Patents

Literature

70results about How to "Guaranteed fit quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film sticking method and equipment

ActiveCN107934018AEven by forceEffective fitPackagingVolume expansionElectrical and Electronics engineering

Owner:SHENZHEN WEIHONGKE TECH

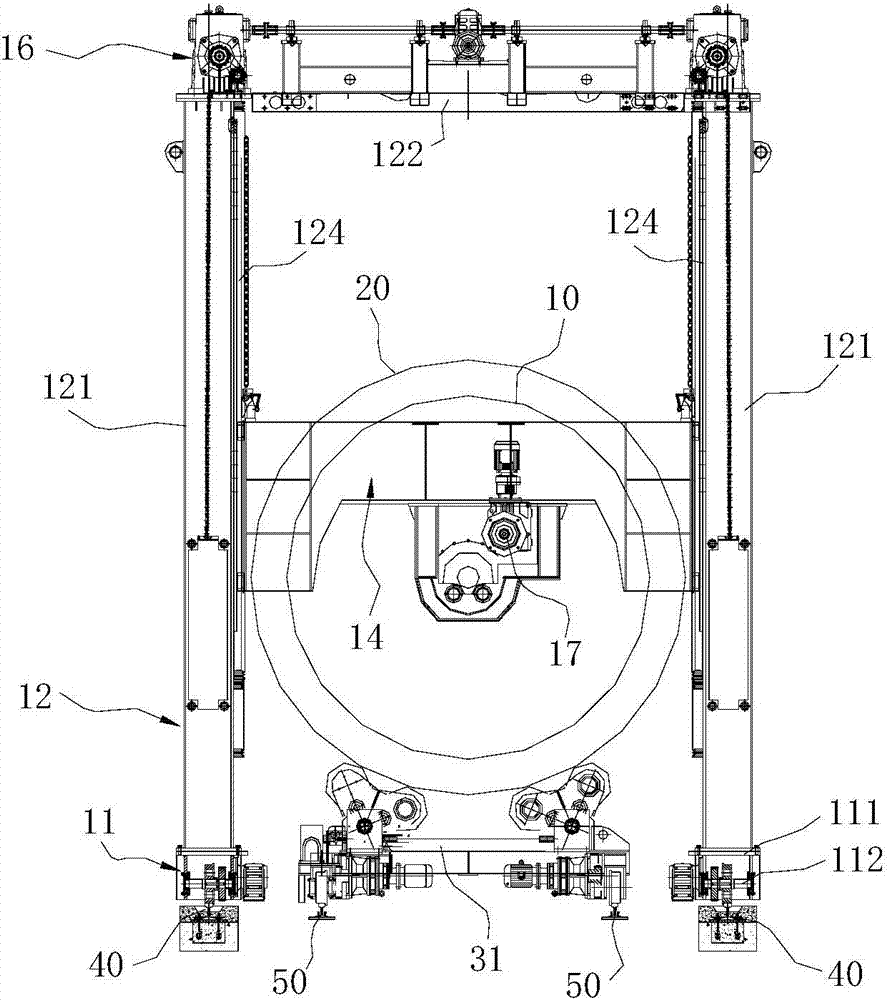

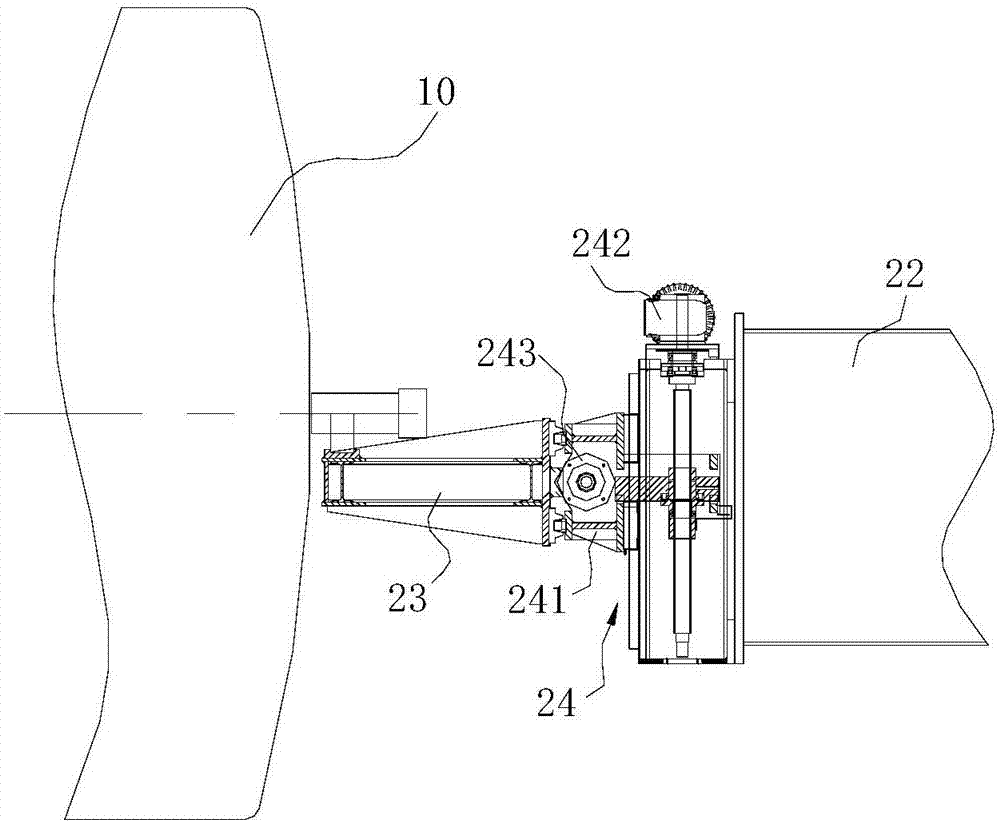

Formation drum of automatic back-edging roller press

The present invention relates to an automatic back contact rolling mechanical forming drum, including coupling flange, back contact rolling arm elastic rubber ring, drive back contact rolling piston component and cylinder body sleeve the the front end of which is equipped with sector block cylinder body, drive sector block piston group, sector block connecting bar group, fastening tire body sector block group and sector guide disk. The rear end of the described piston component is symmetrically equipped with back contact rolling arm component, back contact rolling wheel group and free guide bearing group. The rear end of the described cylinder body sleeve is equipped with dished pushing disk, and a slide-fit cylinder body rear end cover is mounted on the cylinder body sleeve, and the rear portion of the described back contact rolling arm component is connected at the rear end cover place of the cylinder body.

Owner:TIANJIN PLASTIC RUBBER MACHINERY INST

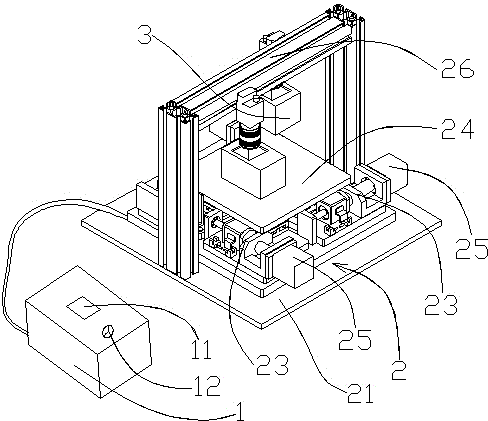

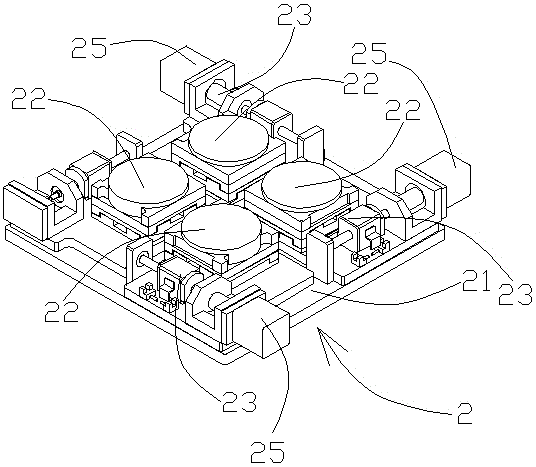

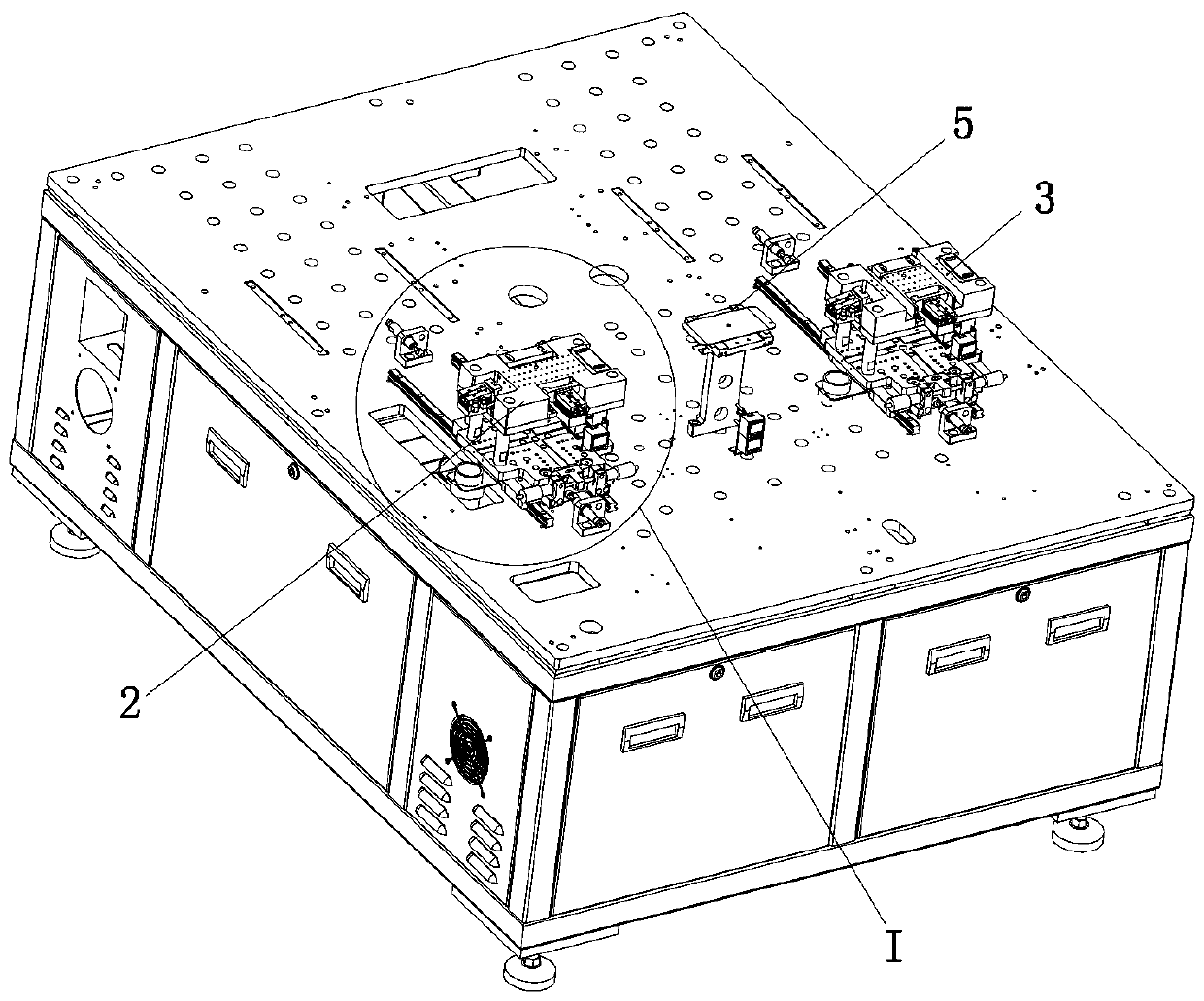

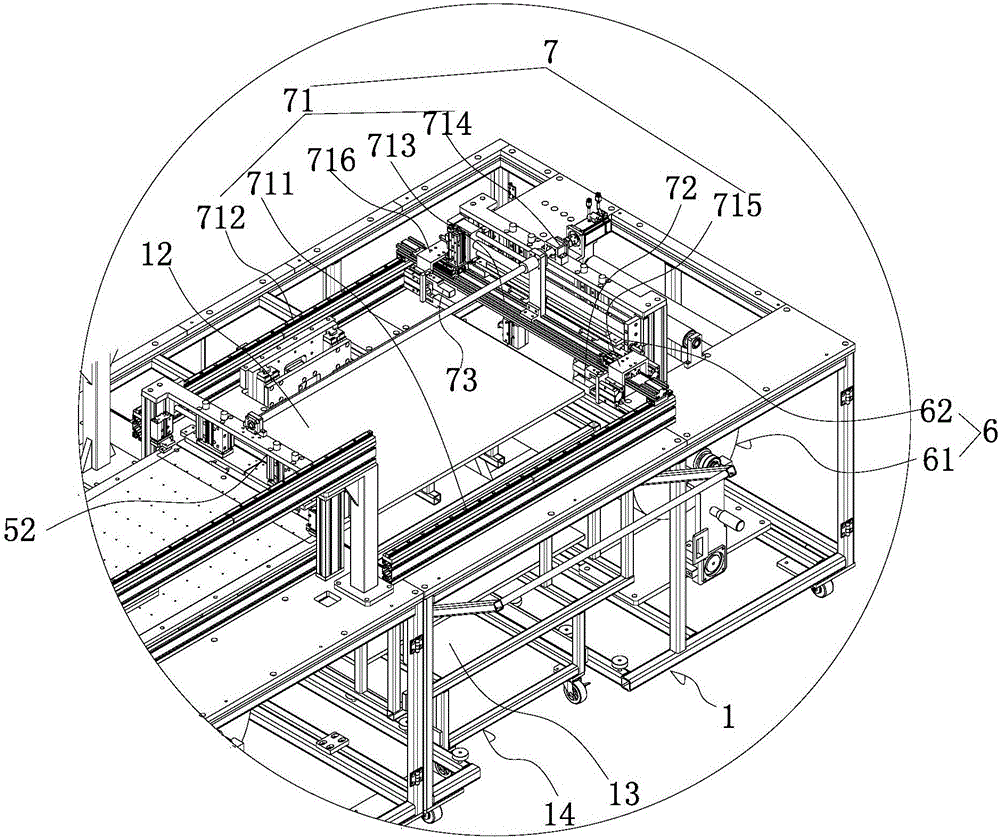

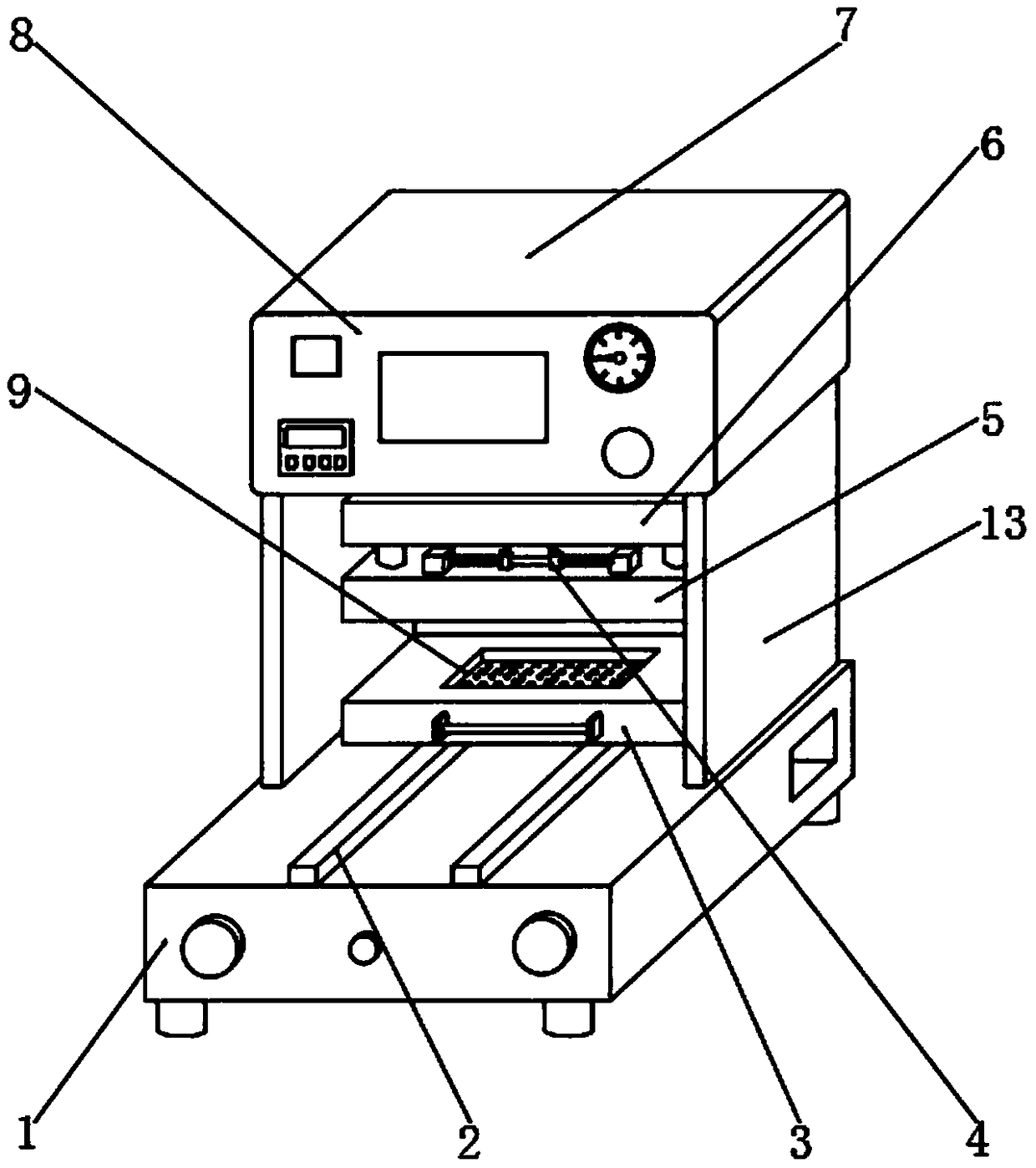

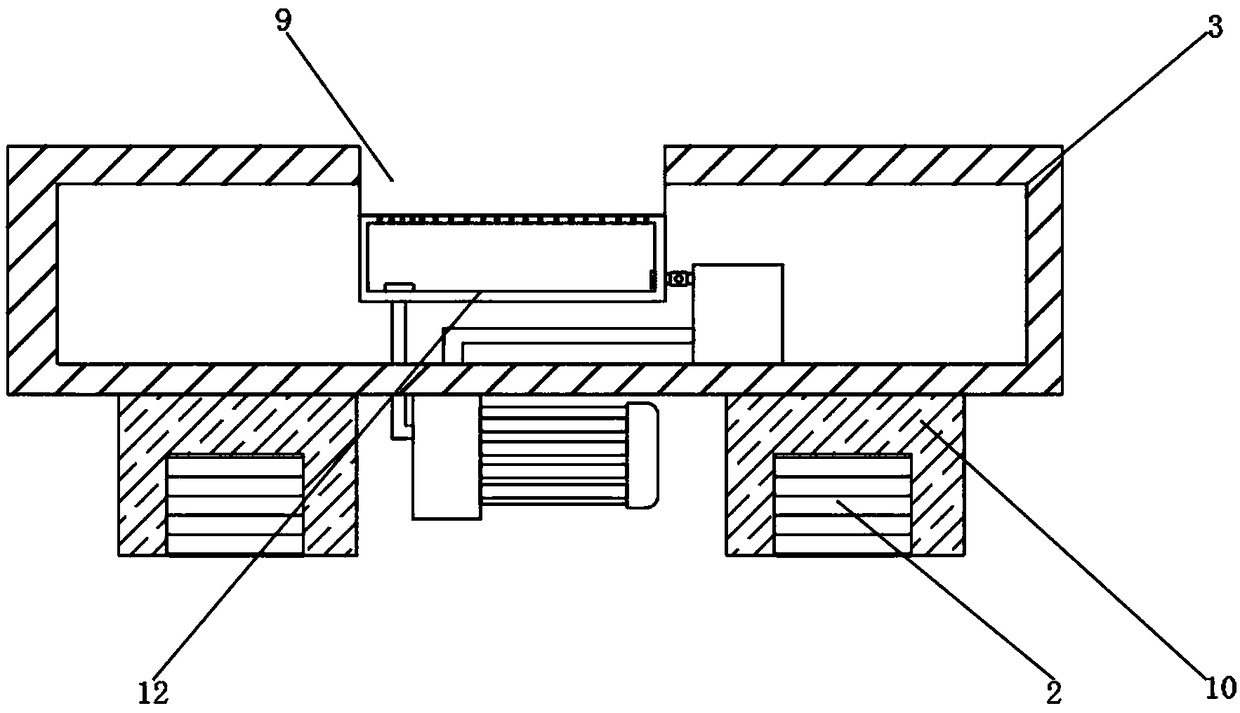

Vision alignment platform

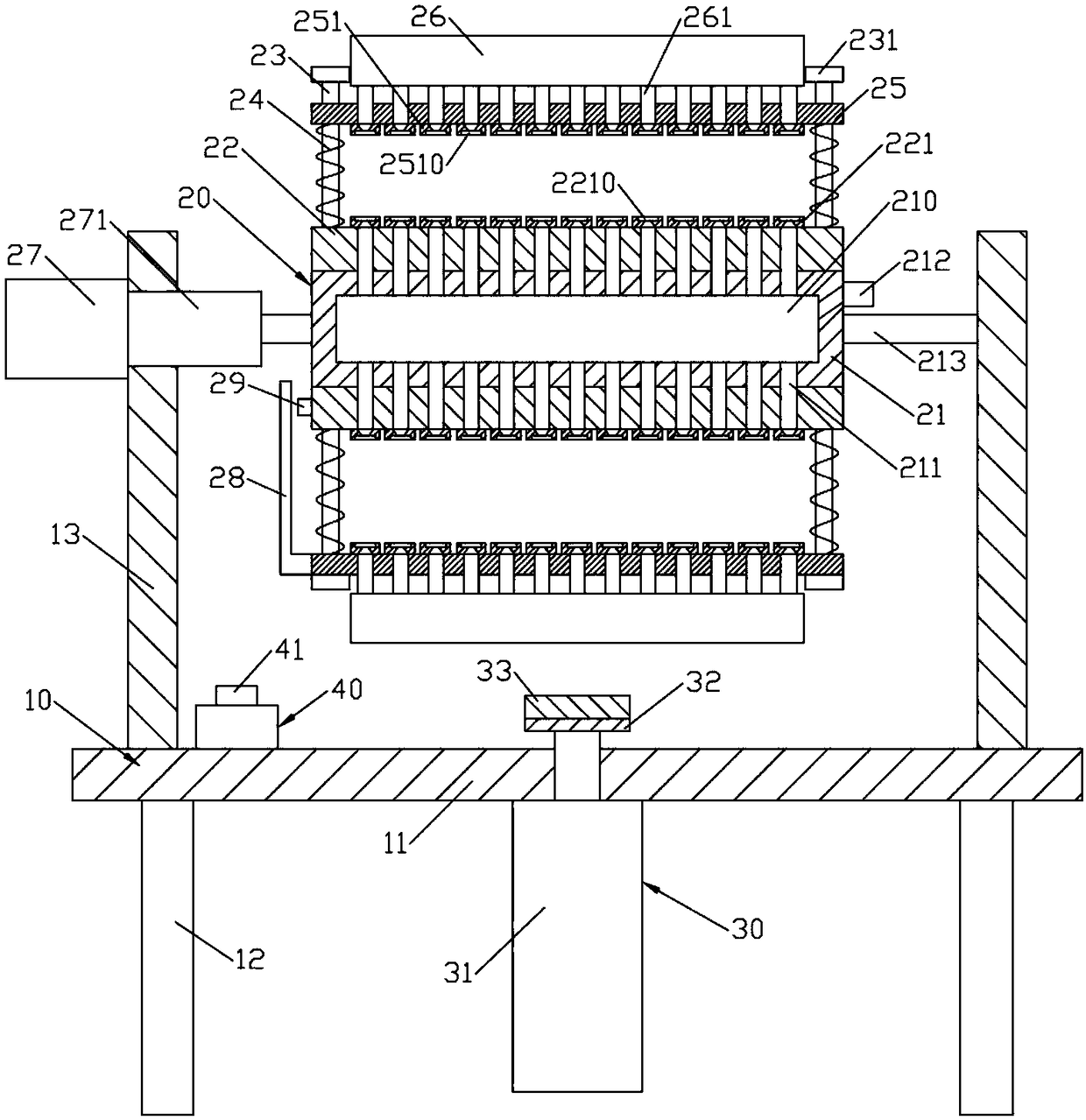

InactiveCN104859888AQuick alignmentAlignment quick preparationPackaging automatic controlElectric machineryEngineering

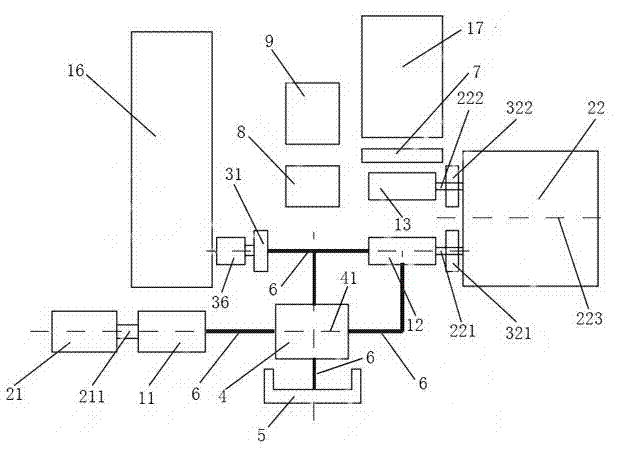

The invention discloses a vision alignment platform. The platform comprises a controller, an alignment mechanism and a photographing unit, wherein a display screen is arranged on the controller, analysis and calculation software is embedded in the controller, the controller is in signal communication with the alignment mechanism through a signal line, the alignment mechanism comprises a base, four XYtheta sliding platforms, three adjusting screw rods and a working platform, the four XYtheta sliding platforms are evenly distributed in the center of the base, the three adjusting screw rods are arranged on outer sides of the four XYtheta sliding platforms and act under the driving of three external motors respectively to drive the XYtheta sliding platforms to act, and the photographing unit is fixed above the working platform through a fixing support; positions of products are acquired by the photographing unit, position deviations are calculated accurately by the analysis and calculation software in the controller, the products are moved to accurate positions by the alignment mechanism, so that quick and accurate alignment is realized, the alignment accuracy is high, the error is very small, the yield of the products produced through aligned lamination is high, the lamination efficiency is improved, and the lamination quality is guaranteed.

