Patents

Literature

82results about How to "Avoid uneven attachment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

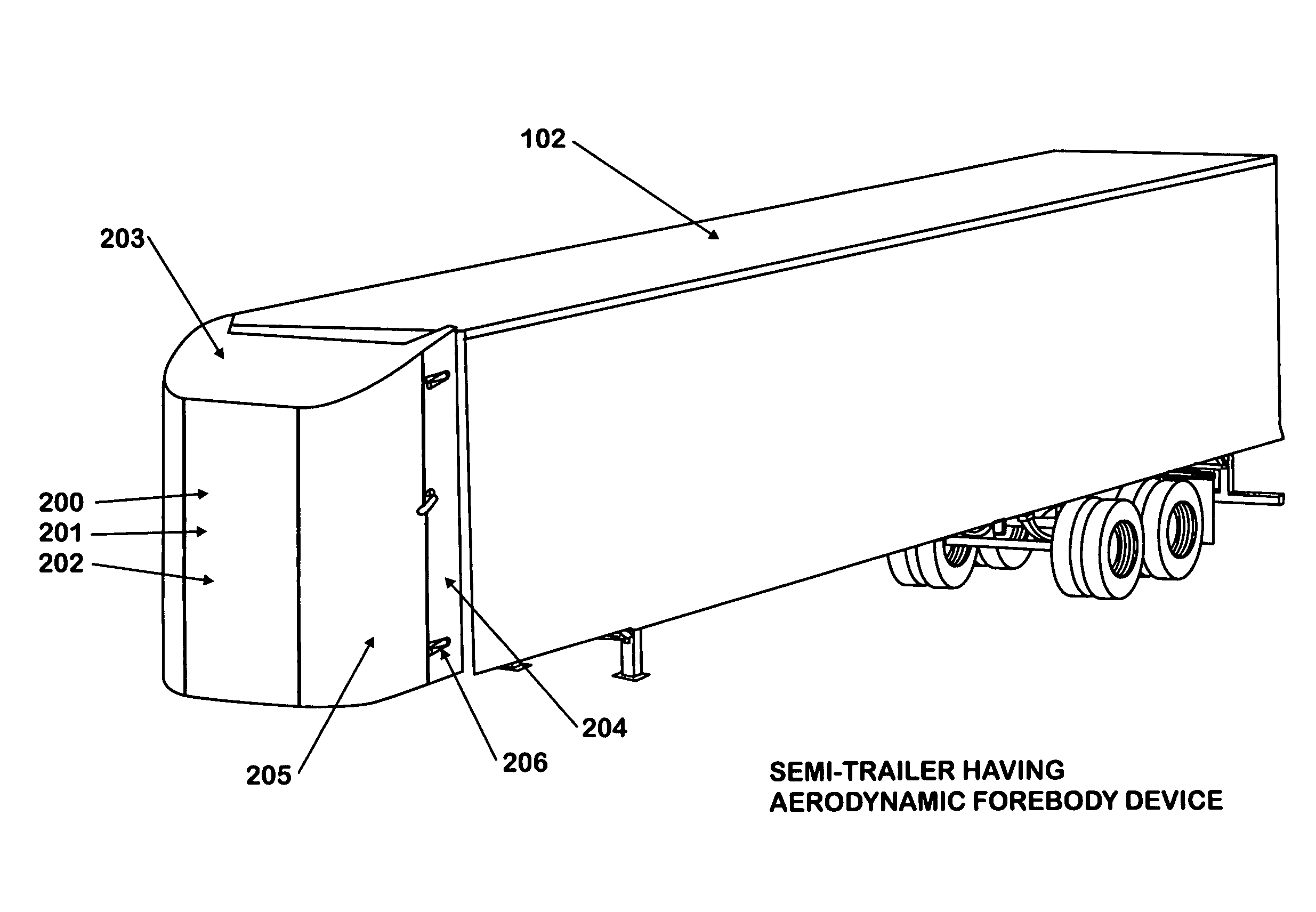

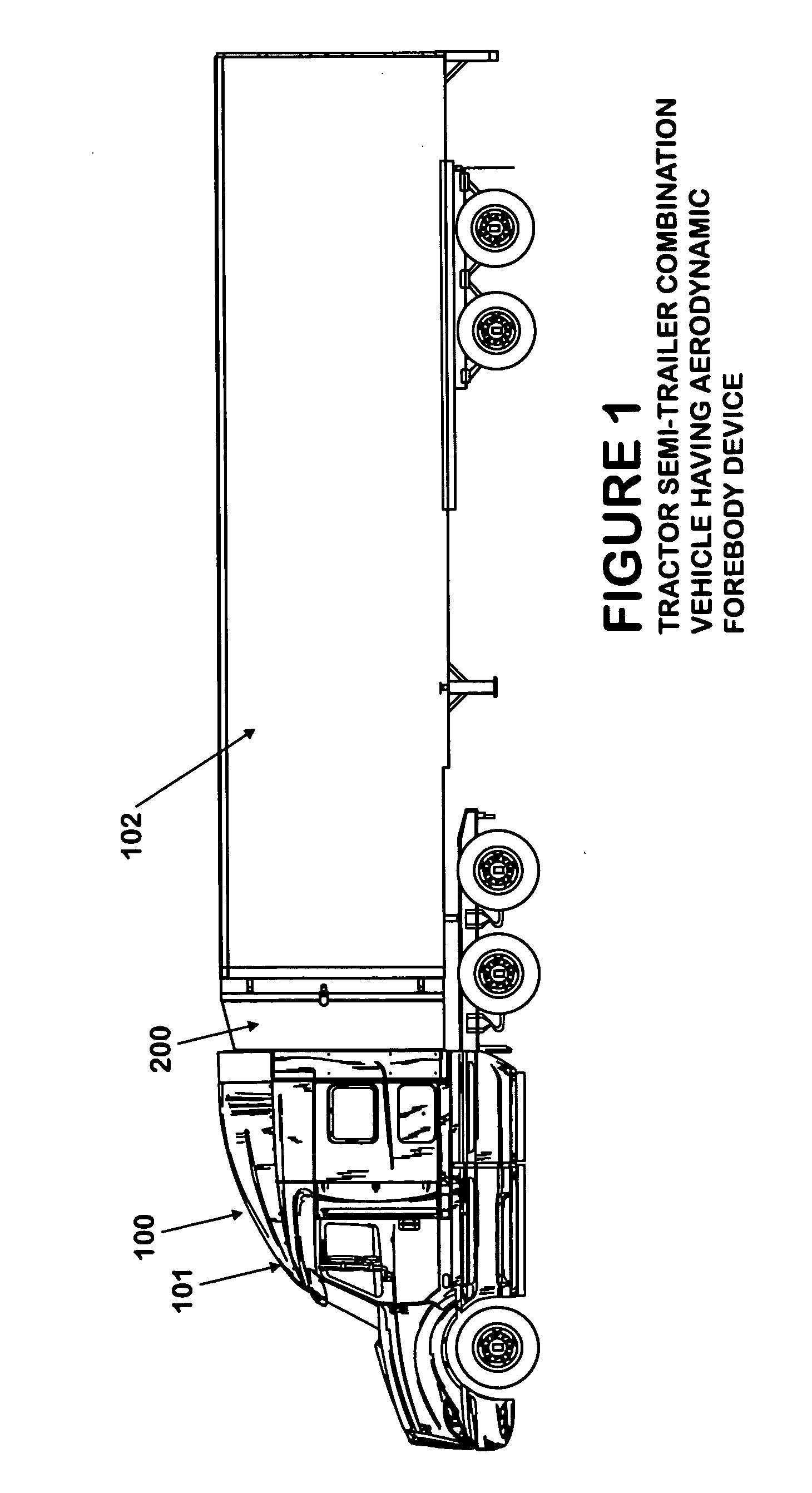

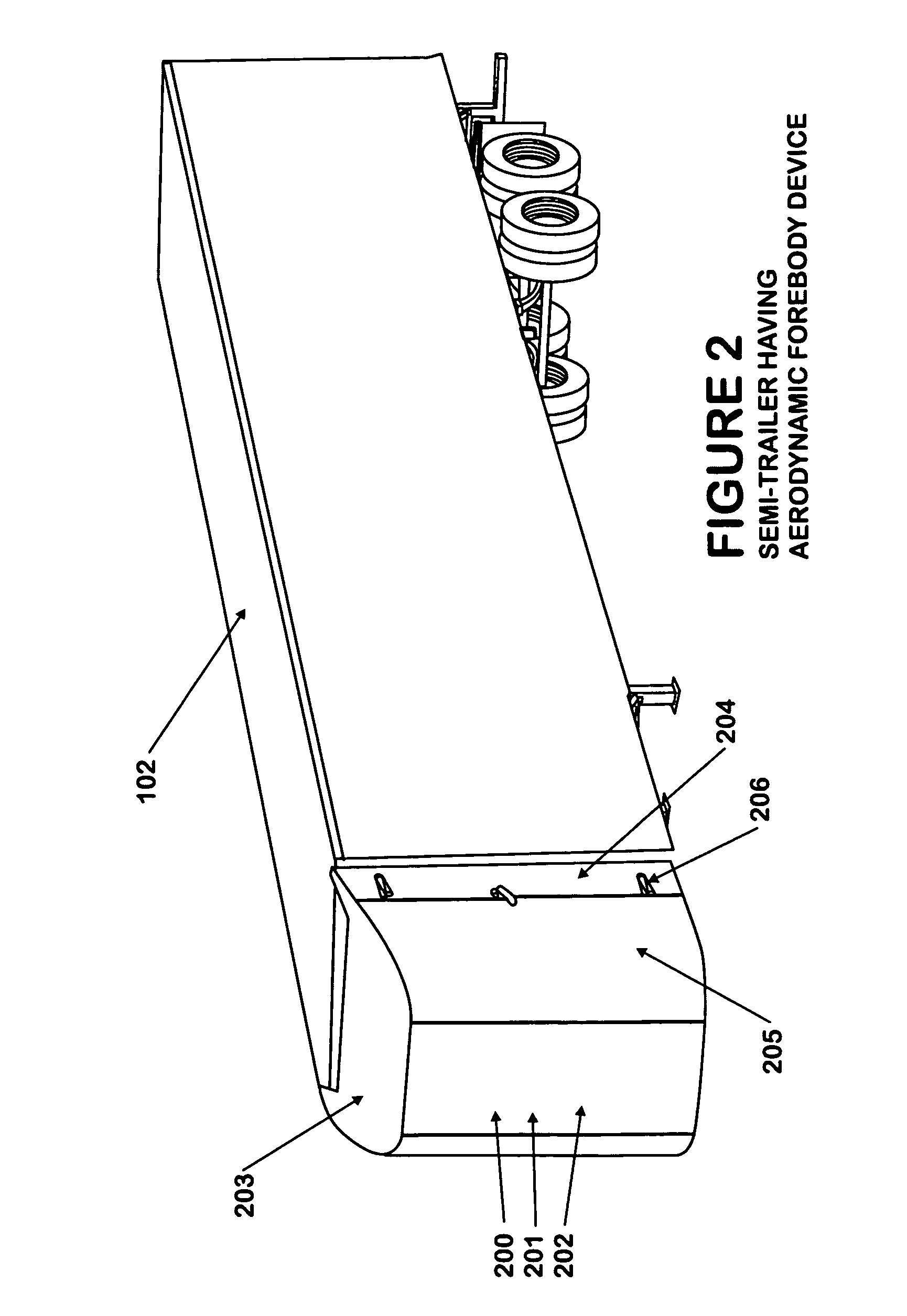

Aerodynamic forebody shape for van trailer

InactiveUS20080217957A1Reduce static pressureReduce air resistanceVehicle seatsWindowsAerodynamic dragSubject matter

An aerodynamic forebody device is provided for use with a tractor-trailer combination vehicle to be installed on the front of the semi-trailer. By optimizing the inclination angle of the top surface of the aerodynamic forebody device, aerodynamic drag is minimized. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:INT TRUCK INTPROP LLC

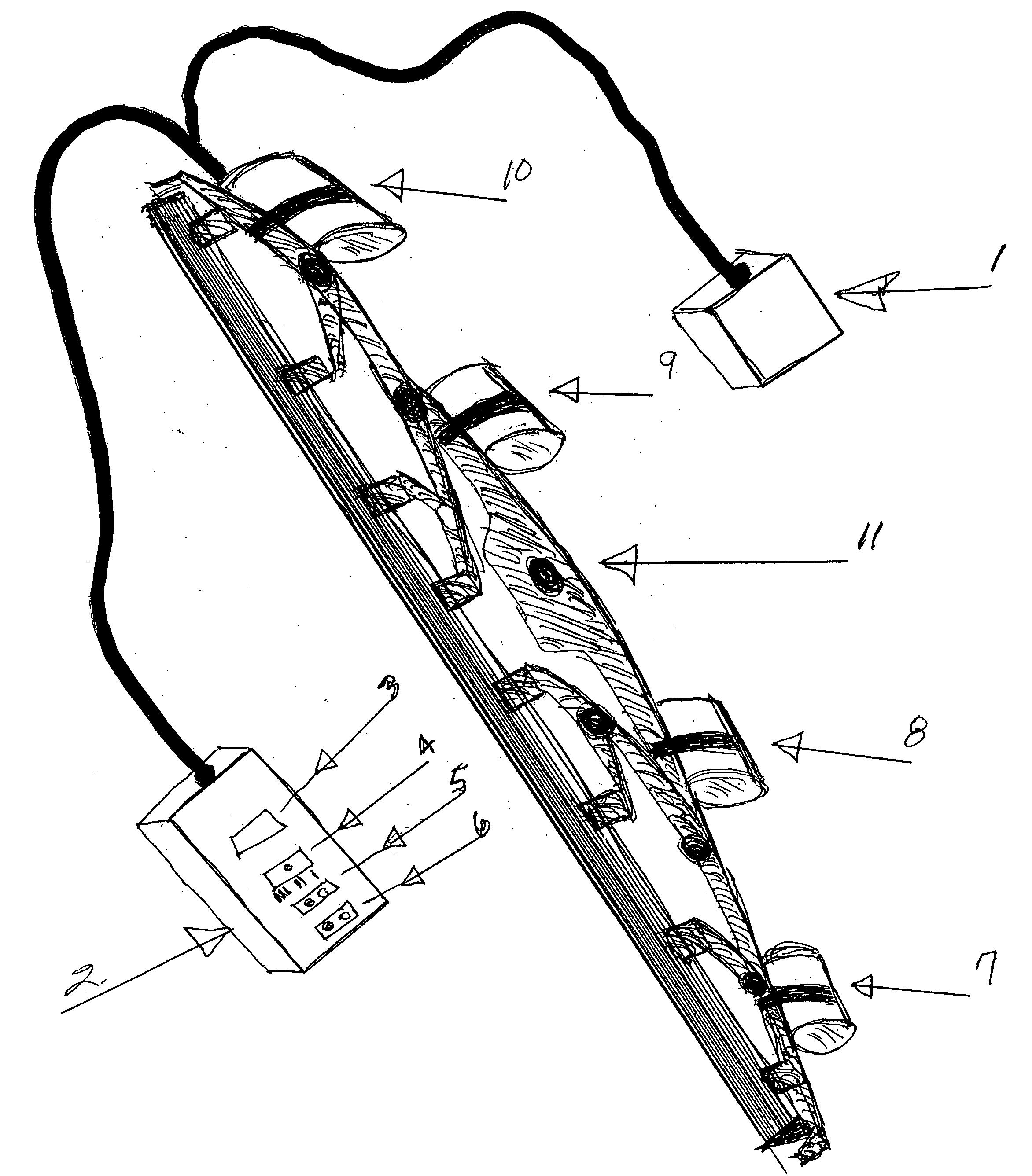

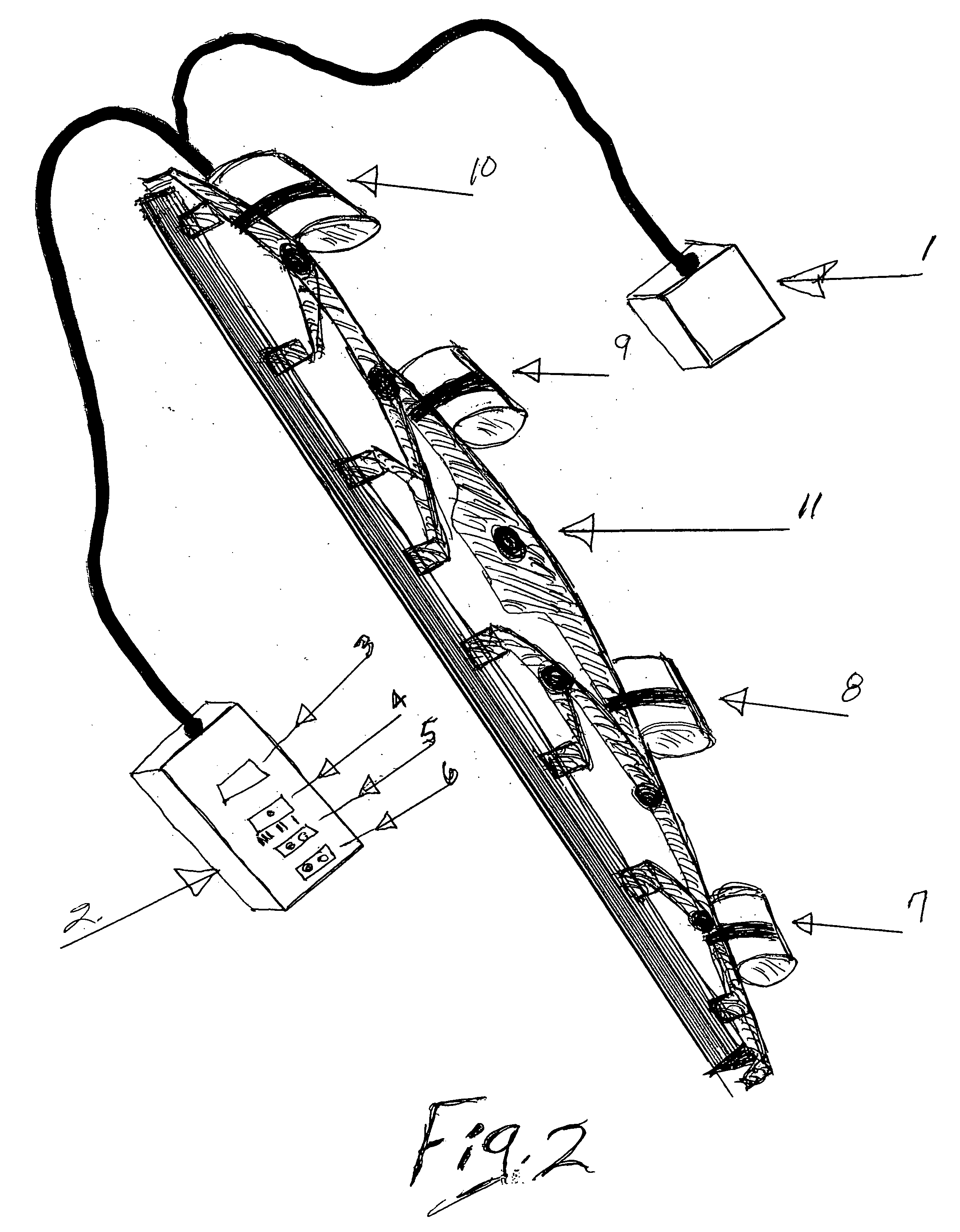

Vibrating wiper blade

InactiveUS20080034531A1Easy to disassembleAvoiding hoppingWindow cleanersVehicle cleaningElectric machineryEngineering

A vibrating wiper blade that is functional and attractive. A standard wiper blade can be engineered to accommodate vibrating motors in a sleek and decorative design. Attached to the wiper blades and vibrating motors are tailor made and smoothly attached and designed electrical wiring. The vibrating motors may be engineered on wiper blades from the manufacturing stage, or provide at outlet stores and travel plazas as clip-on models with wiring attached under the hood, and / or controls quickly extended through a driver window. The vibrating motors will facilitate the removal of ice and snow from windshield wiper blades while avoiding hopping and skipping on the windshield. Tailor engineered models may be designed with a direct vibrating spring loaded pin or pistion to strike the wiper blade head. All of this is designed at minimal cost and complexity.

