Patents

Literature

81results about How to "Smooth design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

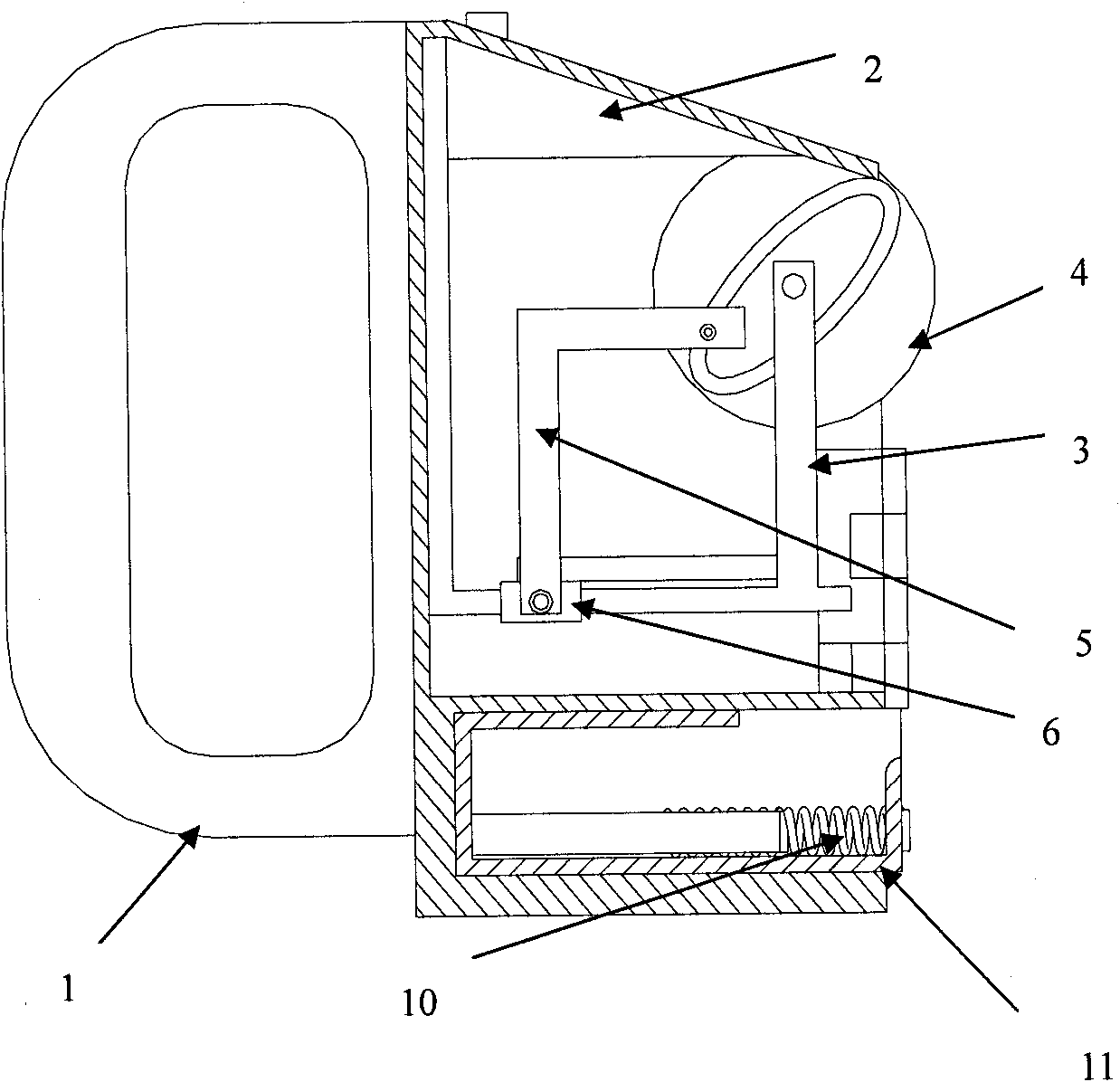

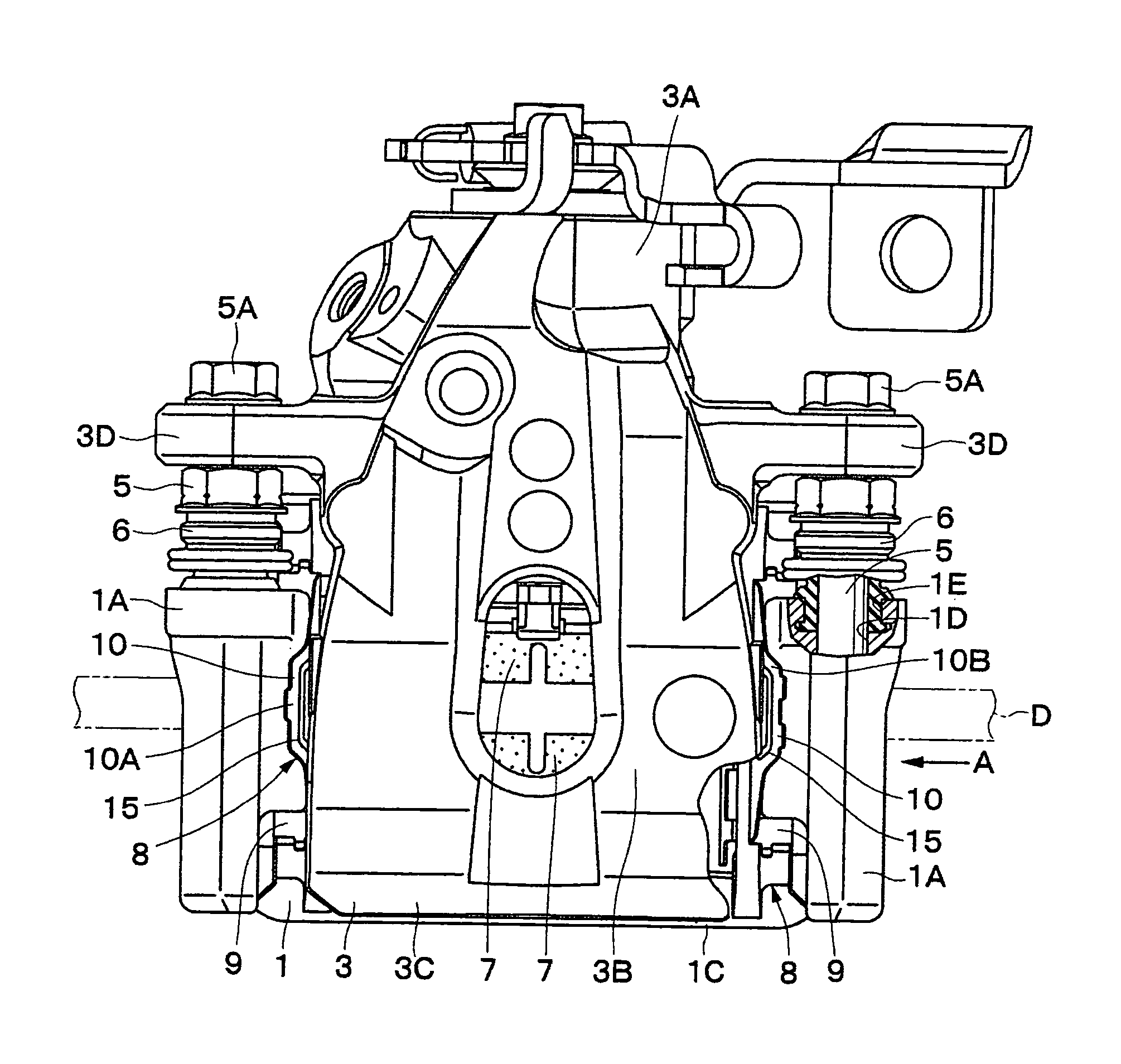

