Patents

Literature

39results about How to "Meet actual processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

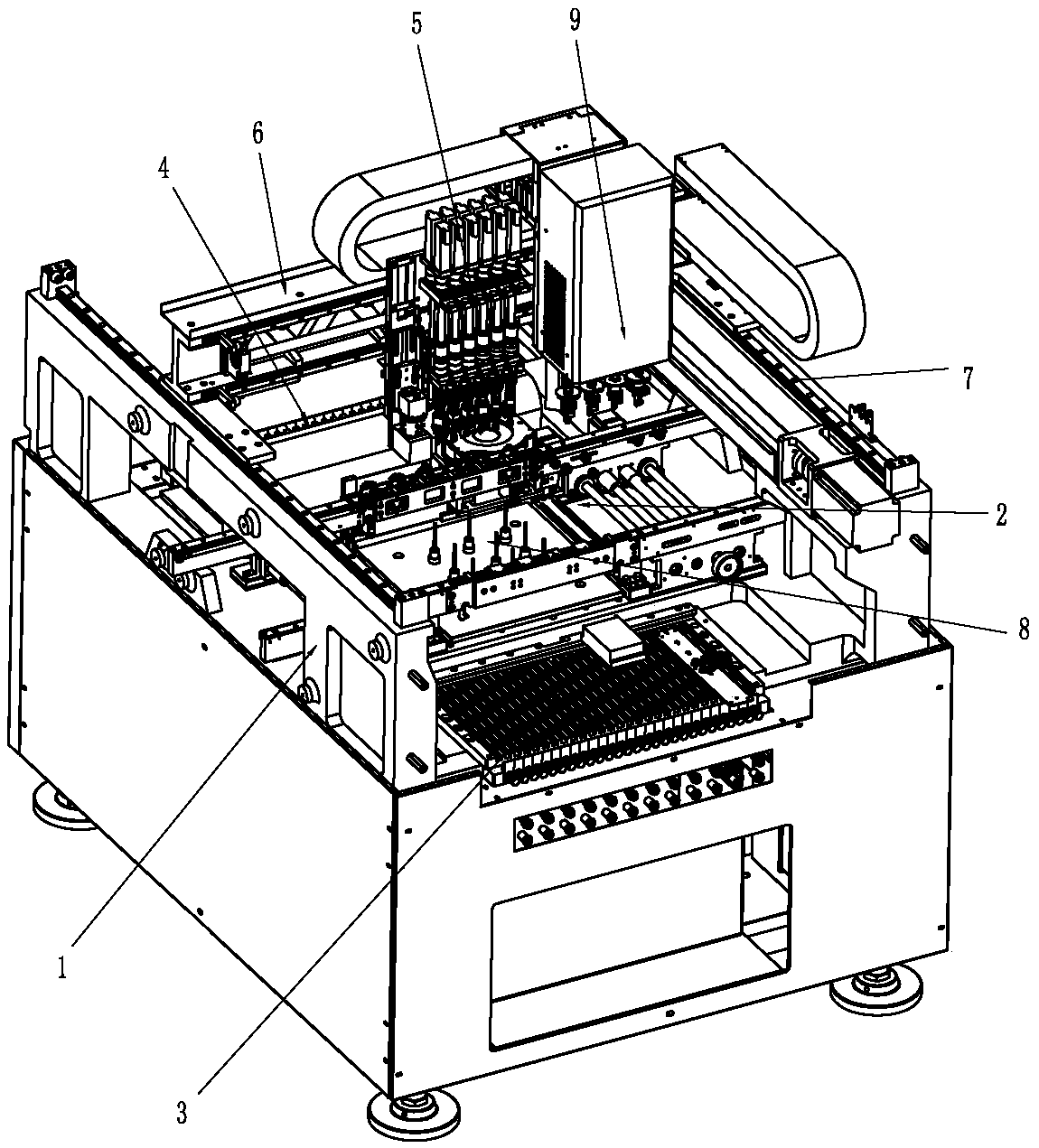

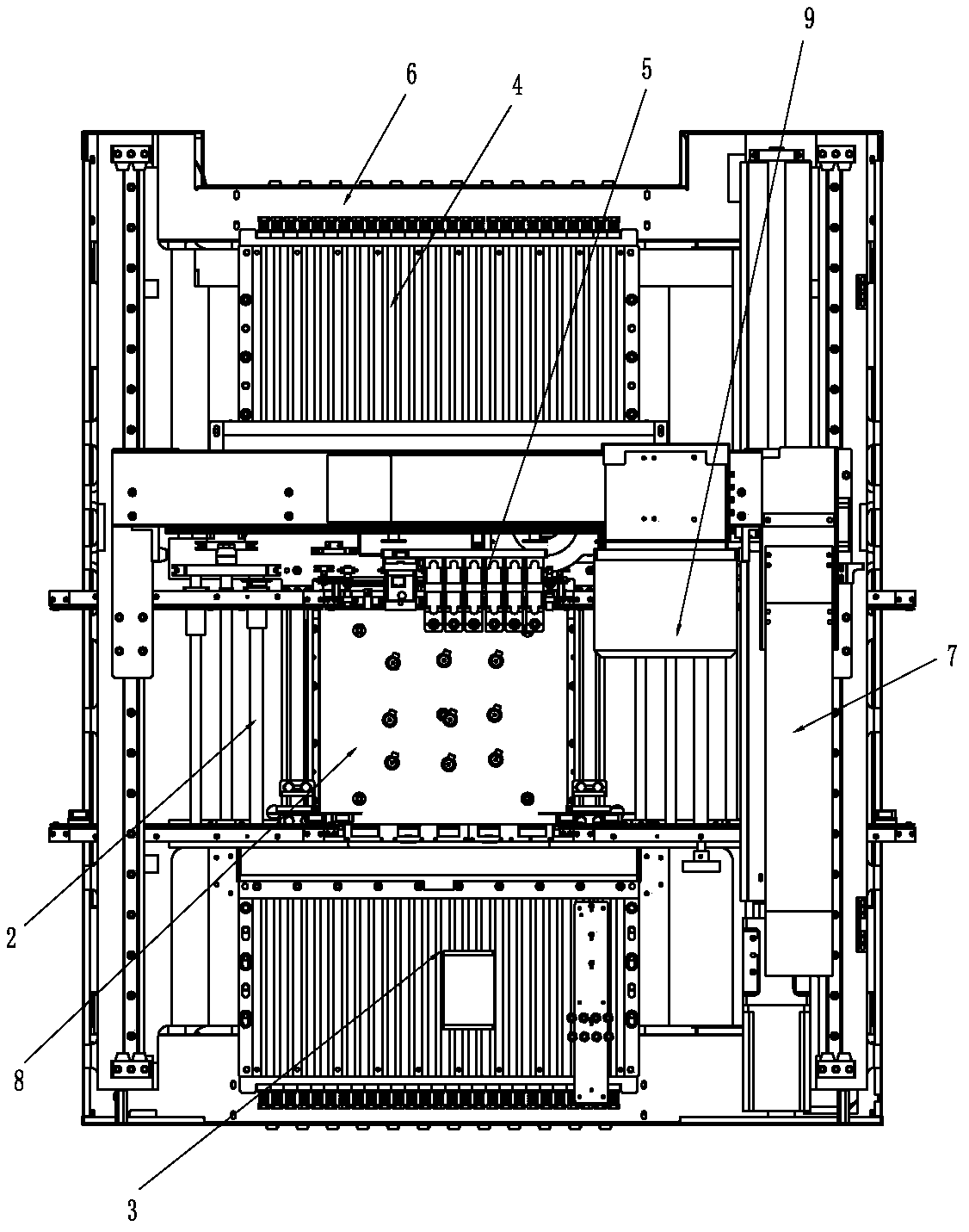

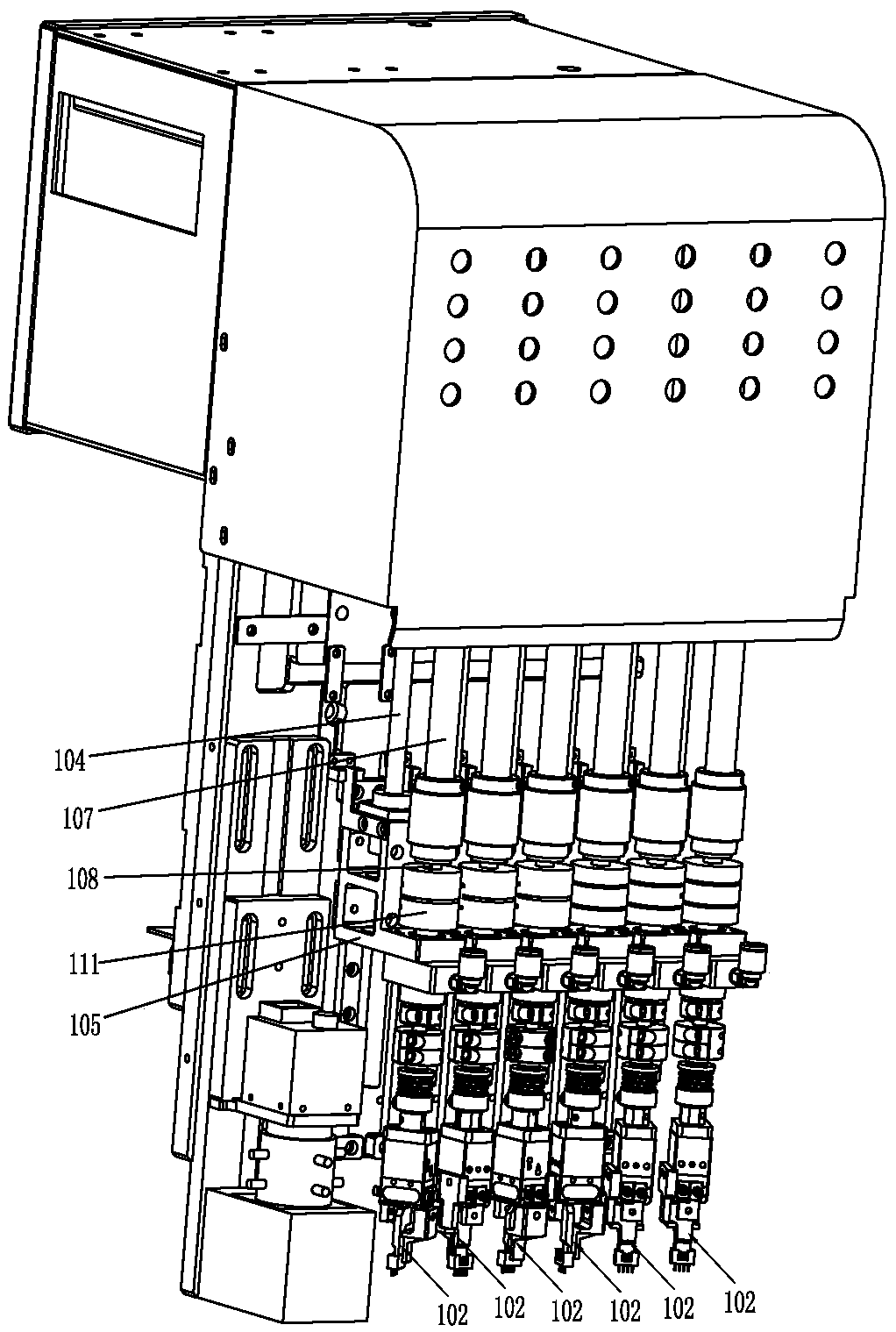

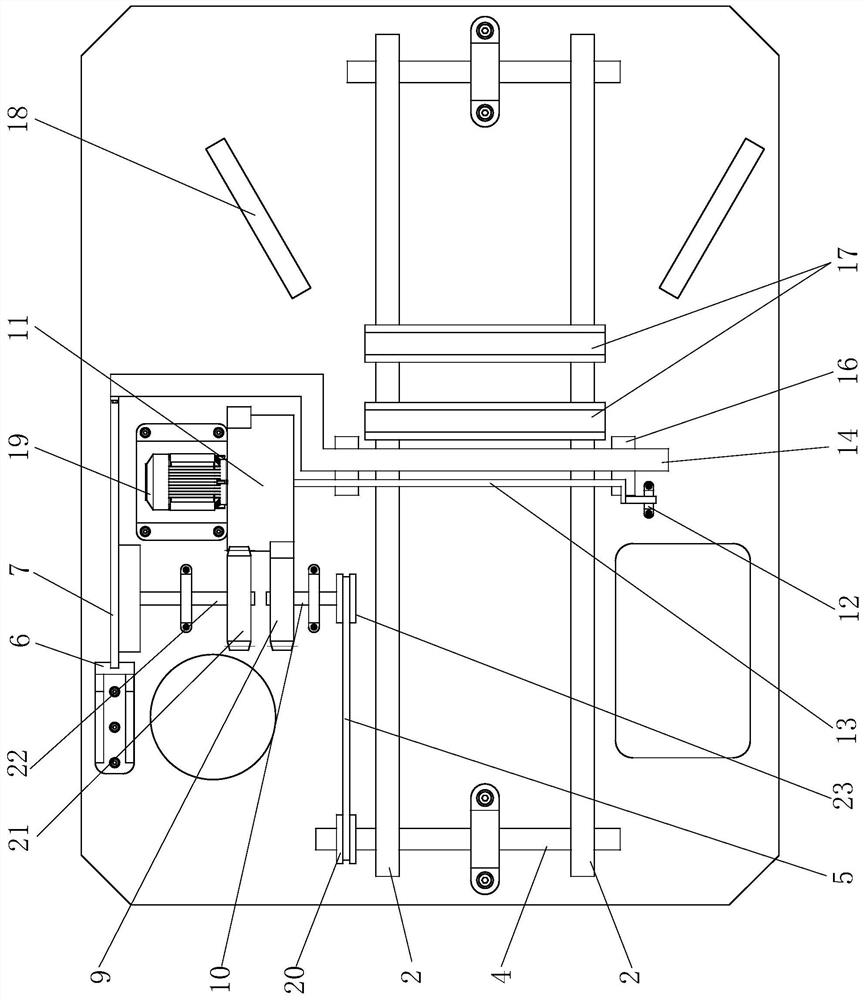

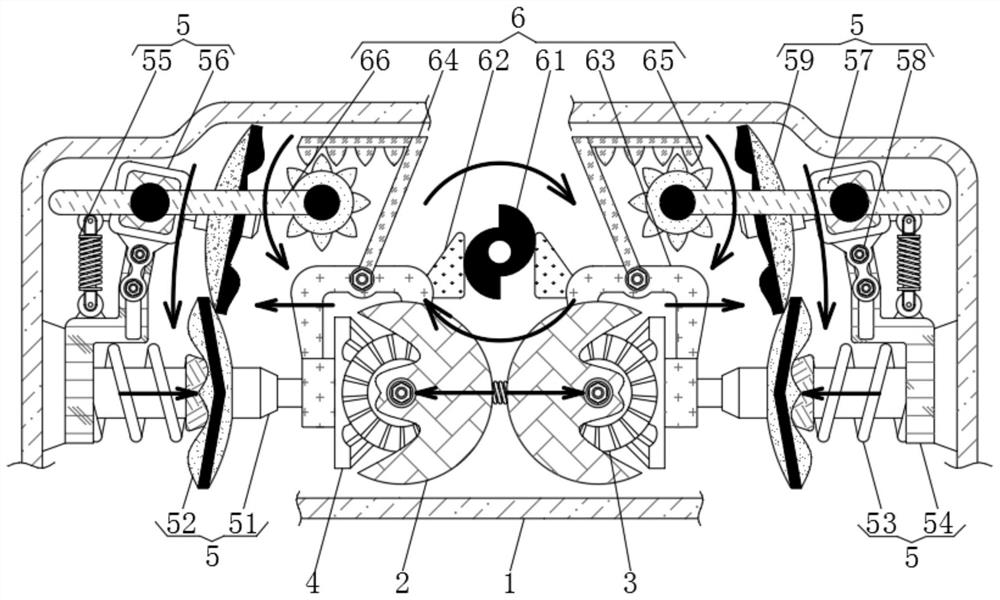

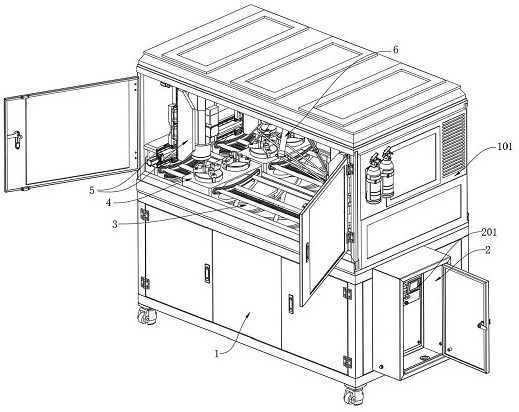

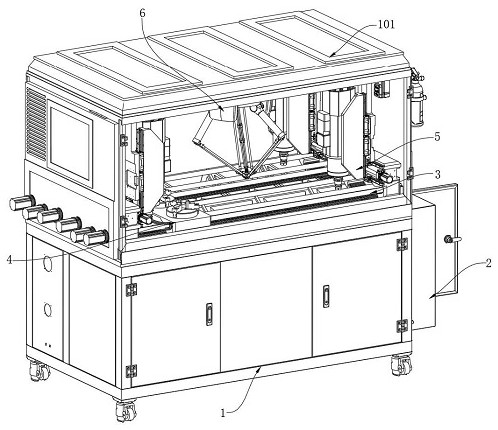

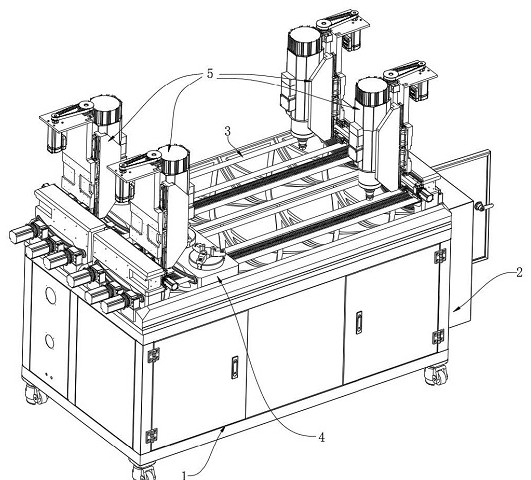

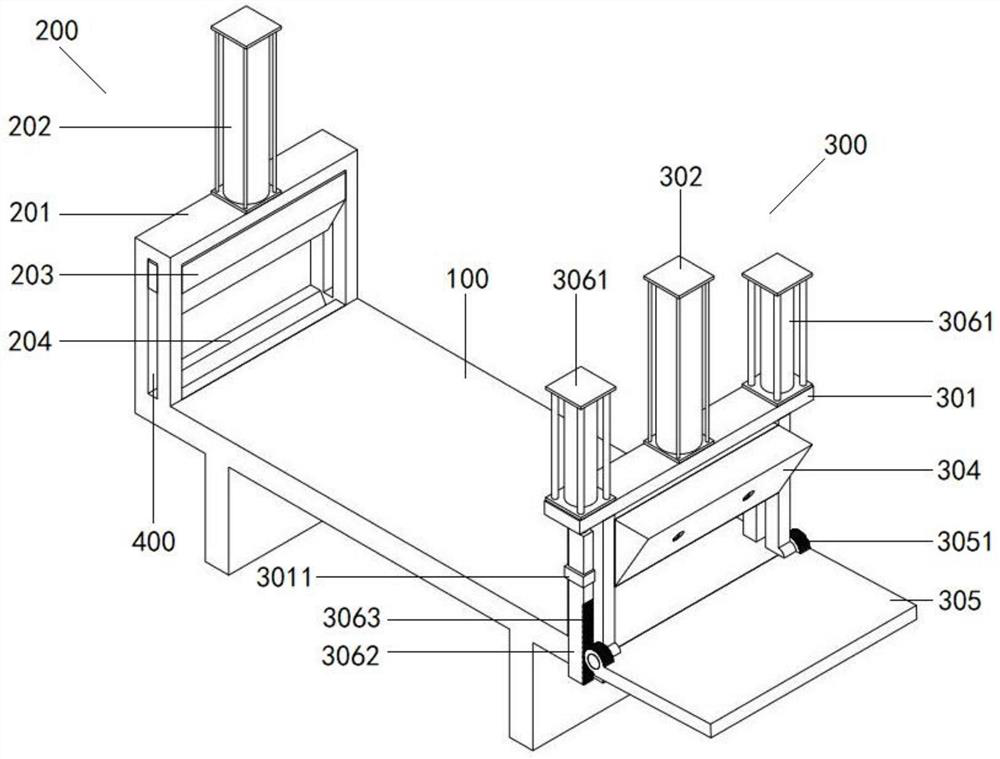

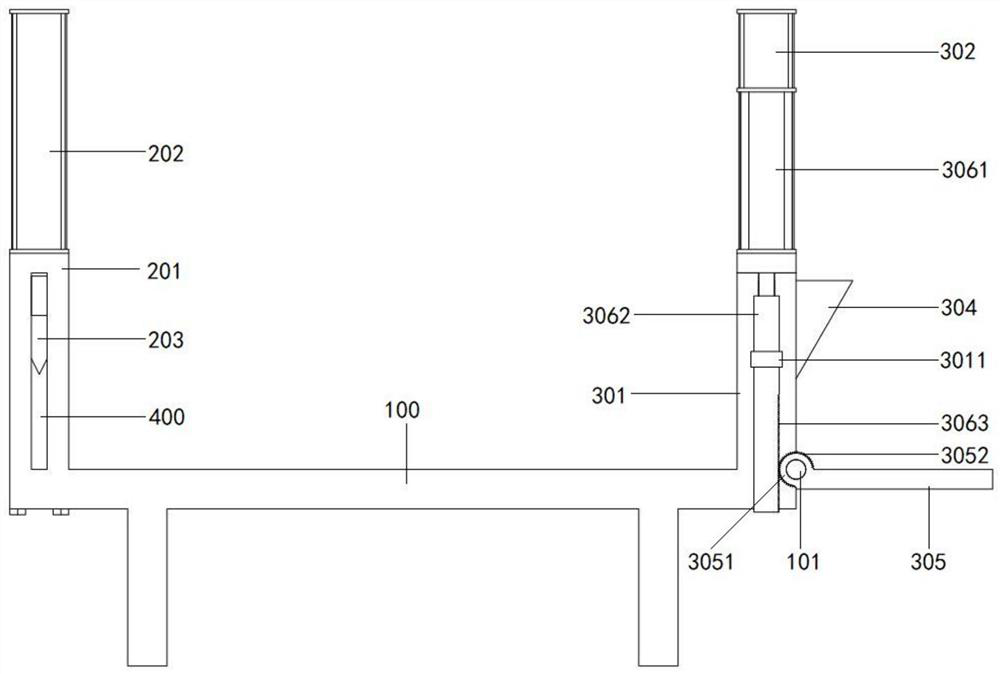

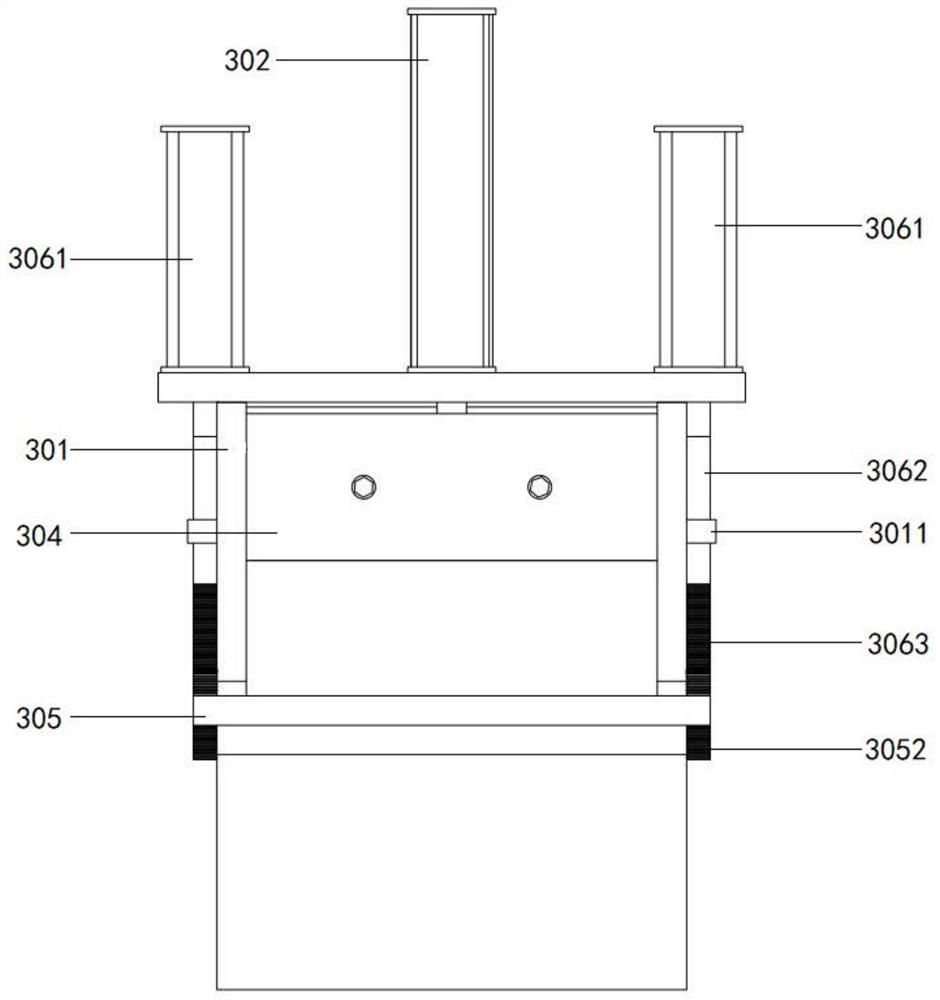

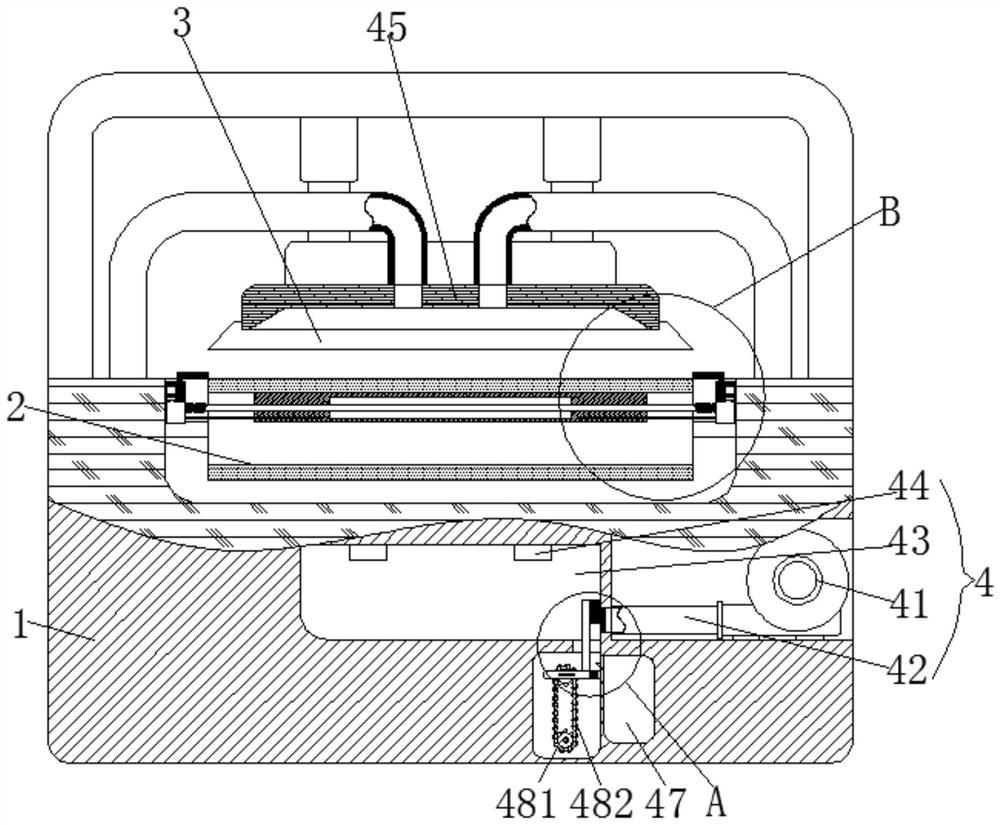

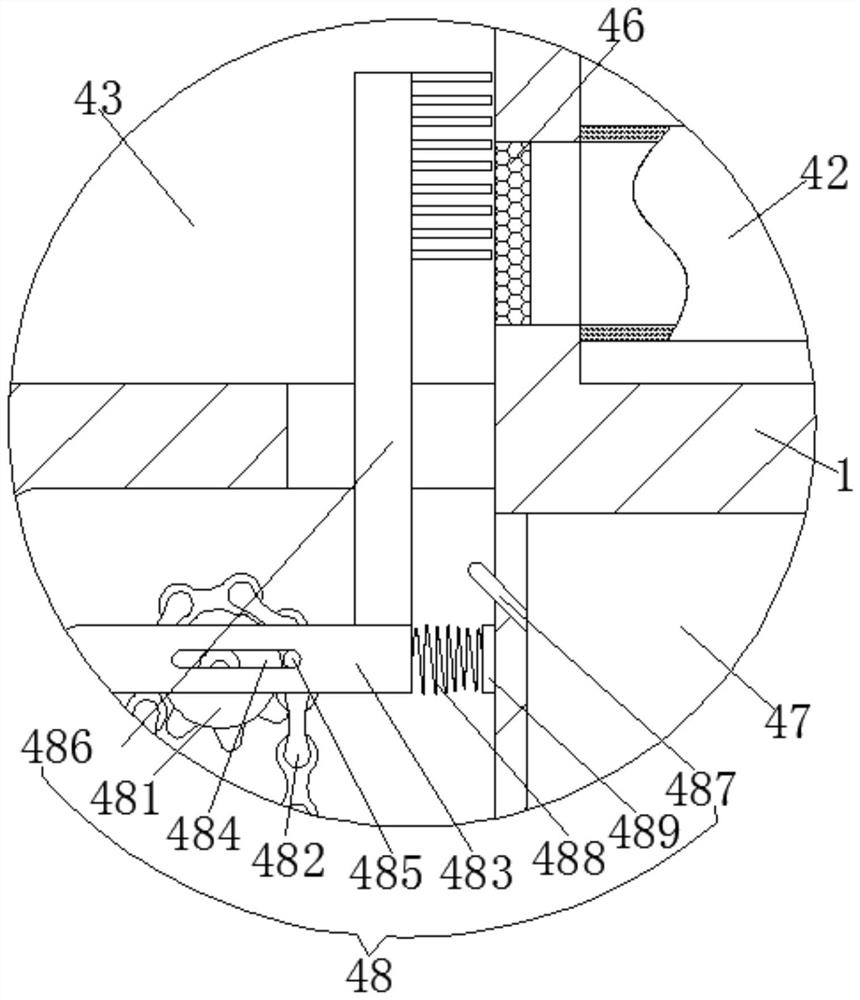

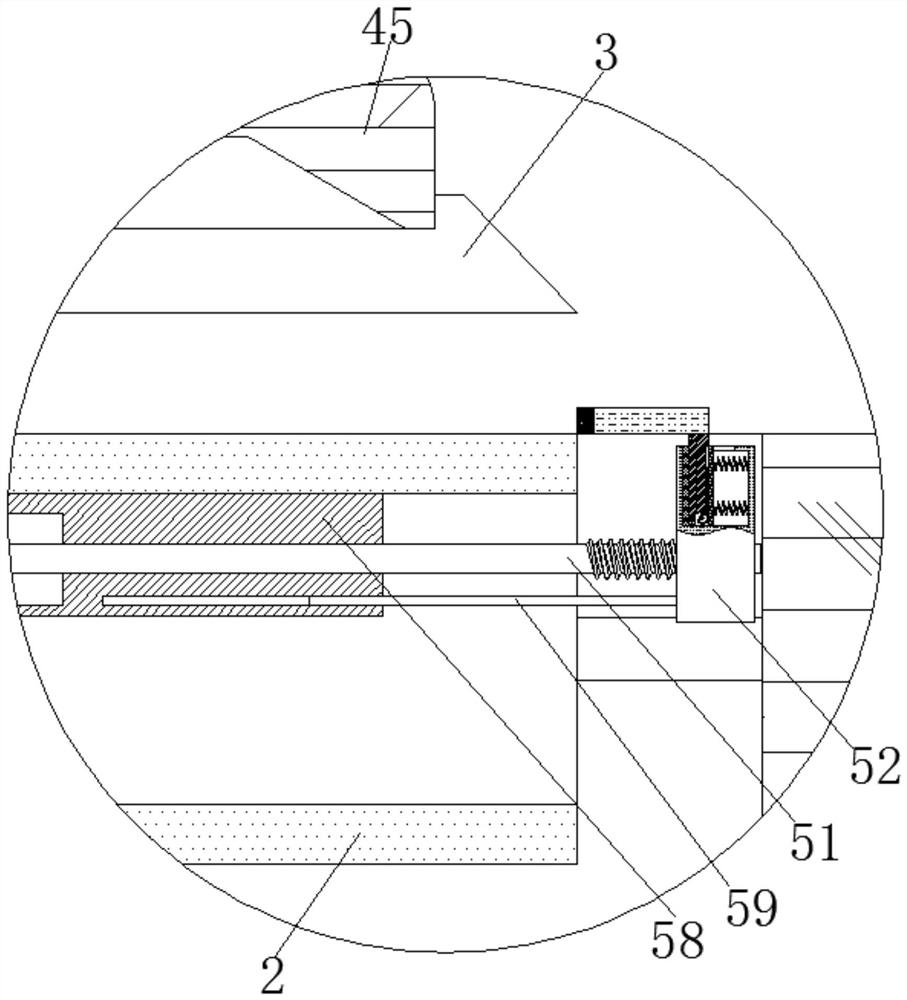

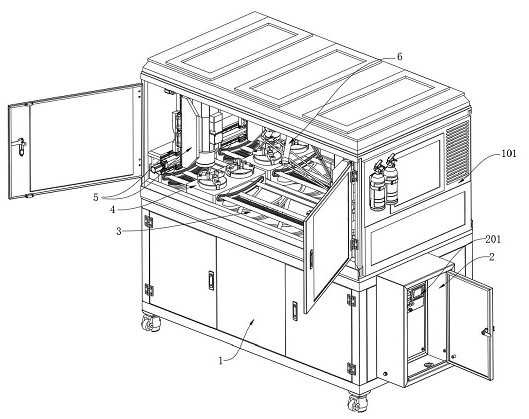

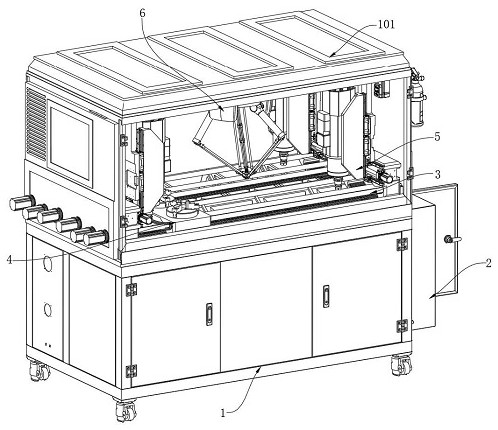

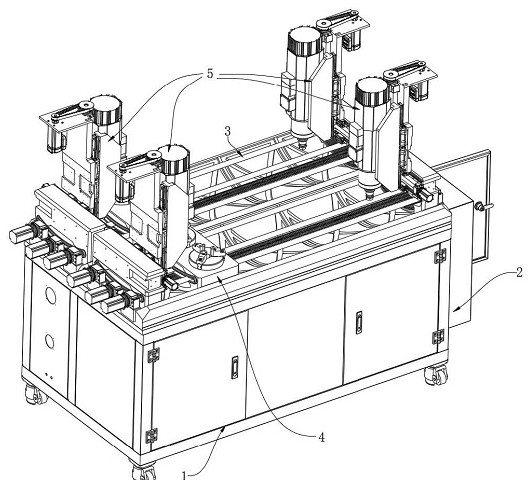

Efficient and accurate automatic component insertion machine

PendingCN109462976AHigh running precisionPrecise positioningElectrical componentsEngineeringInsertion - action

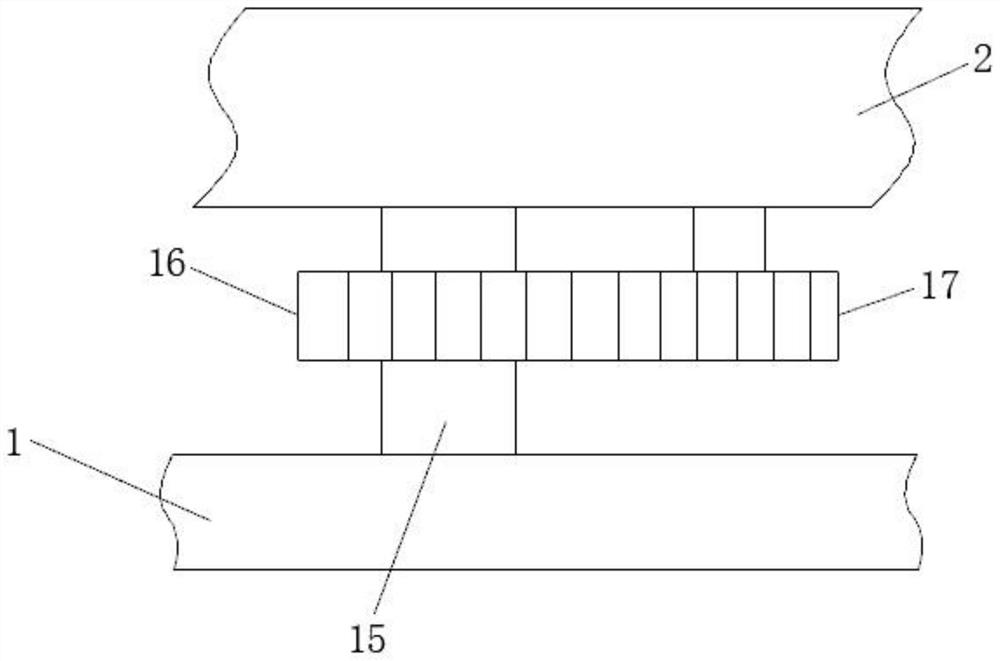

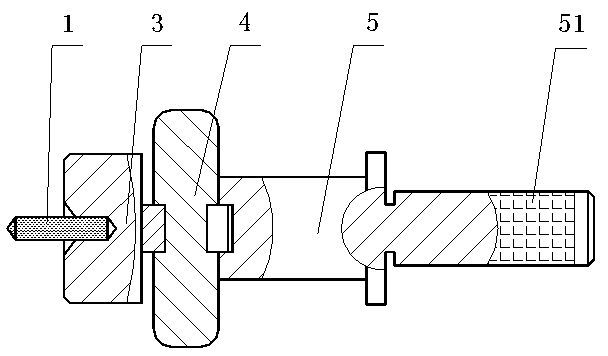

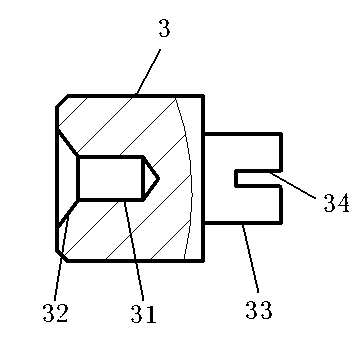

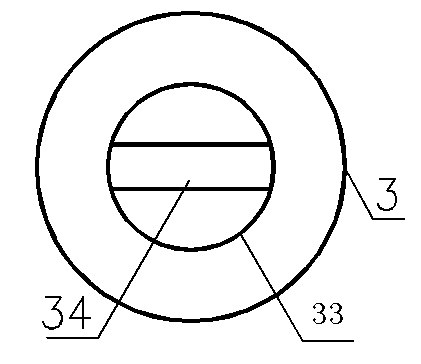

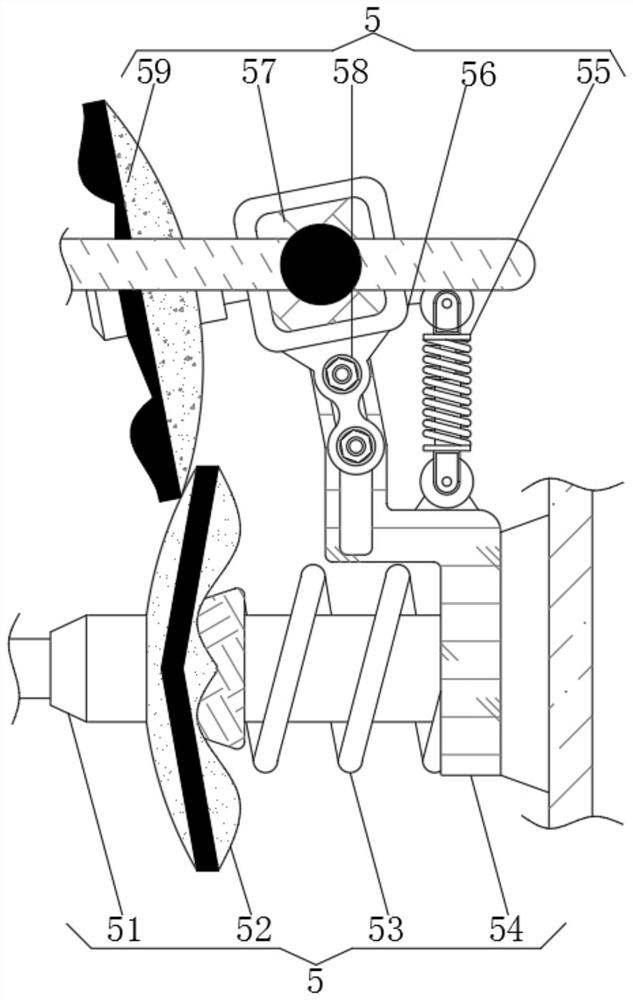

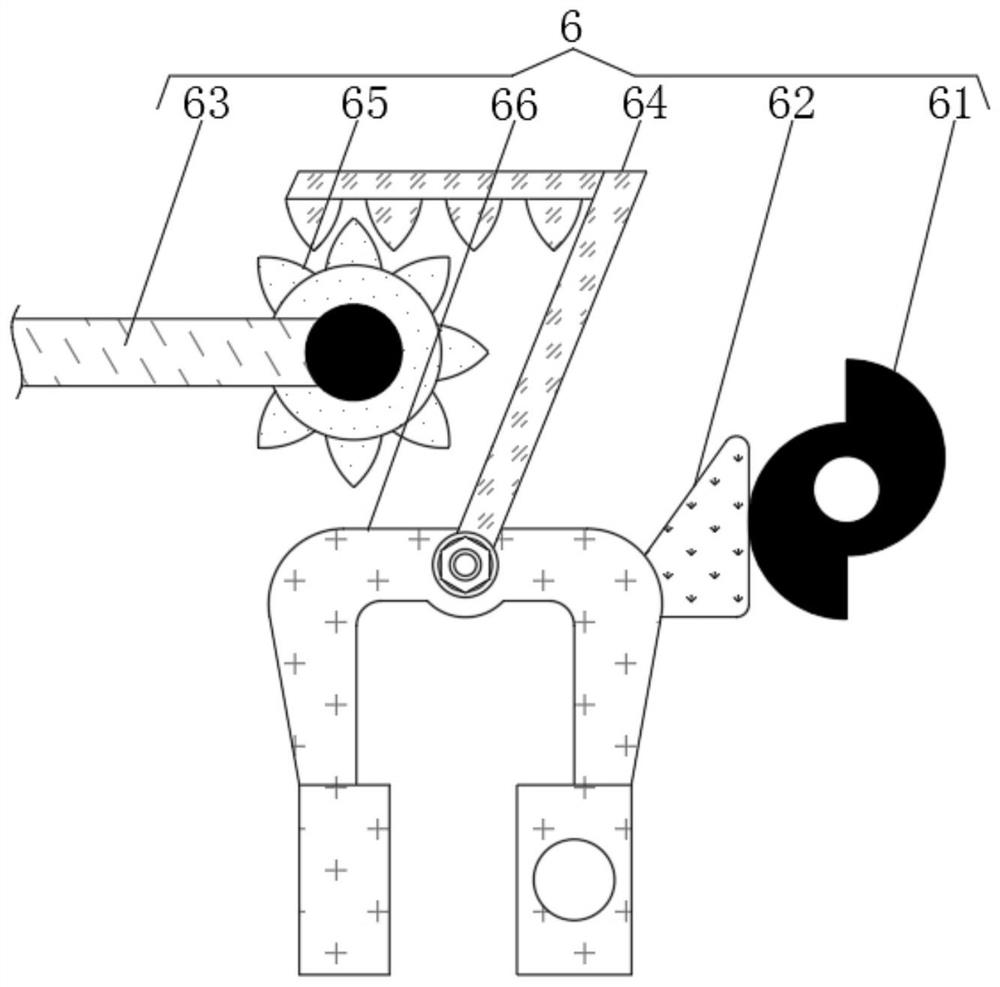

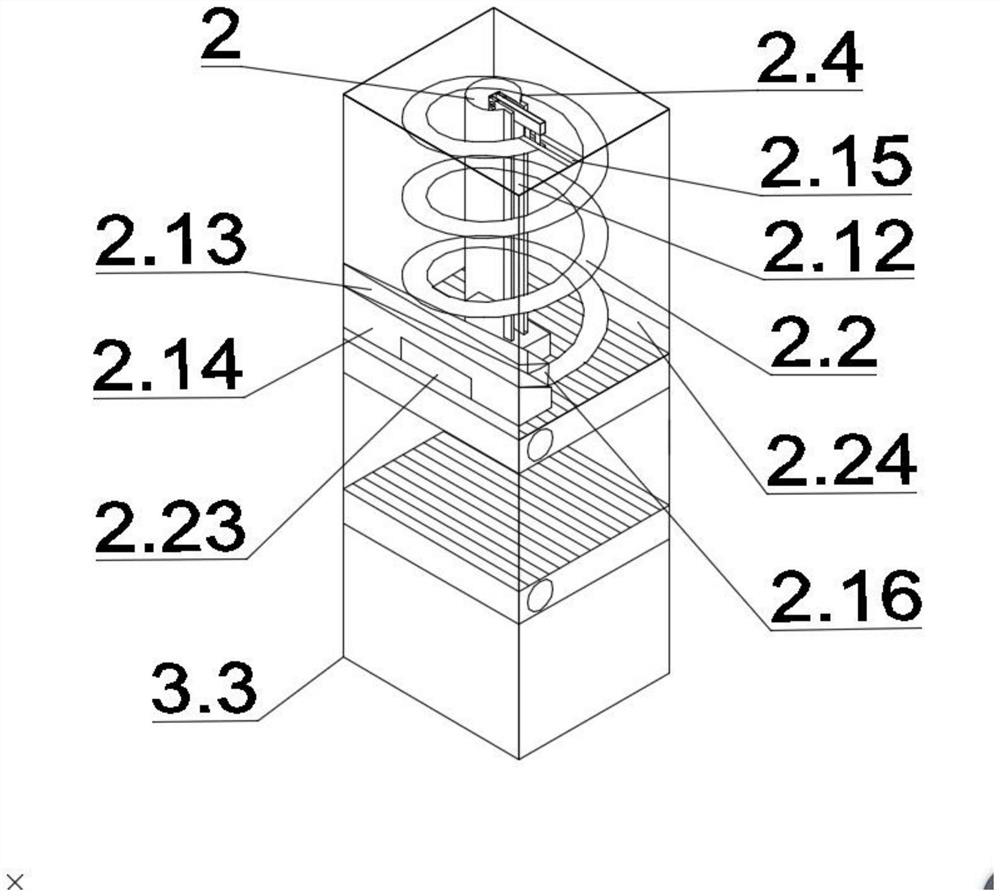

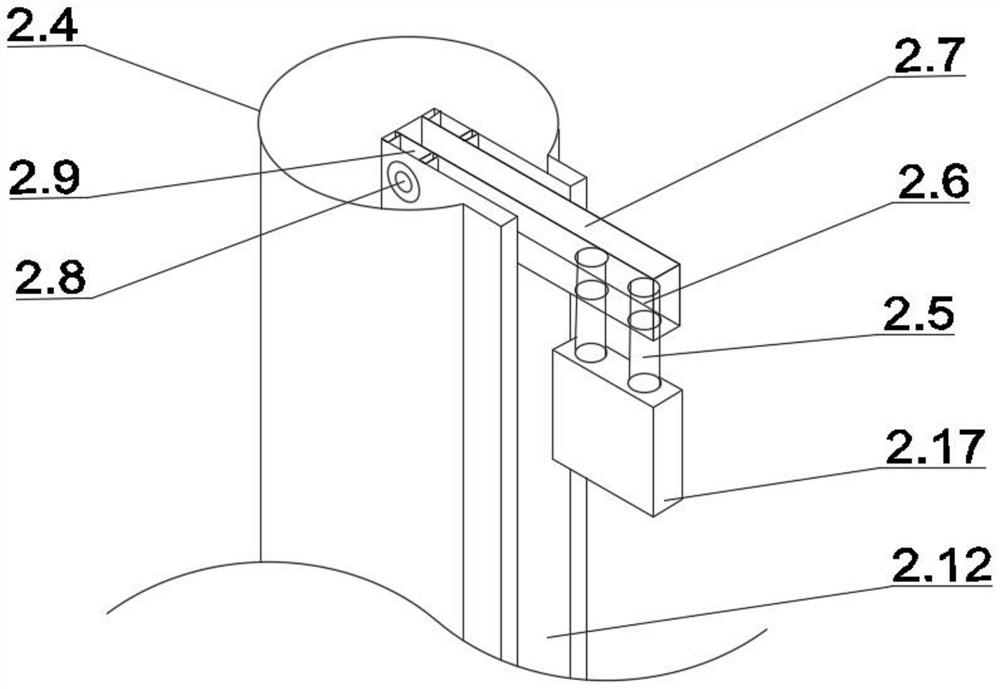

The invention discloses an efficient and accurate automatic component insertion machine. The component insertion machine comprises a rack assembly, and a PCB conveying track, a feeding device, a discharging device and a component insertion machine head which are arranged on the rack assembly; the feeding device and the discharging device are arranged on the two sides of the PCB conveying track respectively; the component insertion machine head is movably arranged above the PCB conveying track; the PCB conveying track comprises a fixed track assembly and a movable track assembly which are arranged oppositely; an adjustable conveying track is formed between the fixed track assembly and the movable track assembly, and can be applied to the component insertion machining of PCBs with various width specifications, so that the universality of equipment is improved; the component insertion machine head comprises a machine head base and a plurality of component insertion mechanical arms mountedon the machine head base; each component insertion mechanical arm is independently connected with a driving assembly; and each driving assembly comprises a lifting motor, a lifting screw rod, a sliding seat, a rotary motor, a spline shaft sleeve and a spline shaft. Therefore, the running precision of the automatic component insertion machine is higher, the precision of a component insertion action is higher, and the action is quicker and more efficient.