Owner:BEAVER BENNIE MAX

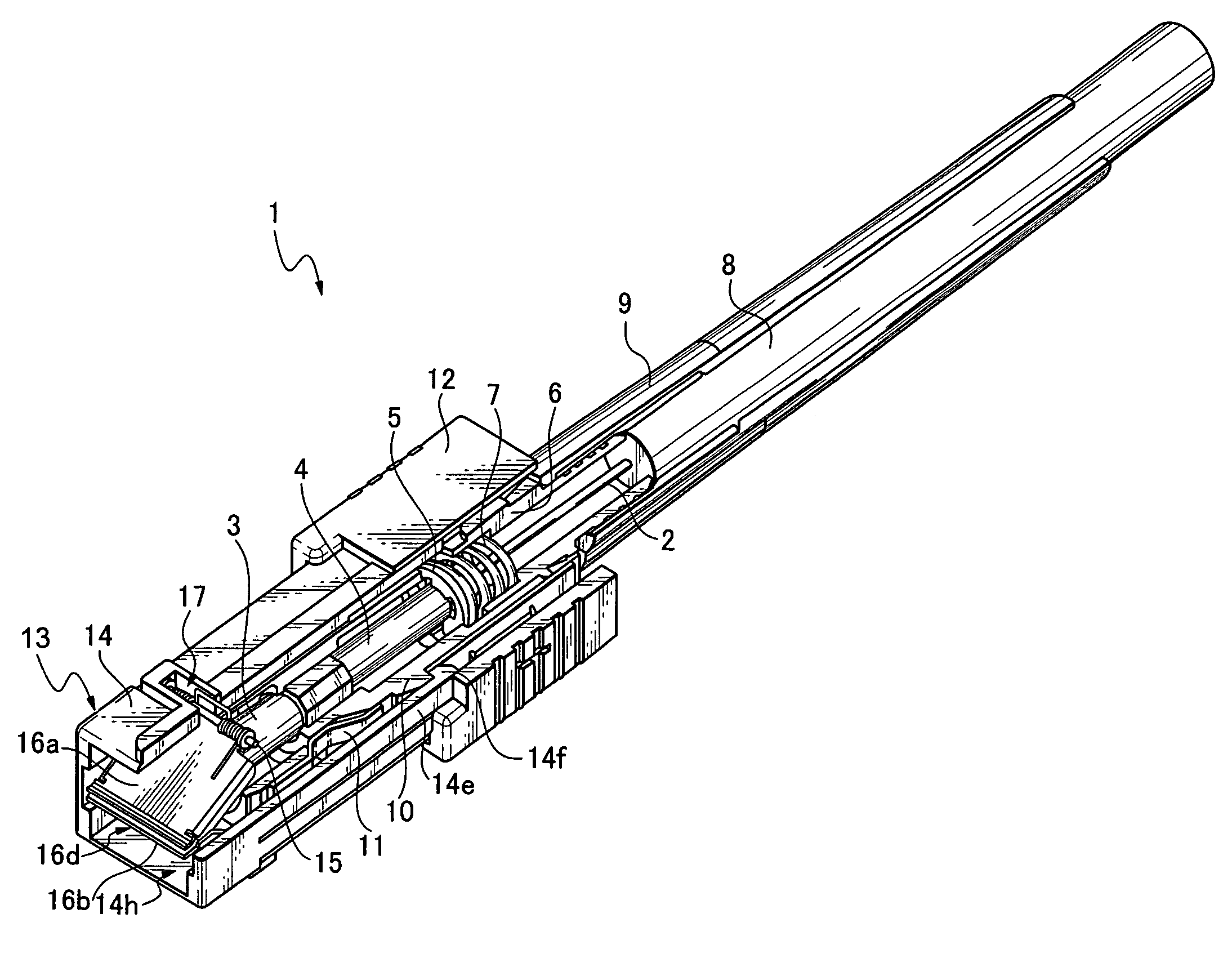

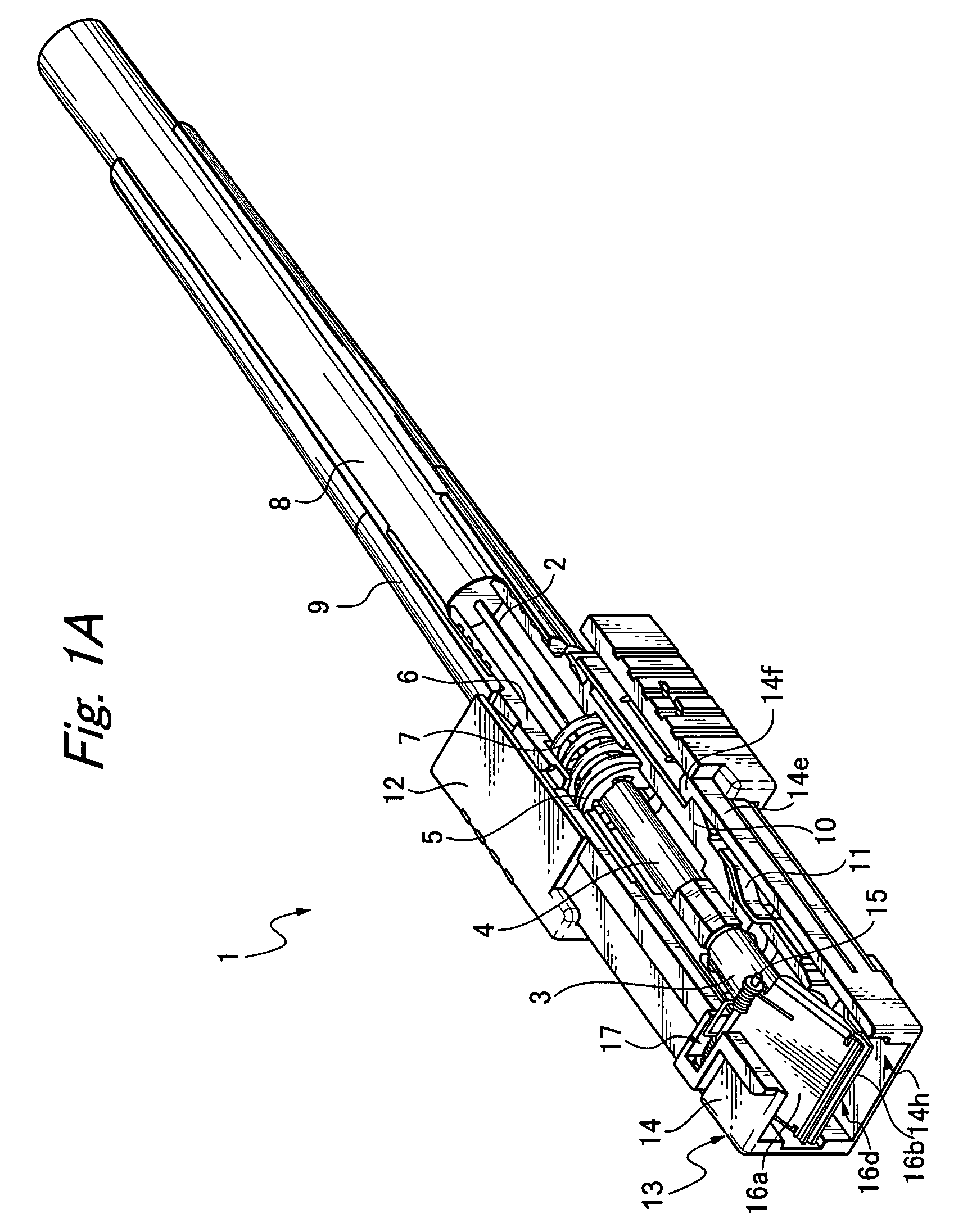

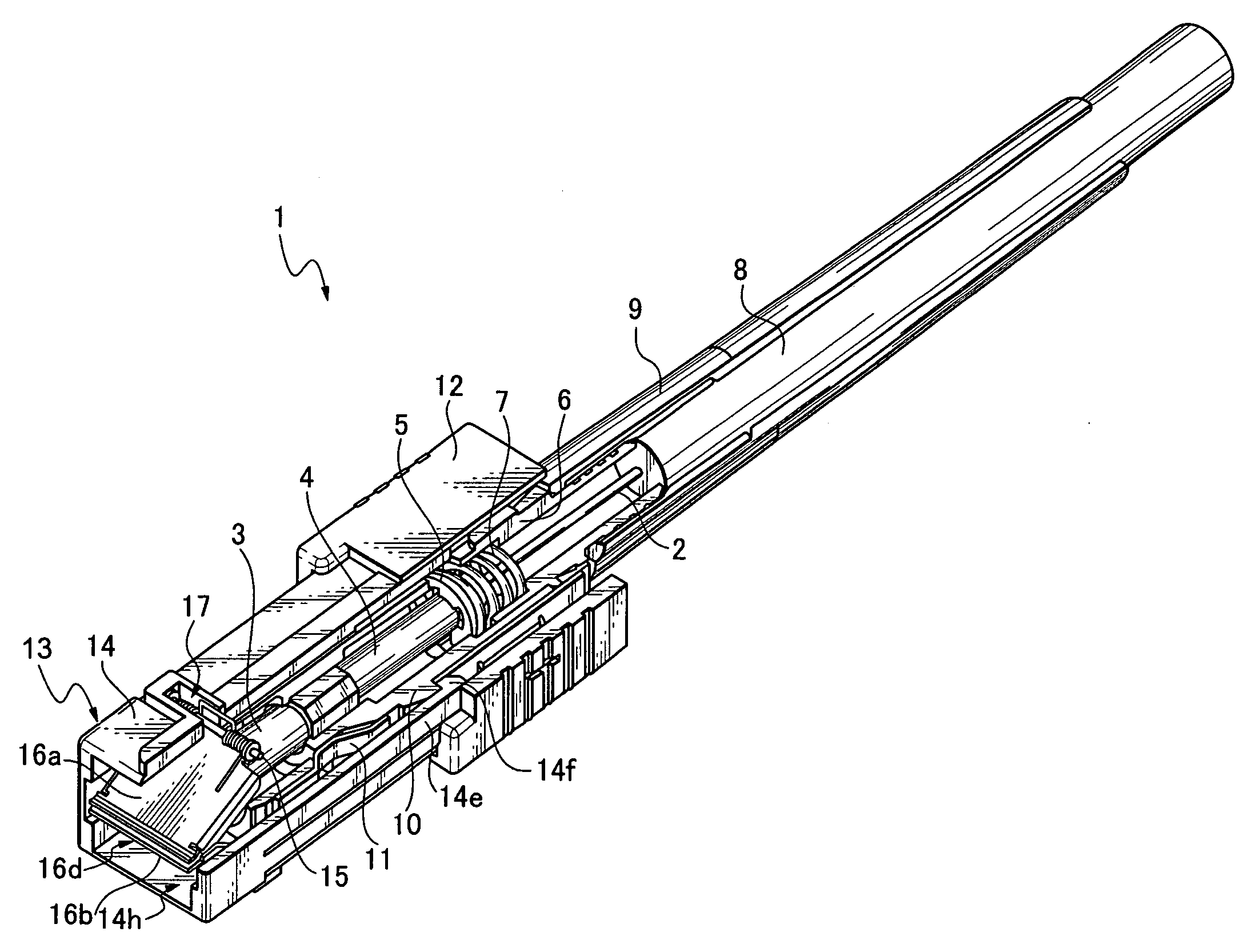

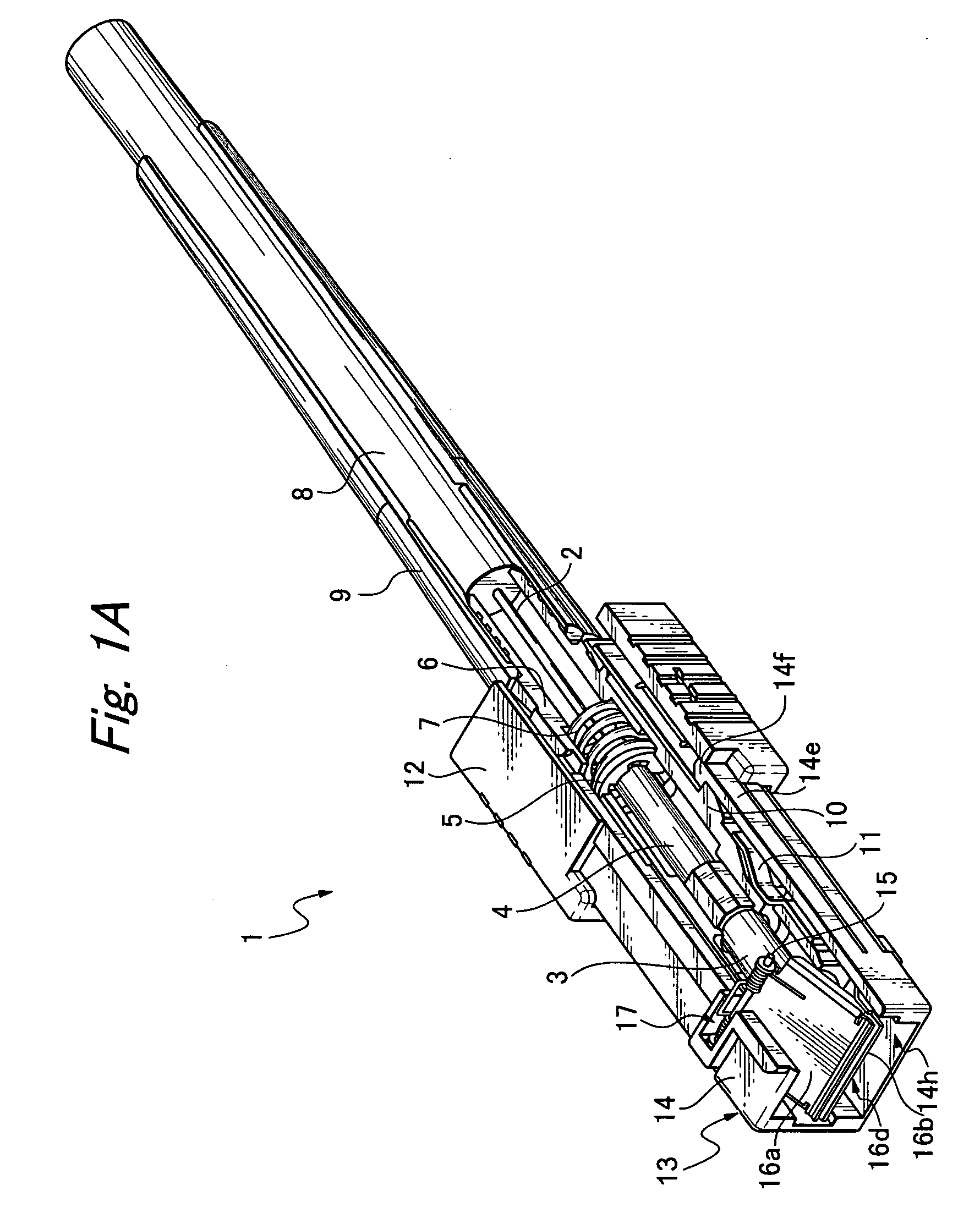

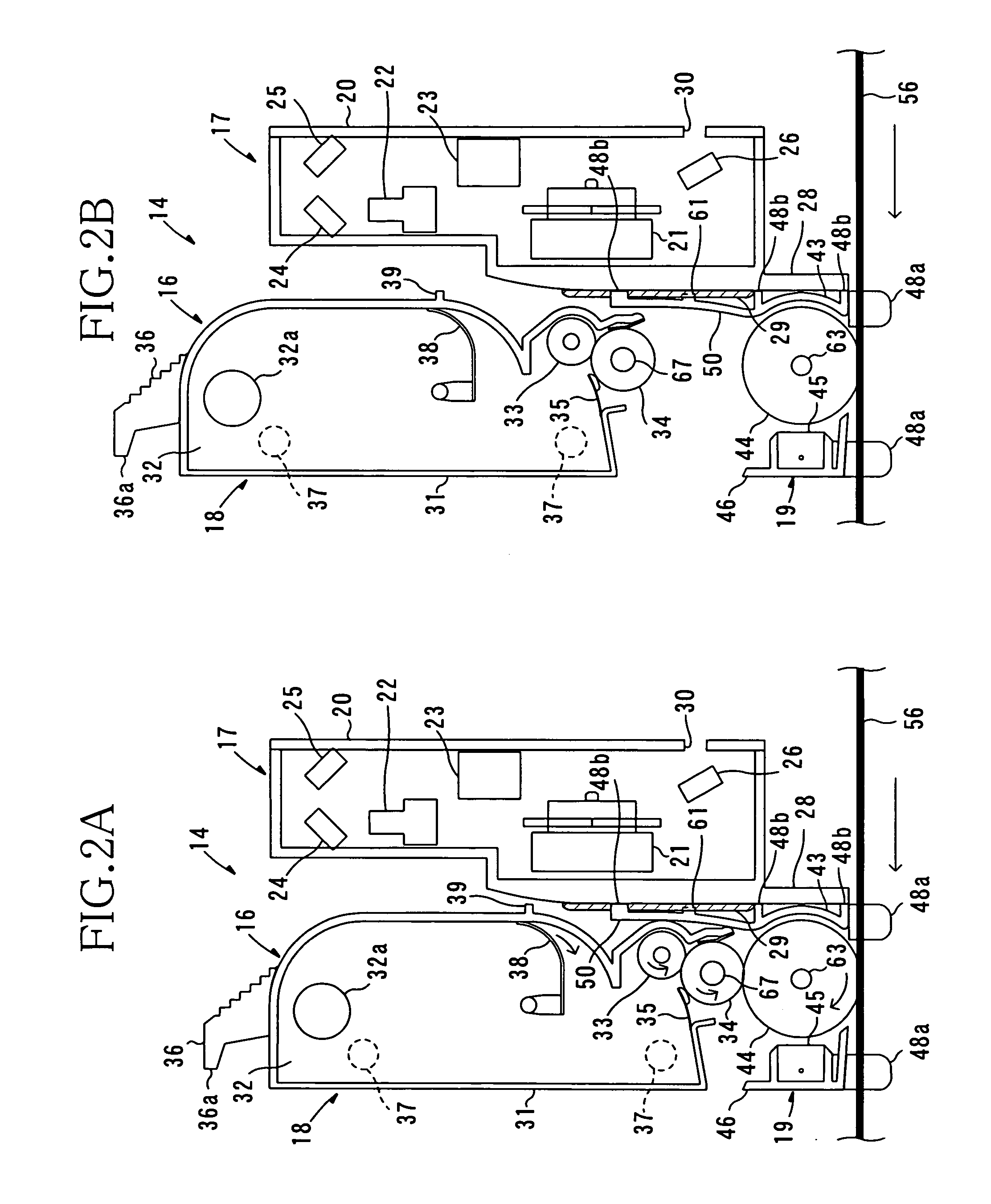

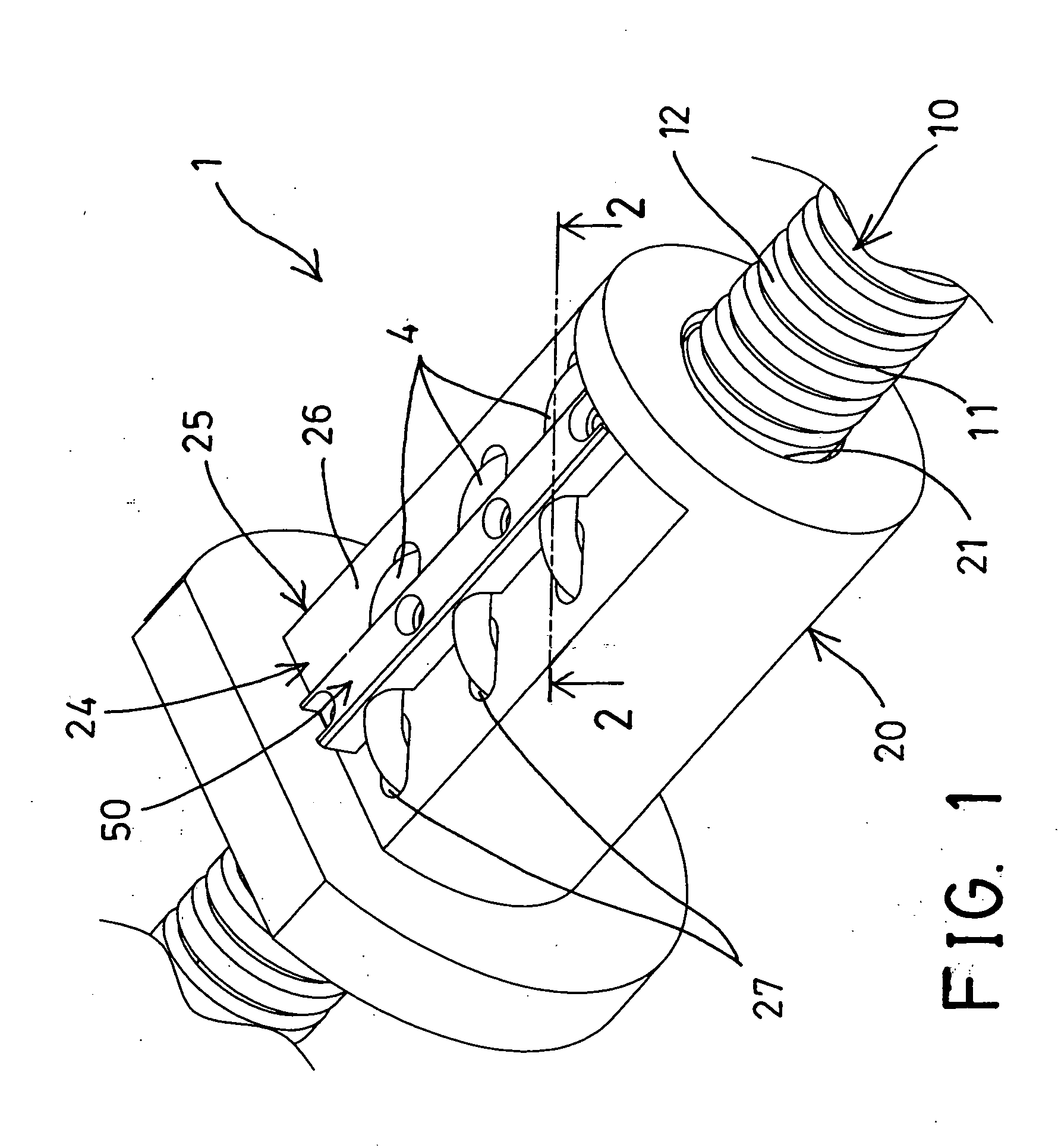

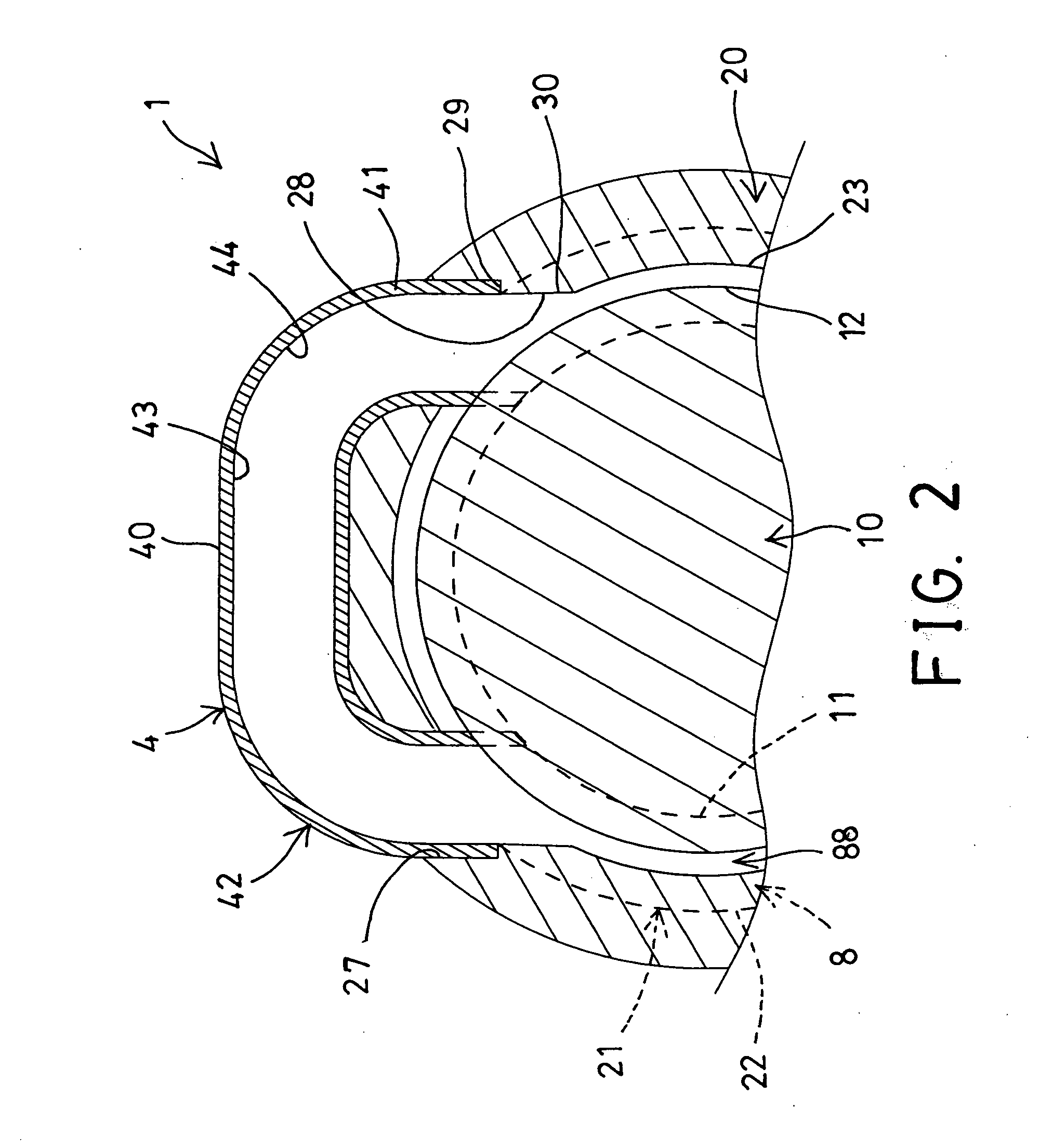

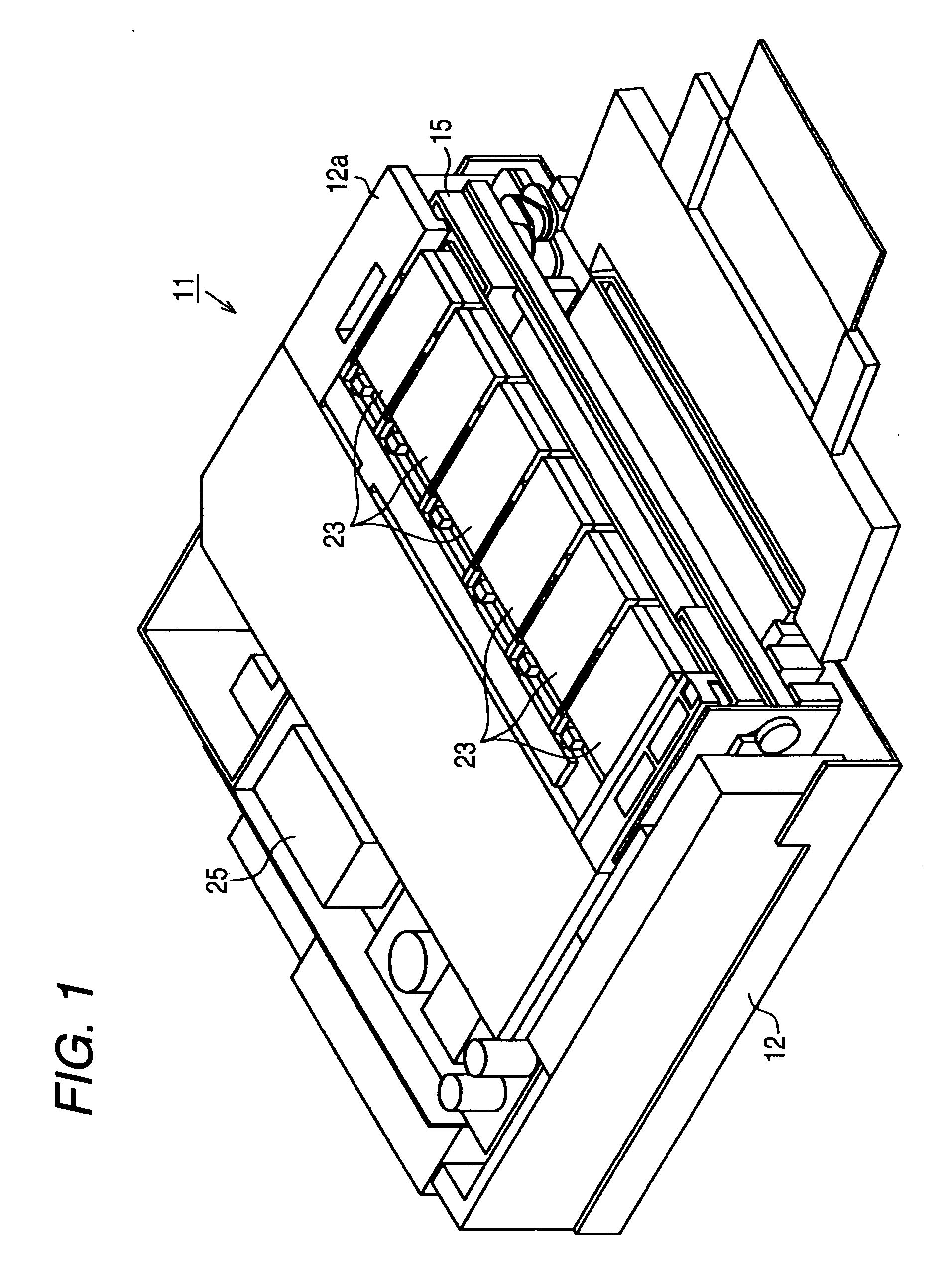

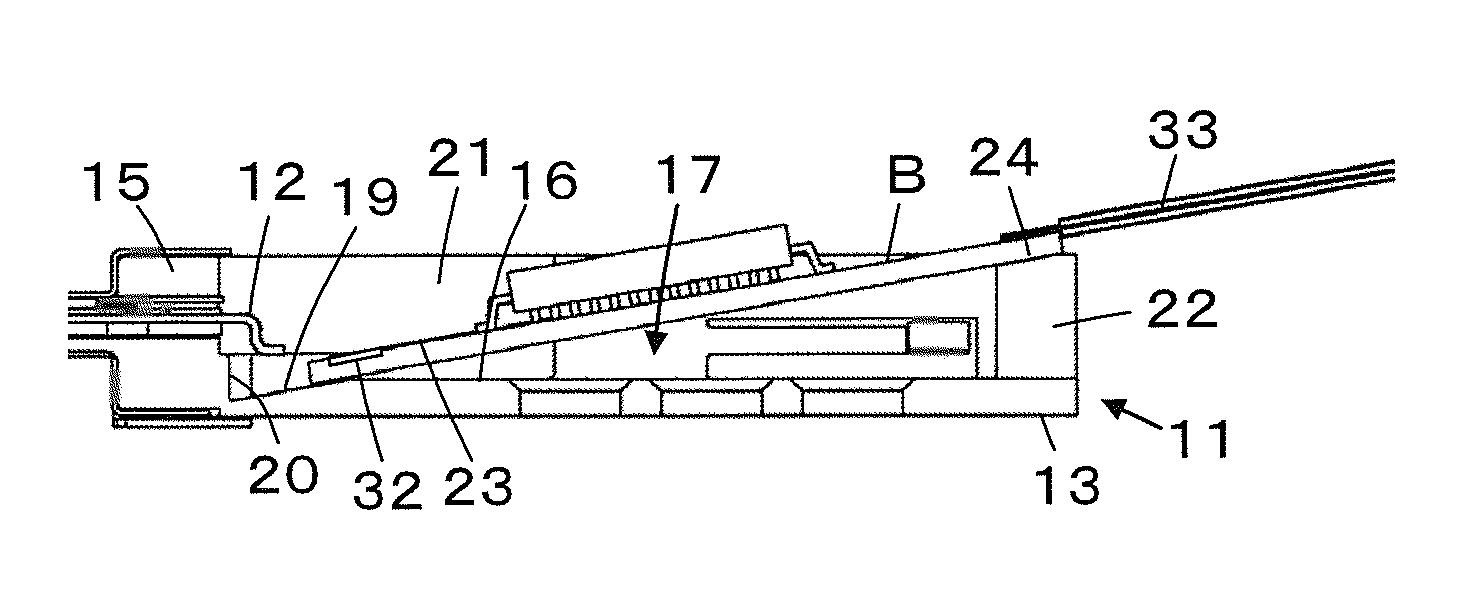

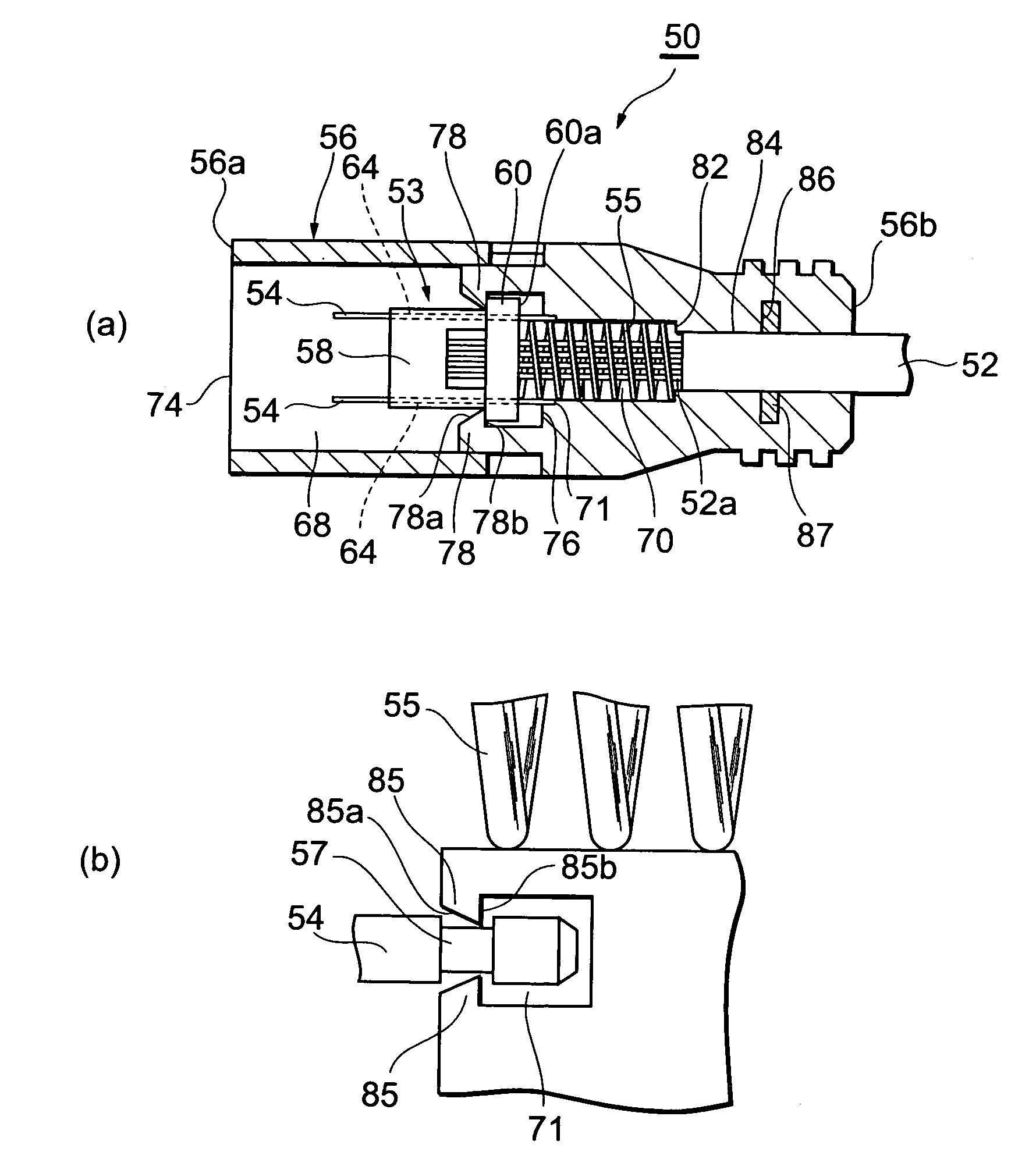

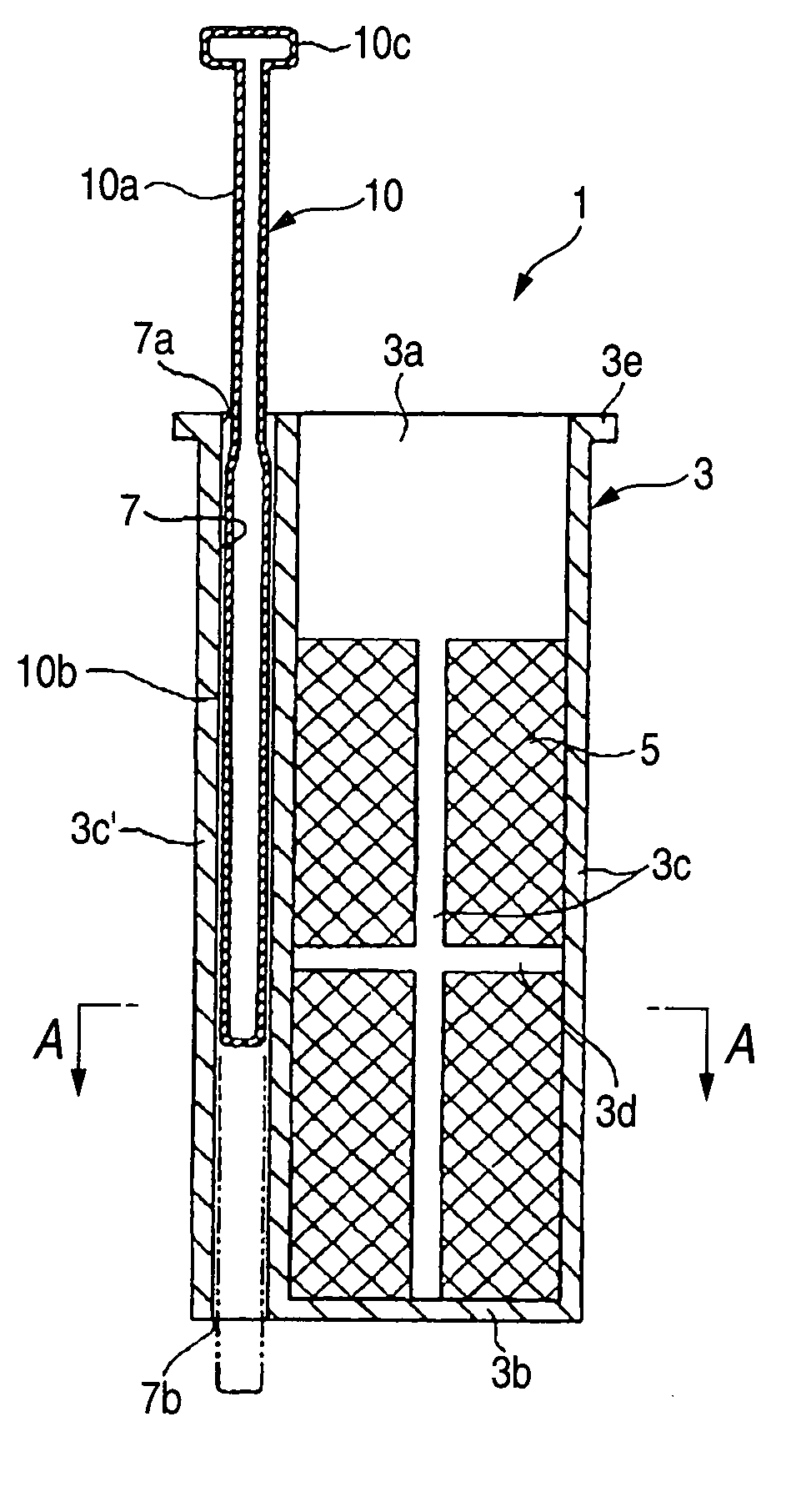

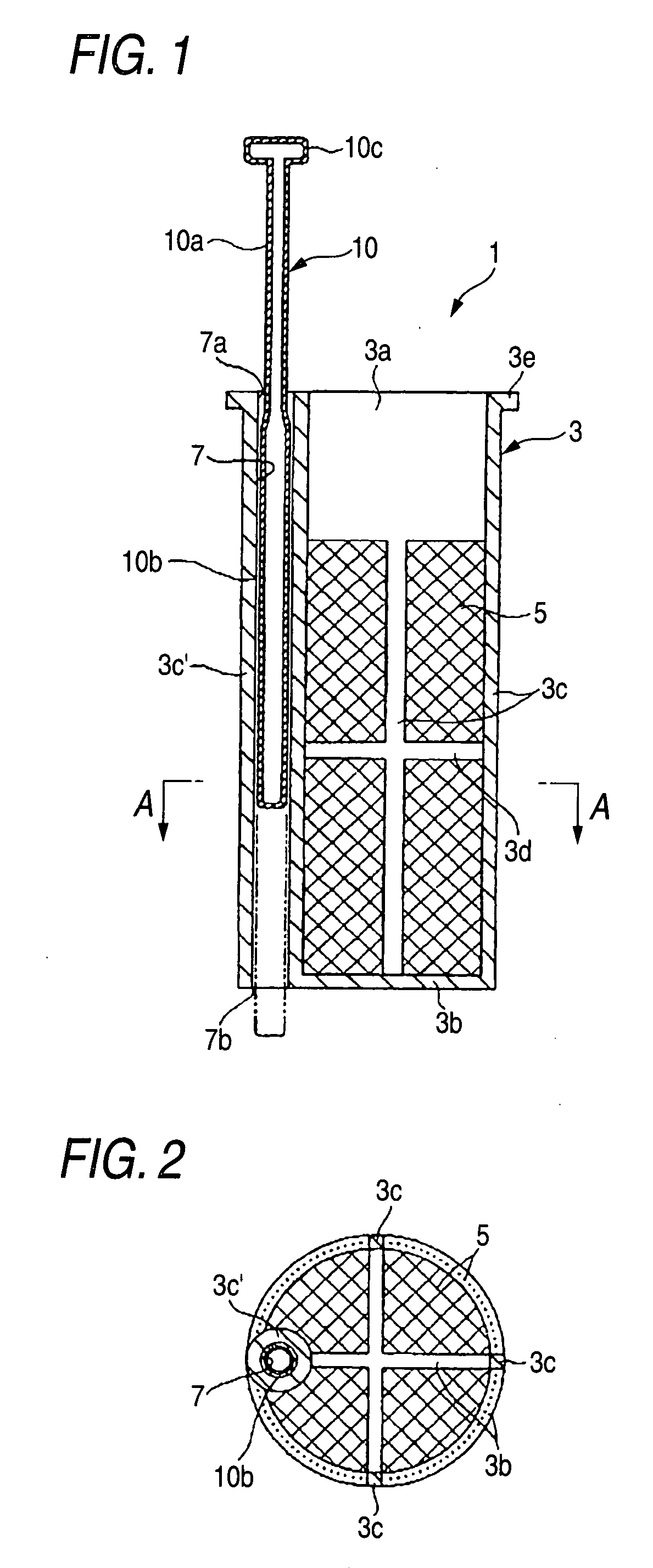

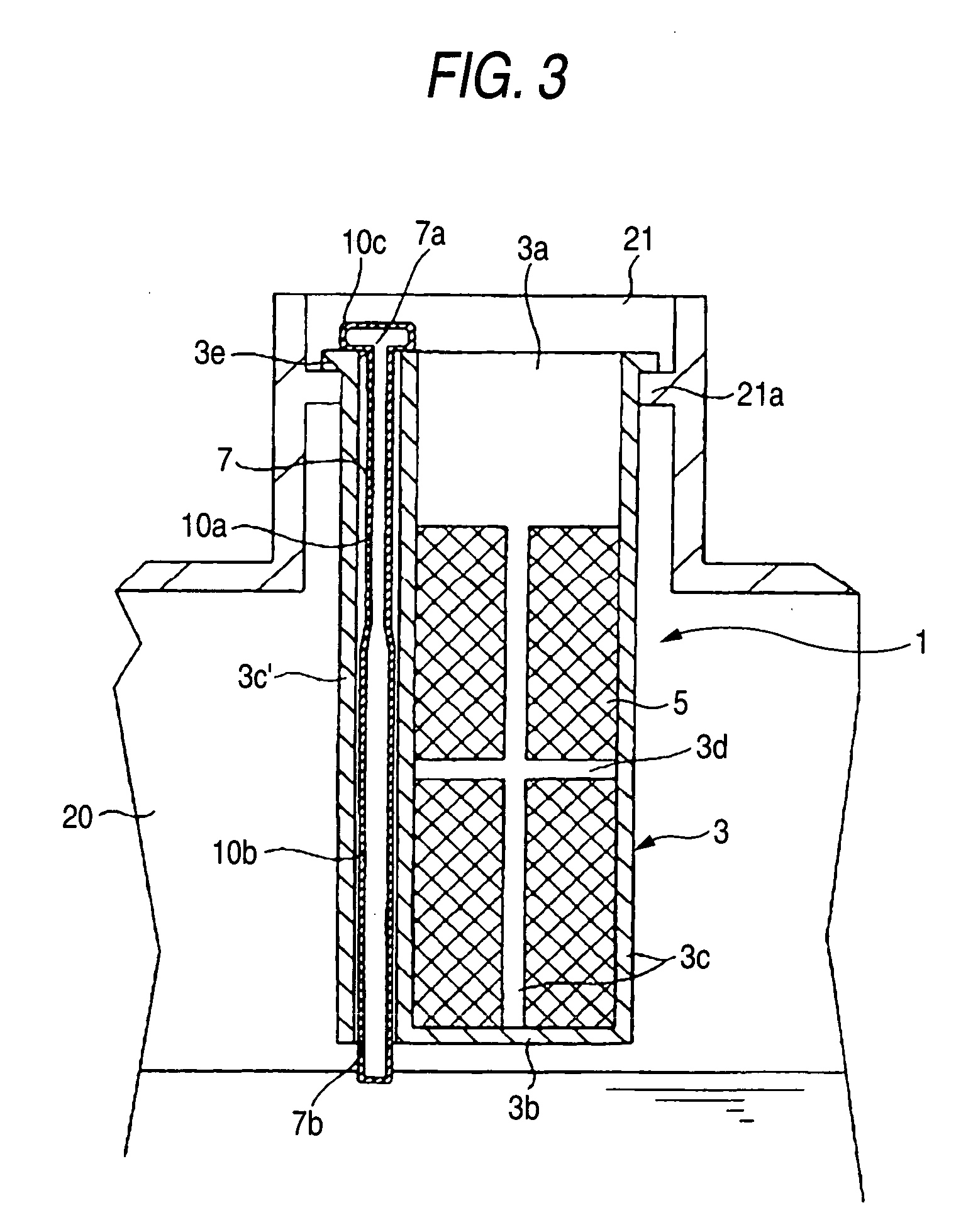

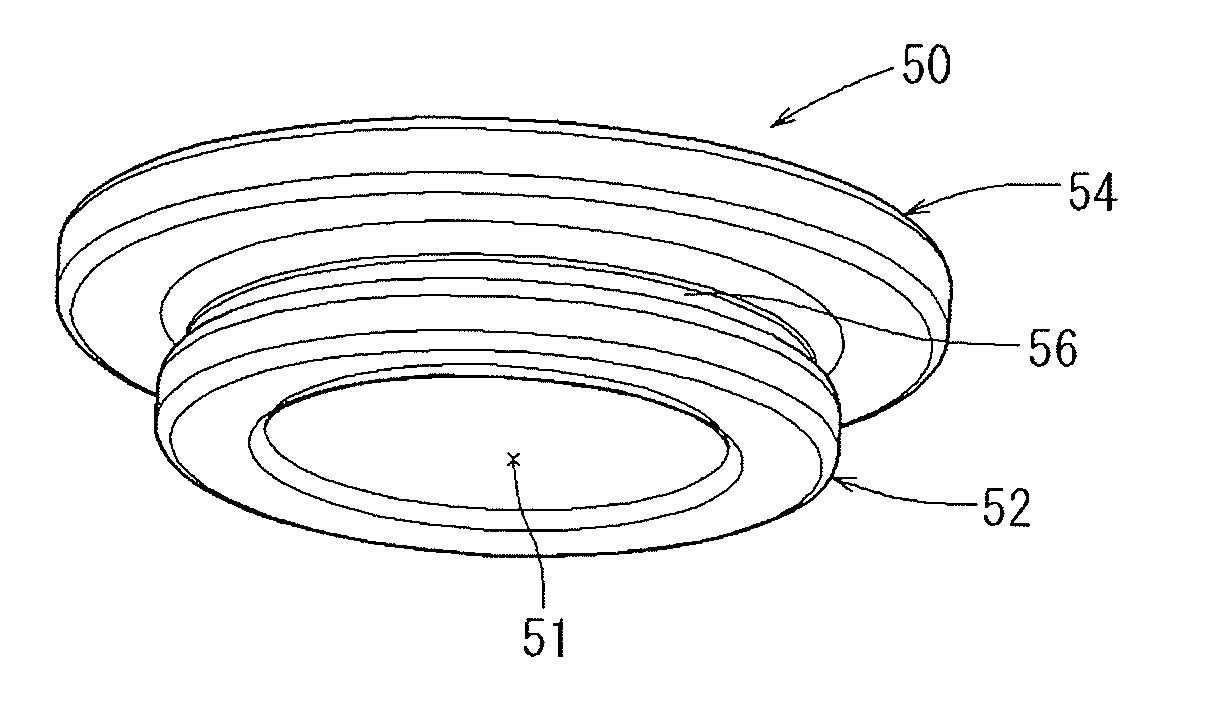

Shading member-equipped optical connector plug

InactiveUS7559700B2Avoid uneven attachmentImprove compatibilityCoupling light guidesShutterEngineering

A shading member-equipped optical connector plug is compact while having the compatibility to engage existing connector receptacles. The connector plug includes a shading member having a shutter housing enclosing a plug frame slidably on an outside thereof. The shutter housing is inserted into an engagement opening of a connector receptacle to be engaged when the shading member-equipped optical connector is connected. The shading member also has a shutter one end of which is supported by the shutter housing at a front part of the housing and another end of which is urged by an elastic force and closes so as to shade the optical fibers at a position in front of the ferrule, and an elastic member disposed between the plug frame and the shutter housing that urges the shutter housing forward.

Owner:HONDA TSUSHIN IND

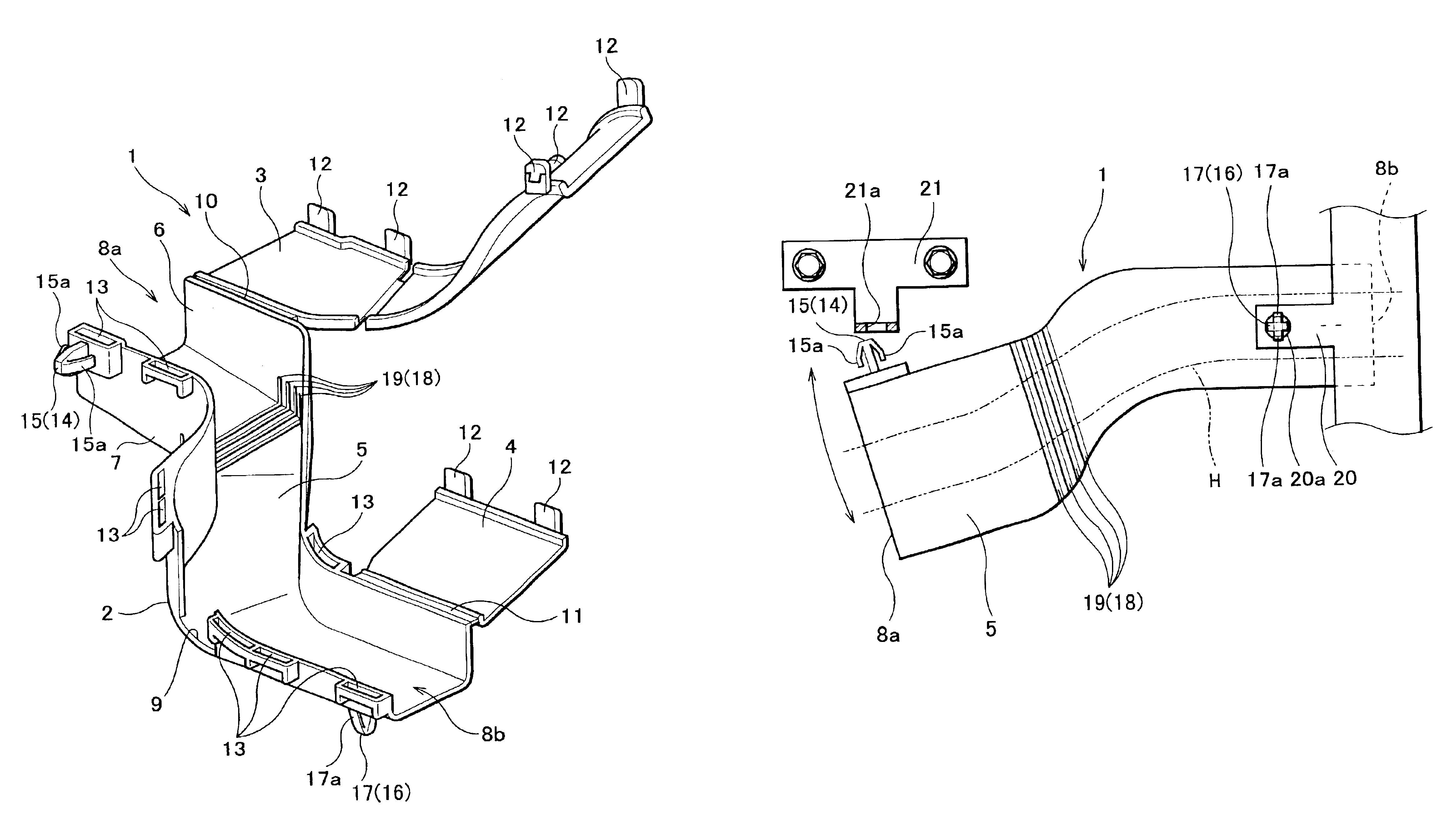

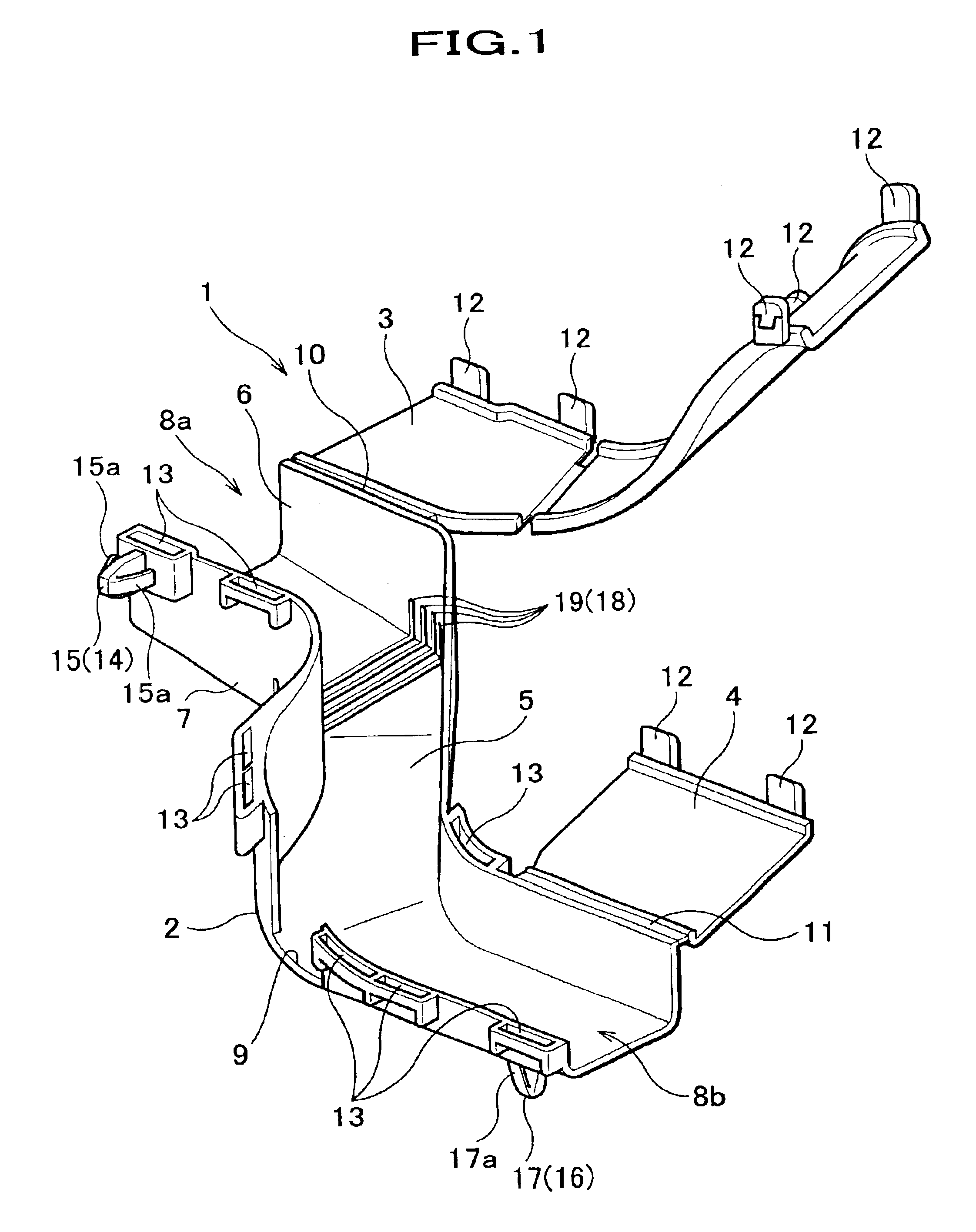

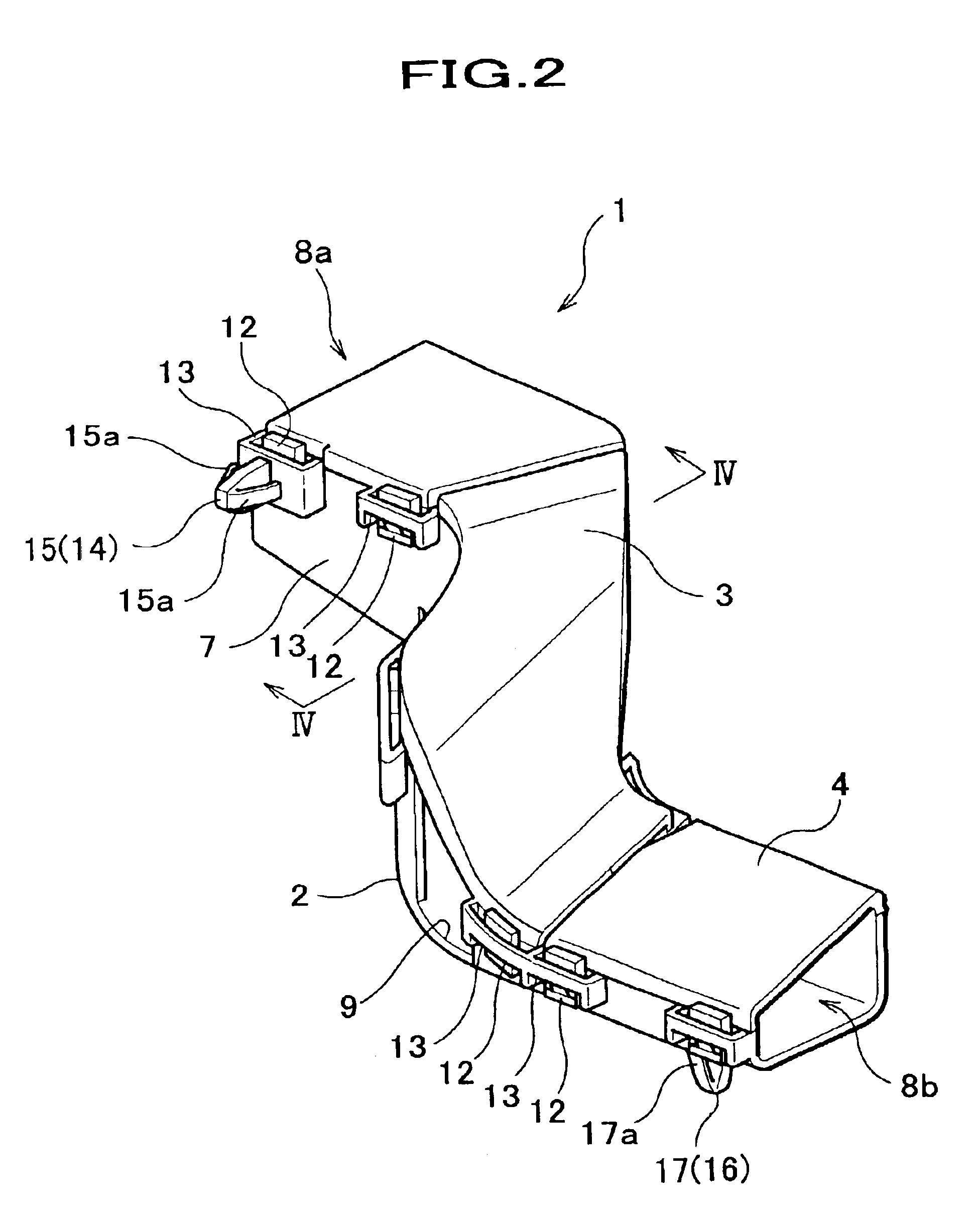

Protector for wire harnesses and mounting mechanism

InactiveUS6878879B2Smoothly attachEasily attachExtensible conductorsExtensible conductor cablesMechanical engineeringCable harness

Owner:HONDA MOTOR CO LTD

Shading member-equipped optical connector plug

InactiveUS20080247709A1Avoid uneven attachmentImprove compatibilityCoupling light guidesEngineeringMechanical engineering

A compact, highly compatible shading member-equipped optical connector plug that makes the optical connector plug compact while having the compatibility to engage existing connector receptacles. The shading member includes a shutter housing enclosing a plug frame slidably on an outside thereof, and inserted into an engagement opening of a connector receptacle to be engaged when the shading member-equipped optical connector is connected, a shutter one end of which is supported by the shutter housing at a front part of the housing and another end of which is urged by an elastic force and closes so as to shade the optical fibers at a position in front of the ferrule, and an elastic member disposed between the plug frame and the shutter housing that urges said shutter housing forward.

