Eyeglass chamfering machine

A chamfering device and spectacle lens technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of large differences in the wear of spectacle lenses, the quality of spectacle lenses cannot be guaranteed, and the chamfering effect of spectacle lenses is not ideal and other problems, to achieve the effect of good processing consistency, simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

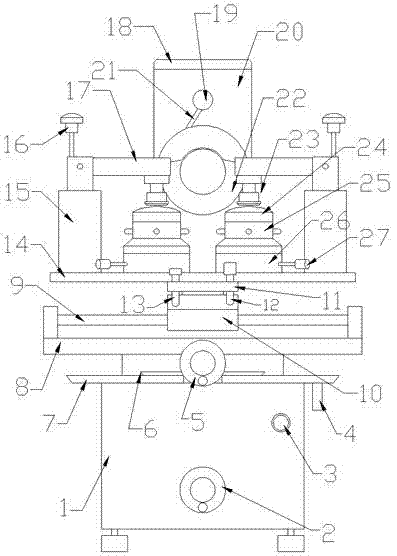

[0029] The main structure of the spectacle lens chamfering device of the present invention includes a base 1, a motor, a chamfering wheel 22, and a clamping assembly. The motor is connected with the bevel wheel 22, and drives the bevel wheel 22 to rotate during work. The clamping assembly is used for clamping the spectacle lens. After the spectacle lens is clamped, the clamping component can be moved by hand to make the spectacle lens rotate. There is a frustoconical chamfering surface on the chamfering wheel 22, and the chamfering surface is used as the processing surface of the chamfering wheel 22 for processing the peripheral edge of the spectacle lens, thereby processing a blunt chamfer at the peripheral edge of the spectacle lens noodle. The base 1 is a closed shell, the motor is arranged in the base 1, and the base 1 is provided with a button 3 for controlling whether the motor is working or not. Also be provided with lifting handwheel on the front panel of base 1, tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com