328471BEasy chamferingEasy to operatePositioning apparatusMetal-working holdersMachiningOsteosynthesis

A straight bone plate processing jig is used to facilitate the clamping of the bone plate and ensure the processing accuracy of the bone plate. It includes a first base, a support, a support block, a pressure plate and a handle. A pair of supports are arranged on the top of the first base, and a support block is rotatably installed on the support. The rotating shaft that the support rotates and cooperates with, one of the rotating shafts is provided with two first fixing holes whose axes are perpendicular to each other, a first bolt is provided between the rotating shaft and the support; a clamping bone plate is provided on the top of the supporting block groove, a pressure plate is hingedly installed on the support block, and a second bolt is installed on the pressure plate, and the second bolt extends into the second fixing hole on the support block to fix the bone plate; on the first base One side is fixed with a second base, and a long hole is arranged on the top of the second base, and a plurality of third bolts for clamping the bone plate are arranged in the long hole. The invention has the advantages of convenient operation, simple structure and convenient popularization and application.

Owner:UNIV OF JINAN

Passenger conveyors and steps for passenger conveyors

The invention provides a passenger delivery apparatus and steps of the passenger delivery apparatus, which enable the connection part of the side end boundary member of an anti-slip plate and the side end boundary member of a kickplate to be substantially smooth. Provided are the passenger delivery apparatus or the steps used therein. The passage delivery apparatus includes a frame body (4) spanning the upper floors and the lower floors of a building, and a plurality of steps (16) in circular connection in the frame body to perform circulated movement, each step is provided with a pedal (19) and a kickplate (20), the end of the pedal in the width direction is provided with the side end boundary member (24) of the anti-slip plate, each kickplate covers between the pedals of two adjacent steps to generate step difference, and the end of the pedal in the width direction is further provided with the side end boundary member (28) of the kickplate, and at least one connection part of the connection part of the side end boundary member of the anti-slip plate and the side end boundary member of the kickplate and the connection part of the side end boundary member of the kickplate and the side end boundary member of the anti-slip plate is subjected to chamfering or fillet machining.

Owner:HITACHI LTD

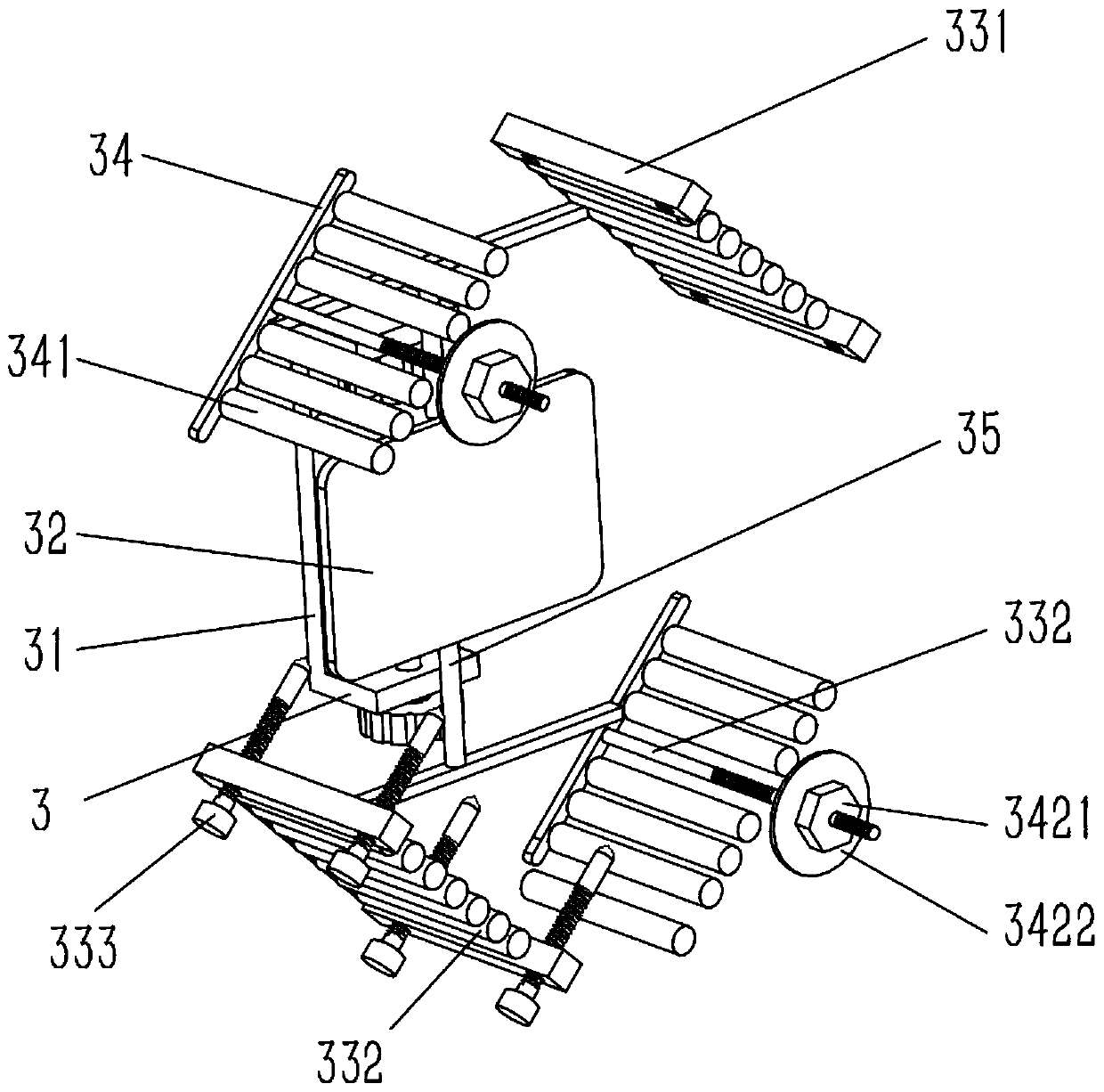

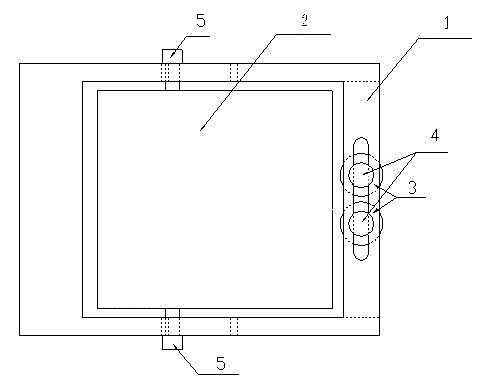

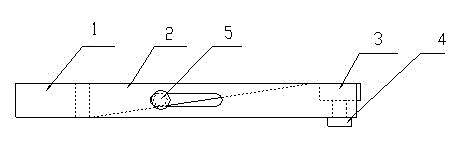

Edge chamfering device and chamfering method of a circular blade

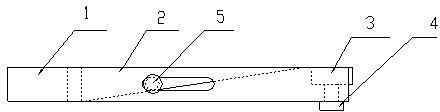

ActiveCN102873599BEasy chamferingSimple and fast operationOther manufacturing equipments/toolsEngineeringTriangular prism

The invention discloses a round blade cutting edge chamfering method and a chamfering device. The chamfering device comprises a support plate, an angle adjusting plate, two limiting sheaves and a mandril with one end provided with a sheave. The support plate is of a rectangular frame structure, one end of the support plate is fixed with a tool sharpener through a bench vice, and the other end and the two sides of the support plate are respectively provided with a straight groove. The angle adjusting plate is of a triangular prism structure, and the two sides of the angle adjusting plate are fixed in the two straight grooves at the two sides of the support plate. The two limiting sheaves are fixed in the straight groove at the other end of the support plate through sheave fastening pieces, and a gap at certain width is left between the two limiting sheaves and the angle adjusting plate for the cutting edge of a blade to stretch out.