Owner:HONDA TSUSHIN IND

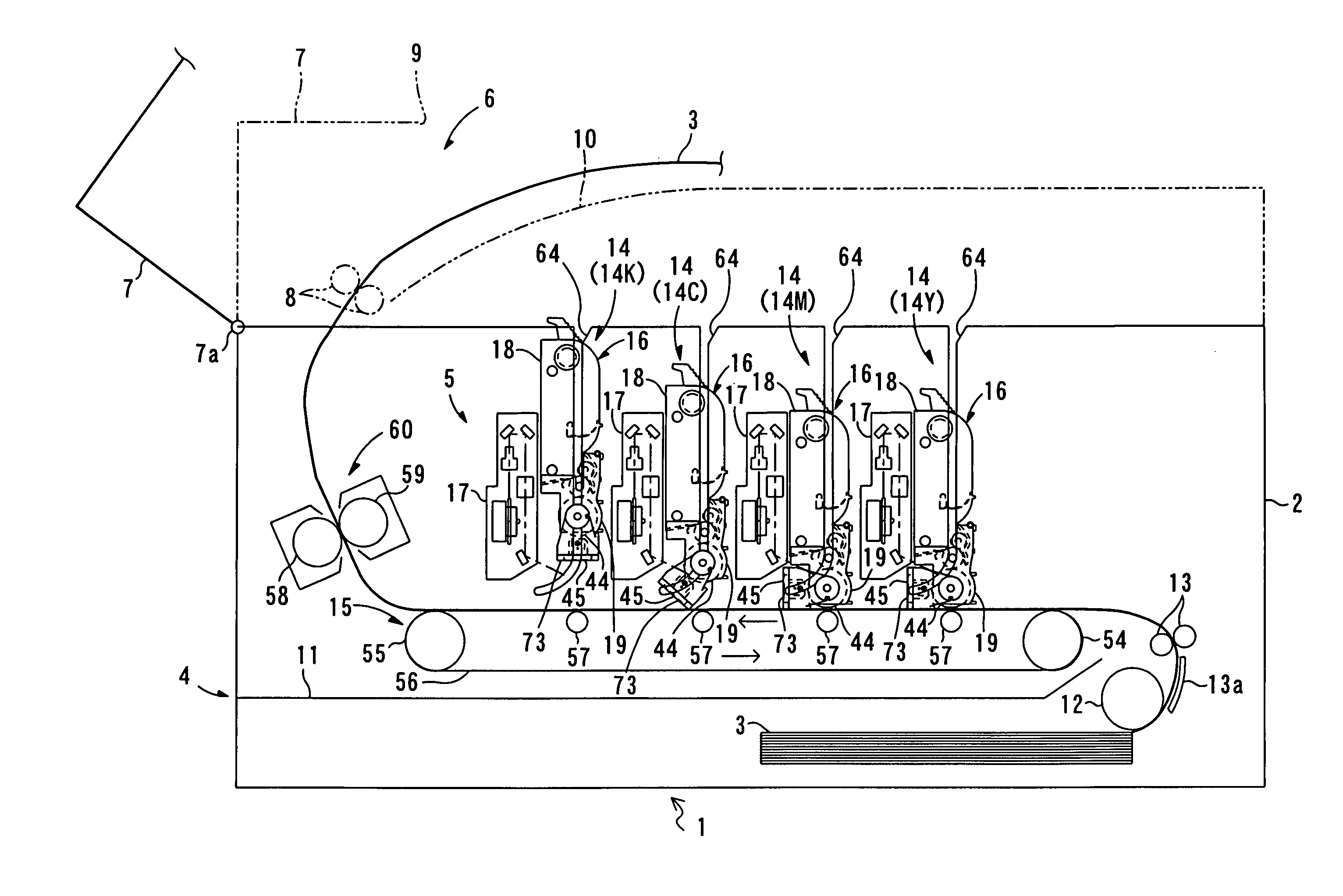

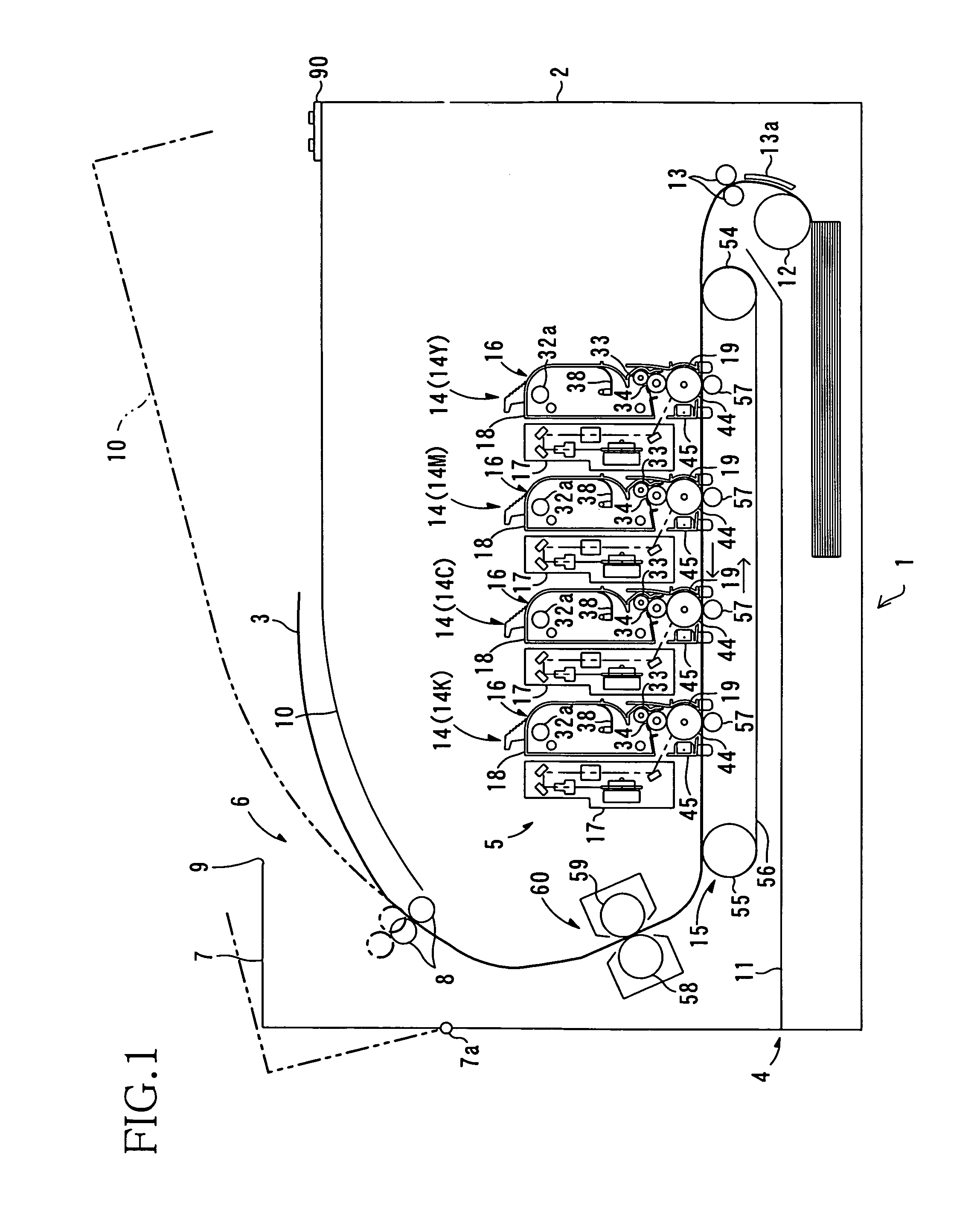

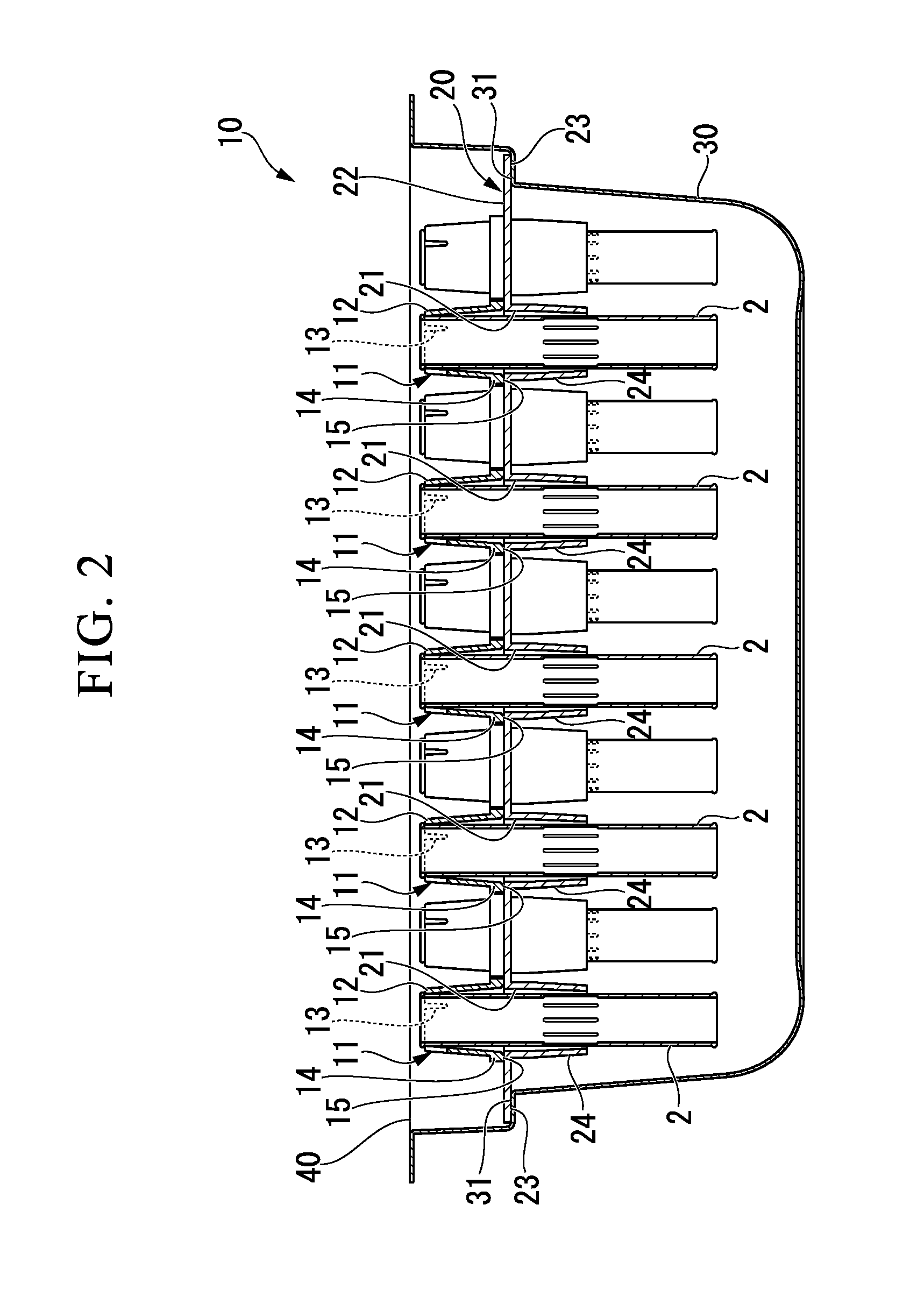

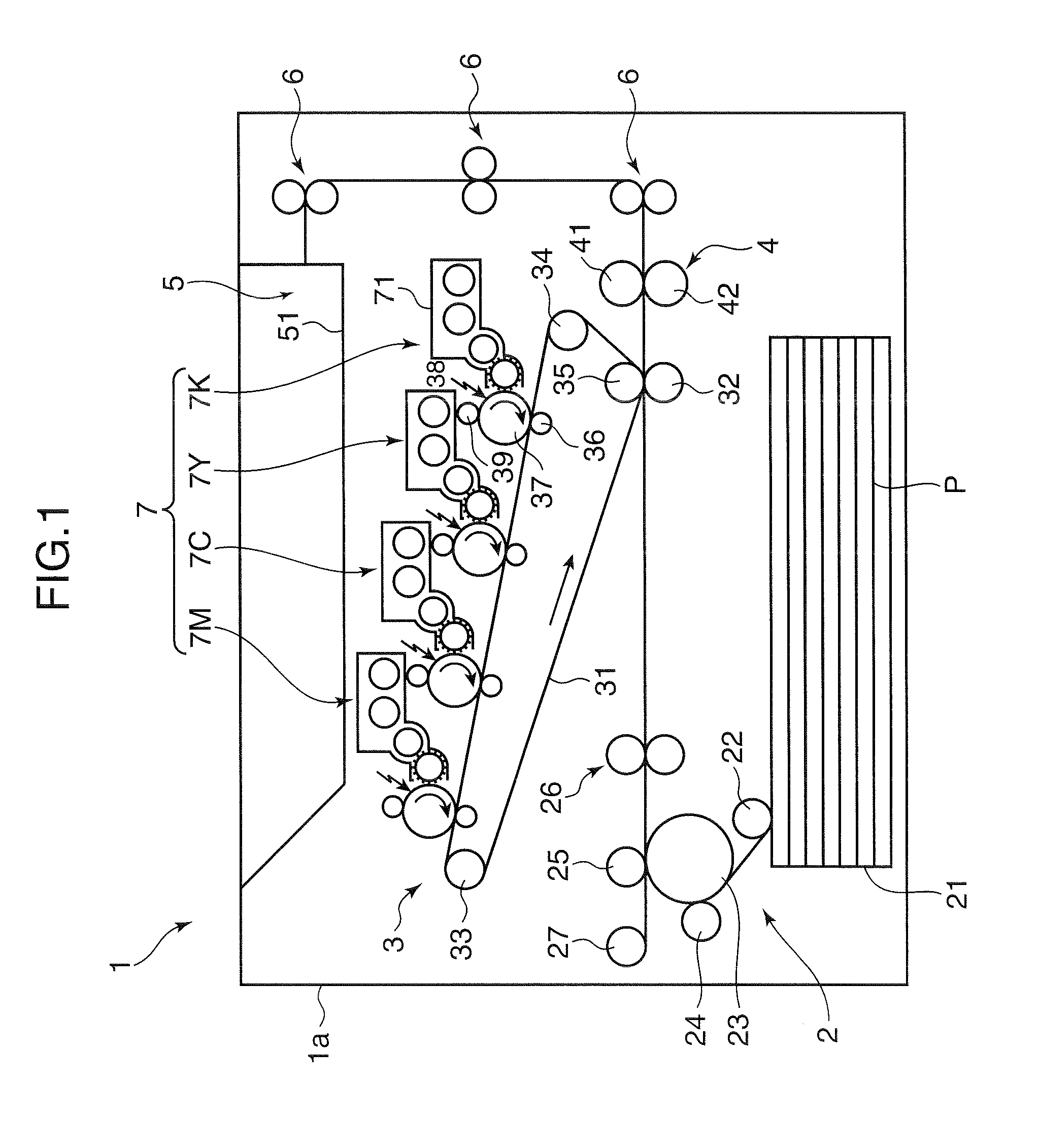

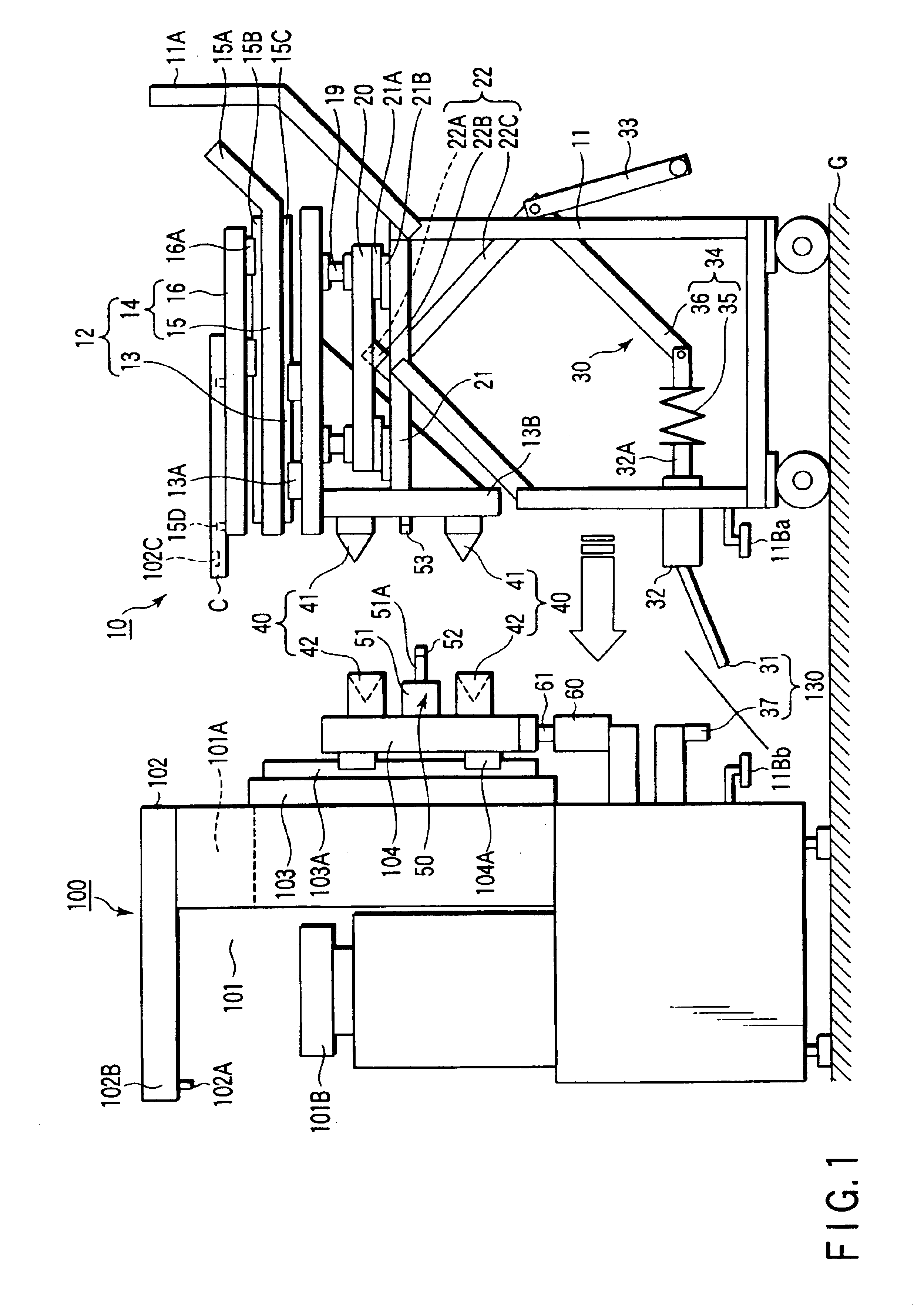

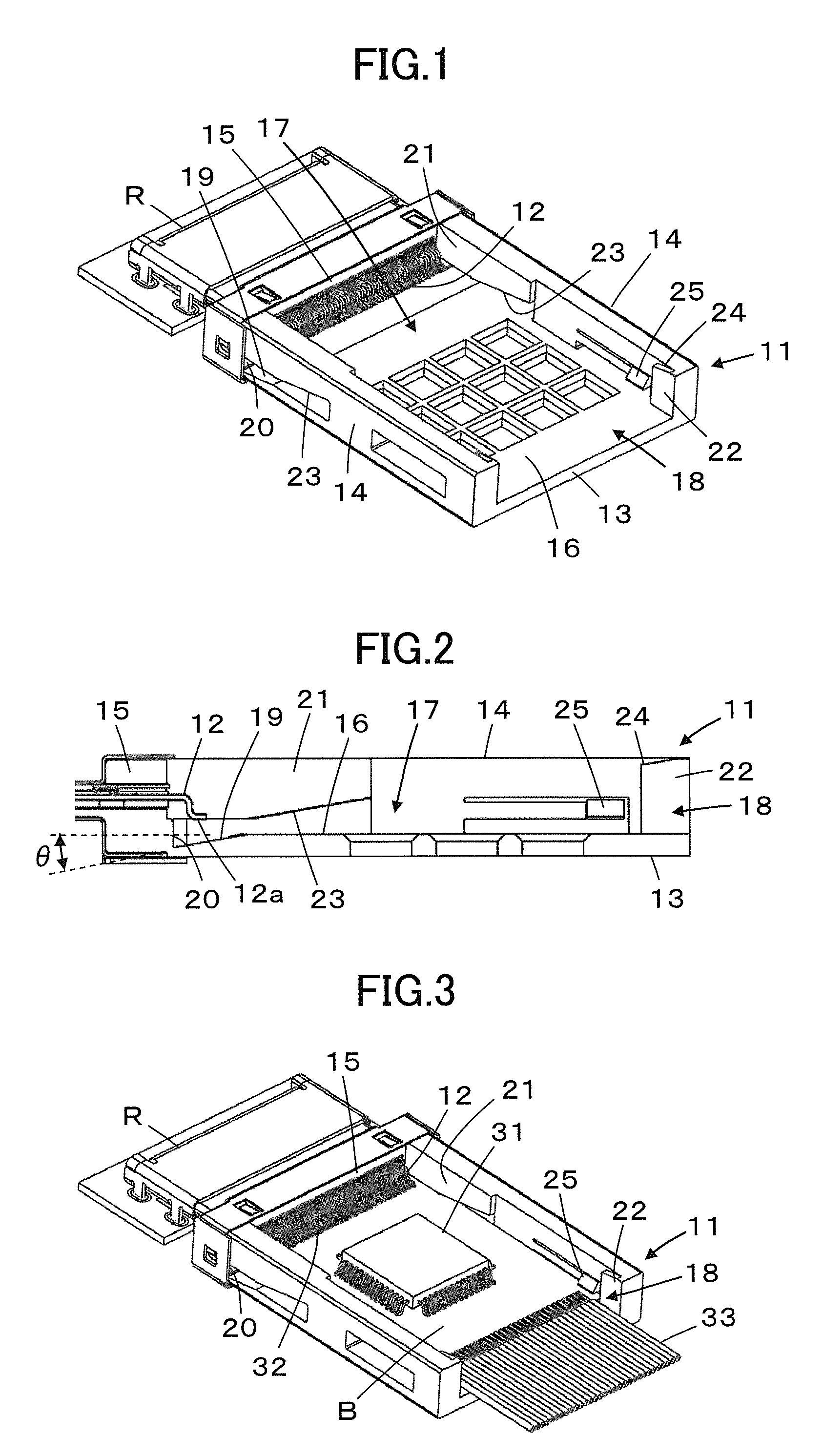

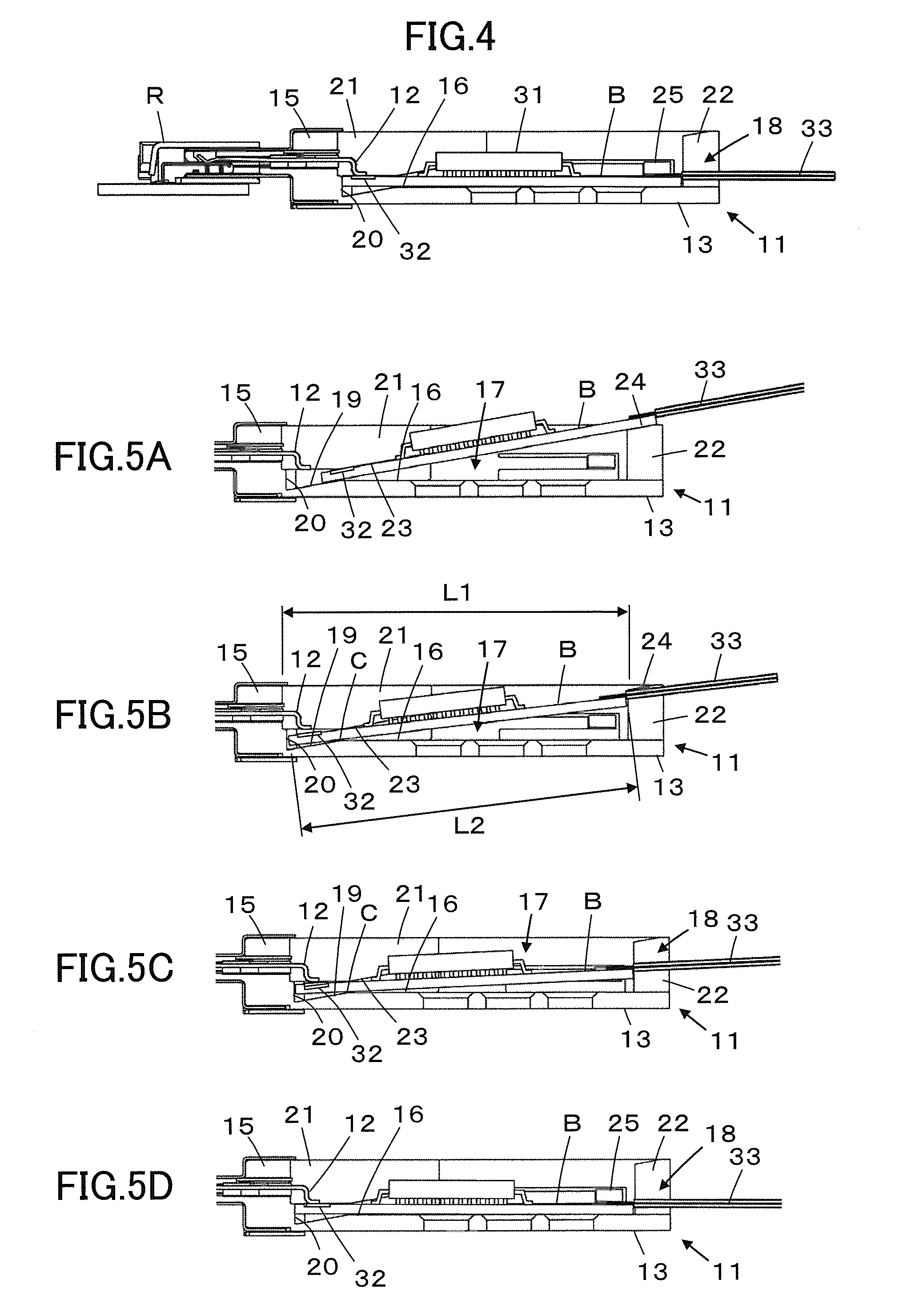

Image forming apparatus with processing unit that can be removed from the image forming apparatus without removing exposing devices

ActiveUS7242888B2Avoid uneven attachmentSmoothly to detachedElectrographic process apparatusCorona dischargeEngineeringTop cap

A tandem color laser printer, in which processing units can be smoothly attached to and detached from its casing, is provided while an adequate accuracy of exposure to photosensitive drums is maintained. In the color laser printer, scanning units are fixed to the printer casing. The processing units and the scanning units are alternately aligned and overlapped. A top cover is provided to a side opposite to a transfer position where the photosensitive drums contact a conveyor belt so as to freely open and close with respect to the printer casing. With this structure, the adequate accuracy of exposure by the scanning units can be maintained. The processing units can be attached to and detached from the printer casing via an upper opening of the printer casing defined by the opened top cover. Thus, the processing units can be smoothly attached to and detached from the printer casing without being interfered by the scanning units.

Owner:BROTHER KOGYO KK

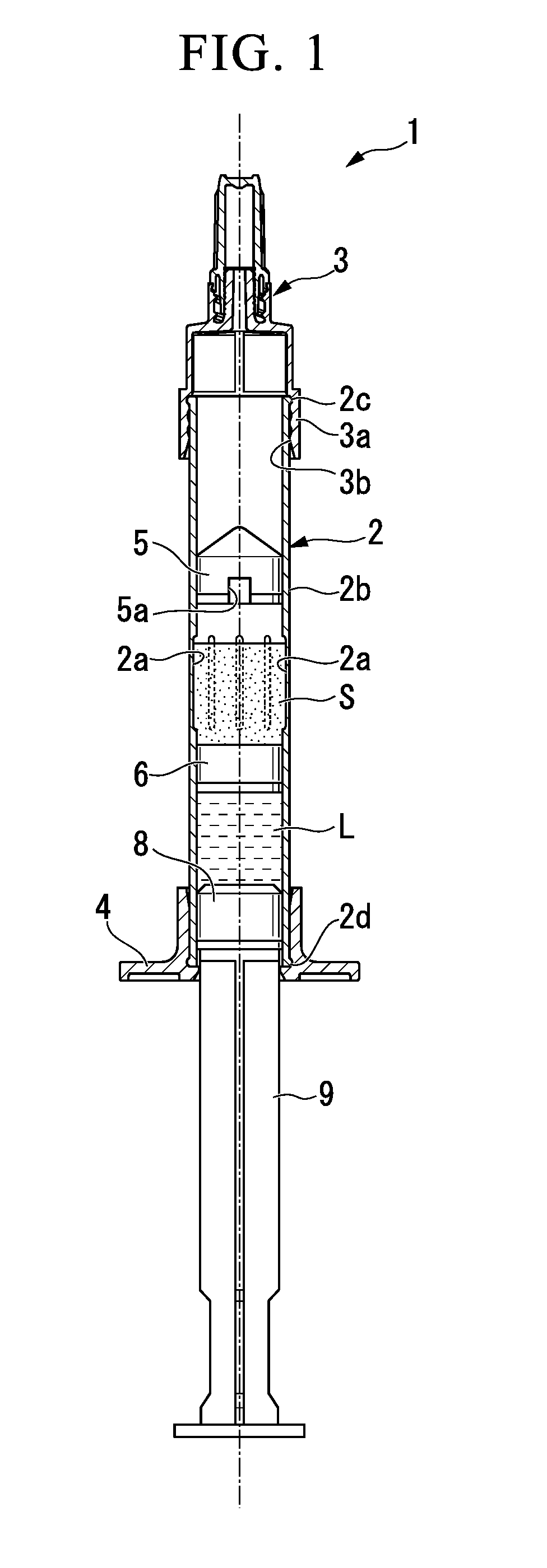

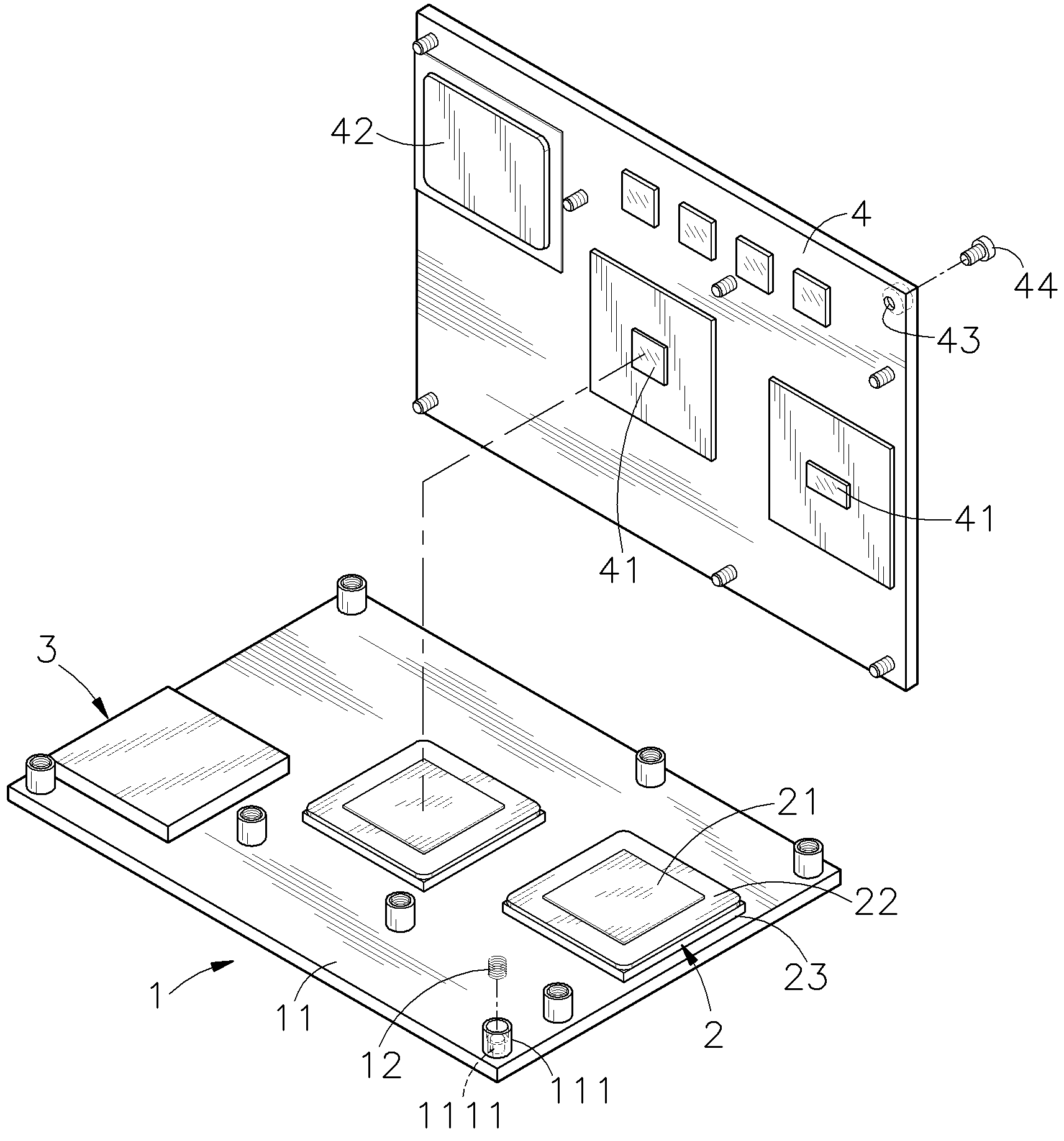

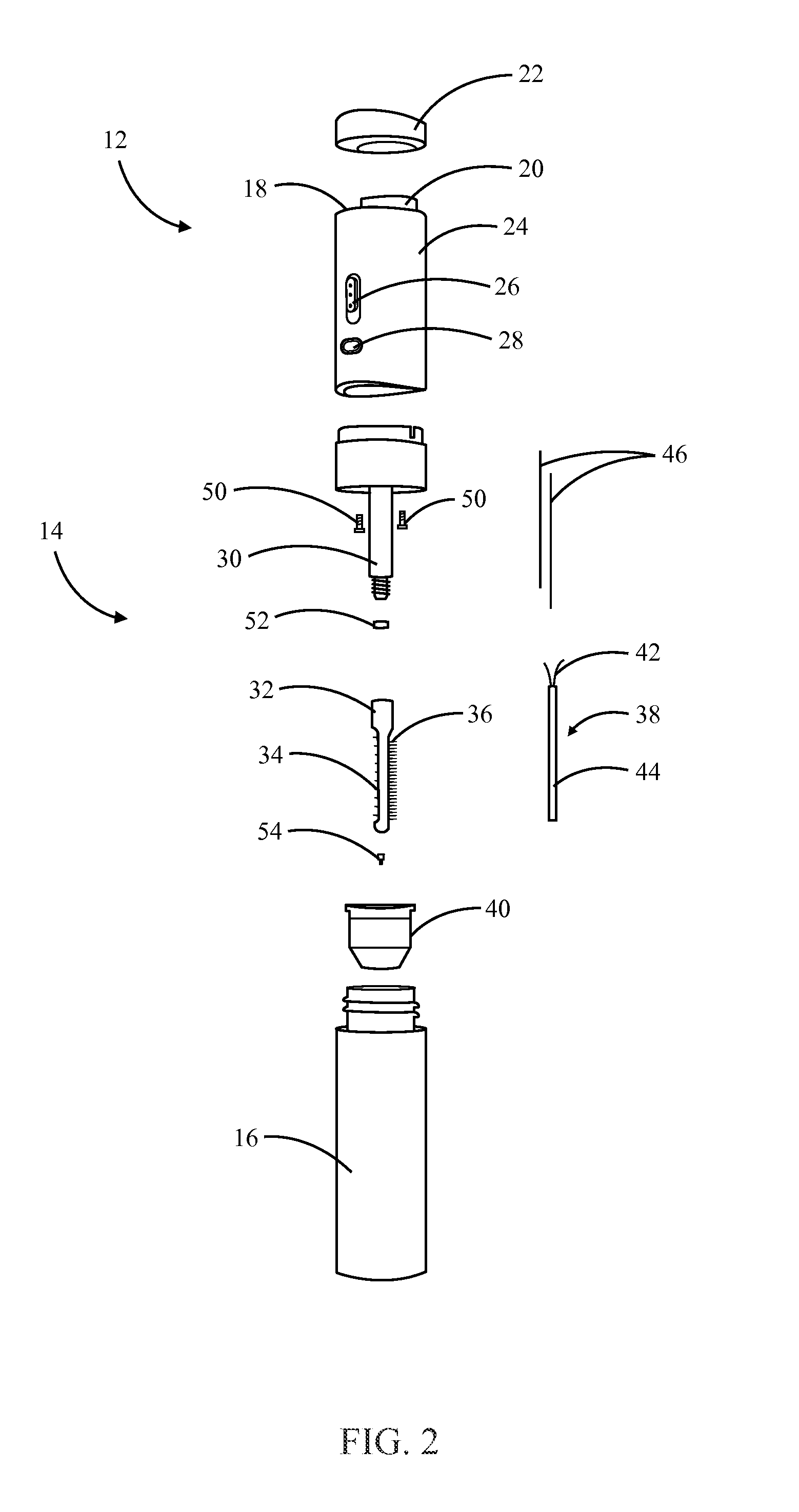

Cartridge set for manufacturing syringe and method for manufacturing dual-chamber type combined container-syringe

ActiveUS20130341849A1Easy to disassembleAdjustable positionDrying solid materials without heatInfusion syringesSyringe

A cartridge set including: a plurality of cartridges; a plurality of holders, each of which has an upper end externally fitted to the outer peripheral surface of each of the cartridges, and has a lower end face whose outer diameter is greater than the outer diameter of the outer peripheral surface of the cartridge; a supporting plate that has a plurality of through-holes, each of which has an inner diameter greater than the outer diameter of the outer peripheral surface of the cartridge and has each of the plurality of cartridges inserted therethrough; a storage box that stores the supporting plate therein; and a lid member that blocks an upper end opening of the storage box.