Owner:东莞市南部佳永电子有限公司

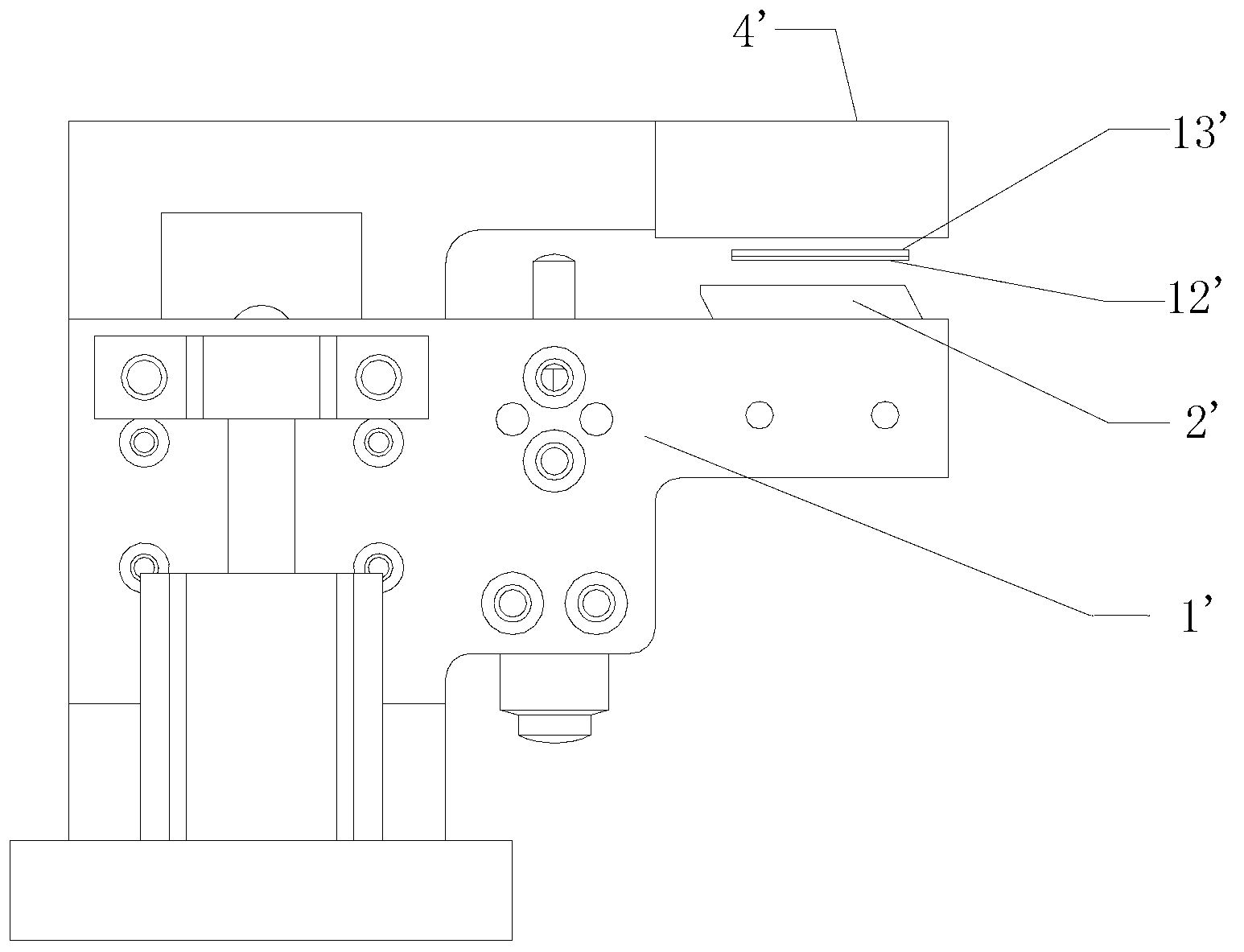

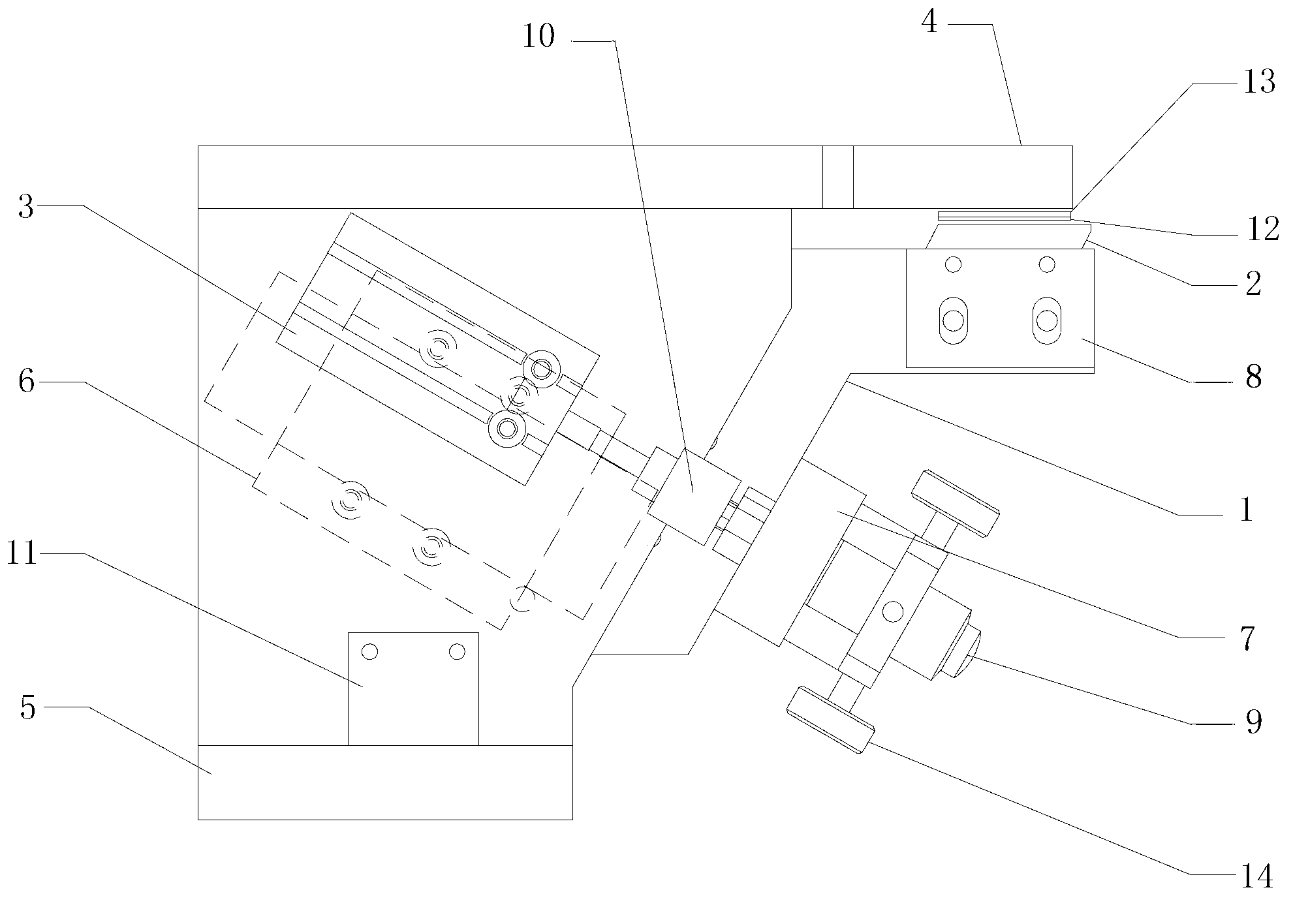

Precise electric-conducting adhesive film cutting device

The invention relates to the technical field of transmission mechanisms, and discloses a precise electric-conducting adhesive film cutting device comprising a substrate board. A cutter moving block, a power unit and an air cylinder system driven by the power unit and driving the cutter moving block to move are arranged on the substrate board, and included angle between moving direction of the cutter moving block and a horizontal plane is an acute angle. With the precise electric-conducting adhesive film cutting device, conventional cutting mechanisms in production lines are essentially improved, and a beveling method is adopted to cut, and no damages on productions during cutting are caused. The precise electric-conducting adhesive film cutting device is high in automation degree, cutting process can be precisely controlled, operation is facilitated and rapid, and production efficiency is greatly improved.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

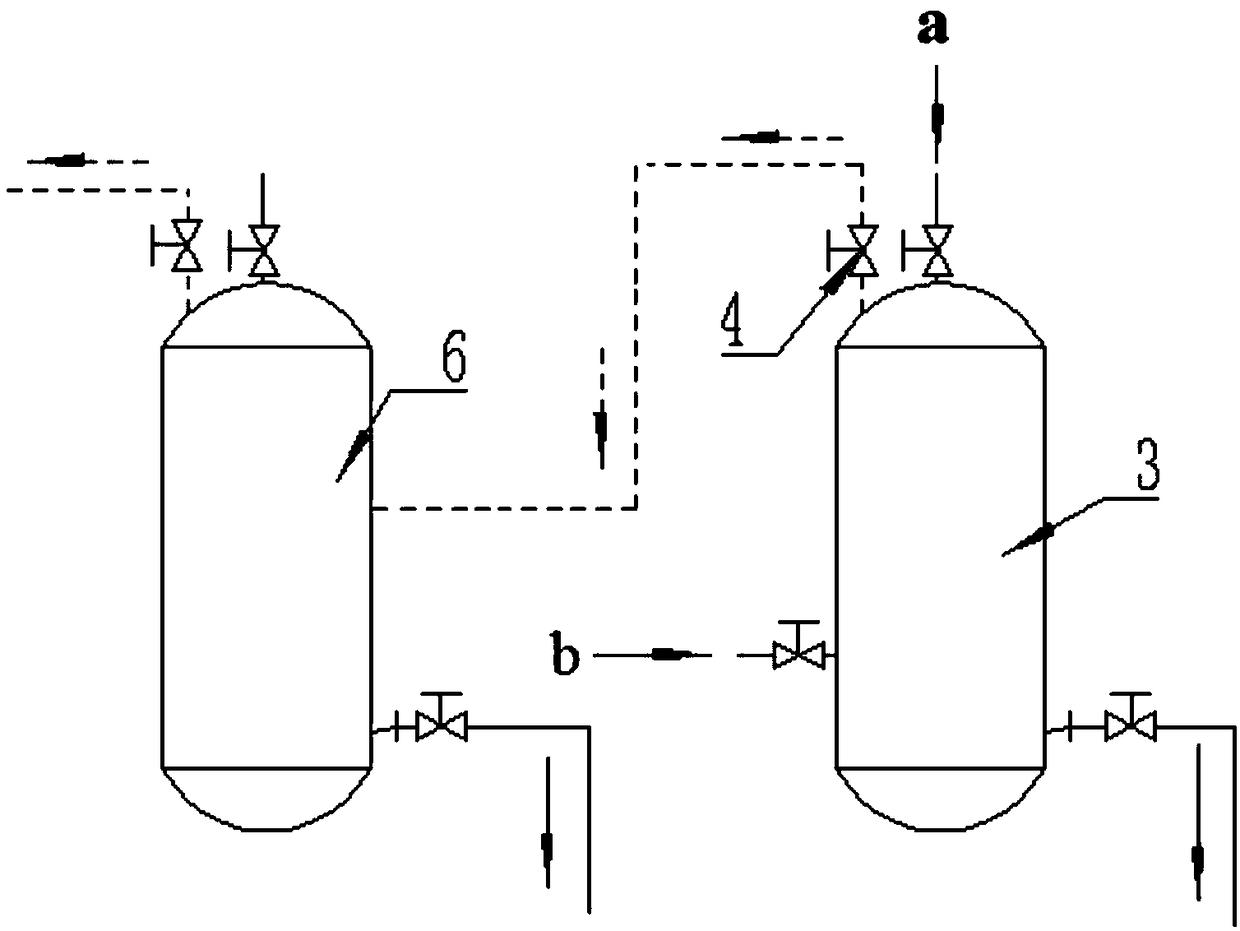

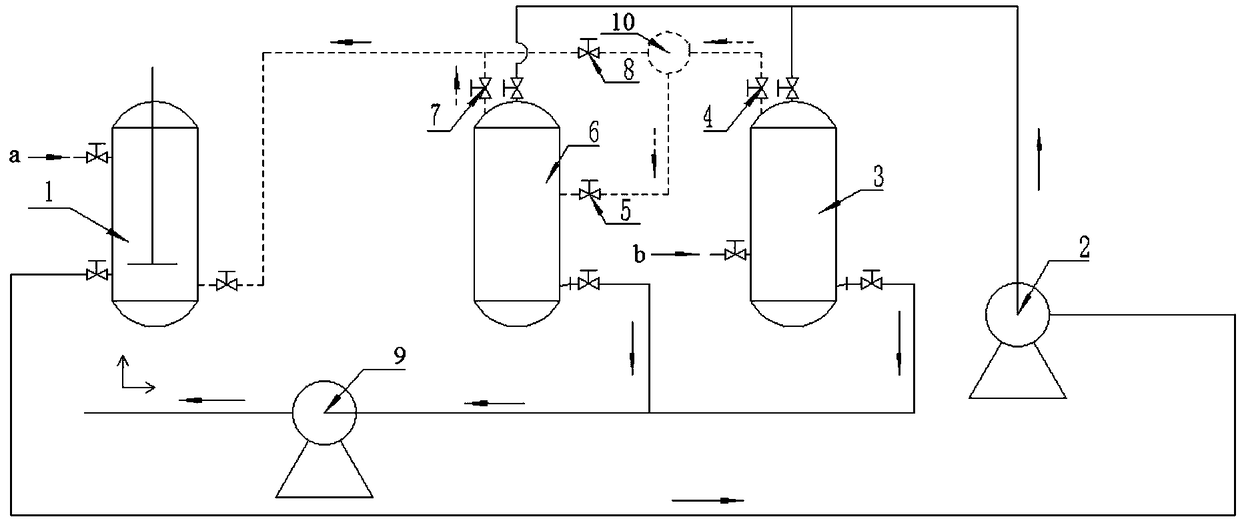

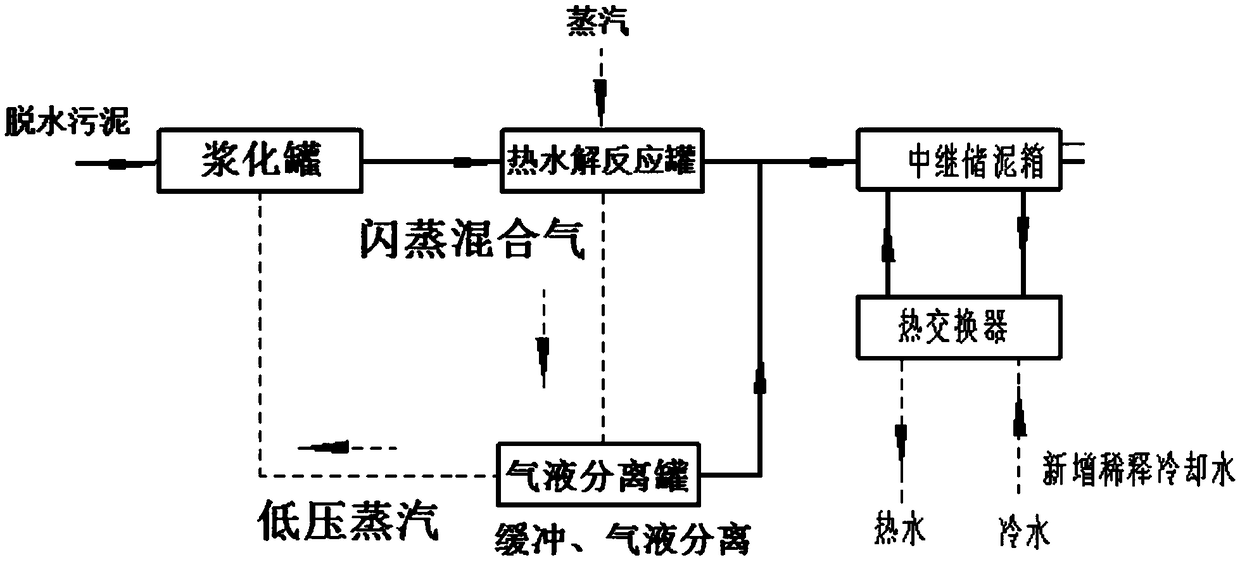

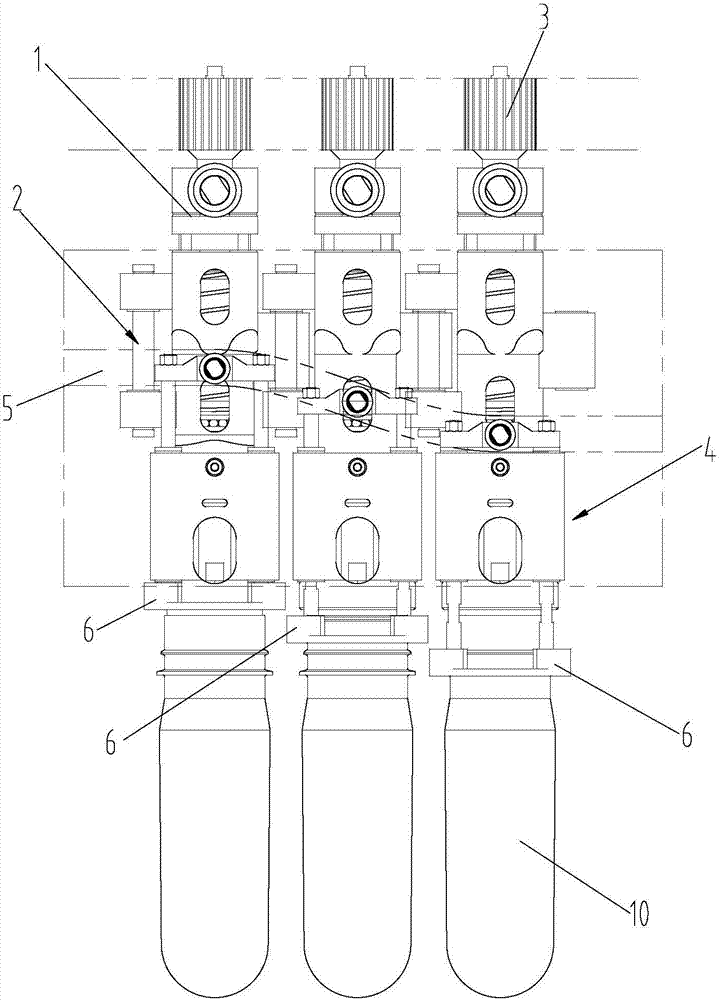

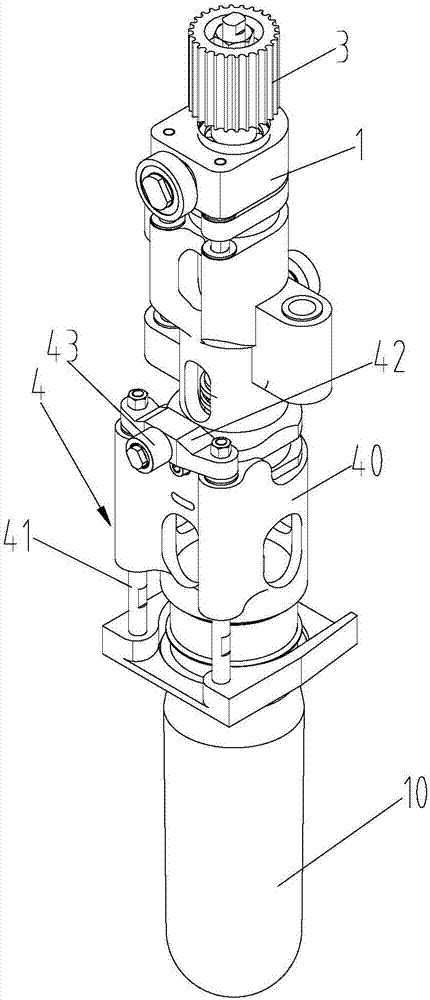

Pyrohydrolysis flash separation device, pyrohydrolysis flash separation technology, pyrohydrolysis system and pyrohydrolysis technology

PendingCN108840548ASmall pressure fluctuationsReduce vibrationSludge treatment by thermal conditioningSludge treatment by pyrolysisTreatment needRelief valve

The invention discloses a pyrohydrolysis flash separation device, a pyrohydrolysis flash separation technology, a pyrohydrolysis system and a pyrohydrolysis technology. The pyrohydrolysis flash separation device comprises a pyrohydrolysis reaction tank and a gas-liquid separation tank which are communicated through a pipe, wherein a pressure relief valve is arranged on the pipe therebetween. By the pyrohydrolysis flash separation technology, the pyrohydrolysis flash separation device is used for flash separation. The pyrohydrolysis system comprises a slurrying tank, a mud inlet pump, the pyrohydrolysis reaction tank and the gas-liquid separation tank which are sequentially communicated end to end through pipes; the pressure relief valve is arranged on the pipe between the pyrohydrolysis reaction tank and the gas-liquid separation tank. By the pyrohydrolysis technology, the pyrohydrolysis system is used for pyrohydrolysis. The pyrohydrolysis flash separation device and the pyrohydrolysis system have the advantages of small floor area, low production cost, a high safety production factor and the like, and the pyrohydrolysis flash separation technology and the pyrohydrolysis technology have the advantages of a simple process, easy operation, high treatment efficiency, a good gas-liquid separation effect and the like, so that actual treatment needs can be met and an application prospect is very good.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