Owner:ZHUZHOU KINGTAL CEMENTED CARBIDE

A fixture for chamfering the end of a steel pipe

InactiveCN102806478BEasy chamferingSimple structurePositioning apparatusMetal-working holdersEngineeringMachining

The invention provides a fixture for chamfering ends of steel pipes, and is applied to the technical field of machining of steel pipes. A concave portion I (4) of an upper die holder (1) and a concave portion II (5) on a lower die holder (2) of the fixture for chamfering the ends of the steel pipes form a die hole (6), an upper body (7) and a lower body (8) of a clamp die (3) are respectively connected with the upper die holder (1) and the lower die holder (2), an upper pipe diameter portion (9) of the upper body (7) and a lower pipe diameter portion (10) of the lower body (8) are fastened to form a cylindrical pipe diameter portion (11), and the pipe diameter portion (11) penetrates through the die hole (6) and is of a structure capable of accommodating a steel pipe (12) in a sleeved manner. The fixture can clamp the steel pipes, so that the ends of the steel pipes can be chamfered conveniently. In addition, the fixture is simple in structure, and only clamp dies comprising pipe diameter portions with different sizes need to be changed before the steel pipes with different pipe diameters are machined.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

A chamfering tooling for the slider of the rack of the slotting machine

ActiveCN111152089BConvenient and stable positioningEasy chamferingEdge grinding machinesGrinding carriagesStructural engineeringMachine

Owner:JIANGSU HAIRUI CNC MACHINE TOOL CO LTD

Bearing seat of working roller of cold rolling machine

InactiveCN102371275AEasy chamferingAvoid the disadvantages of easy chafingMetal rolling stand detailsMetal rolling arrangementsEngineeringUltimate tensile strength

The invention relates to a bearing seat of a working roller of a cold rolling machine, which comprises a bearing seat body of a working roller; and the first end of the bearing seat body of the working roller is provided with chamfers which are symmetrically distributed. According to the bearing seat of the working roller of the cold rolling machine, the chamfers which are symmetrically distributed are arranged on the first end of the bearing seat body of the working roller in a four-roller cold rolling machine. In this way, a working roller system can be arranged into a rack very easily by utilizing the chamfers at the first end as a guide when the working roller is arranged into the rack by the bearing seat body of the working roller, and the defects that the working roller system is difficult to enter the rack when a roller is exchanged and the bearing seat body of the working roller is easy to scratch with a small lining plate of the rack are avoided. Meanwhile, the labor intensity of a worker is lowered, and the production efficiency is enhanced; moreover, the chamfers at the corresponding first end of the bearing seat body of the working roller are simple to manufacture, the installation of the roller system is convenient and easy, the labor intensity is small, the auxiliary time is little, the working efficiency is high, and the quality stability of a rolled product is enhanced; and moreover, the structure is simple, and the manufacture is convenient.

Owner:WUXI WUYE HEAVY IND MACHINERY

Round blade cutting edge chamfering device and method

ActiveCN102873599AMeet chamferEasy chamferingOther manufacturing equipments/toolsEngineeringTriangular prism

The invention discloses a round blade cutting edge chamfering method and a chamfering device. The chamfering device comprises a support plate, an angle adjusting plate, two limiting sheaves and a mandril with one end provided with a sheave. The support plate is of a rectangular frame structure, one end of the support plate is fixed with a tool sharpener through a bench vice, and the other end and the two sides of the support plate are respectively provided with a straight groove. The angle adjusting plate is of a triangular prism structure, and the two sides of the angle adjusting plate are fixed in the two straight grooves at the two sides of the support plate. The two limiting sheaves are fixed in the straight groove at the other end of the support plate through sheave fastening pieces, and a gap at certain width is left between the two limiting sheaves and the angle adjusting plate for the cutting edge of a blade to stretch out.

Owner:ZHUZHOU KINGTAL CEMENTED CARBIDE

A Fixing Device Used in Motor End Cover Processing

ActiveCN112091679BAvoid troubleEasy to drillPositioning apparatusMetal working apparatusEngineeringStructural engineering

The invention discloses a fixing device for processing an electric motor end cover, and relates to the technical field of electric motor processing. The fixing device for motor end cover processing includes a mounting box, the inside of which is welded with a ring plate, the top of the ring plate is provided with a mounting plate, the inside of the ring plate is provided with a ring chute, and inside the ring chute The ring slider is slidably installed, the bottom of the installation plate is fixedly installed with the top of the ring slider, the installation plate and the ring slider are slidably installed, and the top of the installation box is welded and installed with a fixed plate. The invention can clamp and fix the end cover of the motor, which is convenient for the next step of opening operation, and can still be rotated after fixing, avoiding the need to repeatedly clamp and adjust the position of the transposition opening, and avoiding the influence of repeated clamping on the processing The problem of efficiency, on the other hand, avoids the trouble caused by repeated clamping to the operator, and effectively enhances the practicability and convenience of this device.