Owner:ARTE

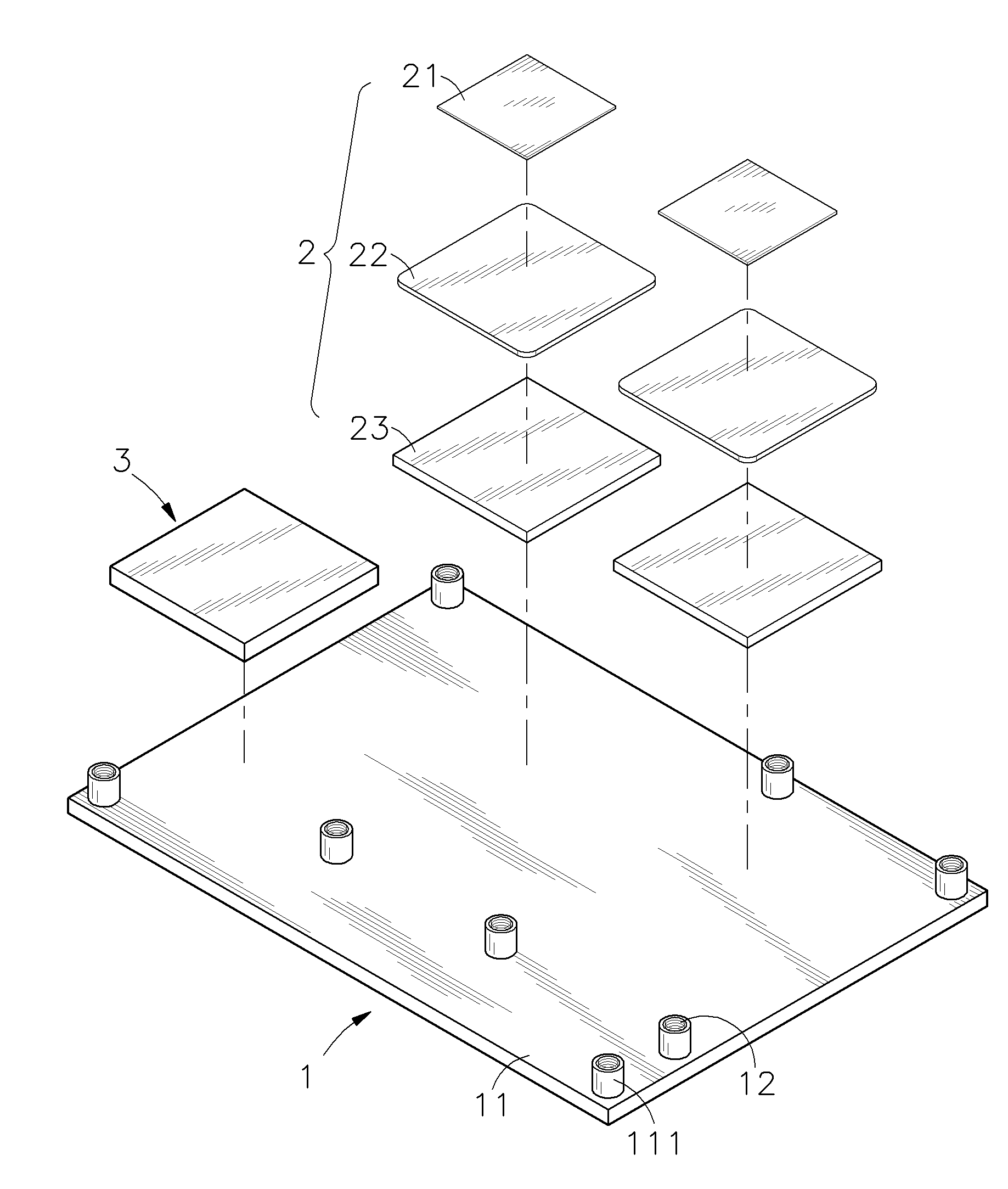

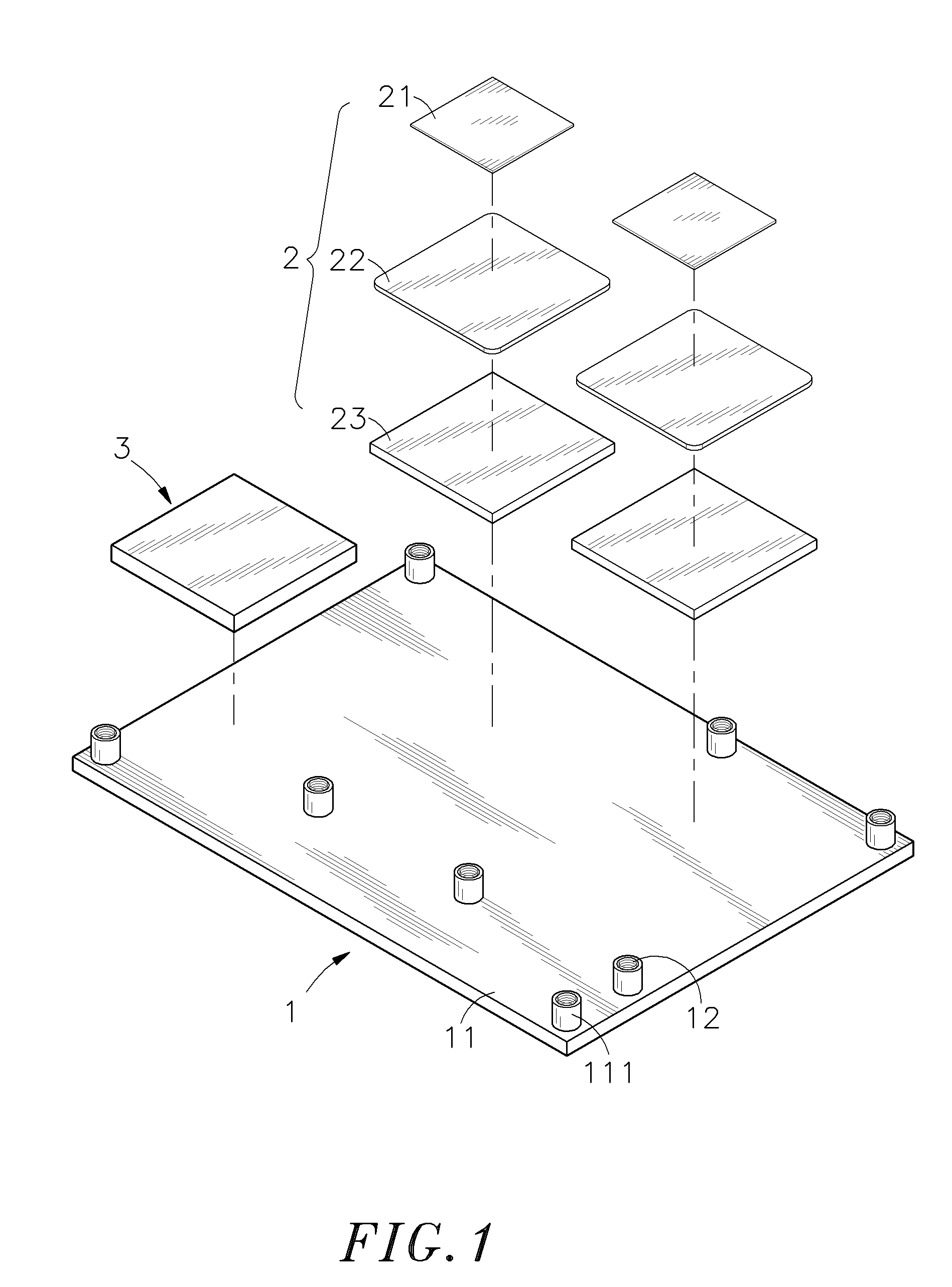

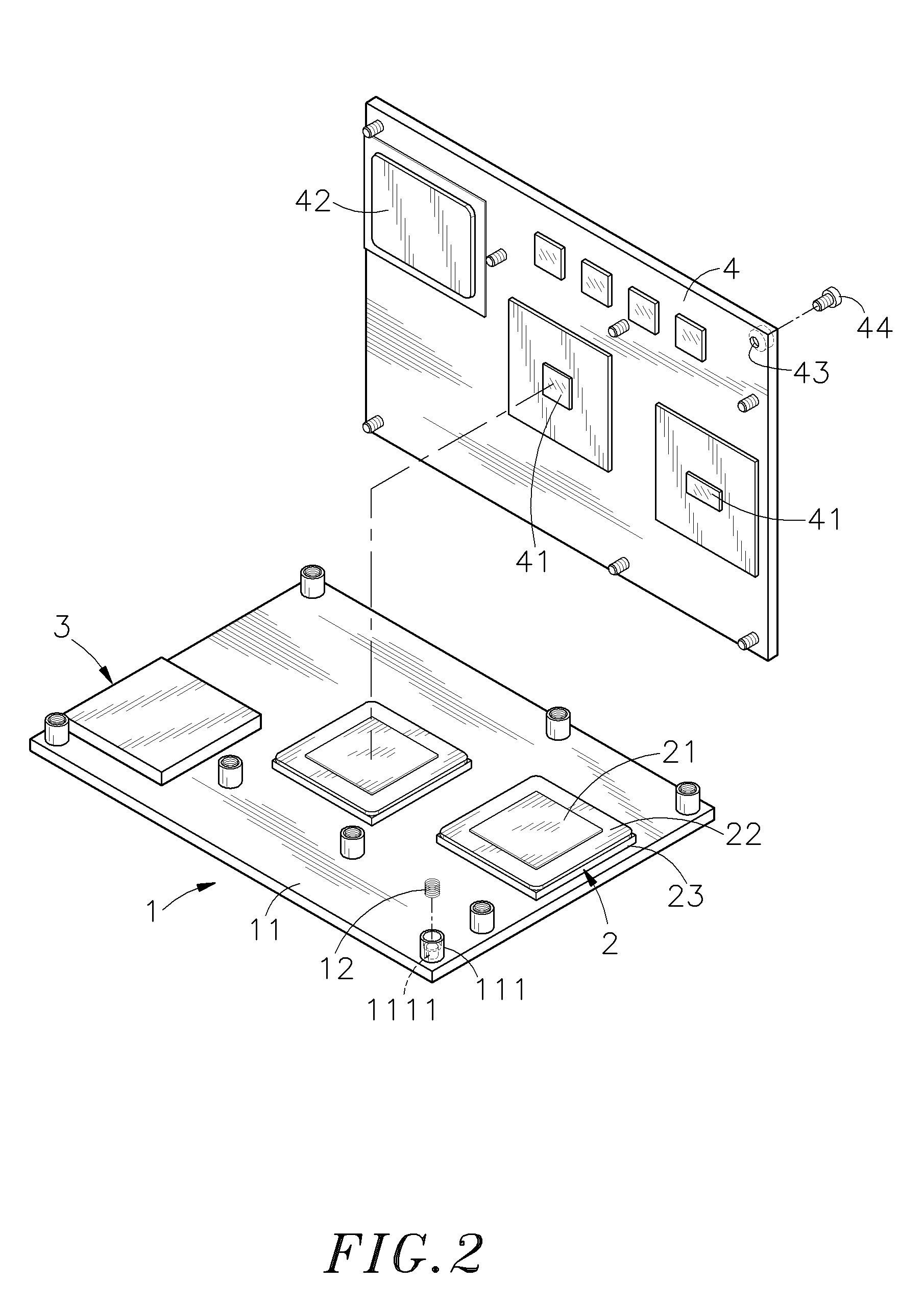

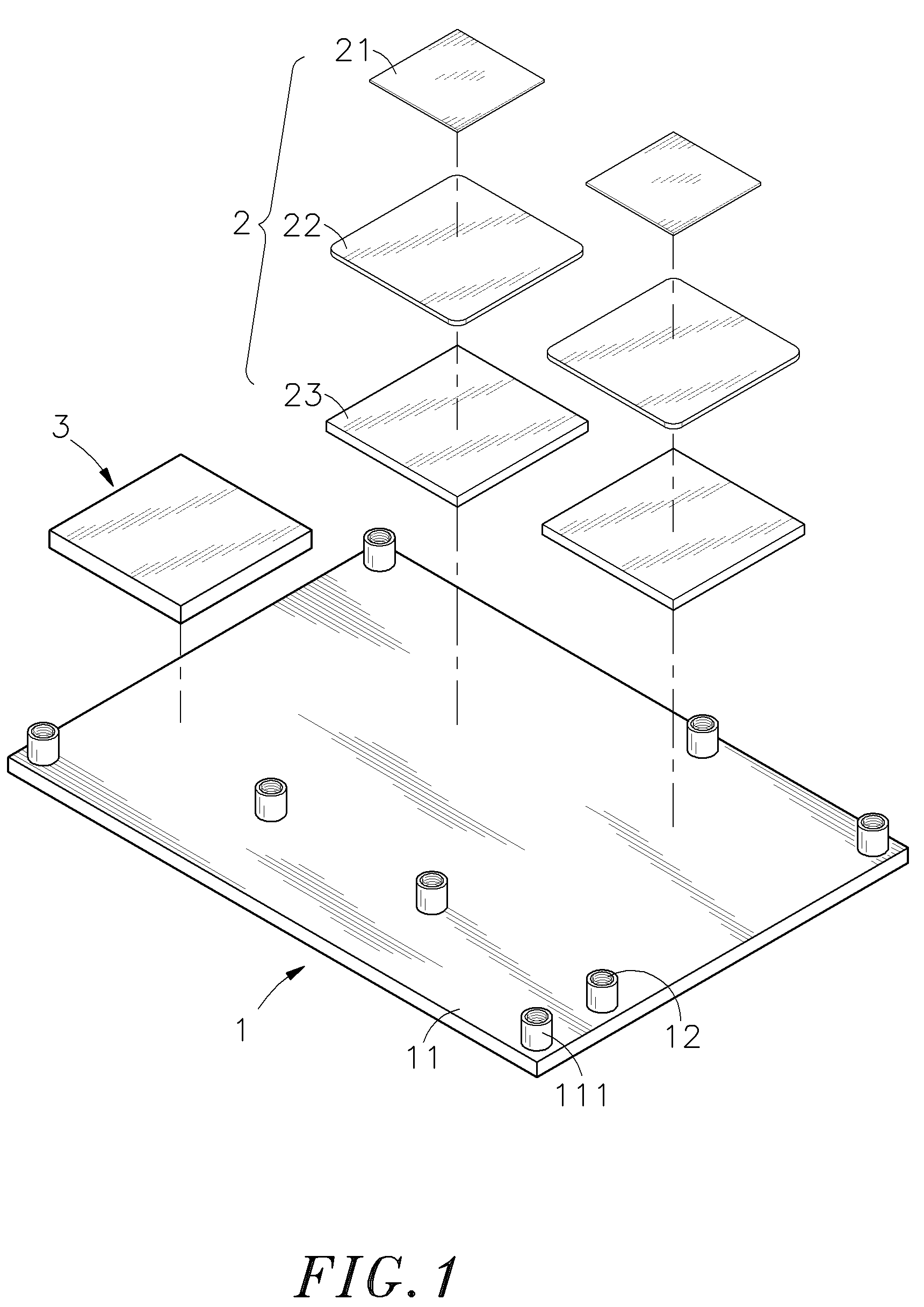

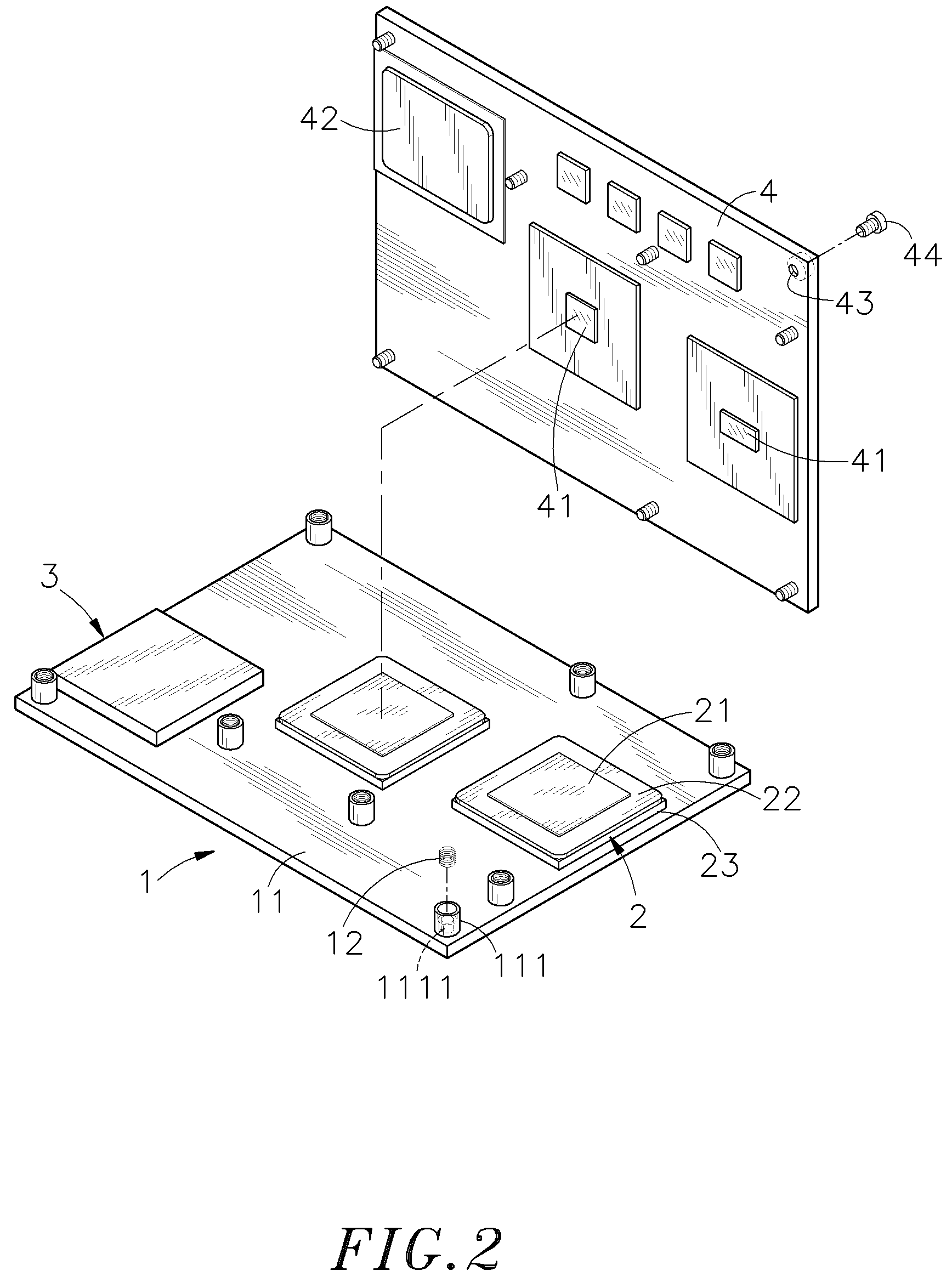

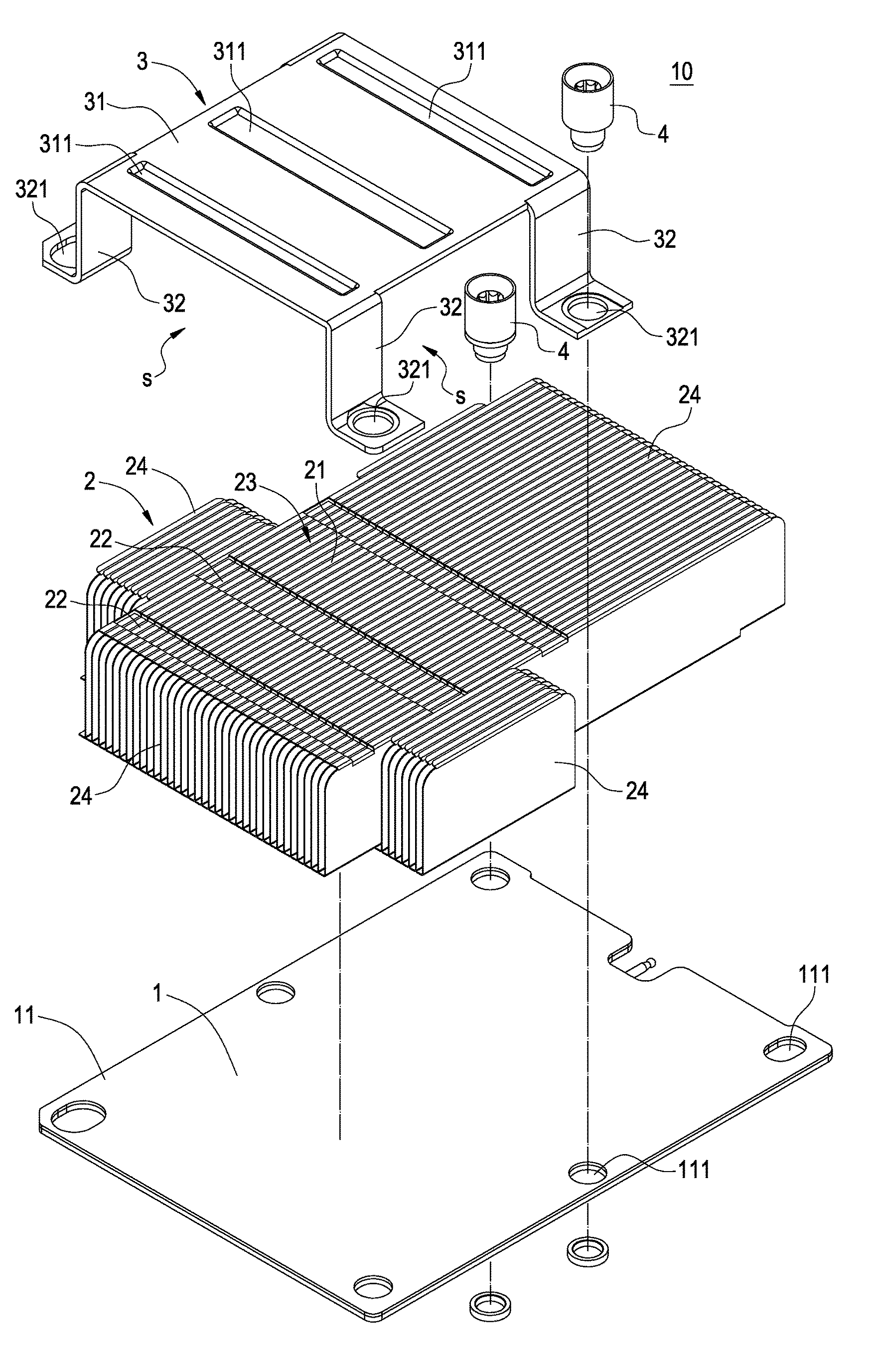

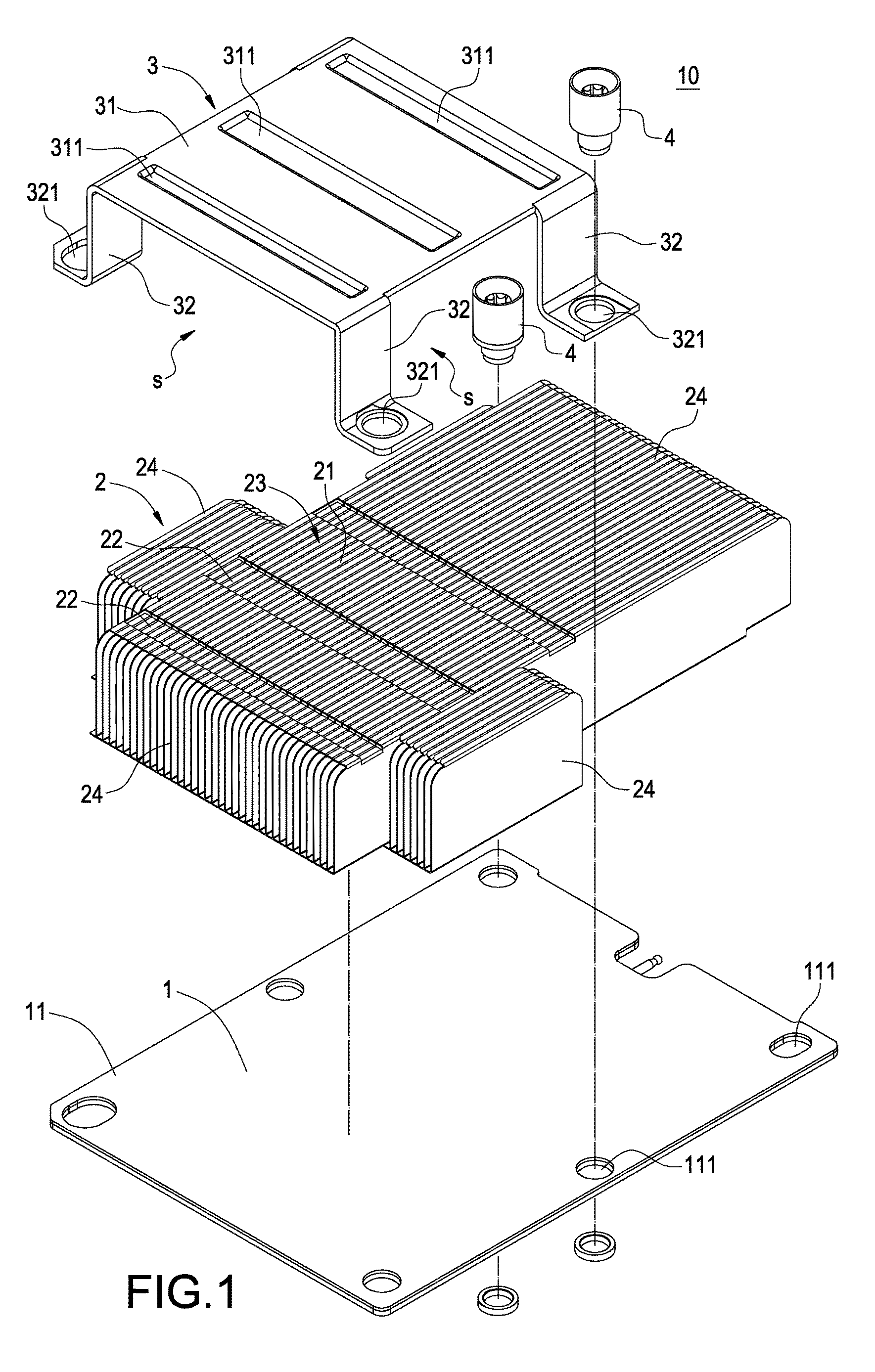

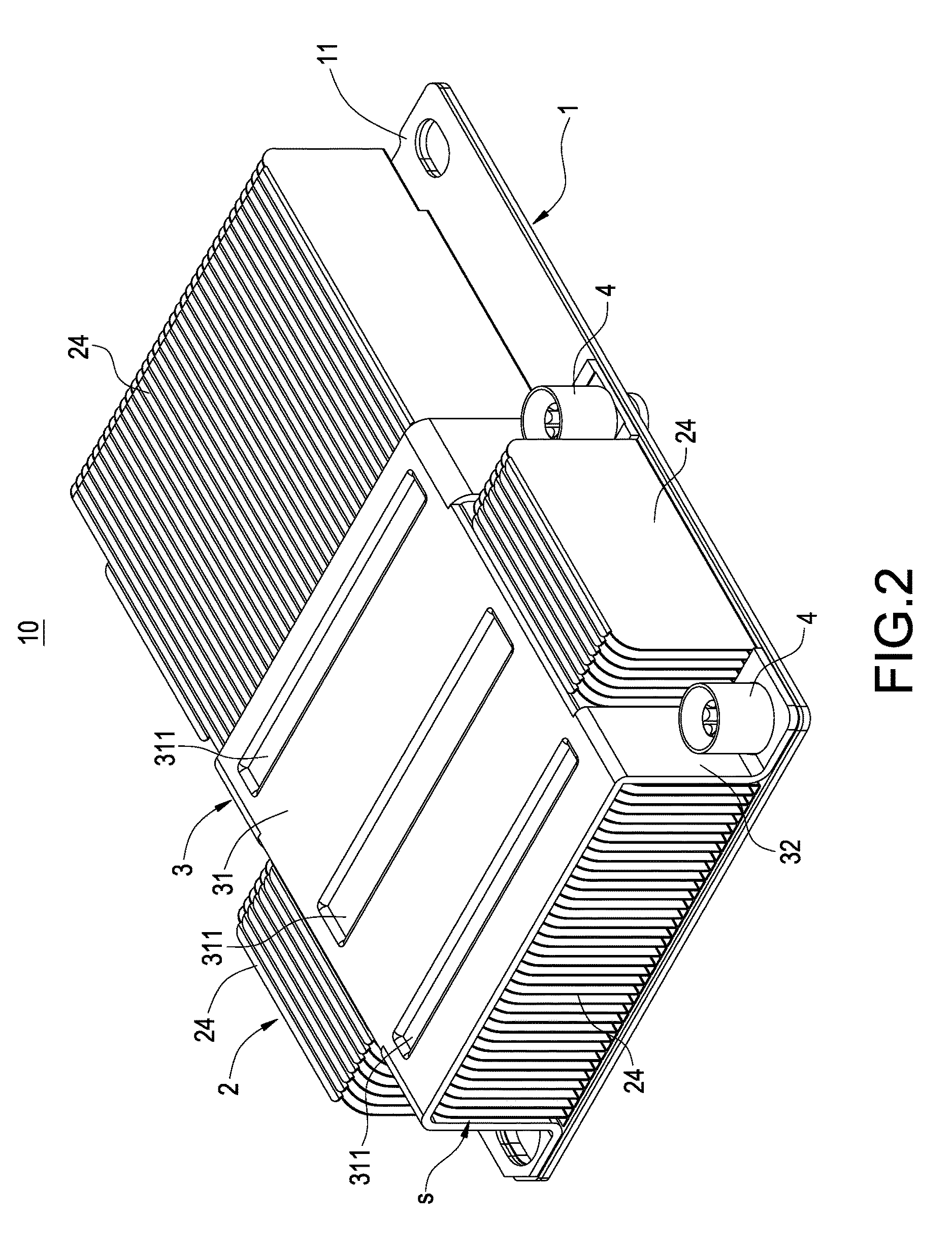

Stacked heat-transfer interface structure

ActiveUS20090021918A1Avoiding pressure injuriesSmoothly attached to surfaceSemiconductor/solid-state device detailsSolid-state devicesHeat energyThermal transmittance

A stacked heat-transfer interface structure for dissipating heat from a circuit board is disclosed to include a heat plate affixed to the circuit board, and relatively thinner first heat transfer devices and relatively thicker second heat transfer devices respectively attached to first and second heat generating electronic devices of the circuit board that have different heights for transferring heat from the first and second heat generating electronic devices of the circuit board to the heat plate for dissipation. Each first heat transfer device comprises a first heat-transfer sheet member having a high heat conductivity and a low thermal resistance and bonded to one first heat generating electronic device, an elastically deformable second heat-transfer sheet member having a low heat conductivity and a high thermal resistance and bonded to the heat plate to compensate for height tolerance of the respective first heat generating electronic device, and a heat-transfer block for spreading heat energy from the first heat-transfer sheet member onto the heat plate through the second heat-transfer sheet member.

Owner:ADLINK TECH INC

Electric toothbrush handle laser etching process

ActiveCN105750734AHighlight the sense of technologyStrong sense of technologyLiquid surface applicatorsVacuum evaporation coatingLaser etchingOptoelectronics

The invention relates to the technical field of electric toothbrushes, in particular to an electric toothbrush handle laser etching process.The process includes the following steps of firstly, injection molding, wherein a resin layer is arranged on a handle light source area through injection molding and is a transparent body or a semitransparent white body; secondly, electroplating, wherein a metal layer or a metal oxide layer is arranged on the resin layer through vacuum electroplating; thirdly, laser etching, wherein the metal layer or metal oxide layer is hollowed out to form a required shape through laser etching; fourthly, spraying, wherein gloss oil is sprayed on the metal layer or metal oxide layer and then cured.The prepared product abandons the simple and crude mode of an existing indicator lamp on the aspect of appearance, and the metal texture, smoothness, light permeability and science and technology feeling of an electric toothbrush handle indication panel are enhanced; the process is bold and innovative and is combined with the vacuum electroplating and laser etching technology for machining the product of a structure with the resin layer, the metal layer or metal oxide layer and the gloss oil layer, steps are simple, machining patterns are variable due to the laser etching technology, and different production requirements can be met.

Owner:GUANGDONG ROMAN TECH CO LTD

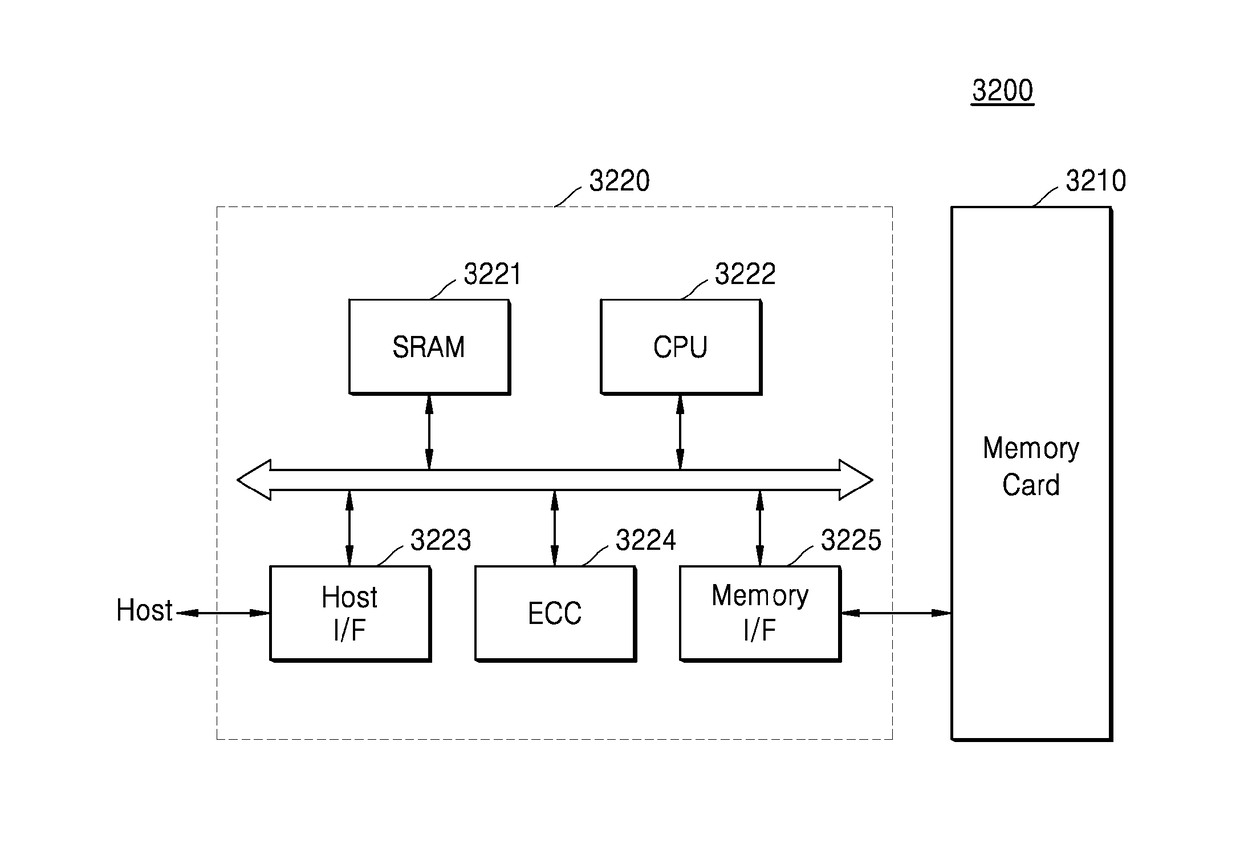

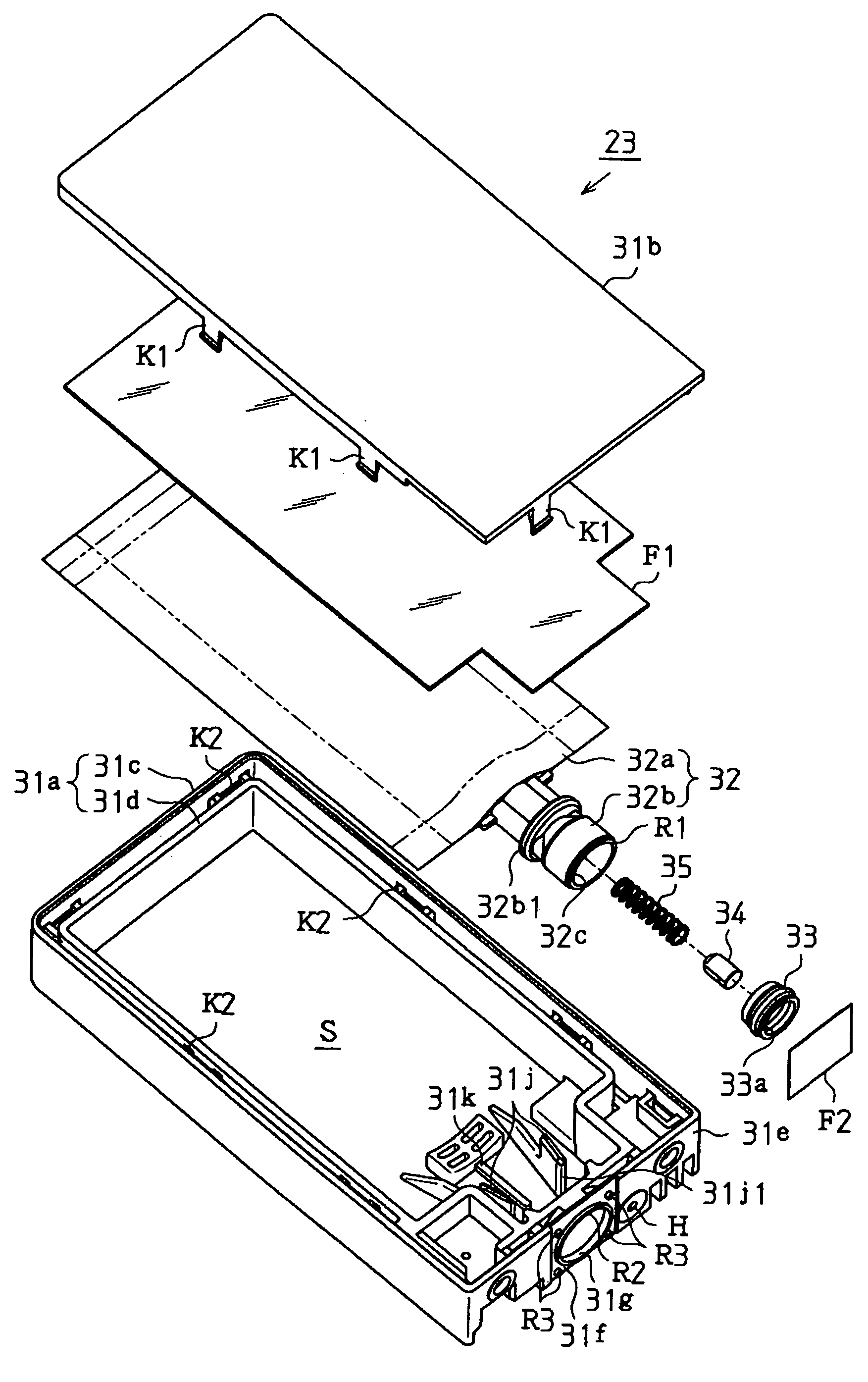

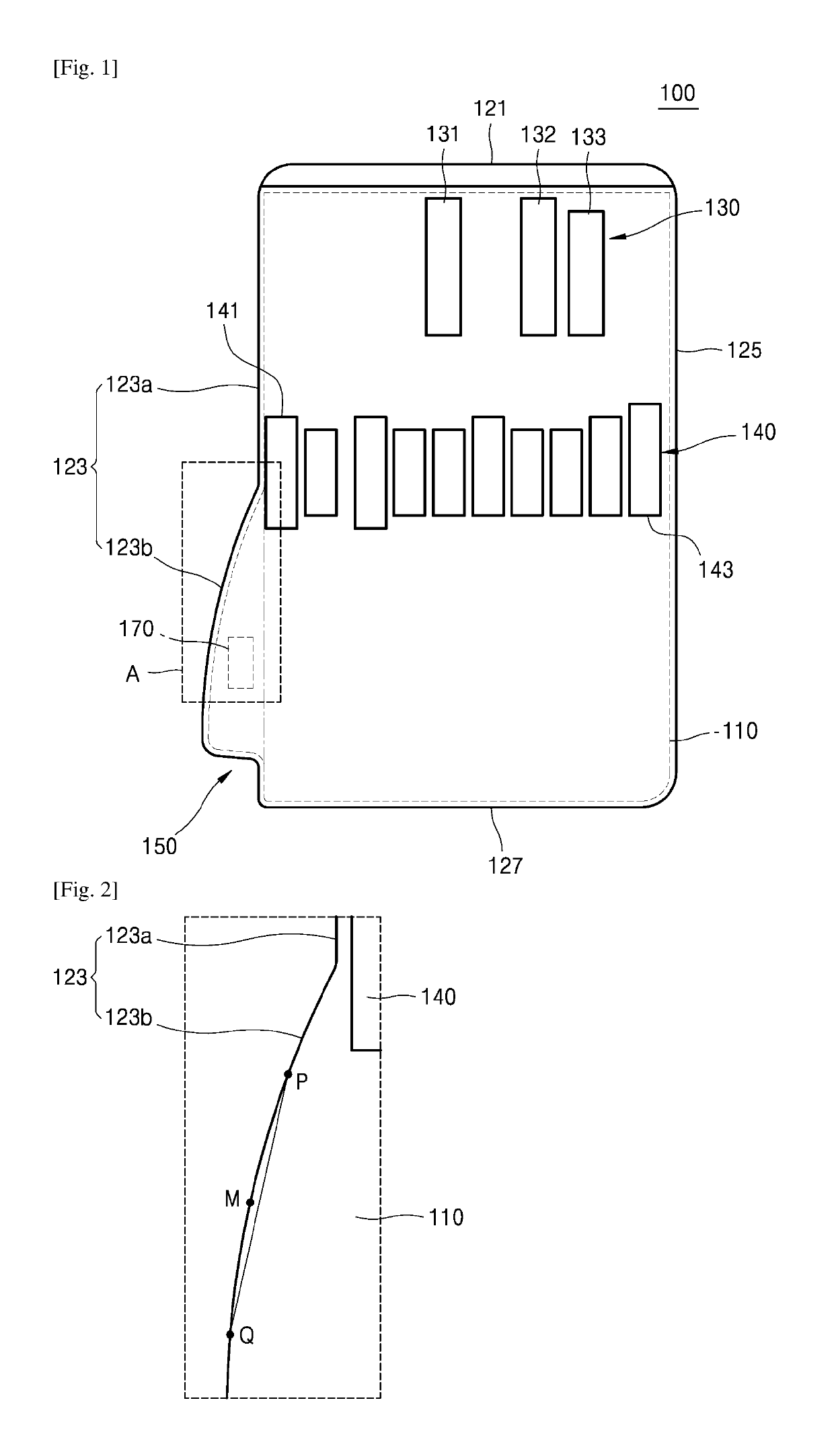

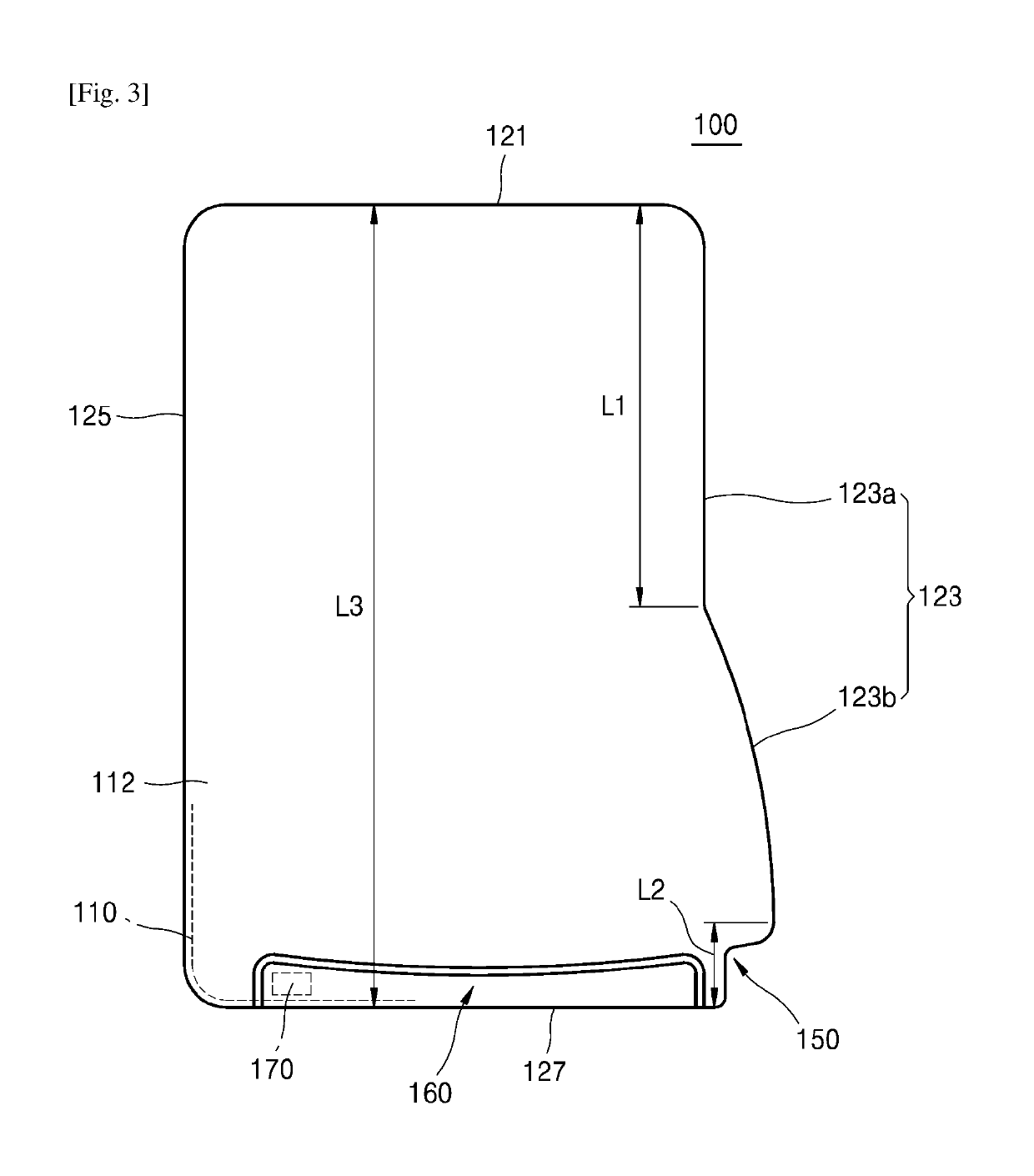

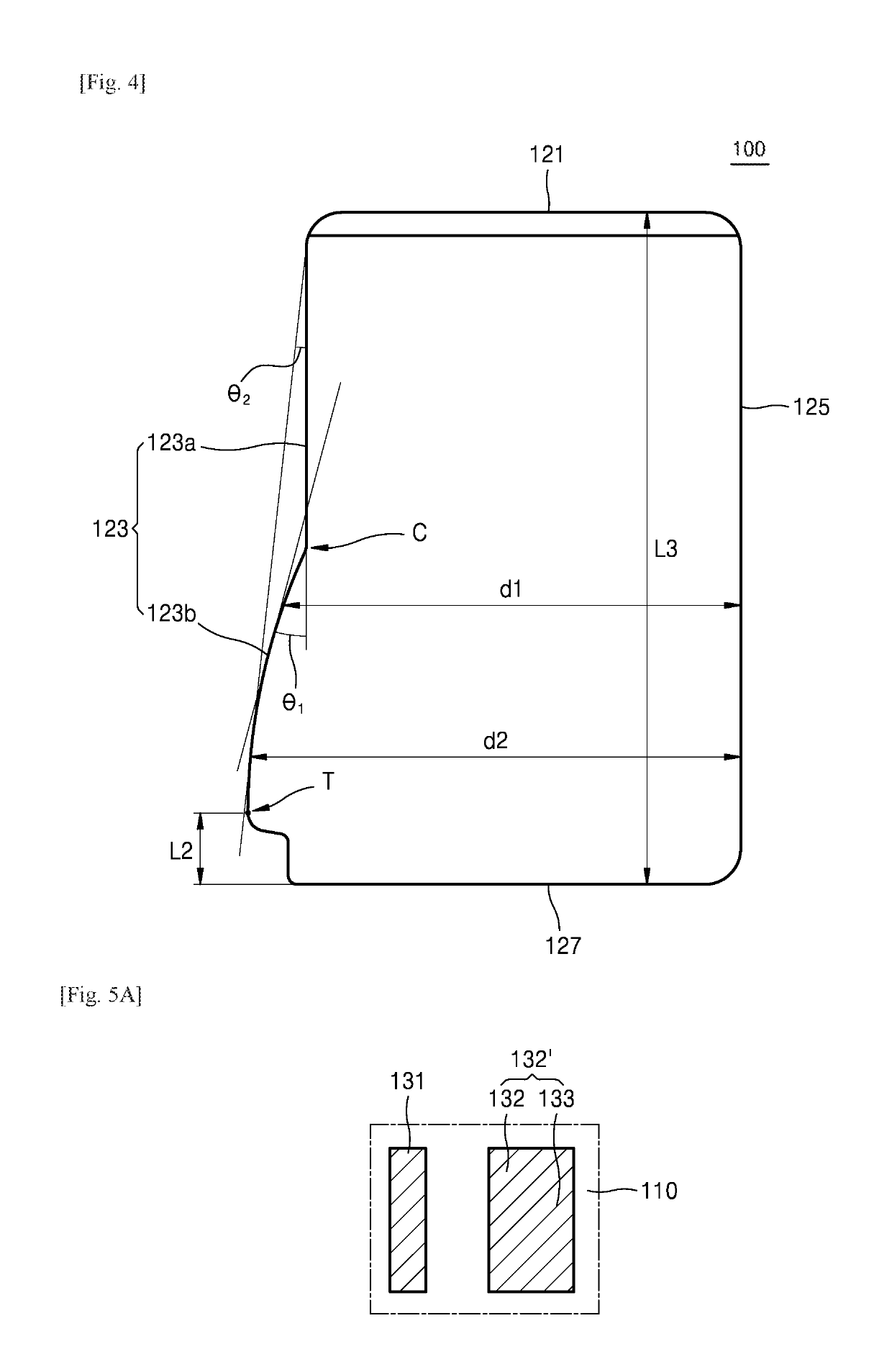

Memory card

ActiveUS20170154003A1Easy resetReduce harmConveying record carriersStatic storageControl powerMemory cards

Provided is a memory card, which includes two pairs of opposite edges, first row terminals arranged adjacent to an insertion-side edge of the memory card, and second row terminals arranged apart from the insertion-side edge of the memory card. The memory card can be easily reset in terms of software without controlling power supply in terms of hardware. Also, the memory card can be smoothly attached and detached during insertion of the memory card into a socket and reduce damage to a device.