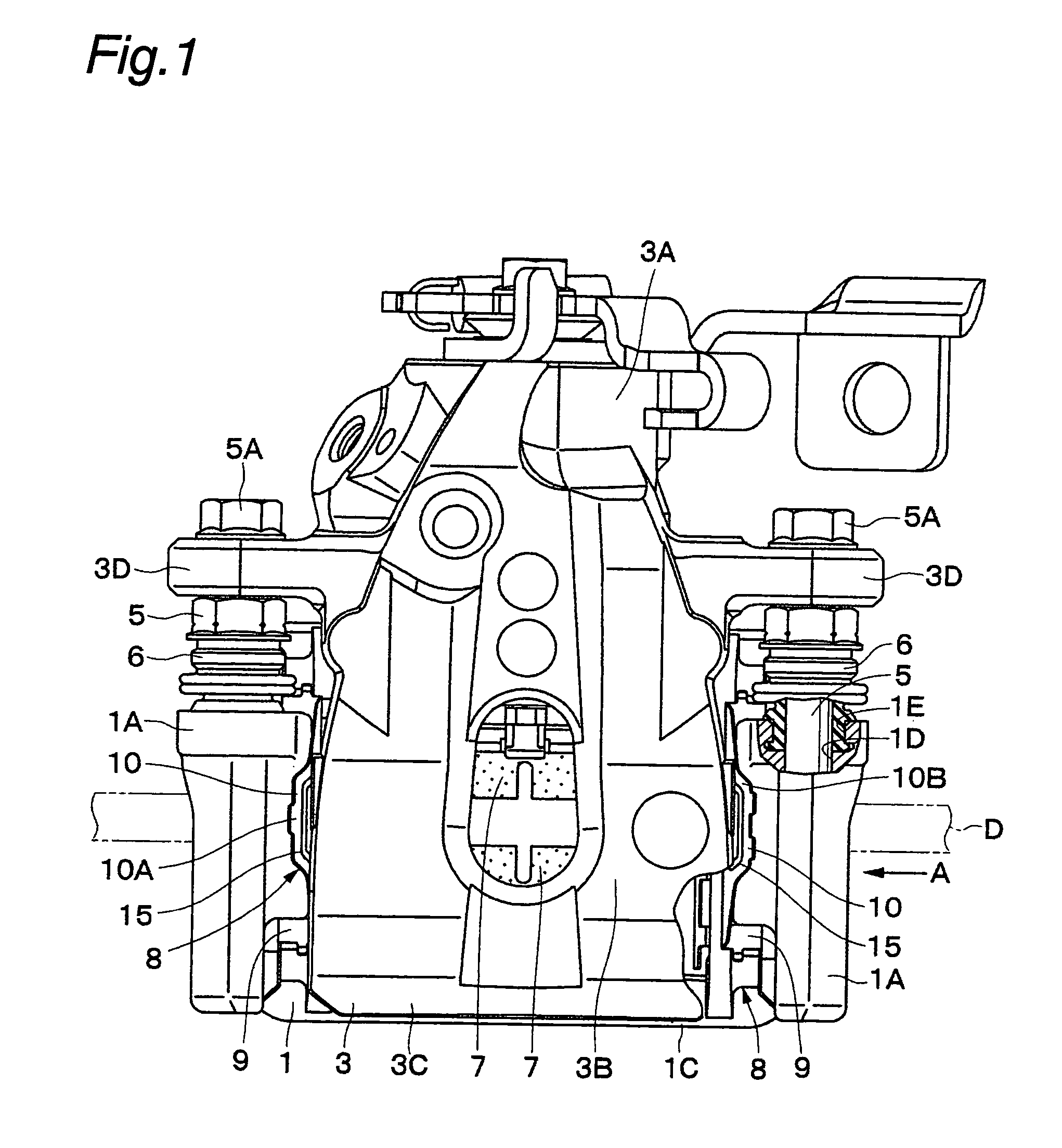

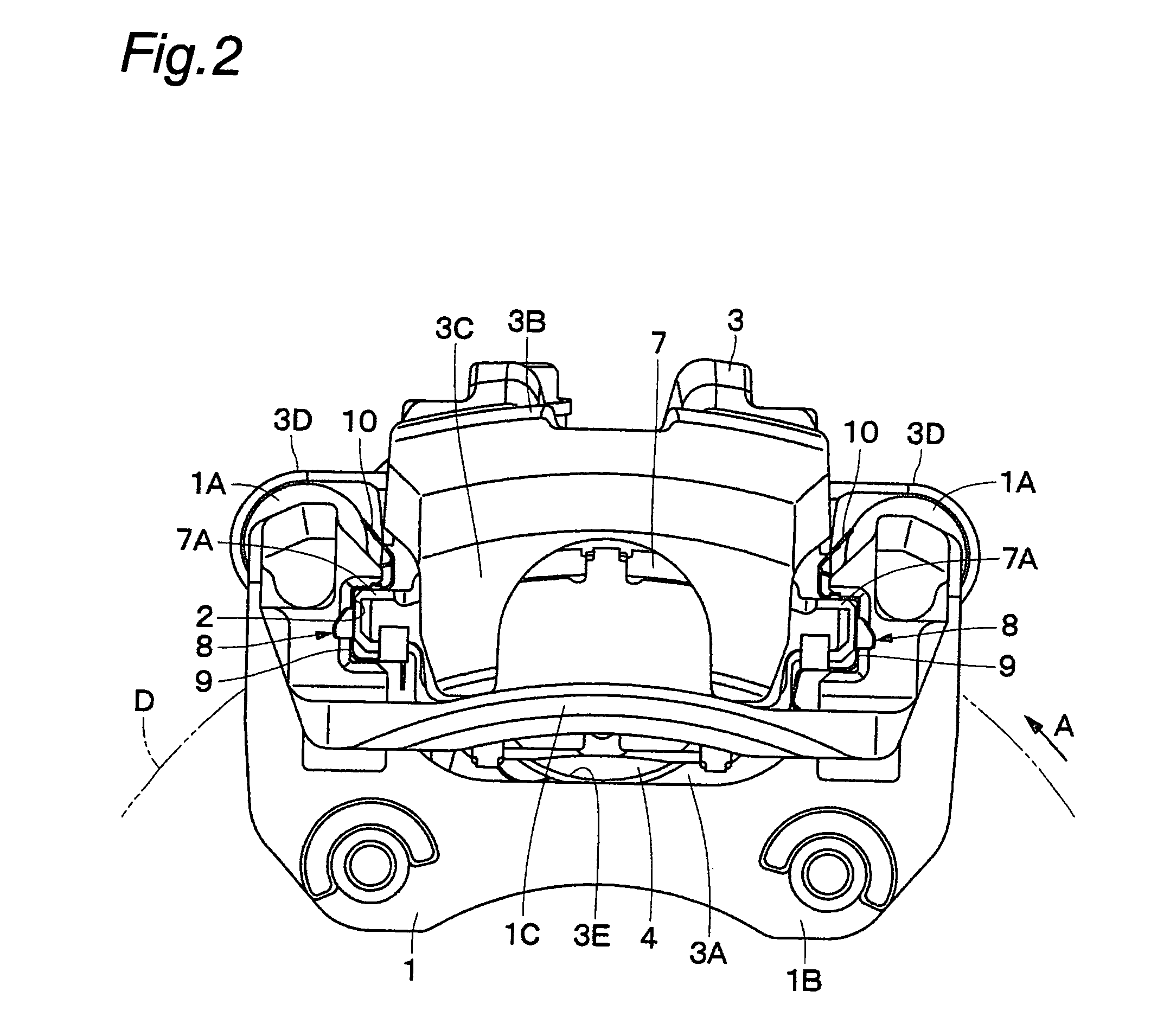

Disk brake

ActiveUS20070251772A1High strengthAvoid deformationAxially engaging brakesSlack adjustersMechanical engineeringDisc brake