Owner:浙江德易精密机械有限公司

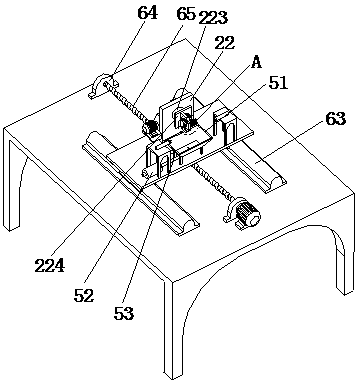

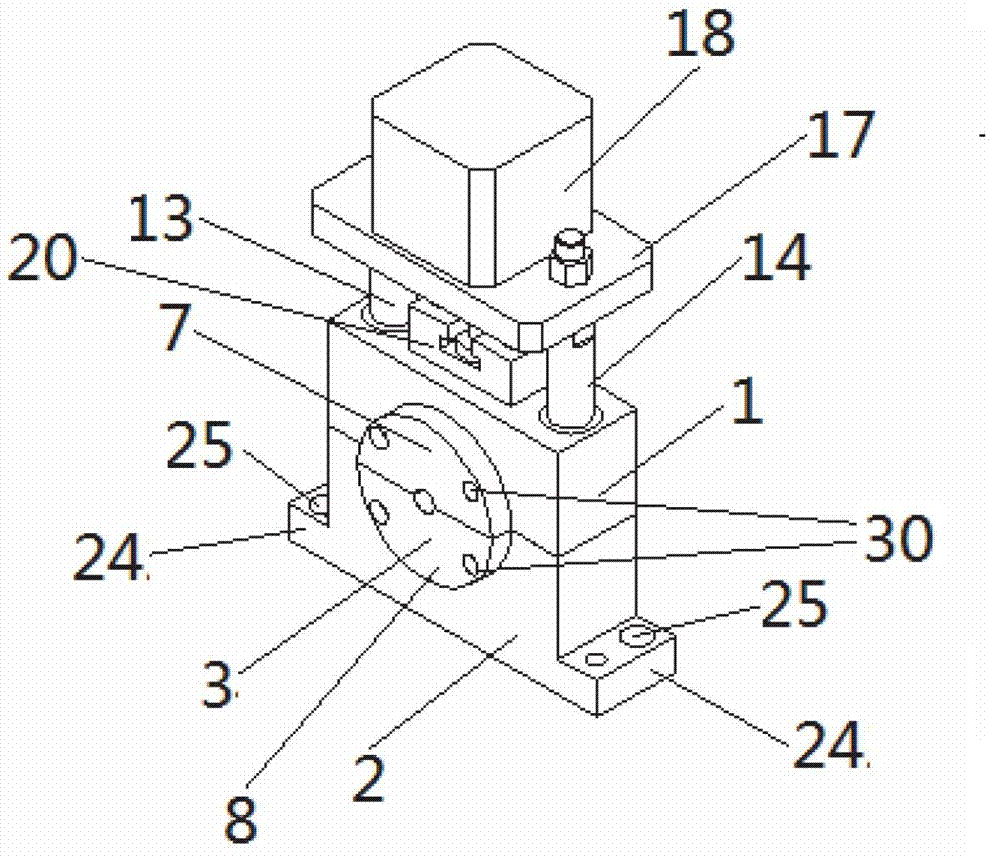

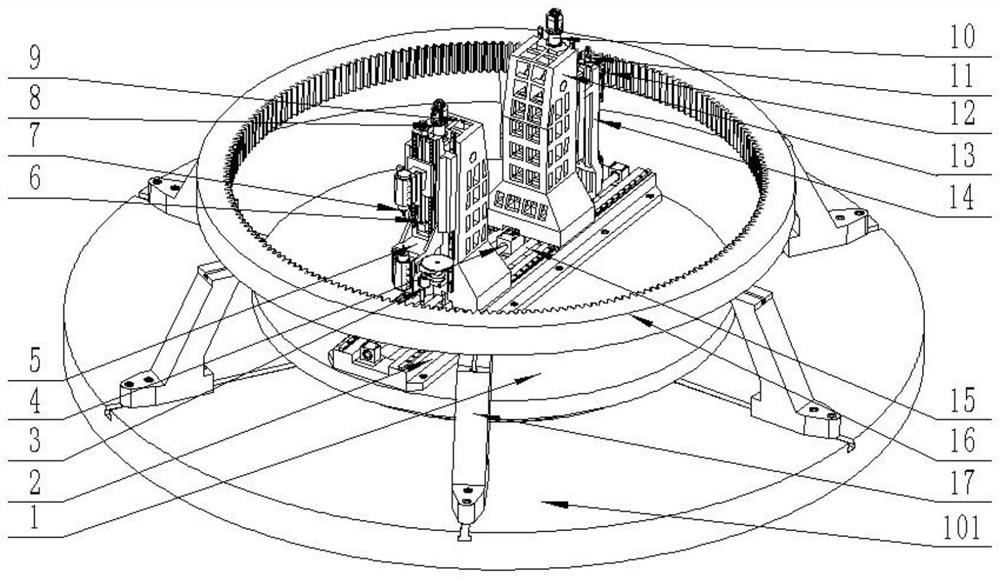

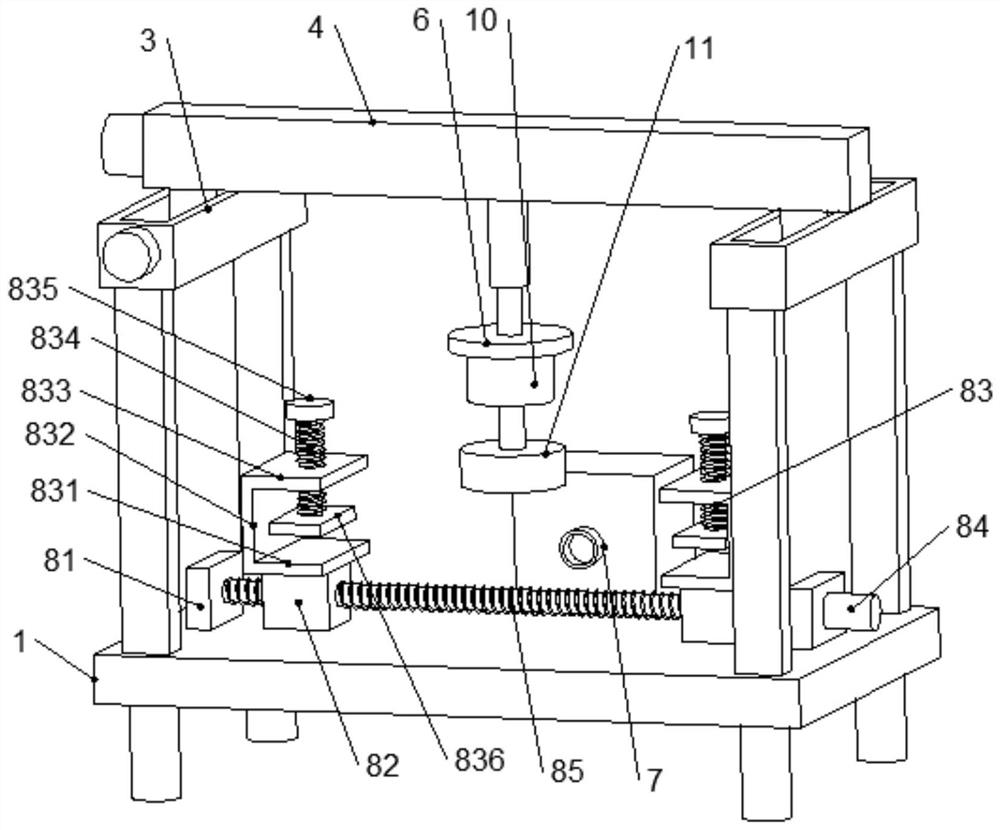

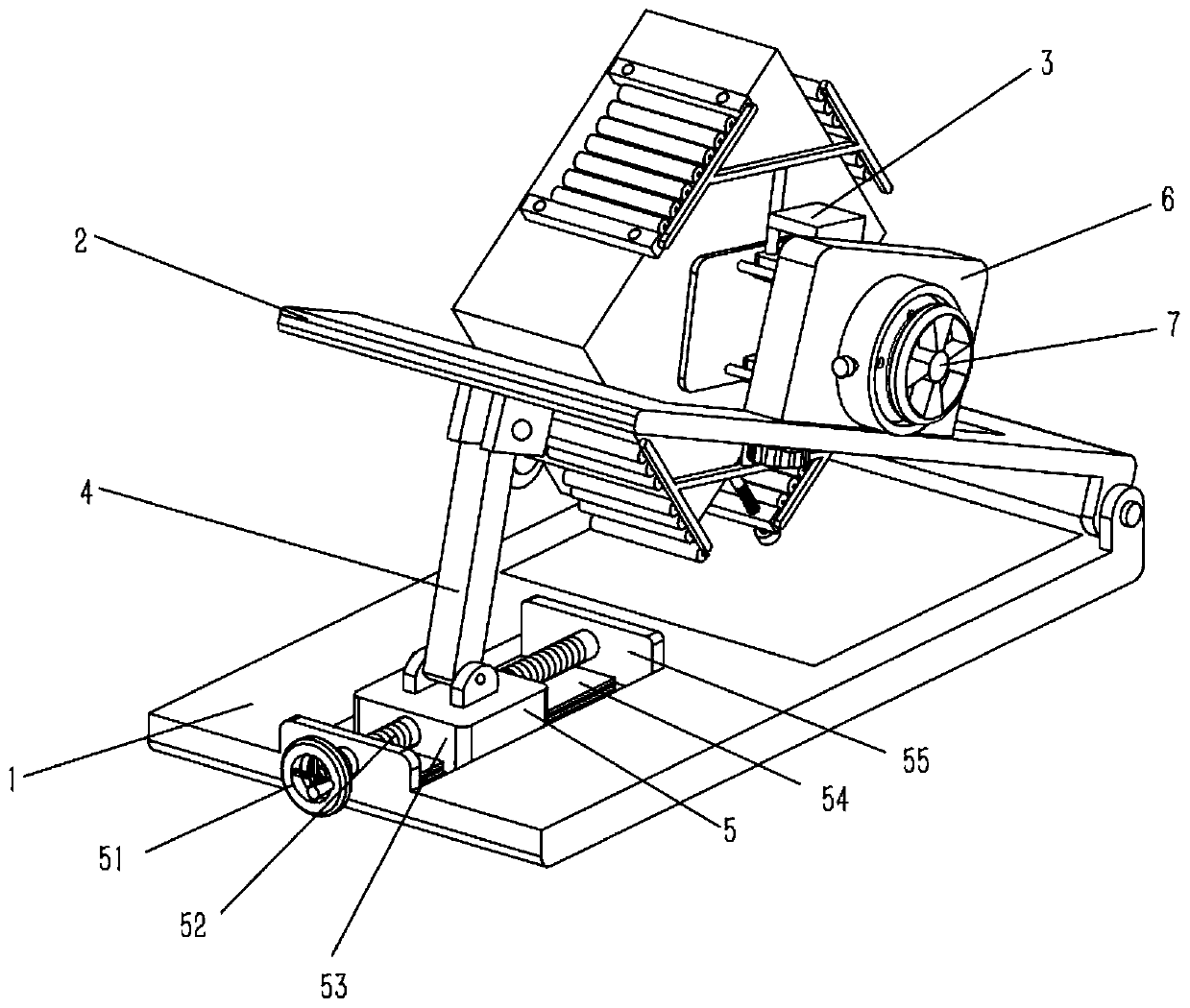

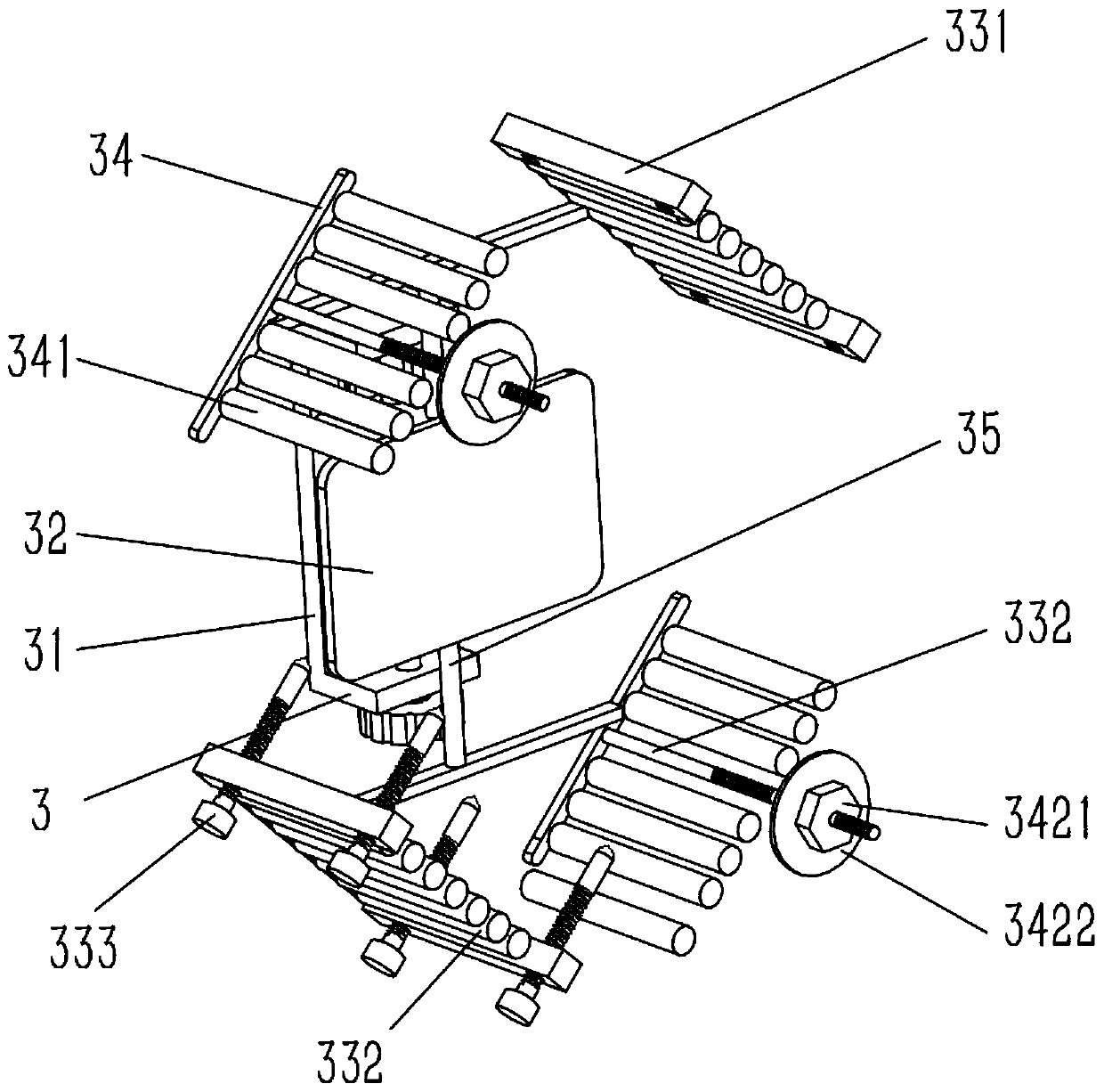

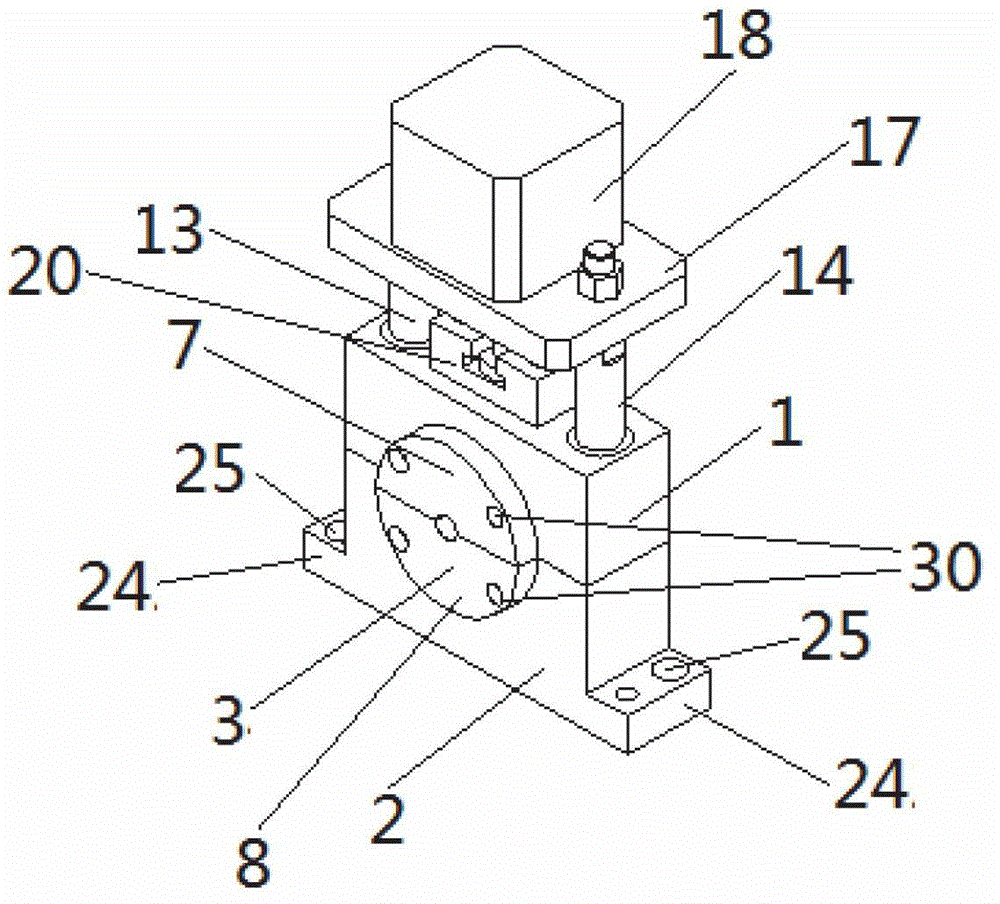