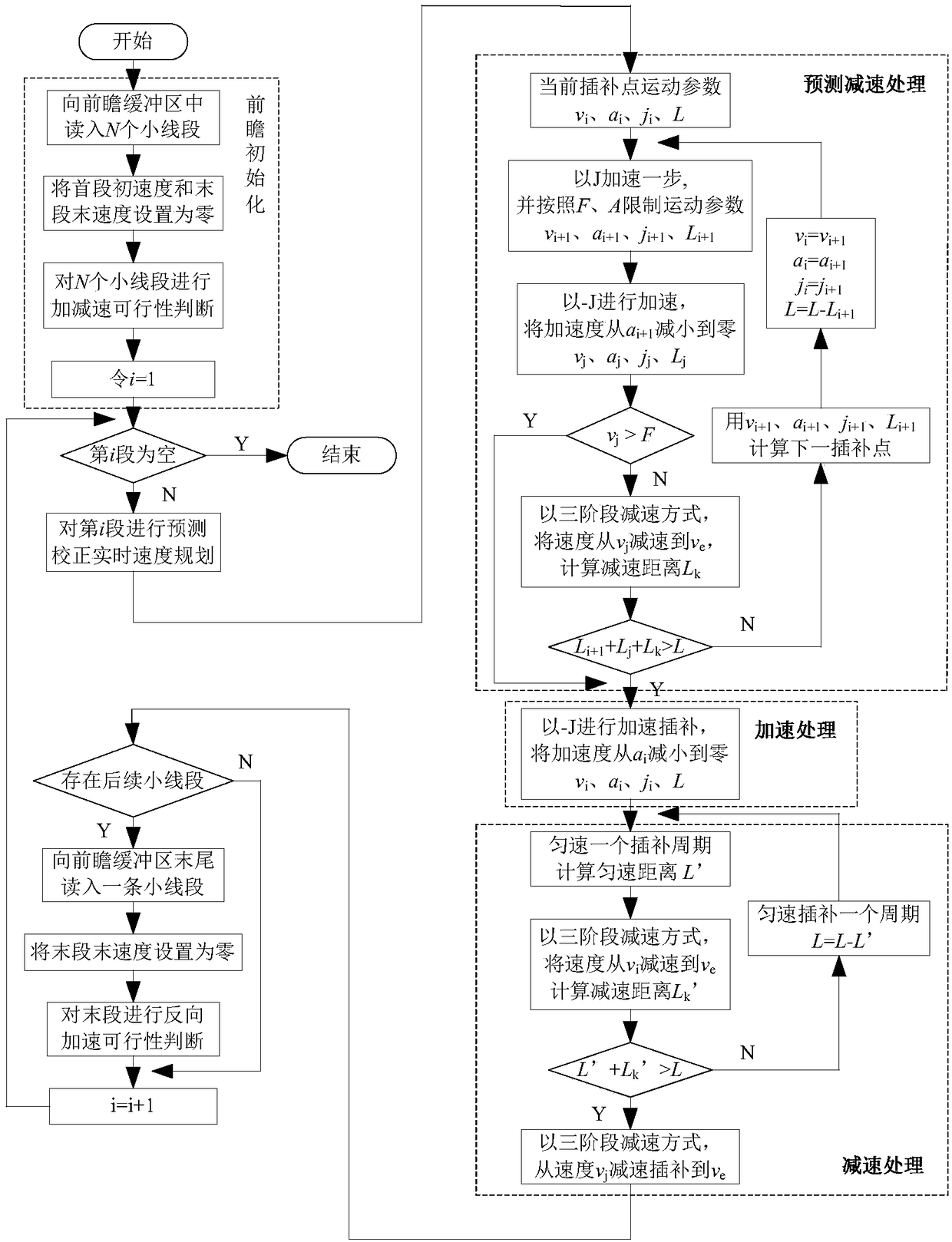

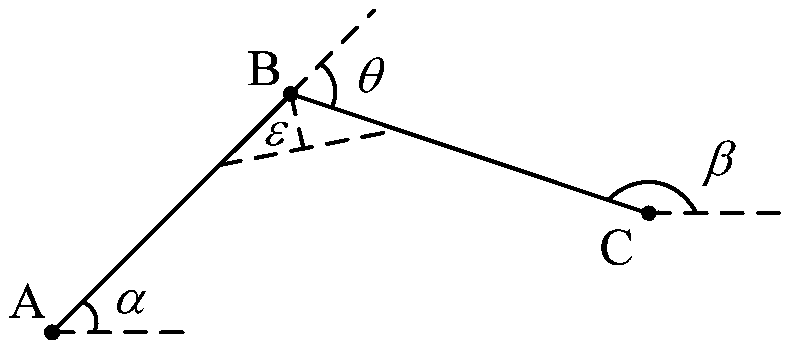

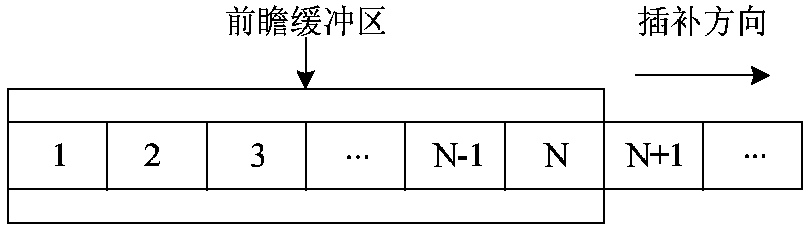

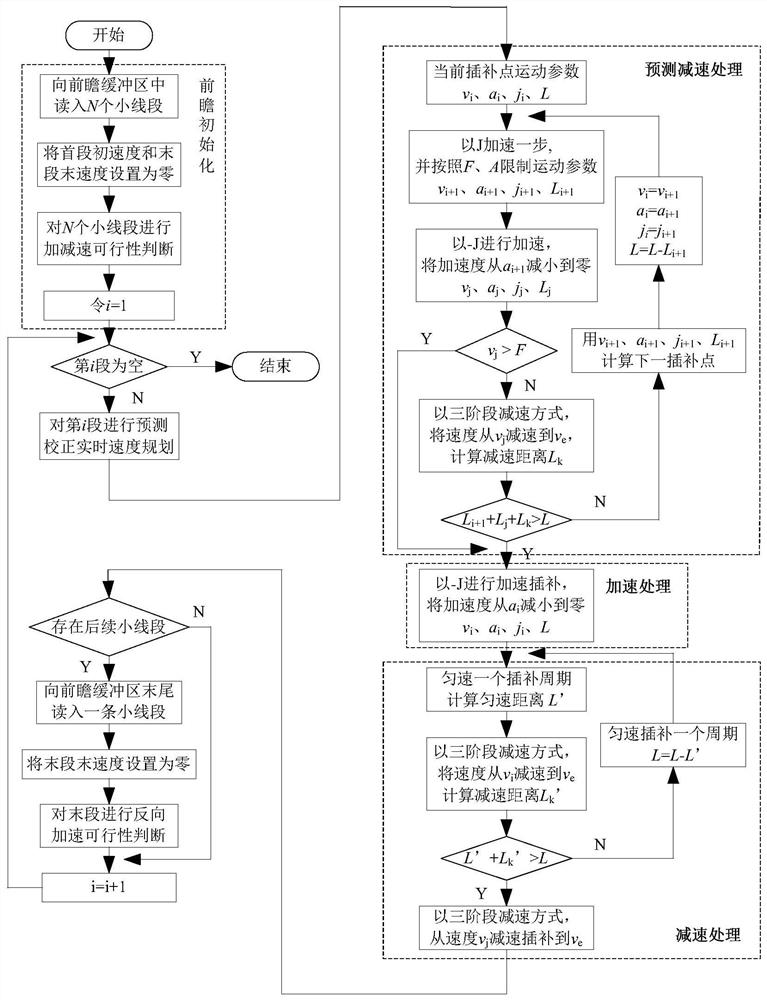

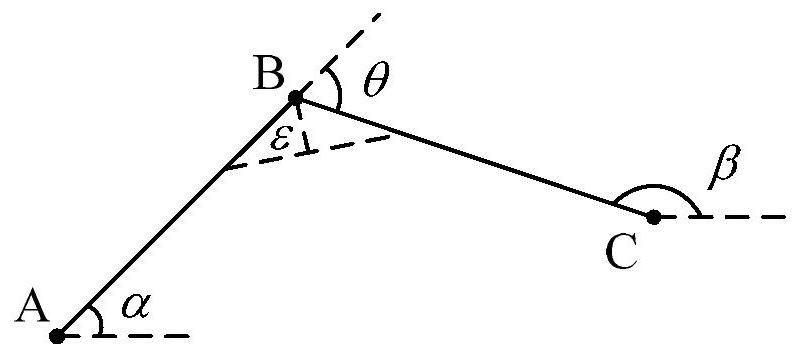

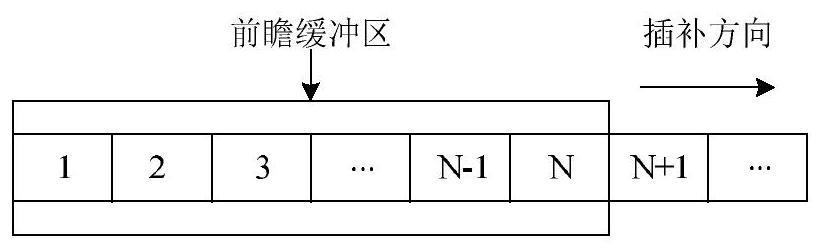

Real-time flexible acceleration and deceleration control algorithm based on adaptive prospection and predicative correction

ActiveCN109426151ASimple controlEnable real-time velocity planningAdaptive controlSelf adaptiveProcessing accuracy

The invention relates to a real-time flexible acceleration and deceleration control algorithm based on adaptive prospection and predictive correction, which comprises the steps of carrying out prospection processing by adopting an acceleration and deceleration feasibility judgment condition to ensure the accessibility of acceleration and deceleration and the real-time performance of prospection; calculating the feeding speed of the next interpolation cycle in real time by applying a predication correction method to ensure the continuous change of speed and acceleration in the processing process; and adjusting the current prospection processing result and speed planning result under the premise of meeting the dynamic performance of machine tools to timely respond to the change of machine tool parameters in the processing. The real-time flexible acceleration and deceleration control algorithm is high in processing speed and processing accuracy. The real-time flexible acceleration and deceleration control algorithm can realize real-time flexible acceleration and deceleration control for a numerical control system, supports dynamic adjustment, improves the processing efficiency and processing quality and meets the actual processing requirements.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

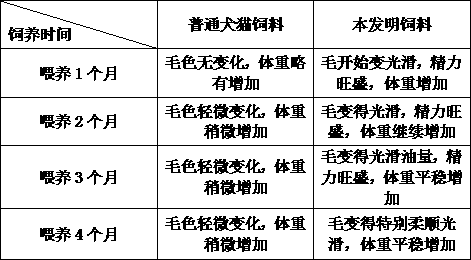

Dog-cat liquid wet food taking enzymolysis meat as main raw material and preparation method of food

InactiveCN108684967AIncrease concentrationMeet actual processing needsAnimal feeding stuffAccessory food factorsLocust bean gumHydrolysate

The invention relates to a dog-cat liquid wet food taking enzymolysis meat as a main raw material. The food is characterized by comprising the following components in percentage by weight: 40 to 50 percent of a fresh meat enzymolysis liquid, 5 to 8 percent of starch, 0.3 to 0.5 percent of locust bean gum, 0.8 percent of lysine, 0.2 percent of taurine, 0.3 to 0.5 percent of composite vitamin, 0.3 to 0.5 percent of composite mineral, 0.1 to 0.5 percent of beer yeast, 0.1 to 0.2 percent of salt and the balance of water. The product is a thick semi-liquid, is easy to lick and ea for pet dogs and catst, rich in nutrients, delicious in taste and easy to digest and absorb for pets. The method prolongs the reaction time of enzymolysis, improves the concentration of the hydrolysate while ensuring the ful enzymolysis of soup base, and improves the viscosity of the product without adding other raw materials.