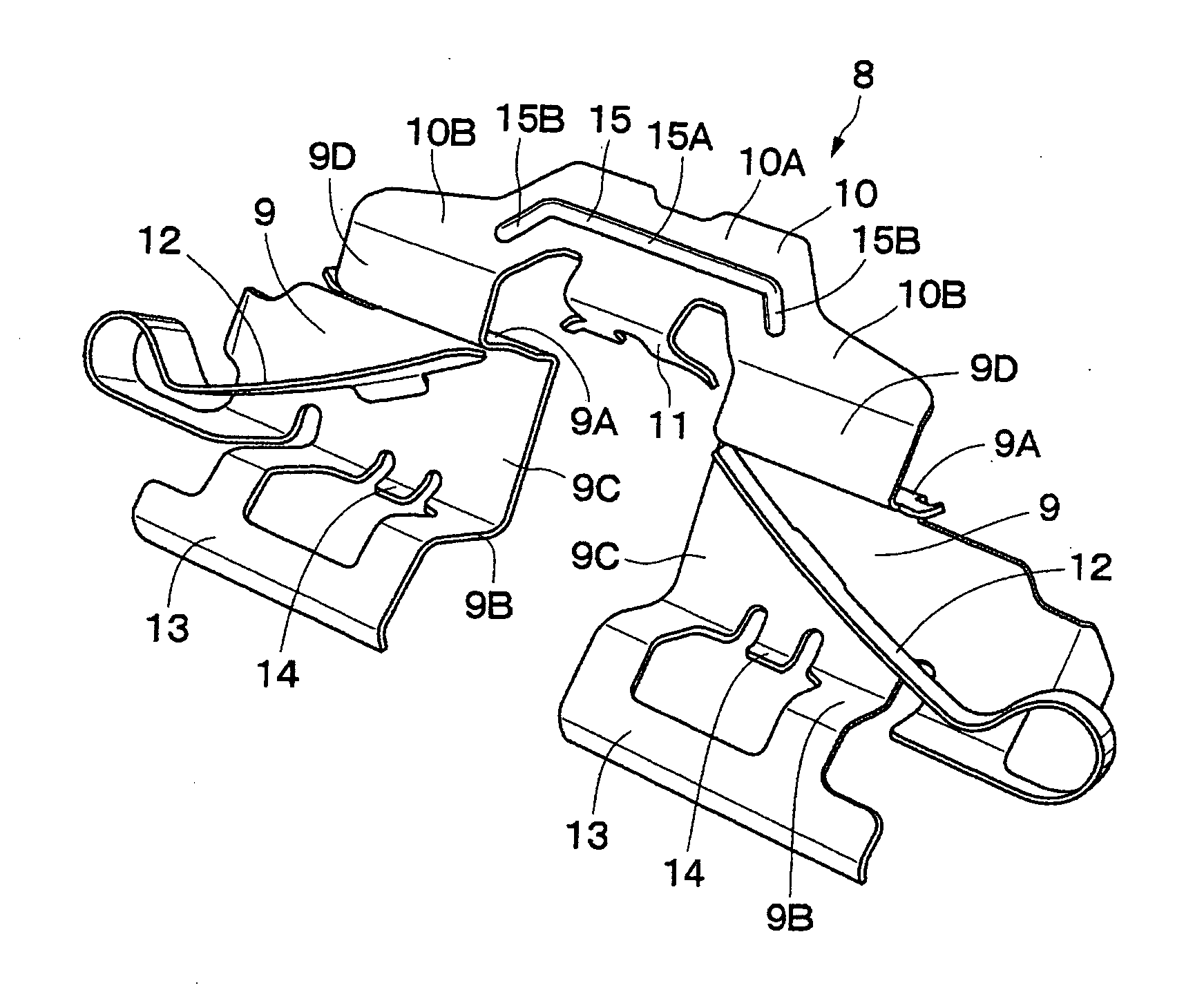

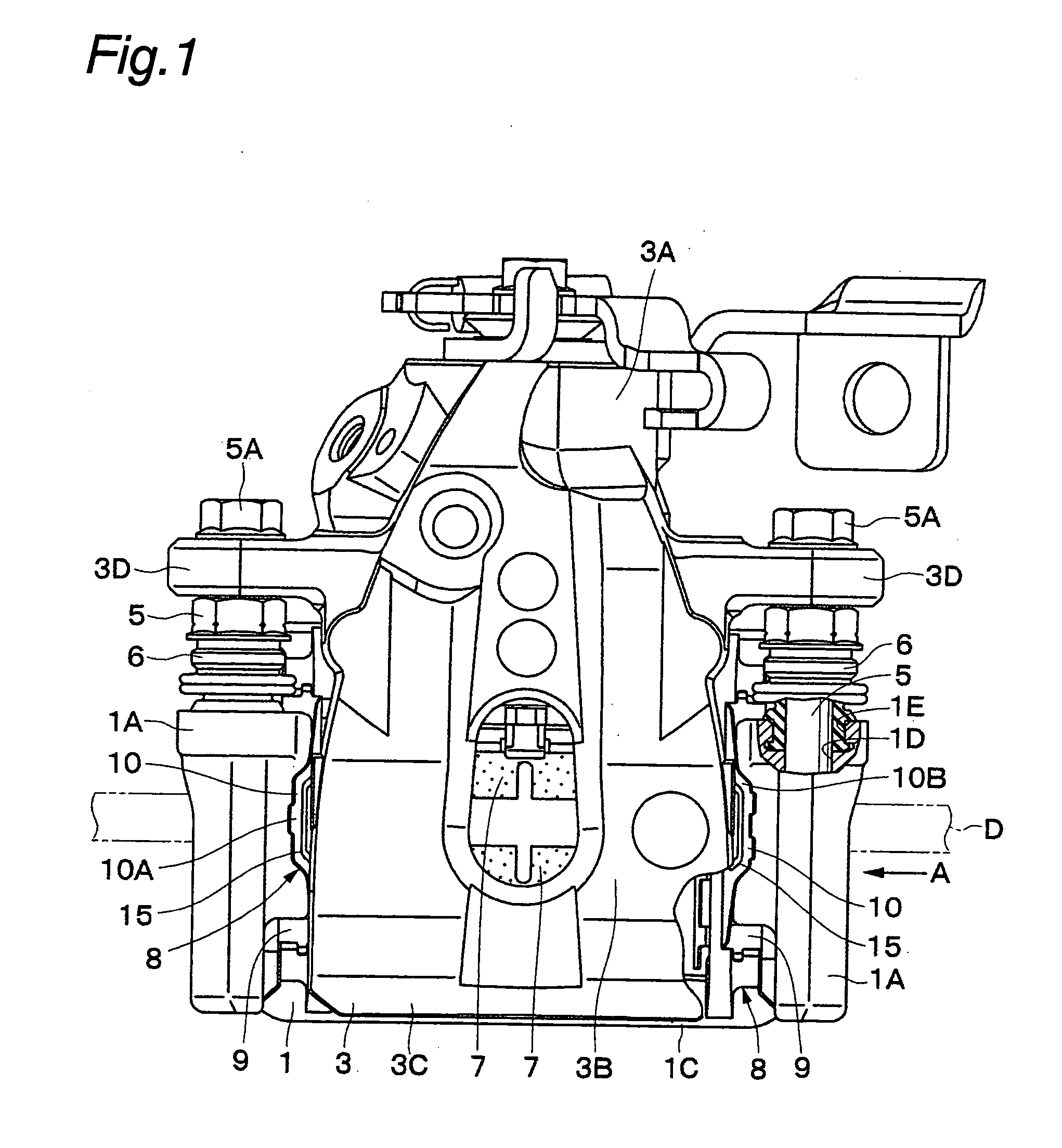

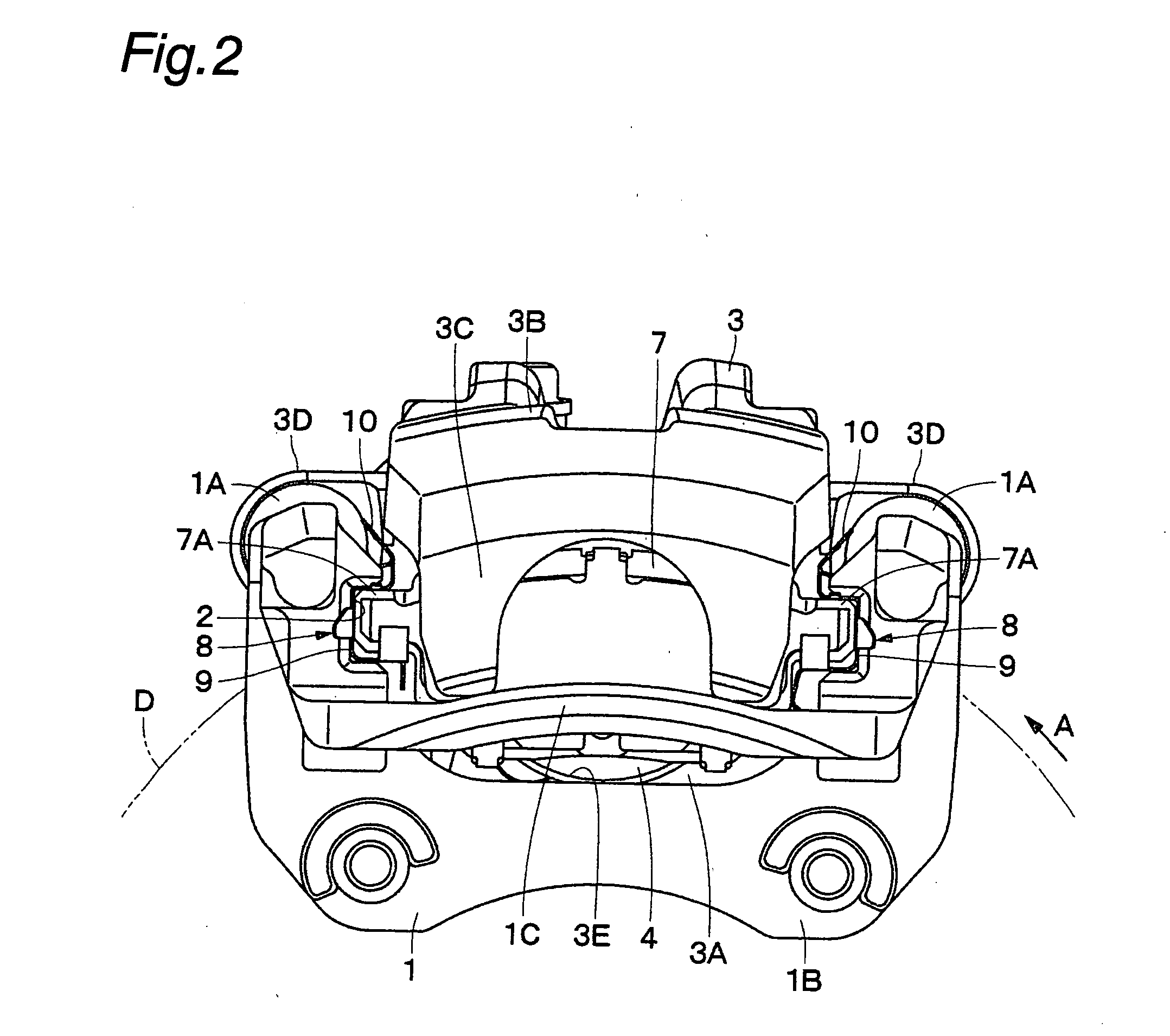

The strength and rigidity of pad springs are increased with a simple structure to prevent deformation and so forth of the pad springs caused by external force. A mounting member 1 is provided with pad springs 8 for resiliently supporting friction pads 7. Each pad spring 8 has guide plates 9, a connecting plate 10, an engagement plate 11, radially urging portions 12, circumferentially urging portions 13, reinforcement 15, etc. The reinforcement 15 includes a rectilinear reinforcement 15A formed on a flat plate portion 10A of the connecting plate 10 by embossing, for example, and oblique reinforcements 15B formed on joint portions 10B of the connecting plate 10. Thus, the joint portions 10B and so forth of the pad springs 8 can be prevented from being deformed by external force when the brake is activated or during assembling operation, for example, and hence it is possible to prevent positional displacement of the guide plates 9, etc. that would otherwise be caused by the deformation of the joint portions 10B.