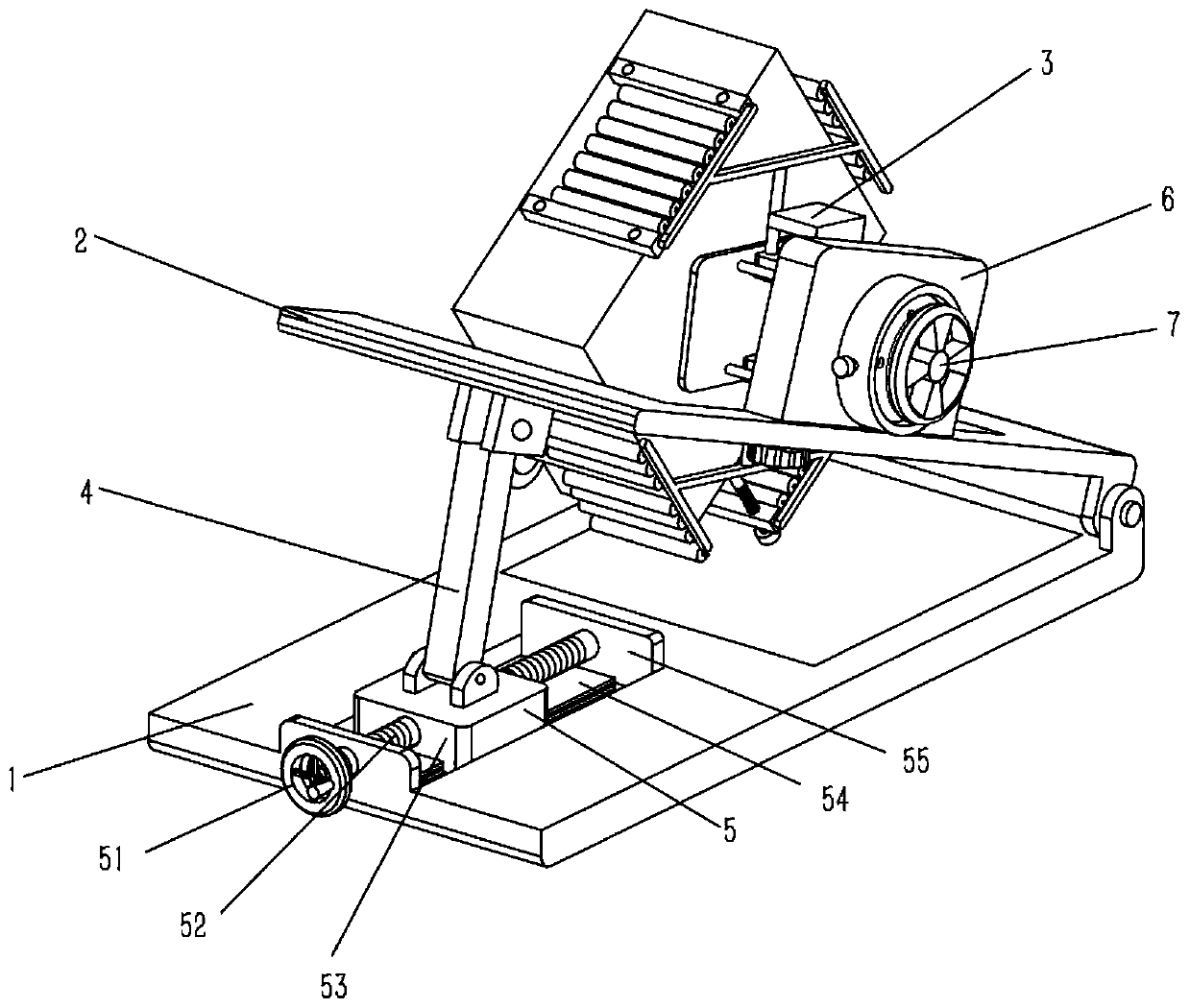

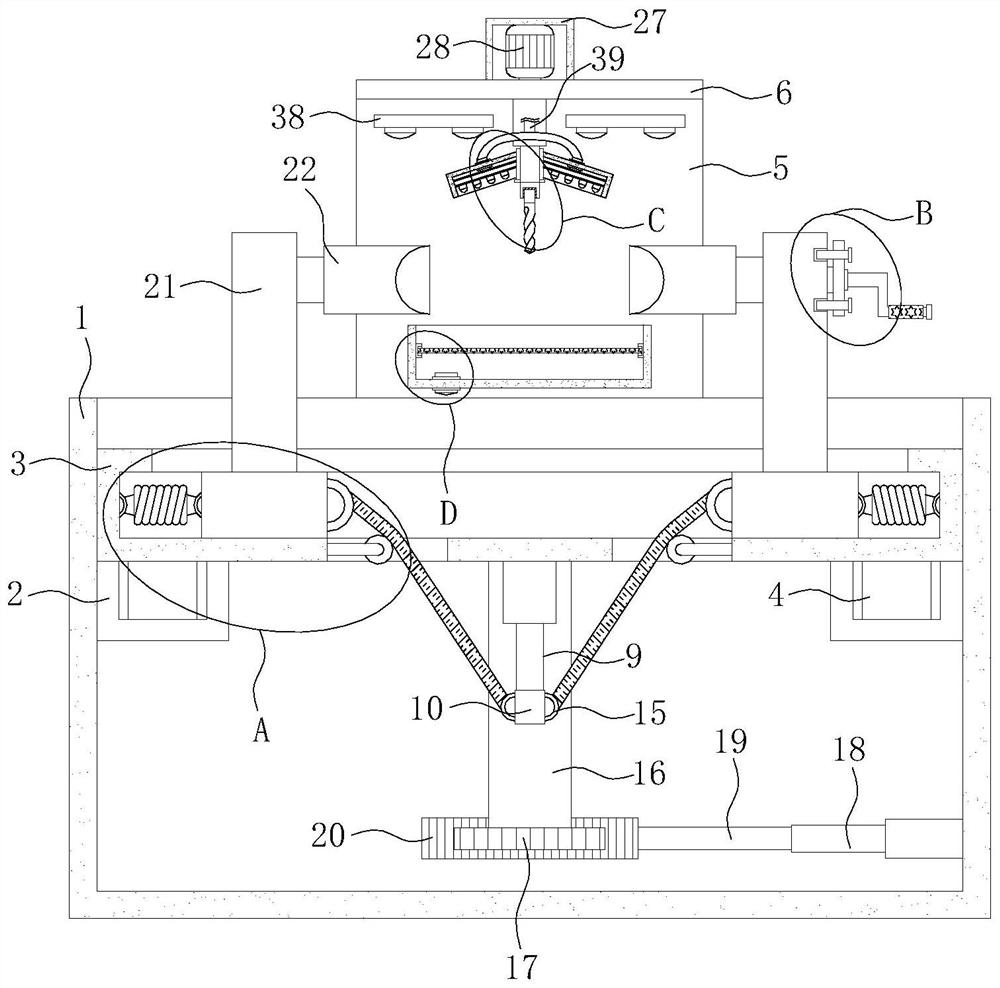

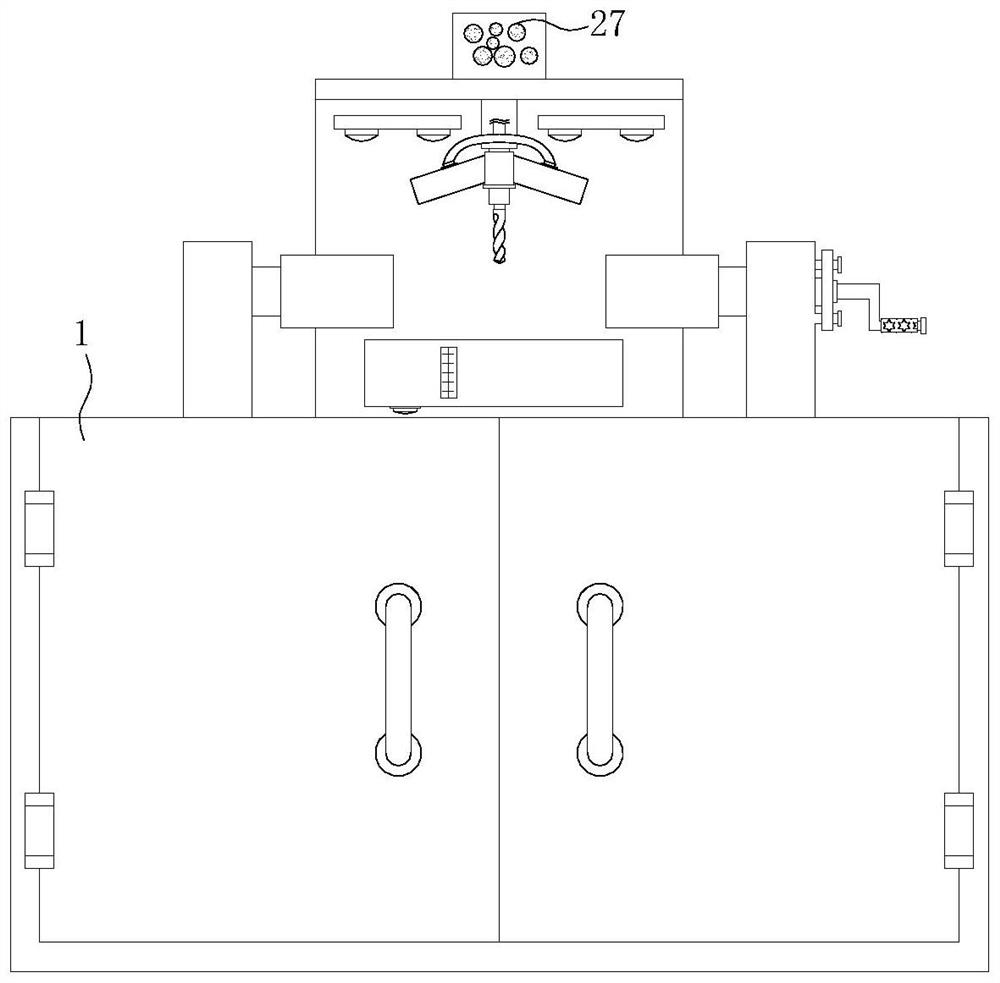

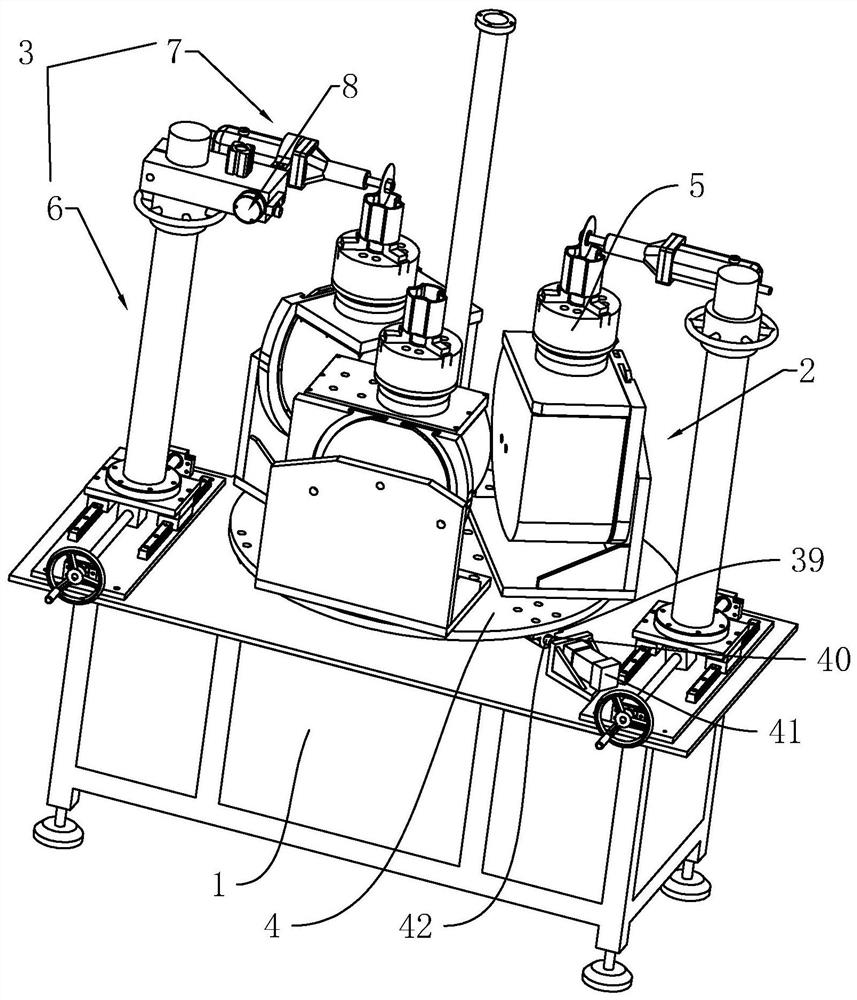

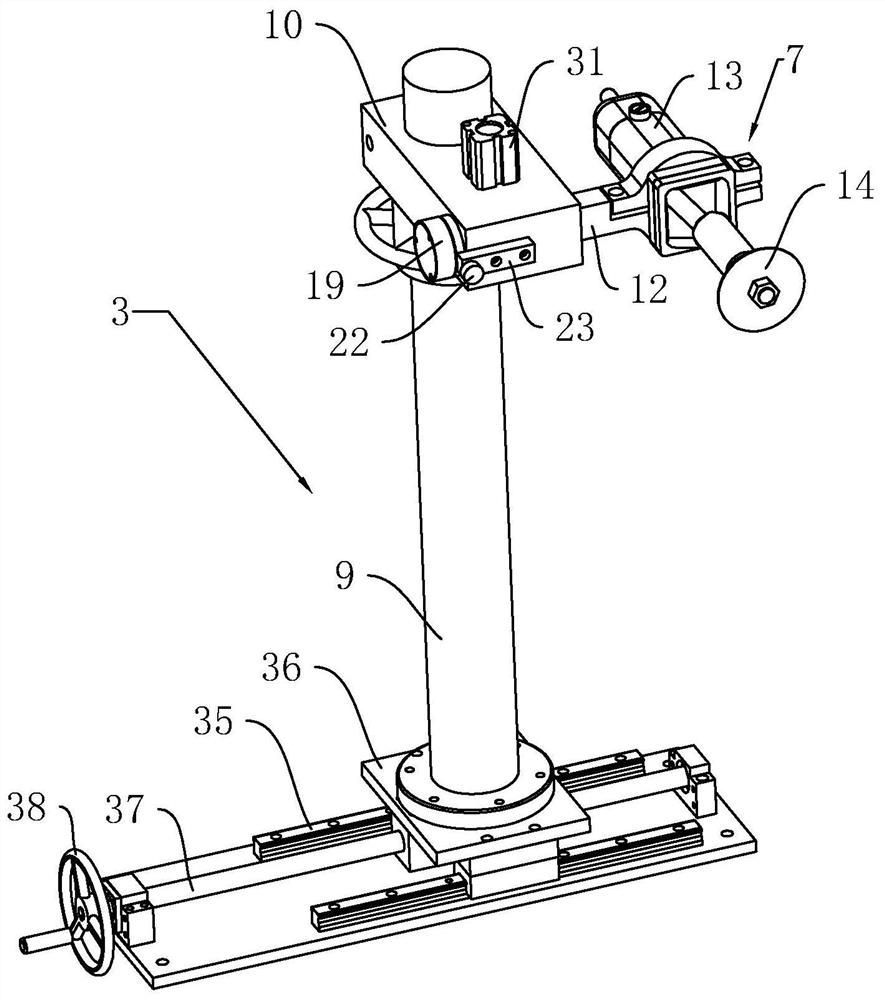

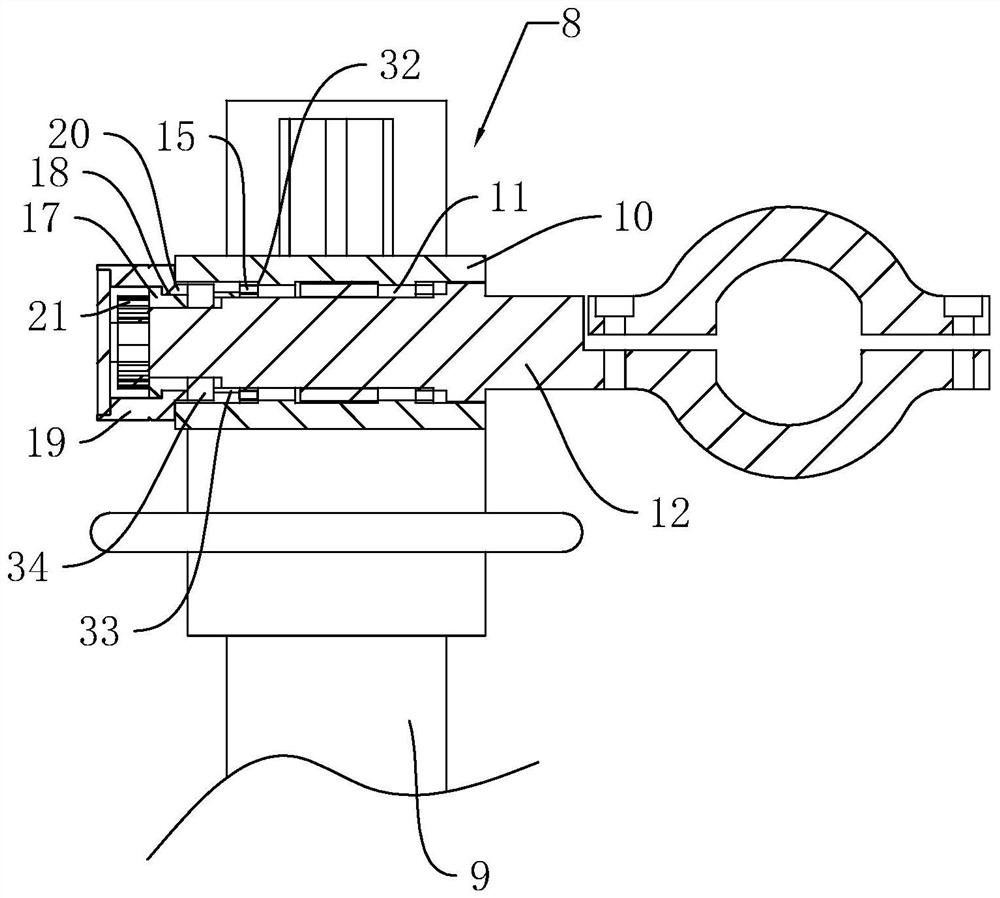

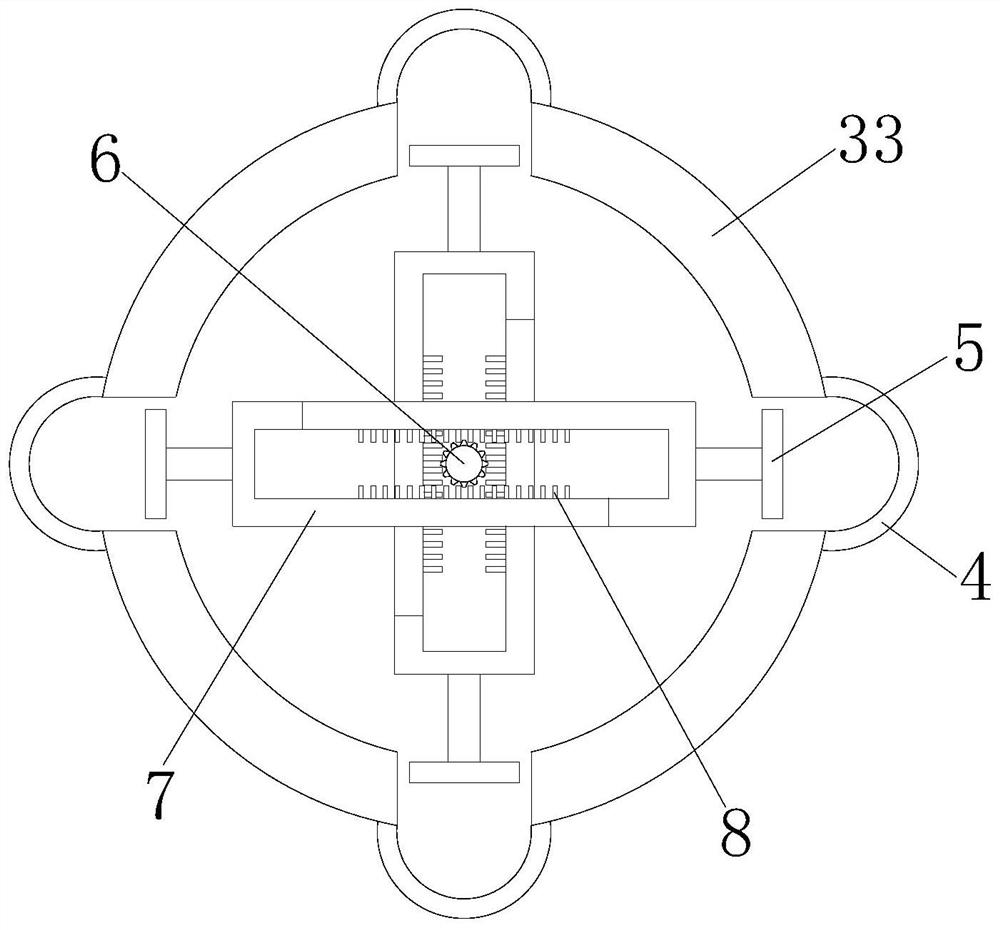

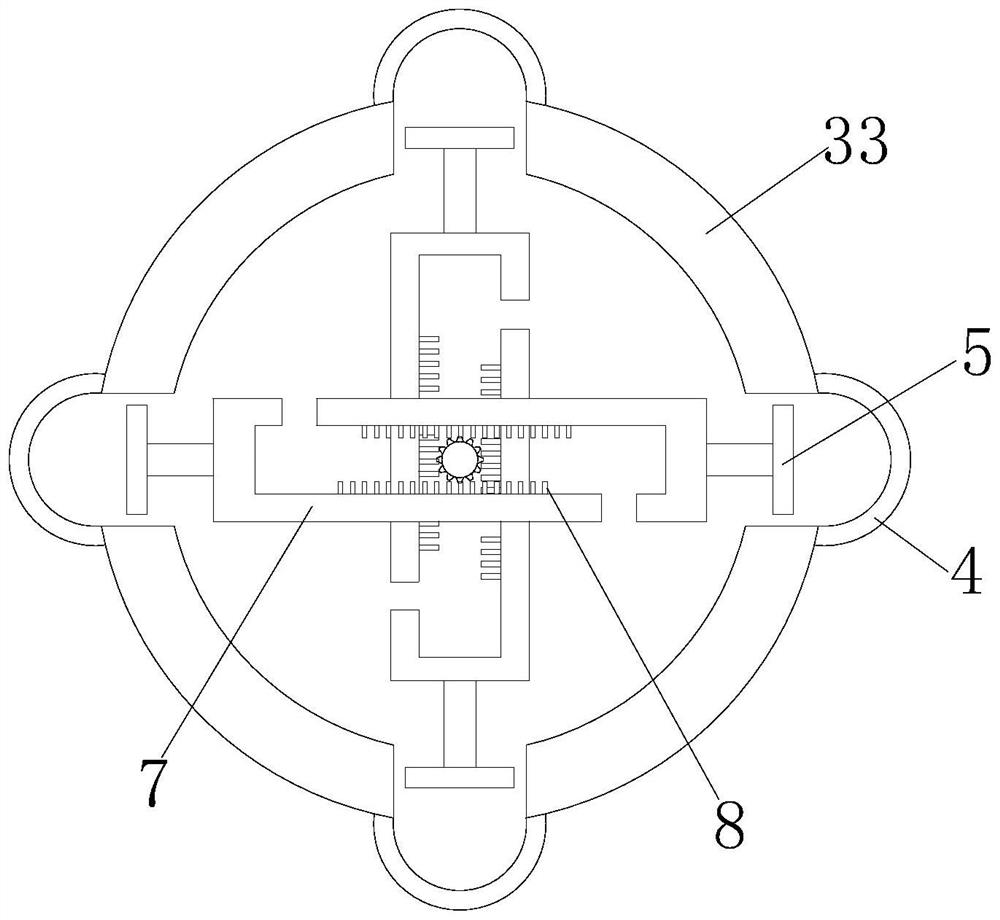

A multi-station universal joint special-shaped automatic chamfering machine

ActiveCN111136534BEasy chamferingGuaranteed continuous grindingEdge grinding machinesGrinding drivesUniversal jointElectric machinery

The invention relates to a multi-station universal joint special-shaped automatic chamfering machine, comprising a body, a feeding mechanism arranged on the body, and a chamfering mechanism arranged on the body. The drive plate, at least two clamping parts connected to the drive plate, the chamfering mechanism includes a support assembly connected to the body, a chamfering assembly that is rotatably connected to the support assembly and acts on the workpiece, and the support assembly is provided with a pair of The chamfer assembly is a floating assembly that applies a torque that rotates toward the workpiece. The invention has the advantages of high degree of automation, improved processing efficiency, reduced labor intensity and good grinding effect.