Owner:厦门坚端精密机械有限公司

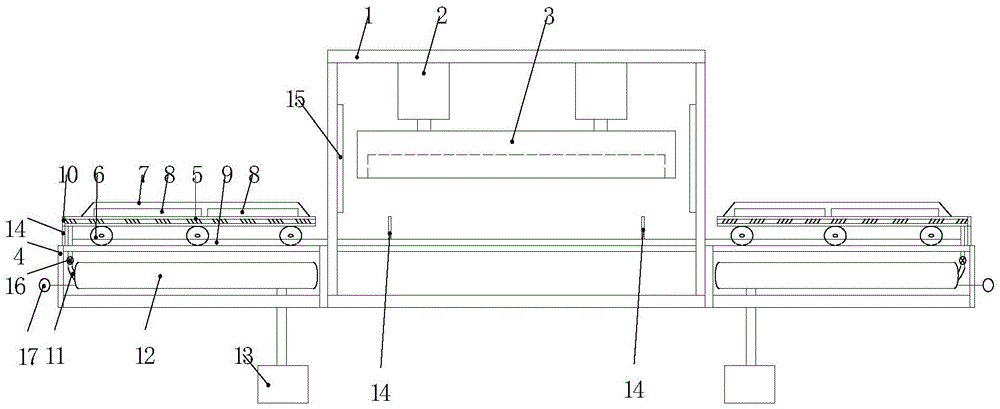

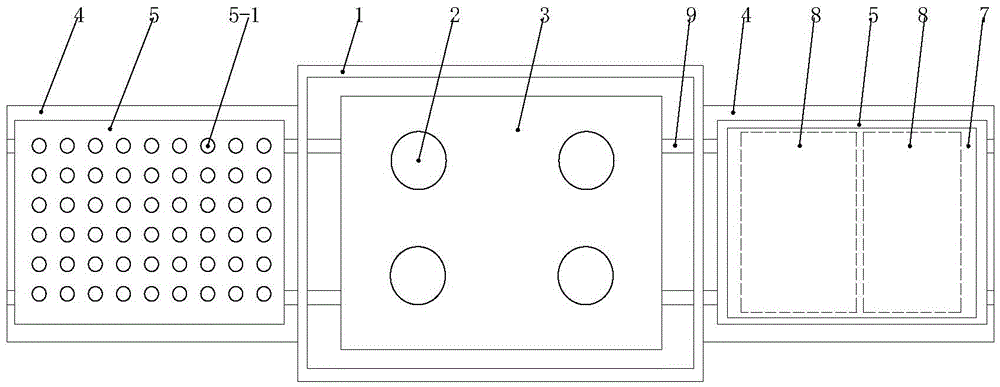

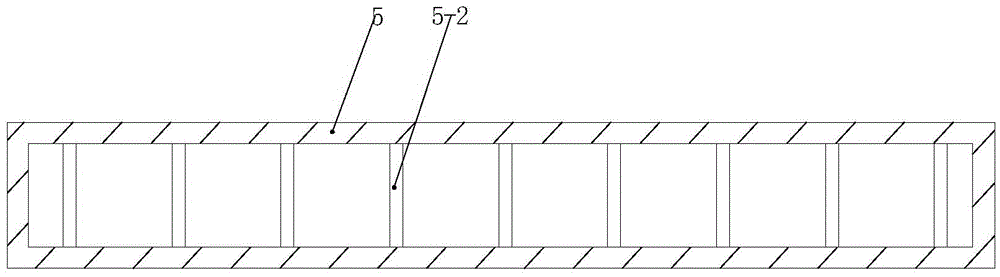

An efficient vacuum plane film laminating machine and a film laminating method

InactiveCN105459563AGuaranteed fit qualityUniform constant temperature heatingLaminationLamination apparatusControl systemEngineering

The invention relates to an efficient vacuum plane film laminating machine and a film laminating method. The machine comprises a rack, workbench supports and a control system and is provided with one or two groups of plane workbenches, wherein a vacuumizing device is connected to each plane, the workbench supports are provided with guide rails, each plane workbench moves along the guide rails through transmission devices, air cylinders are mounted on the rack and drive a heating box to move, each vacuumizing device comprises a vacuum pump and a negative pressure cavity which are connected, and each negative pressure cavity is connected to the corresponding plane workbench through a hose. The inside of each plane workbench is a cavity provided with supporting devices. The surface of each plane workbench is provided with a plurality of vacuumizing ports. Each vacuumizing device is connected to the corresponding cavity. The machine and the method are igneous in design, convenient to operate, high in efficiency, and capable of ensuring product quality, saving a large quantity of PVC film, saving labor, saving consumed power and reducing the cost. The rate of finished products is 100%.

Owner:冯乃元

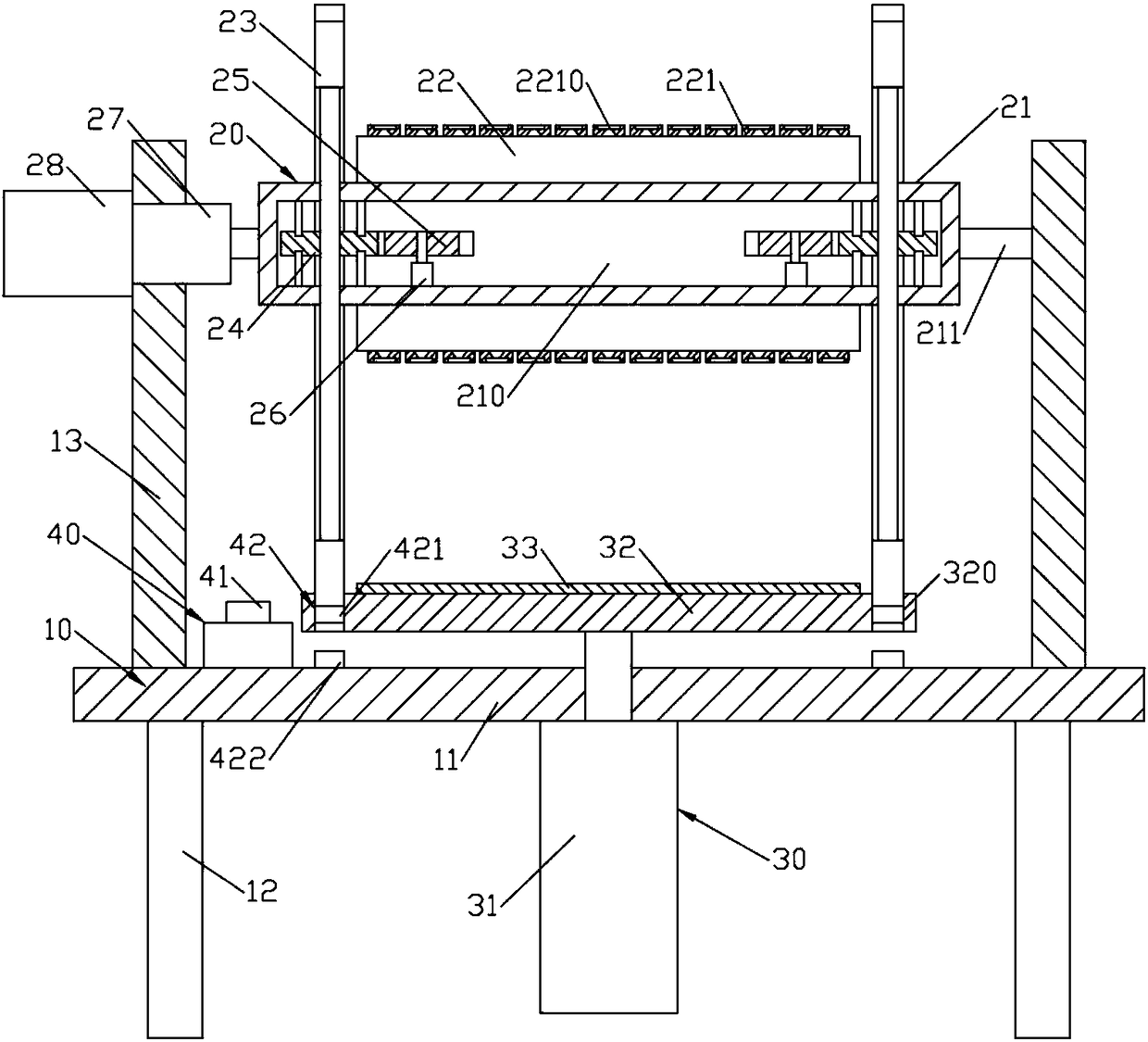

Negative-pressure high-temperature plank laminating equipment

InactiveCN108115779AEffective fitCooperate effectivelyLaminationLamination apparatusHydraulic cylinderEngineering

The invention discloses negative-pressure high-temperature plank laminating equipment. The negative-pressure high-temperature plank laminating equipment comprises a rack. A machine box is mounted at the top of the rack. A plurality of hydraulic cylinder mounting bases are arranged on a crossbeam of the bottom of the rack. Hydraulic cylinders are fixedly mounted on the hydraulic cylinder mounting bases. A sealing frame is fixed to the top end of a piston rod of each hydraulic cylinder. A rail bracket is mounted on the inner side of the bottom of the rack. Double supporting crossbeams are mounted on the rail bracket. The upper top surface of each supporting crossbeam is provided with a sliding rail. A plank material storing bed device is mounted on each sliding rail in sliding and matched modes. The side surface of each plank material storing bed device is provided with a laminating bracket device used for storing laminating films. The upper part of each sealing frame is provided with ahot air device. The hot air devices, the sealing frames and the plank material storing bed devices are matched mutually to conduct laminating on plank materials. The negative-pressure high-temperatureplank laminating equipment can conduct laminating on the plank materials, the laminating efficiency is improved, and the laminating quality is ensured.

Owner:YICHANG PANBAOBAO NEW MATERIAL TECH CO LTD

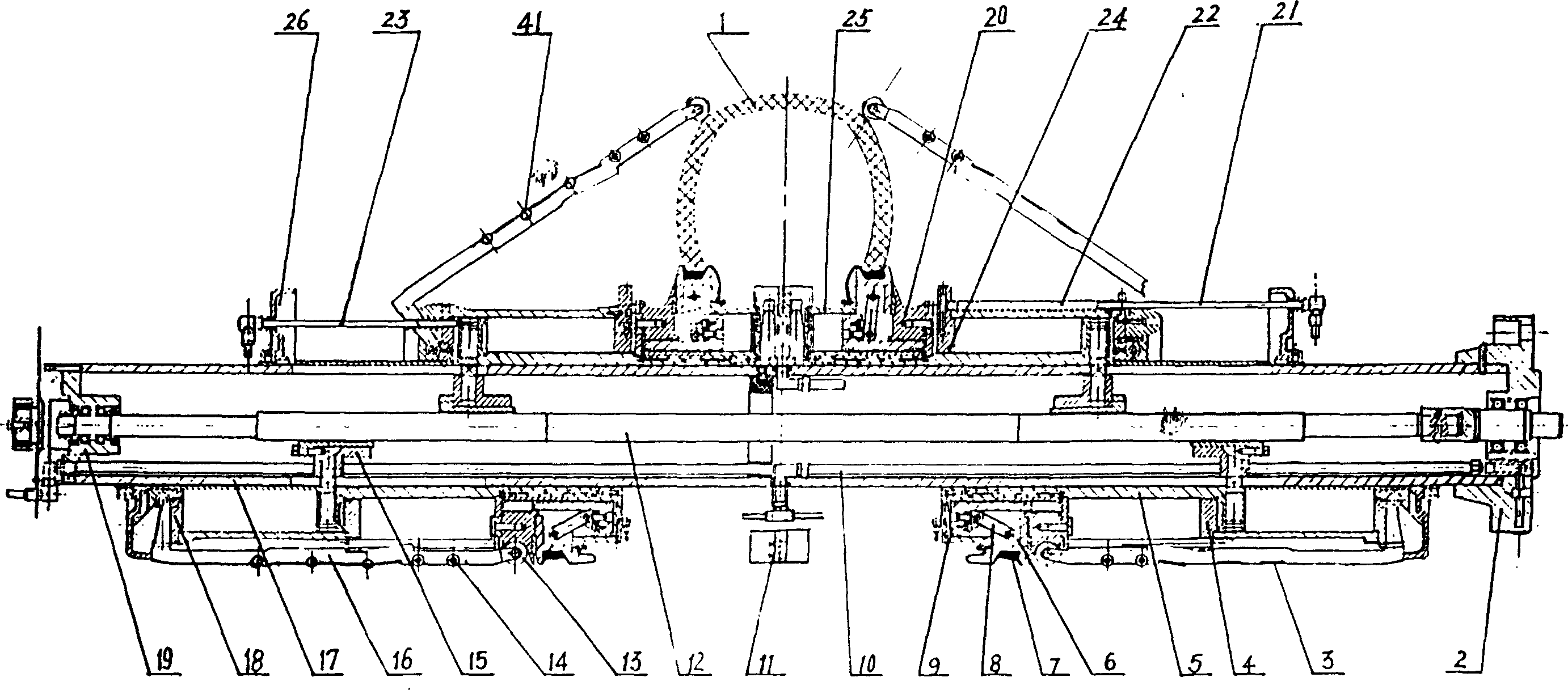

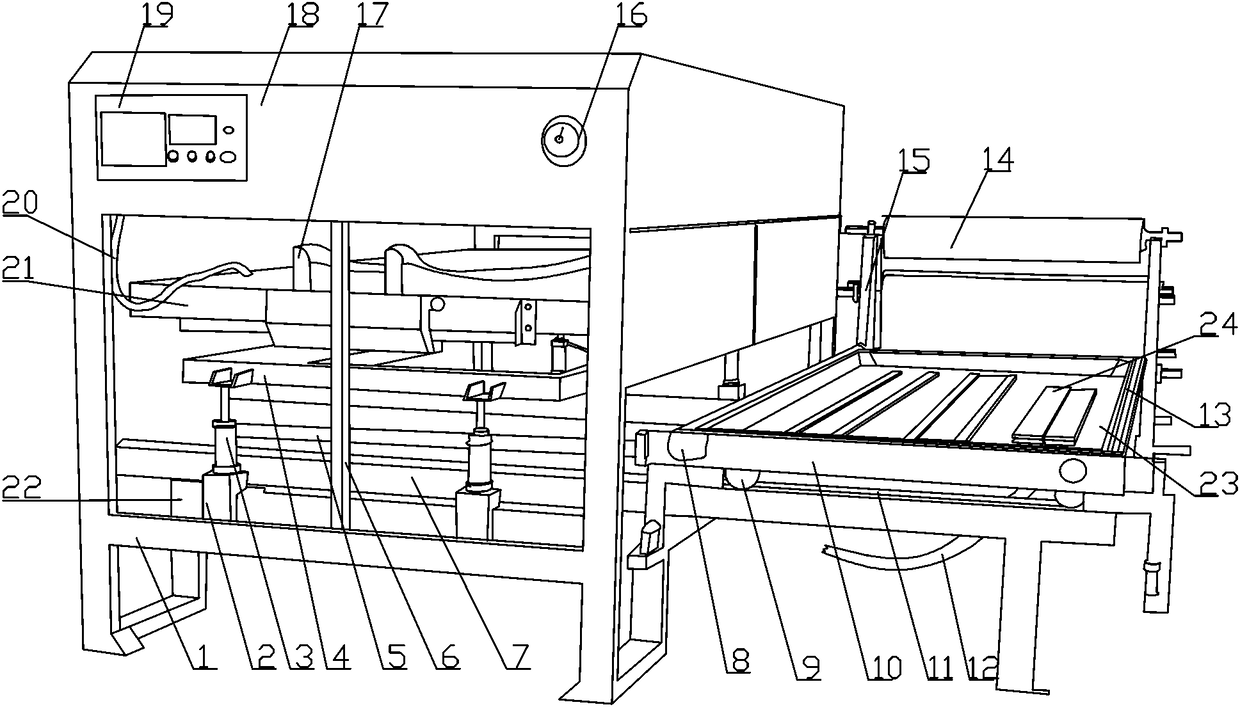

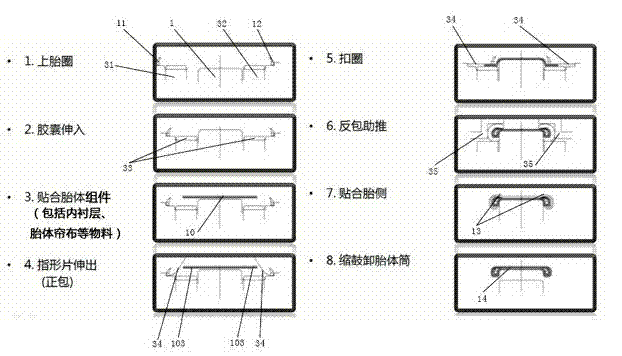

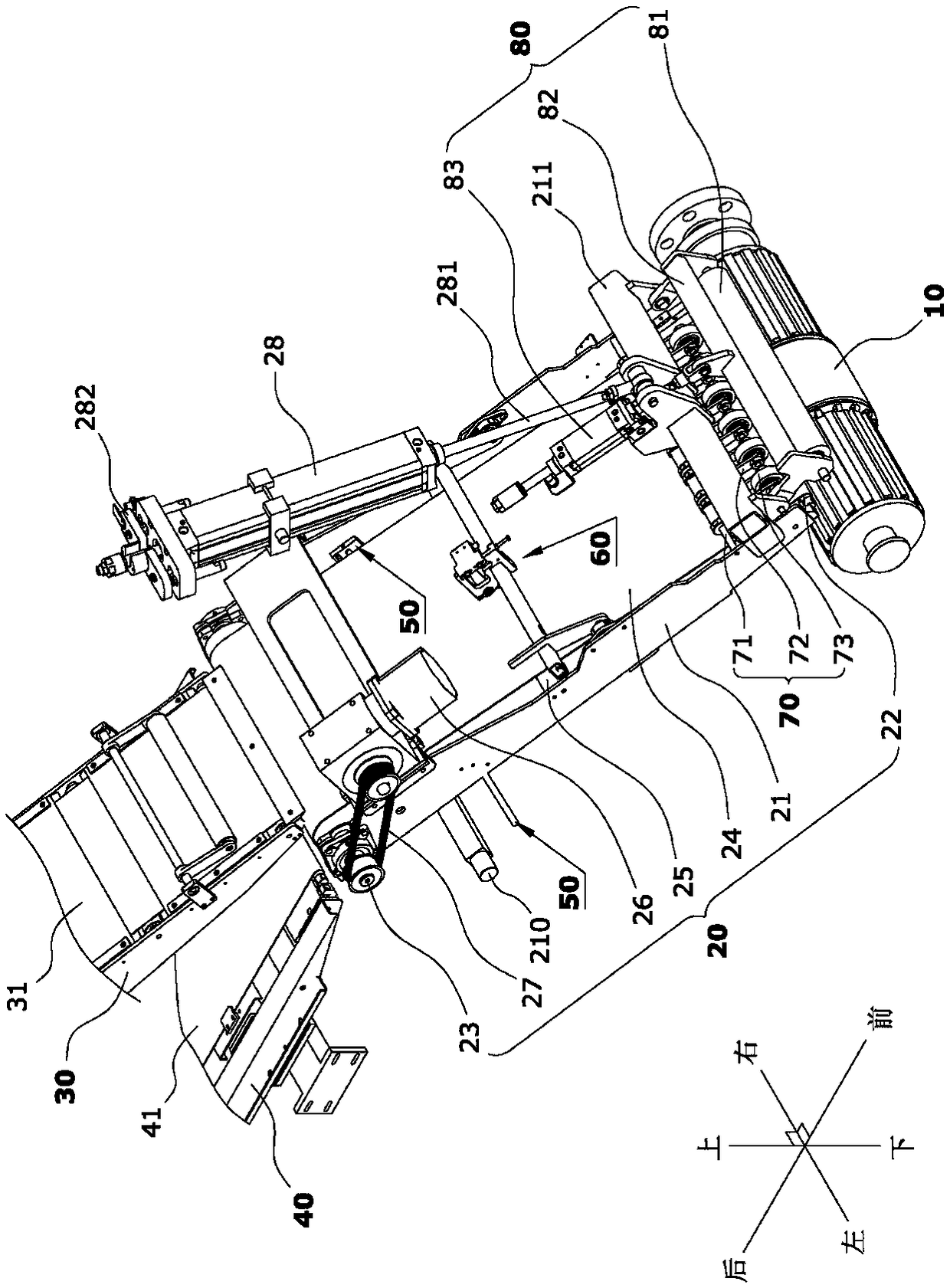

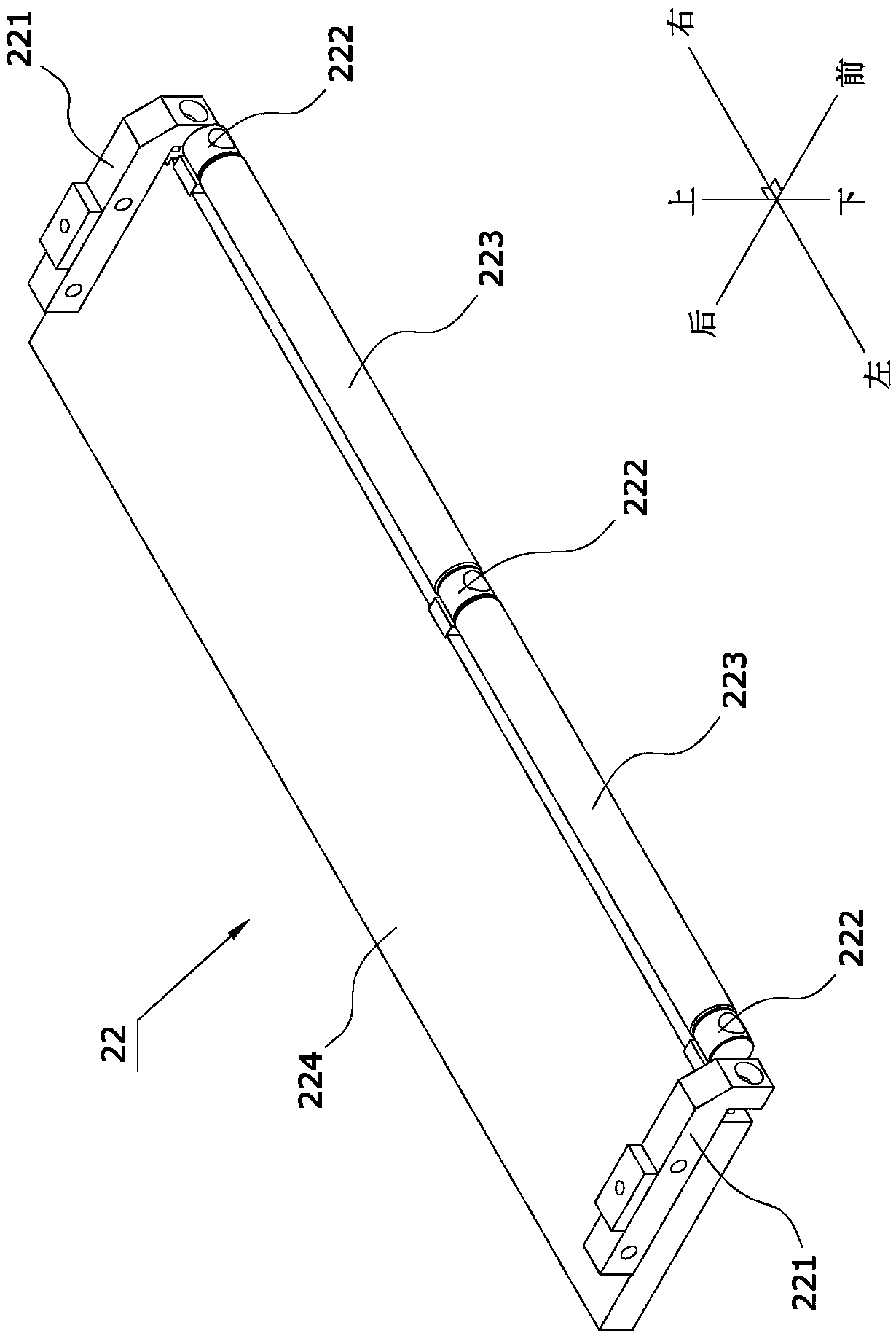

One-section forming method and one-section forming machine for producing radial tire with two-time method

ActiveCN103496182AImprove molding efficiencyAchieve flat drum fitTyresEngineeringUltimate tensile strength

The invention discloses a one-section forming method and one-section forming machine for producing a radial tire with a two-time method. In the method, the forming process, the forward buckle ring covering process, the reverse covering process, the tire side attaching process and the rolling and pressing process of a tire component are carried out on different drums, and an attached drum, a forming drum and a transmitting ring for transmitting the tire component formed on the attached drum to the forming drum are arranged in the forming machine. All processes carried out on a single drum in the traditional process are carried out on the drums simultaneously, the problem that at present, a lining layer, tire body curtain fabric, a reinforcing layer and the like cannot achieve flat drum attaching is solved, forming efficiency is obviously improved, device automation is achieved, and labor intensity is lowered.