Owner:HITACHI ASTEMO LTD

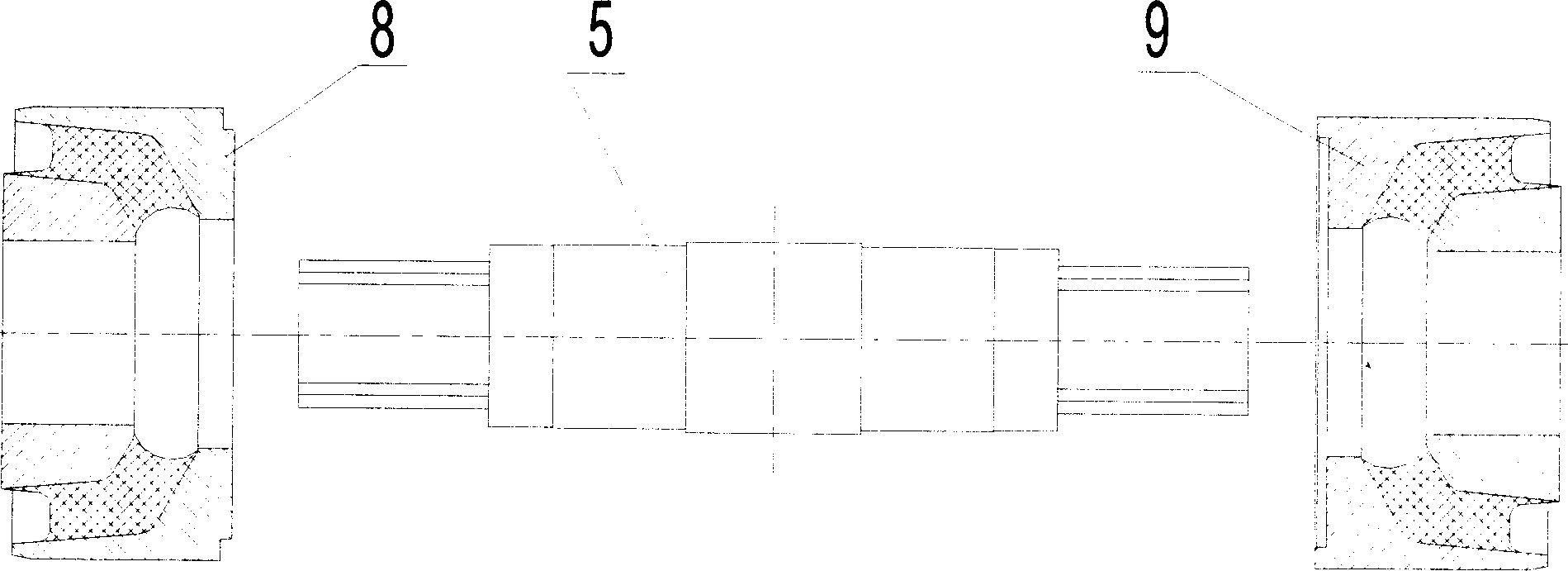

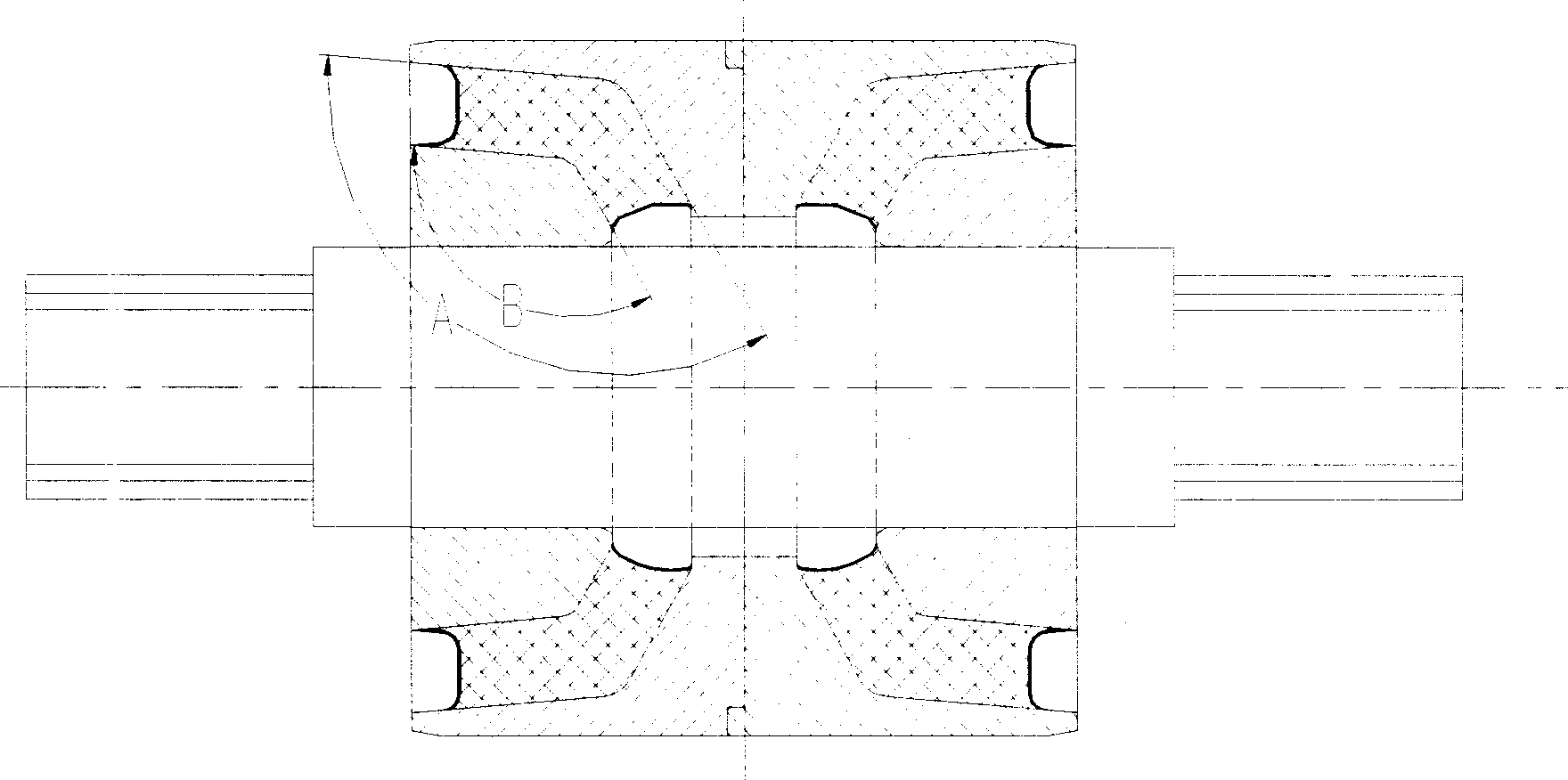

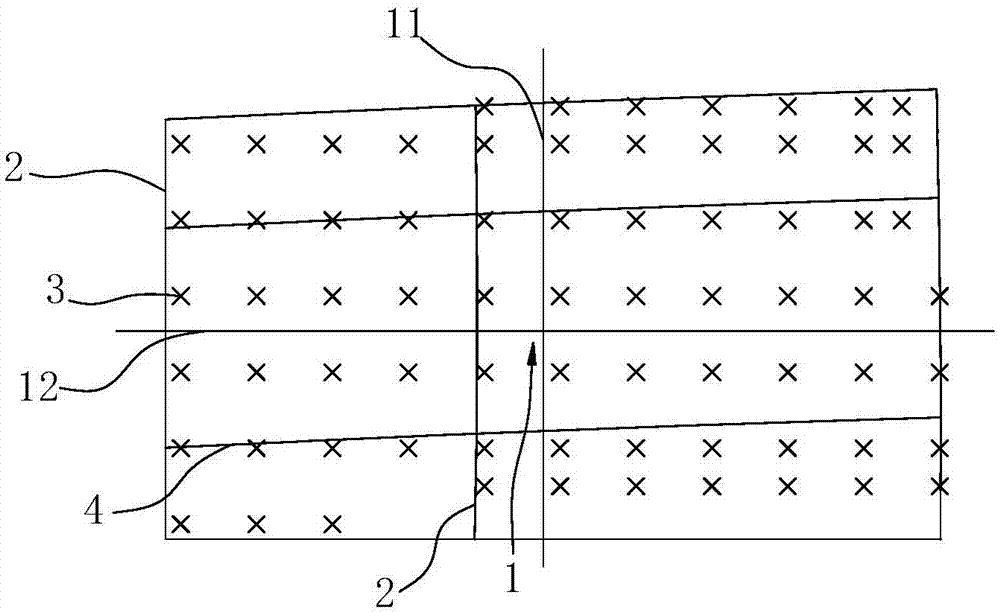

Axial precompression method for combined ball hinged rubber elastic element and product obtained thereby

ActiveCN1828084AImprove fatigueSmooth designElastic dampersRailway couplingsElastomerBiomedical engineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