Owner:ZHEJIANG ODM TRANSMISSION TECH

A stainless steel pipe chamfering equipment and its processing technology

ActiveCN113182611BEasy to completeEnsure accuracy andMetal working apparatusMachining processSteel tube

The application relates to a stainless steel pipe chamfering equipment and its processing technology, including a chamfering machine body and a frame located at the feeding position of the chamfering machine body, the frame is provided with a feeding slideway, and is located on the side of the beginning end of the feeding slideway The lifting pallet used to support the steel pipe and the transfer device located at the end of the feeding chute; To rotate, the frame is also provided with a linear drive assembly for driving the transfer device close to or away from the chamfering machine body. The present application sets up the lifting pallet, utilizes the advantages of the convenient loading of the lifting pallet and the ability to lift multiple steel pipes to be processed at one time, and can quickly and conveniently complete the process of feeding the steel pipe to the feeding slideway, reducing labor intensity, and the transfer device The steel pipe to be processed on the feeding chute can be accurately moved to the processing position of the chamfering machine body to ensure the accuracy and efficiency of chamfering processing.

Owner:宁波永享不锈钢管道有限公司

A piece of insulation materials that are convenient to adjust the angle cutting equipment for the processing material processing materials

ActiveCN112092046BConvenience for limit deliveryEasy to adjustMetal working apparatusThermal insulationElectric machinery

The invention discloses a chamfering cutting device for heat-insulating material processing which is convenient for angle adjustment, comprising a worktable, a driving motor and a cutting blade. One end of the slot is fixedly connected with a mounting plate, and the connecting shaft under the table plate is fixedly connected with an auxiliary plate, the side of the mounting plate close to the mounting seat is welded with a limit rod, and the mounting plate is far from the limit rod. Track rods are installed on the left and right ends through bolts, a protective cover is installed on the right end of the front side of the carrier frame, and a pressure rod is fixedly connected to the middle part of the front side of the carrier plate. The chamfering cutting equipment for processing thermal insulation materials, which is easy to adjust the angle, is convenient for the limit transportation of the thermal insulation board, and it is convenient to adjust the limit size. The chamfering treatment improves the practicality.

Owner:山东明世达建筑科技有限公司

Metal pipe fitting chamfering device

PendingCN114346325AImprove processing efficiencyEasy to holdFeeding apparatusDriving apparatusPipe fittingEngineering

The invention provides a metal pipe fitting chamfering device which comprises a base, a chamfering head, a rotary drum and two pipe fitting clamping mechanisms, the base is horizontally arranged, and the chamfering head is installed on the base in a sliding mode; the rotary drum is horizontally arranged and installed on the base in the sliding direction of the chamfering head. Openings are formed in the two ends of the rotary drum, and the two pipe fitting clamping mechanisms are arranged at the two openings correspondingly. The pipe fitting clamping mechanism comprises a plurality of fixed clamping plates located at an opening of the rotary drum, the multiple fixed clamping plates are installed at the opening in a circumferential array mode, and a plurality of movable clamping plates are slidably installed at the opening in the circumferential direction of the opening. The pipe fitting chamfering device is novel in design and easy to operate, through the arrangement of the rotating cylinder, the driving piece and the like, a plurality of to-be-machined pipe fittings can be clamped and fixed to the rotating cylinder, the chamfering head can conduct chamfering machining in sequence, and the machining efficiency is improved; and meanwhile, the driving piece can drive the movable clamping plate and the fixed clamping plate to clamp the pipe fitting to be machined at the same time, clamping is convenient, operation is easy, and the machining efficiency is further improved.

Owner:芜湖三江高频焊管有限公司

A chamfering jig for a flat block at the end of a shaft

ActiveCN105127796BEasy chamfering operationPrecise positioningWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention discloses a chamfering clamping apparatus of a shaft end flat block. The chamfering clamping apparatus comprises a shaft end sleeve, a plug board and a fixed board, wherein the plug board is an arch-shaped baffle plate fixed on the inner wall of the left end of the shaft end sleeve; at least one arch-shaped baffle plate is arranged; the fixed board is fixedly connected onto two sides of the sleeve. According to the invention, the plug board is the arch-shaped baffle plate and is penetrated into the shaft end sleeve by a processing shaft; the arch-shaped baffle plate blocks a shaft shoulder; the shaft end flat block stretches out of the shaft end sleeve, and is convenient to position and easy for chamfering processing. Two shaft end sleeves are adopted to mount and fix two ends of a processed shaft in a sleeving manner, the shaft end flat blocks at two ends stretch out respectively, the plug board blocks the shaft shoulder and supports the shaft end flat blocks to prevent rotation, and an operator can conveniently carry out chamfering operation; the chamfering clamping apparatus is simple in structure and convenient to use, can ensure the chamfering quality without damaging the shaft surface, can alleviate the labor intensity, and improves the production efficiency.

Owner:JIHUA 3534 CLOTHING

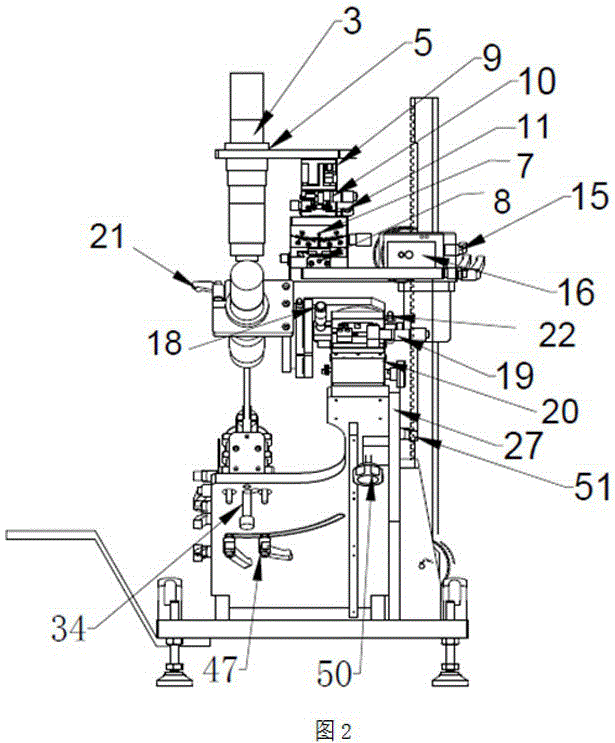

Eyeglass chamfering machine

InactiveCN102069436BMeet actual processing needsGood processing consistencyEdge grinding machinesEngineeringMechanical engineering

Owner:林小郎

Chamfering device for filter screen frames

PendingCN112894010AImprove chamfering efficiencyAvoid dumpingAutomatic control devicesFeeding apparatusElectric machineryKnife blades

The invention discloses a chamfering device for filter screen frames. The chamfering device comprises a workbench, a storage plate, a first hydraulic cylinder, a chamfering machine, a chamfering sleeve, chamfering tools, a first screw block, a first rotary motor, a first lead screw, a second lead screw, a chip suction device and an auxiliary rotating mechanism, wherein a mounting groove is formed in the top end of the workbench in a penetrating mode, sliding grooves are formed in the two sides of the storage plate in a penetrating mode, an anti-skid pad is fixedly embedded in the output end of the first hydraulic cylinder, the output end of the chamfering machine penetrates through a baffle, connecting grooves are formed in the periphery of the chamfering sleeve, the chamfering tools are connected into threaded holes in a threaded manner through fixing bolts and are fixed to the periphery of the chamfering sleeve, a connecting plate is fixed to the bottom of the first screw block, a driving bevel gear is fixed to the output end of the first rotary motor, and a driven bevel gear is fixed to the top end of the left side of the first lead screw. The chamfering device for the filter screen frames is provided with the chamfering sleeve, and the chamfering sleeve is connected with the chamfering tools in the threaded mode through the fixing bolts so that the chamfering tools can be replaced conveniently and can also be rapidly assembled and disassembled.

Owner:岚山环保科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com