Owner:青岛双安生物科技有限公司

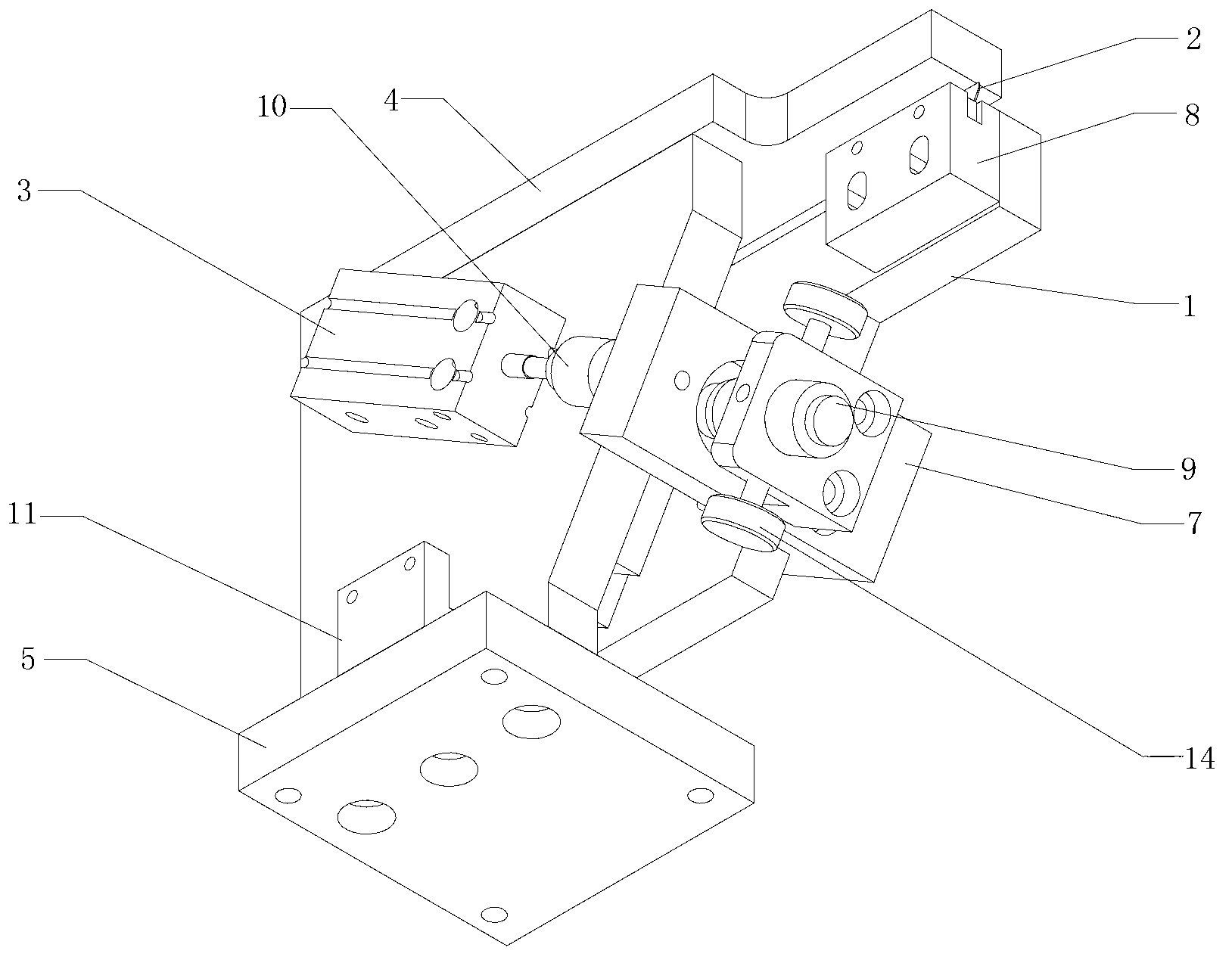

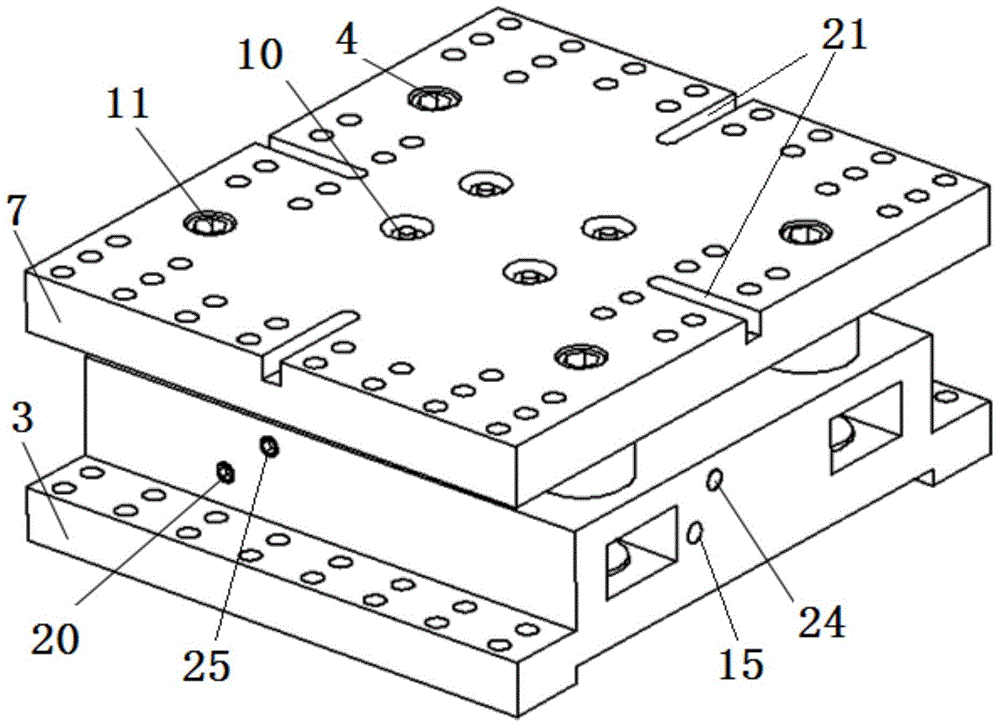

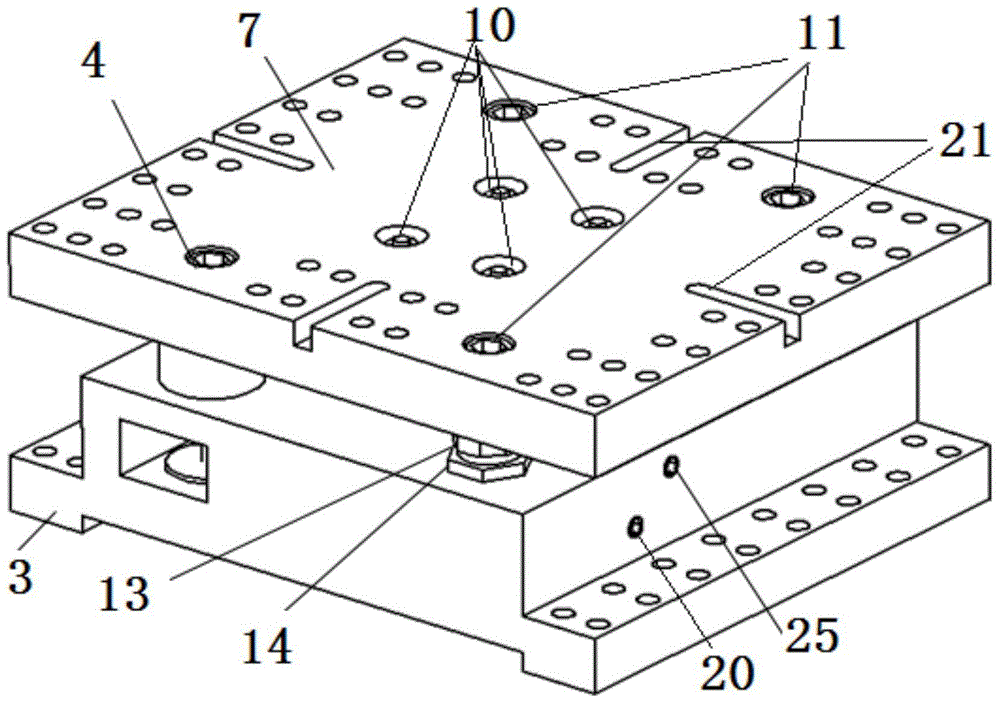

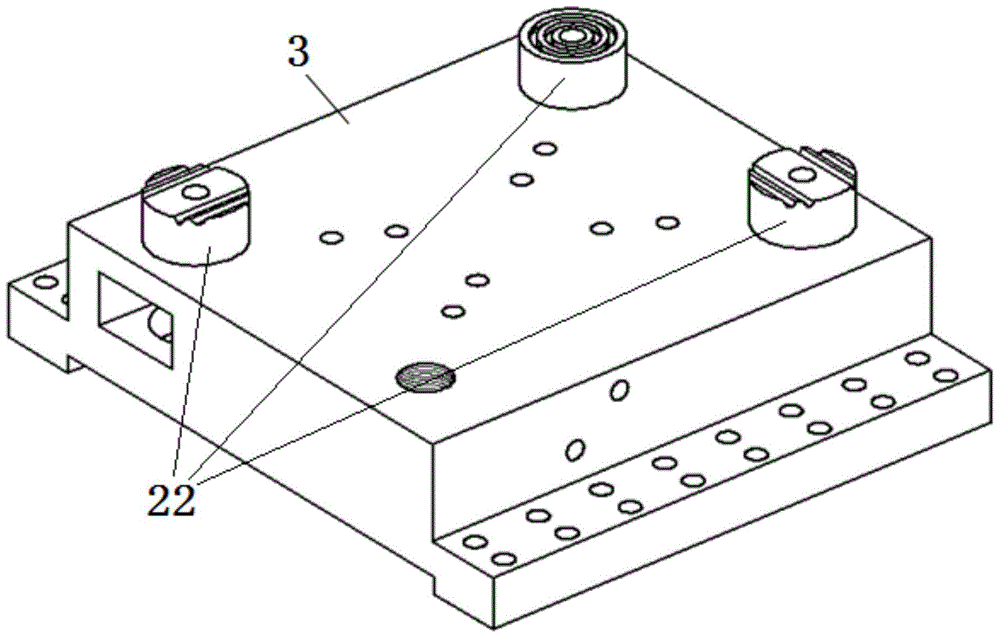

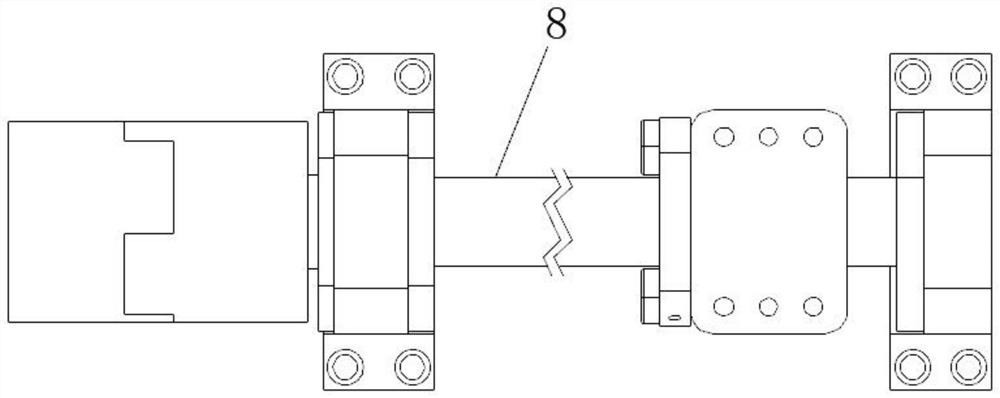

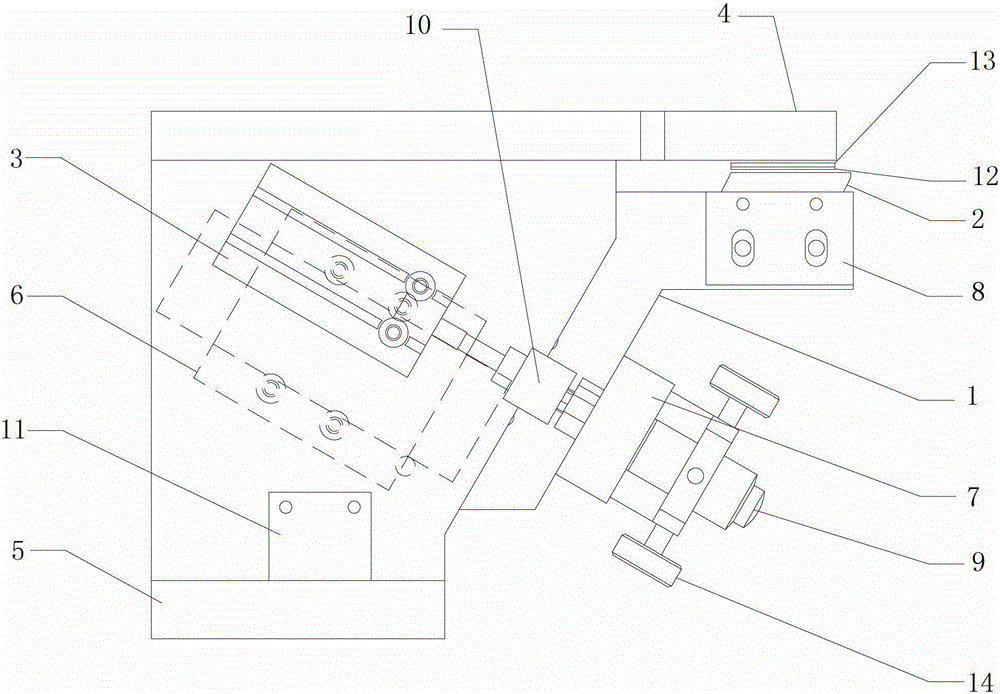

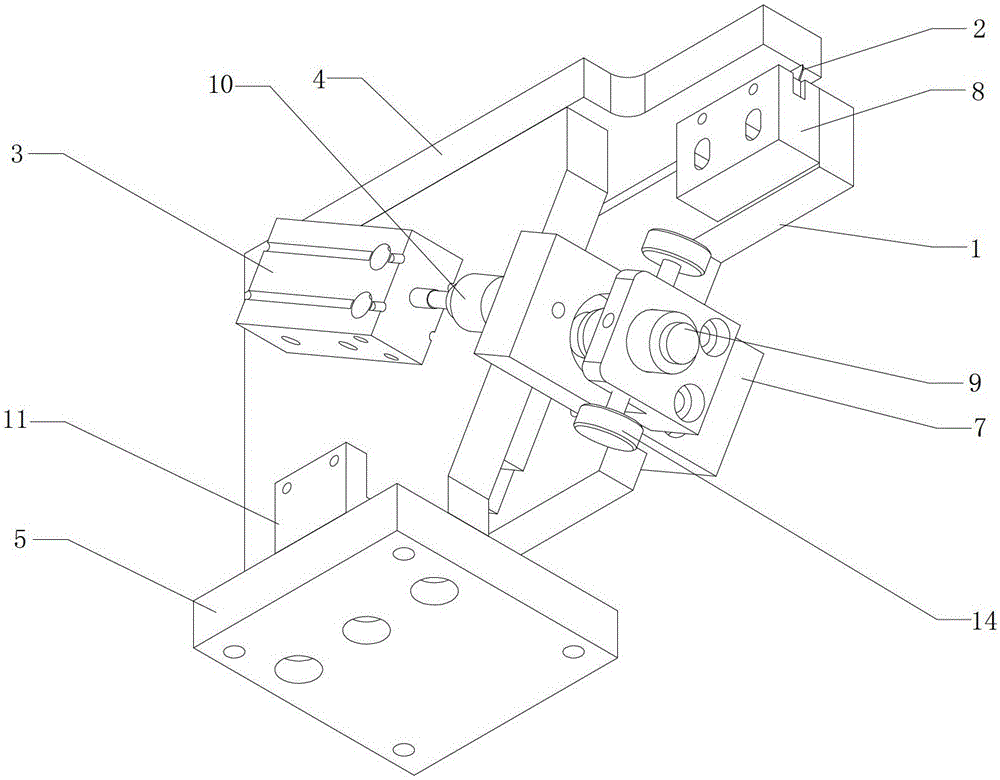

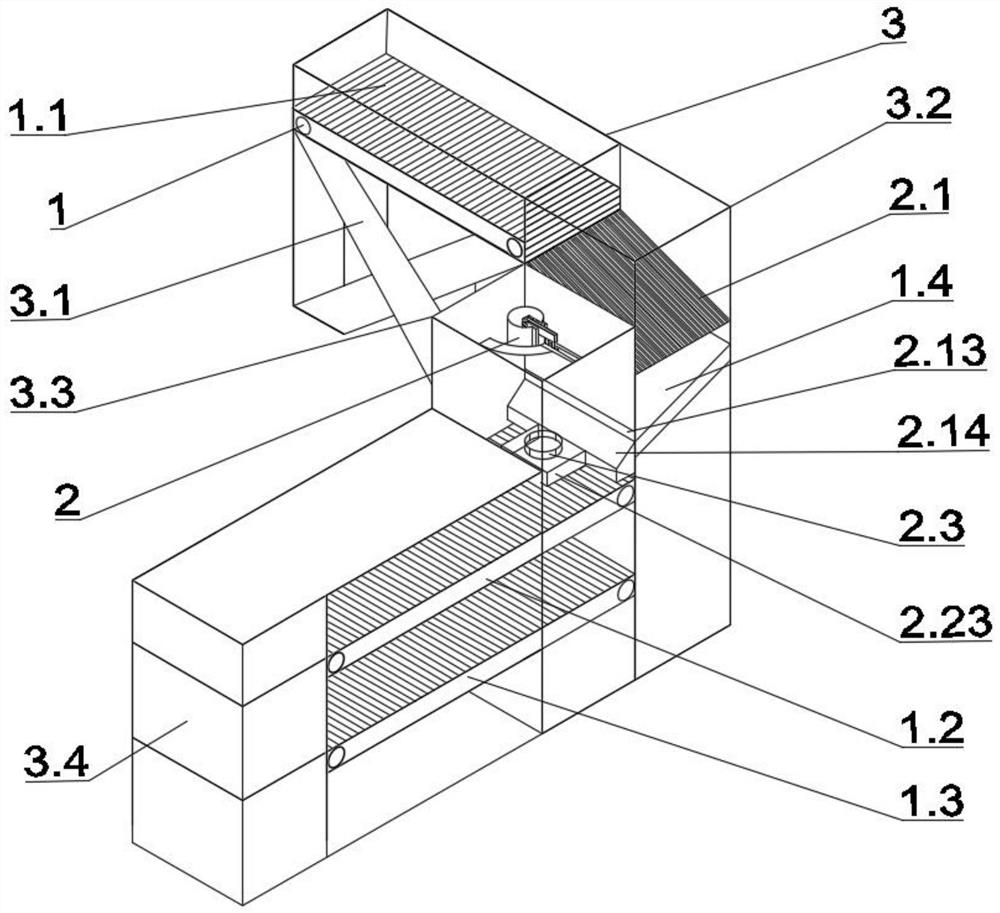

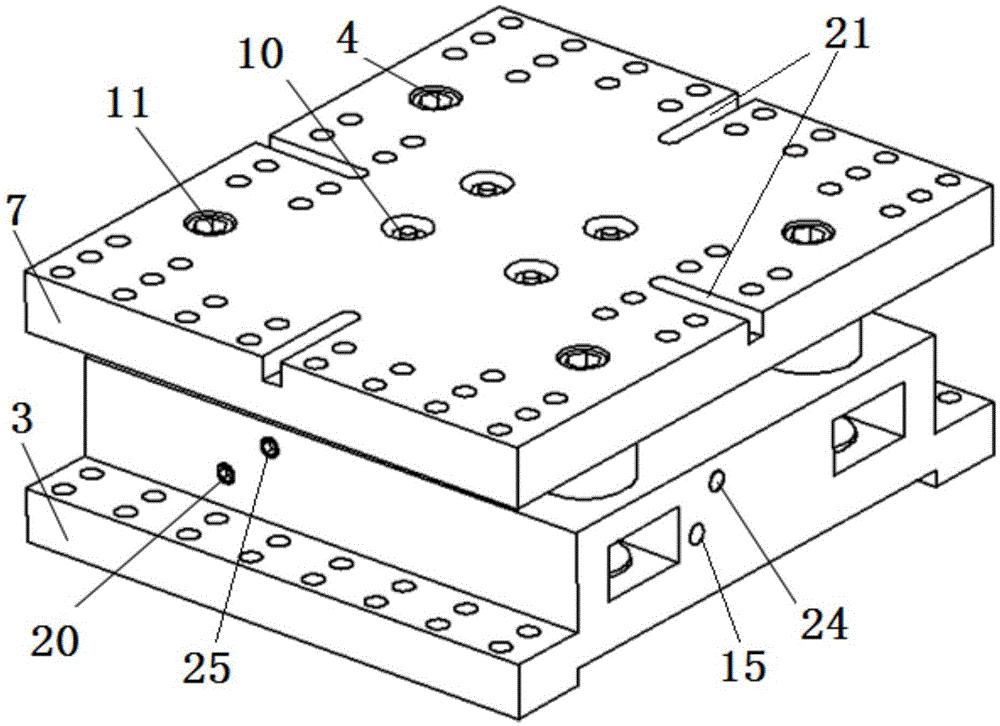

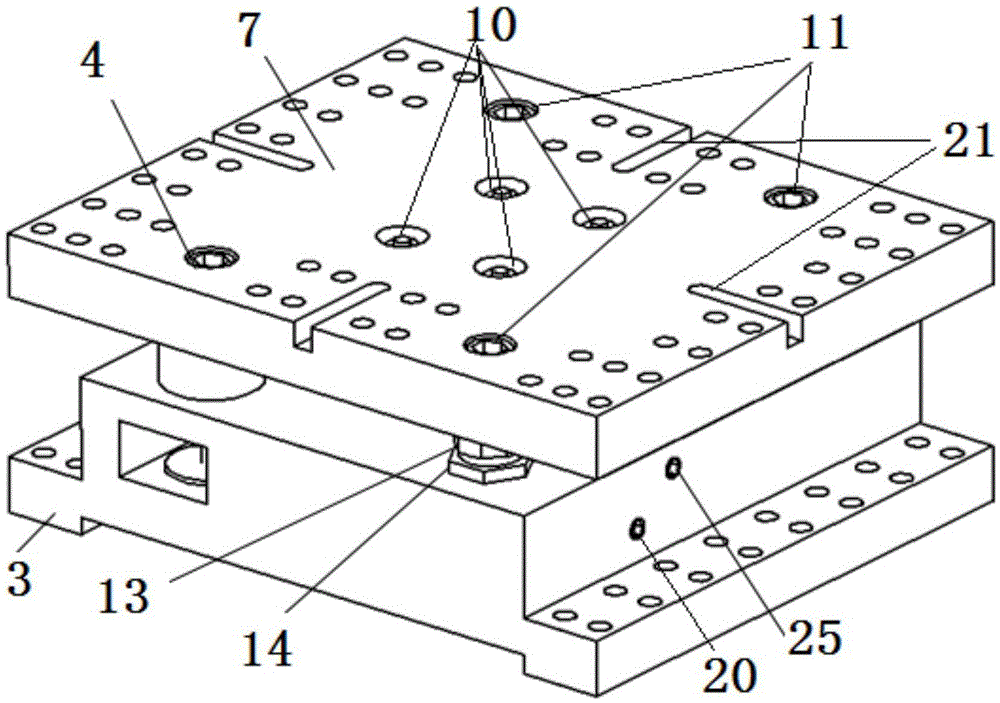

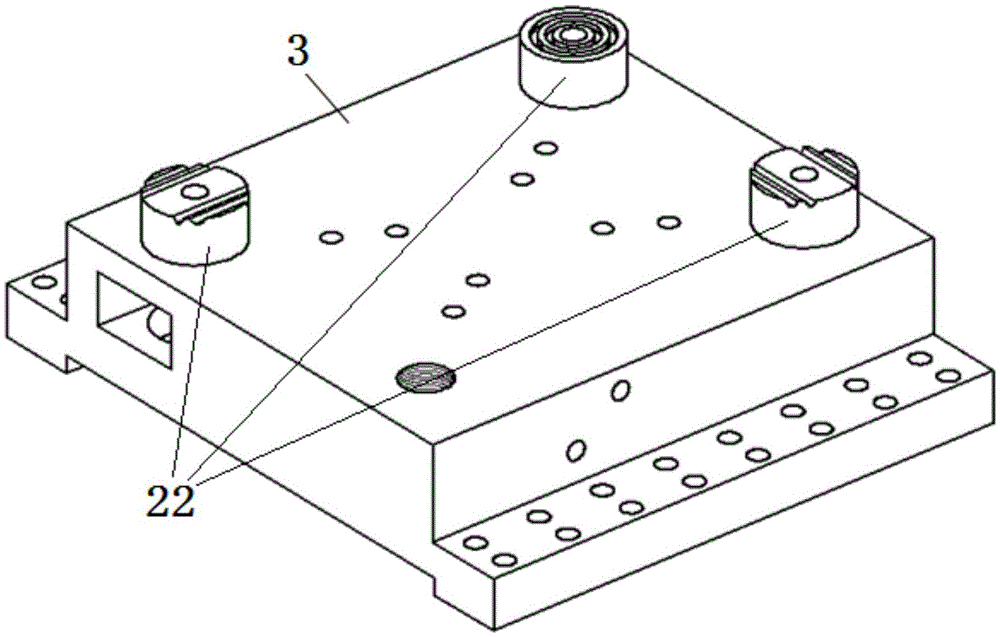

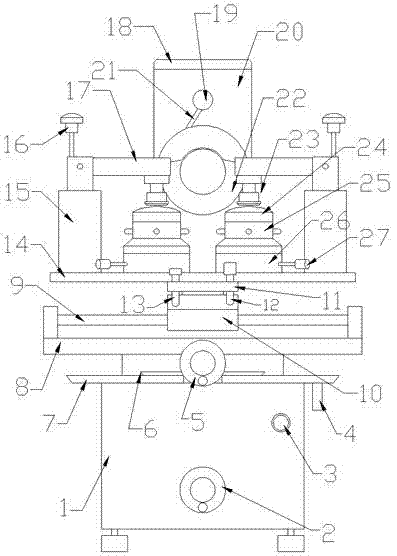

Mechanical interface device of machine tool module

ActiveCN105033660AMeet actual processing needsSimple structureLarge fixed membersComputer moduleEngineering

The invention discloses a mechanical interface device of a machine tool module. The mechanical interface device comprises a base body and an interface connecting plate, wherein the interface connecting plate is mounted above the base body; three groups of primary supports and a group of auxiliary supports are arranged on positions, close to four corners, between the base body and the interface connecting plate; and an equal-pressure pulling and pressing mechanism is further arranged between the base body and the interface connecting plate. According to the mechanical interface device of the machine tool module disclosed by the invention, the three groups of primary supports and one group of secondary supports are combined with the equal-pressure pulling and pressing mechanism, so that geometric accuracy and rigidity after the assembled modularized machine tool are regulated with a relatively large range, and interface rigidity and the interface plane can be flexibly regulated according to practical processing conditions, and therefore, practical processing needs of products are met. The mechanical interface device is simple in structure, convenient to operate, and accurate and firm to position.