Owner:SAMSUNG ELECTRONICS CO LTD

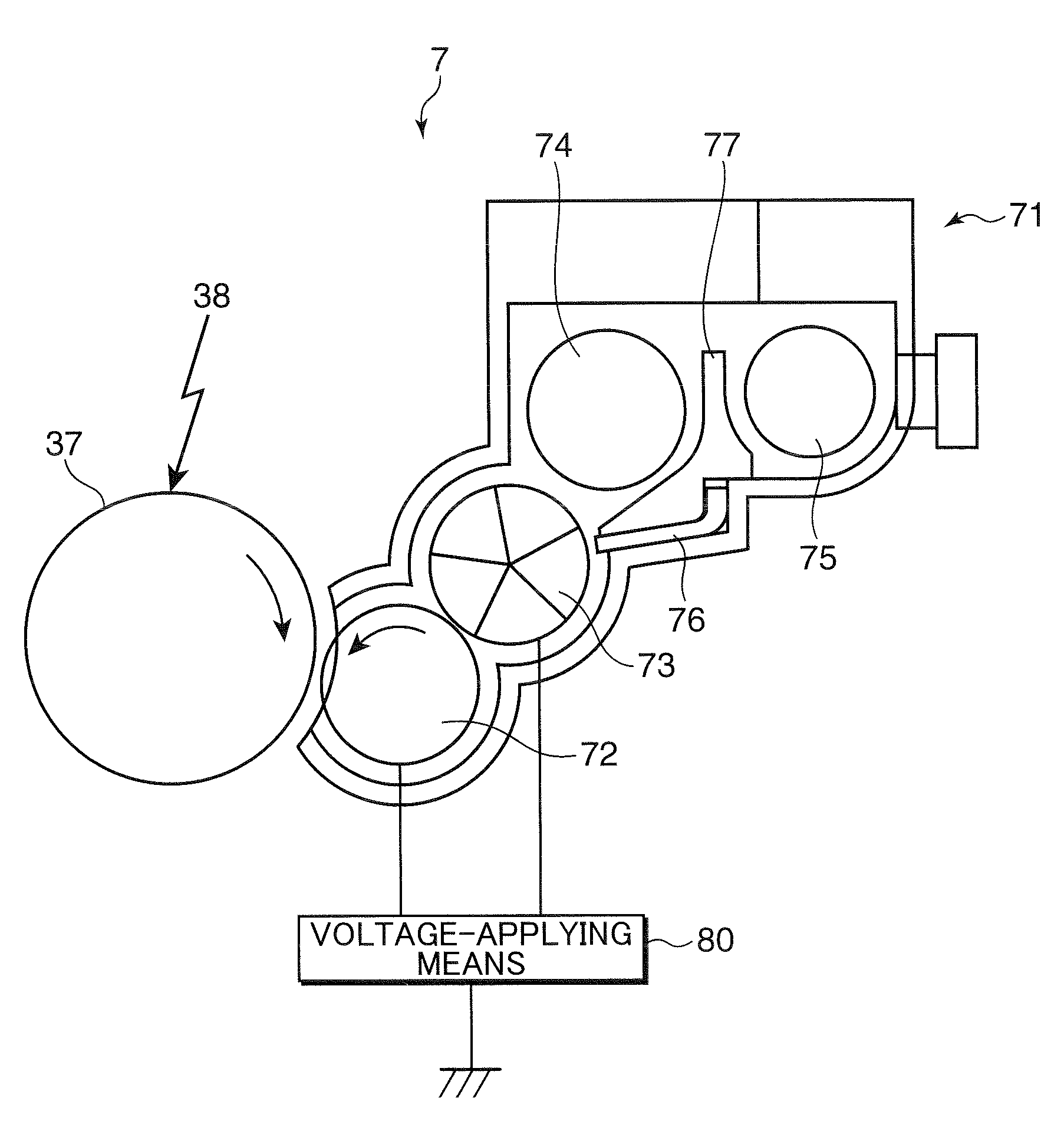

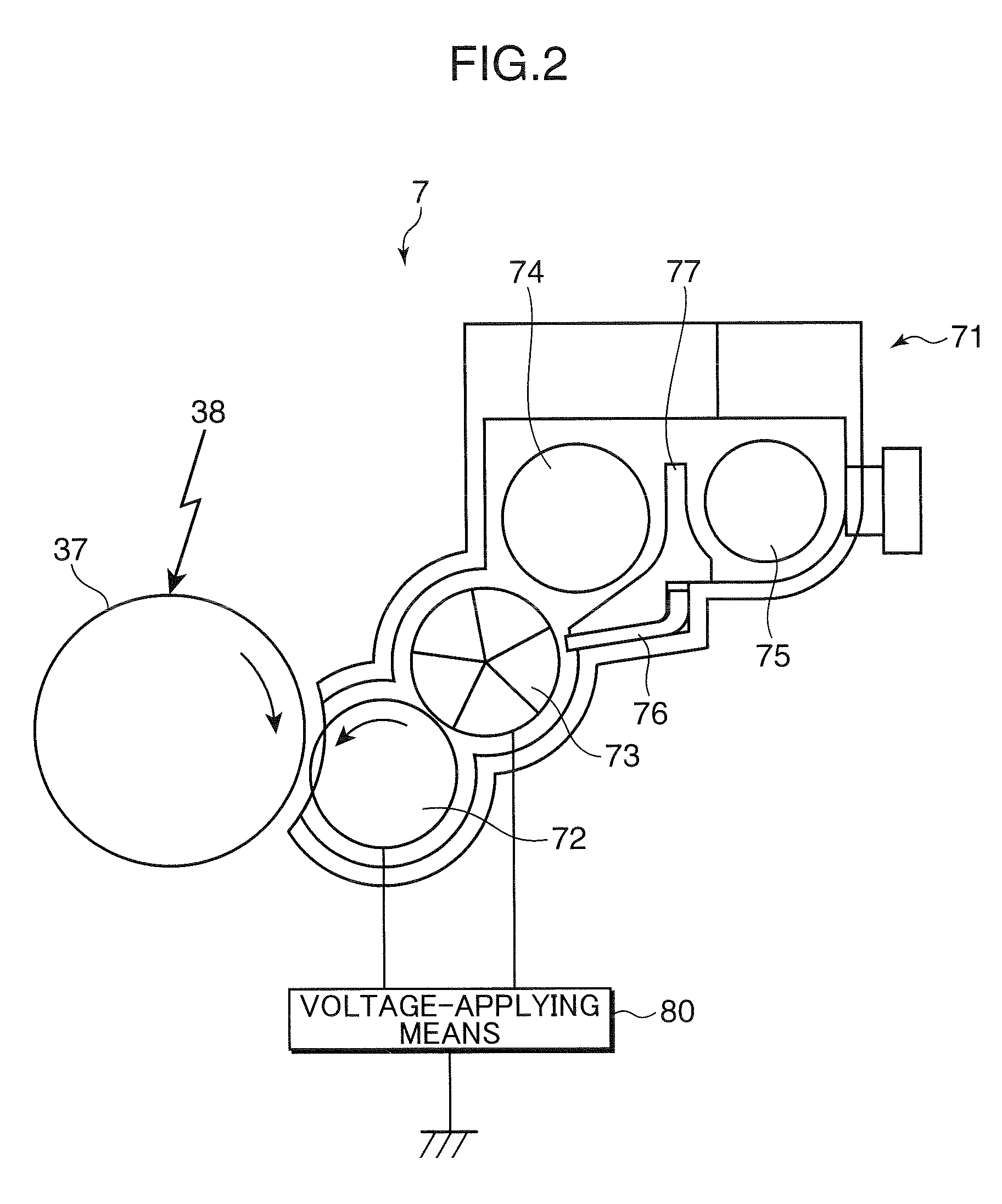

Developing unit and image forming apparatus

ActiveUS20080226320A1Suppress image unevennessLow densityElectrographic process apparatusLatent imageImage formation

A developing unit has a voltage-applicator (80) to apply a developing bias voltage to a developing roller (72). The voltage-applicator (80) applies the developing bias voltage for a first duration to apply an AC voltage having a rectangular waveform, and a second duration to stop applying the AC voltage. The AC voltage has a duty ratio of 50% or more in a direction for causing toner to develop an electrostatic latent image. The number of cycles of the AC voltage in the first duration is two or more, and the AC voltage has a voltage in a direction for pulling the toner back to the developing roller, just before transition to the second duration. The developing unit suppresses occurrence of image unevenness due to a fluctuation in developing gap. Thus, an image forming apparatus equipped with the developing unit forms a high-quality image while suppressing image unevenness.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Stacked heat-transfer interface structure

ActiveUS7684198B2Efficient transferDissipate quicklySemiconductor/solid-state device detailsSolid-state devicesHeat energyThermal transmittance

A stacked heat-transfer interface structure for dissipating heat from a circuit board is disclosed to include a heat plate affixed to the circuit board, and relatively thinner first heat transfer devices and relatively thicker second heat transfer devices respectively attached to first and second heat generating electronic devices of the circuit board that have different heights for transferring heat from the first and second heat generating electronic devices of the circuit board to the heat plate for dissipation. Each first heat transfer device comprises a first heat-transfer sheet member having a high heat conductivity and a low thermal resistance and bonded to one first heat generating electronic device, an elastically deformable second heat-transfer sheet member having a low heat conductivity and a high thermal resistance and bonded to the heat plate to compensate for height tolerance of the respective first heat generating electronic device, and a heat-transfer block for spreading heat energy from the first heat-transfer sheet member onto the heat plate through the second heat-transfer sheet member.

Owner:ADLINK TECH INC

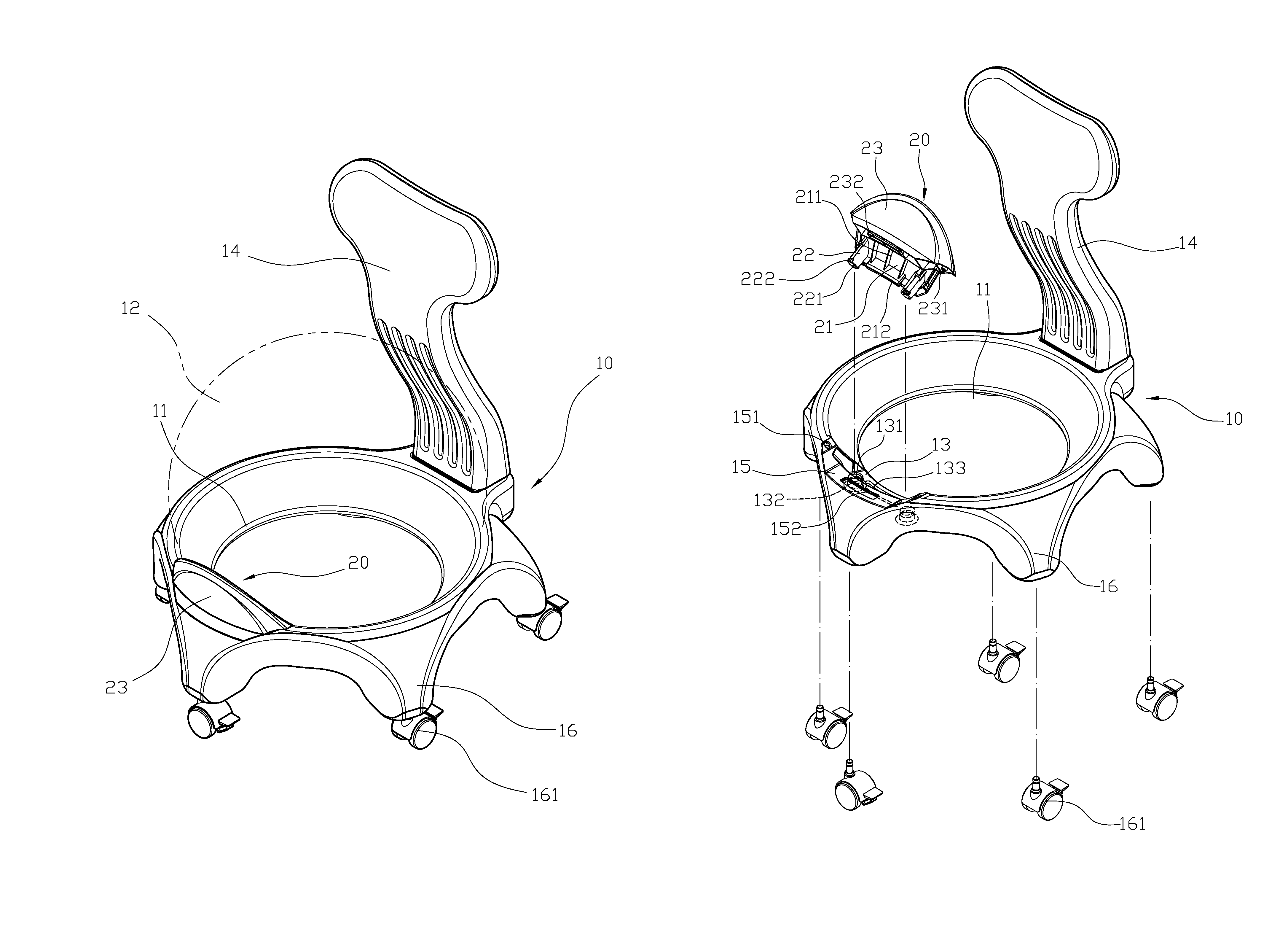

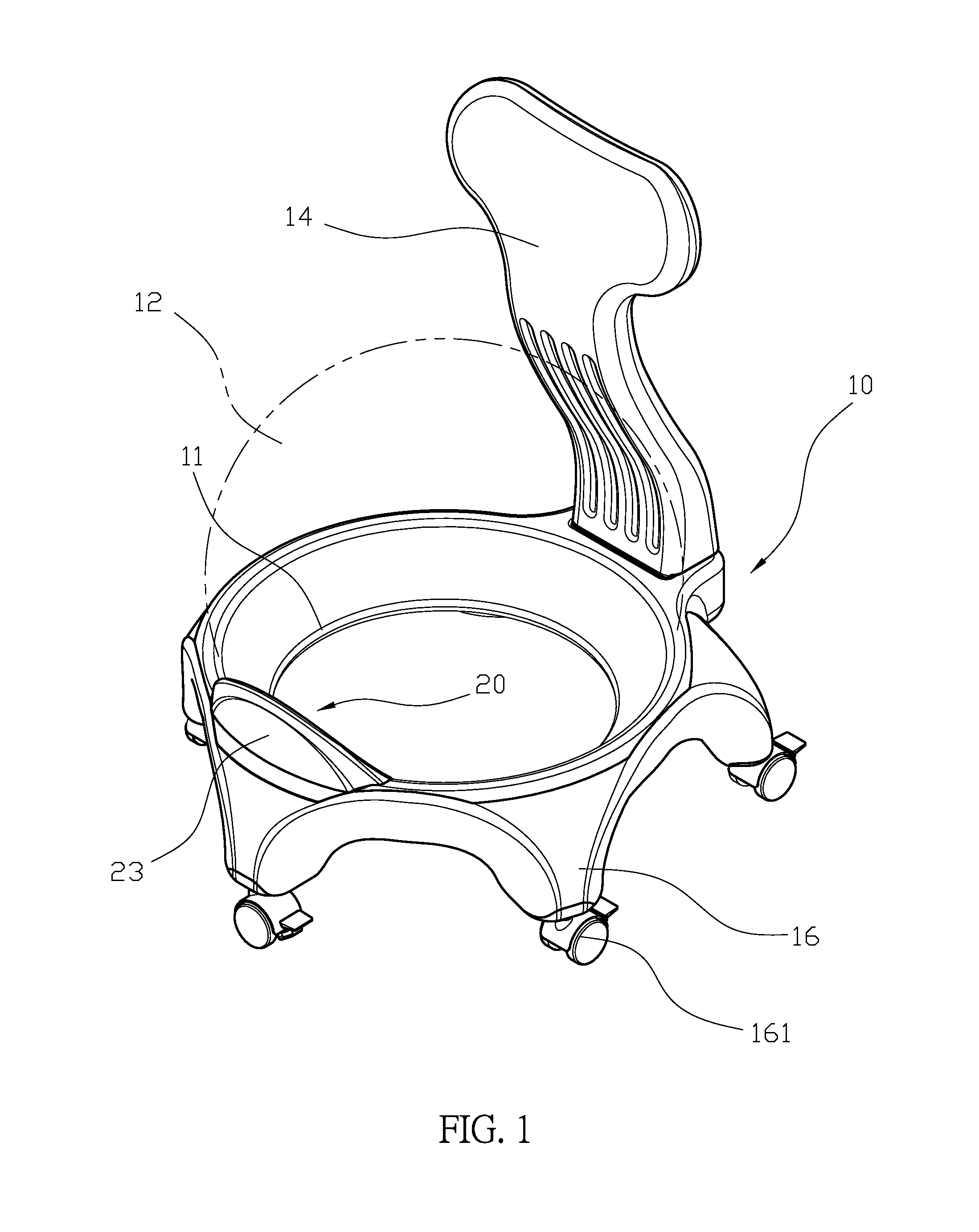

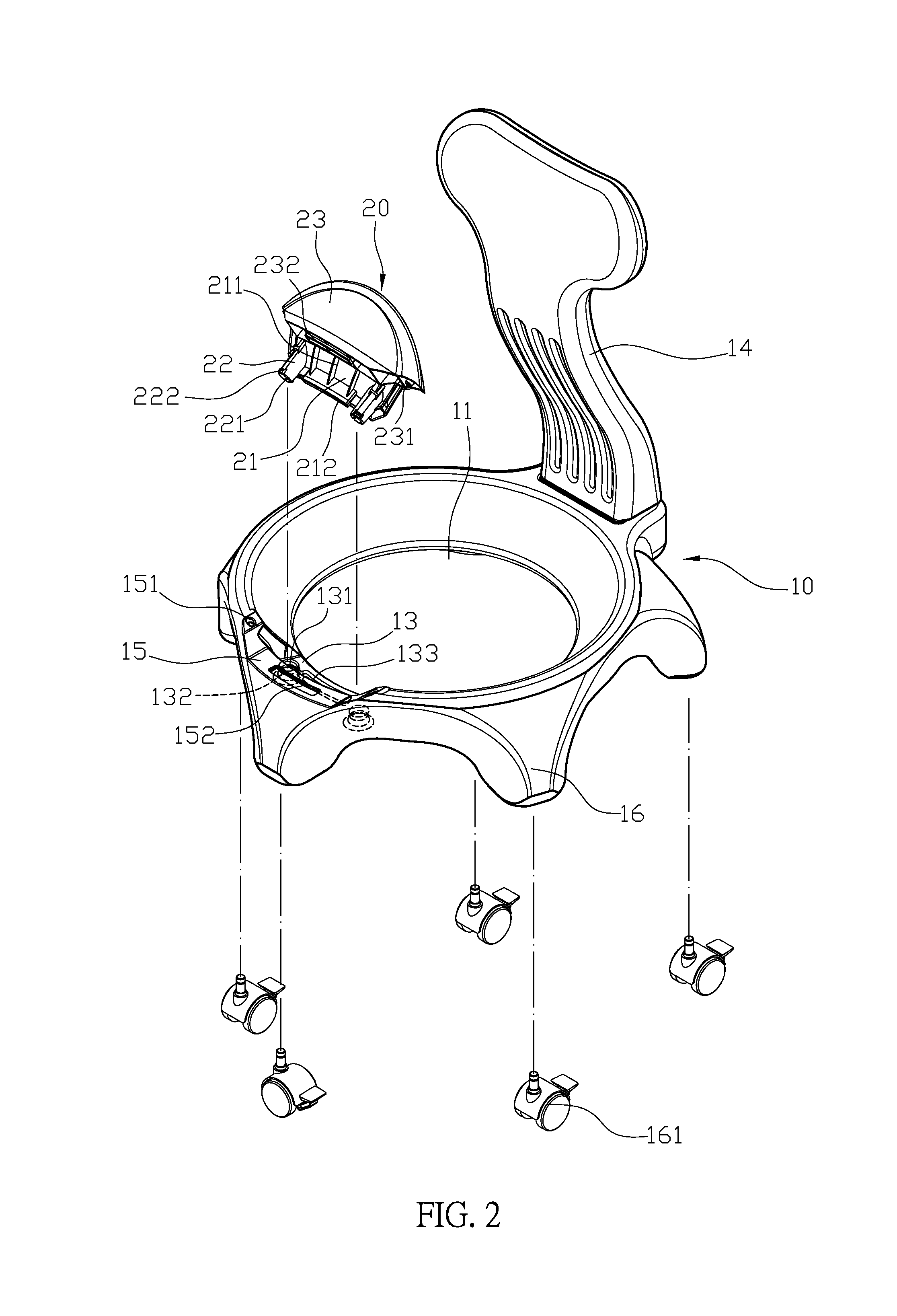

Ball chair

ActiveUS9408469B1Quickly and easily engagedImprove convenienceDismountable chairsFoldable chairsMechanical engineeringEngineering

A ball chair may include a chair base and a restricting unit. The chair base has a circular receiving space to receive a ball and an inner portion of the receiving space has a connecting portion that has at least two through holes. The restricting unit has an arc board and a connecting post conjugating with the connecting portion. A restricting board extends from the arc board corresponding to the connecting recessed portion, and the restricting board is protruding from an upper portion of the receiving space. The connecting portion of the chair base is provided for the restricting unit to restrict the ball, and the restricting unit and the connecting portion can be quickly and easily engaged increase the convenience during the assembling process and prevent the ball from being damaged.

Owner:FAMOSA CORP

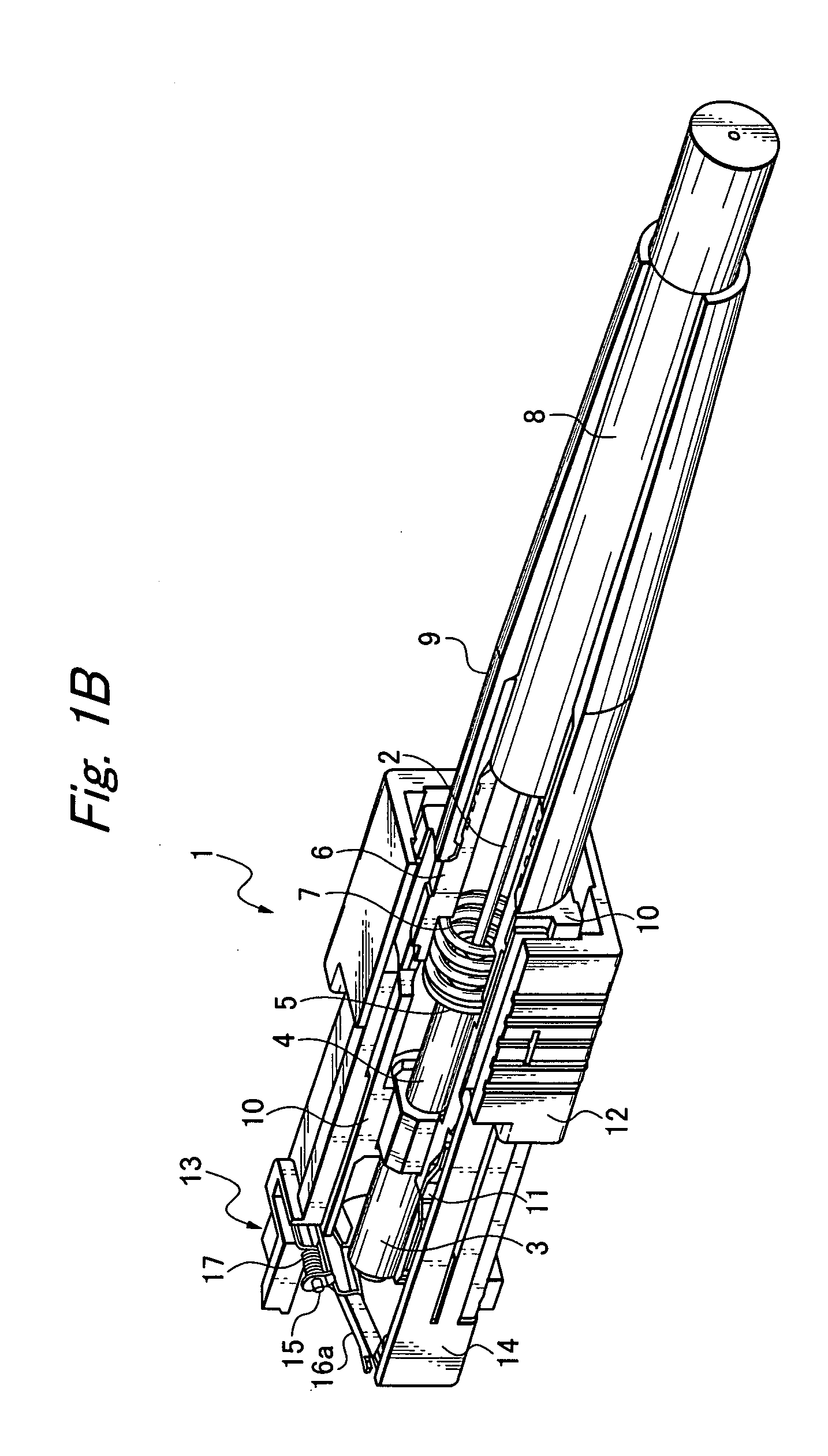

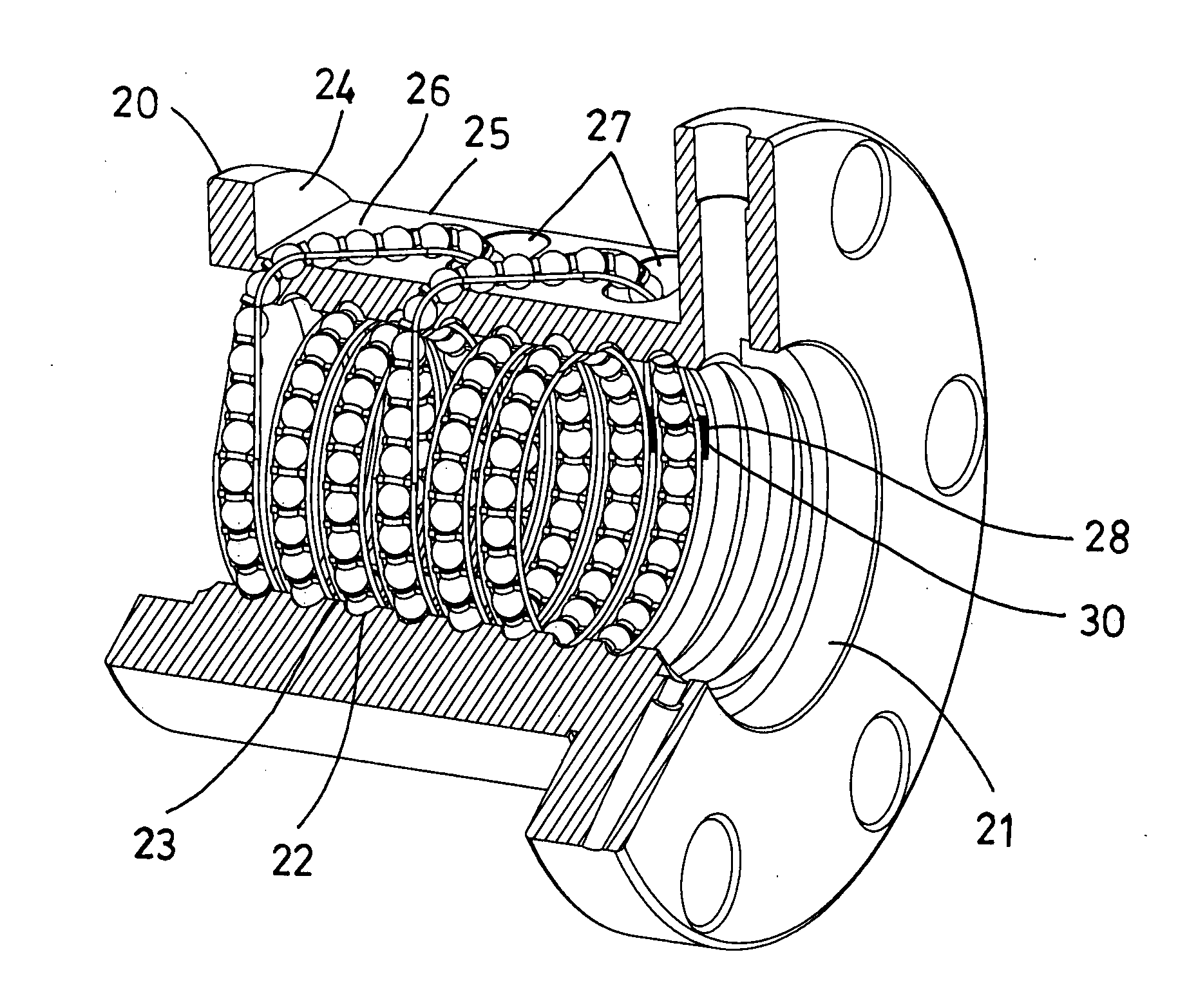

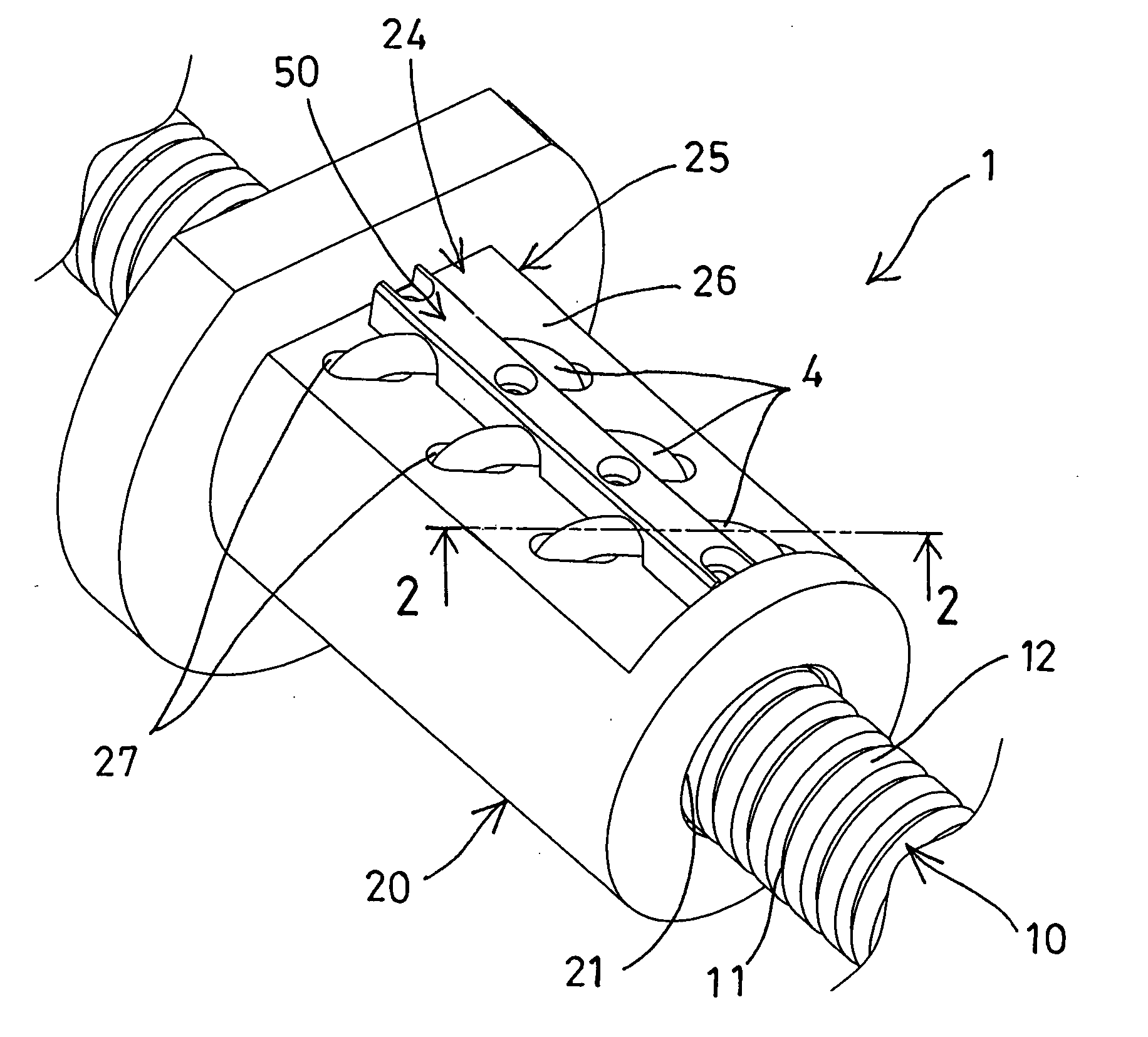

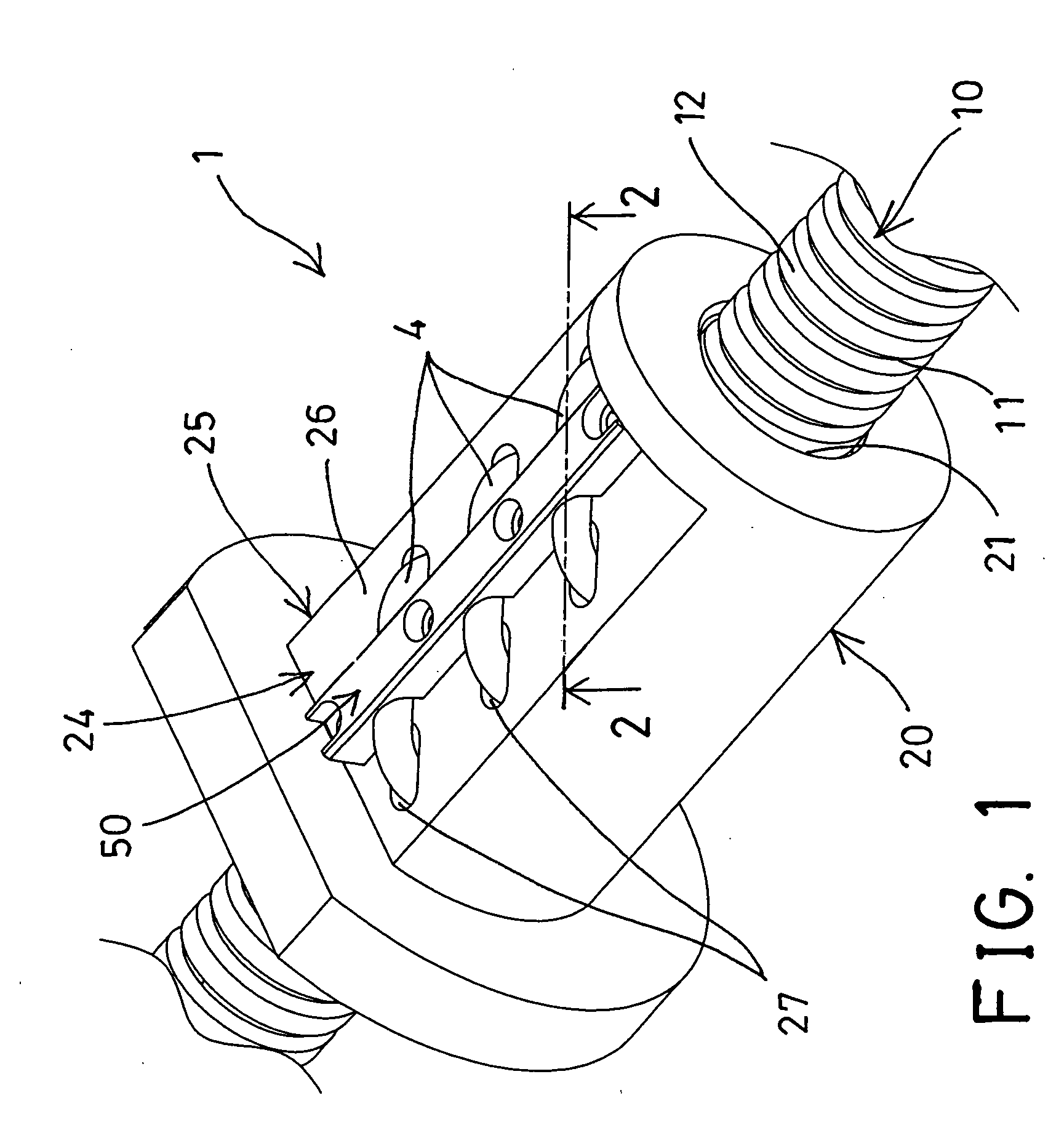

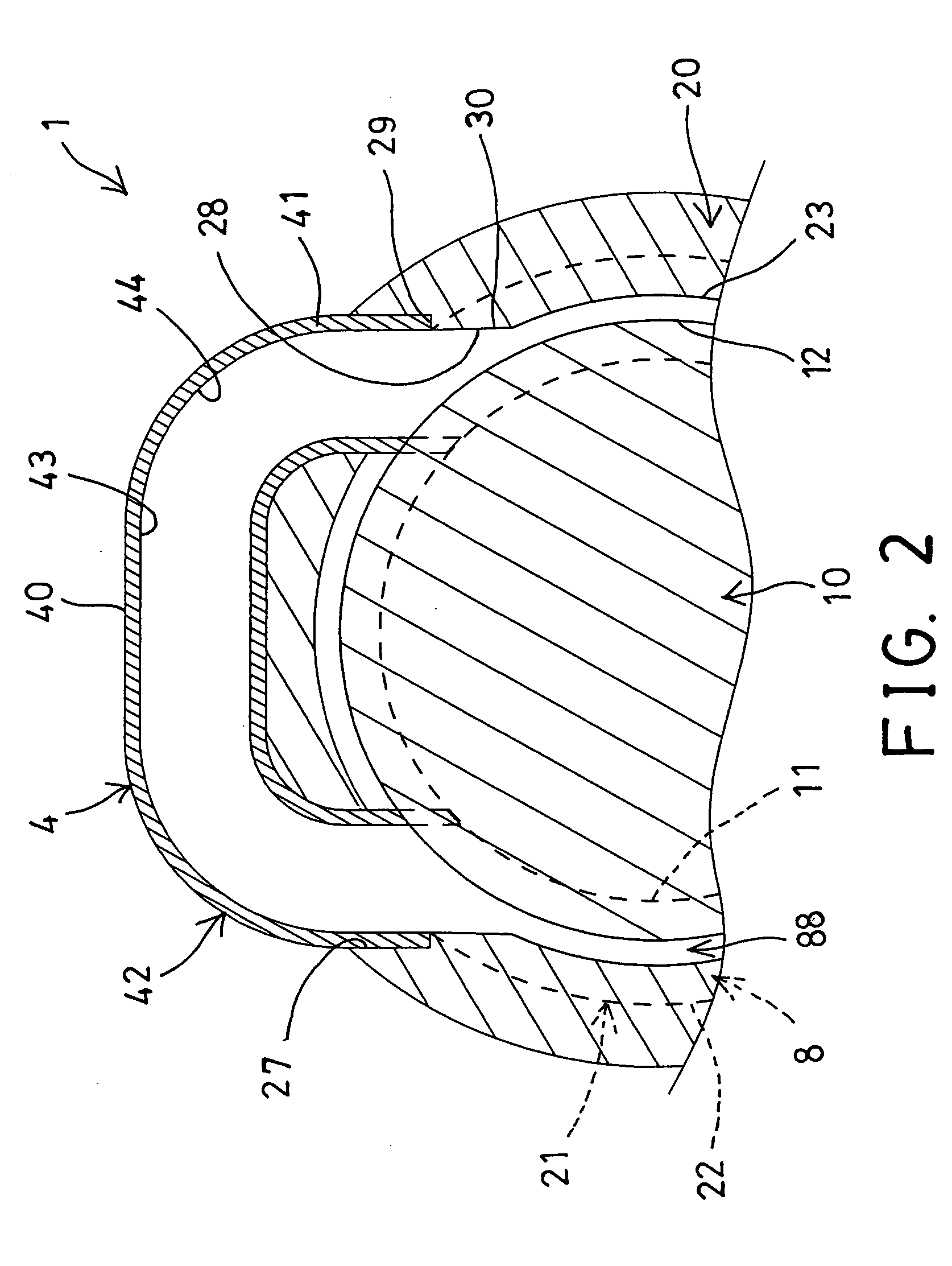

Ball screw device having ball return pipe

ActiveUS20120103121A1Smooth movementAvoid uneven attachmentPortable liftingToothed gearingsBall bearingBall screw

A ball screw device includes a screw engaged into a nut member for forming an endless ball guiding passage between the nut member and the screw and for receiving a number of ball bearing members, a ball return pipe includes a U-shaped structure having a central tubular member and two ends for engaging into two orifices of the nut member, and the nut member includes a straight fence formed between the orifice and the screw hole of the nut member for guiding the ball bearing members to move through a ball return pathway of the ball return pipe and the endless ball guiding passage of the nut member and for preventing the teeth of the nut member from being broken by the ball bearing members.