Owner:北京敬业机械设备有限公司

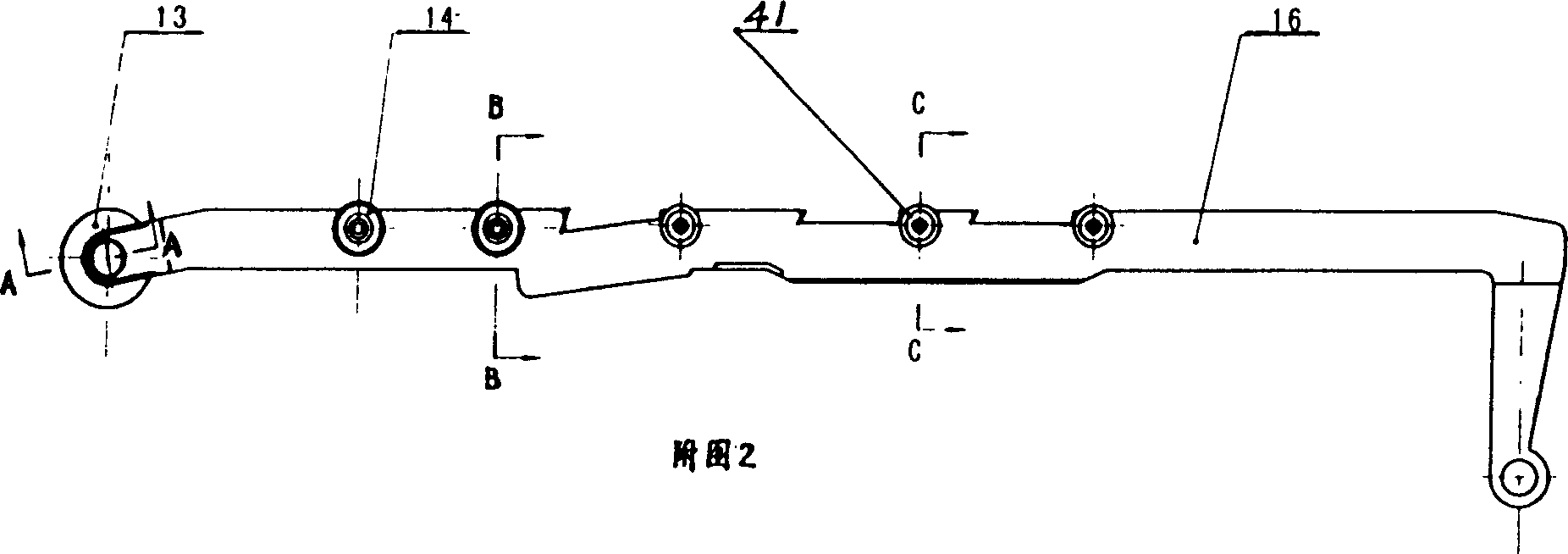

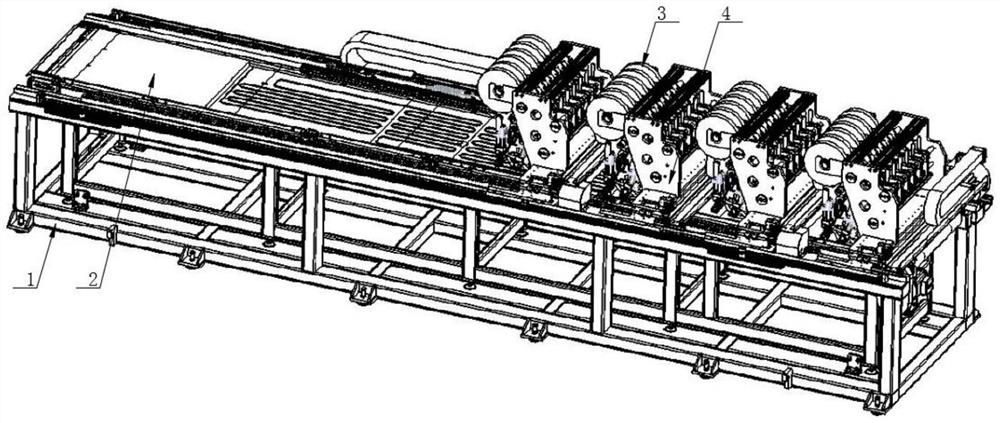

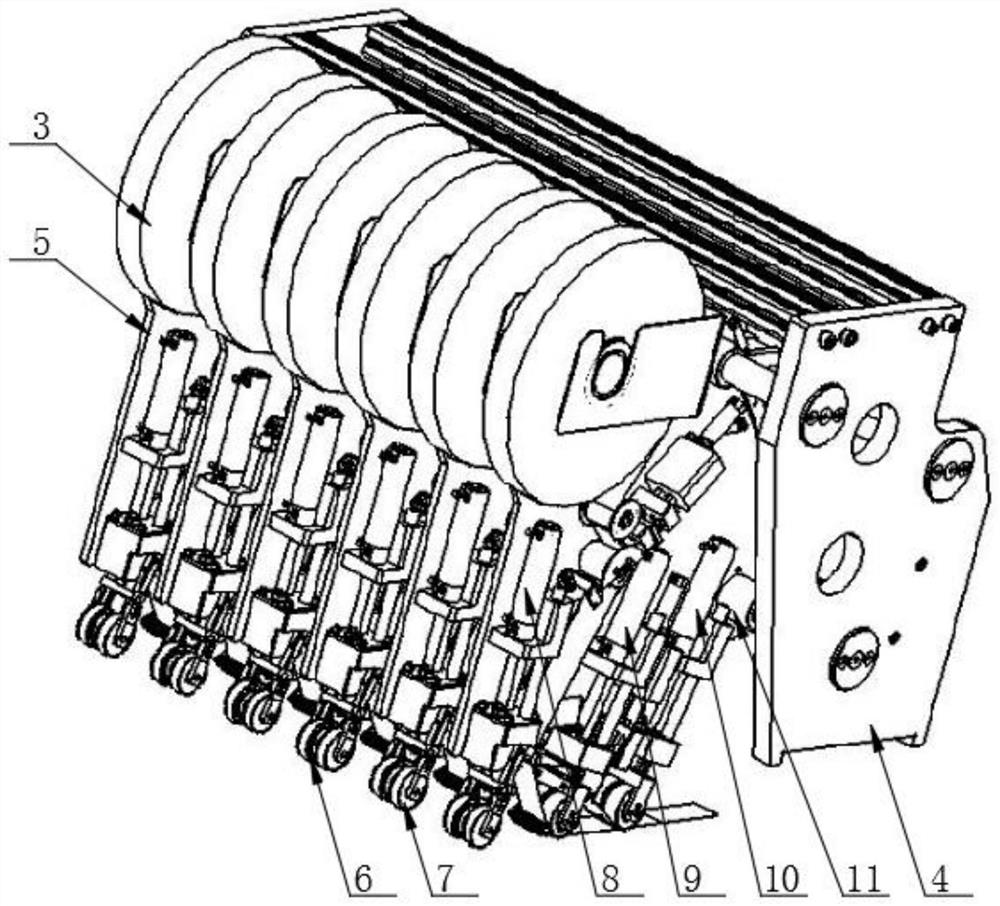

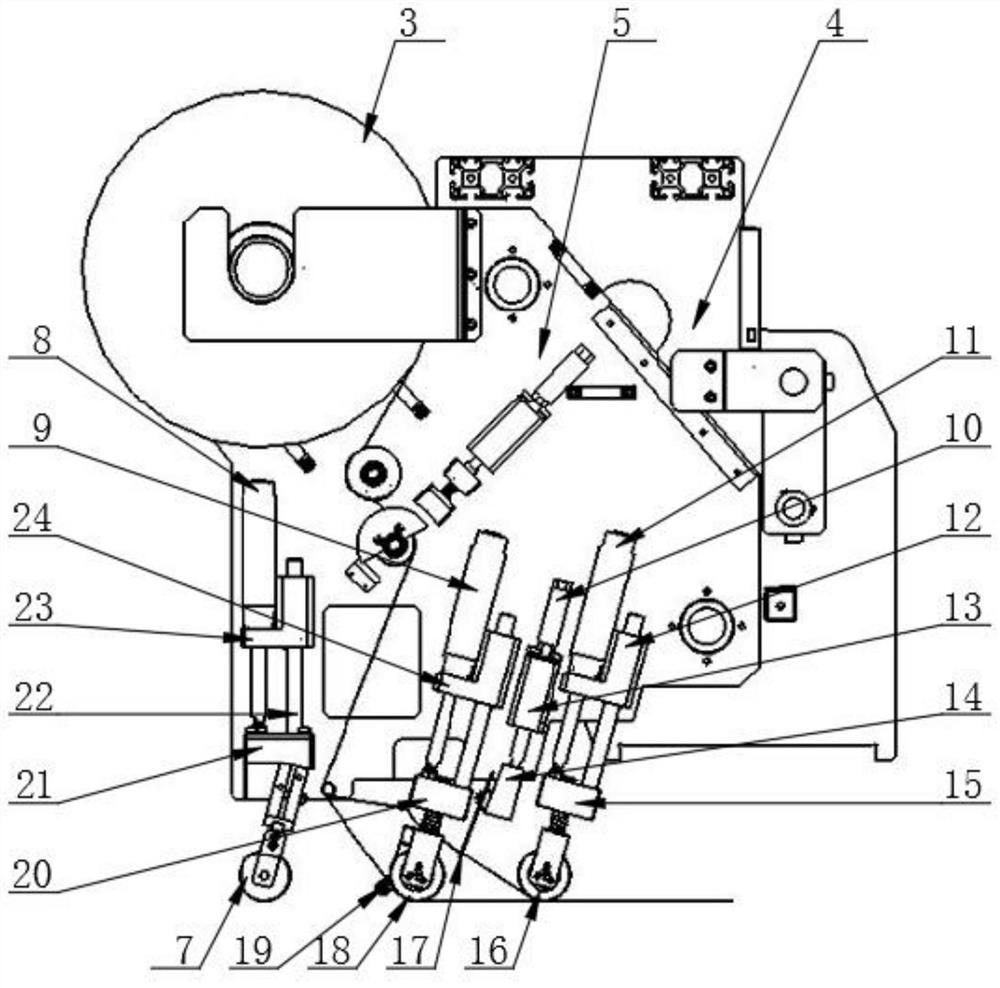

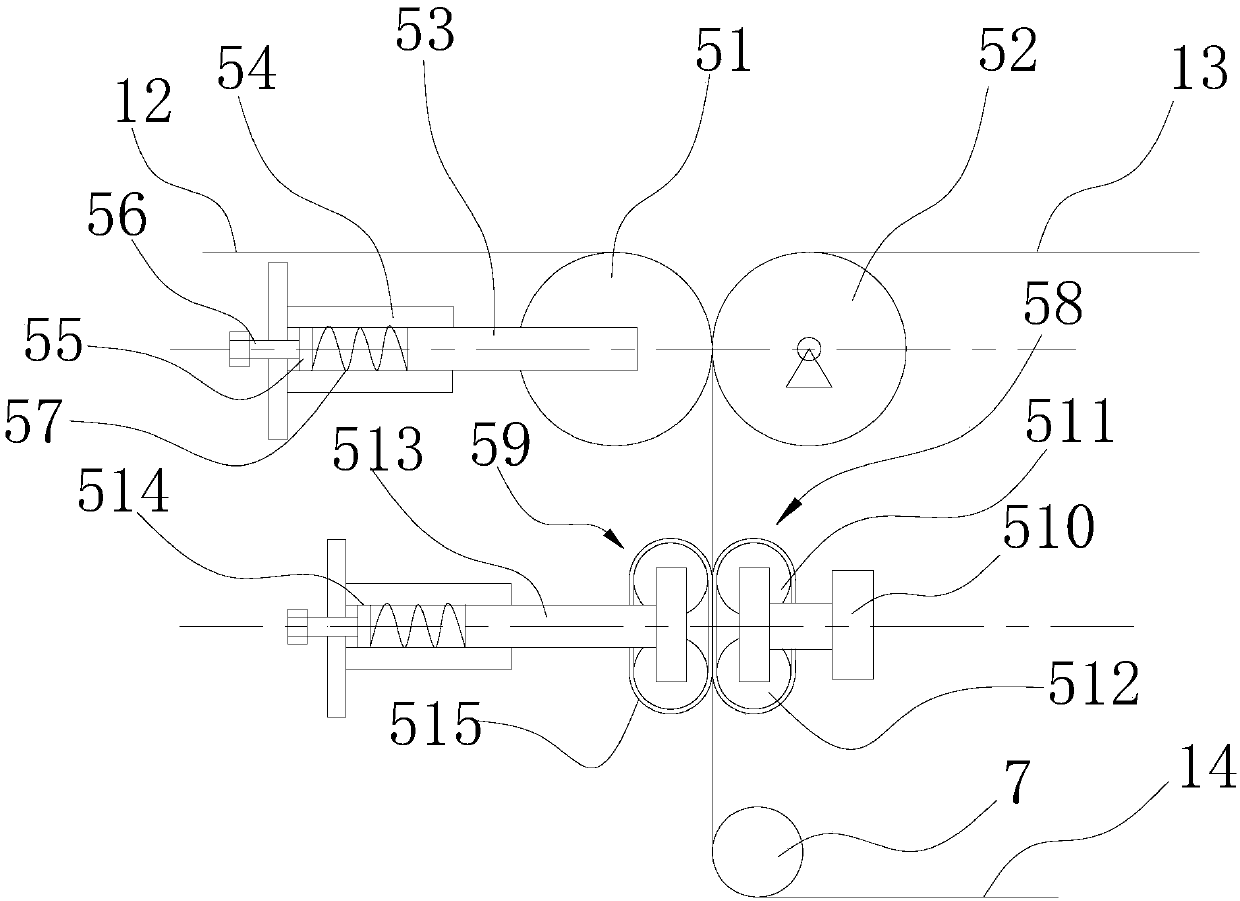

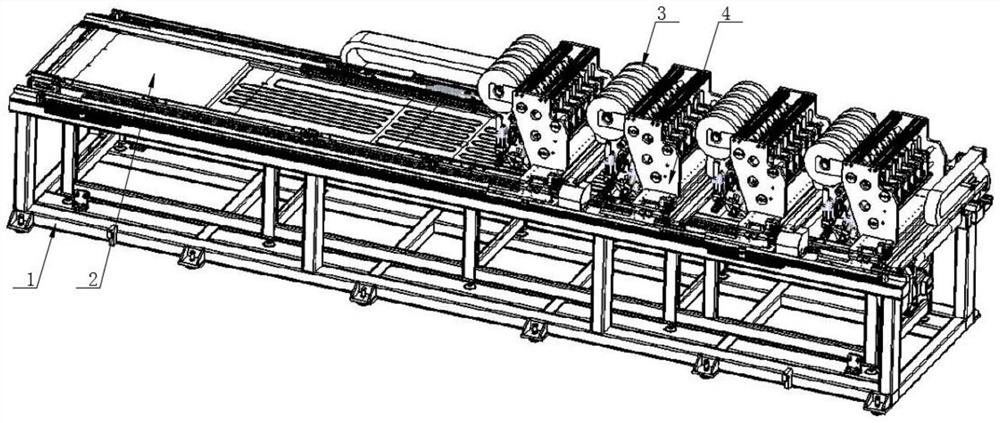

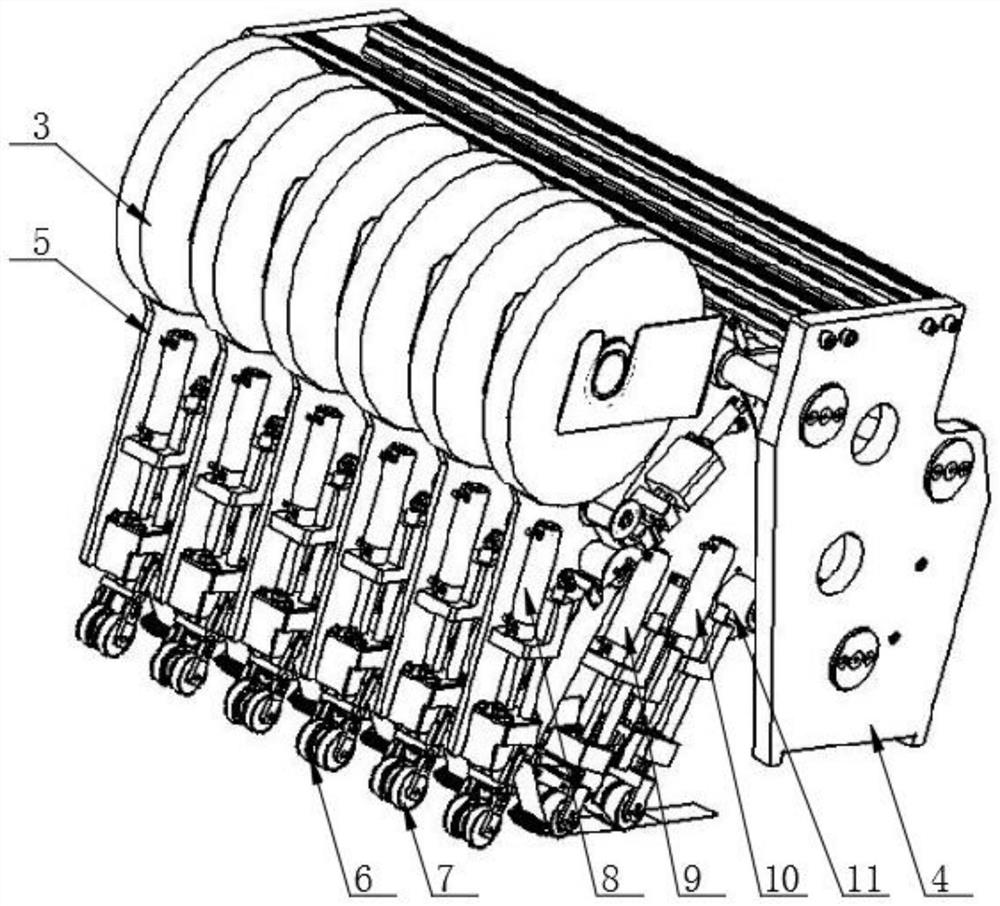

Device for automatically fitting liners and treads of tires of electric vehicles or motorcycles

The invention discloses a device for automatically fitting liners and treads of tires of electric vehicles or motorcycles. The device comprises a tire body drum; a seesaw type material guiding frame is mounted above the rear part of the tire body drum; a tread conveying frame and a liner conveying frame parallel with the tread conveying frame in an up-down direction are fixed at the rear side of the material guiding frame; the rotating material guiding frame is capable of guiding sizing materials conveyed by the tread conveying frame and the liner conveying frame onto the tire body drum to berolled and fit; a deviation rectification mechanism capable of guiding the sizing materials is mounted below the lower part of the material guiding frame; and a material head detection mechanism for detecting whether sizing materials exist or not, a material pressing mechanism for preventing the positions of the sizing materials from deviation and a rolling mechanism for pressing the sizing materials on the tire body drum to roll are mounted above the material guiding frame according to a sequence from the middle part to the front end. In the production of tires of electric vehicles or motorcycles, the device is capable of fitting the liners and the treads, so as to improve the automation level of the whole tire building machine, reduce the labor intensity of workers, improve the productivity and improve the tire production quality.

Owner:XIAMEN HONGHAI MACHINERY

Fabrication method for PCB having local electrical thick gold PAD

ActiveCN110351955AGood appearanceGood lookingConductive pattern formationConductive material chemical/electrolytical removalMaterials scienceCopper deposition

The invention discloses a fabrication method for PCB having local electrical thick gold PAD. The fabrication method comprises the following steps of performing pad pasting on a production plate, and forming an outer-layer circuit pattern after exposure and developing, wherein the outer-layer circuit pattern comprises PAD; etching to remove a copper layer at a non-outer layer circuit pattern, and obtaining an outer-layer circuit after film withdrawing; plating a thin copper layer on a panel by copper deposition and full-board electroplating; filling a panel of a non-outer layer circuit part with an electrical-resistant gold ink, and allowing an upper end of the electrical-resistant gold ink to be flush with an upper end of the outer-layer circuit; performing pad pasting on the production plate, and forming a window in a position corresponding to the PAD; electroplating nickel and thin gold on the PAD, and then electroplating thick gold on the PAD; sequentially stripping a film and the electrical-resistant gold ink on the production plate; removing a thin copper layer by etching, and making the outer-layer circuit again; and performing post-process treatment to obtain the PCB. By themethod, the fabrication process flow is optimized, the problem of diffusion coating during fabrication of the local electrical thick gold PAD is solved, and the appearance quality and favorable performance of the PCB are ensured.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