Owner:XIAN UNIV OF TECH

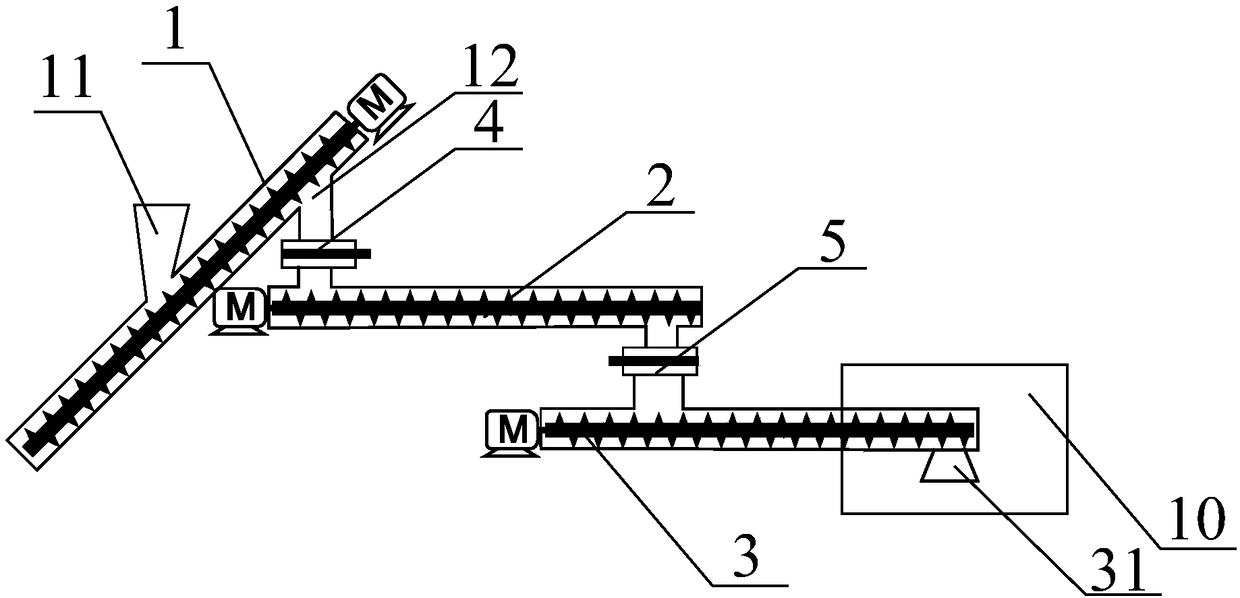

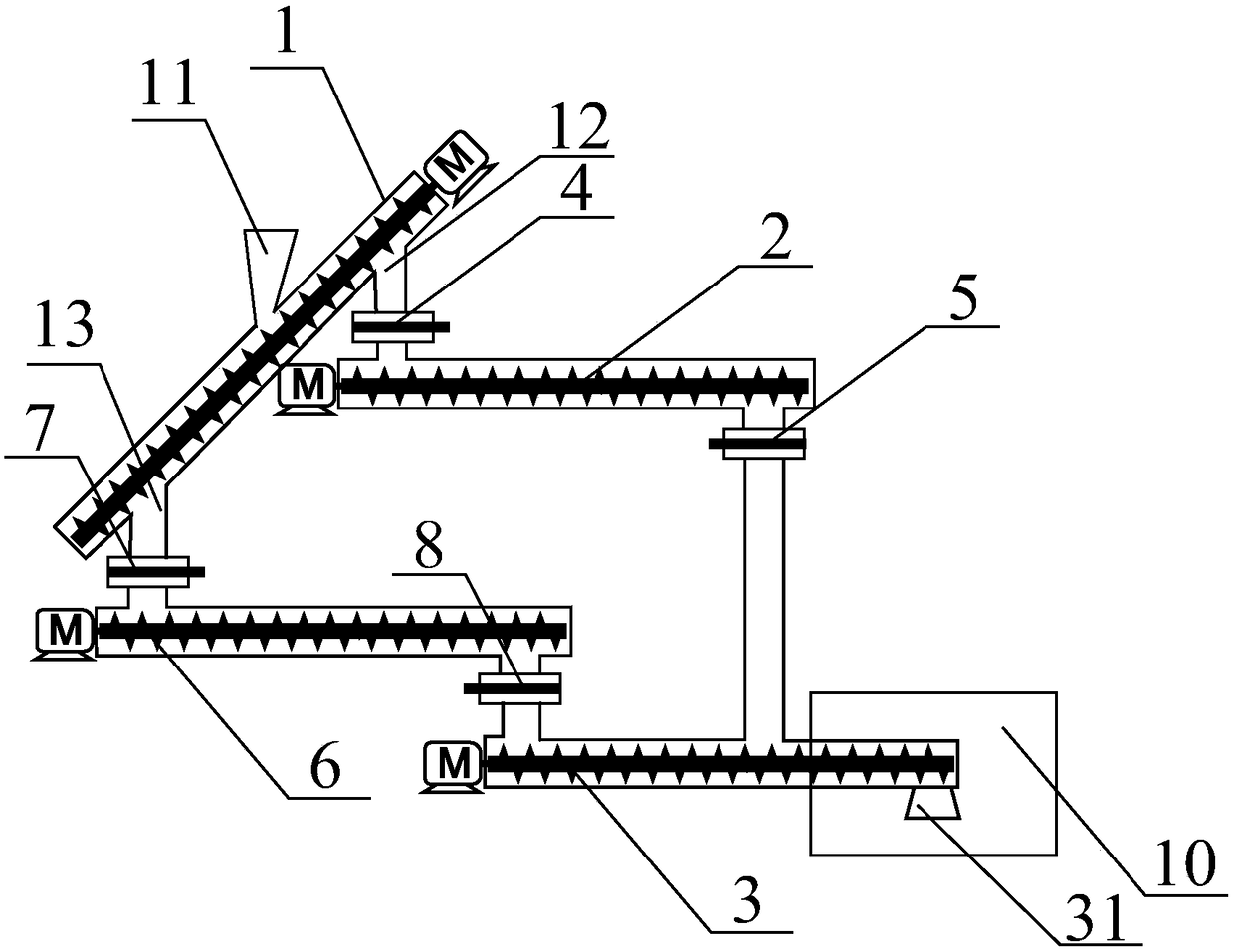

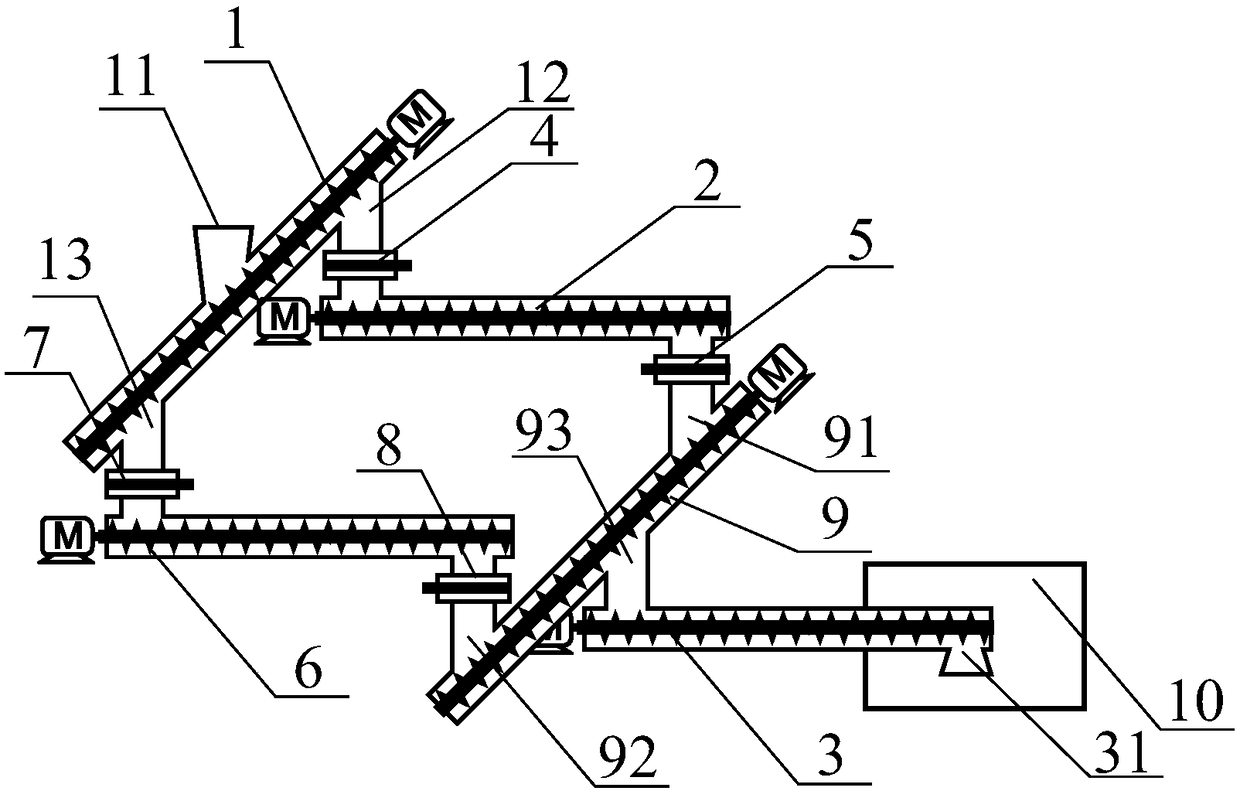

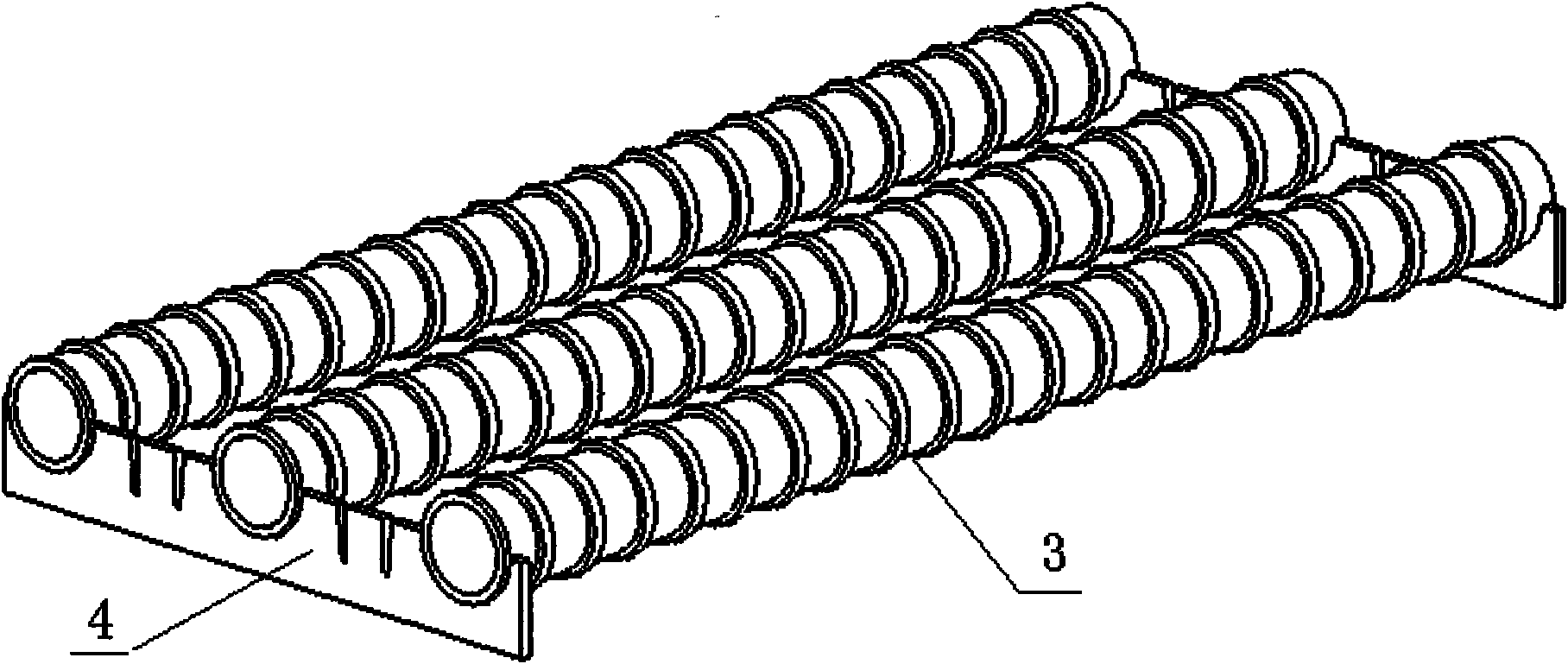

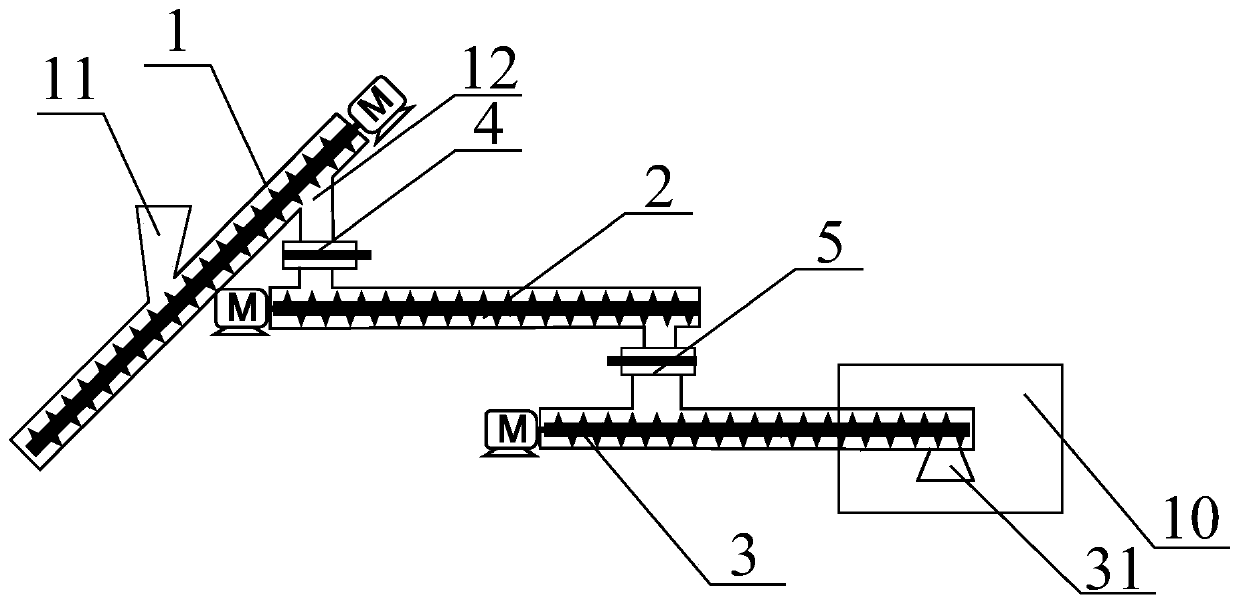

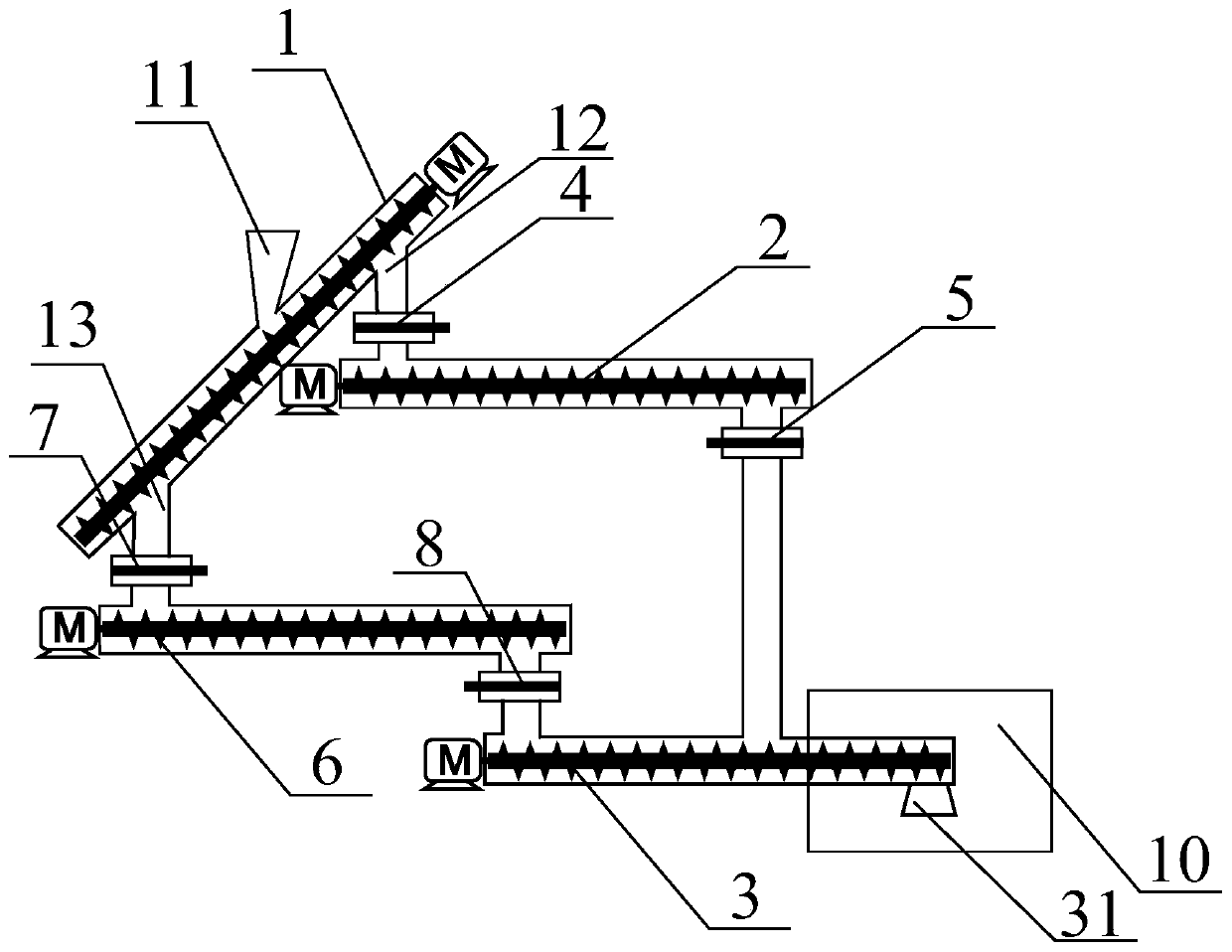

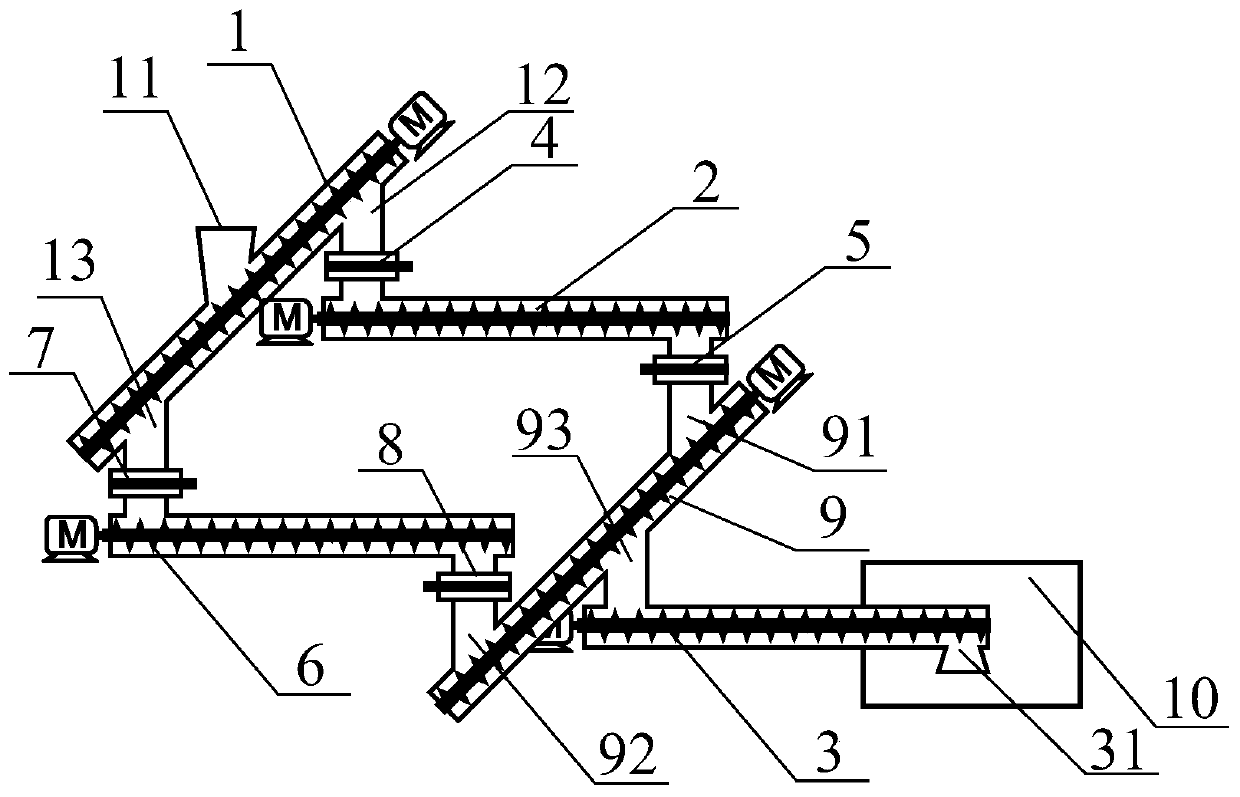

Spiral exhaust continuous feeding device and method for thermal cracking of waste tires

The invention provides a spiral exhaust continuous feeding device and method for thermal cracking of waste tires. The continuous feeding device comprises a sub-feed screw conveyor, a first spiral exhaust conveyor and a feeding screw conveyor which are sequentially connected, a first feeding port and a first discharging port are formed in the sub-feed screw conveyor, a third discharging port communicated with a thermal cracking reactor is formed in the feeding screw conveyor, and the discharge end and the feed end of the first spiral exhaust conveyor are respectively provided with a first plugvalve and a second plug valve for sealing the first spiral exhaust conveyor. According to the continuous feeding device and the method, the sealing between the continuous feeding device and the thermal cracking reactor is achieved, compared with the sealing by pressing and crushing tires, the safety and environmental protection of thermal cracking are ensured, oxygen in the air can be effectivelyprevented from entering the reactor or high temperature oil and gas in the reactor can be effectively prevented from being leaked into the air.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

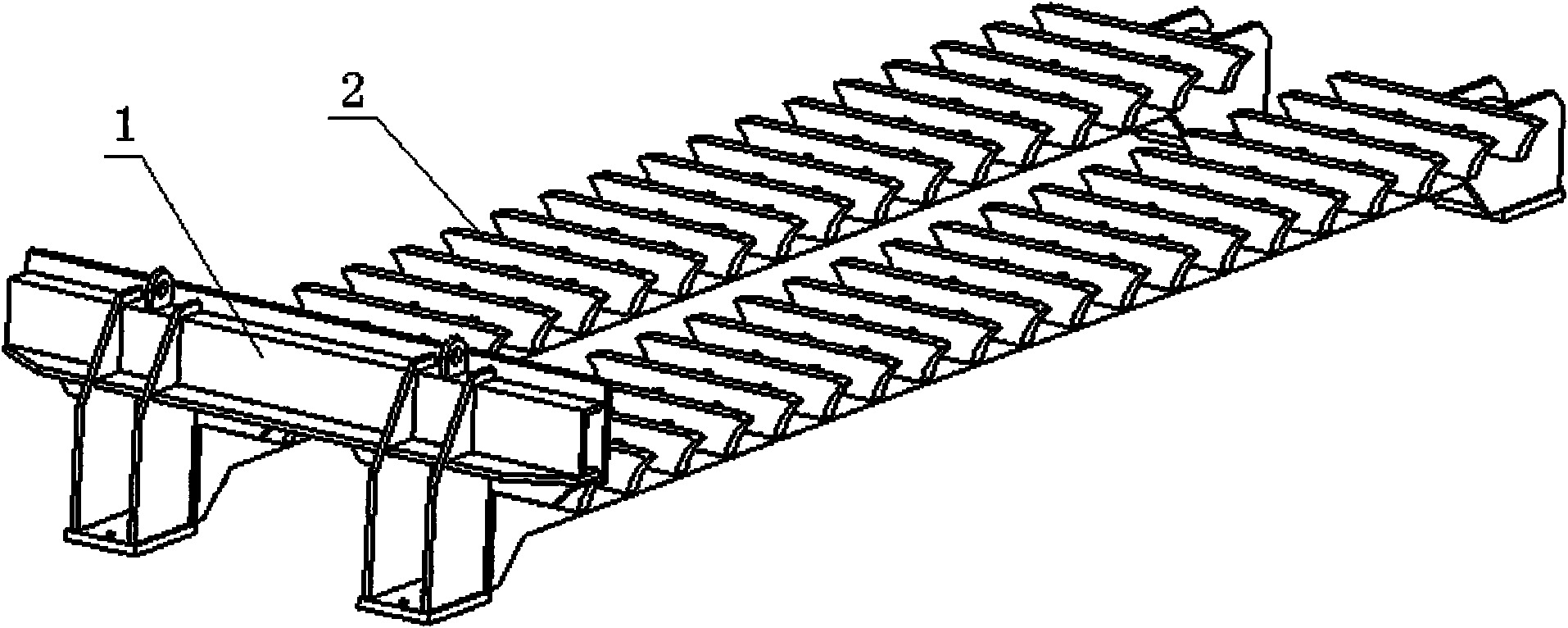

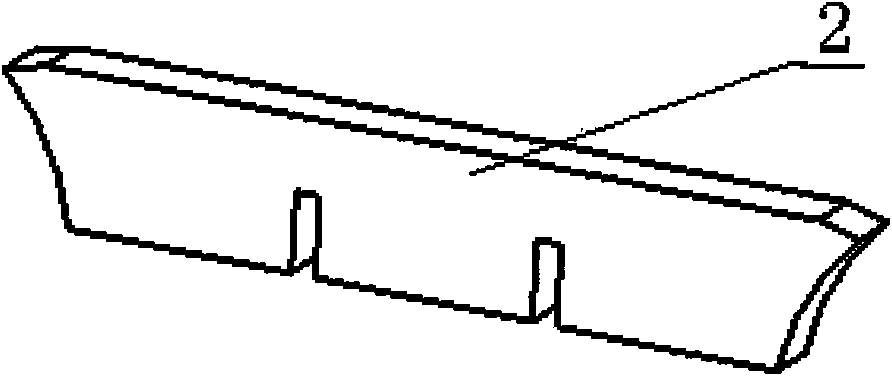

Manufacturing method of steel-rolling cooling bed roller-oriented support platform

InactiveCN101579787ASimple processEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesMachiningWelding deformation

The invention relates to a manufacturing method of a steel-rolling cooling bed roller-oriented support platform, belonging to the technical field of mechanical processing. The manufacturing method of the steel-rolling cooling bed roller-oriented support platform is characterized in by comprising the following process steps of: 1), blanking: single pieces required by the oriented support platform are cut; 2), grouping: a tooling is utilized to accurately fix the position of an overpress after blanking, and every piece is grouped so as to ensure an assembly relation; 3), welding: welding is carried out on the tooling, and welding deformation is restricted and controlled; and 4), aging: vibration aging is carried out together with the tooling so as to eliminate welding interior stress. The invention utilizes the tooling to carry out manufacturing, and has the advantages of simplified process, high production efficiency, high processing precision, low production cost and the like.

Owner:TIANJIN SERI MACHINERY EQUIP

Base rotation type milling machine

PendingCN112828363AMeet actual processing needsFeeding apparatusMilling equipment detailsBall screwGear wheel

The invention discloses a base rotation type milling machine. The base rotation type milling machine comprises a built-in base and a first motor, wherein an upper rotary disc is rotatably mounted at the top of the built-in base; a lower pressing plate is arranged between the built-in base and the upper rotary disc; a cover plate is mounted at the top of the upper rotary disc; a needle valve type oil cup is mounted on one side of the surface of the upper rotary disc; a ram is mounted on one side of the upper rotary disc; a tool rest gear assembly is mounted on one side of the ram; a ball screw is rotatably mounted in the ram; one end of the ball screw is fixedly connected with one end of the first motor; a speed changing assembly is mounted on one side of the ram; a ram pressing block is mounted at the top of the ram; a first fixed plate is mounted at the top of the ram pressing block; and a sliding ring base is mounted on one side of the top of the first fixed plate. According to the base rotation type milling machine disclosed by the invention, a part of structure of a milling machine body is changed so that transverse and longitudinal strokes of the milling machine body can be adjusted and the requirements of actual machining are met.

Owner:上海孚洛环保科技有限公司

Drilling component used for drilling technique of hard alloy materials

InactiveCN102699390AStable processingGuaranteed machining accuracyTransportation and packagingTool adaptersWrenchDrill bit

The invention discloses a drilling component used for the drilling technique of hard alloy materials, which is used for drilling the hard alloy material with the thickness being not more than 5mm. The drilling component comprises a drill bit, a top end sleeve piece and a rod body piece which are connected coaxially; the drill bit and the drill body piece are arranged at both ends of the top end sleeve piece respectively, the end face of the top end sleeve piece, opposite to the drill bit, is provided with a center hole, an annular groove is arranged at an opening end of the center hole; the end face of the top end sleeve piece, opposite to the rod body piece, is provided with a connecting structure, a channel is arranged on the outer end face of the connecting structure; a tungsten steel drill bit used for the drill bit is arranged in the center hole of the top end sleeve piece in series; the end part of the drill bit is stretched out of the center hole of the top end sleeve piece; the rod body piece is connected with the top end sleeve piece through sheathing the connecting structure; a knurling section is arranged on one end of the rod body piece opposite to the top end sleeve piece, and the knurling section of the rod body piece is arranged in an externally connected spanner drill chuck in series. The drilling component is good in structure integrity, high in precision, low in cost, strong in generality, and wide in application scale; furthermore, the processing quality is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

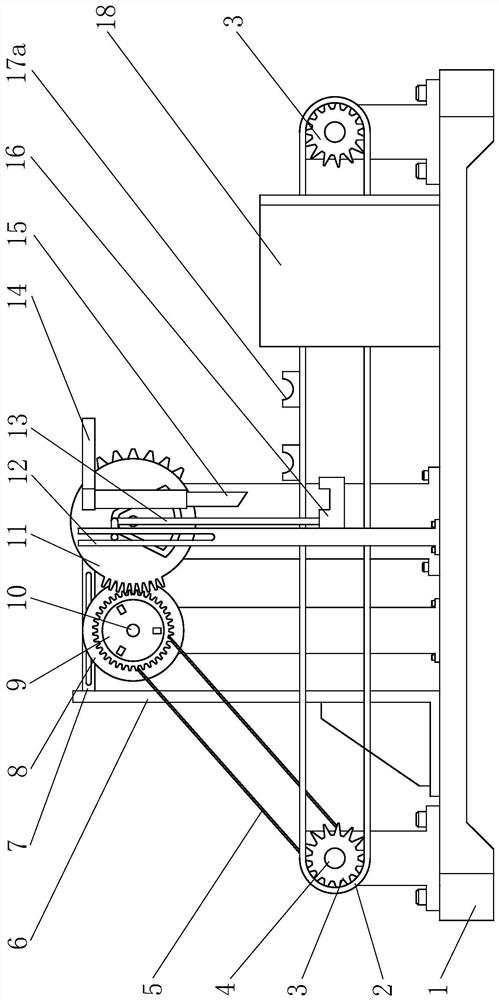

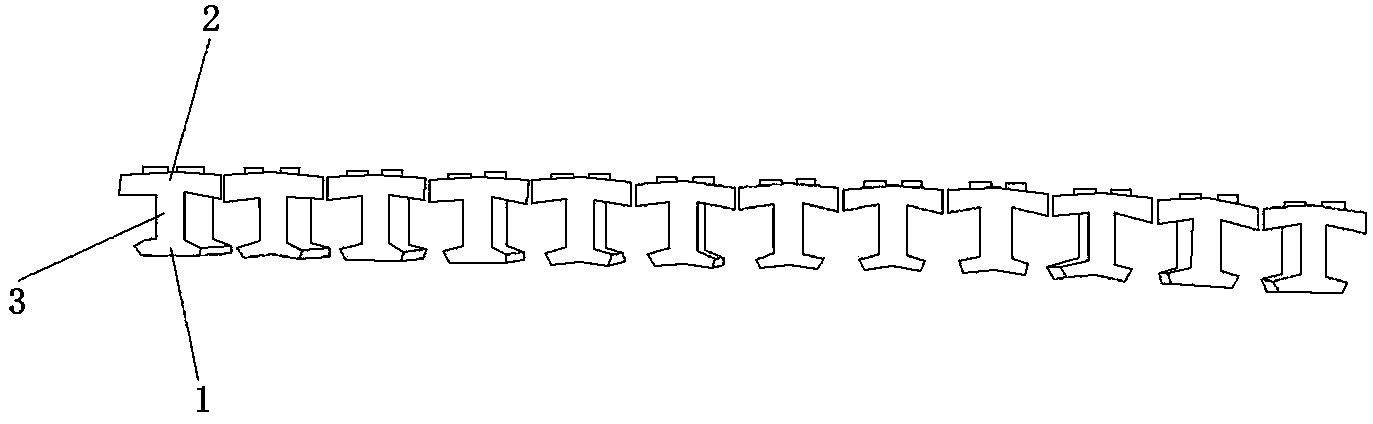

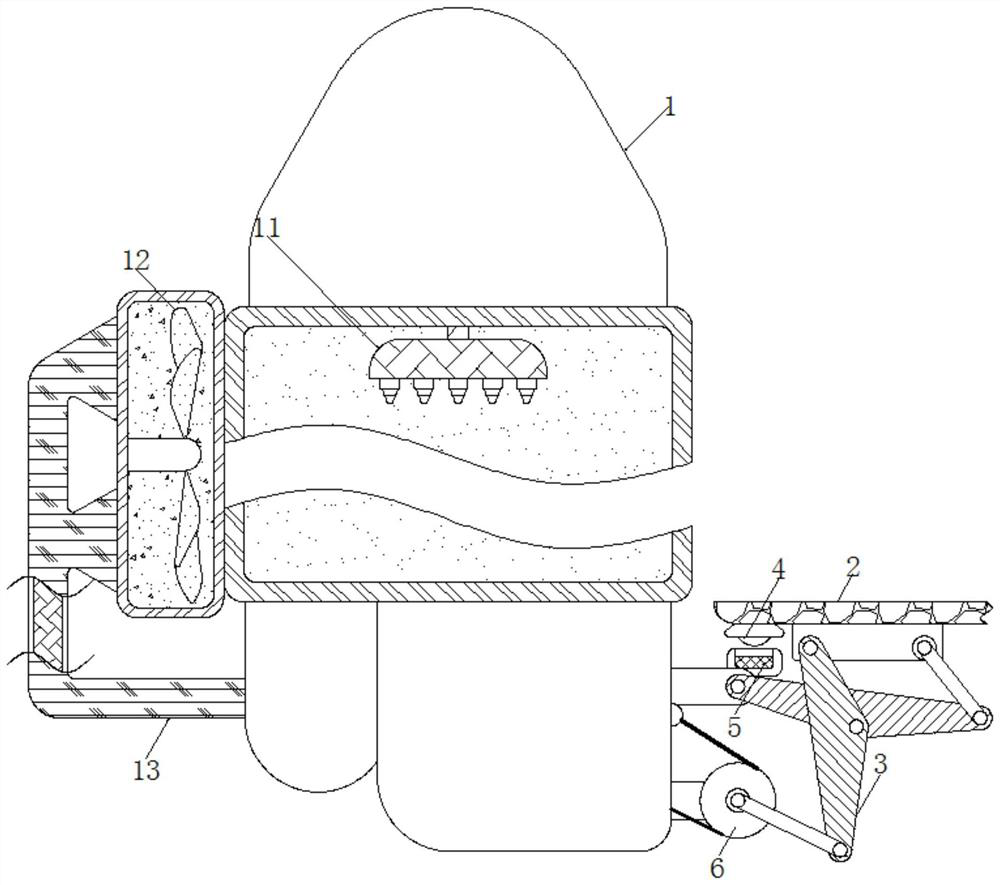

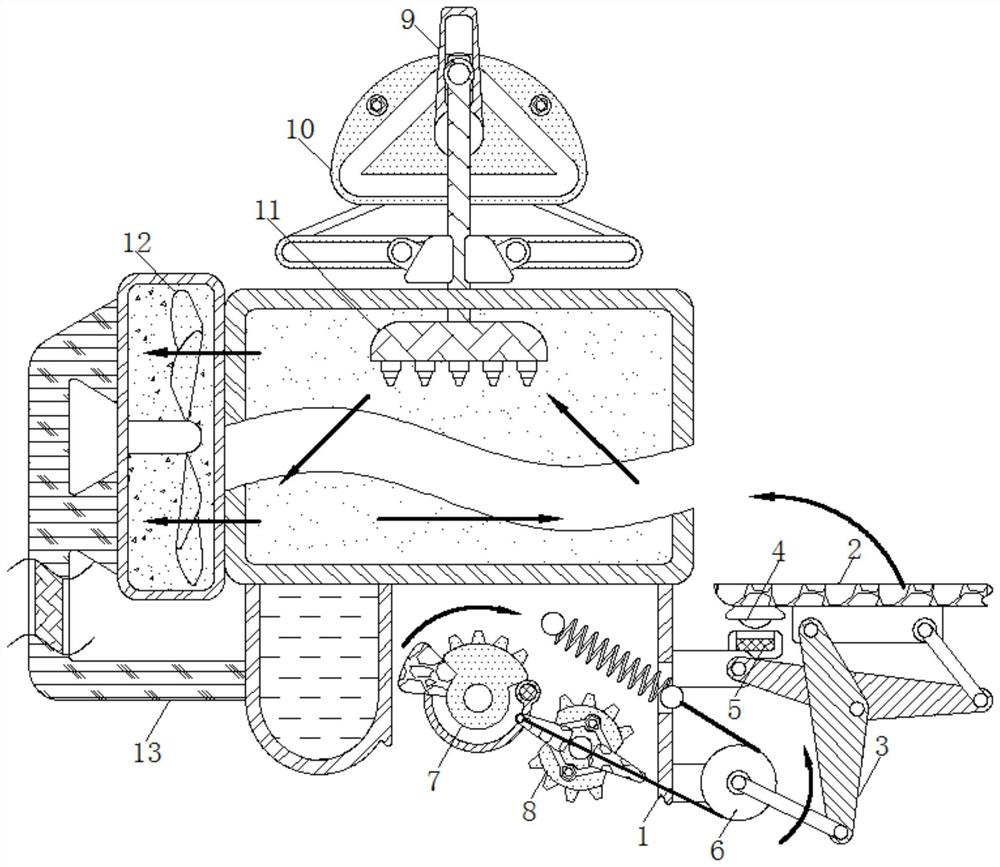

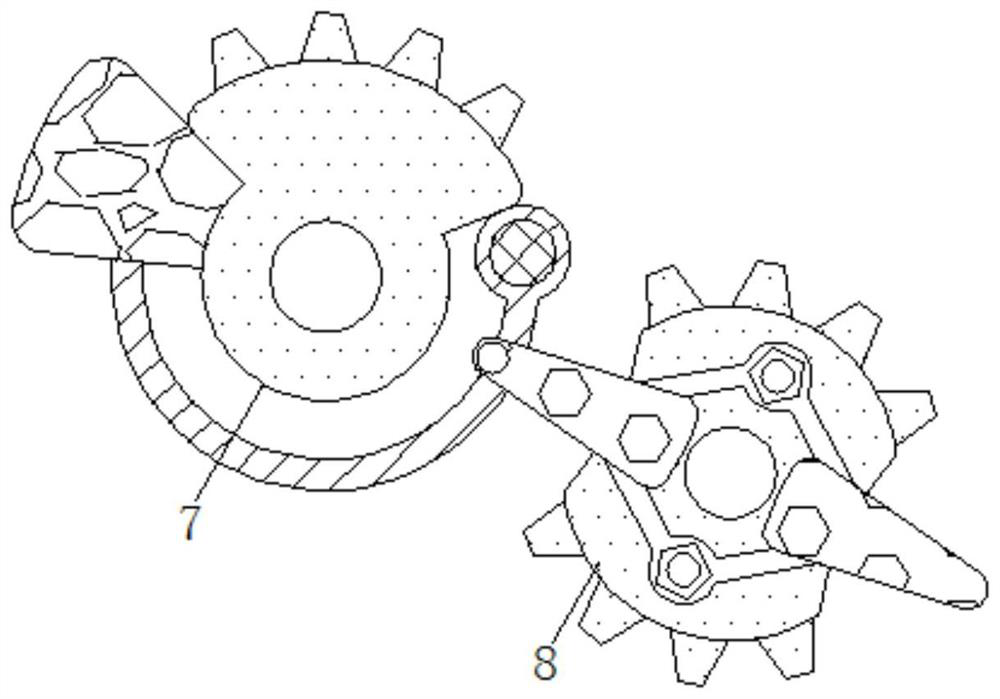

Integrated furnace chains and heating heads

PendingCN107081896ACompact structureEffective protectionDomestic articlesBottleElectrical and Electronics engineering

The invention relates to an integrated furnace chains and heating heads. The integrated furnace chains and heating heads comprises heating head devices, furnace chains, mandrel belt wheels, nuts, a synchronous belt, lifting devices, a lifting rail and light baffles; the multiple heating head devices are sequentially arranged on the furnace chains correspondingly; the mandrel belt wheels are inserted into the upper ends of the heating head devices and are fixed through the nuts; the multiple mandrel belt wheels are arranged in the synchronous belt; the lifting devices are arranged on the lower portions of the heating head devices correspondingly, and the lifting devices are slidably arranged in the part, located on one sides of the heating head devices, of the lifting rail; and the light baffles are arranged at the lower ends of the lifting devices correspondingly, and the lifting devices drive the light baffles to lift up and down when the lifting devices slide in the lifting rail. The integrated furnace chains and heating heads is simple and compact in whole structure, the furnace chains and the heating heads are integrated, the mandrel belt wheels are in contact with the rubber synchronous belt, and thus noise is reduced, the bottle openings of bottle performs are effectively protected through the light baffles which can lift up and down in the bottle perform heating process, and accordingly the integrated furnace chains and heating heads has high practicability.