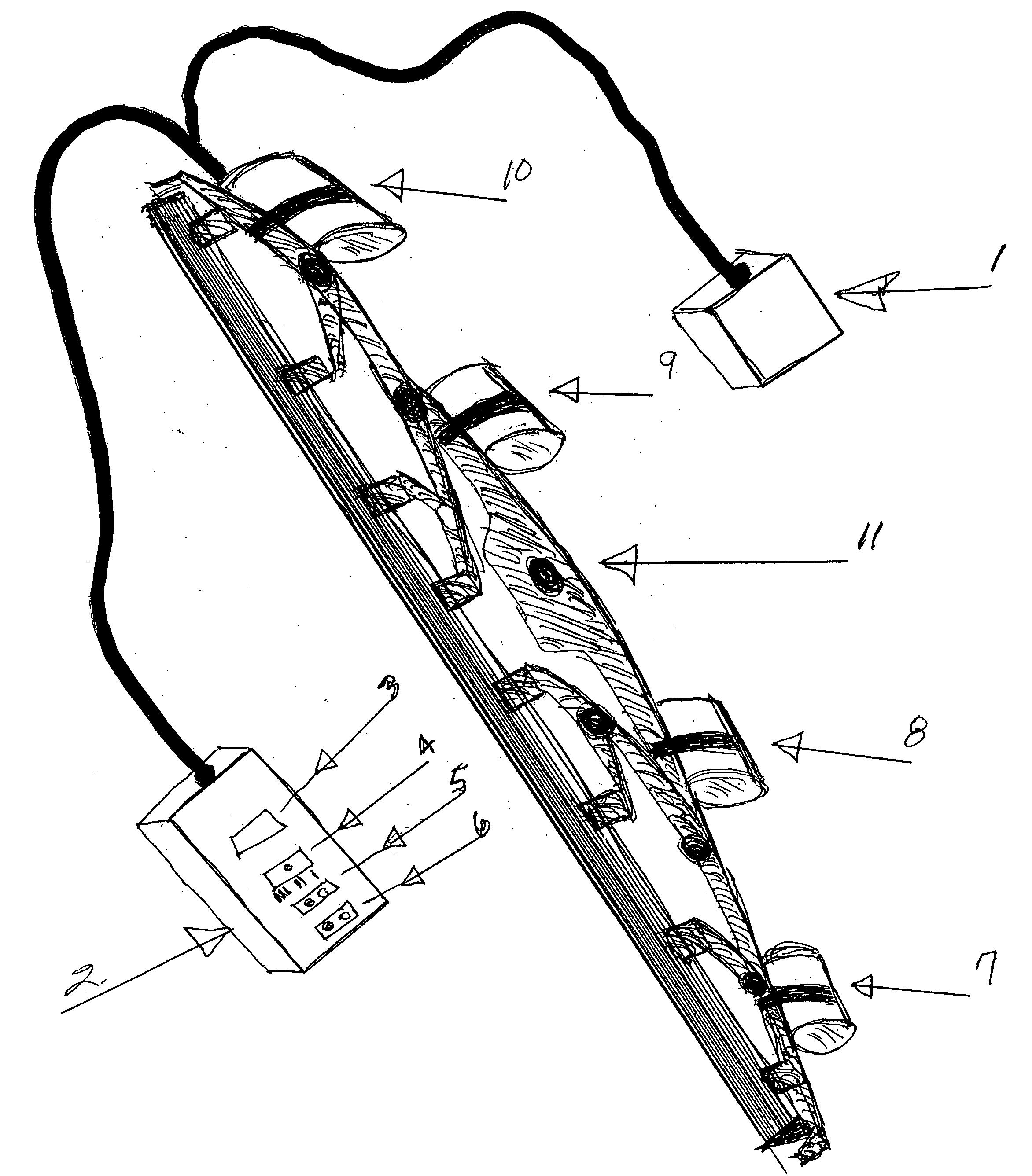

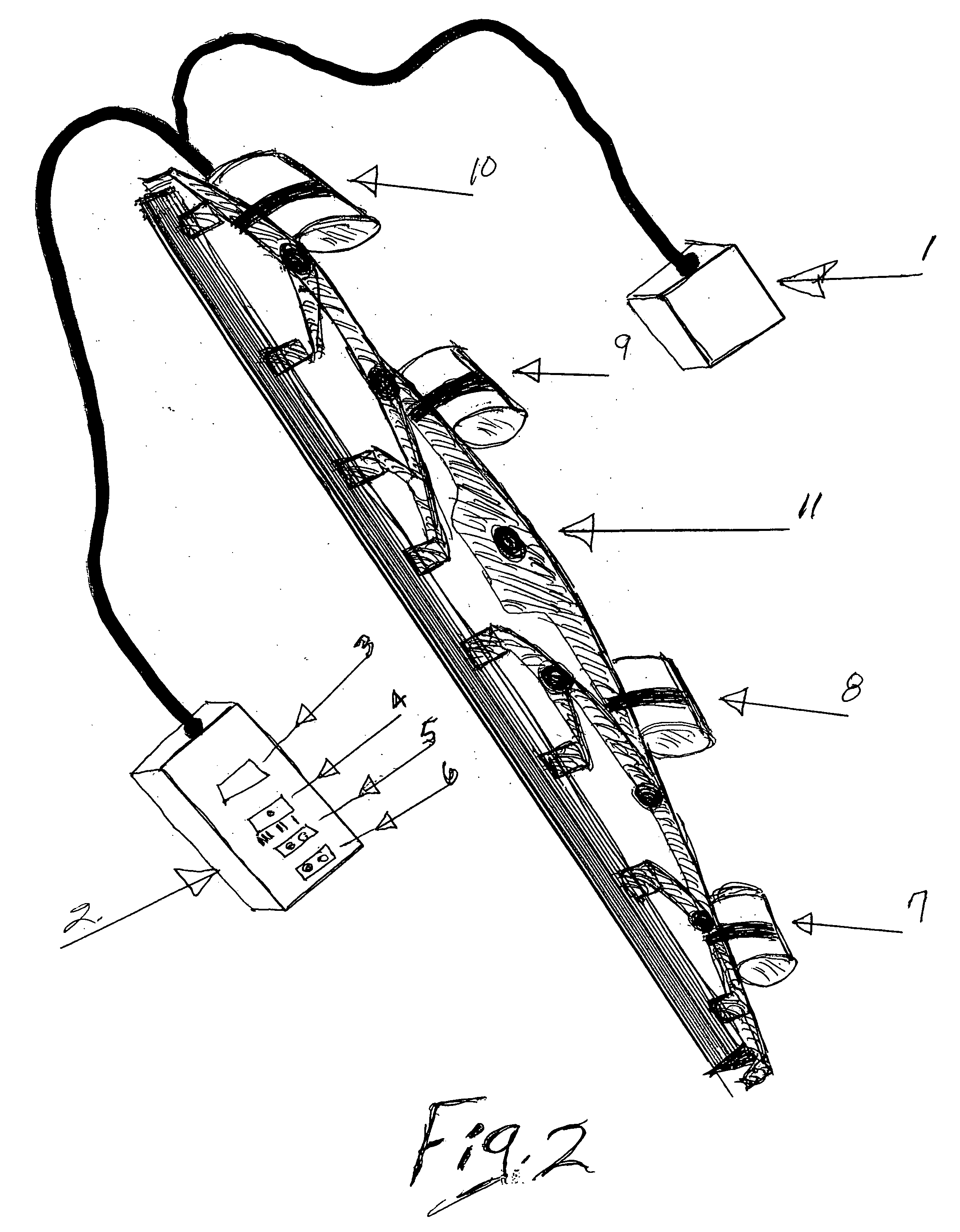

Vibrating wiper blade

InactiveUS20080034531A1Easy to disassembleAvoiding hoppingWindow cleanersVehicle cleaningElectric machineryEngineering

A vibrating wiper blade that is functional and attractive. A standard wiper blade can be engineered to accommodate vibrating motors in a sleek and decorative design. Attached to the wiper blades and vibrating motors are tailor made and smoothly attached and designed electrical wiring. The vibrating motors may be engineered on wiper blades from the manufacturing stage, or provide at outlet stores and travel plazas as clip-on models with wiring attached under the hood, and / or controls quickly extended through a driver window. The vibrating motors will facilitate the removal of ice and snow from windshield wiper blades while avoiding hopping and skipping on the windshield. Tailor engineered models may be designed with a direct vibrating spring loaded pin or pistion to strike the wiper blade head. All of this is designed at minimal cost and complexity.