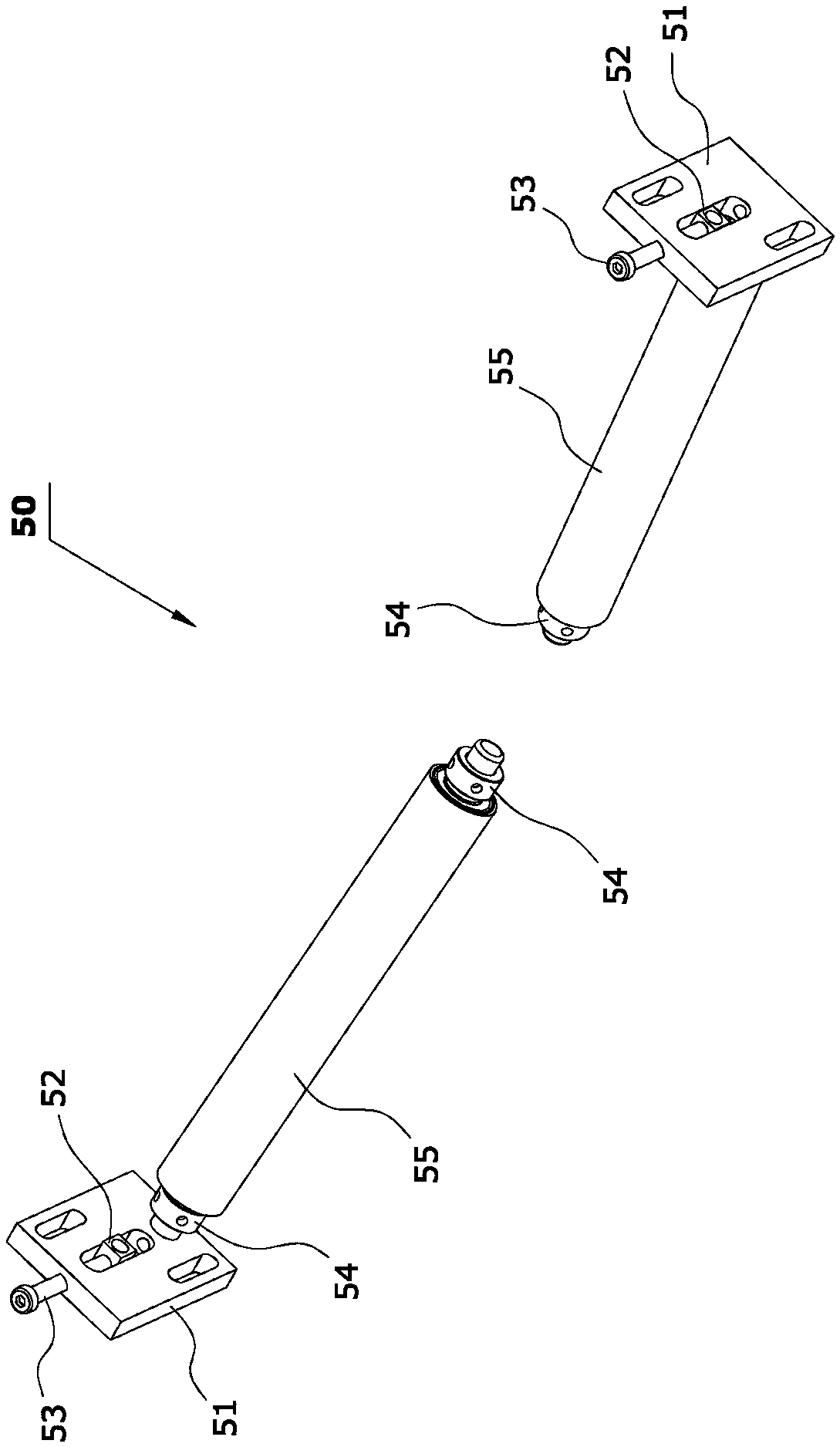

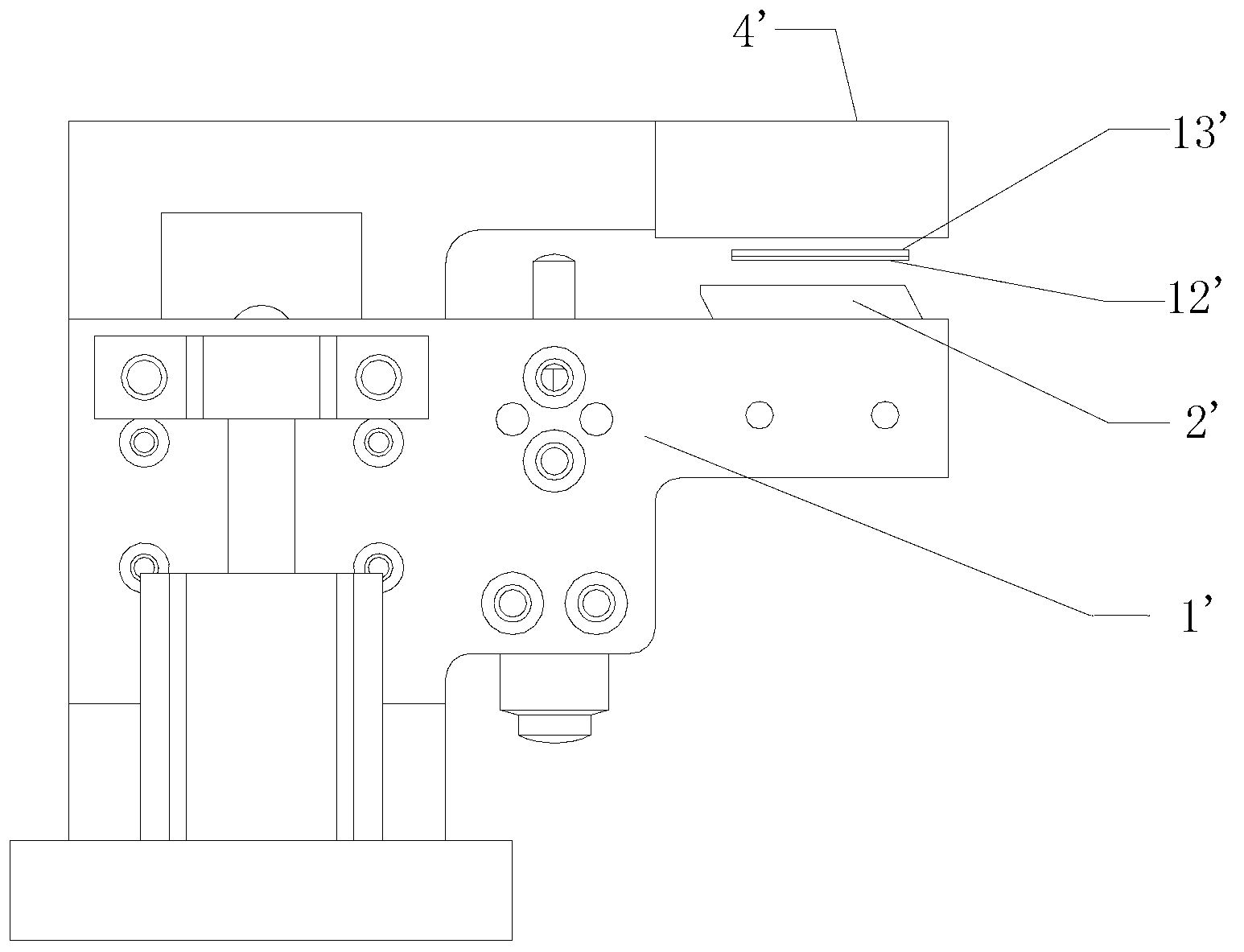

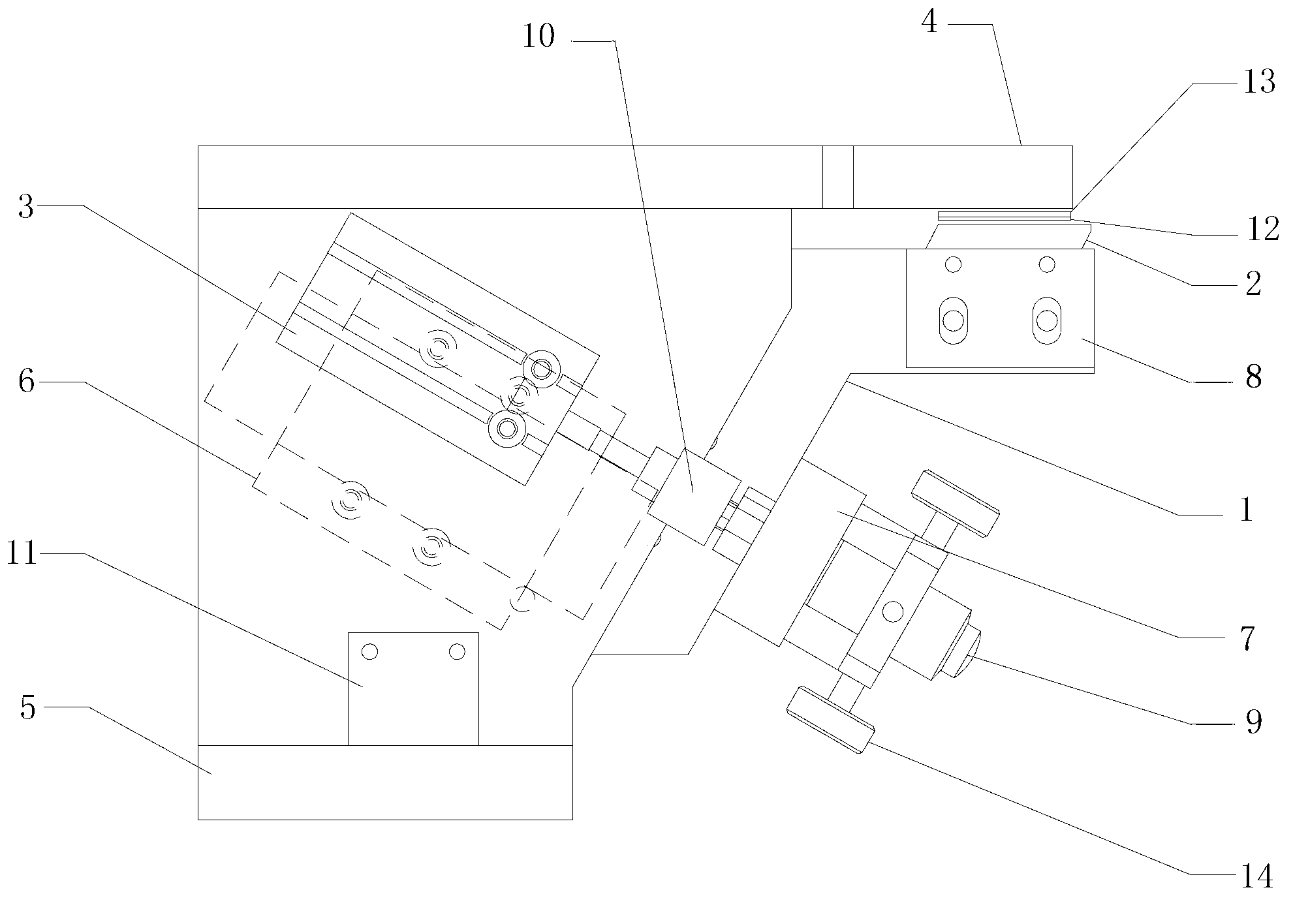

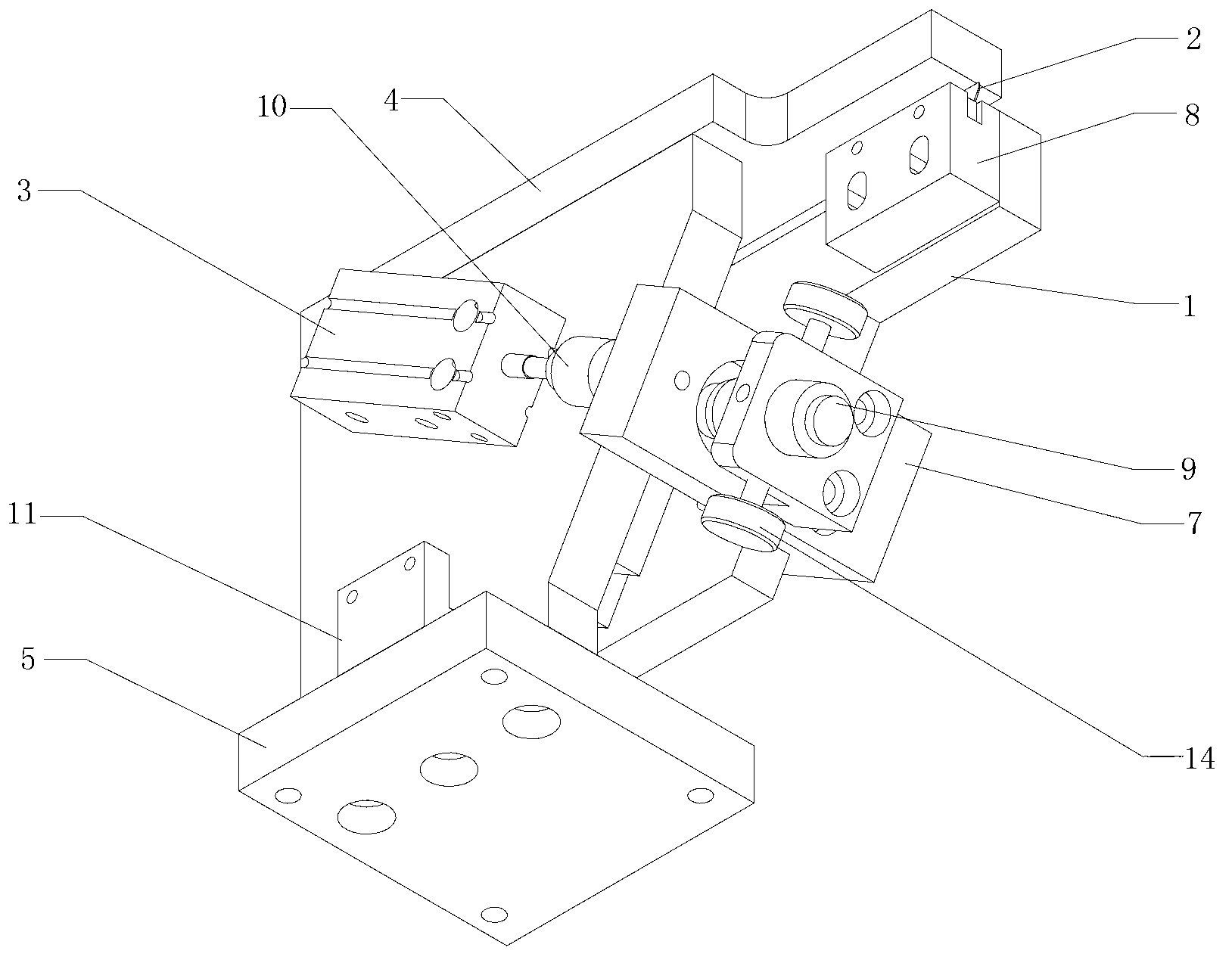

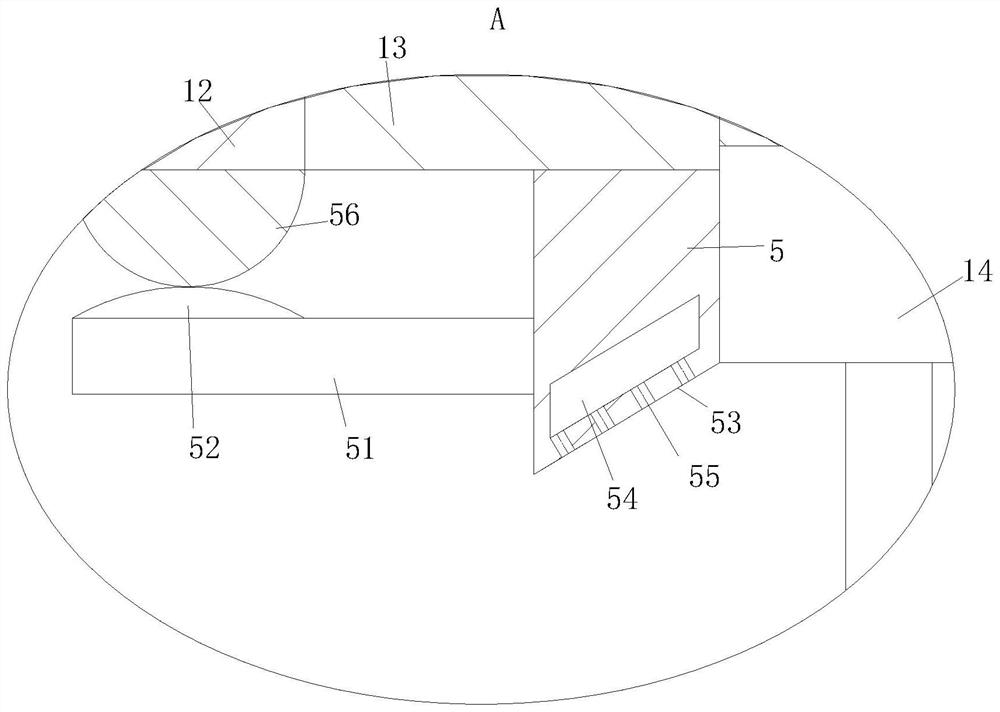

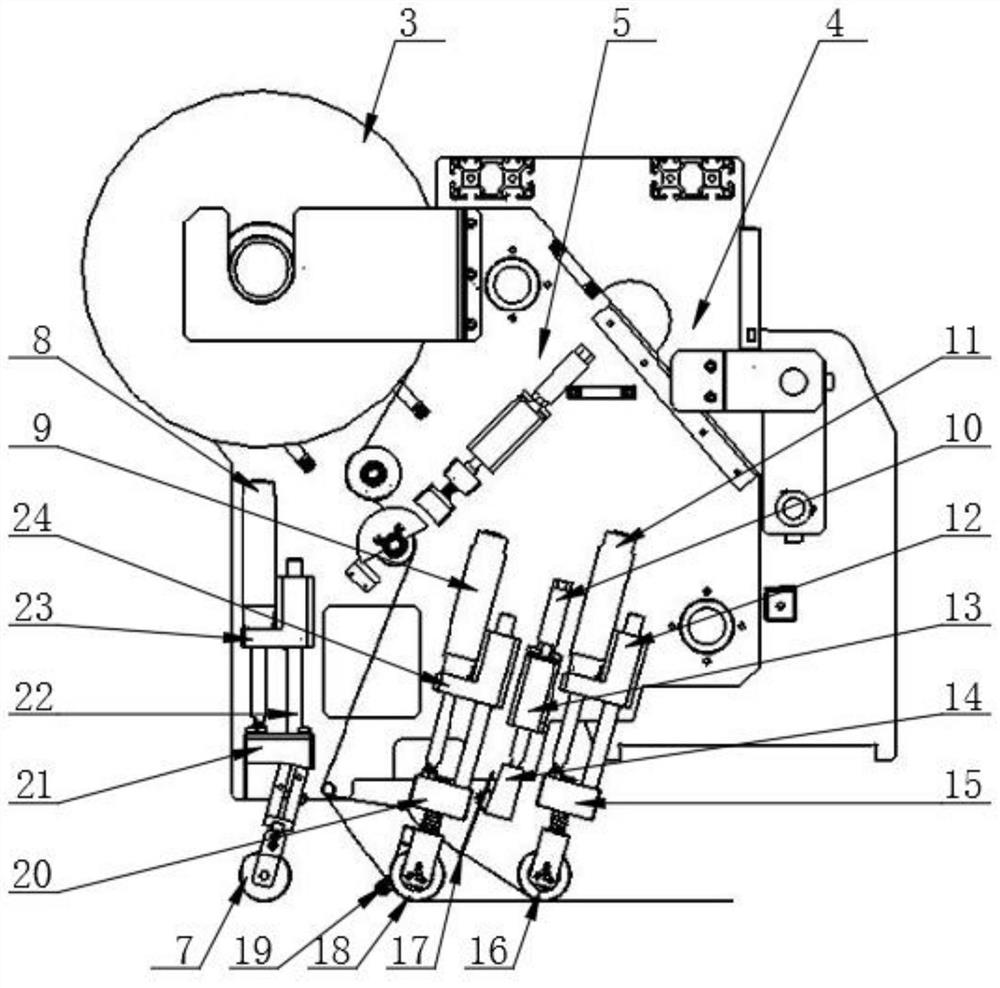

Precise electric-conducting adhesive film cutting device

The invention relates to the technical field of transmission mechanisms, and discloses a precise electric-conducting adhesive film cutting device comprising a substrate board. A cutter moving block, a power unit and an air cylinder system driven by the power unit and driving the cutter moving block to move are arranged on the substrate board, and included angle between moving direction of the cutter moving block and a horizontal plane is an acute angle. With the precise electric-conducting adhesive film cutting device, conventional cutting mechanisms in production lines are essentially improved, and a beveling method is adopted to cut, and no damages on productions during cutting are caused. The precise electric-conducting adhesive film cutting device is high in automation degree, cutting process can be precisely controlled, operation is facilitated and rapid, and production efficiency is greatly improved.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

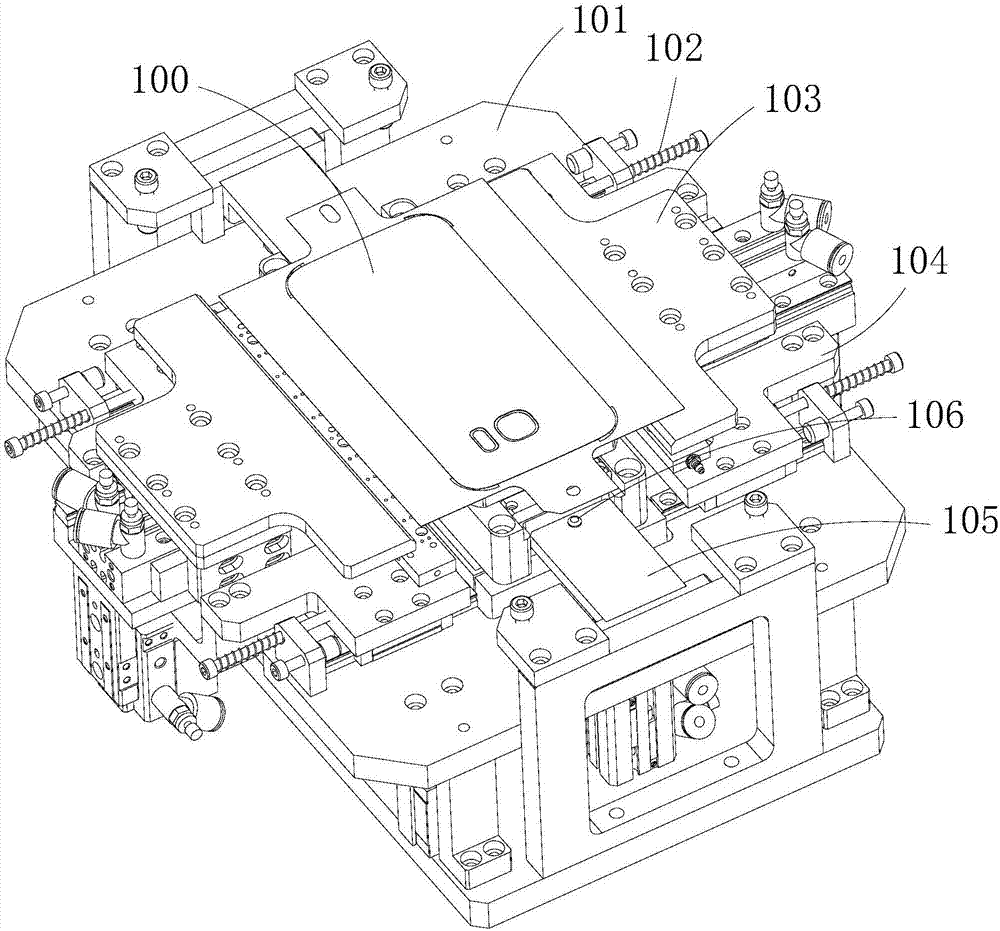

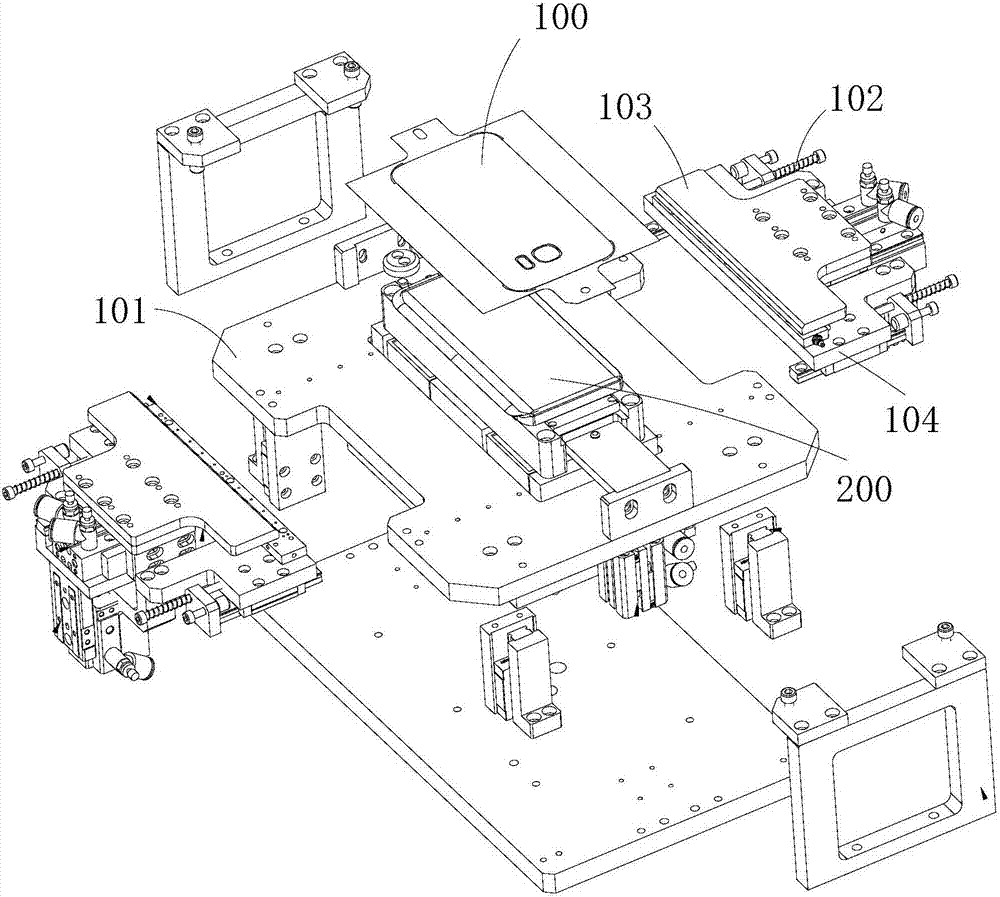

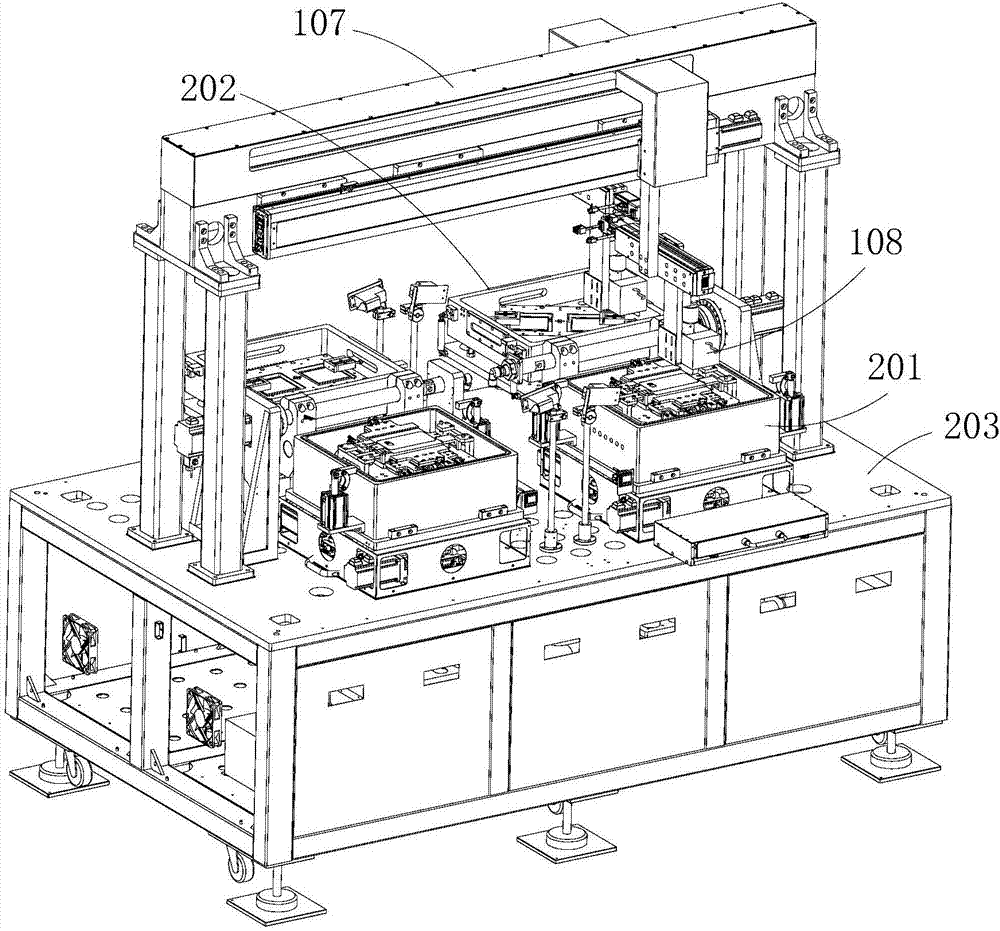

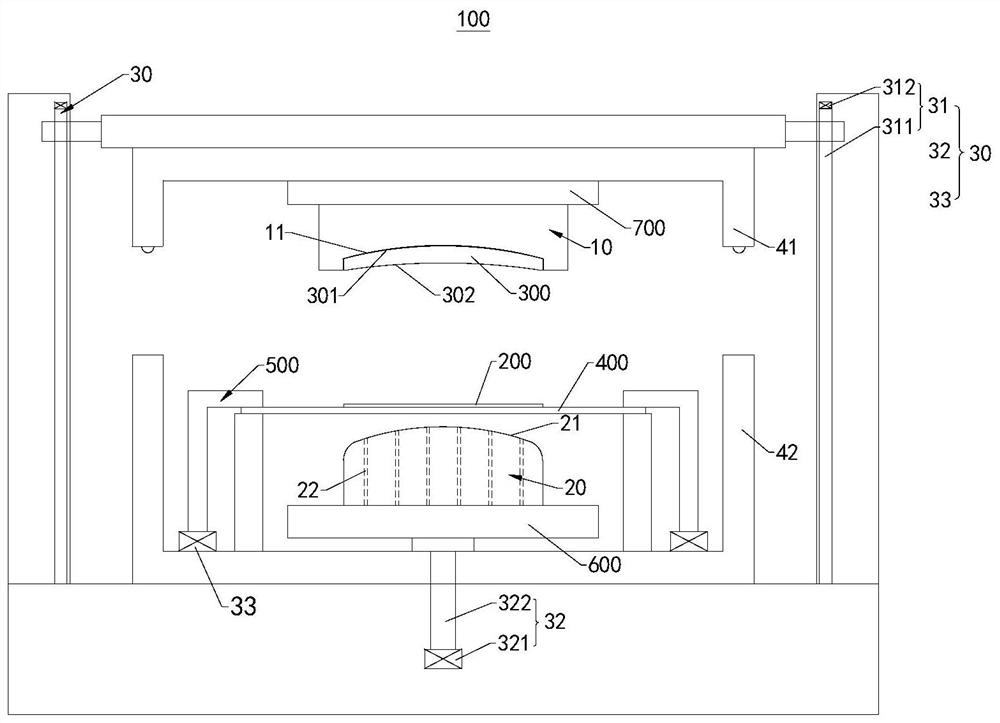

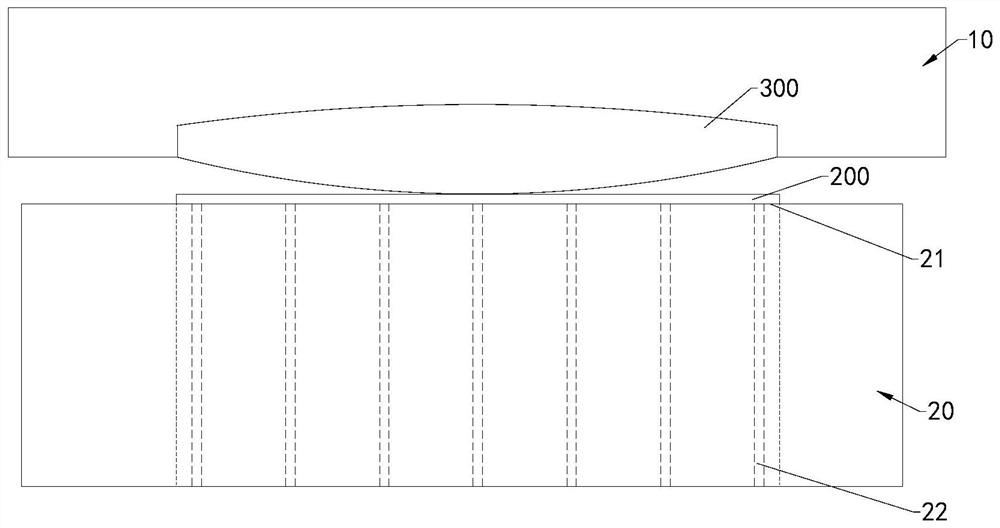

High-precision and automatic curved surface adhering device

ActiveCN106891597AAvoid kink linesGuaranteed fit qualityLaminationLamination apparatusEngineeringMechanical engineering

