Full-automatic soft-to-hard laminating machine and laminating process thereof

A fully automatic laminating machine technology, applied in the direction of conveyor objects, packaging, instruments, etc., can solve the problems that the cover cannot be attached to the OCA smoothly and the surface is uneven, so as to improve the lamination quality and reduce lamination air bubbles , Improve the effect of bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

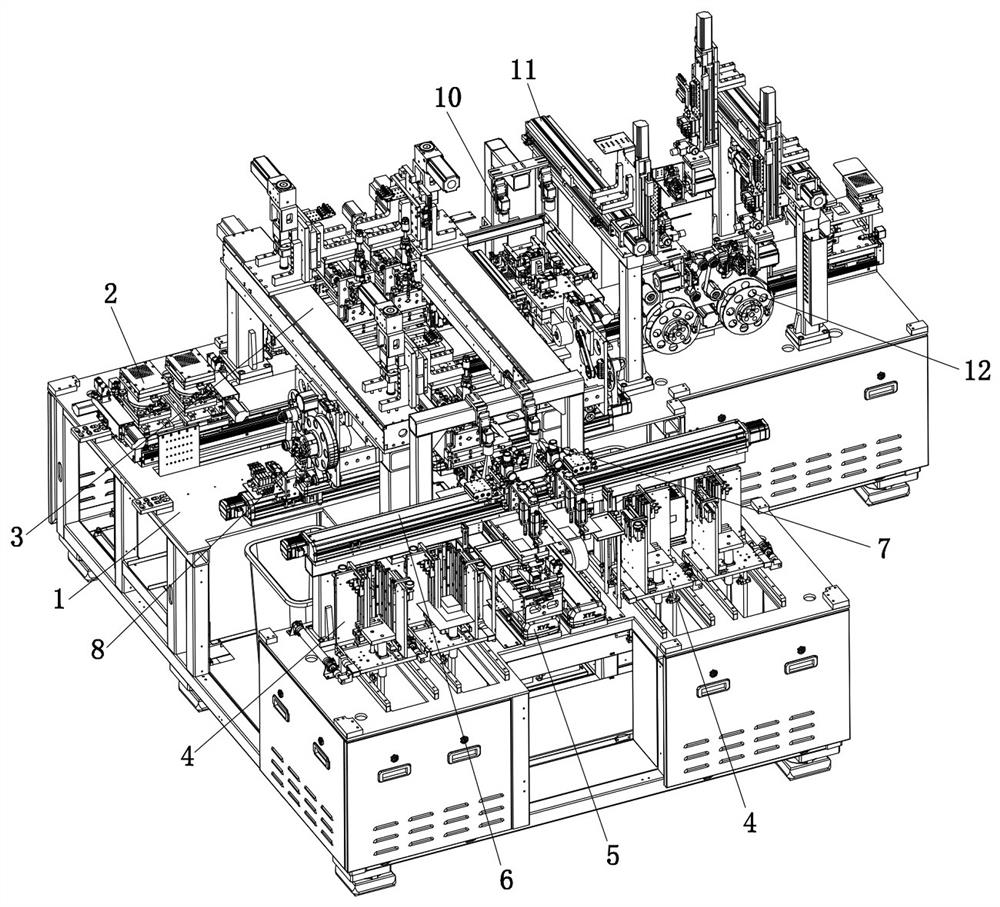

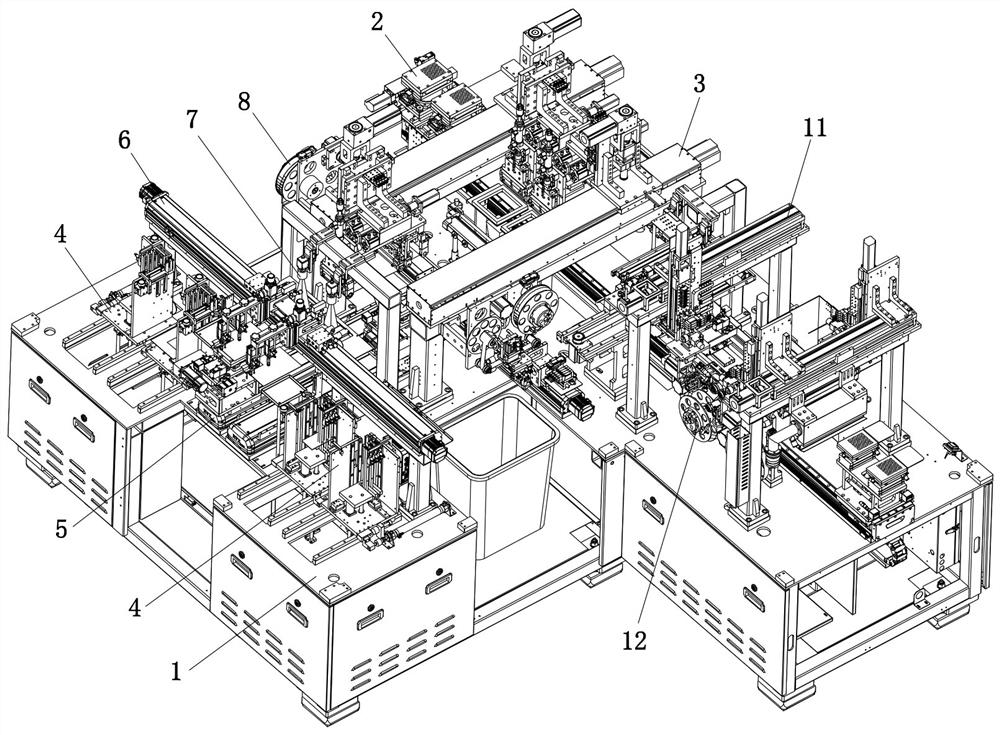

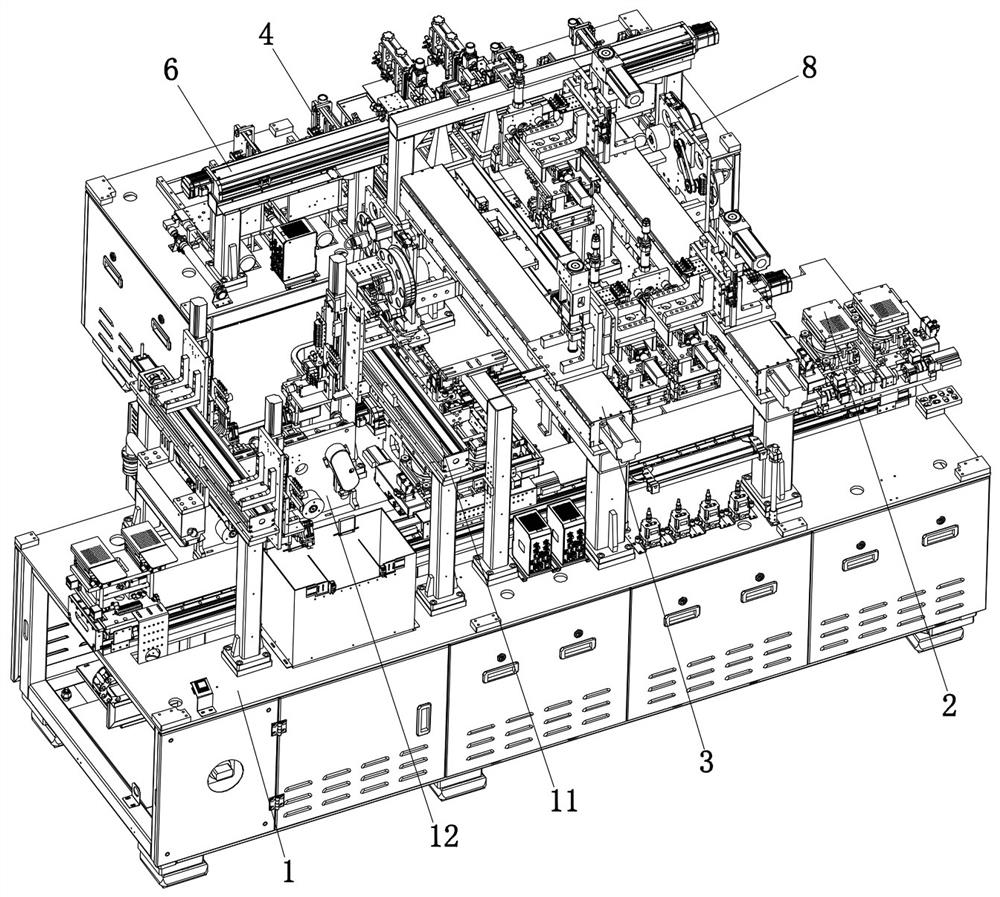

[0053] The present invention will be further described below in conjunction with the accompanying drawings:

[0054] like Figure 1 to Figure 22 As shown, the technical solution adopted by the present invention is as follows: a fully automatic soft-to-hard laminating machine, comprising a horizontally arranged machine 1, an LCD feeding platform 2, a laminating mechanism 3, an OCA feeding mechanism, and an OCA transferring mechanism. The detection mechanism, the first film tearing mechanism and the second film tearing mechanism, wherein, the above-mentioned LCD feeding platform 2 is horizontally arranged on one side of the machine table 1, and extends along a linear direction to form an LCD feeding channel; the above-mentioned laminating mechanism 3 is erected On the LCD feeding platform 2; the above-mentioned OCA feeding mechanism is arranged on the other side of the machine 1, and at least two pieces of OCA are stored up and down; The OCA is taken out in the feeding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com