Owner:BEAVER BENNIE MAX

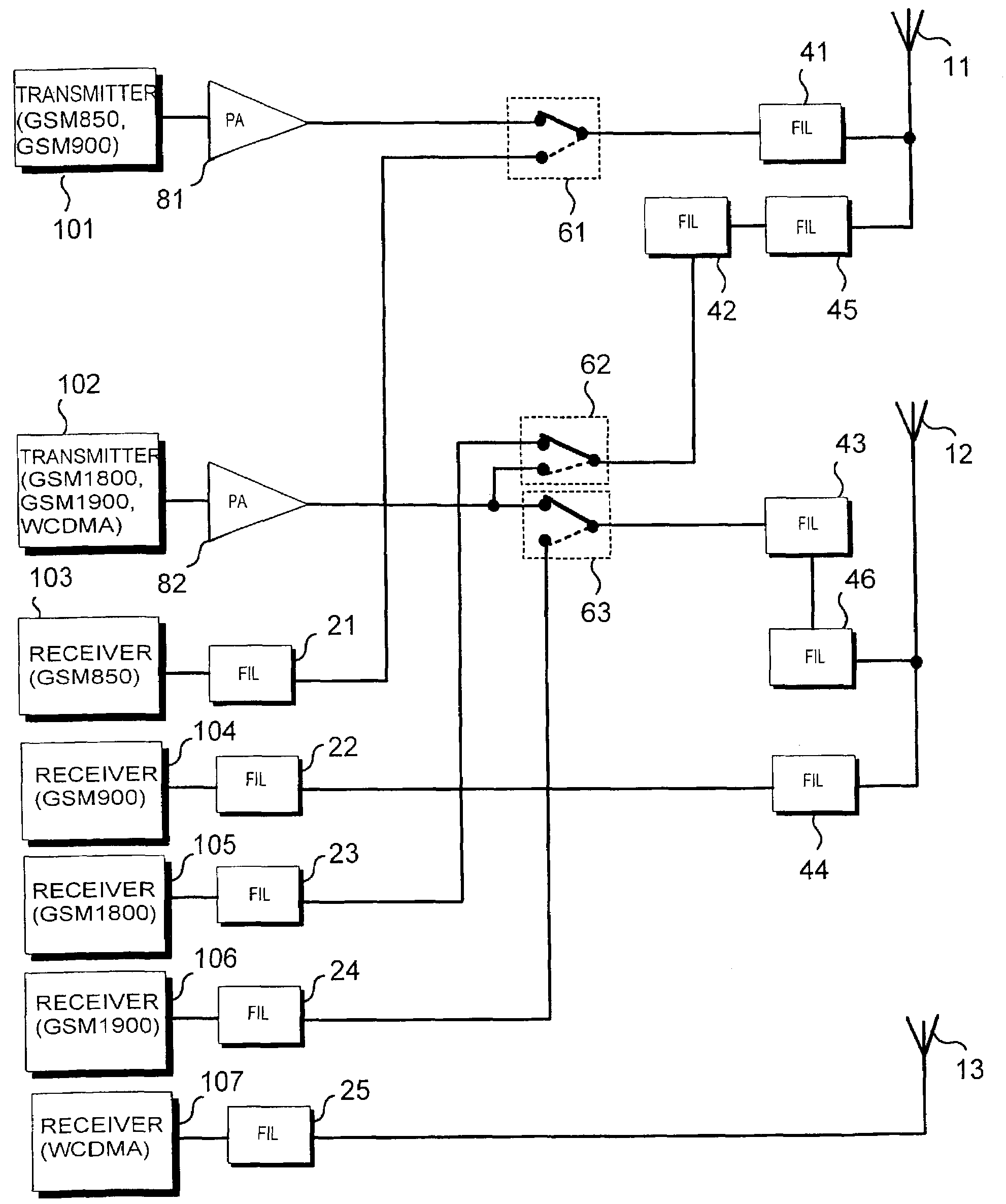

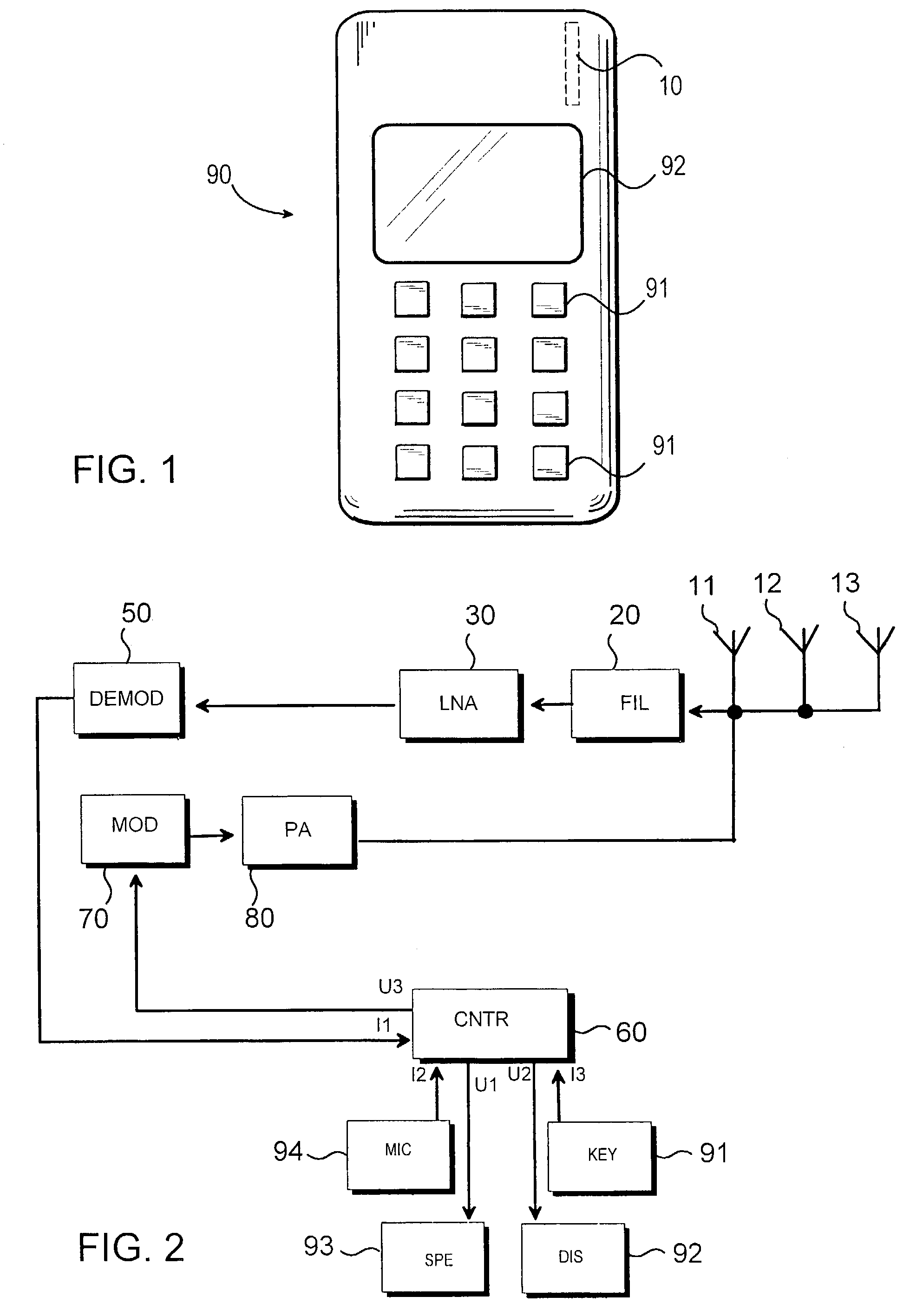

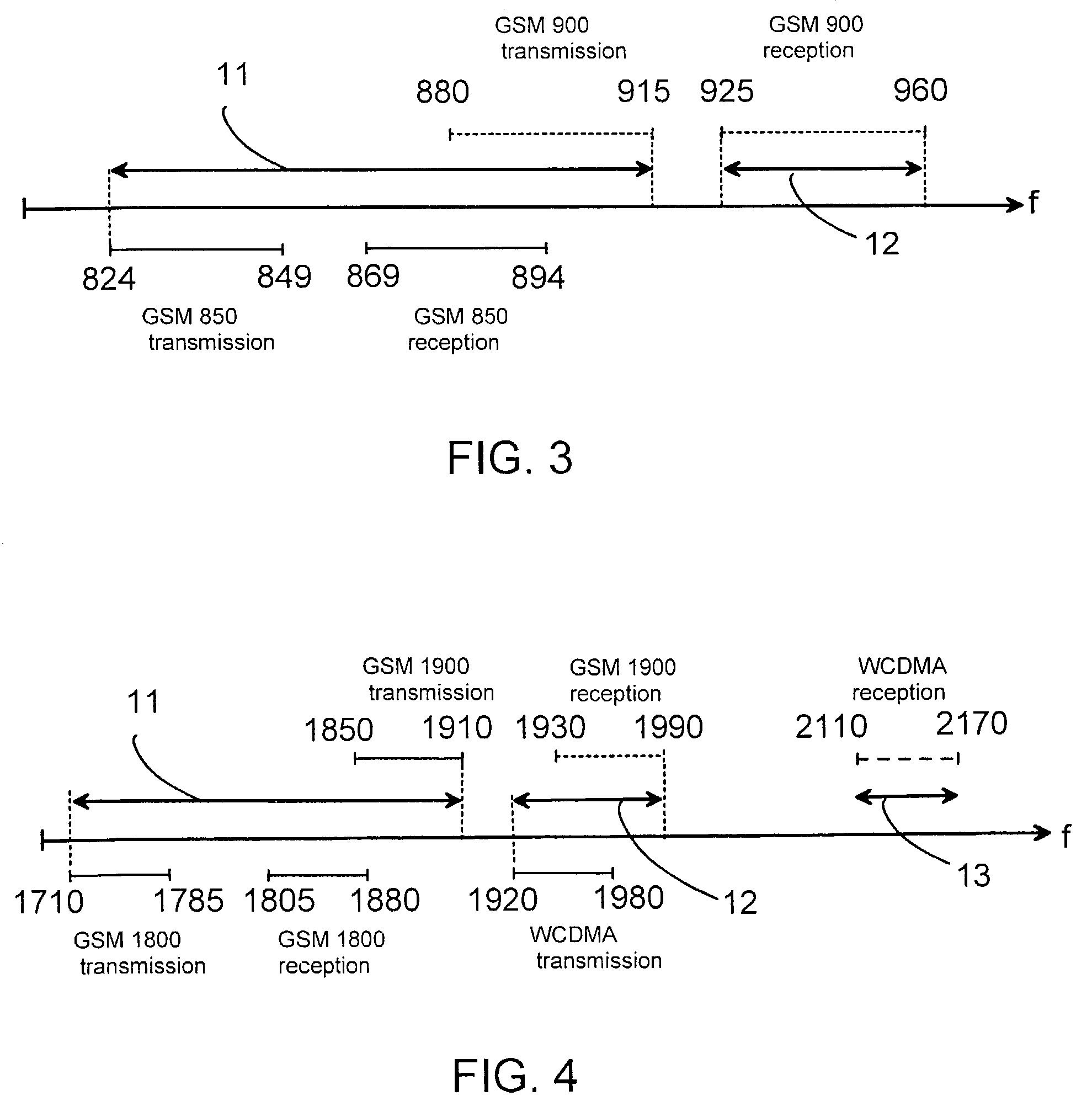

Antenna arrangement and mobile terminal device

ActiveUS7412255B2Easy to produceEasy to adaptSimultaneous aerial operationsAntenna supports/mountingsMulti bandTerminal equipment