Owner:SHENZHEN SKING INTELLIGENT EQUIP

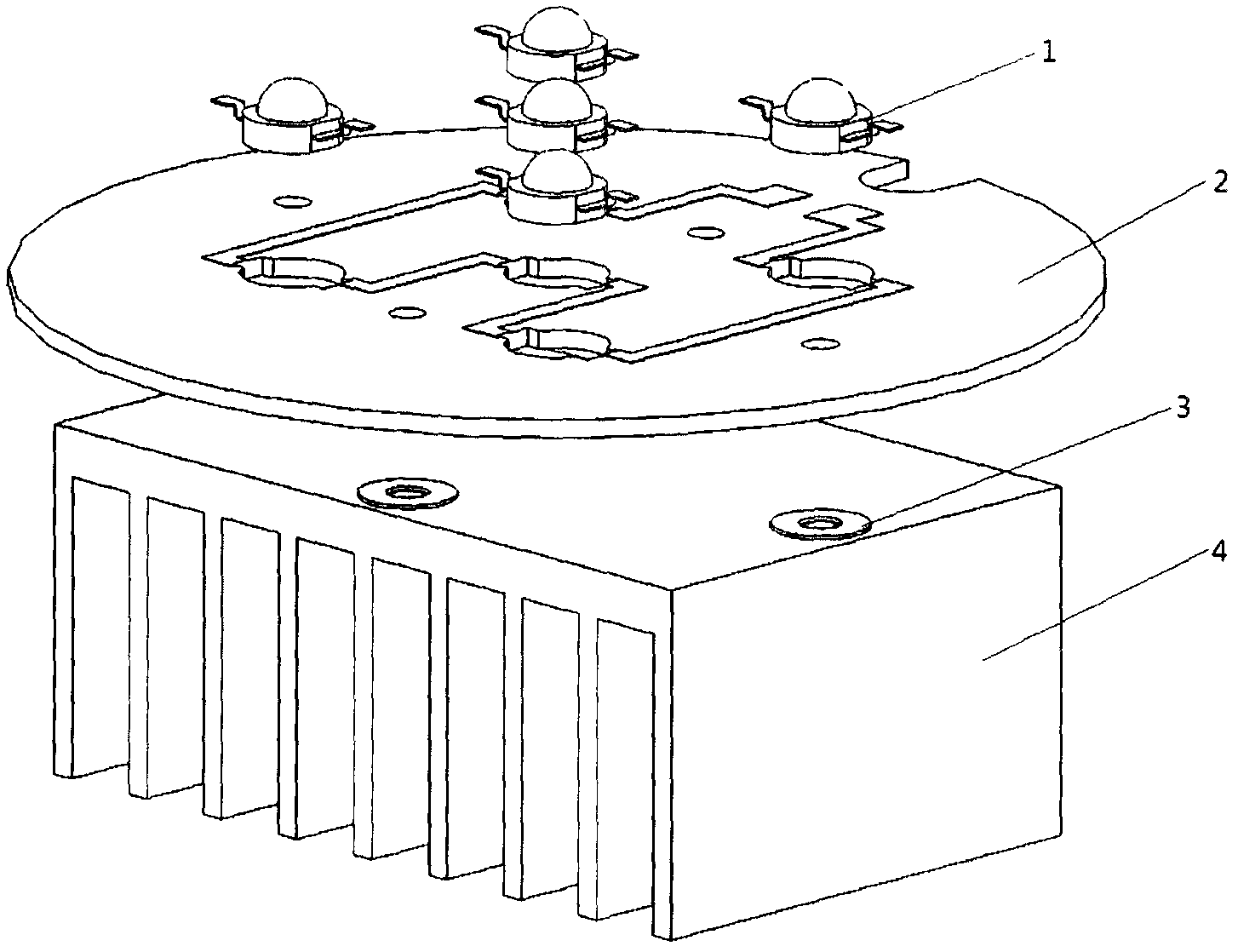

Novel high-power light emitting diode (LED) light source structure based on non-metal-based printed circuit board

InactiveCN102661516AOmit thermal resistanceReduce thermal resistancePoint-like light sourceElectric circuit arrangementsElectrical connectionEngineering

The invention discloses a novel high-power light emitting diode (LED) light source structure based on a non-metal-based printed circuit board (PCB). The novel high-power LED light source structure mainly comprises high-power LEDs, non-metal-based PCBs, a radiator, and a corresponding insulating spacer or gasket which is added according to the needs of electrical insulation and fastening degree control, wherein LEDs have a thermoelectrically separated pin type packaging structure, the pins can be bent toward the direction of a lens or a base, provide electrical connection and provide high fastening force; the non-metal-based PCBs are common hard single-sided copper-clad plates and are provided with LED assembling through holes which have the same number as that of the LEDs, and two sides of each assembling through hole are uniformly provided with circuits and pads; and therefore, the welded LEDs can give out light outwards through the assembling through holes, and the assembling through holes have the functions of clamping the LEDs at fixed points and can provide high fastening force. The LED bases with the novel structure can be directly contacted with the radiator, so that the radiating thermal resistance is obviously reduced.

Owner:TIANJIN POLYTECHNIC UNIV

Double-face automatic laminating machine for bent glass and laminating technology thereof

PendingCN109533454ARealize independent filmImprove film application efficiencyPackagingManipulatorAir bubble

The invention discloses a double-face automatic laminating machine for bent glass and a laminating technology thereof. The double-face automatic laminating machine comprises film laminating platforms,a linking carrying mechanical arm, a transfer platform and film taking and laminating mechanisms, the film laminating platforms comprise the first film laminating platform and the second film laminating platform, and the transfer platform is arranged between the first film laminating platform and the second film laminating platform; the two film taking and laminating mechanisms are arranged on the rear side of the first film laminating platform and the rear side of the second film laminating platform respectively; the linking carrying mechanical arm is arranged on the front sides of the filmlaminating platforms and the front side of the transfer platform in the left-and-right direction, and is provided with three sucking assemblies. Through the double-face automatic laminating machine, linking feeding and discharging are realized, films are independently laminated on the two side faces of the bent glass, and therefore the efficiency of film laminating is improved greatly; by pullingout a material belt, individual films are stripped onto a stripping plate, laminating mounting heads are used for forming laminating height difference on the two sides of the films, laminating actionsare completed through line contact, laminating air bubbles are effectively reduced, and the yield of laminating is increased.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

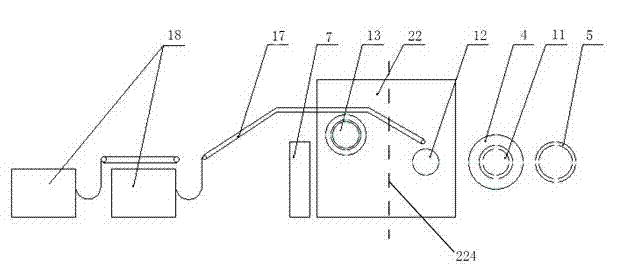

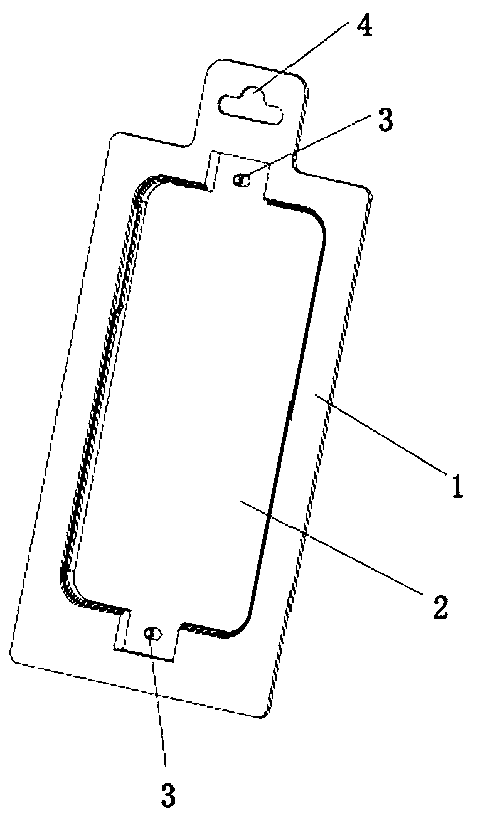

Screen protective layer mounting device and method

The invention provides a screen protective layer mounting device and a using method of the device. The screen protective layer mounting device is convenient to operate, excellent in pasting quality and high in working efficiency. The screen protective layer mounting device comprises a base plate (1), wherein the upper plane and the lower plane of the base plate (1) intersect to form an included angle, at least two positioning protruding blocks (2) are arranged on the base plate (1), an area defined by the at least two positioning protruding blocks (2) is the same as equipment with a protective layer to be pasted in shape and right clamps the equipment with the protective layer to be pasted, a boss (3) is arranged on the inner edge of each positioning protruding block (2), the height of each boss (3) is consistent with the thickness of the protective layer to be pasted, the size of an area defined by the bosses (3) is the same as the screen size of the equipment with the protective layer to be pasted, and a tight absorbing layer is arranged in the area defined by the positioning protruding blocks (2). The method is easy to operate, mounting is rapid, and mounting efficiency and mounting precision can be effectively improved. The screen protective layer mounting device and method can be applied to the mounting field of protective layers.

Owner:ZHUHAI BENYANG OPTICAL TECH

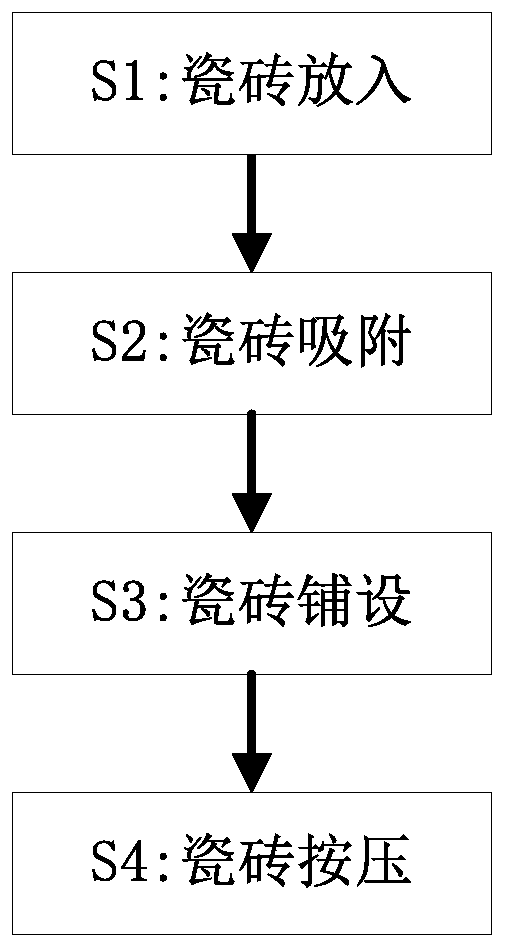

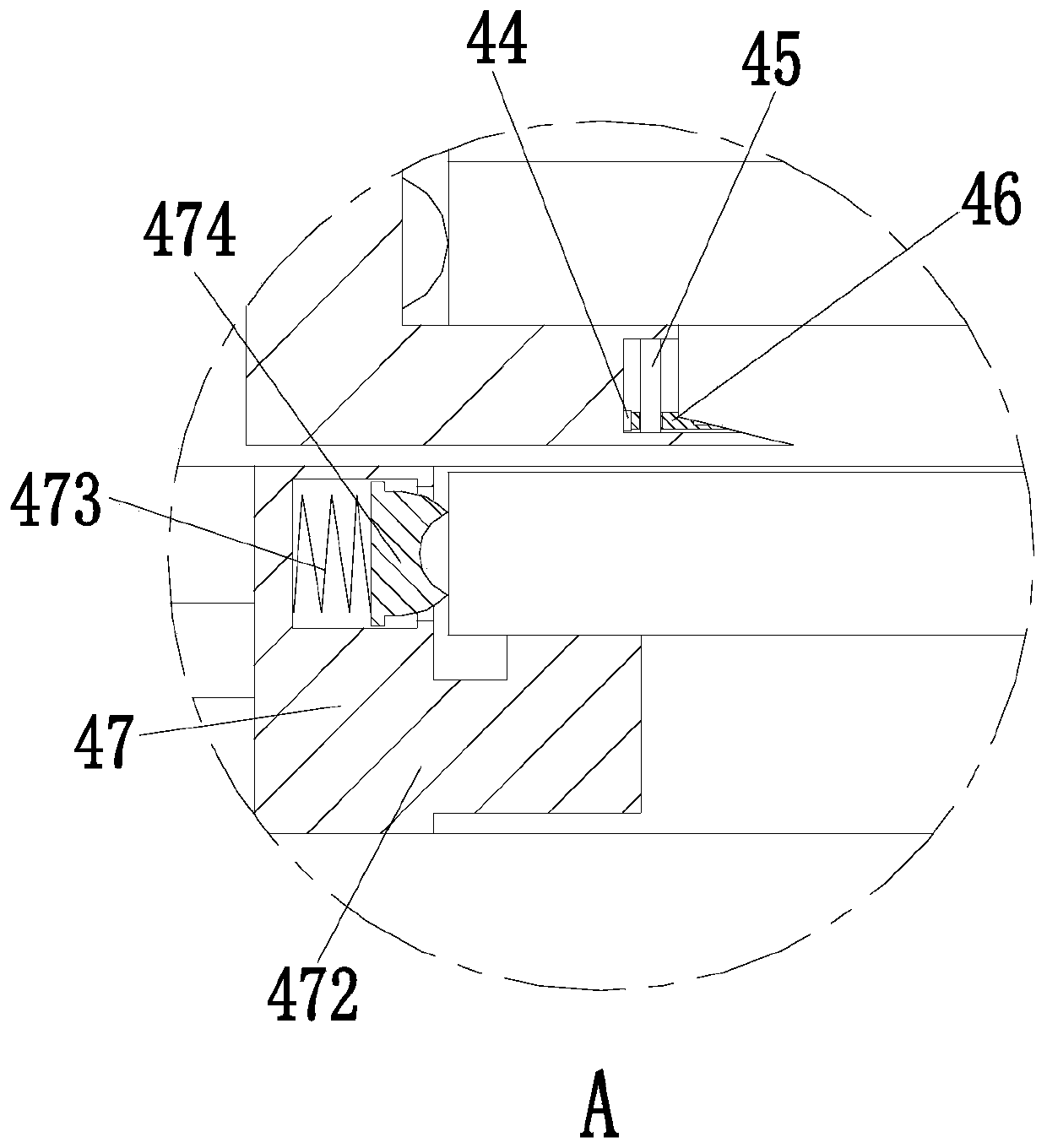

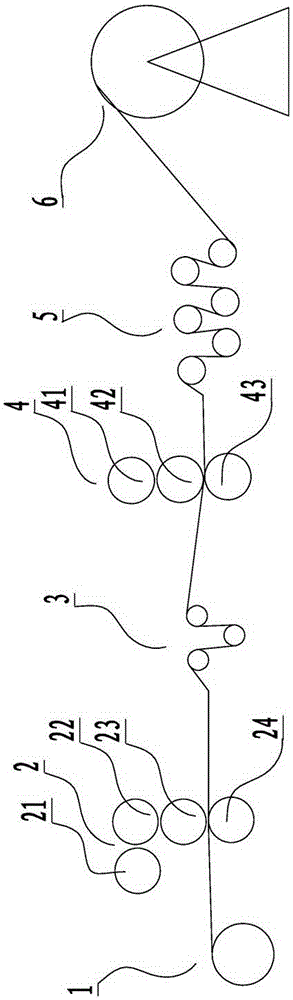

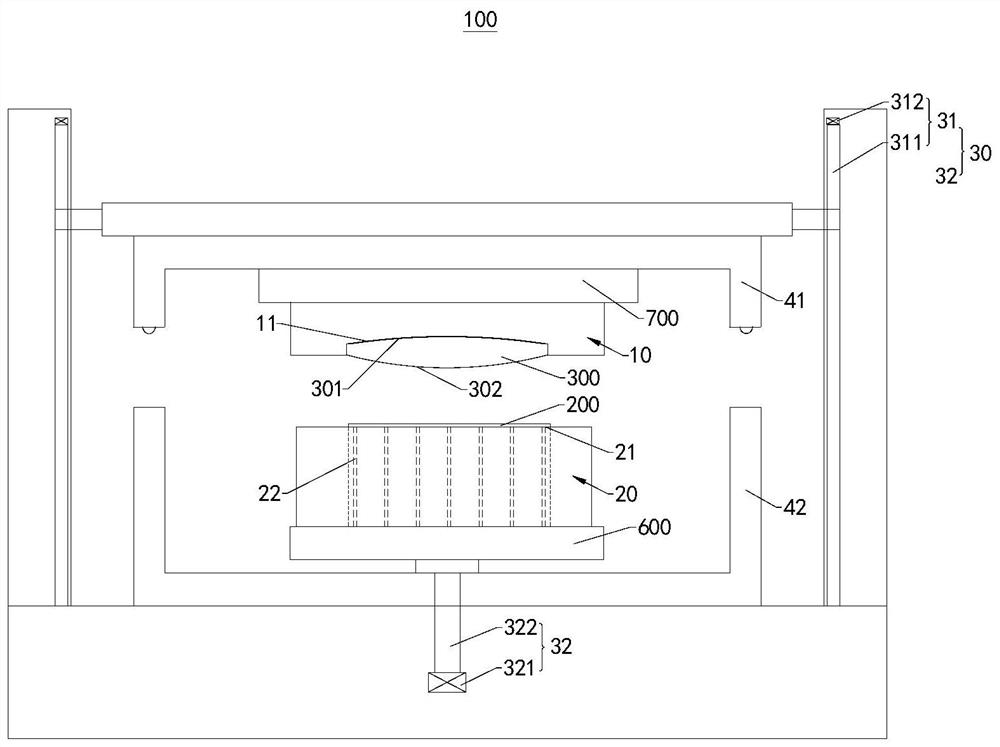

Indoor building decorative material tile laying construction process

ActiveCN111456393AGuaranteed fit qualityImprove laying efficiencyBuilding constructionsMuscle strainsConstruction engineering

The invention provides an indoor building decorative material tile laying construction process. According to the process, a supporting unit, an auxiliary basket, a laying unit and a discharging unit cooperate to complete indoor tile laying construction. Through the process, the problems that in the prior art, manual laying is mostly adopted for tile laying, manual laying is low in efficiency, a worker is prone to lumbar muscle strain because the worker is required to squat on the ground for a long time to work during manual laying, cavities generally exist between tiles and the ground during manual laying and affect tile laying quality, and the tiles are prone to damage in the hammering process by the worker through a rubber hammer in the existing tile laying process can be solved.

Owner:天津铧呈建设集团有限公司

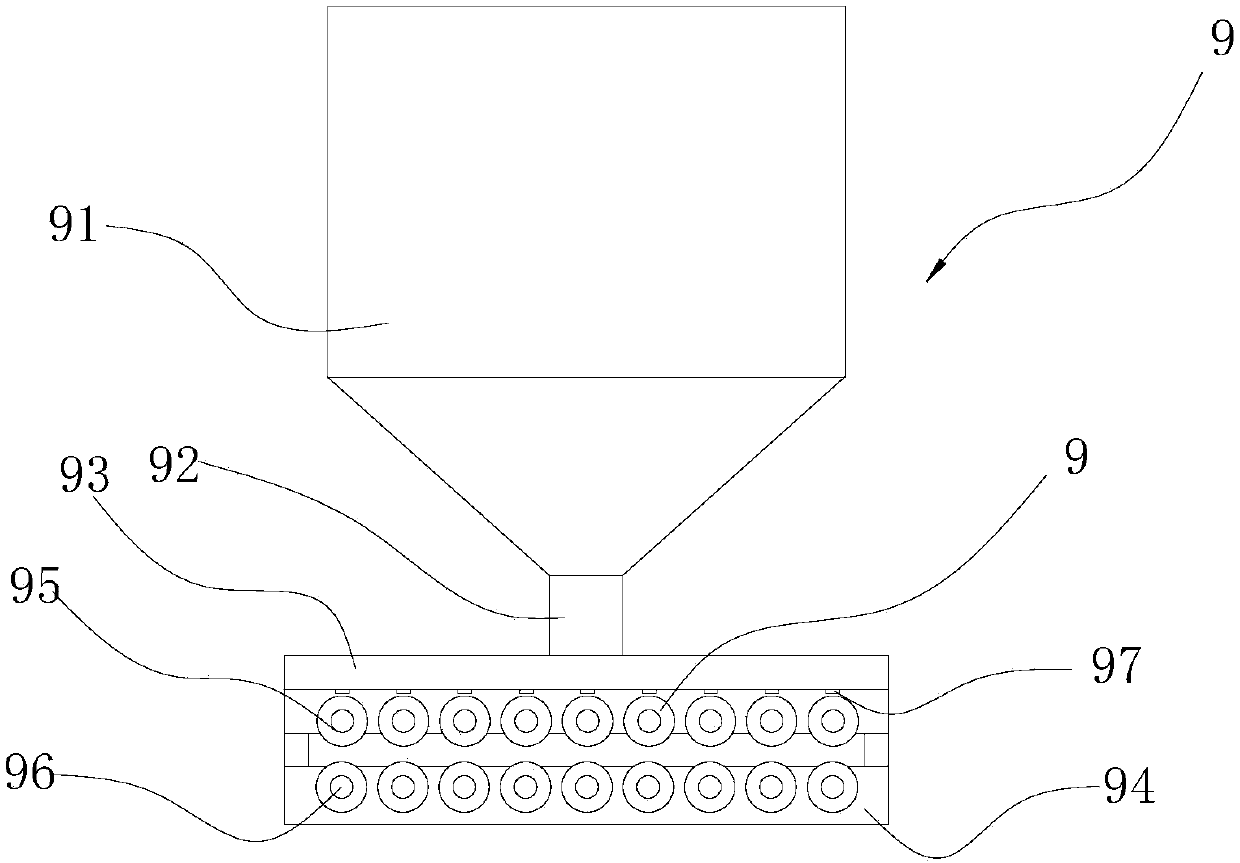

One-time thermal lamination molding device for middle rubber and covering rubber of rubber conveyor belt of steel wire rope core

The invention discloses a one-time thermal lamination molding device for middle rubber and covering rubber of a rubber conveyor belt of a steel wire rope core, aiming at solving the problem that the efficiency of an existing device is low. The one-time thermal lamination molding device is characterized by being sequentially composed of a canvas sending frame, a four-roller calender, a deviation correction and tensioning device, a three-roller calender, a six-roller cooling roller machine and a double-station crimping machine, wherein the canvas sending frame is used for sending a rubber piece cloth liner; the four-roller calender is used for molding the middle rubber; the deviation correction and tensioning device is used for deviation correction, conveying, tensioning and guiding of the cloth liner and a rubber piece of the middle rubber; the three-roller calender is used for rubber discharging of a covering rubber piece and thermal lamination of the middle rubber and the covering rubber; and the six-roller cooling roller machine is used for cooling the rubber piece, and the double-station crimping machine is used for crimping the two types of laminated rubber pieces. With the adoption of the one-time thermal lamination molding device, one path of procedure on a molding platform is reduced and a process is simplified; through one-time thermal lamination, the density and lamination quality of the rubber piece are guaranteed; and the staying time of the rubber pieces and secondary heating in a lamination process are reduced, energy conservation and environment protection are realized, and the sticking effect is relatively good.