Owner:苏州普洽吹瓶科技有限公司

A support type aluminum tube cutting device

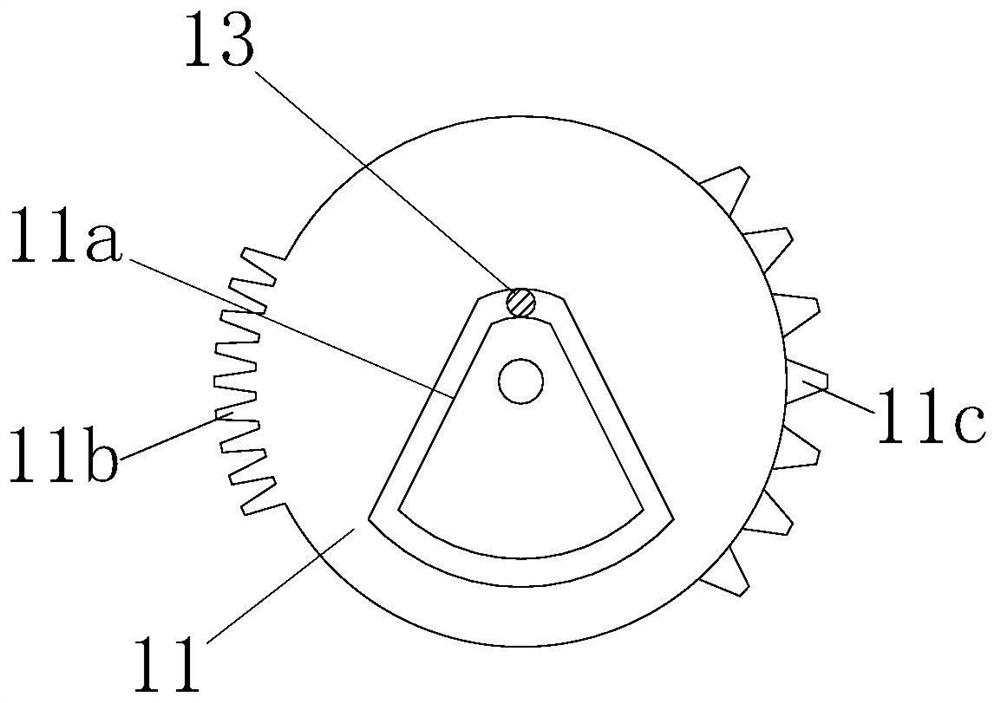

ActiveCN110625179BHigh degree of automationImprove practicalityTube shearing machinesMetal working apparatusClassical mechanicsSprocket

The invention relates to a supporting type aluminum pipe cutting device. The device comprises a bottom plate and rotating shafts arranged on the bottom plate through bearing seats, wherein two chain wheels are mounted on each rotating shaft, and a chain which is used for transmission connection between the left and right chain wheels for each rotating shaft is arranged between the corresponding left and right chain wheels. Bearing frames are arranged at the upper ends of the two chains in a transmission mode, a placing groove is formed in the upper end of each bearing frame, and regulation plates are fixedly arranged on the right front side and the right rear side on the bottom plate. According to the device, the automation degree is high, an aluminum pipe is automatically lifted and cut on the two sides during the conveying stopping period on the basis that the aluminum pipe is subjected to position arrangement and intermittent type conveying, so that a large number of aluminum pipesare cut into a specific length one by one, the actual machining requirements are met, and the practicability is high.

Owner:WUHU HENGHAO MACHINERY MFG

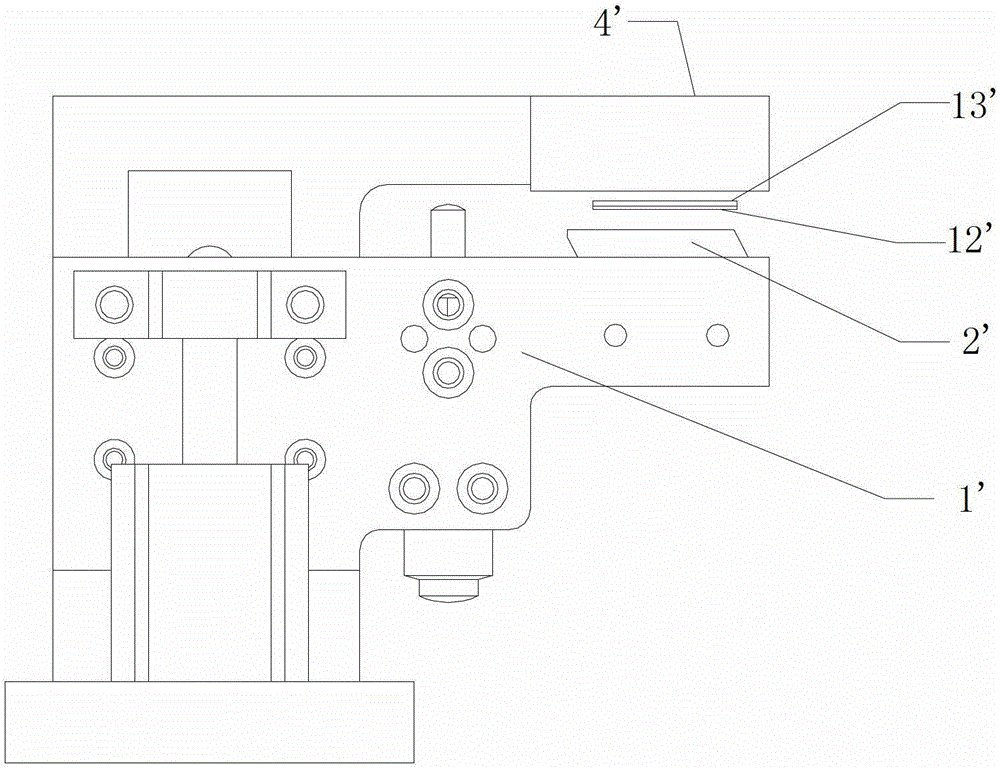

Precision Conductive Film Cutting Device

The invention relates to the technical field of transmission mechanisms, and discloses a precise electric-conducting adhesive film cutting device comprising a substrate board. A cutter moving block, a power unit and an air cylinder system driven by the power unit and driving the cutter moving block to move are arranged on the substrate board, and included angle between moving direction of the cutter moving block and a horizontal plane is an acute angle. With the precise electric-conducting adhesive film cutting device, conventional cutting mechanisms in production lines are essentially improved, and a beveling method is adopted to cut, and no damages on productions during cutting are caused. The precise electric-conducting adhesive film cutting device is high in automation degree, cutting process can be precisely controlled, operation is facilitated and rapid, and production efficiency is greatly improved.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

Spiral exhaust type continuous feeding device and method for thermal cracking of waste tires

The invention provides a spiral exhaust continuous feeding device and method for thermal cracking of waste tires. The continuous feeding device comprises a sub-feed screw conveyor, a first spiral exhaust conveyor and a feeding screw conveyor which are sequentially connected, a first feeding port and a first discharging port are formed in the sub-feed screw conveyor, a third discharging port communicated with a thermal cracking reactor is formed in the feeding screw conveyor, and the discharge end and the feed end of the first spiral exhaust conveyor are respectively provided with a first plugvalve and a second plug valve for sealing the first spiral exhaust conveyor. According to the continuous feeding device and the method, the sealing between the continuous feeding device and the thermal cracking reactor is achieved, compared with the sealing by pressing and crushing tires, the safety and environmental protection of thermal cracking are ensured, oxygen in the air can be effectivelyprevented from entering the reactor or high temperature oil and gas in the reactor can be effectively prevented from being leaked into the air.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

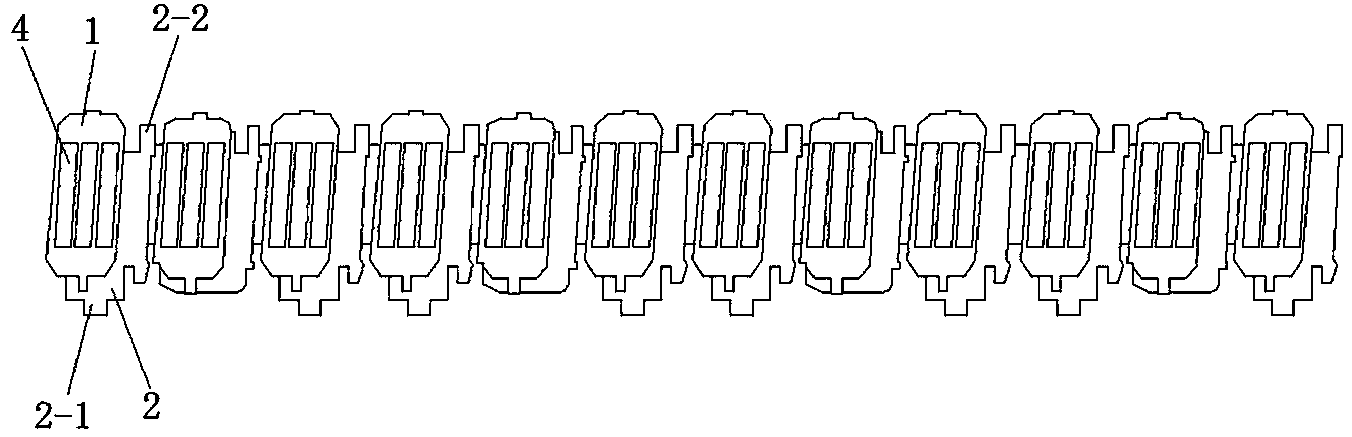

Stator coil support of winding machine

ActiveCN103647376AImprove work efficiencyEasy to useManufacturing dynamo-electric machinesWinding machineStator coil

The invention relates to the technical field of winding machine equipment, particularly to a stator coil support of a winding machine. The stator coil support of the winding machine comprises twelve coil support unit groups; each group unit comprises a front plate, a back plate, a connection portion connecting the front plate and the back plate, and a core; the core extends from the front plate to the back plate and passes through the connection portion; a wire is wound on the connection portion. By use of the above structure, the wire is wound on the connection portion of the stator coil support conveniently via the winding machine, the efficiency of the winding machine is effectively improved and the needs of the actual processing are met. In addition, the stator coil support of the winding machine has the characteristics of reasonable design, simple structure, easy usage, easy manufacturing and processing, low production costs and the like.

Owner:NANTONG YUANQUAN INTELLIGENT INSTR PROD

Device for treating harmful gas generated in paint spraying process of new energy automobile door

InactiveCN112295814AReduce spreadIncrease linkagePretreated surfacesCoatingsNew energyProcess engineering

The invention relates to the technical field of new energy, and discloses a device for treating harmful gas generated in the paint spraying process of a new energy automobile door. The device comprises an outer shell, the outer side of the outer shell is movably connected with a baffle plate, the opening and closing conditions of an operation opening of an operation room are automatically controlled, so that the operation room is kept in a closed state in the paint spraying process, harmful gas dispersion is reduced, spraying operation and air exhaust operation are triggered by utilizing the principle of a photoresistor, materials are automatically close to conduct linear moving spraying, the problem that the coloring effect of the materials is weakened while the paint is wasted due to thefact that a large amount of paint is sprayed to areas outside the materials because the distance between a spray head and the materials is too long and the spraying range of the paint is too large isavoided, the harmful gas in the operation room is automatically absorbed and purified, the safety of gas emission is improved, the threat of the harmful gas to human health and the harm to the environment are reduced, the environment-friendly concept is followed, meanwhile, air flow in the operation room is also accelerated, drying of the paint is promoted, and the actual machining requirement isbetter met.

Owner:广州市人则众汽车用品有限公司

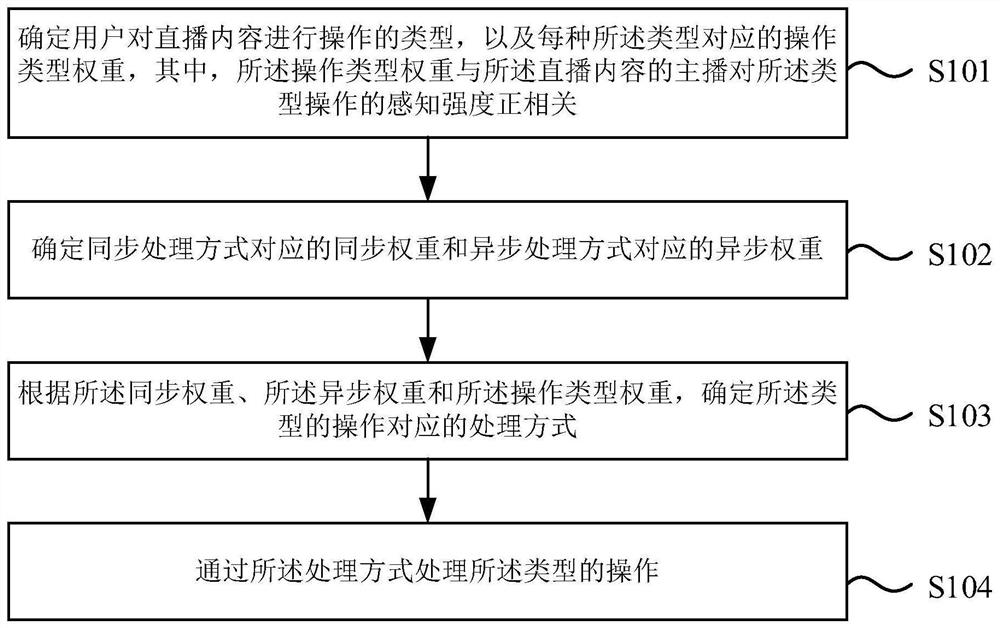

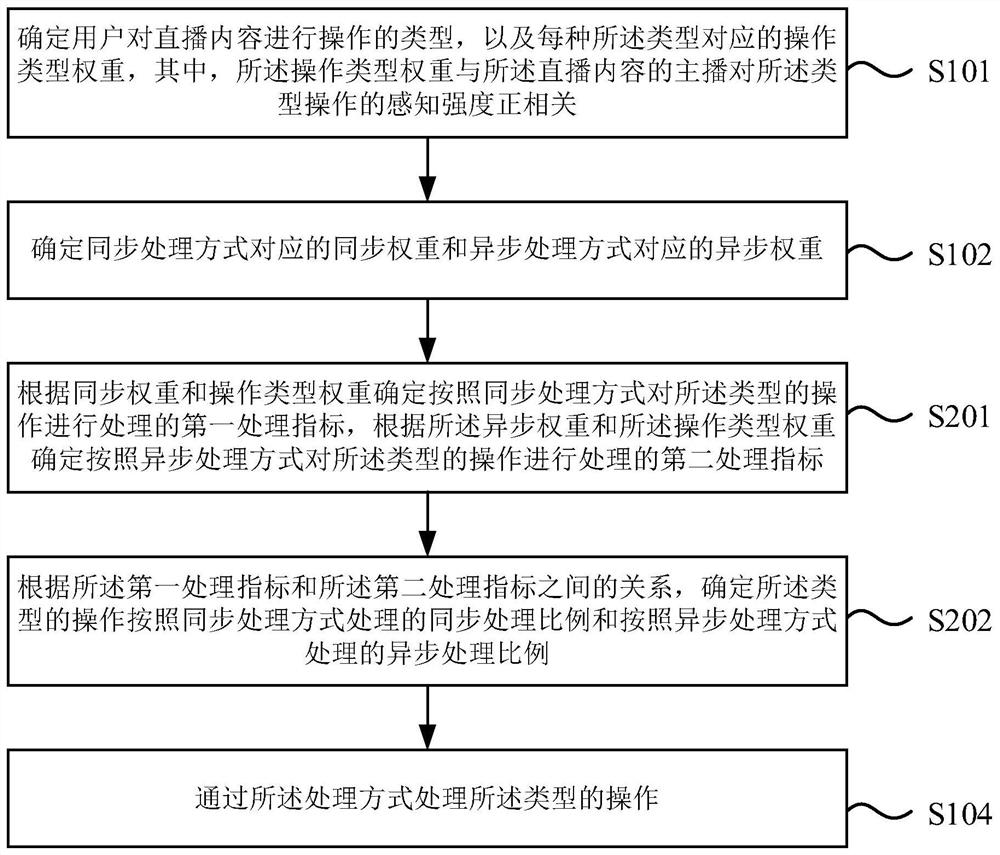

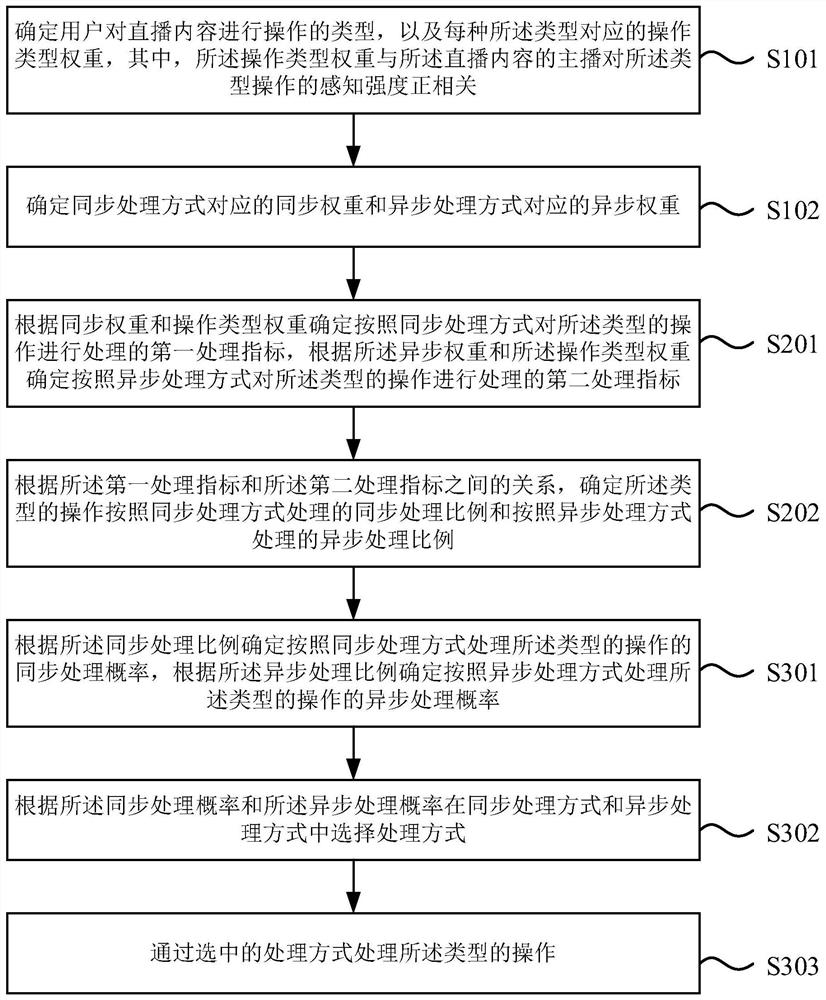

Information processing method and device, electronic equipment and storage medium

PendingCN114125479AMeet actual processing needsSelective content distributionInformation processingProcessing type

The invention relates to an information processing method and device, electronic equipment and a storage medium, and the method comprises the steps: determining the types of live broadcast contents operated by a user, and an operation type weight corresponding to each type, and the operation type weight is in positive correlation with the perception intensity of an anchor of the live broadcast contents on the type operation; determining a synchronous weight corresponding to the synchronous processing mode and an asynchronous weight corresponding to the asynchronous processing mode; determining a processing mode corresponding to the type according to the synchronous weight, the asynchronous weight and the operation type weight; and processing the type of operation through the processing mode. According to the embodiment of the invention, the operation type weights are respectively set for the types of different operations, and the processing modes corresponding to the types are determined by comprehensively considering the synchronous weights, the asynchronous weights and the operation type weights, so that proper modes are selected for processing different types of operations instead of uniformly selecting a certain processing mode for processing, and the processing efficiency is improved. And the processing requirements of different types of operations can be met.

Owner:YOOEEE XINGJI BEIJING TECH CO LTD

Plastic bottle recycling auxiliary device for solid waste treatment

InactiveCN113978011ASmooth rolling operationEasy to handlePlastic recyclingRotary pressElectric machineryProcess engineering

The invention relates to the technical field of solid waste treatment, and discloses a plastic bottle recycling auxiliary device for solid waste treatment, which comprises an adjusting mechanism, and the adjusting mechanism comprises a rotating block; the distance between two hot grinding rollers is changed by rotating the rotating block, so that plastic bottles with different sizes are conveniently treated, a connecting frame moves, a connecting rod pushes the motor and the driving disc to move downwards, subsequent speed change operation is automatically triggered, the contact face of the driving disc and the follow-up disc is changed by moving of the driving disc, and high-speed rotation of the follow-up disc is changed into low-speed rotation, the hot grinding roller on the outer side of the follow-up disc rotates synchronously, the operation speed of the hot grinding roller is reduced, the hot grinding roller extrudes a plastic bottle to soften and seal the plastic bottle, surface packaging treatment is facilitated, the large-size plastic bottle is treated, the contact degree of the hot grinding roller and the large-size plastic bottle is increased through slow operation of the hot grinding roller, the hot grinding roller can effectively soften and flatten the plastic bottles, so that the processing quality of the plastic bottles is guaranteed.

Owner:余芬

Real-time flexible acceleration and deceleration control algorithm based on adaptive forward-looking and predictive correction

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Precision parts processing CNC machine tools

ActiveCN113523380BMeet process requirementsAddressing the drawbacks of multilateral formationMeasurement/indication equipmentsFeeding apparatusNumerical controlMachine parts

Owner:南通福根机械制造有限公司

Metal plate bending device and method

The invention relates to the technical field of bending devices, in particular to a metal plate bending device and method. The metal plate bending device comprises a workbench, a first bending piece and a second bending piece, and a fixing groove is concavely formed in the left end of the workbench; the first bending piece is arranged at the left end of the workbench and comprises a first supporting frame, a first driving air cylinder, a bending knife and a bending shaping groove; a telescopic shaft of the first driving air cylinder vertically penetrates through the first supporting frame downwards; the bending knife is fixed to the lower end of the telescopic shaft of the first driving air cylinder; the bending shaping groove is fixed in the fixing groove; and the second bending piece is arranged at the right end of the workbench and is used for bending a metal plate positioned at the right end of the workbench into a right angle or an obtuse angle. By designing the workbench, the first bending piece, the second bending piece and other parts, the metal plate can be bent into various angles according to actual needs, and the actual machining needs are met. The whole device is novel in structure and good in stability.

Owner:广西亮剑实业集团有限公司

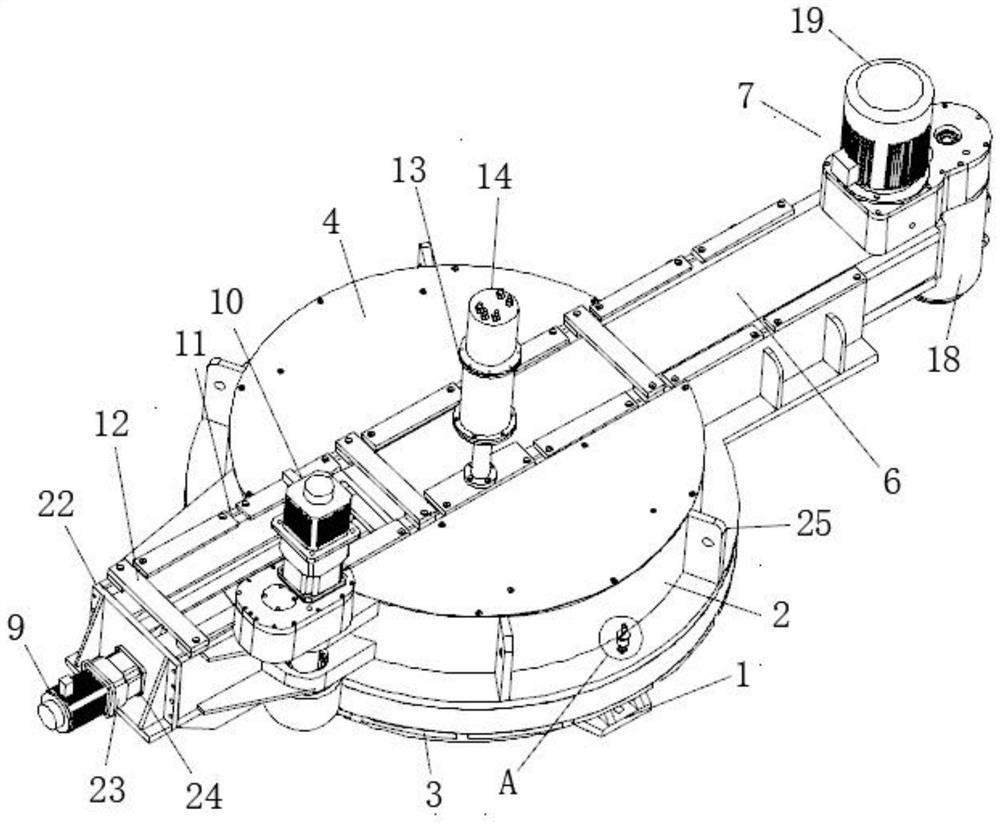

A sorting table with a circular picking structure

ActiveCN110052412BImprove product qualityMeet actual processing needsSolid separationGrain treatmentsProcess engineeringIndustrial engineering

The invention discloses a sorting table with a circular picking structure, which comprises a transmission mechanism, a picking mechanism and a limiting mechanism. The transmitting mechanism is arranged in the limiting mechanism, and the picking mechanism is arranged in the limiting mechanism. Through the present invention, before the ingredients enter the grinding machine, the ingredients of different sizes are accurately sorted and transported, the production quality of the ingredients is improved, the processing efficiency is improved, the failure of the grinding machine is prevented, potential safety hazards are avoided, and the actual processing needs of the ingredients are met. .