Owner:FLEXTRONICS SALES & MARKETING A P

Method for designing asymmetric hull outer panel tyre frame

ActiveCN107985503AAvoid negligenceAvoid the build processVessel designingEngineeringBuilding construction

The invention discloses a method for designing an asymmetric hull outer panel tyre frame. The method includes the steps of S10, establishing models of a left outer panel seam and a left frame materialof an asymmetrical molded line area of a segment respectively to obtain a left outer panel seam model and a left frame material model, and establishing models of a right outer panel seam and a rightframe material of the asymmetrical molded line area respectively to obtain a right outer panel seam model and a right frame material model; S20, generating a left outer panel model according to the left outer panel seam model and a left outer panel molded line respectively, combining the left outer panel model and the left frame material model to obtain a left outer panel frame model, generating aright outer panel model according to the right outer panel seam model and a right outer panel molded line respectively, and combining the right outer panel model and the right frame material model toobtain a right outer panel frame model; S30, obtaining a left tyre frame model and a right outer panel tyre frame model according to the left outer panel frame model and the right outer panel frame model respectively. The method can be applied to the construction of the asymmetric hull outer panel tyre frame.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

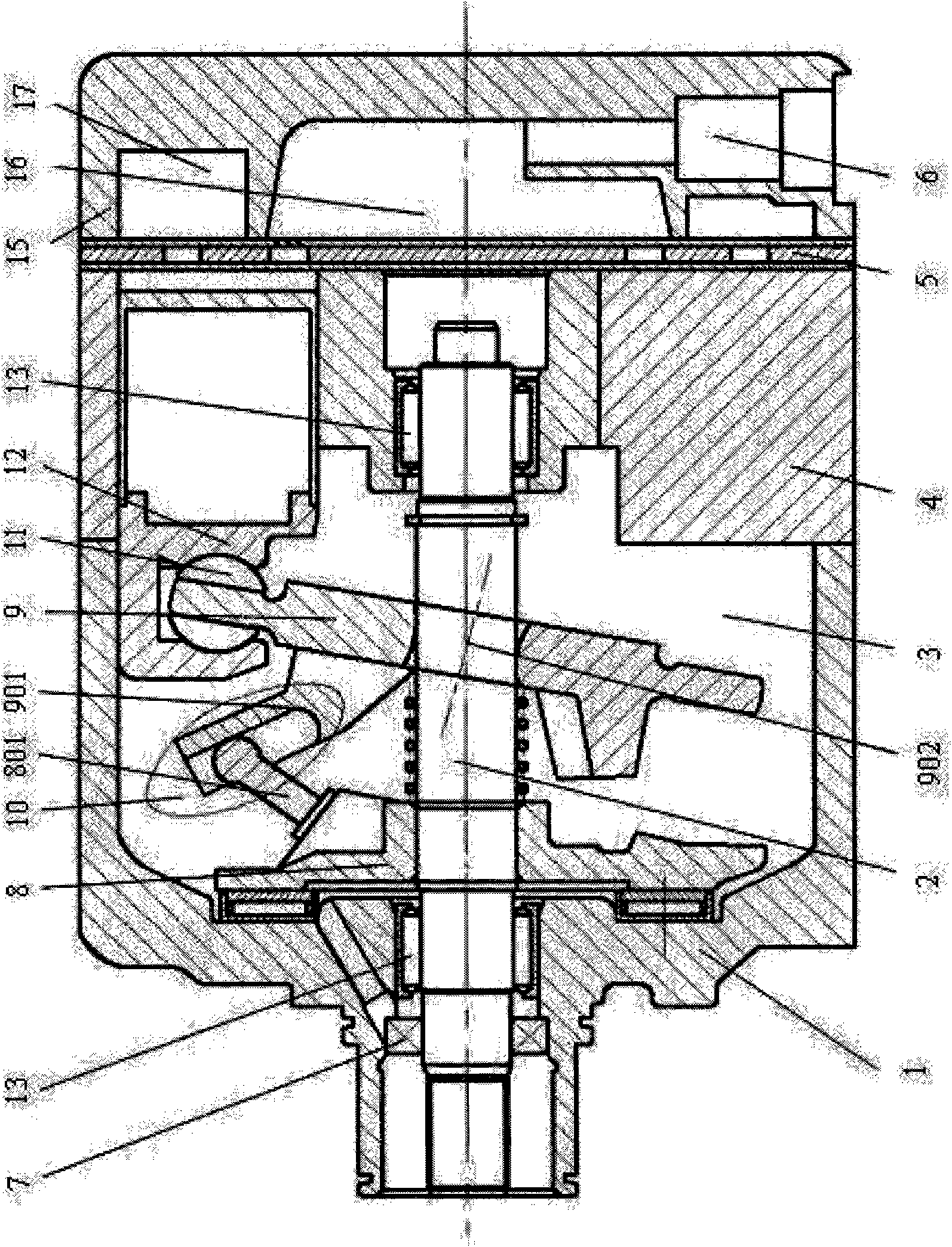

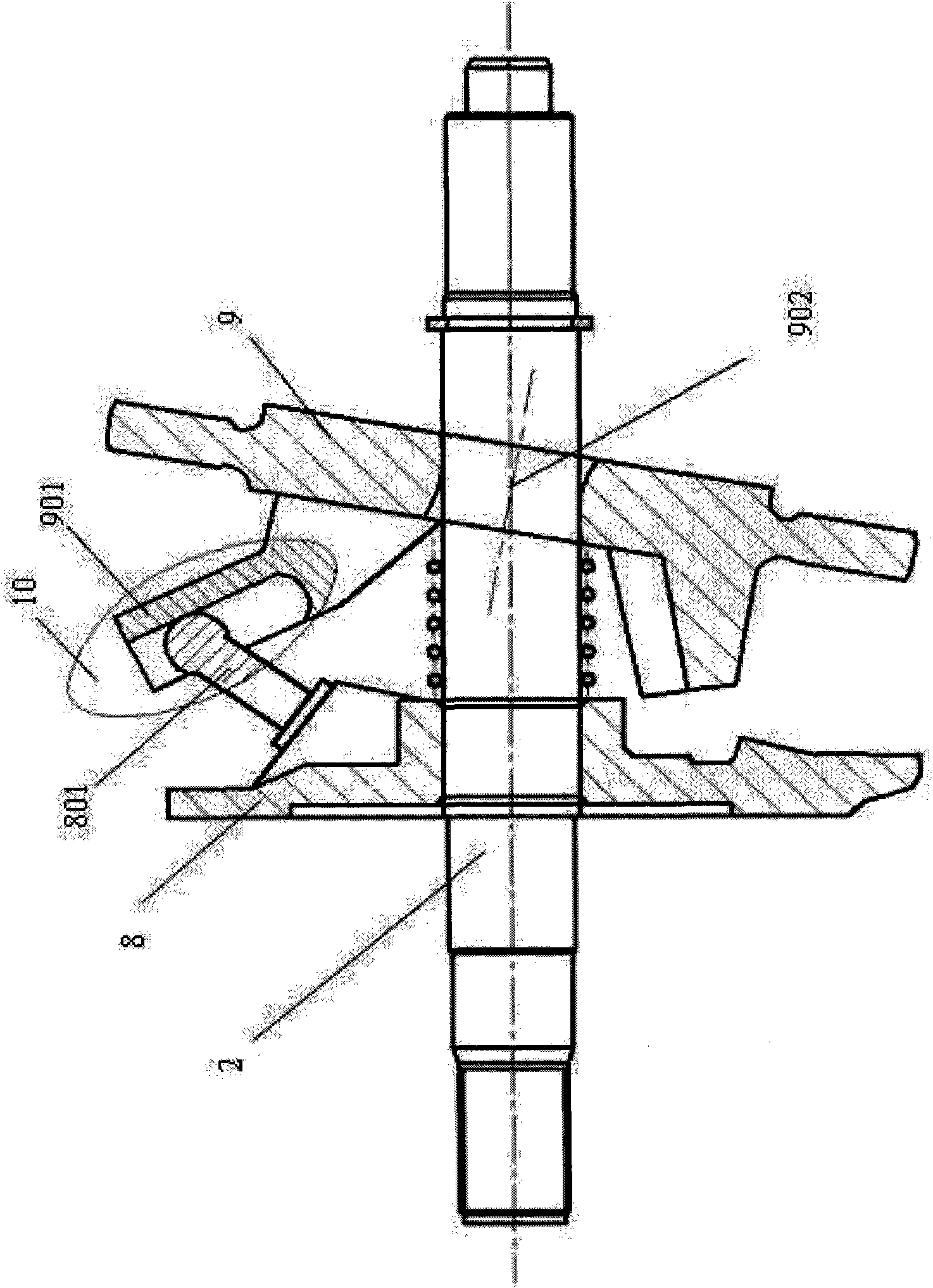