Owner:ANHUI ZHONGYI RUBBER BELTS

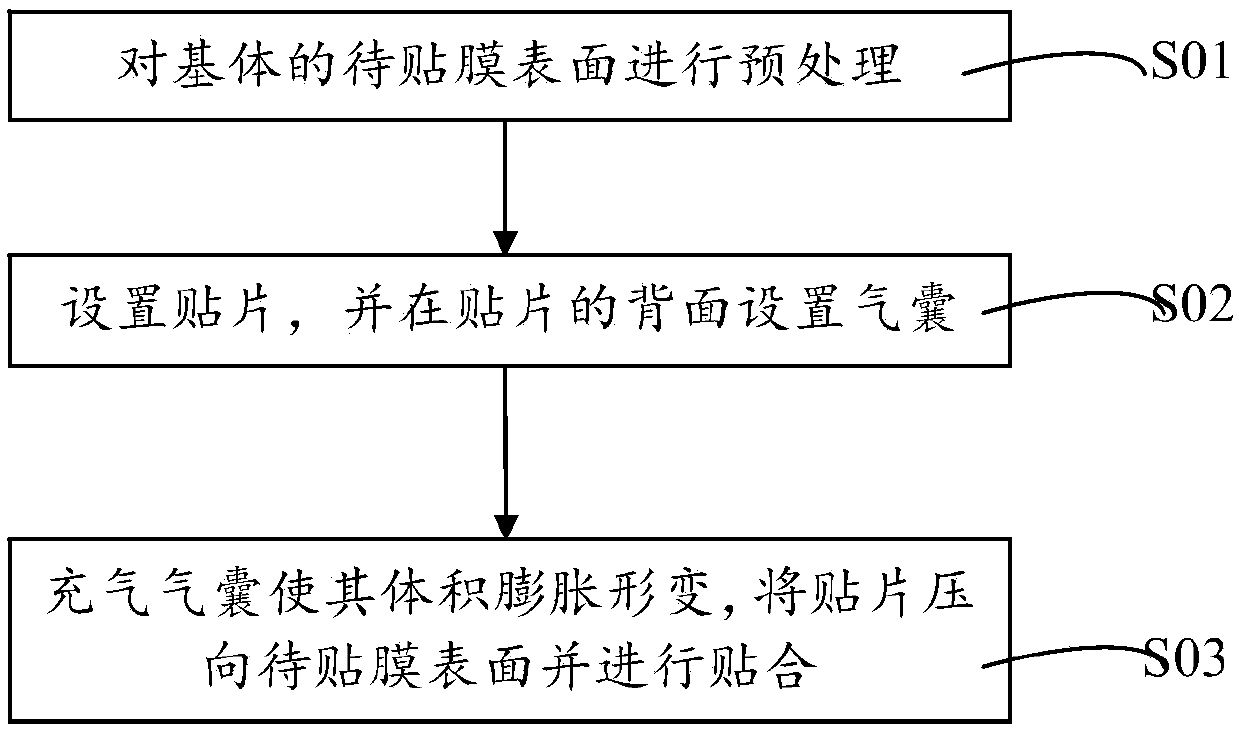

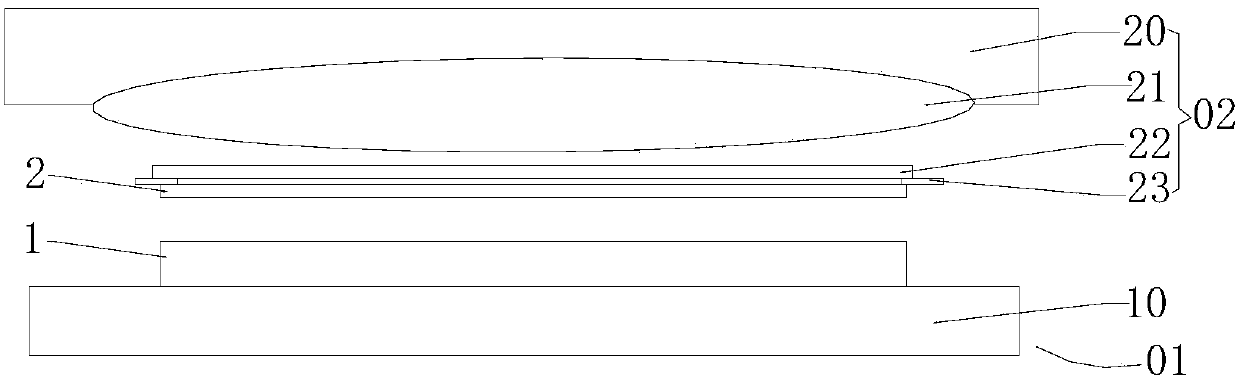

Membrane attaching method of lens

ActiveCN114523655AUniform deformationAffect optical performanceControlling laminationLaminationEngineeringMaterials science

Owner:HUAWEI TECH CO LTD

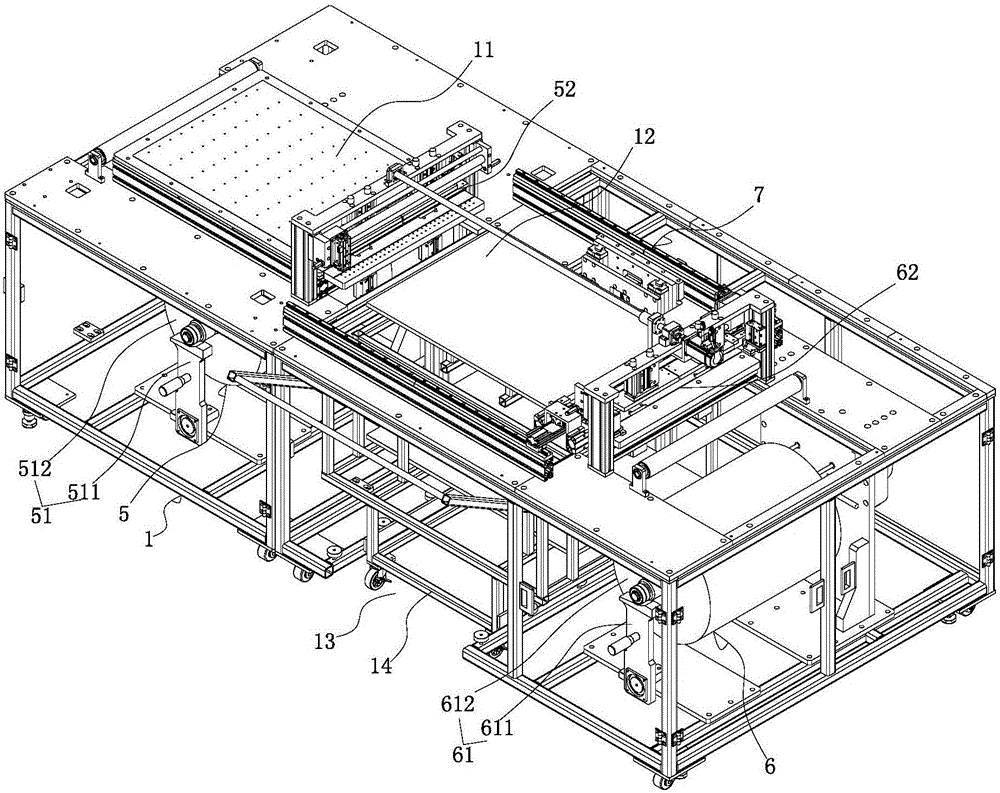

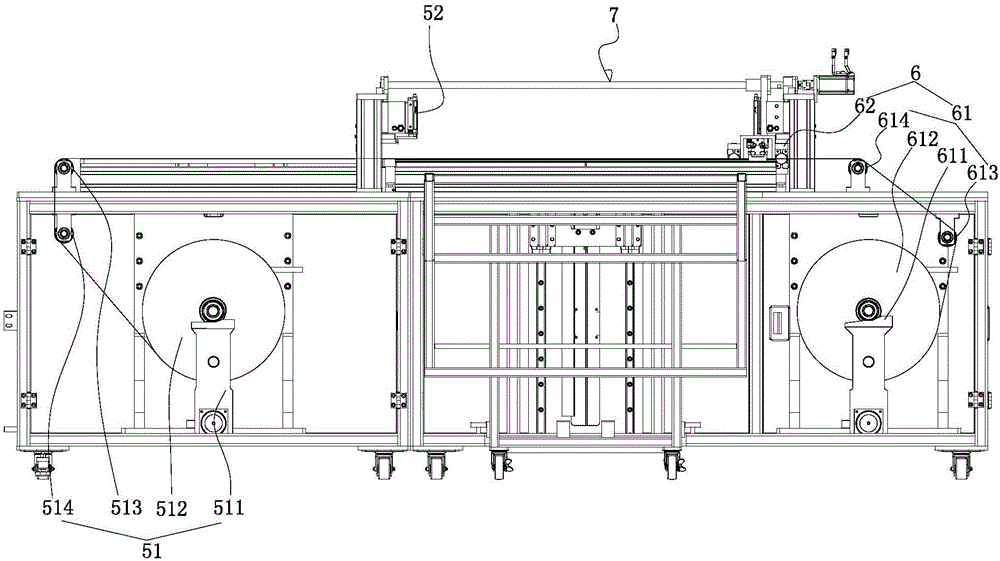

Material film circulating device for mobile phone glass film feeding machine

ActiveCN106628339AAchieve the purpose of circulationGuaranteed fit qualityWrapping material feeding apparatusGlass productionEngineeringManipulator

The invention discloses a material film circulating device for a mobile phone glass film feeding machine. The material film circulating device comprises a rack on which a glass film feeding vacuum platform and a glass film feeding material receiving lifting table are arranged, a glass carrier film discharging device which comprises a glass carrier film discharging mechanism and a first cutting mechanism which are mounted in the rack, a glass adhesion film discharging device which comprises a glass adhesion film discharging mechanism and a second cutting mechanism which are mounted in the rack, and a glass dual-mode material pulling device which comprises a glass dual-mode material pulling manipulator which is mounted on the rack and located above the glass film feeding material receiving lifting table, and first and second material clamps which are mounted on two sides of the glass dual-mode material pulling manipulator and are respectively used for clamping two sides of a glass adhesion film or a glass carrier film to pull material conveying, wherein a distance between the first and second material clamps is adjustable. The material film circulating device is high in automation degree, simple in structure, low in cost and high in working efficiency, and can fulfill the aim of circulating a material film (the glass carrier film and the adhesion film), so that the material film circulating device is extremely high in market competitiveness.

Owner:东莞市星纳特智能科技有限公司

Refrigerator condenser pipe pasting and covering device

ActiveCN111993662AAvoid curlImprove replacement safetyTubular articlesArticle deliveryAdhesive beltStructural engineering

The invention discloses a refrigerator condenser pipe pasting and covering device. The device comprises a fixing frame, a bearing plate, an adhesive tape wheel, a supporting arm, a fixing plate, a guide groove, a guide wheel, a guide air cylinder, a pasting air cylinder, a cutter air cylinder, a pressing air cylinder, a first fixing block, a first connecting block, a second connecting block, a second fixing block, a pressing wheel, a cutter, a pasting wheel, a glue removing roller, a first pasting block, a first guide block, a limiting column, a second guide block, a second pasting block, an upper connecting plate, an upper sliding block, an upper sliding rail, a locking block, a lower connecting plate, a lower sliding block, racks and lower sliding rails, the bearing plate is fixedly arranged on the center of the top of the fixing frame through bolts, the two lower sliding rails are correspondingly arranged into the outer edge of the top of the fixing frame in an embedded mode, and the racks are installed inside the lower sliding rails. According to the refrigerator condenser pipe pasting and covering device, the guiding, pasting, pressing and cutting functions are combined with the safe replacement mode of an adhesive tape, and the replacement safety of the adhesive tape can be improved while the pasting quality of a condenser pipe is guaranteed.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Adhering technology of touch screen

The invention relates to an adhering technology of a touch screen. The adhering technology adopts a machine casing and the touch screen, before the touch screen and the machine casing are adhered, the adhering surface of the touch screen is roughly processed, and then a bonding agent is adopted to enable the touch screen to be bonded on the machine casing; the rough processing adopts corona processing which comprises the following steps: placing the touch screen between a discharger and a corona roller, and generating a corona between the discharger and the corona roller by utilizing a high-frequency high-voltage power supply, so as to form a low-temperature plasma region; through air ionization between two poles, generating ozone, and changing the molecular structure of the plastic surface of the touch screen. so that the molecular structure is converted into polarity from nonpolarity, small uneven holes are formed in the surface of a material after the corona treatment to enable the surface to be roughened, and further the surface activity is improved. According to the adhering technology disclosed by the invention, before the touch screen is adhered, the adhering surface of the touch screen is subjected to rough processing, the wettability and the adhesiveness can be changed, the adhesiveness of the touch screen and the machine casing is improved, and the adhering quality of a product is ensured.

Owner:牧东光电科技有限公司

Reel-to-reel graphene continuous laminating device

InactiveCN107933058AQuality assuranceImprove qualityLaminationLamination apparatusWork in processCopper foil

The invention discloses a reel-to-reel graphene continuous laminating device, so that a graphene semi-finished product copper foil and a PET surface of a laminating film are in contact and laminated,and the laminating quality is improved. The reel-to-reel graphene continuous laminating device comprises a rack, the rack is provided with a graphene semi-finished product copper foil reel tensioningroll, a glue applying device, a laminating finished product reel tensioning roll, a rapid laminating film PET reel tensioning roll and a laminating force adjustable laminating device; a first turningroll is arranged between the graphene semi-finished product copper foil reel tensioning roll and the glue applying device; a second turning roll and a third turning roll are arranged between the laminating device and the laminating finished product reel tensioning roll; the laminating device comprises a sliding laminating roll, a fixing laminating roll, a fixed compressing device, a movable compressing device, a first laminating force regulation device and a second laminating force regulation device. The reel-to-reel graphene continuous laminating device provides laminating accuracy and laminating quality, and the quality of a finished product is guaranteed.

Owner:CHONGQING GRAPHENE TECH

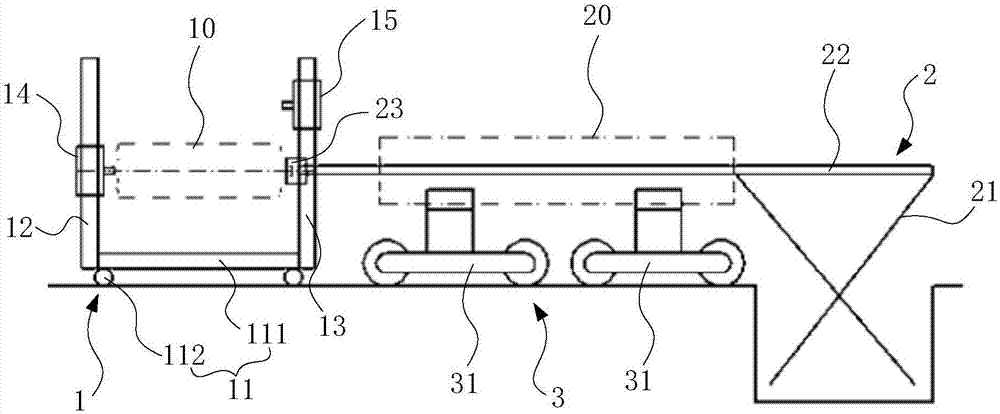

Sleeving device for tank

The invention provides a sleeving device for a tank. The sleeving device for the tank is used for sleeving an inner container of the tank with an outer cylinder of the tank. The sleeving device for the tank comprises supporting equipment, cantilever equipment and conveying equipment. The supporting equipment comprises a traveling trolley, two portal frames arranged on the traveling trolley in a spaced mode, and supporting mechanisms arranged on the portal frames in a lifting mode and used for supporting the ends of the inner container. The supporting equipment can move to a sleeving station through the travelling trolley. The cantilever equipment comprises a support, a supporting arm which is mounted on the support and stretches out of the support, and a supporting head which is movably arranged at the tail end of the supporting arm and used for supporting one end of the inner container. The supporting arm is long enough to be sleeved with the outer cylinder. The supporting head faces the sleeving station and can be used for supporting one end of the inner container when the inner container is located on the sleeving station. The conveying equipment can support and convey the outer cylinder, and the outer cylinder is conveyed to the sleeving station from the supporting arm so as to be arranged on the inner container in a sleeving mode. By adoption of the sleeving device for the tank, hoisting through a crane can be avoided, and the sleeving quality of the tank is improved.

Owner:NANTONG CIMC ENERGY EQUIP CO LTD

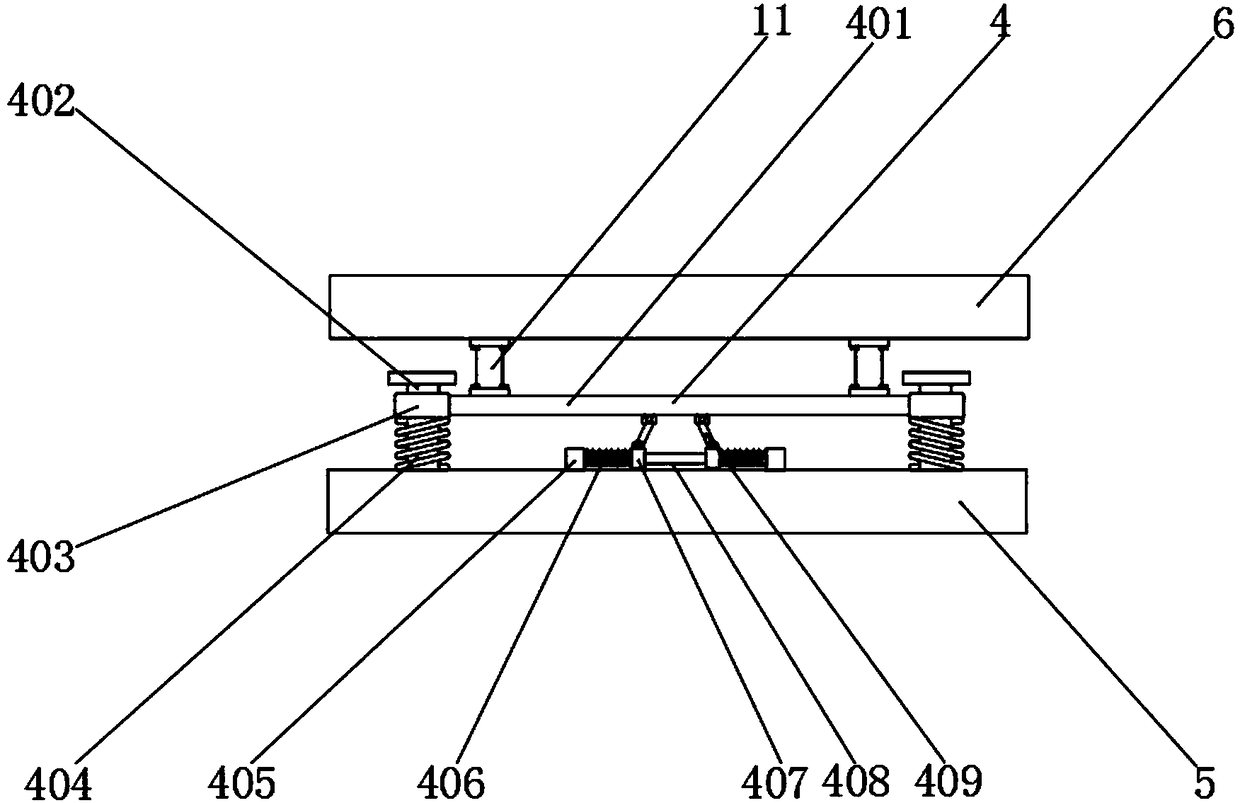

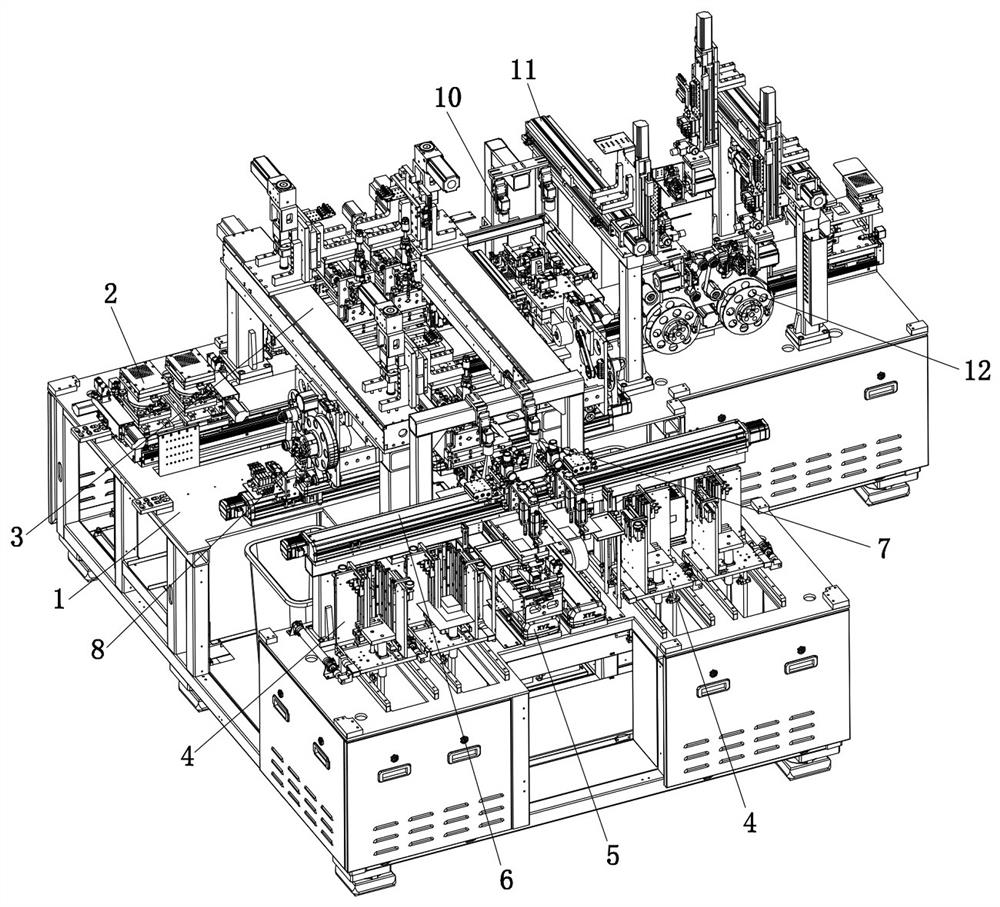

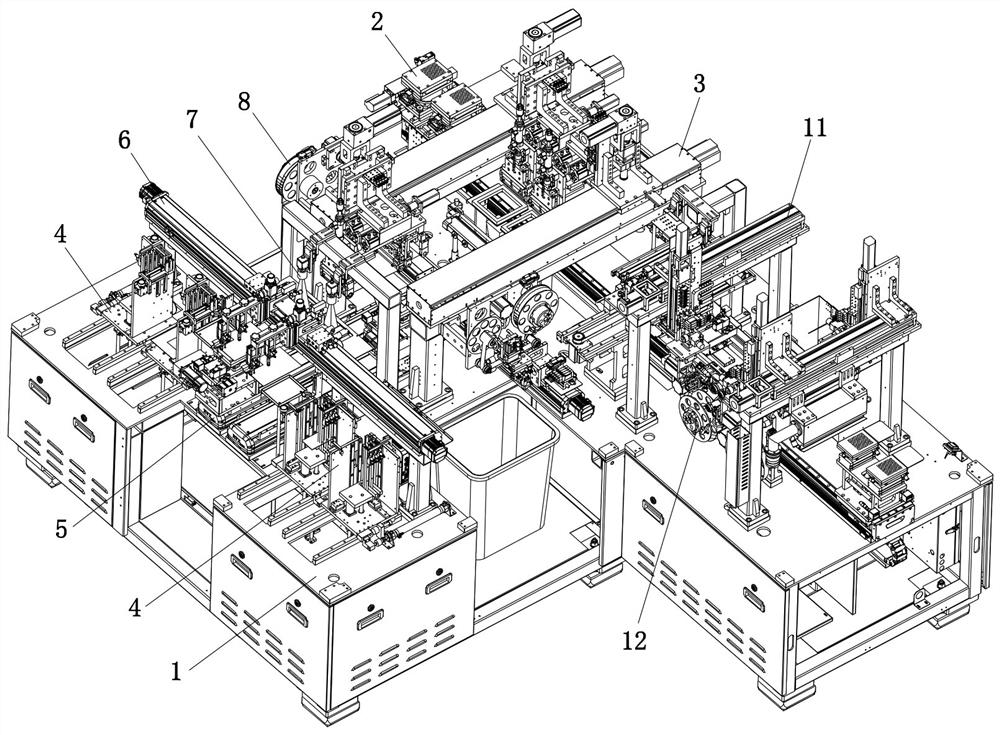

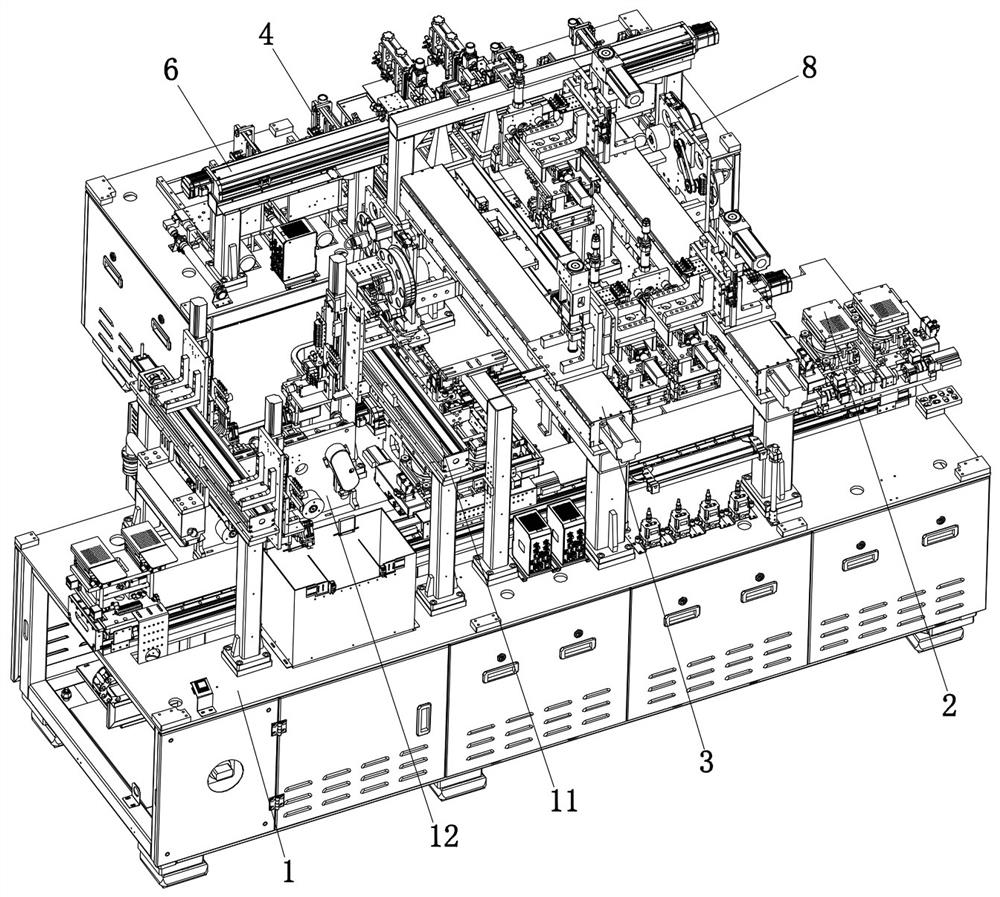

Full-automatic watch full-lamination all-in-one machine

PendingCN108445733AExtended service lifeGuaranteed qualityRepair toolsClock support devicesEngineeringAutomatic watch