Owner:甘肃生平永泰食品有限公司

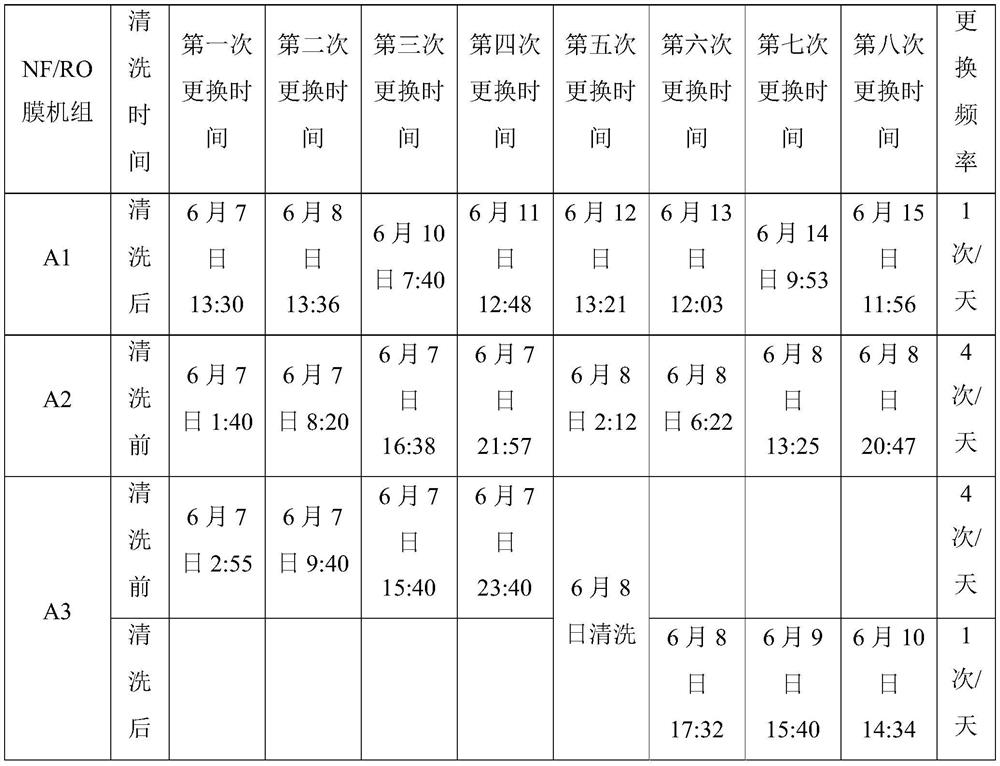

A kind of cleaning method of bacterial sludge on the inner wall of the inlet pipe of nf/ro membrane unit

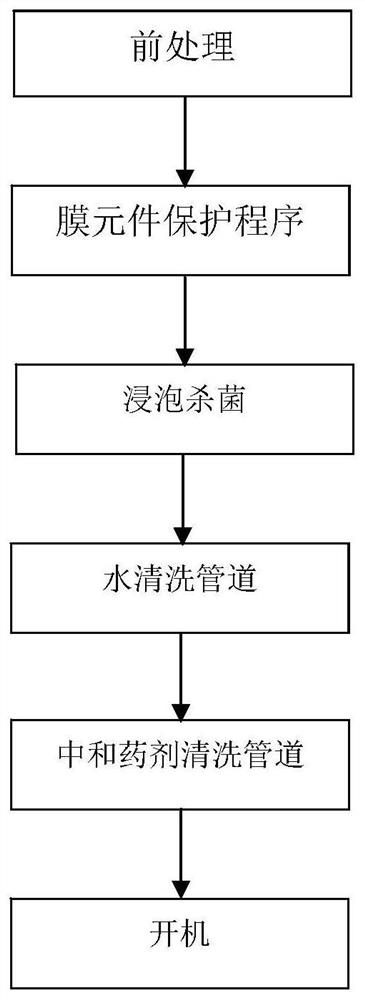

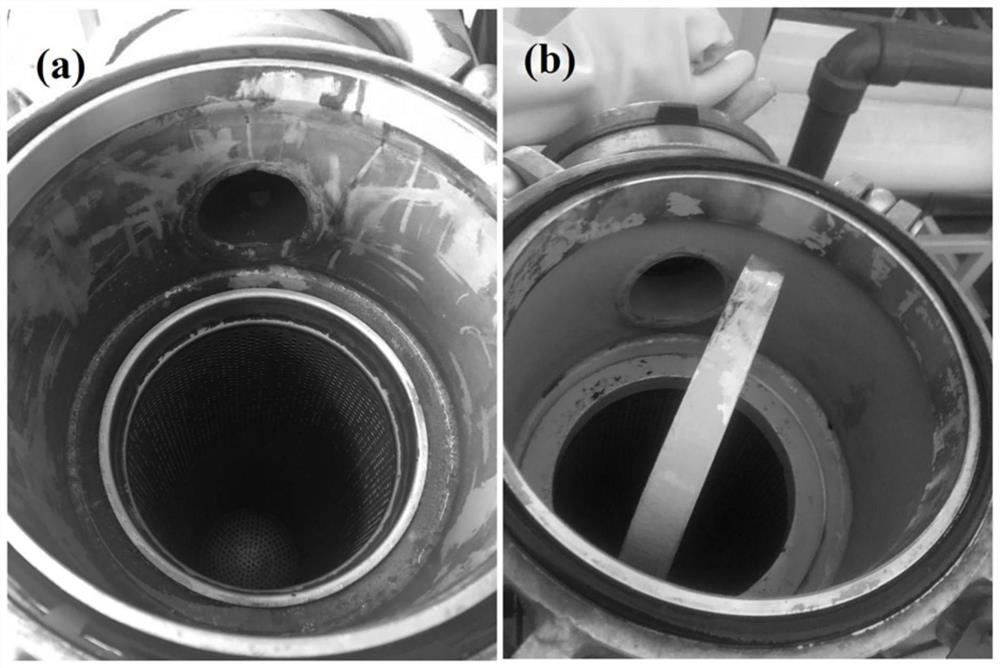

ActiveCN109201644BExtended service lifeImprove water production efficiencyHollow article cleaningSodium bisulfiteCleaning methods

The invention discloses a cleaning method for bacterial sludge breeding on the inner wall of the water inlet pipe of an NF / RO membrane unit, comprising the following steps: emptying the residual sewage in the water inlet pipe, cleaning the inner wall of the water inlet pipe with water, until the water quality of the eluate is The chromaticity is less than 10 times; the inner wall of the water inlet pipe and the NF / RO membrane unit are circularly cleaned with sodium bisulfite solution, so that the NF / RO membrane elements are soaked in the sodium bisulfite solution; the inner wall of the water inlet pipe is cleaned with cleaning agents Carry out soaking; wash the inner wall of the water inlet pipe with water; use neutralizing agents to circularly clean the inner wall of the water inlet pipe, and complete the cleaning of the bacterial sludge on the inner wall of the water inlet pipe of the NF / RO membrane unit. The cleaning method of the present invention can effectively remove the bacterial sludge grown on the inner wall of the water inlet pipe, has the advantages of simple process, easy operation, low treatment cost, high cleaning efficiency, good cleaning effect, etc., can meet the actual treatment needs, and has good advantages Application value and application prospect.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Automatic planing equipment for foamed ceramic insulation board

PendingCN114290539AGood functionalityAvoid damageWorking accessoriesStone-like material working toolsProcess engineeringManufacturing engineering

The invention discloses a foamed ceramic insulation board automatic planing device which comprises a working table, a conveying belt arranged outside the working table and a planing cutter arranged at the top of the working table, and a waste removing mechanism is arranged outside the working table. The waste removal mechanism comprises an exhaust fan, an air suction pipe, a transfer cavity, an air guide pipe, a waste collection cover, a filter plate and a collection cavity; through mutual cooperation of an exhaust fan, a transfer cavity and an air guide pipe, large suction force can be generated at the bottom of a waste collecting cover, so that chippings generated in the heat preservation plate planing process can be cleaned, the situation that the chippings are clamped between a planing cutter and the heat preservation plate in the planing process, and consequently the heat preservation plate is damaged is avoided, and meanwhile, the heat preservation plate is prevented from being damaged by the chippings. And through mutual cooperation of the auxiliary part and the collecting cavity, the cleaned chippings can be collected, so that the heat preservation plate planing equipment is better in functionality in the actual use process, and the actual machining requirement can be met.

Owner:吴志远

A machine tool module mechanical interface device

ActiveCN105033660BMeet actual processing needsSimple structureLarge fixed membersComputer moduleEngineering

The invention discloses a mechanical interface device of a machine tool module, which comprises a base body and an interface connecting plate, and the interface connecting plate is installed above the base body; three sets of main supports and a set of auxiliary supports are arranged near the four corners between the base body and the interface connecting plate, An equal pressure pull-press mechanism is also arranged between the seat body and the interface connecting plate. The machine tool module mechanical interface device of the present invention uses three main supports and one auxiliary support, combined with an isobaric tension-compression mechanism, so that the geometric accuracy and stiffness of the modular machine tool after assembly can be adjusted in a large range, and the interface stiffness and interface plane can be adjusted It can be flexibly adjusted according to the actual processing conditions to meet the actual processing needs of the product; the structure is simple, the operation is convenient, and the positioning is accurate and reliable.

Owner:XIAN UNIV OF TECH

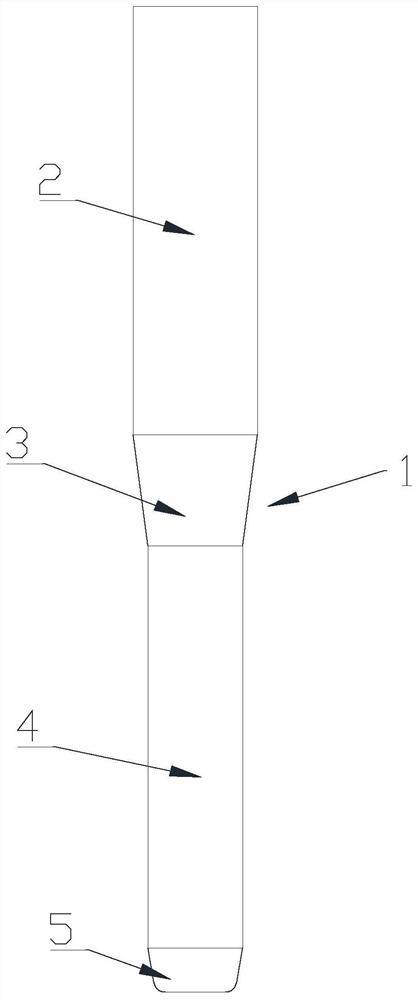

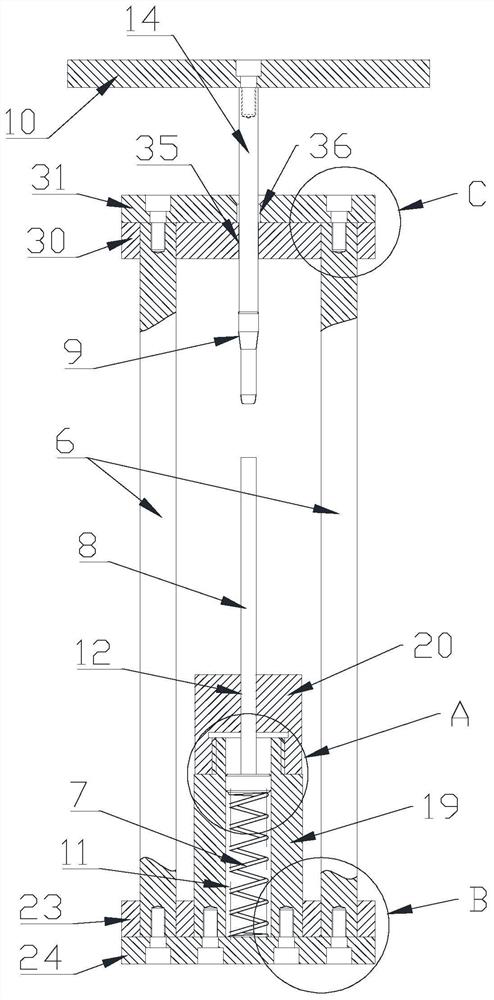

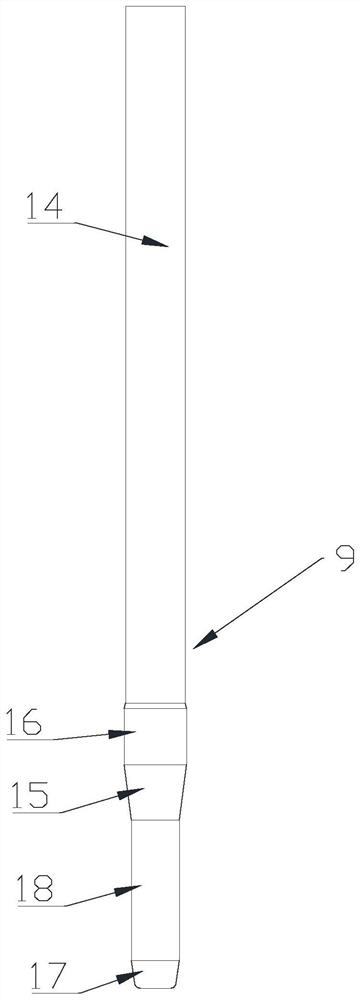

Oil seal transition sleeve and opening expanding tool for machining oil seal transition sleeve

The invention relates to the field of transition sleeves, in particular to an oil seal transition sleeve which is of a thin-wall hollow structure. The oil seal transition sleeve comprises a connecting pipe, a transition pipe and a guide pipe, the connecting pipe is arranged at one end of the transition pipe, the guide pipe is arranged at the other end of the transition pipe, the diameter of the connecting pipe is larger than that of the guide pipe, and the transition pipe is in a circular truncated cone shape. The invention further relates to an opening expanding tool for machining the oil seal transition sleeve, the opening expanding tool for machining the oil seal transition sleeve comprises a lower die lower base, a lower die upper base, a supporting column, a positioning base, a spring, a positioning rod, the opening expanding die and an upper die bottom plate moving up and down, structural design is reasonable, and the connecting pipe and the transition pipe can be conveniently formed through opening expanding machining. According to the oil seal transition sleeve and the opening expanding tool for machining the oil seal transition sleeve, the oil seal transition sleeve is reasonable in structural design and convenient to machine and manufacture, the opening expanding tool is reasonable in structural design, the oil seal transition sleeve meeting actual requirements can be efficiently machined, oil seal transition sleeves of different specifications can be conveniently machined after the tool is replaced. In this way, actual machining requirement can be better met.

Owner:浙江亚之星汽车部件有限公司

Eyeglass chamfering machine

InactiveCN102069436BMeet actual processing needsGood processing consistencyEdge grinding machinesEngineeringMechanical engineering

Owner:林小郎

Precise part machining numerical control machine tool

ActiveCN113523380AMeet process requirementsAddressing the drawbacks of multilateral formationMeasurement/indication equipmentsFeeding apparatusNumerical controlVertical plane

The invention discloses a precise part machining numerical control machine tool. The machine tool comprises a workbench, an electrical box, a machine tool mechanism and a servo adjusting claw, the electrical box is installed at one side of the workbench, and the machine tool mechanism comprises an arc-shaped rack; and a traditional three-section fixed shaft type linear transmission system is abandoned, a set of linear transmission from the Z axis is applied on the basis of X-axis and Y-axis linear transmission directly responsible for part machining, meanwhile, two sets of degree-of-freedom output are kept, a thread pair is responsible for adjusting Z-axis output, meanwhile, angle adjustment is achieved through a gear pair and a servo transmission system, in the actual part machining process, adjustment can be conducted at any angle under the vertical plane projection visual angle, so that a cutter can be directly and perpendicularly matched with an extension line of the outline curve of the part direction plane, the defect of polygon forming in a traditional CNC system is overcome, an actual machining coefficient of a part infinitely approaches a theoretical coefficient, and the process requirements of actual precise parts are effectively met.

Owner:南通福根机械制造有限公司

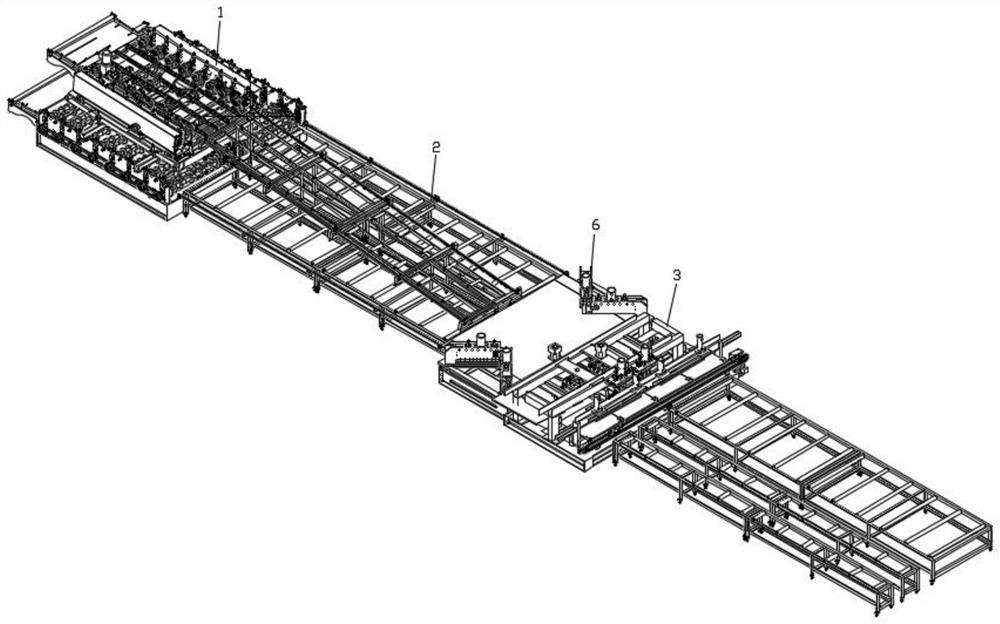

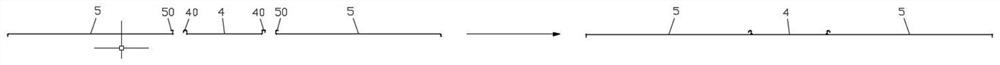

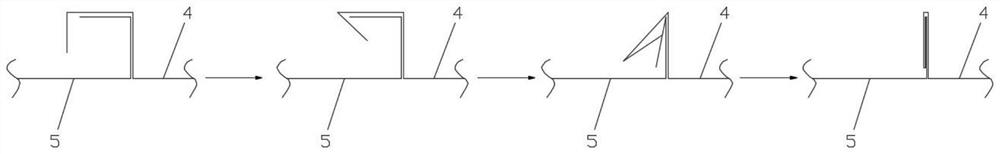

Section bar splicing forming device

PendingCN114273535AImprove processing efficiencyReduce processing costsStructural engineeringMechanical engineering

The invention discloses a sectional material splicing and forming device. The sectional material splicing and forming device comprises an edge turning device, a splicing device and an edge locking device. The flanging device is used for folding the two sides of the middle sectional material to form inverted-U-shaped hasps and folding the sides, close to the middle sectional material, of the two side sectional materials to form inverted-L-shaped lapping shoulders. The splicing device comprises a middle frame and two side frames; the middle frame is obliquely fixed above the middle parts of the two side frames, and the discharge end of the middle frame is connected with the side frames; first limiting rods are arranged on the two sides of the upper end of the middle frame correspondingly, and the middle profile is located on the inner sides of the two first limiting rods. A plurality of first locking pieces are arranged on the first limiting rod; second limiting rods are arranged on the two sides of the upper end of the side frame correspondingly, and the side profile is located on the inner sides of the two second limiting rods. A plurality of second locking pieces are arranged on the second limiting rod; and the edge locking device is used for locking the spliced inverted U-shaped hasp and the spliced inverted L-shaped shoulder together.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

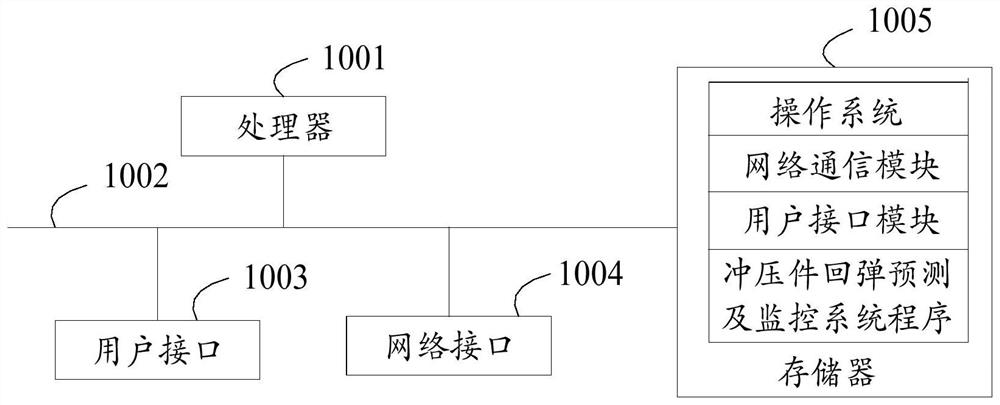

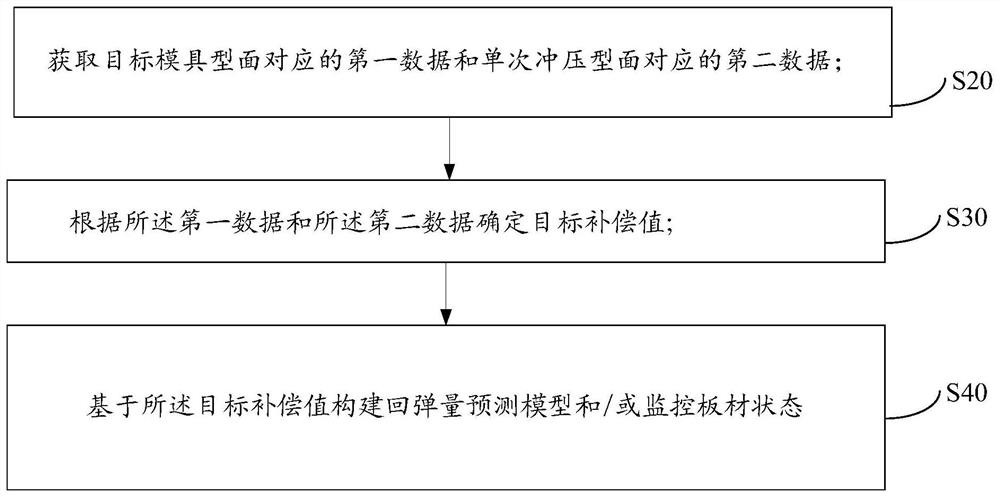

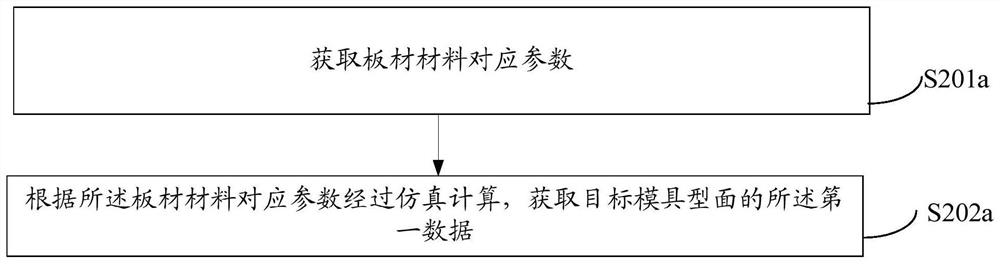

Stamping part springback predicting and monitoring method and system and storage medium

ActiveCN113221402AGuarantee processing qualityMeet actual processing needsDesign optimisation/simulationMetal working apparatusStructural engineeringStamping process

The invention discloses a stamping part springback predicting and monitoring method and system and a storage medium, and the stamping part springback predicting and monitoring method comprises the steps: obtaining first data corresponding to a target mold molded surface and second data corresponding to a single stamping molded surface, and determining a target compensation value according to the first data and the second data, based on the target compensation value, constructing a springback value prediction model and / or monitoring the plate state, obtaining second data of a single-time stamping molded surface in the actual stamping process of the stamping part, determining the target compensation value by combining the first data corresponding to the target mold molded surface with the second data, and guiding stamping part machining according to the springback value prediction model. In this way, the machining mode for guiding the stamping part better meets the actual machining requirement, and / or the machining quality of the stamping part can be guaranteed by monitoring the plate state.

Owner:HUBEI UNIV OF ARTS & SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com