Owner:HIWIN TECH

Liquid container

InactiveUS20050062811A1Easily and reliably performedReduce component countPrintingMechanical engineeringEngineering

Owner:SEIKO EPSON CORP

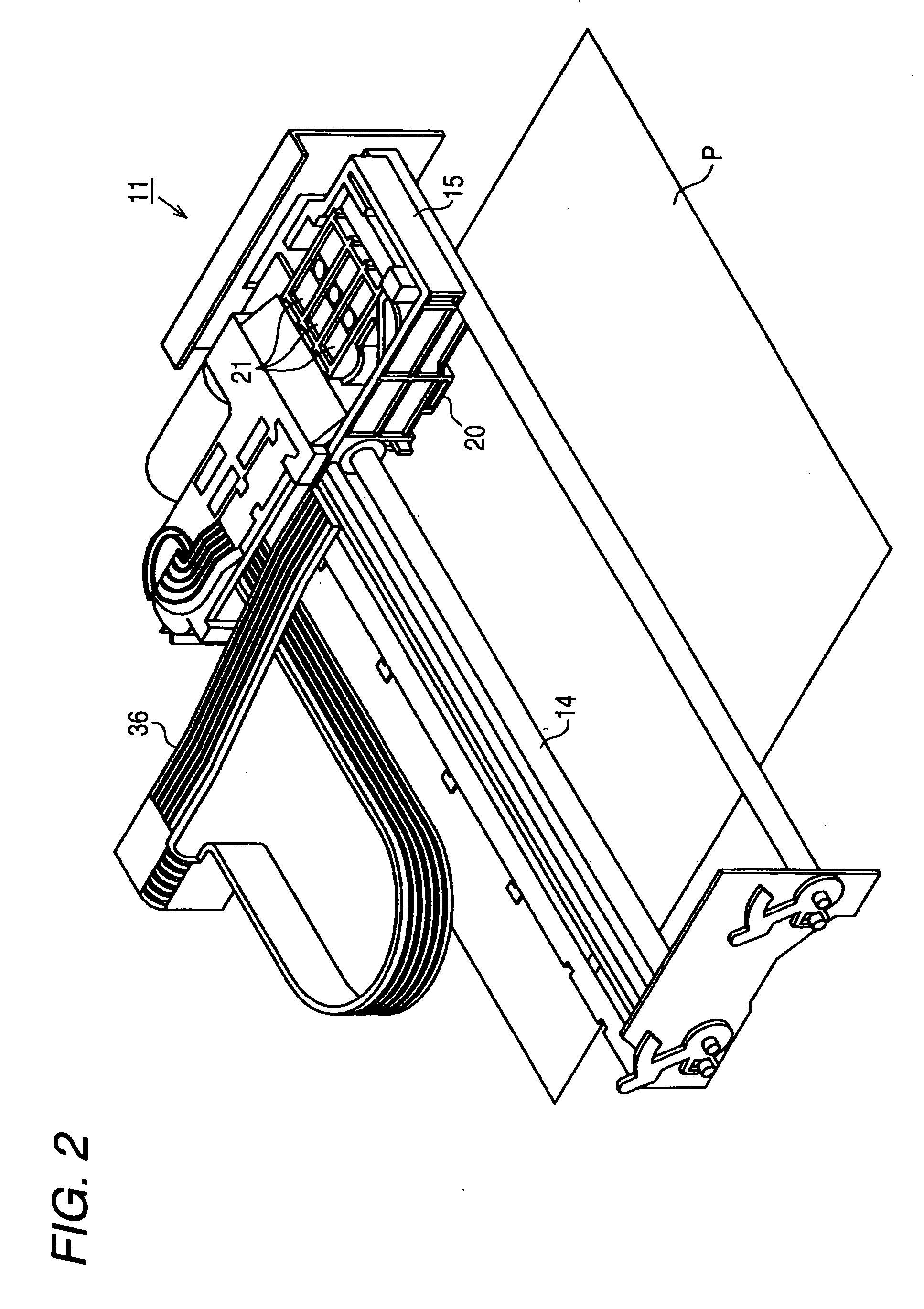

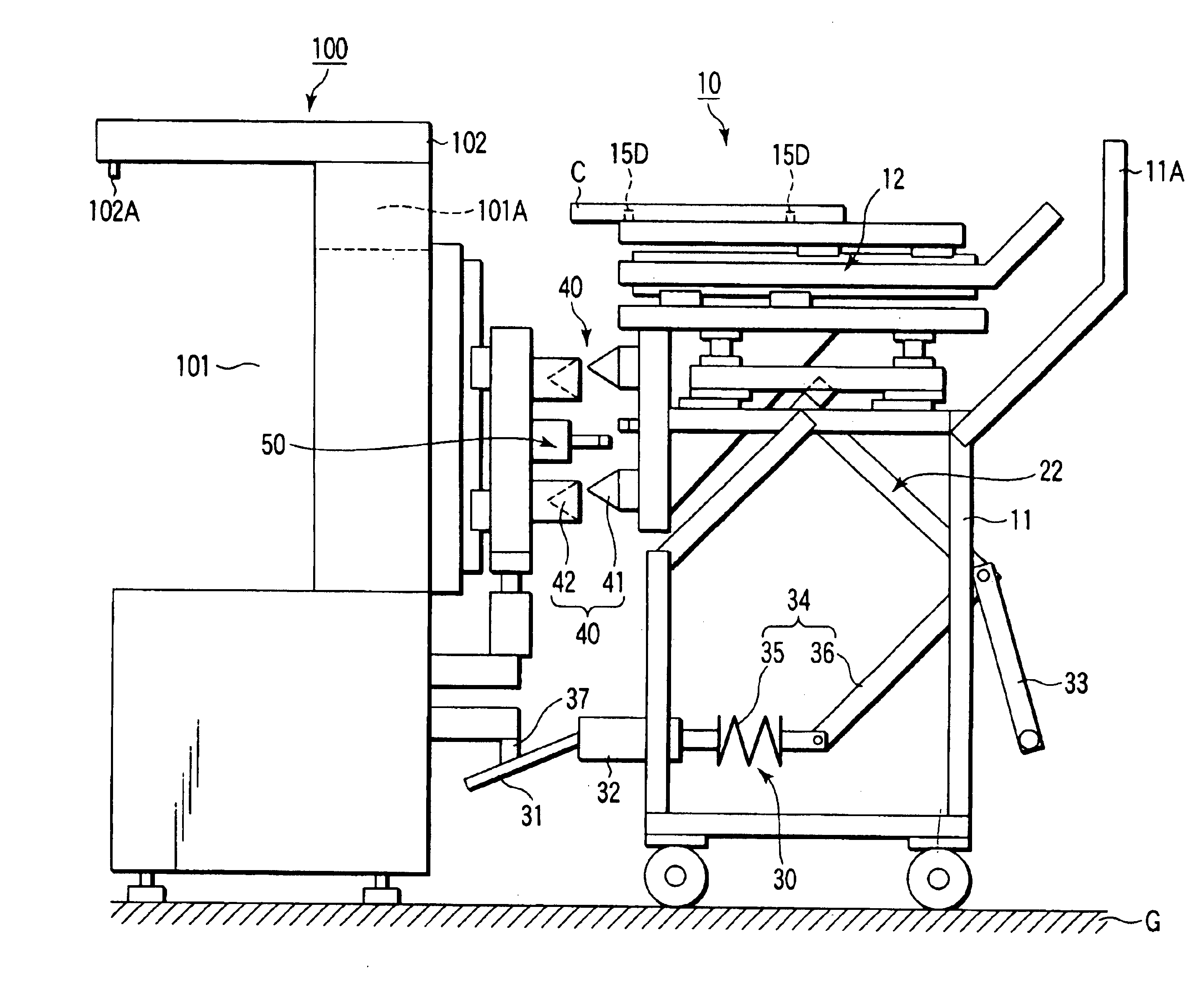

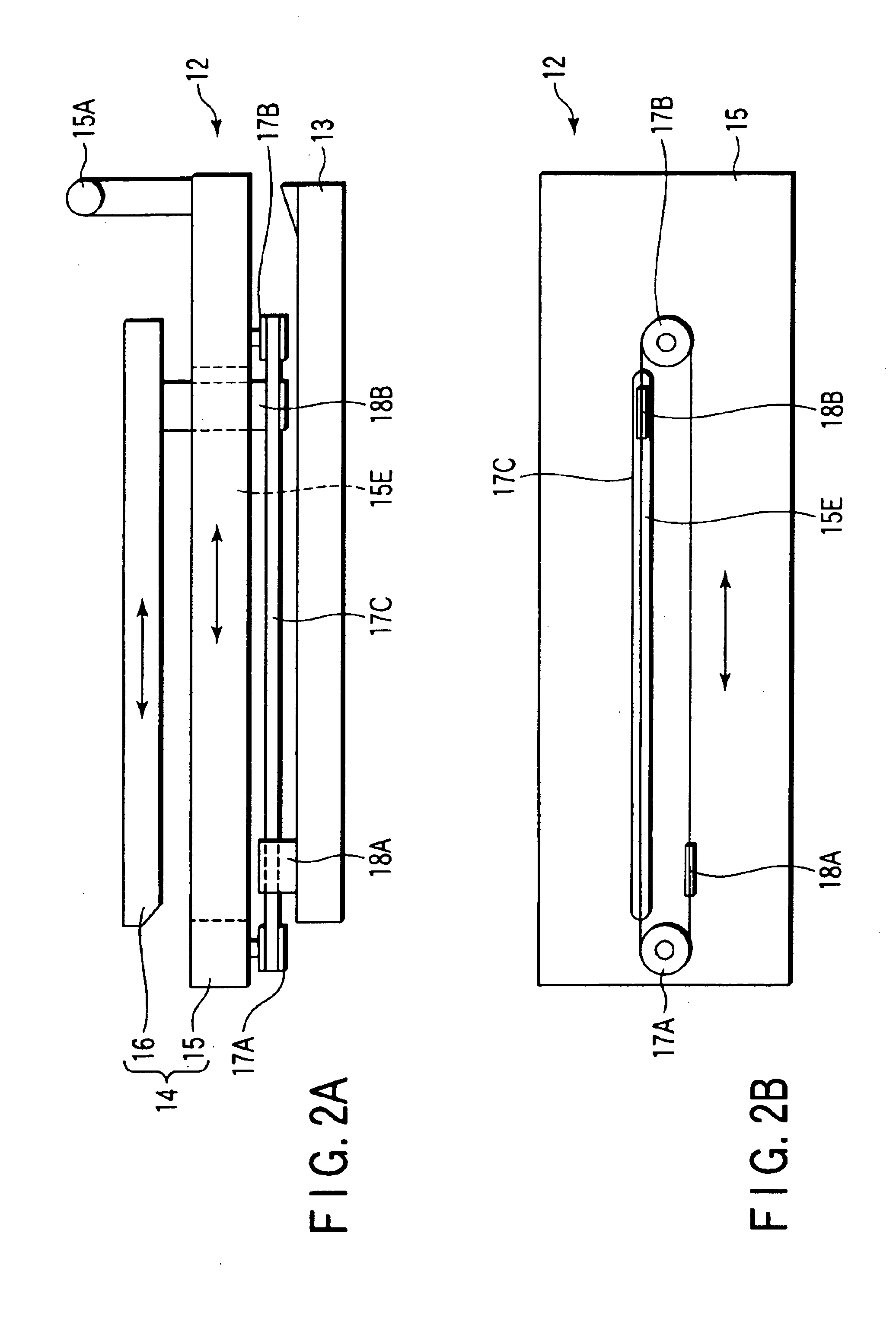

Transporting mechanism, movable probe card transporting apparatus using transporting mechanism, and prober

ActiveUS6958618B2Reduced footprintAvoid uneven attachmentSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardEngineering

A probe card transporting apparatus includes a truck and transporting mechanism. The truck can move on a floor surface freely. The transporting mechanism is arranged above the truck to be able to separate from and come into contact with it. The transporting mechanism transports a probe card between the truck and a prober. The transporting mechanism has a base and arm mechanism. The arm mechanism moves forward / backward on the base. An aligning mechanism and fixing mechanism are provided on the base. The aligning mechanism serves for alignment with the prober. The fixing mechanism serves for fixing to the prober.

Owner:TOKYO ELECTRON LTD

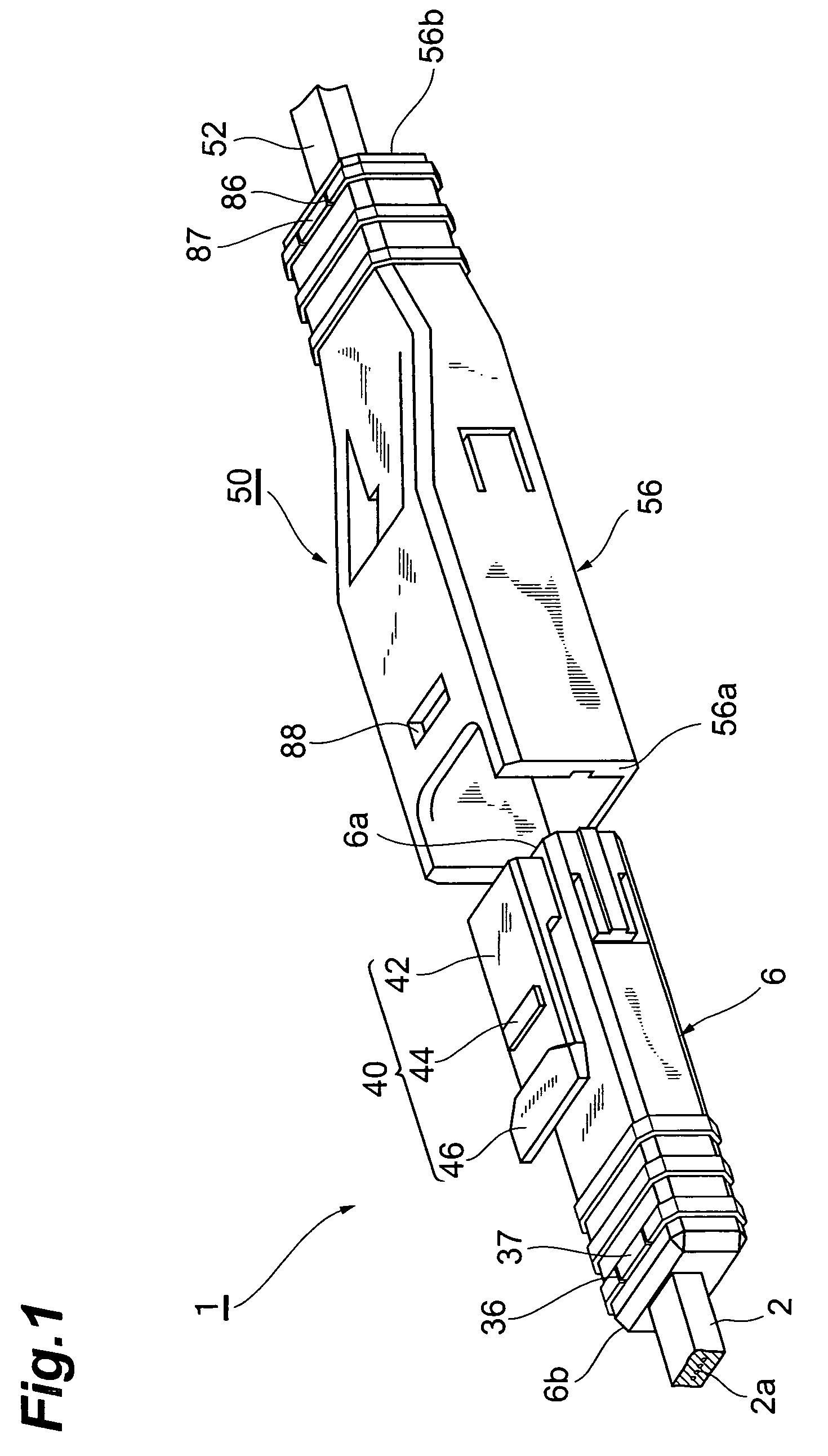

Connecting component

ActiveUS8888534B2Avoid uneven attachmentImprove featuresCoupling device detailsTwo-part coupling devicesAbutmentEngineering

A connecting component includes a housing, housing connection terminals secured to the housing, an abutment located beneath the housing connection terminals, a first guide portion located beneath the housing connection terminals for regulating a position of a bottom surface of the subsidiary board, second guide portions located in front of the first guide portion as seen in a subsidiary board insertion direction for regulating the top surface of the subsidiary board, and third guide portions located in front of the first guide portion as seen in the subsidiary board insertion direction on a straight line passing through the first guide portion and the second guide portions and disposed in a position away from the abutment by a distance longer than an overall length of the subsidiary board, the third guide portions regulating the position of the bottom surface of the subsidiary board.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

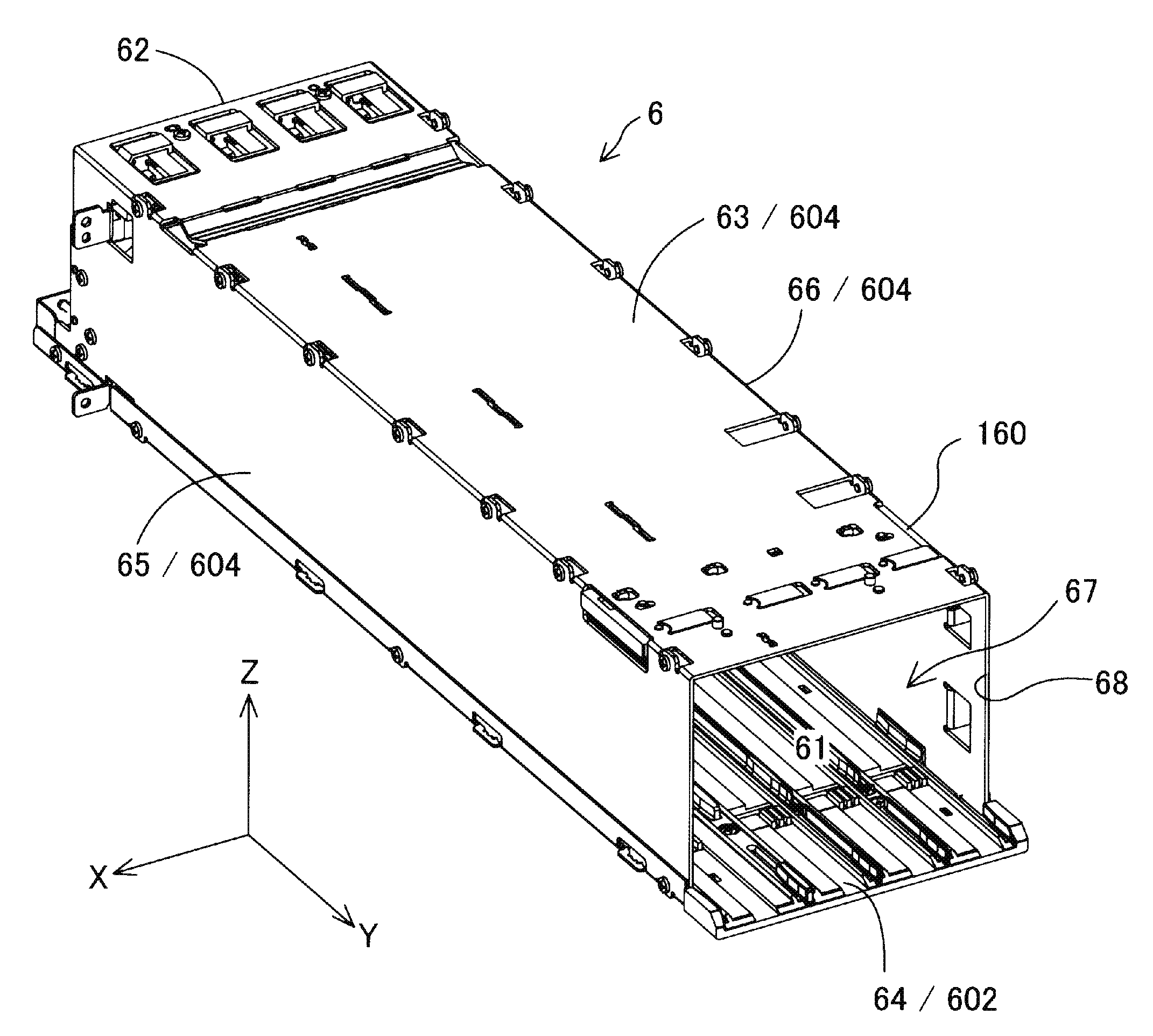

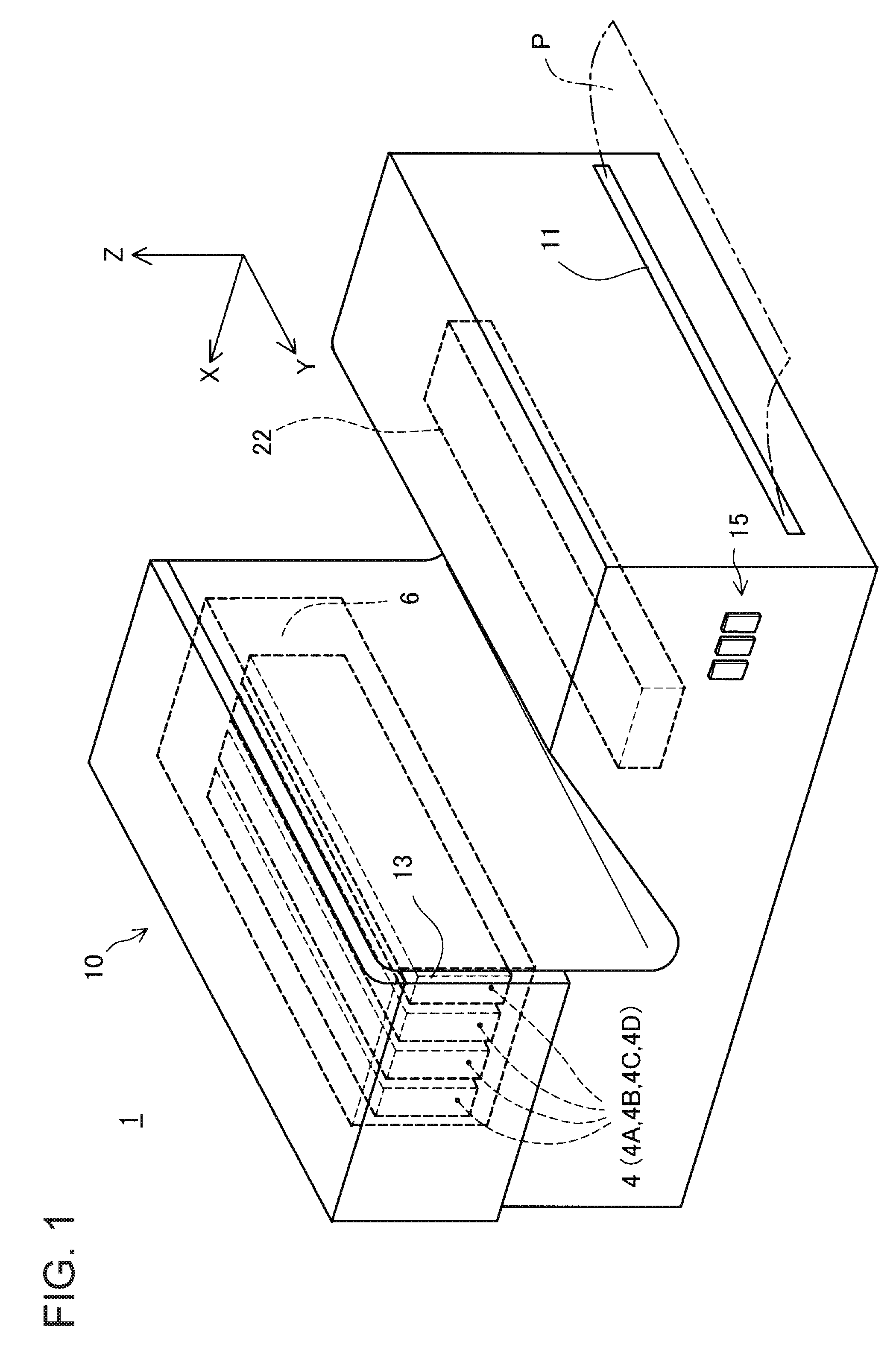

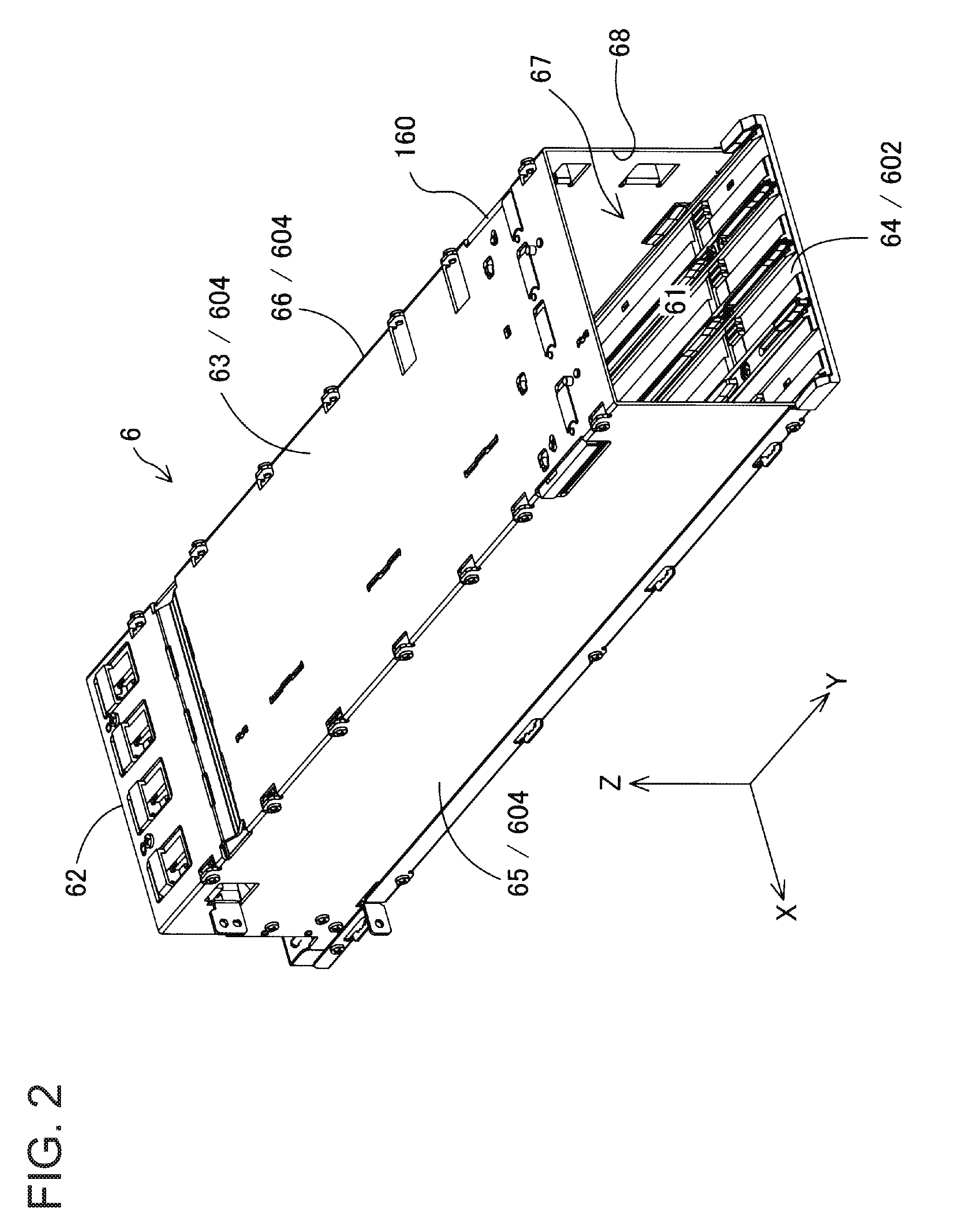

Cartridge and Liquid Ejection Apparatus

ActiveUS20160288512A1Reduce riskImprove adhesionOther printing apparatusEngineeringMechanical engineering

Accuracy in determination of the attaching direction of an elongated cartridge is improved. A cartridge 4A according to this embodiment to be attached to a printer includes an ink supply port 414 that supplies ink to the printer, a misinsertion prevention upper face projection portion 140 that engages with misinsertion prevention portions 671 of a misinsertion prevention plate 160 in a cartridge attachment portion 6, and restriction front upper face projection portions 430 that abut against a first guide rail 650 and a first guide rail 651 and restrict a tilt of the cartridge in an intersecting direction that intersects the attaching direction at the time of attachment. These restriction front upper face projection portions 430 are arranged between a leading end side in the attaching direction CS and the misinsertion prevention upper face projection portion 140.

Owner:SEIKO EPSON CORP

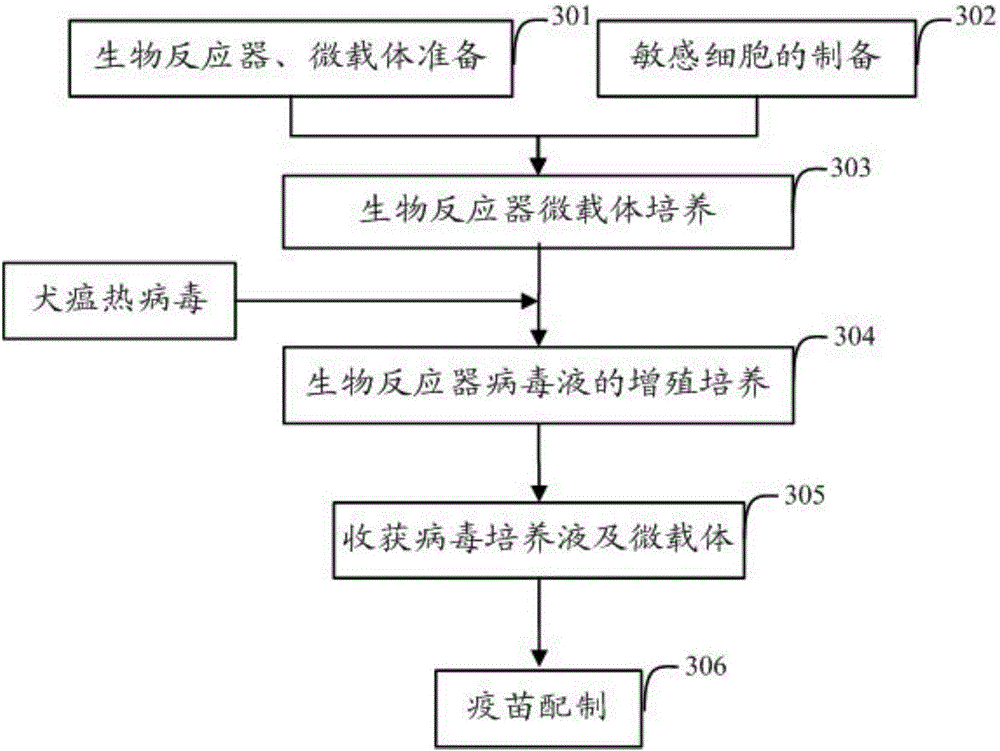

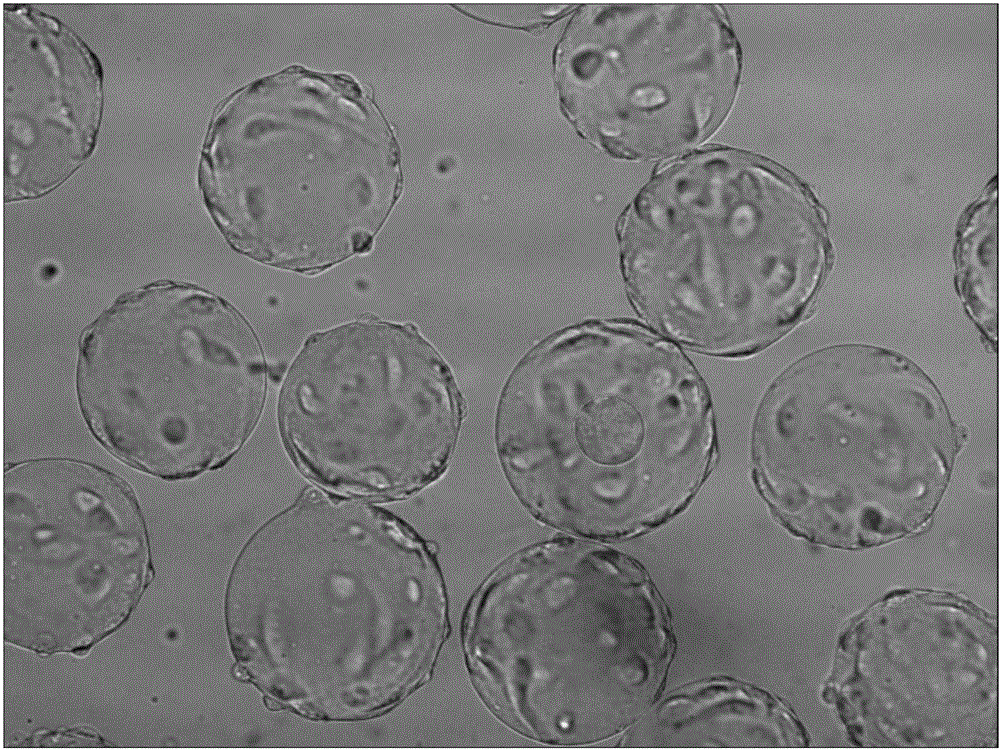

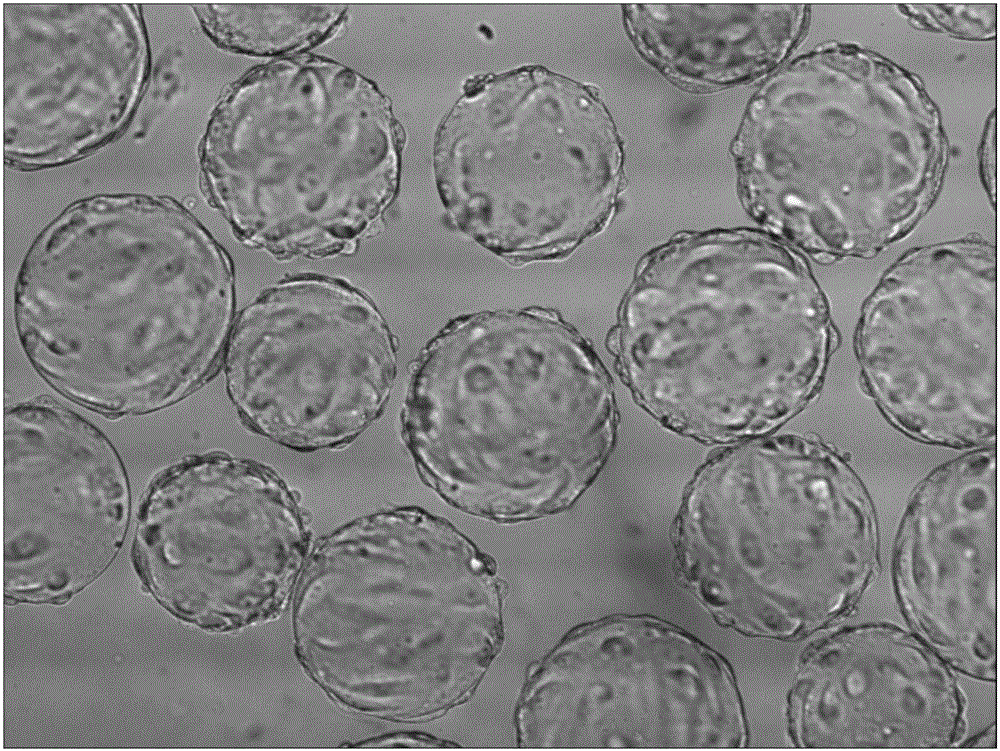

Preparation method of mink canine distemper virus live vaccine and vaccine prepared by same

InactiveCN105816869AIncrease culture densityIncrease productionSsRNA viruses negative-senseViral antigen ingredientsFreeze thawingSide effect

The invention relates to the field of veterinary biological products and particularly relates to a preparation method of a mink canine distemper virus live vaccine. The method comprises the following steps: inoculating a bioreactor with sensitive cells for vaccine preparation, and culturing by using a micro-carrier; after the sensitive cells are cultured by over 50% and grow into a dense single layer, inoculating the bioreactor with canine distemper virus for enrichment culture; harvesting the virus culture liquid and micro-carrier; performing freeze-thawing and removing the micro-carrier and cell debris to obtain virus liquid; and blending the virus liquid to obtain the vaccine. By improving the reaction conditions of each step and optimizing the production flow, the method provided by the invention realizes the technical effects of short production cycle, high virus titer, stable product quality, increased production efficiency and low side effect.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS +1