The invention discloses a full-automatic watch full-lamination all-in-one machine. The all-in-one machine comprises a base. The top end of the base is provided with a cabinet, and the base and the cabinet are fixedly connected through a frame. The upper surface of the base is fixedly provided with a sliding rail. The all-in-one machine is clever in design, excellent in structure, and low in cost,and is simple and practical. The all-in-one machine is provided with a buffer device. Through the buffer device, pressing strength and speed of an upper laminating plate are buffered and decelerated,overall service life of the upper laminating plate and a lower laminating plate is prolonged, and quality of a laminating piece is guaranteed. The all-in-one machine solves a problem that when a pushing impulsive force of the upper laminating plate is excessive, the upper laminating plate and the lower laminating plate of a laminating piece are easily damaged, and cost waste is reduced. A laminating piece rapid fixing device is arranged. Through the laminating piece rapid fixing device, the laminating piece can play a role of rapid fixing, stability is improved, and laminating quality is improved, product quality is guaranteed, market reputation is improved, rework rate is reduced, and cost waste is saved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Full-automatic soft-to-hard laminating machine and laminating process thereof

PendingCN114545666ARealize automatic feeding processRealize moving and transferring detectionArticle unpackingNon-linear opticsEngineeringMechanical engineering

The full-automatic soft-to-hard laminating machine comprises an LCD feeding platform, a laminating mechanism, an OCA feeding mechanism, an OCA moving detection mechanism, a first film tearing mechanism and a second film tearing mechanism, and the LCD feeding platform is horizontally arranged on one side of a machine table; the laminating mechanism is erected on the LCD feeding platform; the OCA feeding mechanism is arranged on the other side of the machine table, and at least two OCAs are stored in the OCA feeding mechanism in an up-down stacked mode. The OCA moving detection mechanism is erected above the OCA feeding mechanism; the first film tearing mechanism is arranged below the laminating mechanism and is used for tearing a film on the OCA bottom surface sucked by the laminating mechanism; the second film tearing mechanism is erected on the LCD feeding platform and located on the side portion of the attaching mechanism. The OCA is attached to the surface of the LCD to avoid the uneven attaching problem of the special-shaped cover plate, meanwhile, LCD automatic feeding, OCA automatic feeding, moving, transferring and detecting, automatic bottom film tearing, OCA automatic attaching and automatic surface tearing are achieved, roller belt type attaching is adopted, attaching bubbles are effectively reduced, and the attaching quality is improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

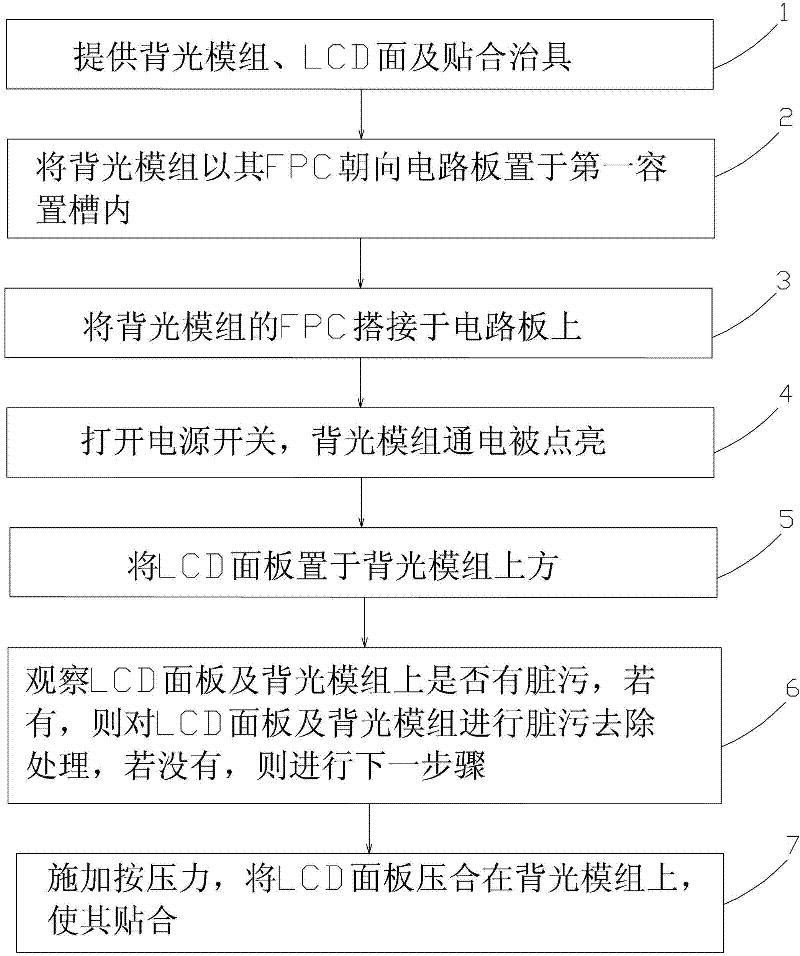

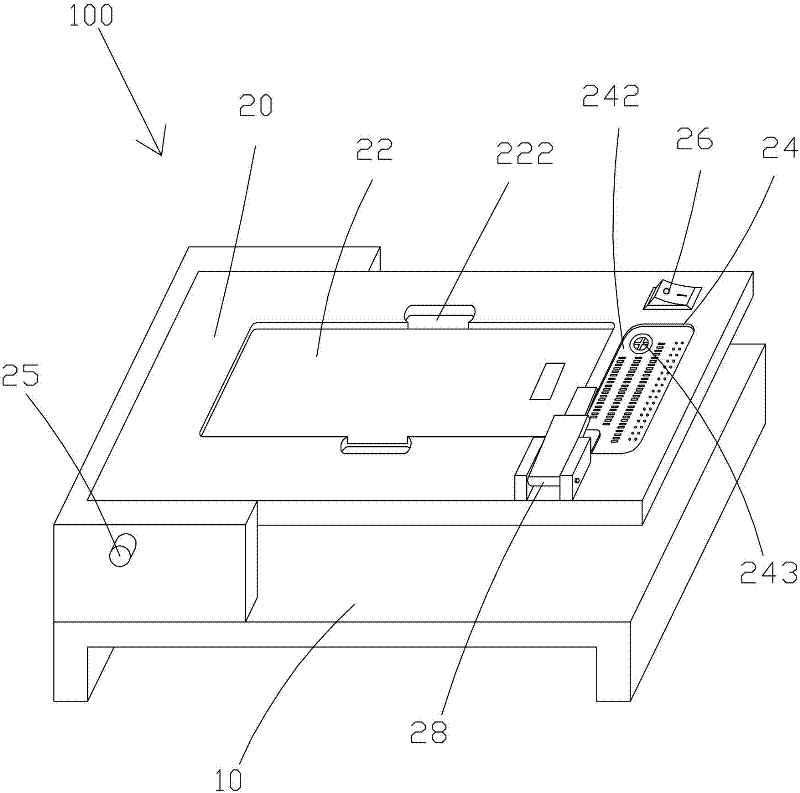

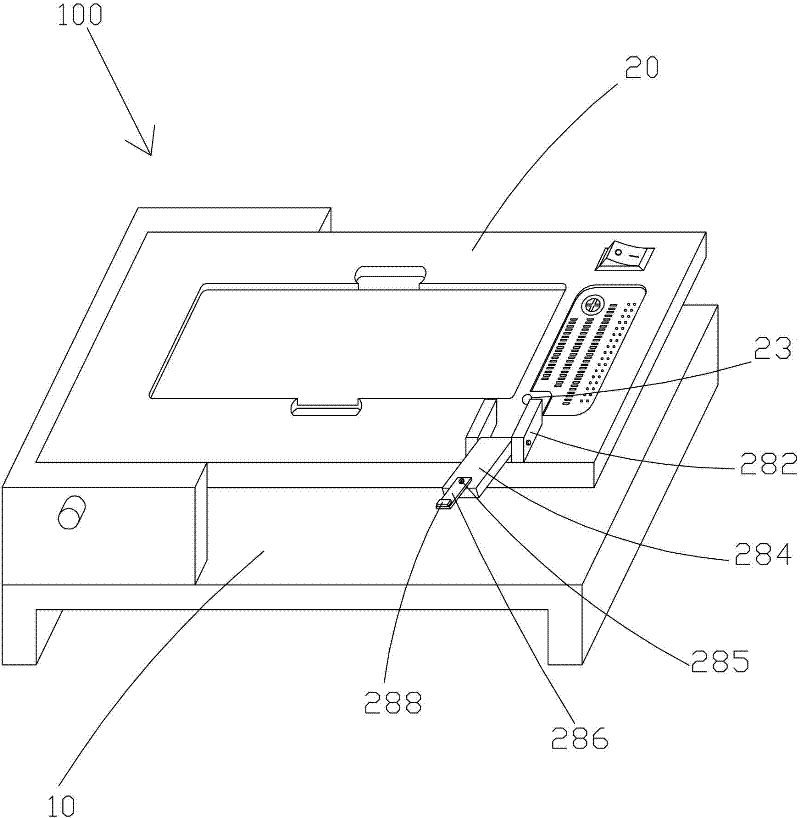

Method for bonding backlight module with LED (liquid crystal display) panel

ActiveCN102689490AGuaranteed fit qualityEasy to checkLaminationLamination apparatusLiquid-crystal displayEngineering

The invention provides a method for bonding a backlight module with an LED (liquid crystal display) panel; the method comprises the step 1 of providing a backlight module, an LED (liquid crystal display) panel and a bonding fixture; the step 2 of arranging the backlight module into a first containing slot in a way that a FPC (flexible printed circuit) of the backlight module faces a circuit board; the step 3 of jointing the FPC (flexible printed circuit) of the backlight module on the circuit board; the step 4 of turning on a power switch in order to lighten the electrified backlight module; the step 5 of arranging the LED (liquid crystal display) panel on the backlight module; the step 6 of observing whether the LED (liquid crystal display) panel and the backlight module are polluted by a sludge, if yes, cleaning the LED (liquid crystal display) panel and the backlight module, and otherwise, performing the next step; and the step 7 of compressing the LED (liquid crystal display) panel on the backlight module in order to bond both the LED panel and the backlight module. The method for bonding the backlight module with the LED (liquid crystal display) panel is simple and convenient in operation, in this way, the bonding quality of the backlight module and the LED (liquid crystal display) panel is guaranteed and the production yield is improved.

Owner:广东金龙机电有限公司

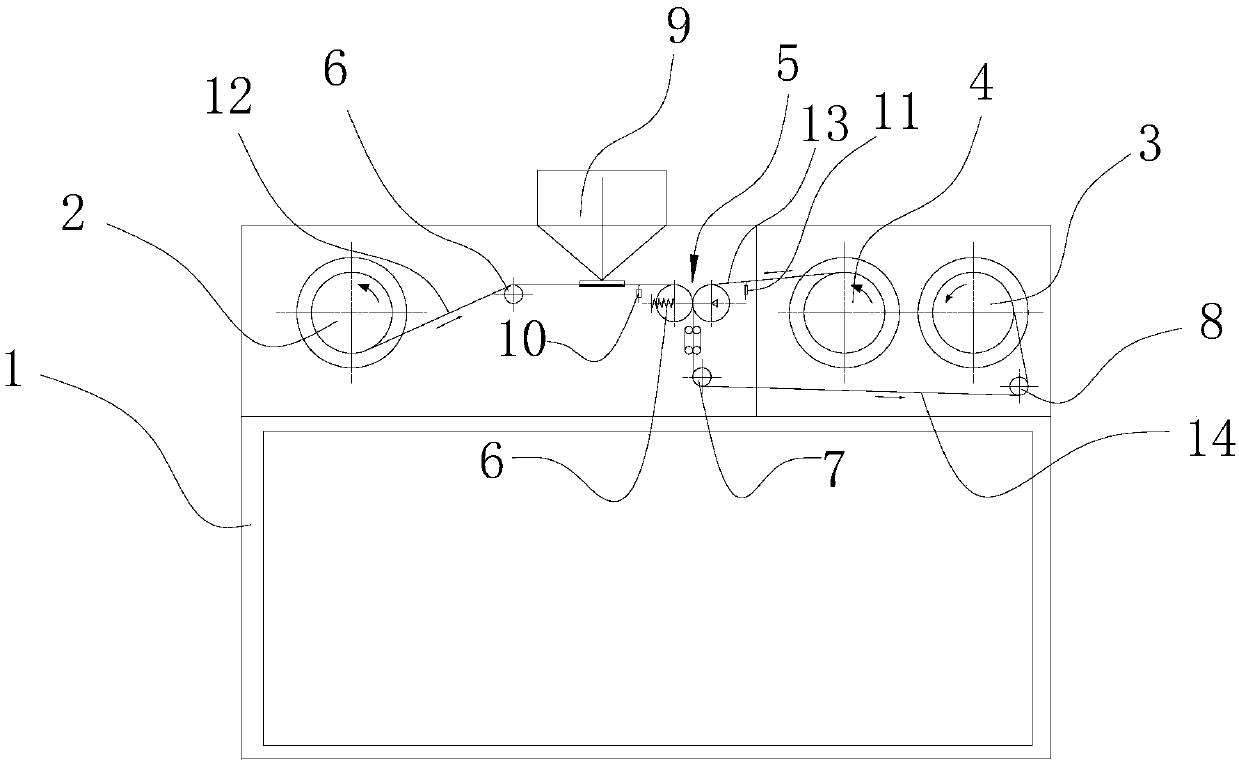

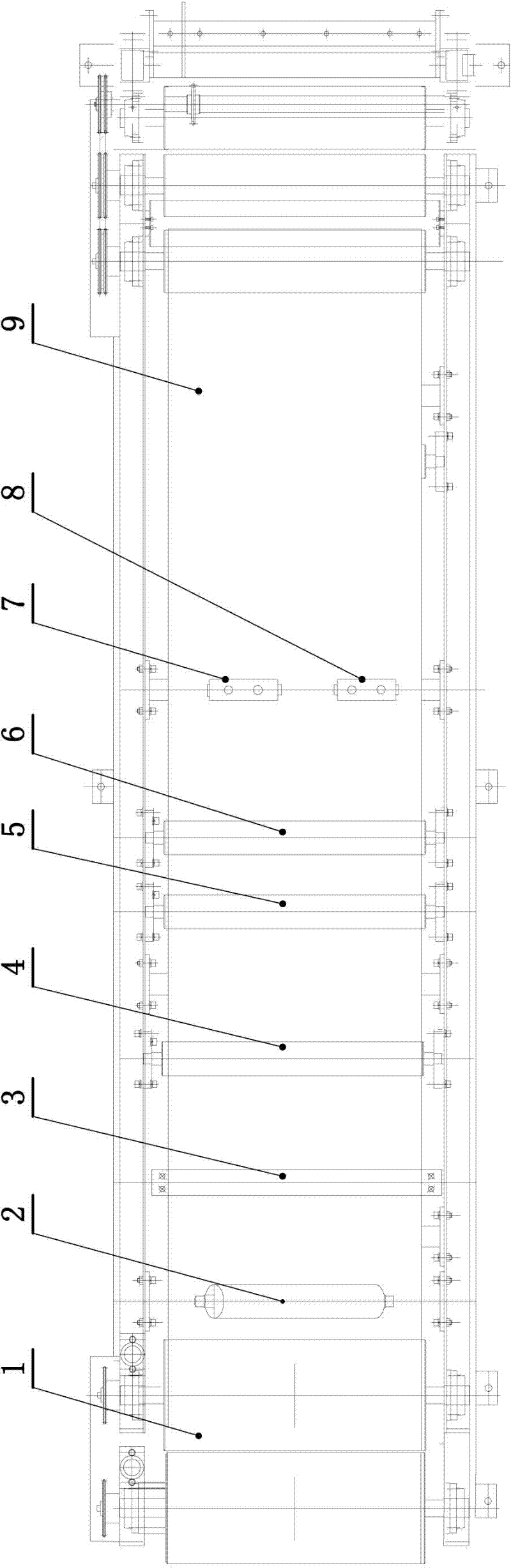

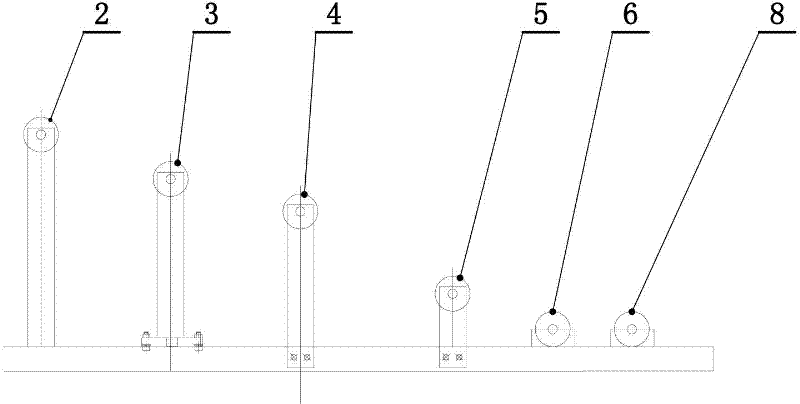

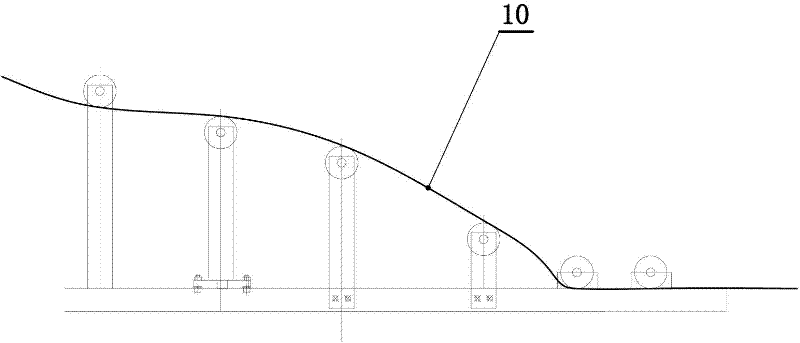

Double composite production line with hot attaching process device and process for producing sidewall by using same

InactiveCN102529289AGuaranteed fit qualityGuaranteed bonding qualityLaminationLamination apparatusProduction lineEngineering

The invention relates to a double composite production line with a hot attaching process device, which comprises a linkage line. The front end of the linkage line is provided with a two-roll calender. A No.1 flat roll is relatively rotationally arranged on the linkage line. The No.1 roll is positioned at the rear of the two-roll calender. A No.2 horizontal roll, a No.3 horizontal roll and a No.4 horizontal roll are also relatively rotationally arranged on the linkage line. The No.2 horizontal roll, the No.3 horizontal roll and the No.4 horizontal roll are sequentially arranged at the rear of the No.1 roll. A No.1 rubber roller is also relatively rotationally arranged on the linkage line. The No.1 rubber roller is positioned at the rear of the No.4 horizontal roll. The horizontal heights of the No.1 flat roll, the No.2 horizontal roll, the No.3 horizontal roll, the No.4 horizontal roll and the No.1 rubber roller are gradually decreased from front to back. A No.2 rubber roller and a No.3 rubber roller are also relatively rotationally arranged on the linkage line. The No.2 rubber roller and the No.3 rubber roller are arranged side by side. According to the invention, in the extrusion process, a hot attaching film is compacted and adhered by using the rubber press rollers, so that the attaching quality of the film is effectively ensured, the air bubble phenomenon is basically solved and the film adhering quality of the sidewall is also ensured.

Owner:八亿橡胶有限责任公司

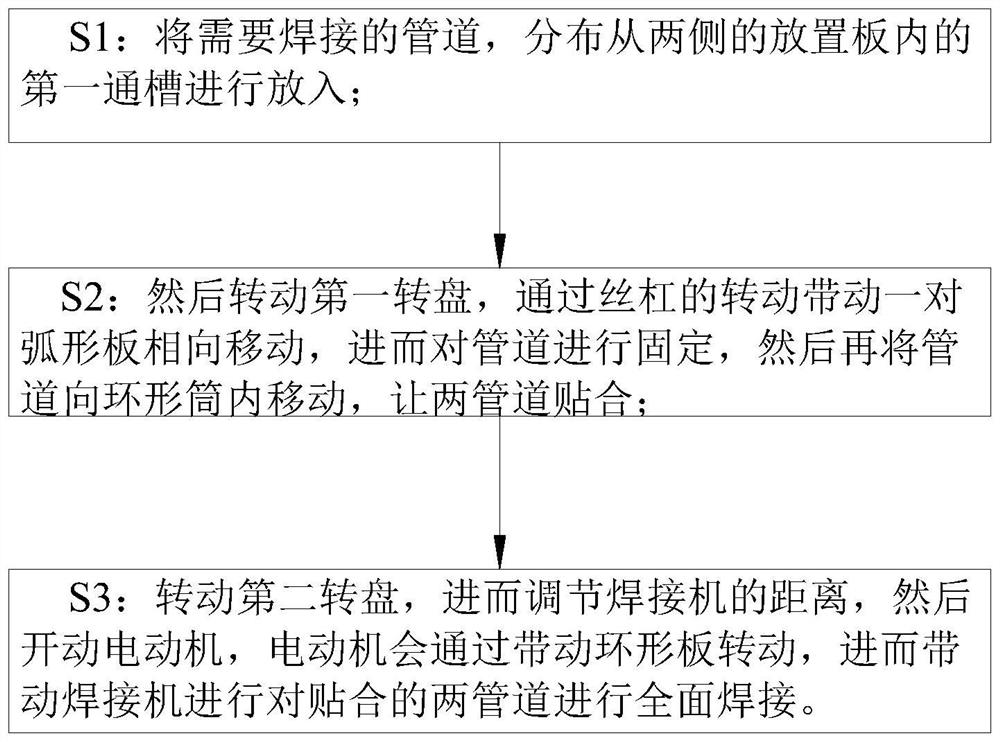

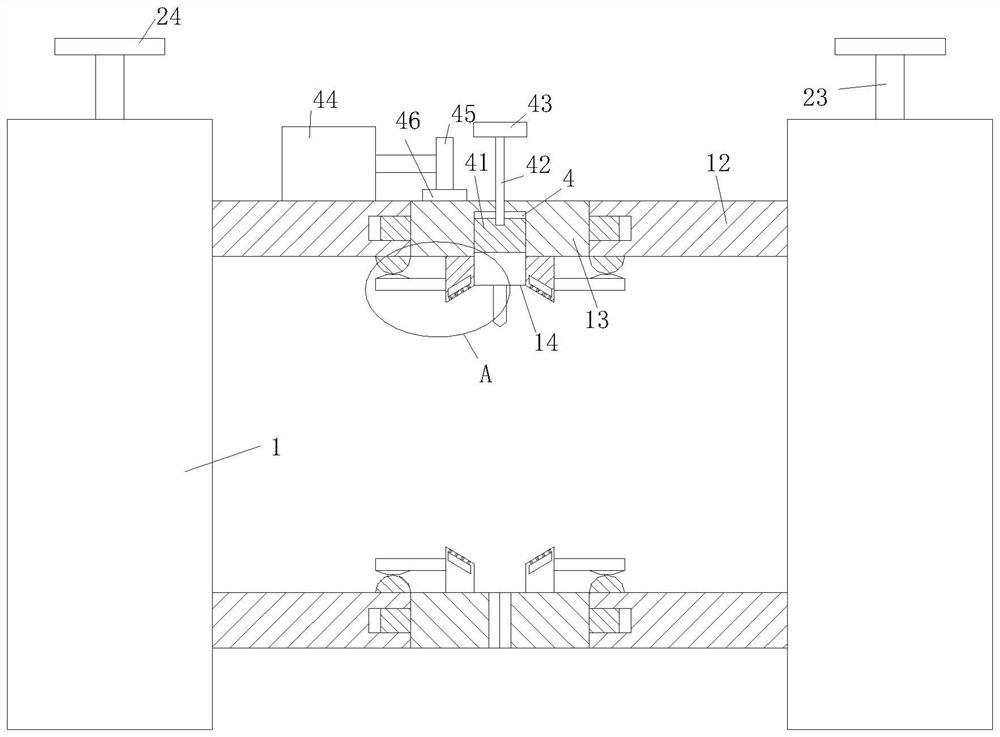

Pipeline welding process

PendingCN114378526AGuarantee welding qualityAvoid fit effectsWelding/cutting auxillary devicesAuxillary welding devicesPhysicsPipe welding

The invention belongs to the technical field of pipeline welding, and particularly relates to a pipeline welding process. The invention provides a pipeline welding process which comprises the following steps: S1, pipelines to be welded are put in from first through grooves in placement plates on two sides; s2, then a first rotating disc is rotated, a pair of arc-shaped plates are driven to move oppositely through rotation of a lead screw, then the pipelines are fixed, then the pipelines are moved into an annular cylinder, and the two pipelines are attached; s3, a second rotating disc is rotated, then the distance of a welding machine is adjusted, then a motor is started, the motor drives an annular plate to rotate, and then the welding machine is driven to conduct comprehensive welding on the two attached pipelines; the problems that centrifugal force can be generated by rotation of the pipelines, the attaching tight quality between the two pipelines can be affected, and then the welding quality is affected are solved.