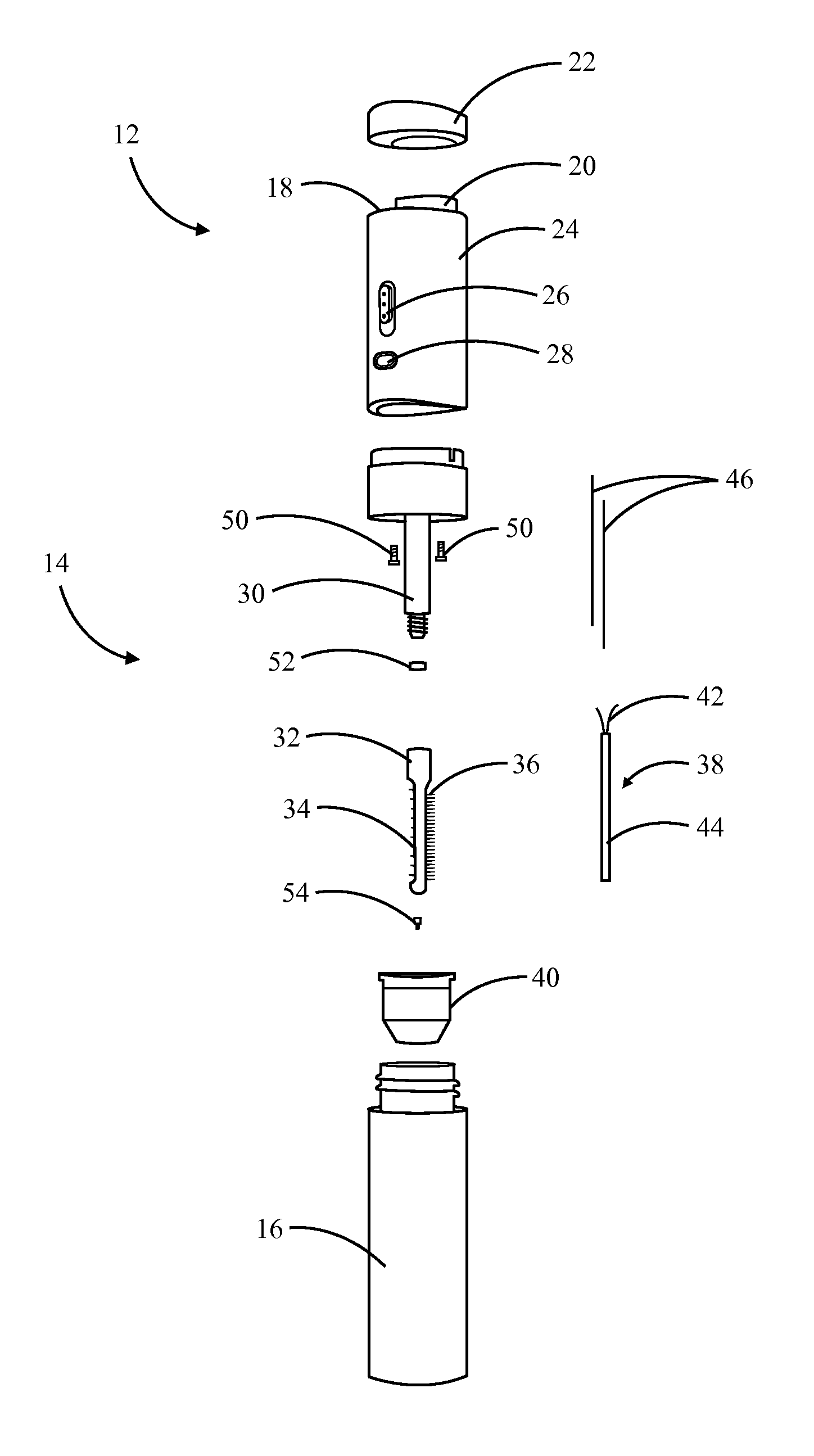

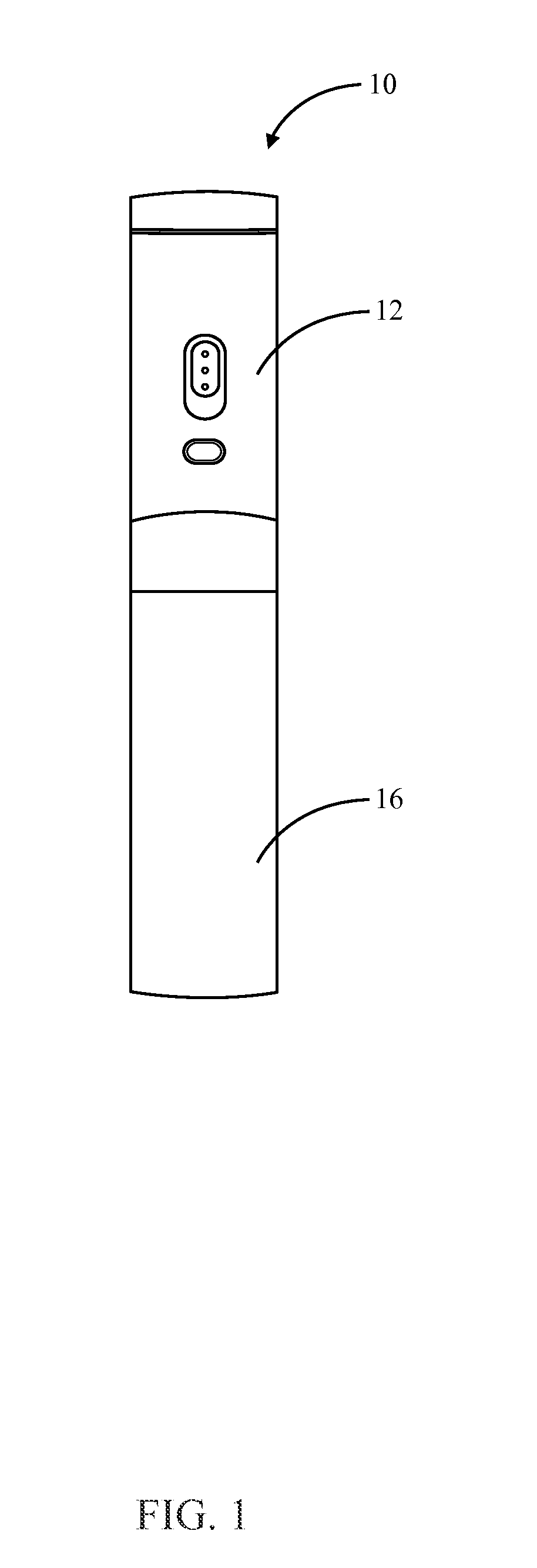

Mascurler (heated mascara)

InactiveUS20130017009A1Efficiently heatMake moreCarpet cleanersFloor cleanersMascaraPrinted circuit board

Owner:CHO YONG HOON

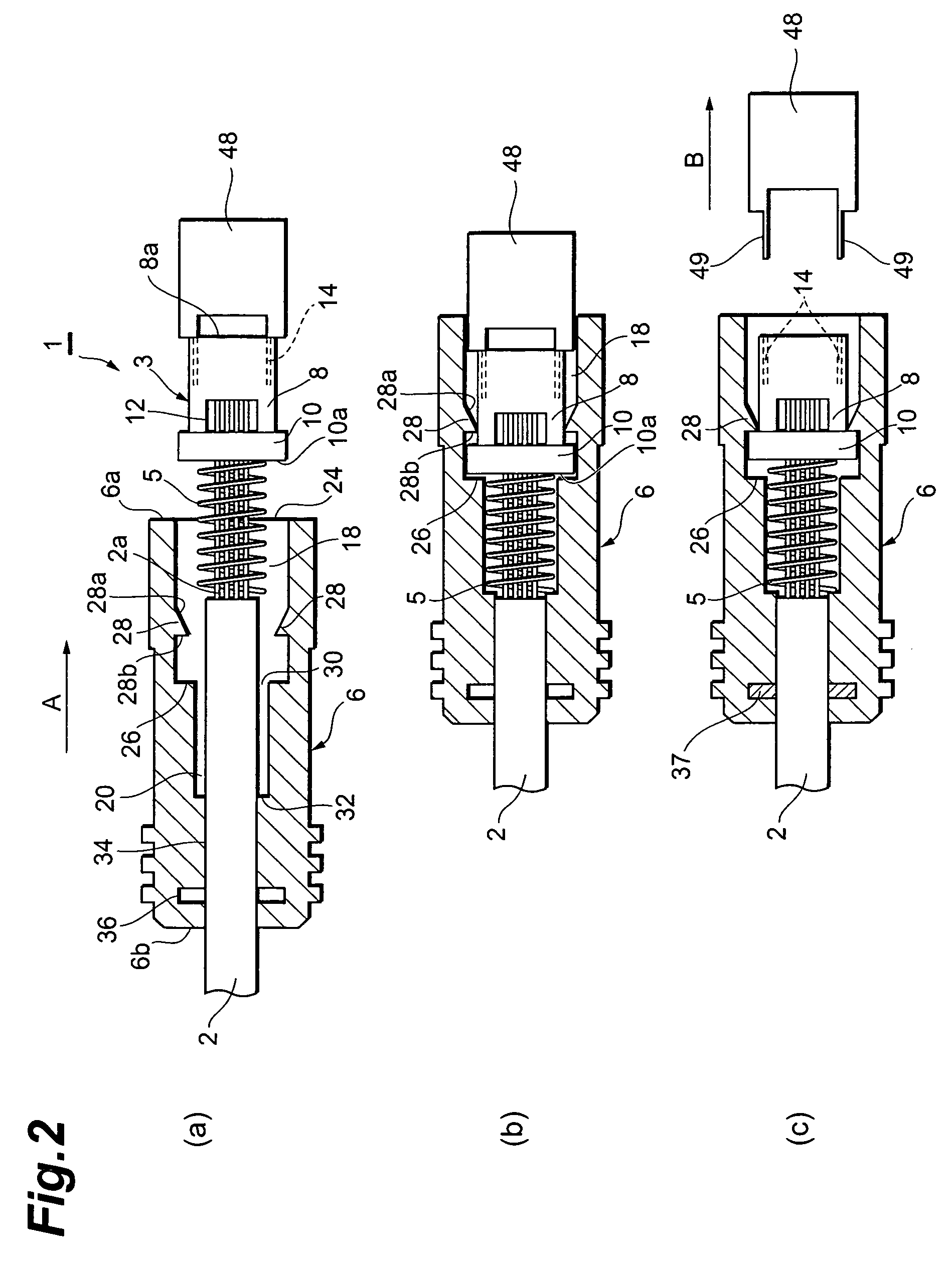

Optical connector and method for assembling optical connector

ActiveUS7722260B2Reduce in quantityEasily attached to optical cableCoupling light guidesEngineeringMechanical engineering

To provide an optical connector that enables the reduction in the number of parts and can be easily attached to an optical cable, a concave portion 18 for a ferrule is formed in a plug housing 6, and a ferrule 3 is inserted from the side of a collar portion 10 into the concave portion 18 for a ferrule. A hook portion 28 for a ferrule is provided in a protruding condition inside the plug housing 6. The collar portion 10 is guided by the hook portion 28 for a ferrule, which has been elastically deformed, and moves toward a bottom surface 26 of the concave portion 18 for a ferrule. Where the collar portion 10 reaches a space between the bottom surface 26 and the hook portion 28 for a ferrule, the hook portion 28 for a ferrule is elastically restored. Therefore, even if the collar portion 10 tries to move toward an opening 24 of the concave portion 18 for a ferrule, the collar portion is locked by the hook portion 28 for a ferrule and the movement is inhibited. Thus, in the plug-type optical connector 1, the ferrule 3 can be positioned by inserting into the plug housing 6 and moving.

Owner:SUMITOMO ELECTRIC IND LTD

Heat dissipating device

ActiveUS9578780B1Improve structural stabilityAvoid deformationSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:CHAUN CHOUNG TECH

Ball screw device having ball return pipe

InactiveUS20100101349A1Avoid uneven attachmentSmooth movementLinear bearingsPortable liftingBall bearingBall screw

A ball screw device includes a screw engaged into a nut member for forming an endless ball guiding passage between the nut member and the screw and for receiving a number of ball bearing members, a ball return pipe includes a U-shaped structure having a central tubular member and two ends for engaging into two orifices of the nut member, and the nut member includes a straight fence formed between the orifice and the screw hole of the nut member for guiding the ball bearing members to move through a ball return pathway of the ball return pipe and the endless ball guiding passage of the nut member and for preventing the teeth of the nut member from being broken by the ball bearing members.

Owner:HIWIN TECH

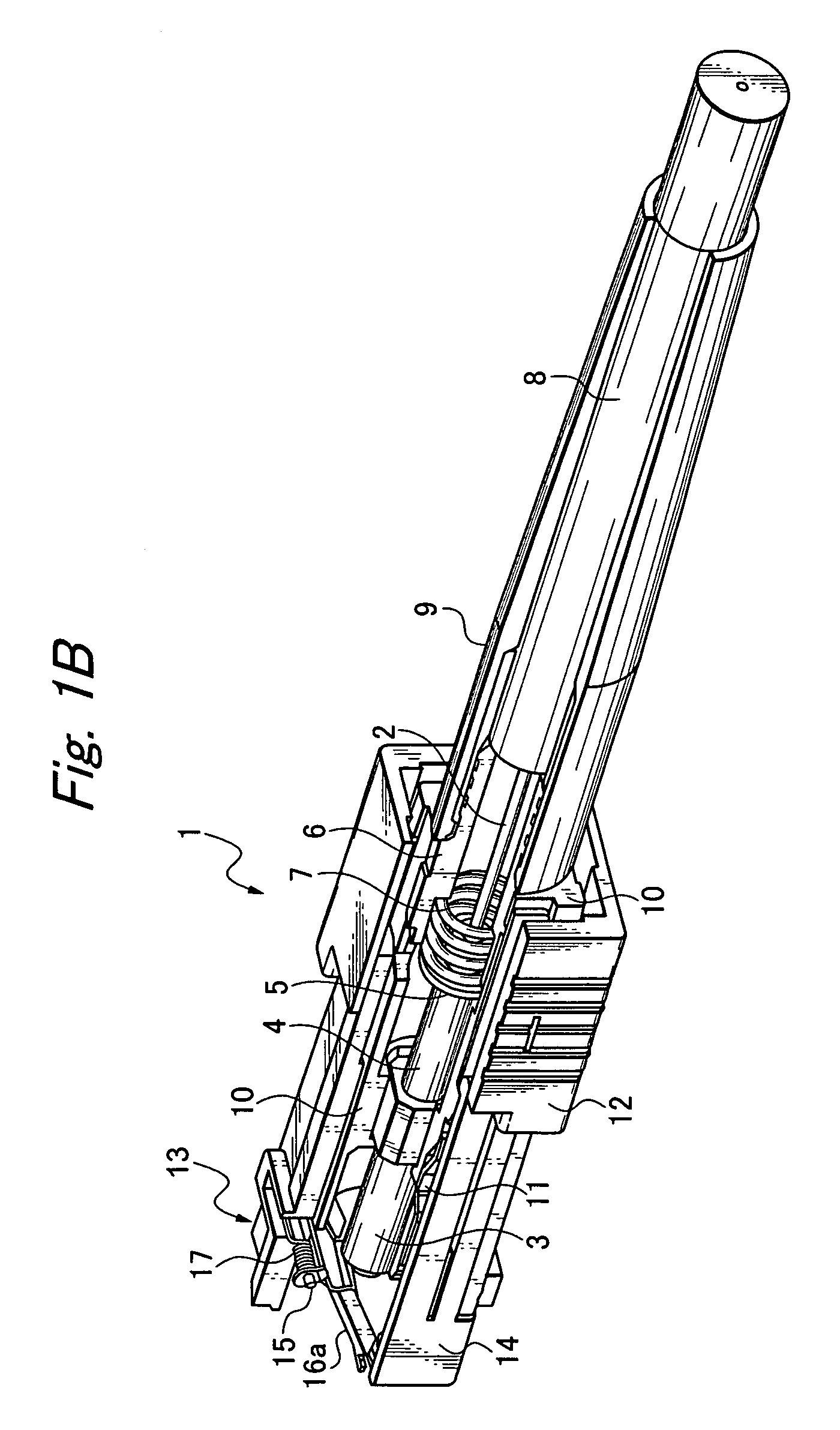

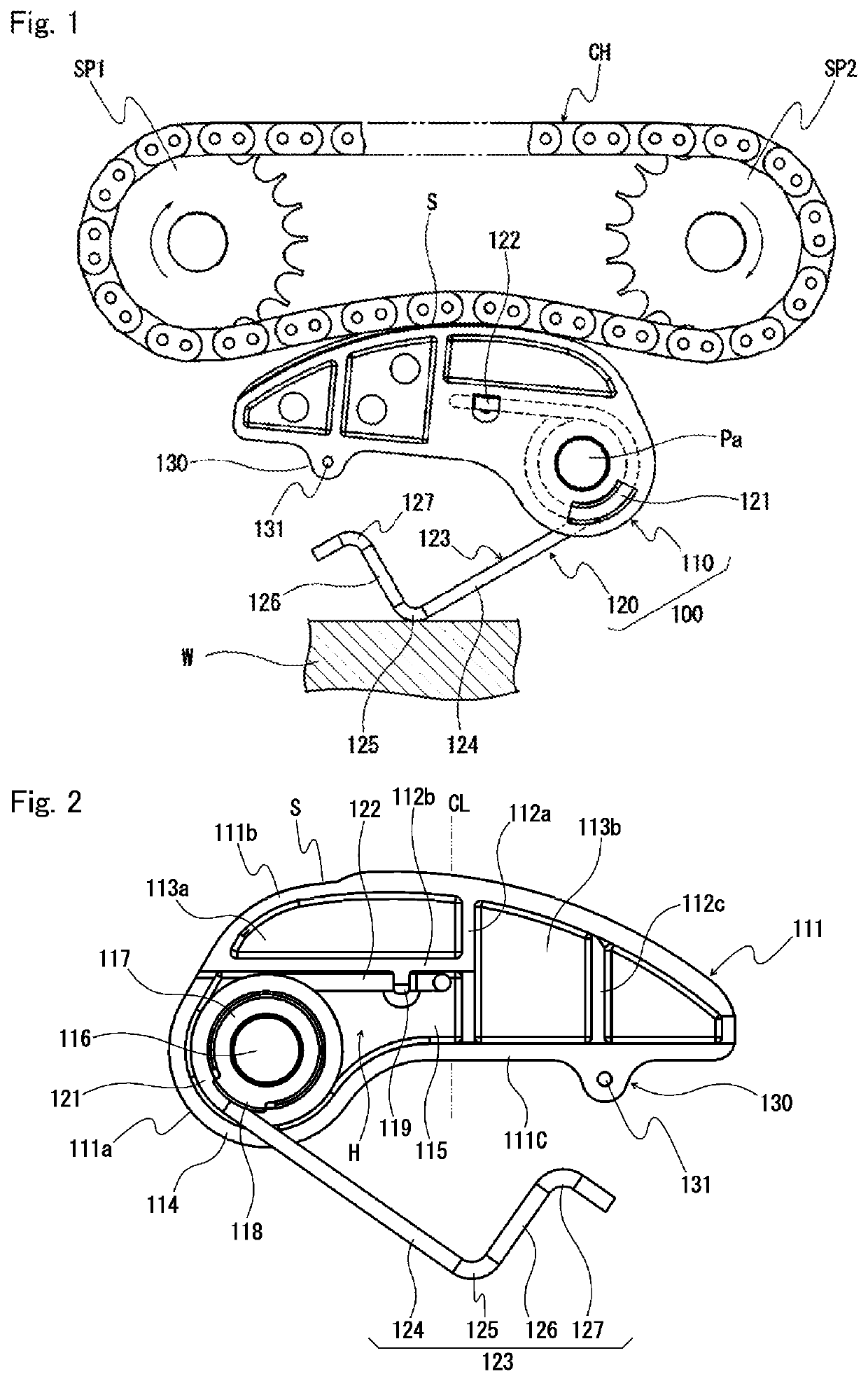

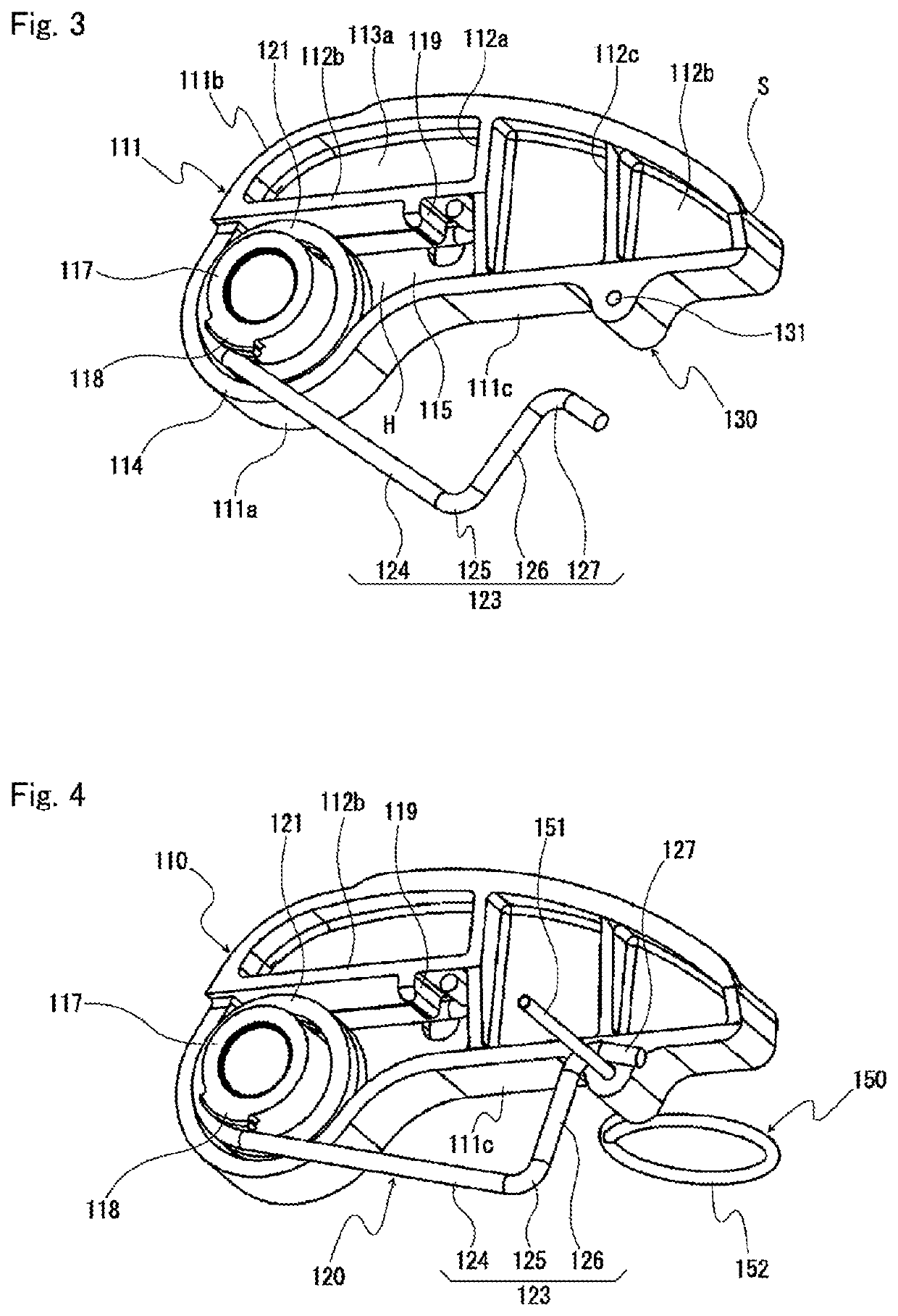

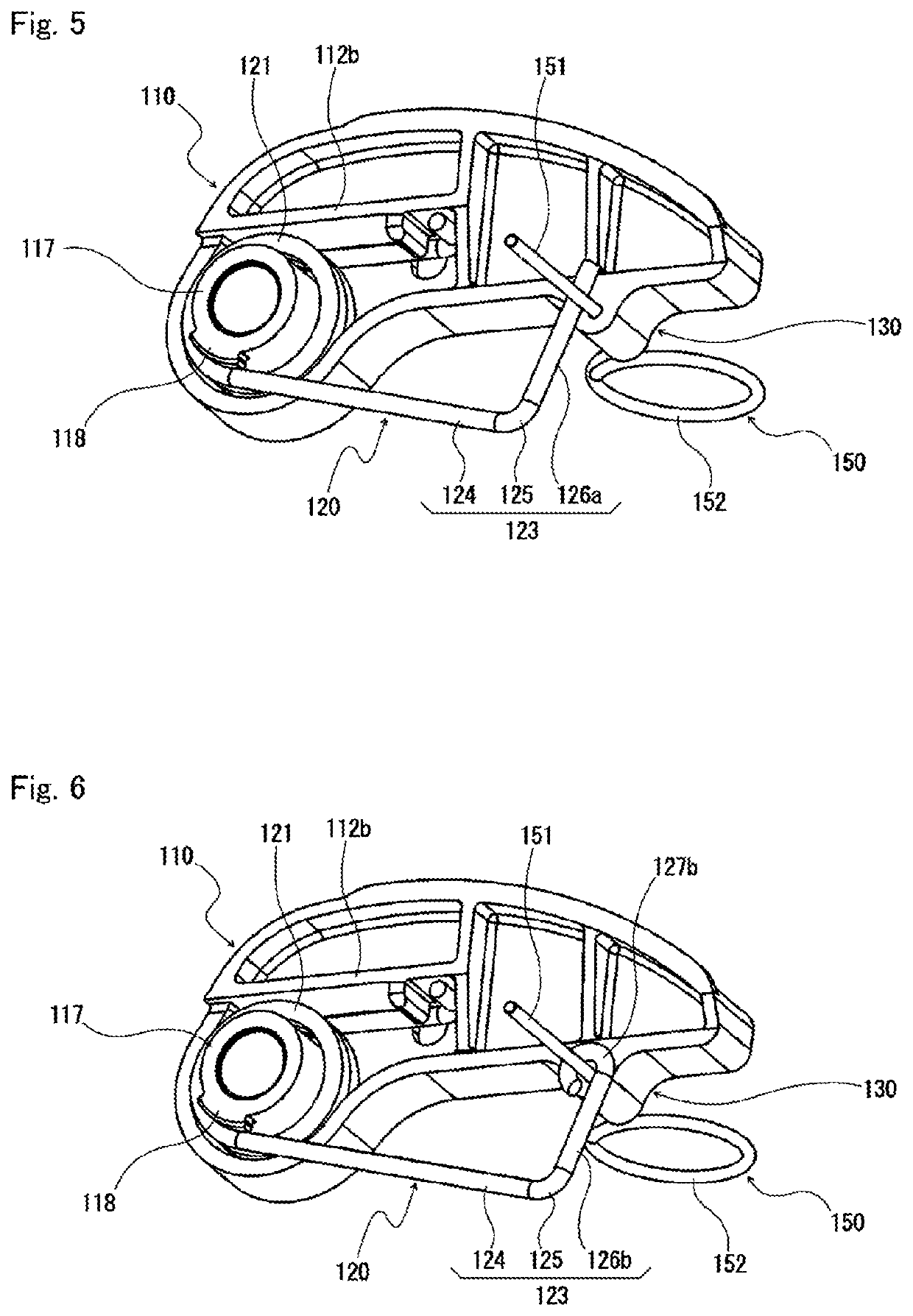

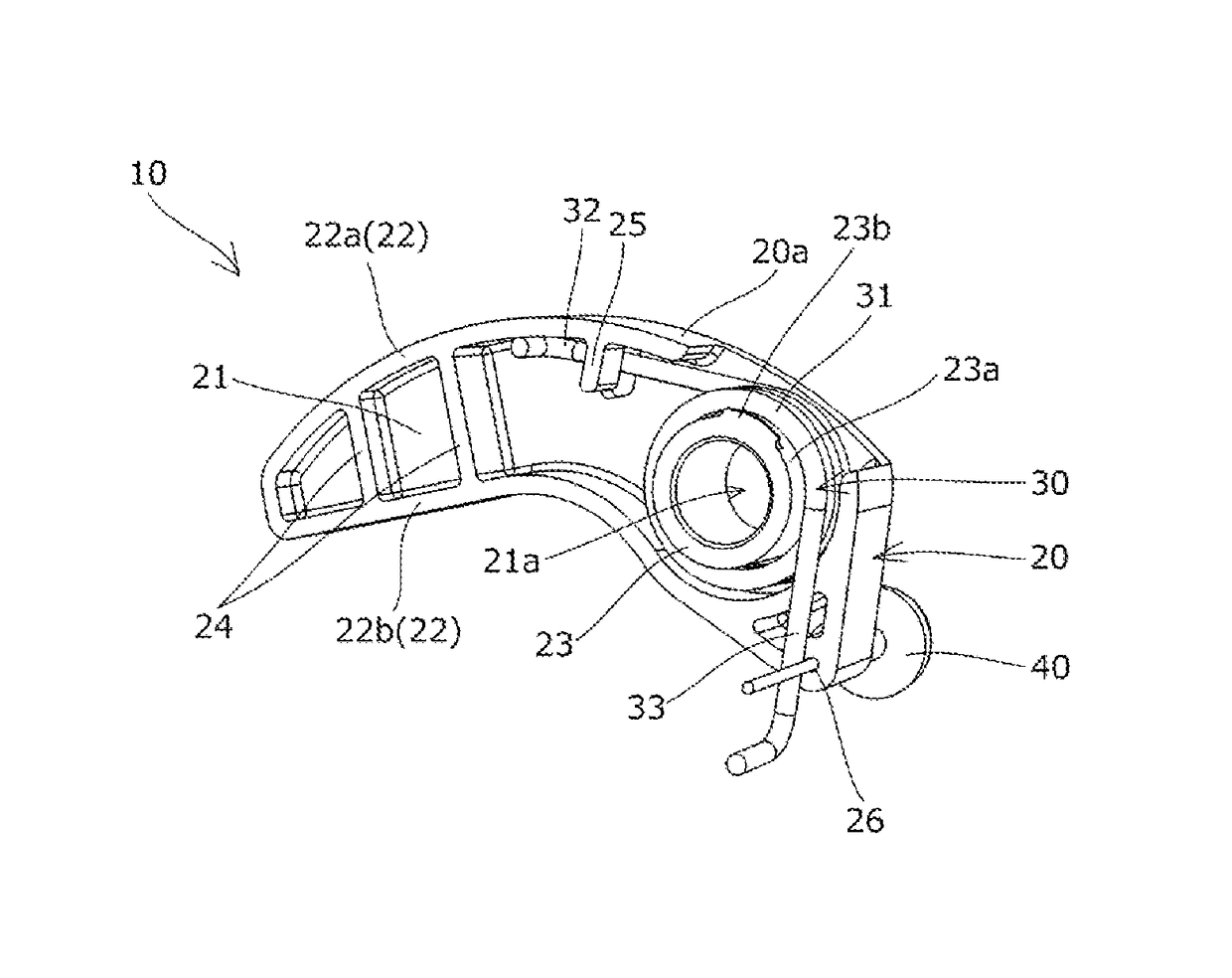

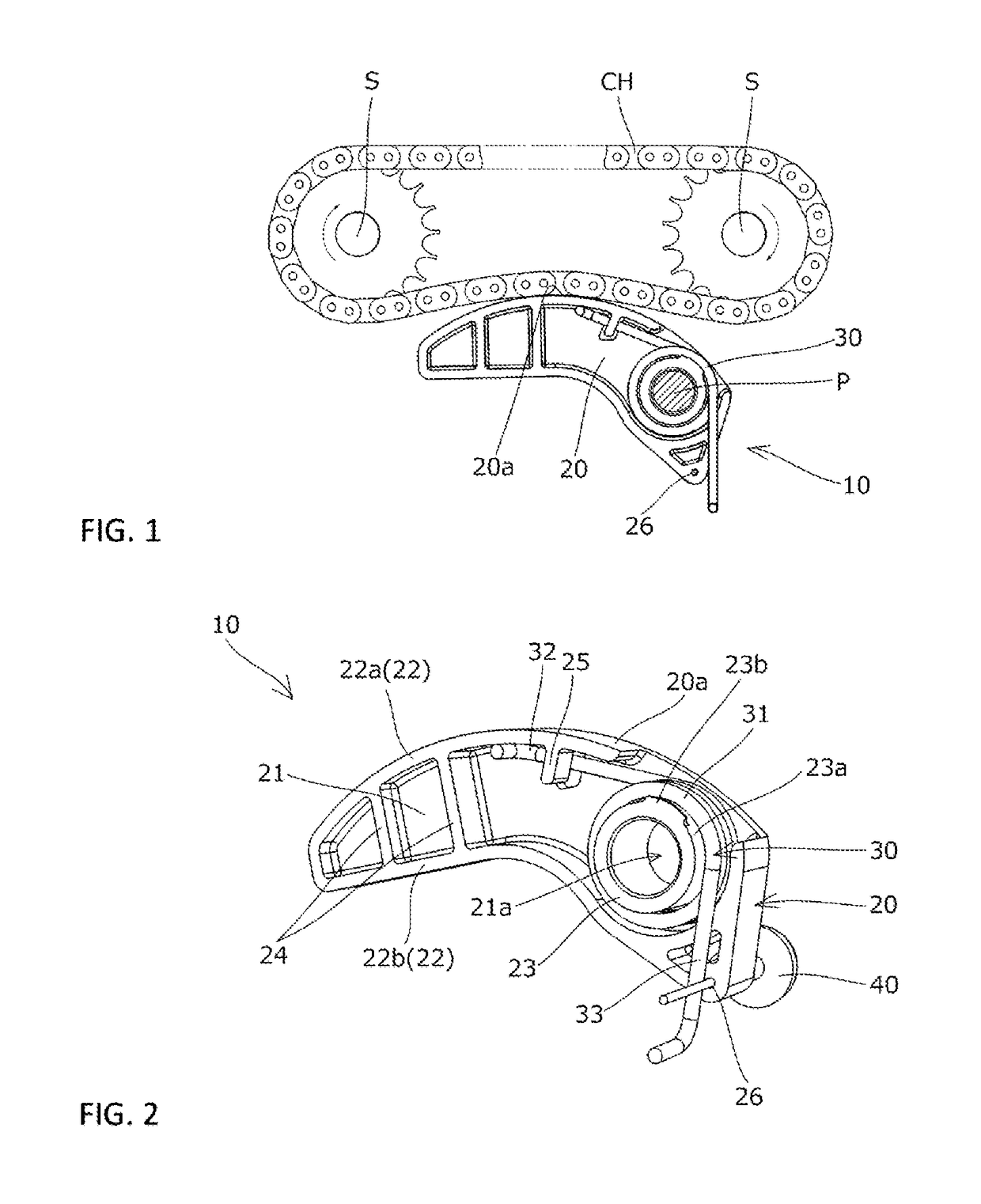

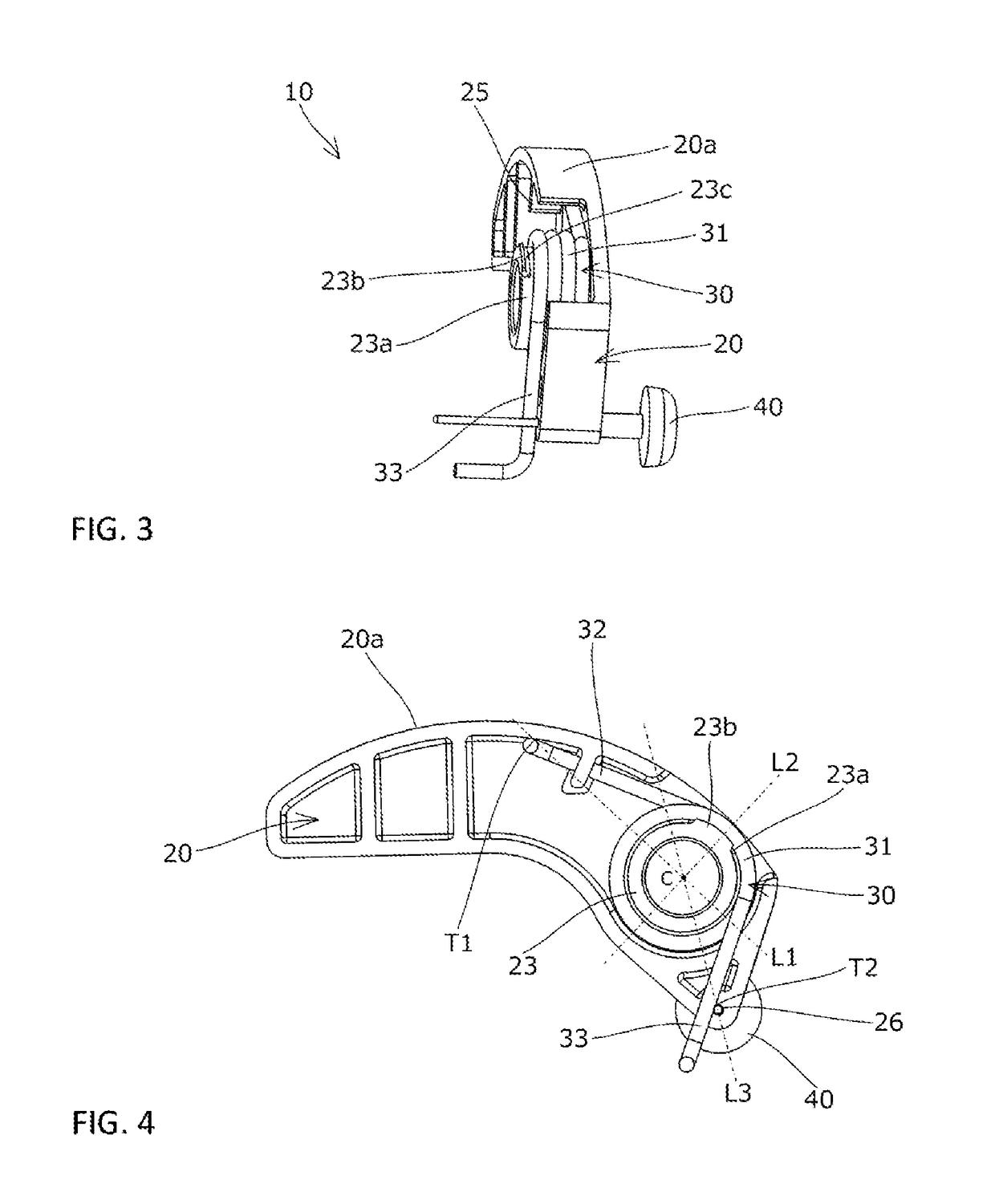

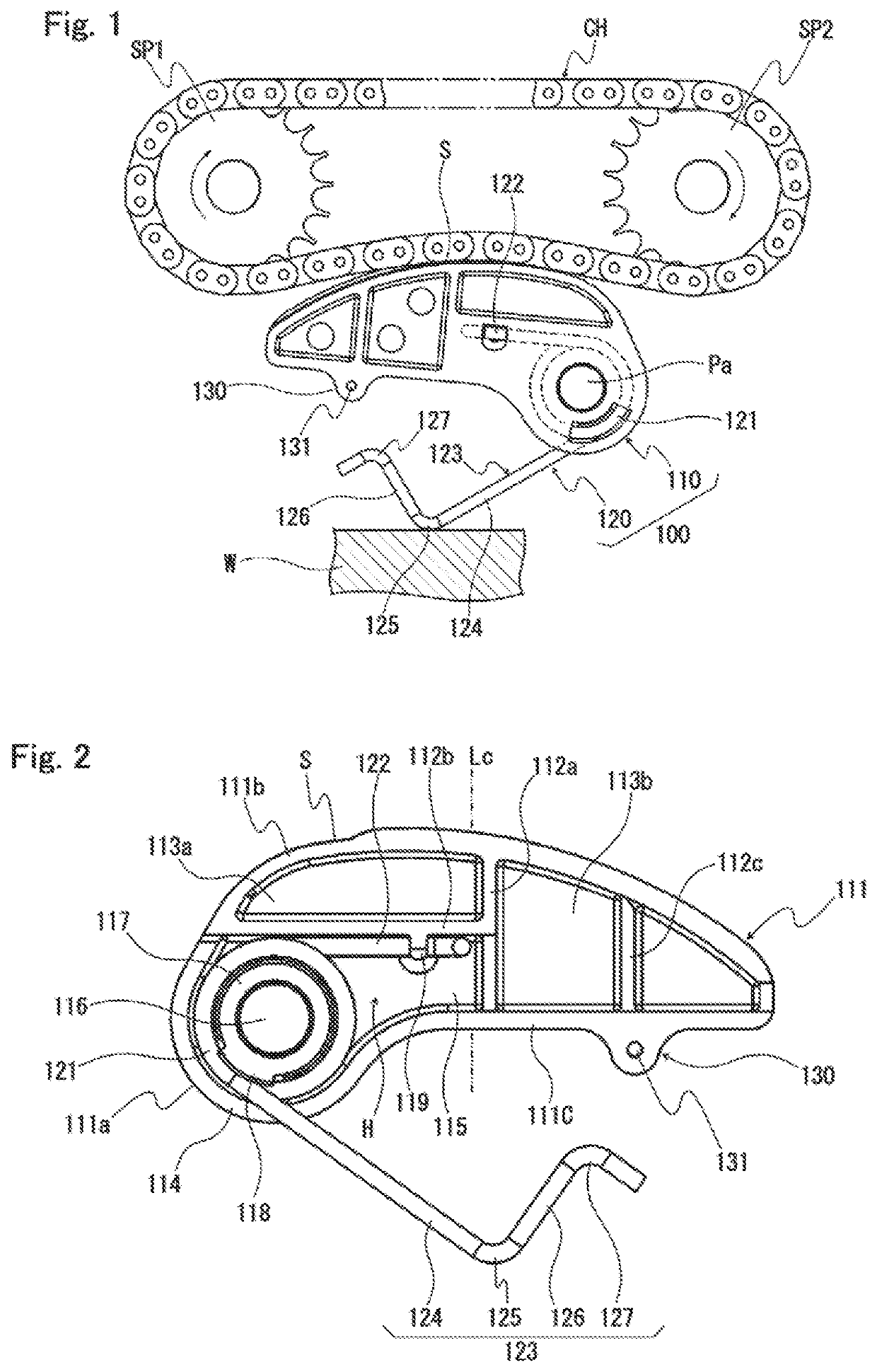

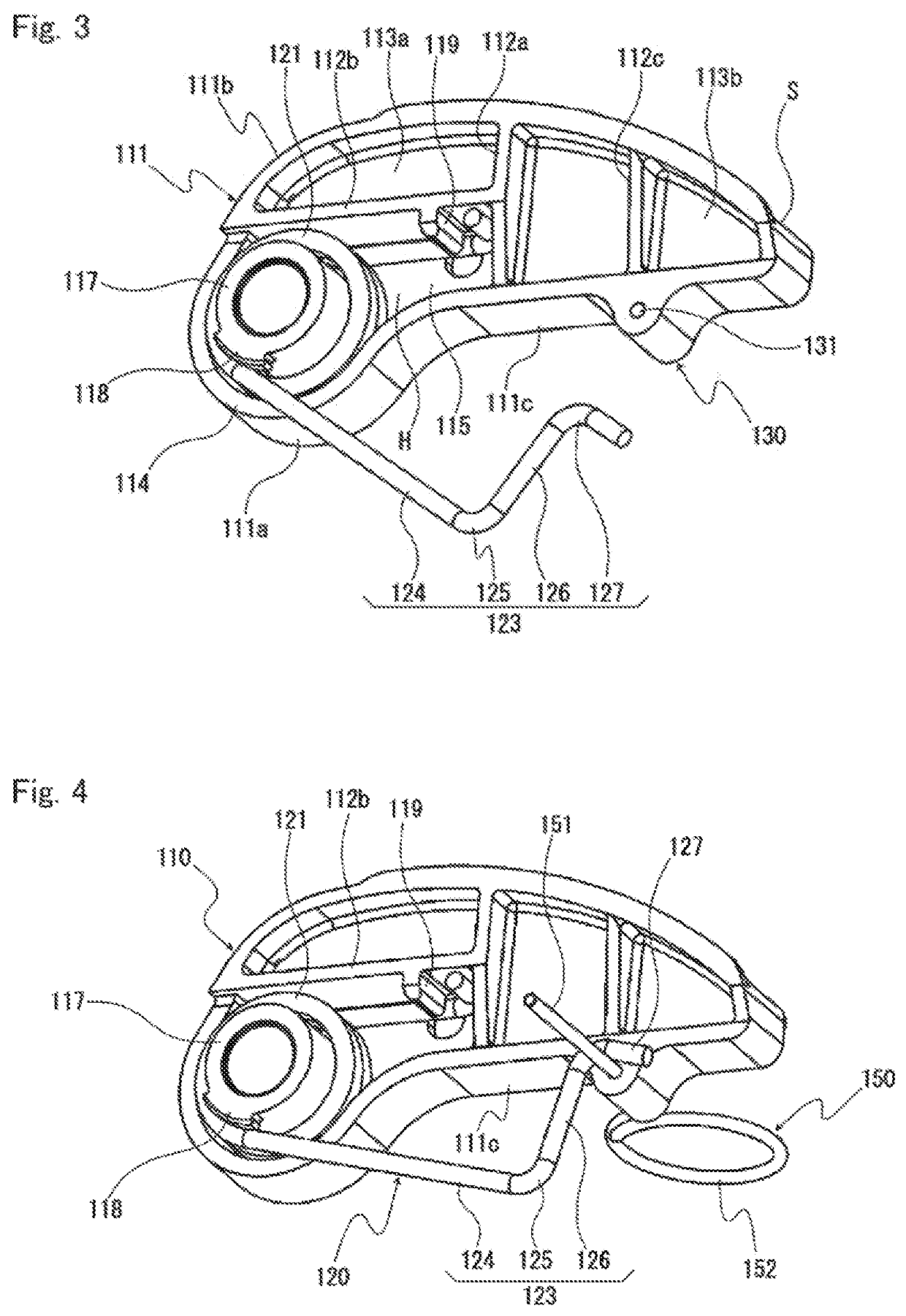

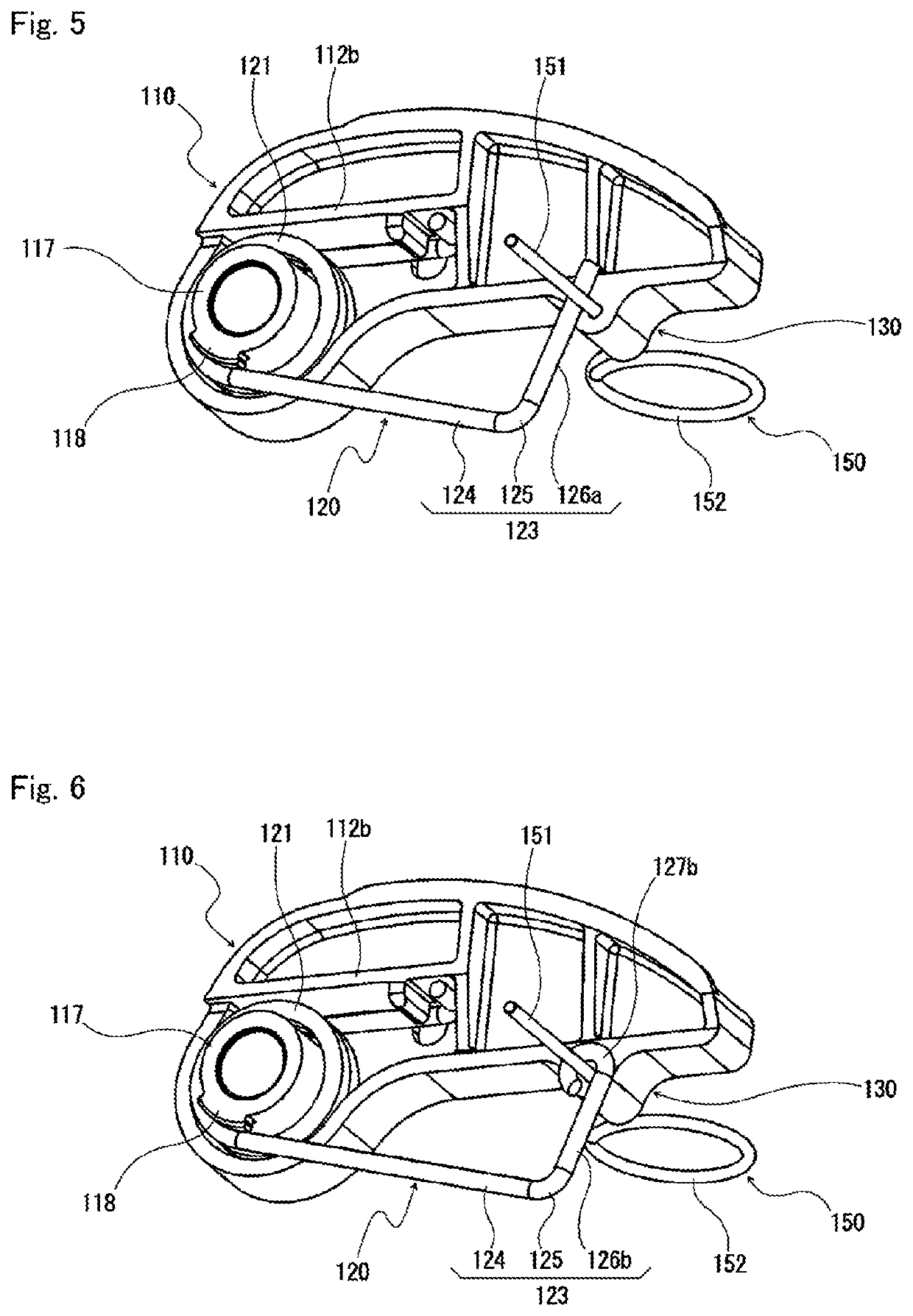

Tensioner lever

An object of the present invention is to provide a tensioner lever that can reduce vibration and noise when the chain runs, and realize smooth attachment into an engine with minimal deformation of the lever body with a simple configuration. A tensioner lever according to the present invention includes a lever body and a torsion coil spring pressed the lever body toward the chain. The lever body includes a stopper member mounting part where a stopper member by which the support arm of the torsion coil spring is locked and which retains the torsion coil spring in a compressed state is removably mounted. The stopper member mounting part is located closer to a distal end of the lever body than a center position in the longitudinal direction of the lever body, or a center of gravity position of the lever body.

Owner:TSUBAKIMOTO CHAIN CO

Tensioner lever

An object of the present invention is to provide a tensioner lever that can reliably prevent displacement or detachment of a torsion coil spring, prevent the torsion coil spring from interfering with an attachment surface, and allow smooth attachment of the tensioner lever to the attachment surface. The tensioner lever includes a lever body having a shoe surface, and a torsion coil spring pressing the shoe surface toward a chain. The lever body includes a base part and a cylindrical boss. The torsion coil spring includes a helical part loosely fitted on an outer circumferential surface of the boss, a pressing arm making contact with the lever body, and a support arm supported on the attachment surface. The outer circumferential surface of the boss includes a restricting protrusion formed at a position closer to the attachment surface than the helical part.

Owner:TSUBAKIMOTO CHAIN CO

Strainer for oil supply mouth

The invention is an object of the invention to provide a strainer for an oil supply mouth, preventing the oil flowing when supplying the oil from colliding with the float so as to accurately detect the height of the liquid level. The strainer for an oil supply mouth of the invention has a guide hole equipped in vertical directions and a float for an oil level gauge passing movably in vertical directions through this guide hole. When the oil comes up to an at least reference liquid level, the float is received at a lower end within the guide hole.

Owner:DAIWA SEIKO CORPORATION +1

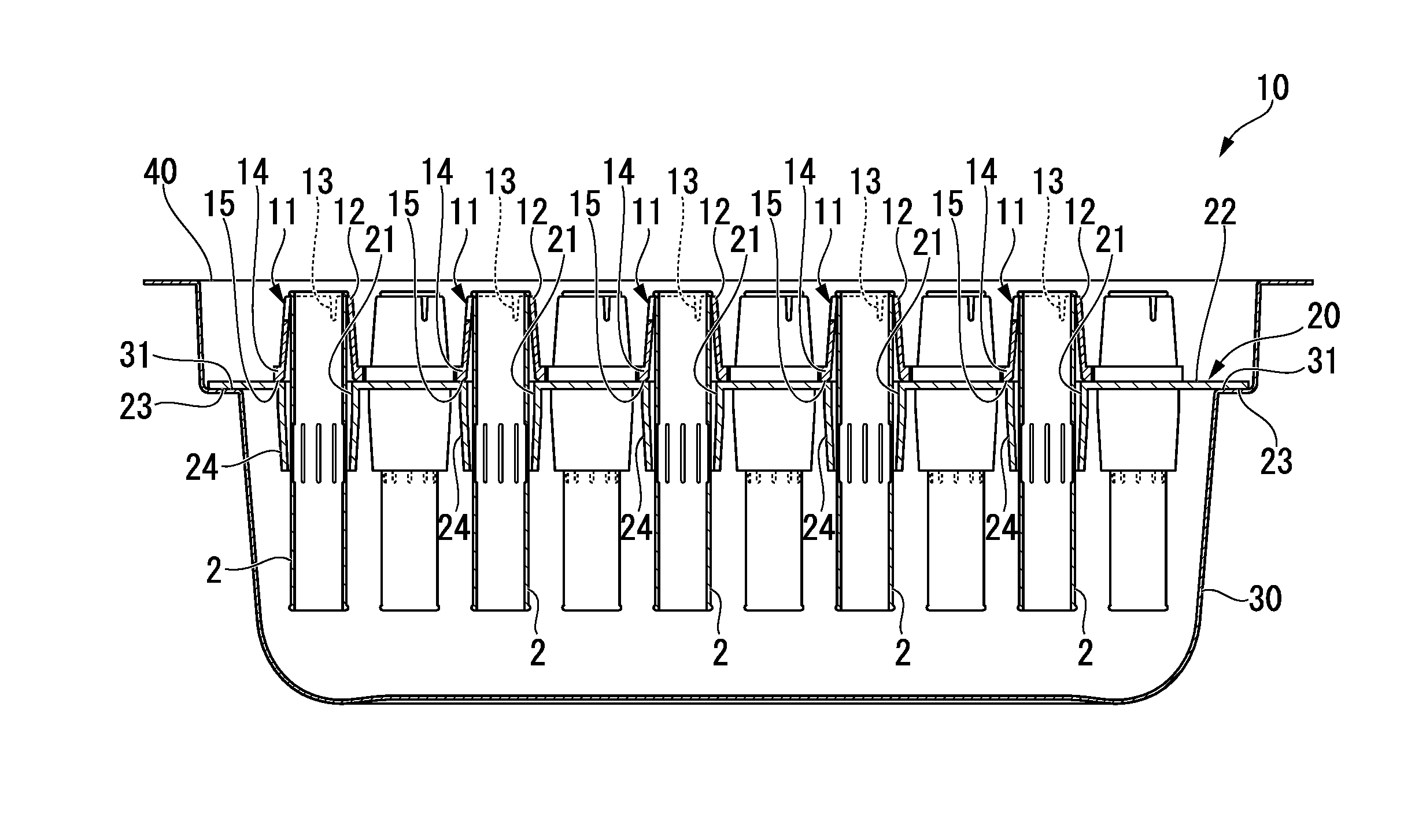

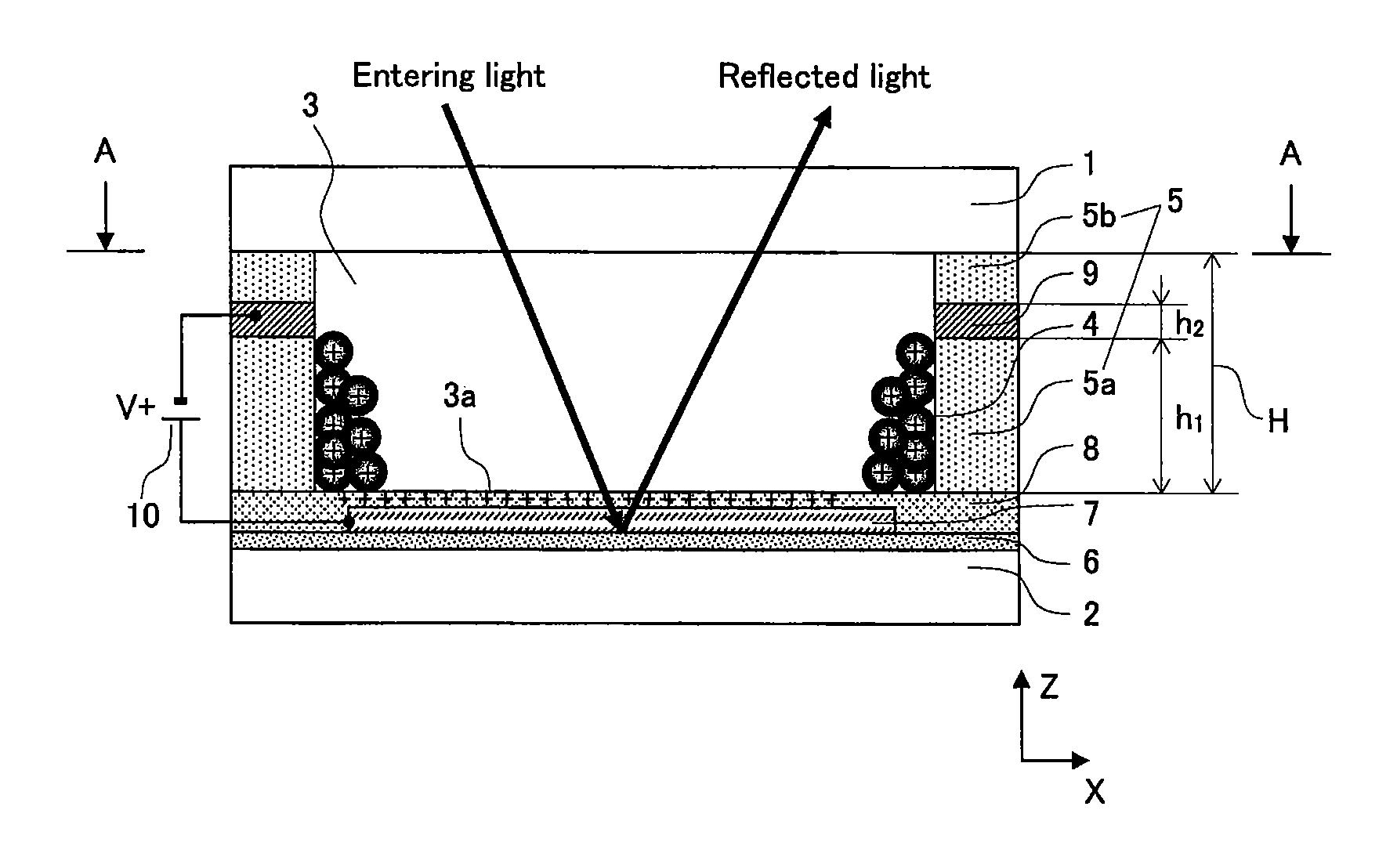

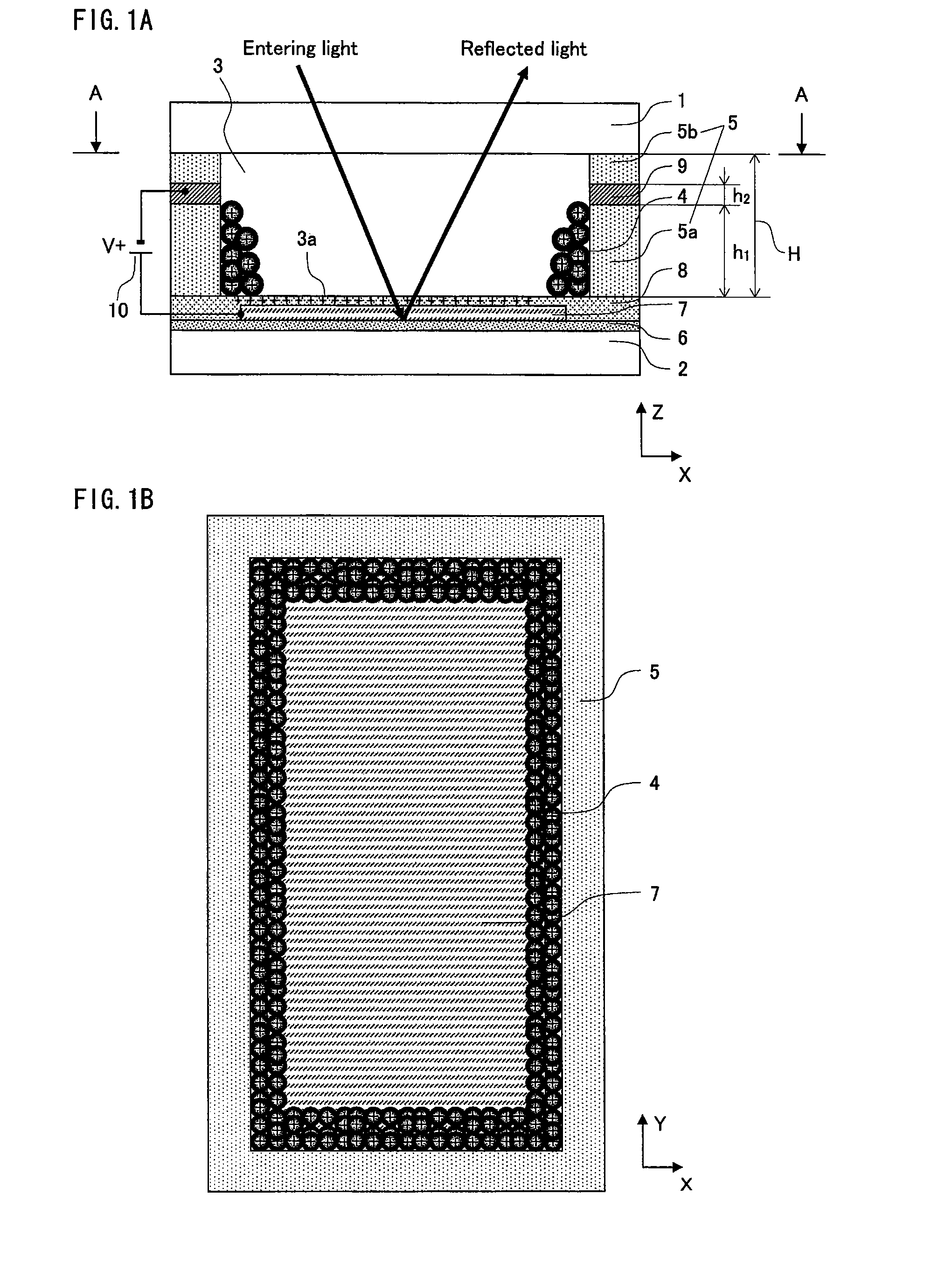

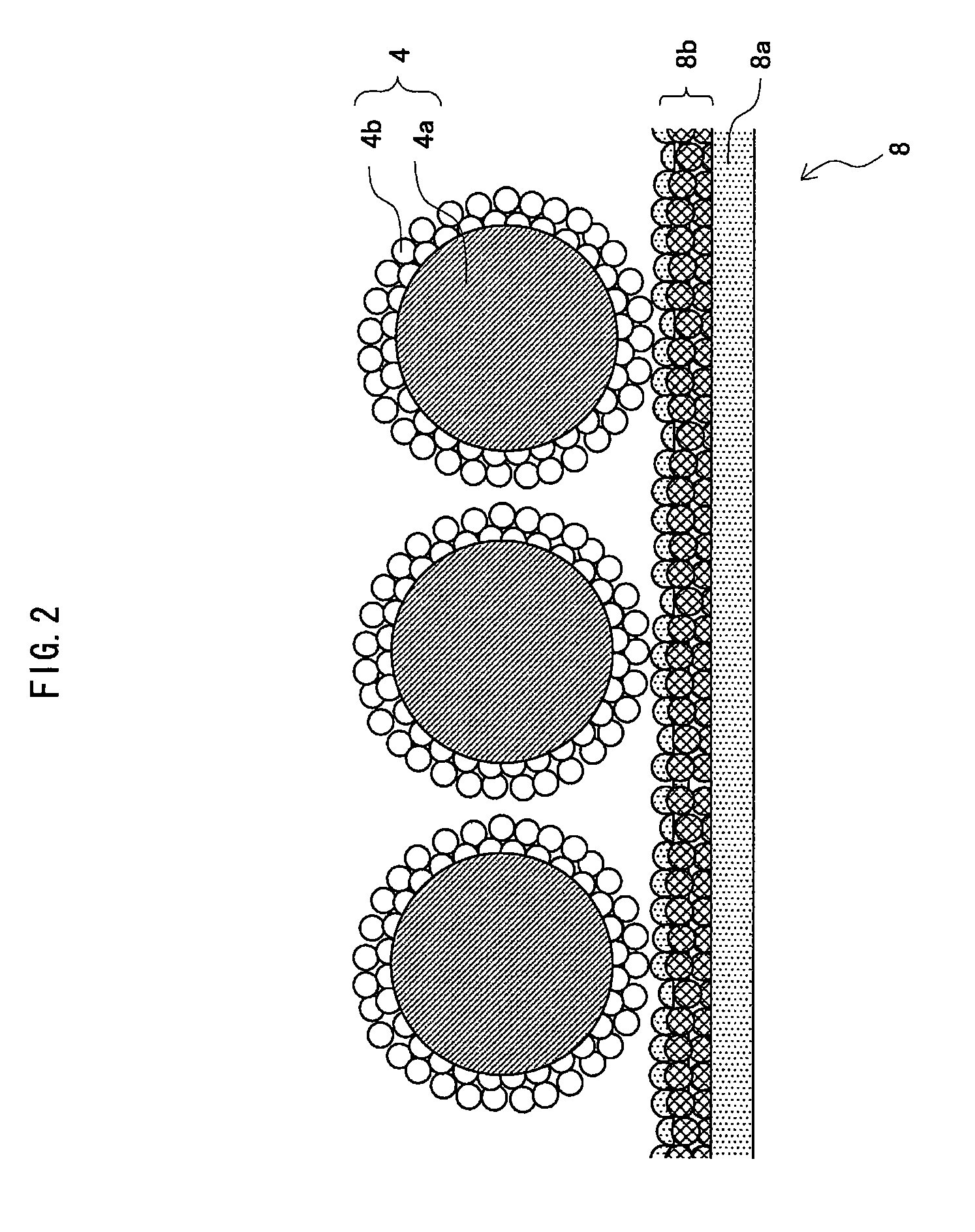

Display device and method of manufacture thereof

InactiveUS8730278B2Increase reflectionIncrease contrastSolid-state devicesDiodeDisplay deviceCell space

Disclosed is a paper-like display device. A front substrate 1 and a back substrate 2 are disposed to face each other with a space therebetween, and partition walls 5 partition the space vertically (Y) and horizontally (X) into cell spaces 3. A predetermined quantity of black-colored particles 4 is enclosed within each cell space 3. A white reflective layer 6, first electrodes 7, and an insulating layer 8 are formed on the inner surface of the back substrate 2. Each first electrode 7 is separately formed for a different pixel and extends along the bottom surface of the cell space 3. Each partition wall 5 includes an upper partition wall 5b, facing the front substrate 1, and a lower partition wall 5a, facing the back substrate 2. A second electrode 9 serving as a common electrode is formed between the upper partition wall 5b and the lower partition wall 5a.

Owner:PANASONIC CORP

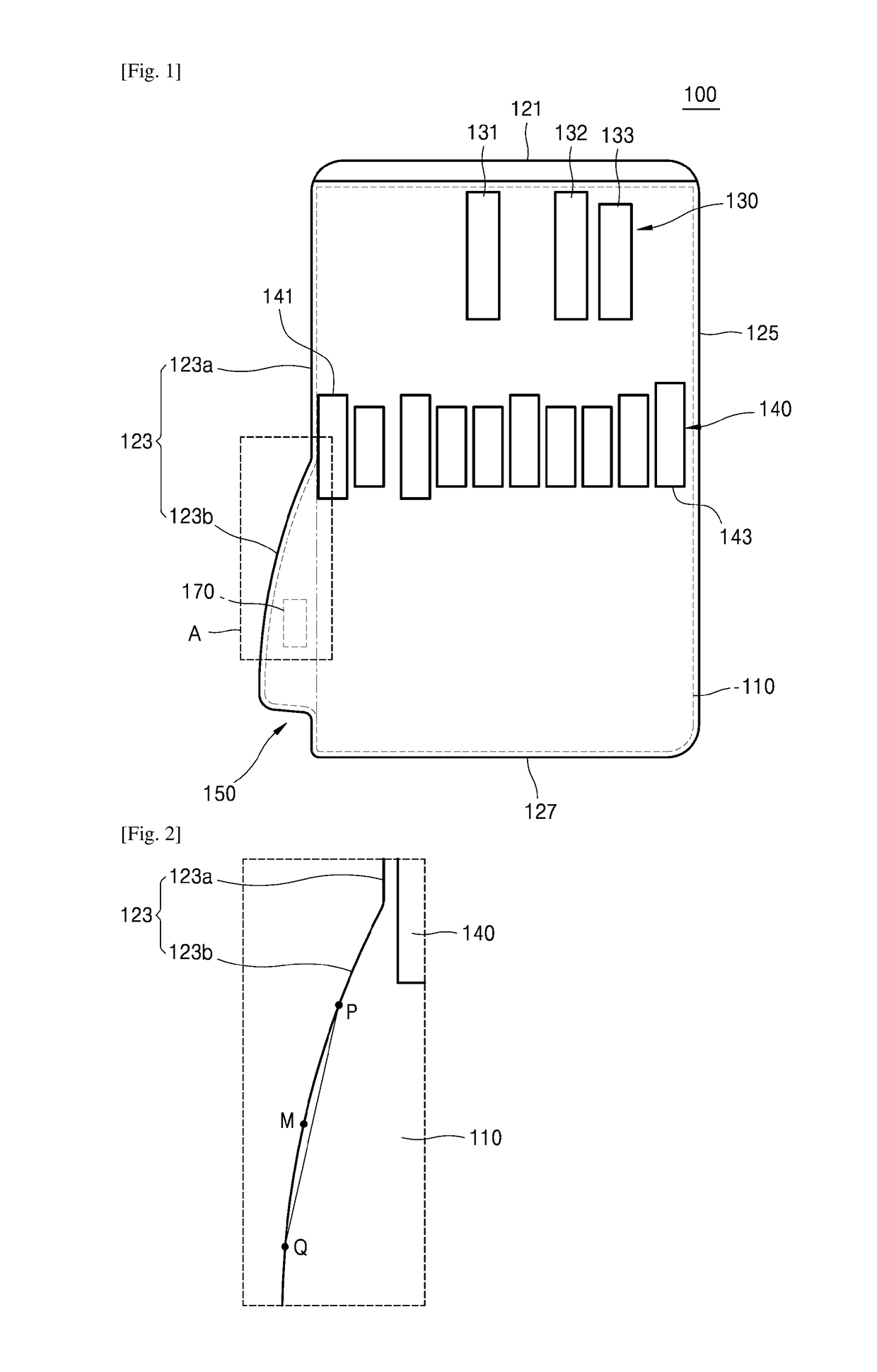

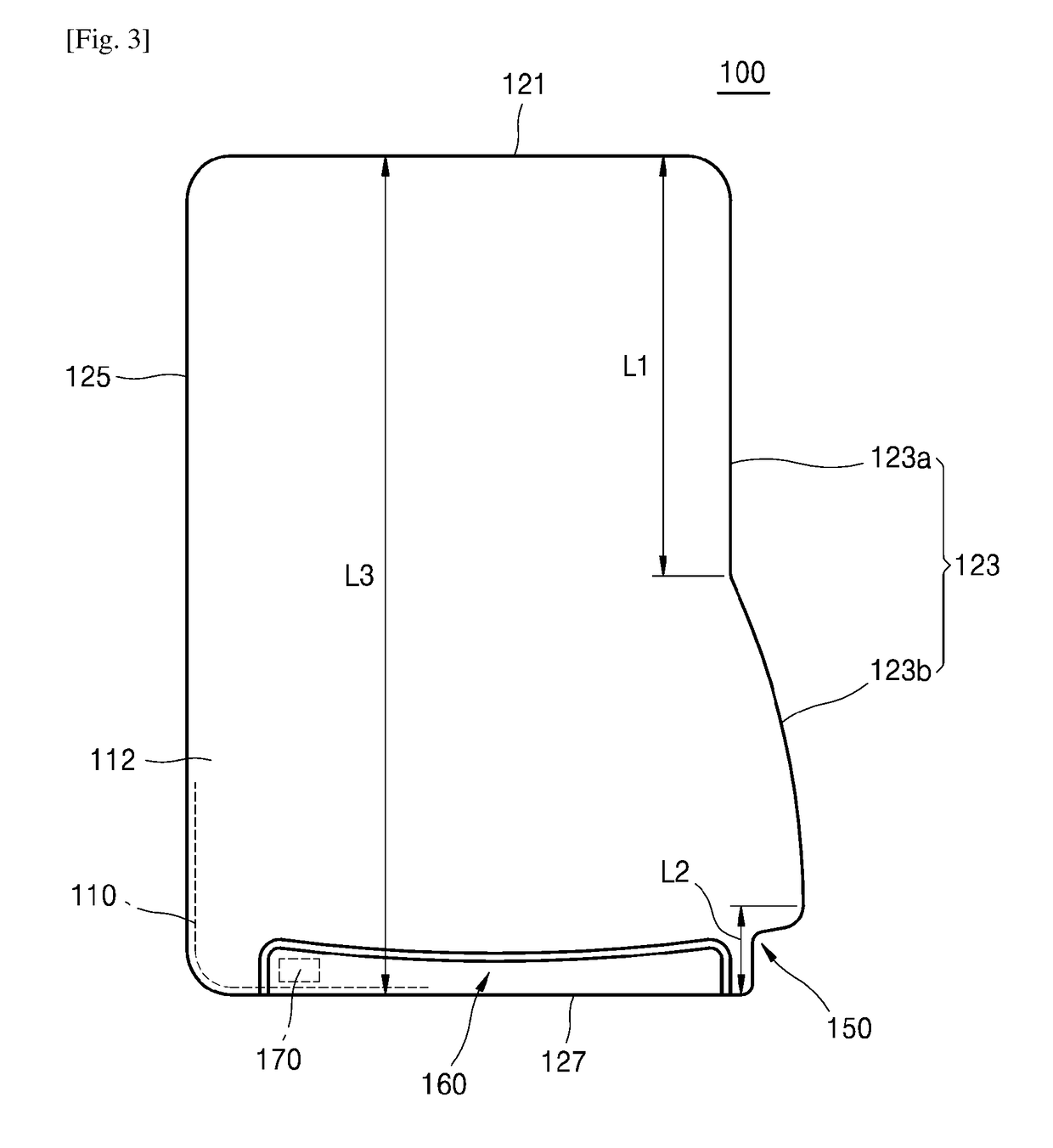

Memory card having multi-row terminals

ActiveUS10380055B2Easy resetReduce harmConveying record carriersStatic storageControl powerMemory cards

Provided is a memory card, which includes two pairs of opposite edges, first row terminals arranged adjacent to an insertion-side edge of the memory card, and second row terminals arranged apart from the insertion-side edge of the memory card. The memory card can be easily reset in terms of software without controlling power supply in terms of hardware. Also, the memory card can be smoothly attached and detached during insertion of the memory card into a socket and reduce damage to a device.

Owner:SAMSUNG ELECTRONICS CO LTD

Tensioner lever

An object of the present invention is to provide a tensioner lever that can reduce vibration and noise when the chain runs, and realize smooth attachment into an engine with minimal deformation of the lever body with a simple configuration. A tensioner lever according to the present invention includes a lever body and a torsion coil spring pressed the lever body toward the chain. The lever body includes a stopper member mounting part where a stopper member by which the support arm of the torsion coil spring is locked and which retains the torsion coil spring in a compressed state is removably mounted. The stopper member mounting part is located closer to a distal end of the lever body than a center position in the longitudinal direction of the lever body, or a center of gravity position of the lever body.

Owner:TSUBAKIMOTO CHAIN CO

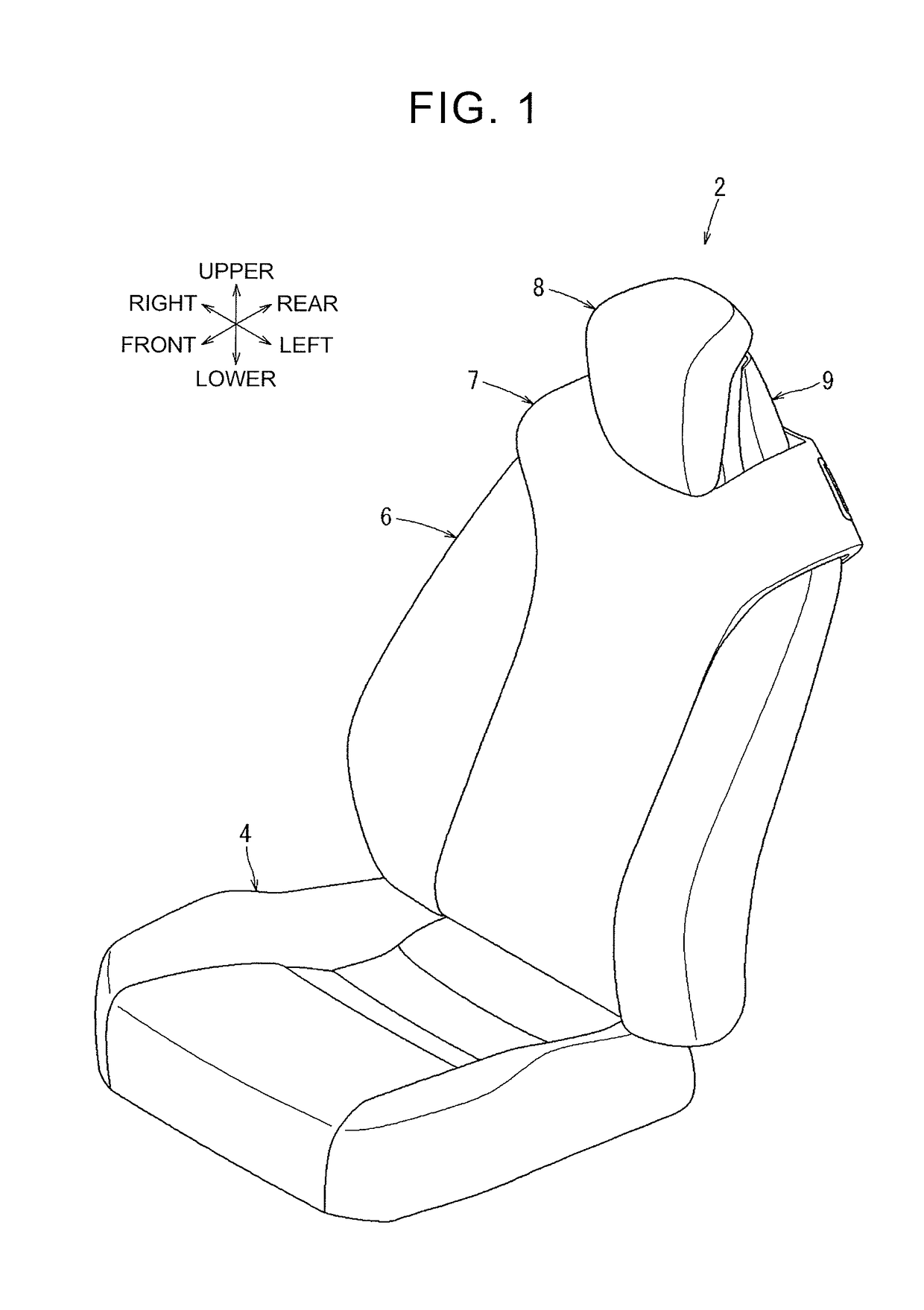

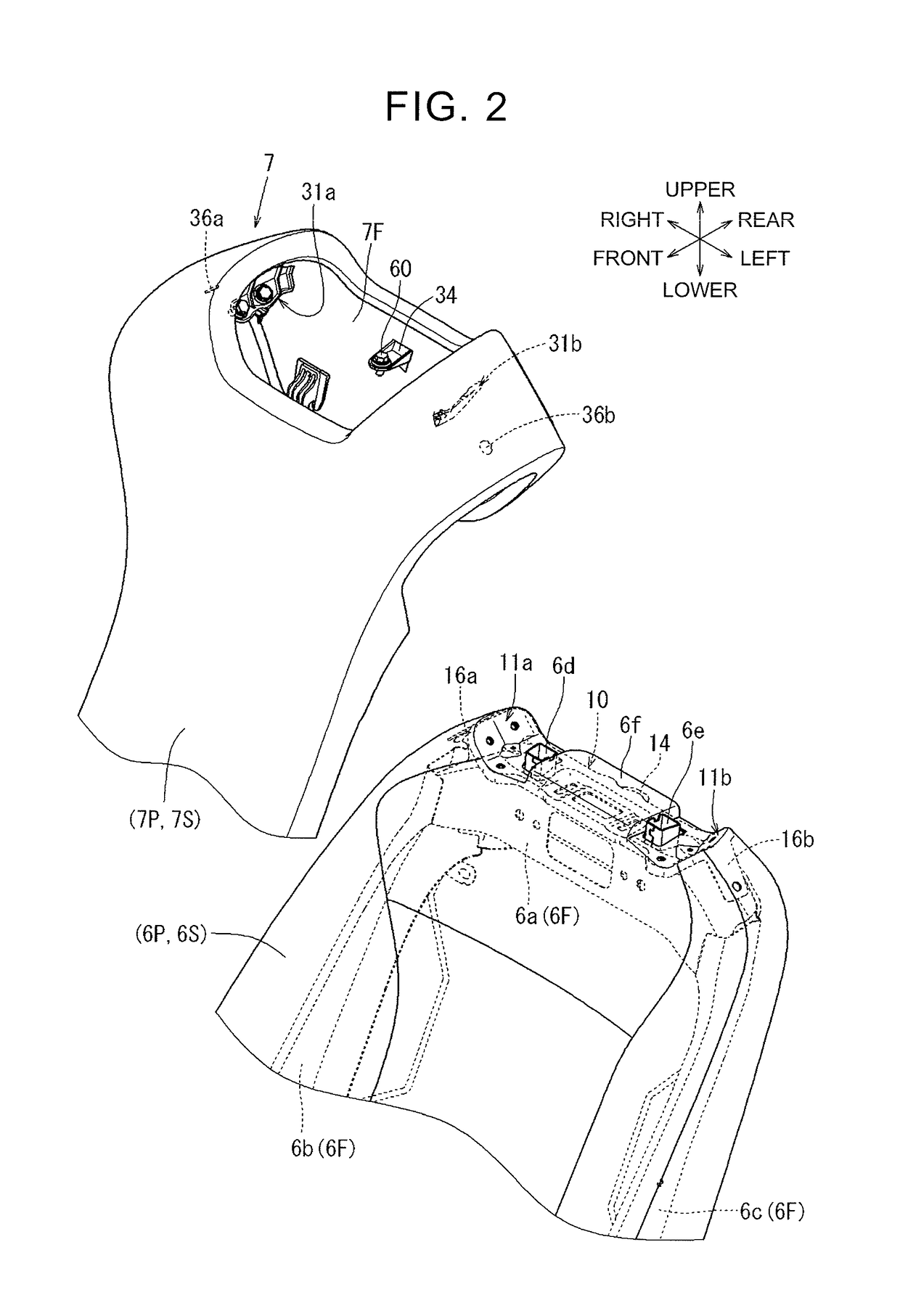

Fastener for fastening a resin component

InactiveUS20180023608A1Reduce manufacturing costEasily employedVehicle seatsSpringsEngineeringFlange

Provided is a fastener for fastening a resin component. The fastener is interposed between an insertion hole provided in the resin component and a fastening member inserted through the insertion hole. The fastener includes: an insertion portion having a tubular shape and insertable through the insertion hole in a non-press-fitted state; a flange portion protruding radially outward of the insertion portion from an end portion of the fastener; and a recessed portion provided on an outer surface of the insertion portion. In the state where the insertion portion is inserted through the insertion hole, the flange portion is disposed outside the insertion hole, and a projecting portion protruding from an inner surface of the insertion hole is disposed in the recessed portion of the insertion portion.

Owner:TOYOTA BOSHOKU KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com