Owner:李明泽

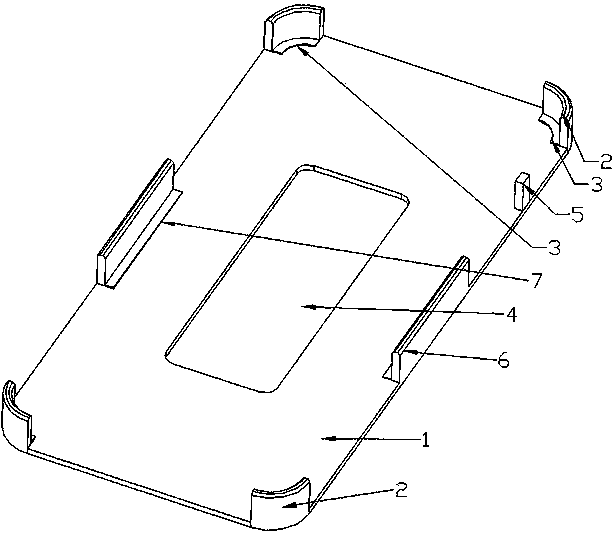

Semi-automatic laminator with lamination degree guaranteeing device

ActiveCN108495478AAvoid poor fit qualityGuaranteed fit qualityPrinted circuit assemblingElectrical componentsSemi automaticLeft–right symmetry

Owner:江苏珍世味食品有限公司

A freezer condensation pipe coating device

ActiveCN111993662BAvoid curlImprove replacement safetyTubular articlesArticle deliveryAdhesive beltEngineering

The invention discloses a freezer condensate pipe coating device, which comprises a fixed frame, a bearing plate, a tape wheel, a support arm, a fixed plate, a guide groove, a guide wheel, a guide cylinder, a pasting cylinder, a cutter cylinder, a pressing cylinder, a first A fixed block, a first connecting block, a second connecting block, a second fixing block, a pressing wheel, a cutter, a pasting wheel, a glue removal roller, a first pasting block, a first guide block, a limit post, and a second guide block, the second pasting block, the upper connecting plate, the upper slider, the upper slide rail, the locking block, the lower connecting plate, the lower slider, the rack and the lower rail, the top center of the fixed frame is fixed with a bearing plate by bolts, There are two sliding rails embedded in the top outer edge of the fixing frame, and racks are installed inside the sliding rails; the present invention combines the functions of guiding, sticking, pressing and cutting, and the safe replacement of tapes to ensure condensation While improving the quality of pipe bonding, it can also improve the safety of tape replacement.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

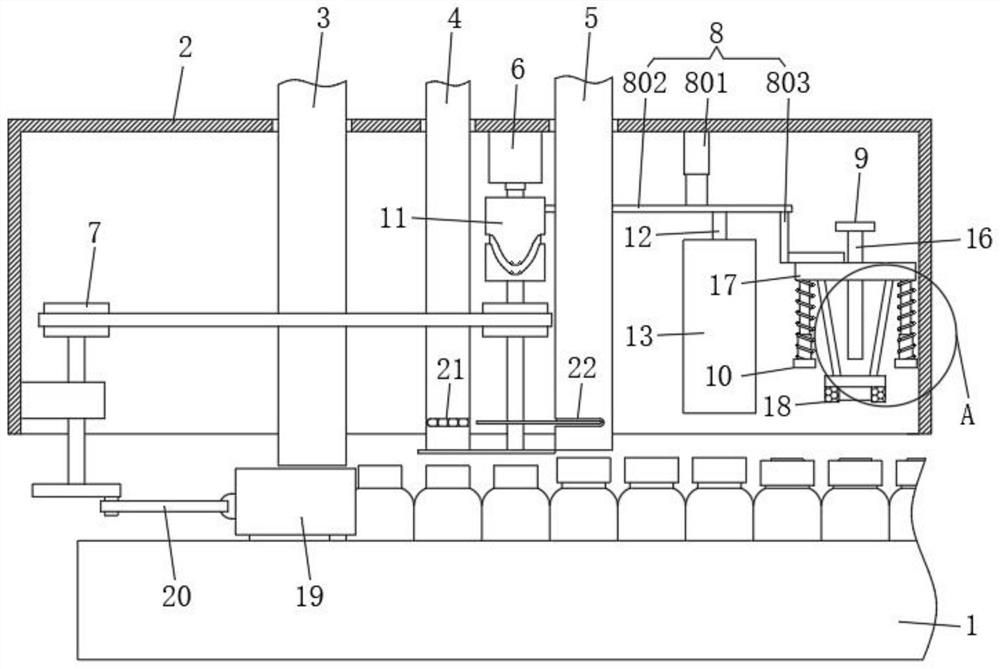

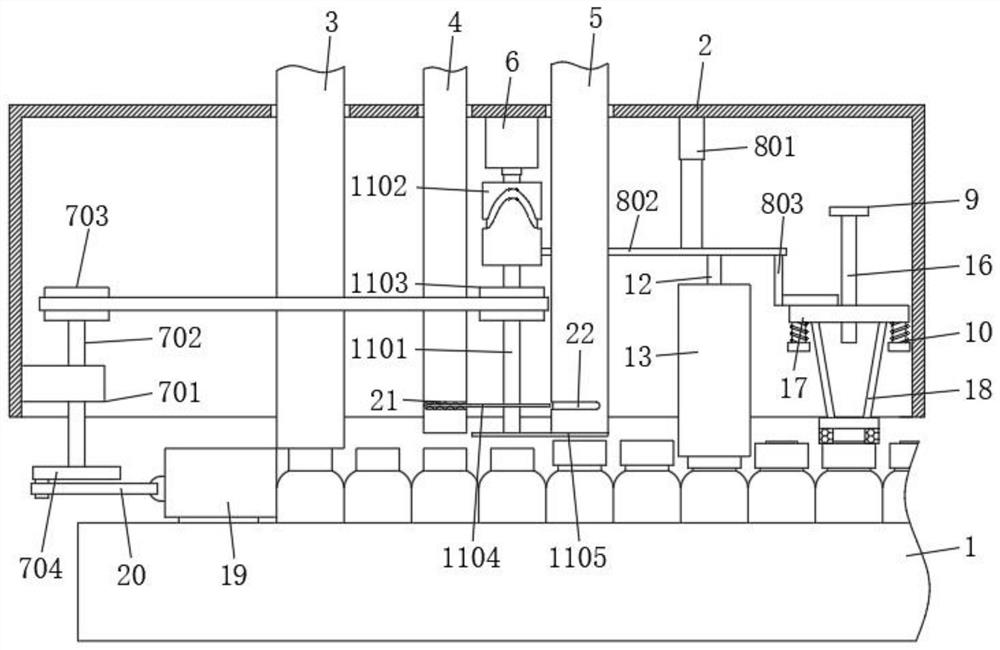

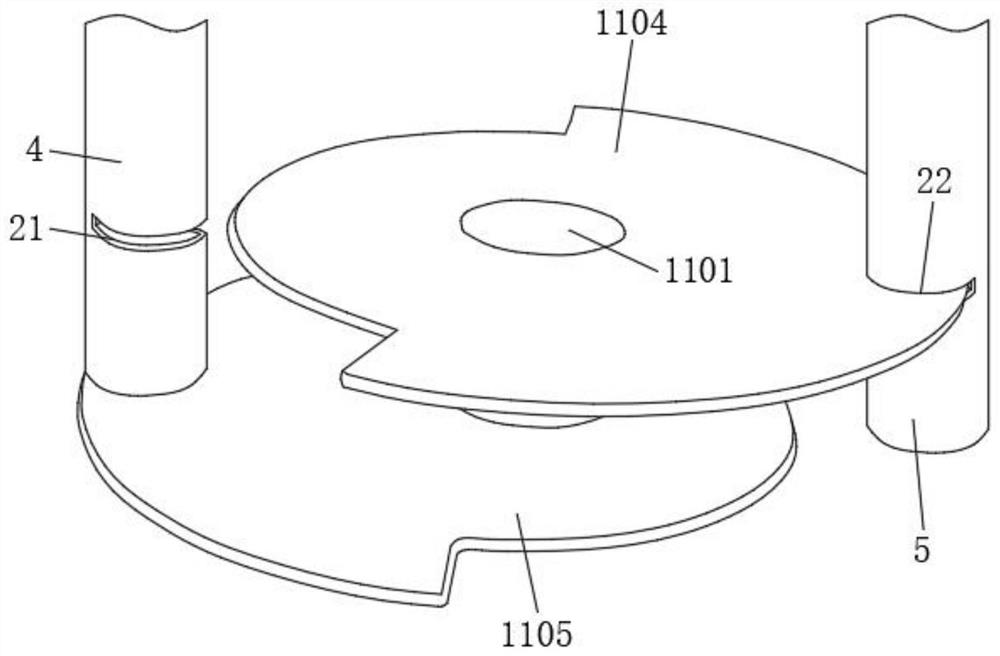

Automatic filling machine for health-care decoction pieces

ActiveCN113525797ARealize automatic feeding processRealize deliveryPackaging protectionElectric machineryEngineering

The invention provides an automatic filling machine for health-care decoction pieces, and relates to the field of filling machines. The automatic filling machine for the health-care decoction pieces comprises a workbench and a box body; a placing groove is formed in the upper surface of the workbench; a bottle conveying pipe, a medicine conveying pipe and a cover conveying pipe penetrate through and are fixedly mounted on the upper surface of the box body; a motor, a pushing component, a moving component, a partition plate and two supporting components are fixedly mounted in the box body; a rotating component is fixedly mounted on an output shaft of the motor; the rotating component is in transmission connection with the pushing component through a belt; and the rotating component is correspondingly connected with the moving component in a clamped mode. Through cooperation of the rotating component, the pushing component, a first opening, a second opening and the like, automatic feeding and conveying of medicine bottles can be achieved, intermittent discharging of decoction pieces and bottle caps can also be achieved, excessive participation of workers is not needed, the labor burden of the workers is greatly relieved, and the working efficiency is also effectively improved.

Owner:ANHUI TIANMA BIOLOGICAL SCI & TECH

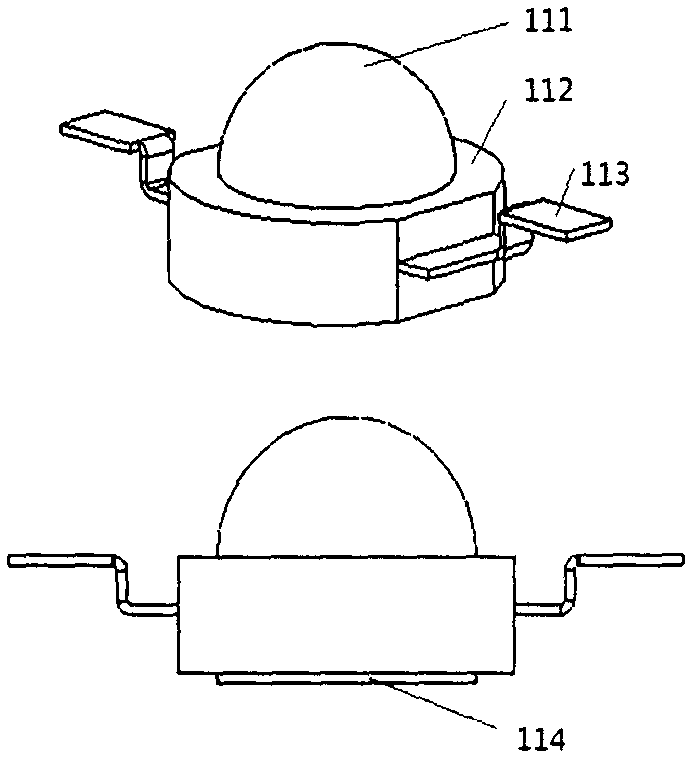

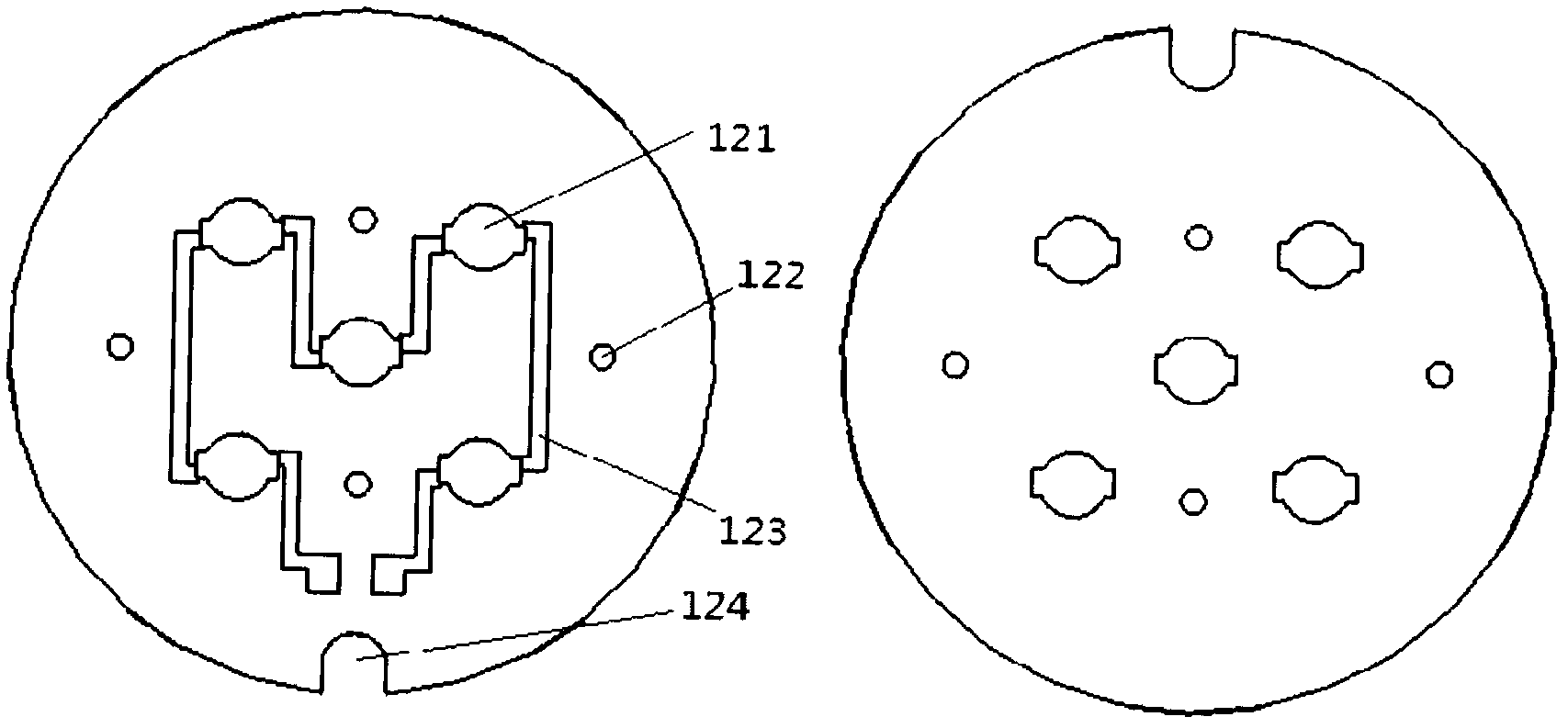

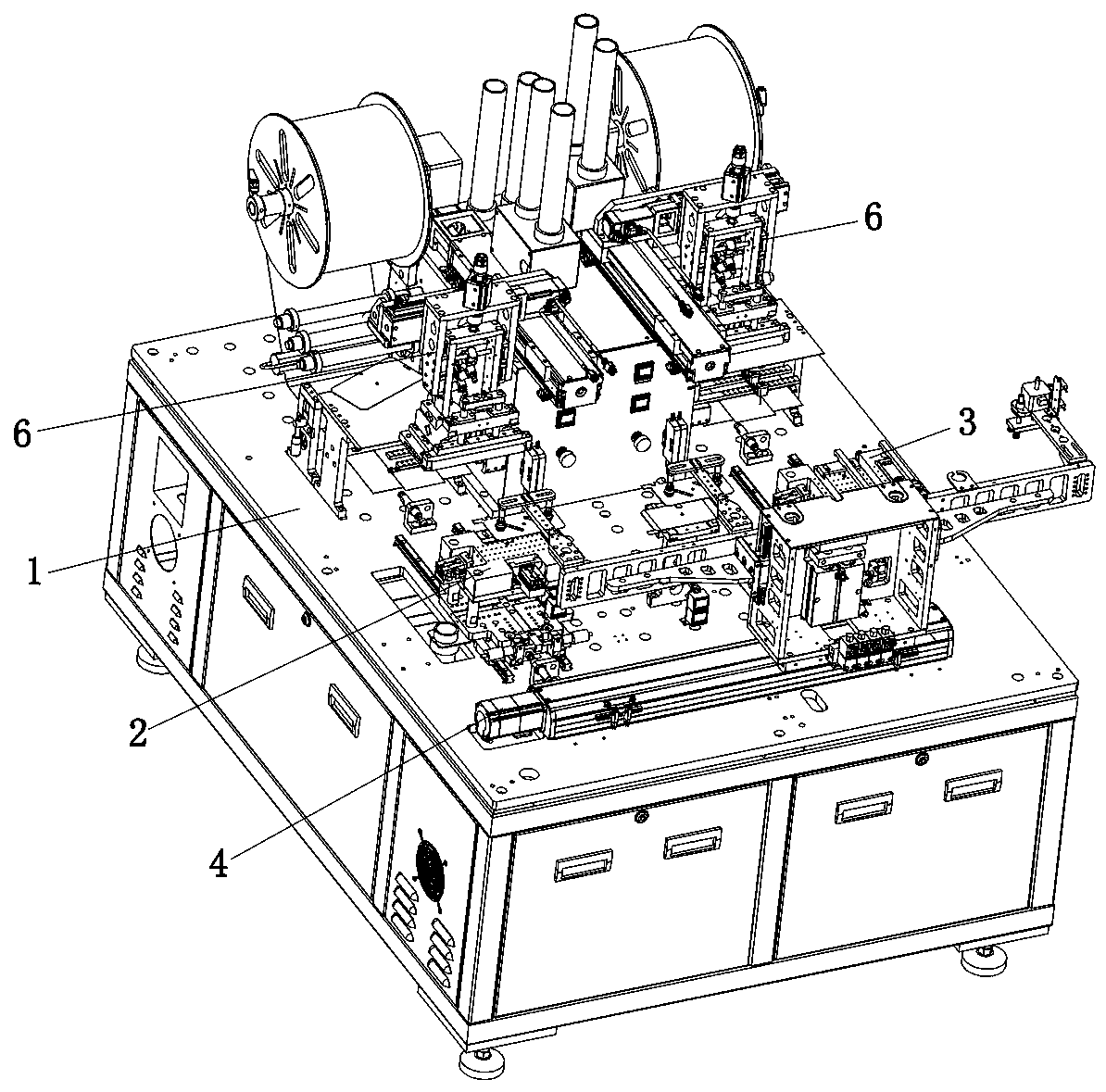

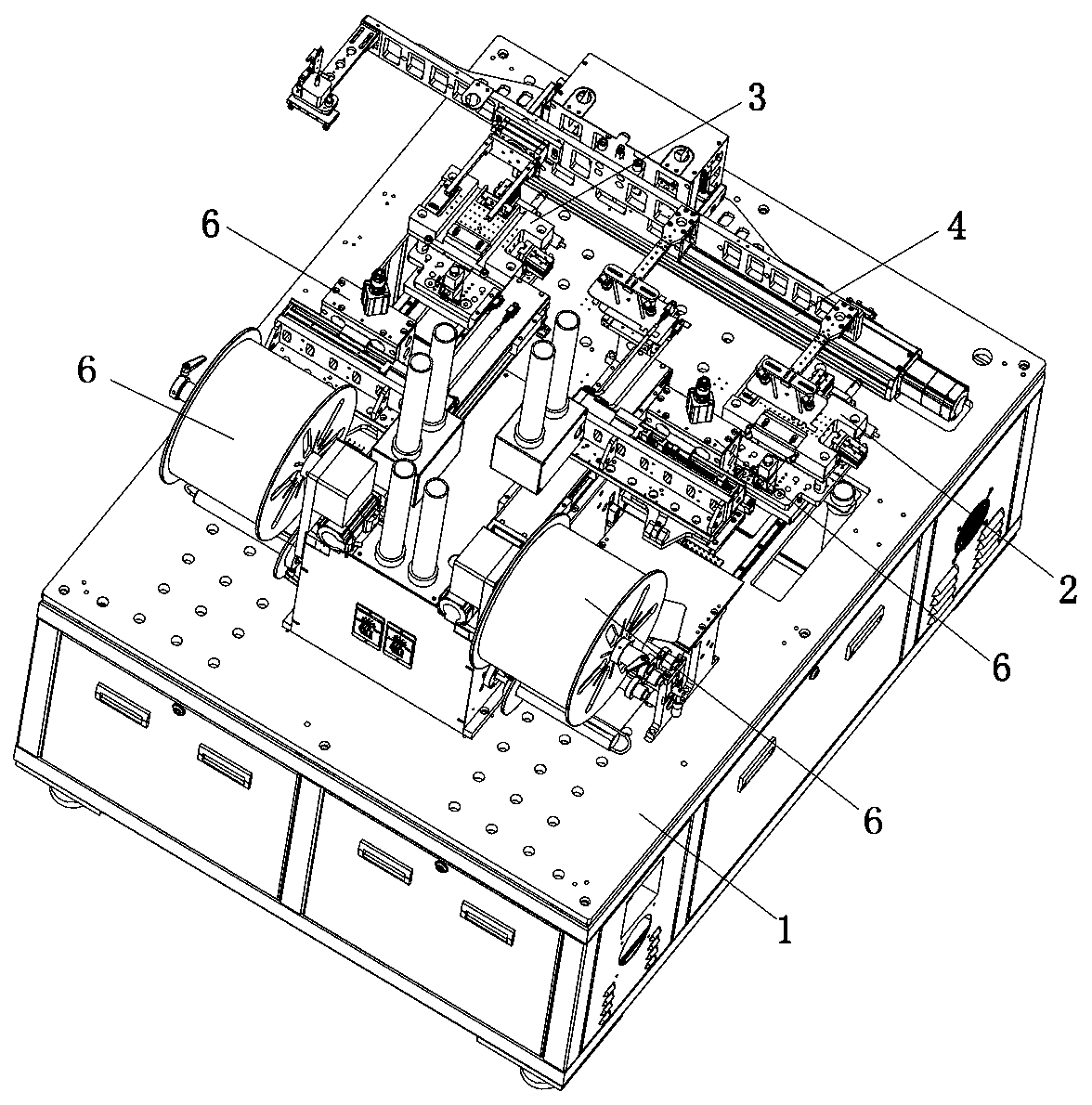

Semi-automatic mylar and rubber dome laminating device

ActiveCN108495458AGuaranteed fit qualityAvoid inaccurate fitsLaminationLamination apparatusEngineeringSemi automatic

Owner:广德众泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com