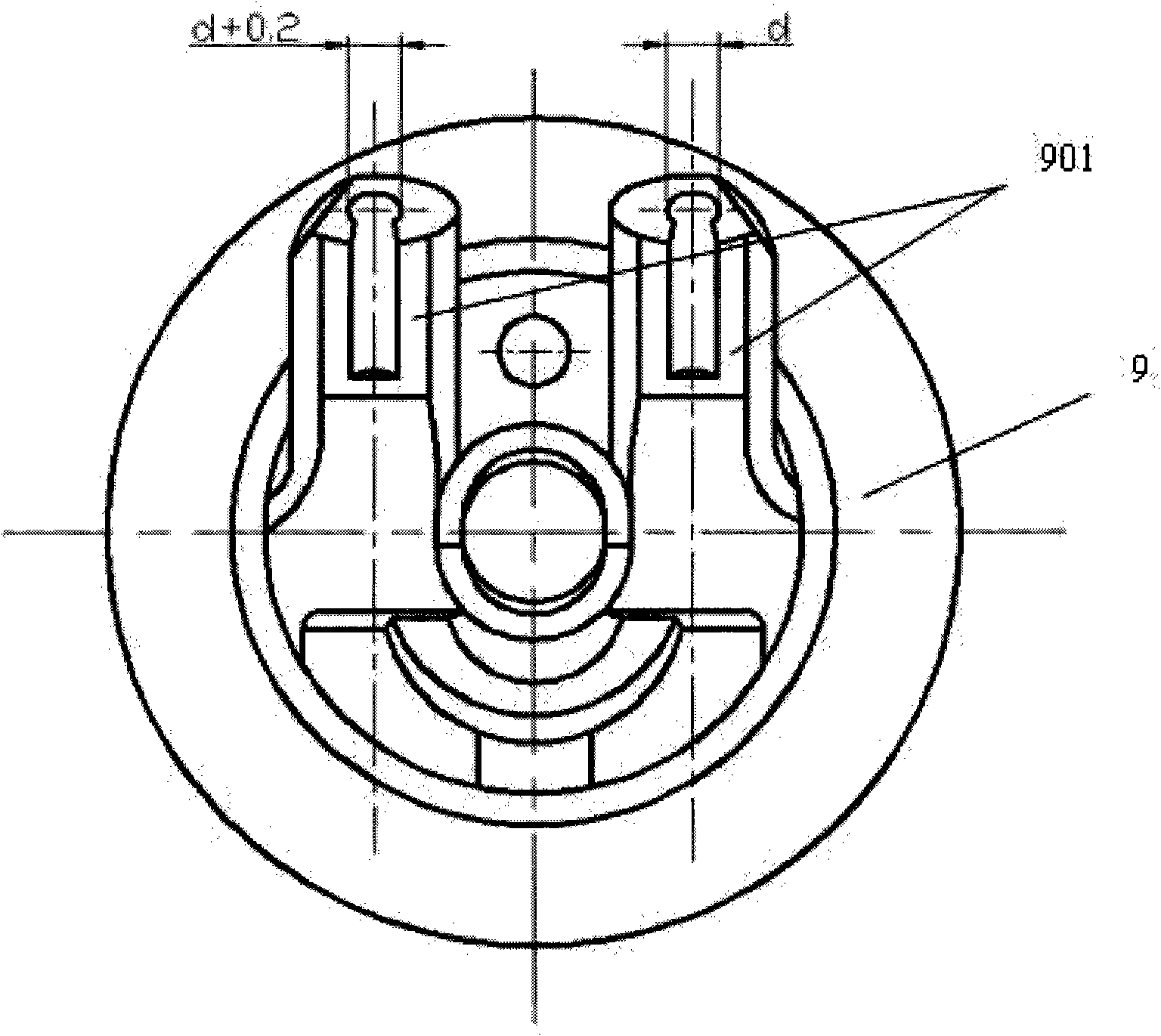

Variable displacement swash plate compressor

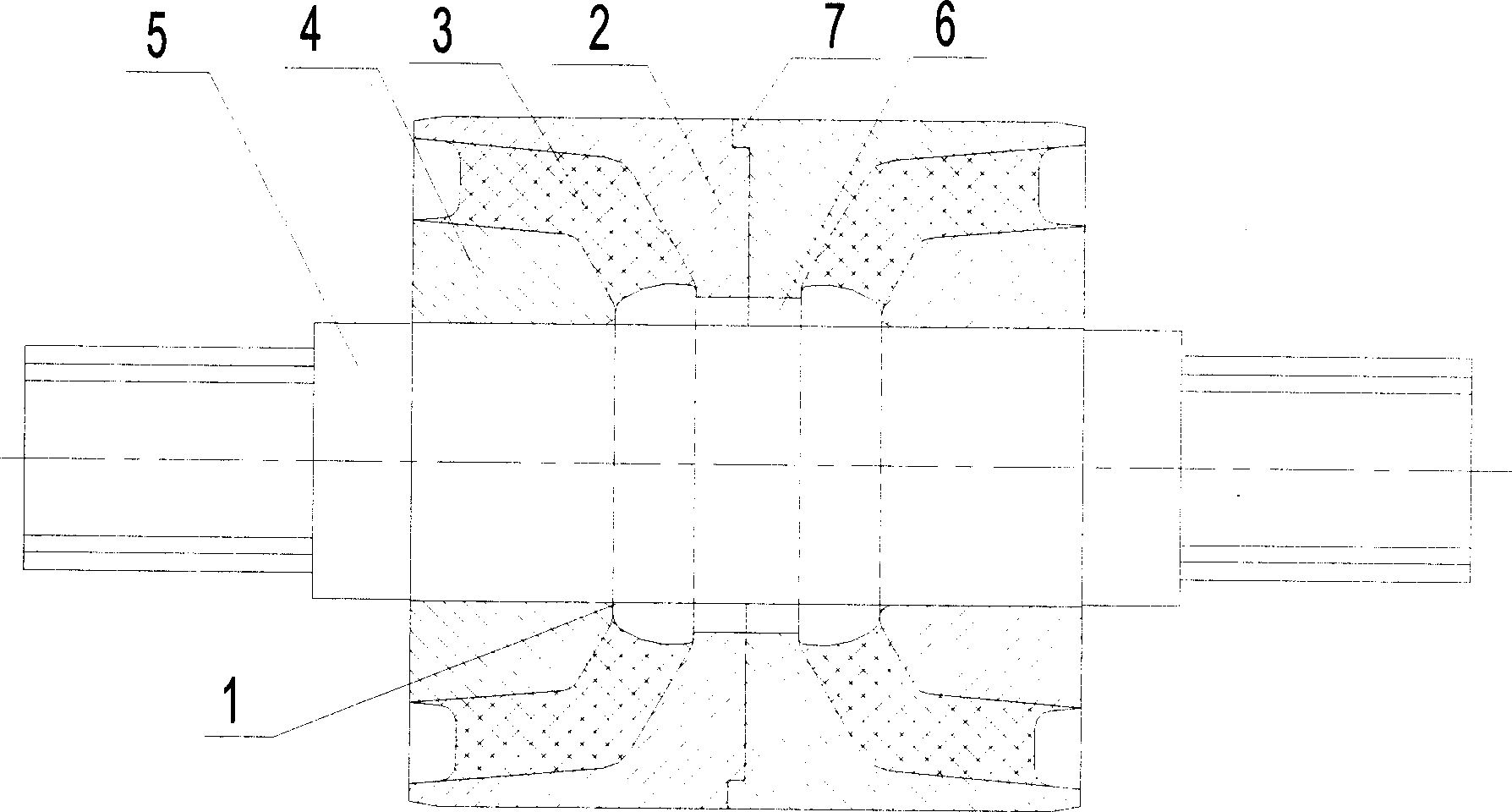

InactiveCN102011721AAppropriate amount of flexibilityReduce machining accuracyPositive displacement pump componentsMulti-stage pumpsReciprocating motionKinematic pair

The invention relates to a variable displacement swash plate compressor. A swash plate driving mechanisms with a flexible driving balance design is provided, has proper flexibility during work, overcomes unbalanced force and moment acting on the swash plate, improves vibration, noise, kinematic pair blockage and excessive wear caused by the unbalanced force and moment, and reduces machining and assembly precision of related workpieces; a piston with a spiral linear oil groove is provided and stores oil, and through the reciprocation of the piston and the acceleration change of the piston, lubricating oil flows reasonably between the kinematic pair and is uniformly distributed on the cylindrical surface of the piston and the peripheral surface of the cylinder to improve the sealing and lubricating properties between the piston and the peripheral surface of the cylinder, improve the performance of the compressor and prolong the service life of the piston; and a cylinder cover capable of being formed at one time through die casting and having simple process is provided, and suction and discharge channels adopt a single-section or multi-section expansion chamber-type cavity consisting of alternate contraction sections and expansion sections to improve the vibration and air flow noise caused by suction and discharge pulsation.

Owner:ZHEJIANG LONGDIAN AUTOMOTIVE PARTS MFG

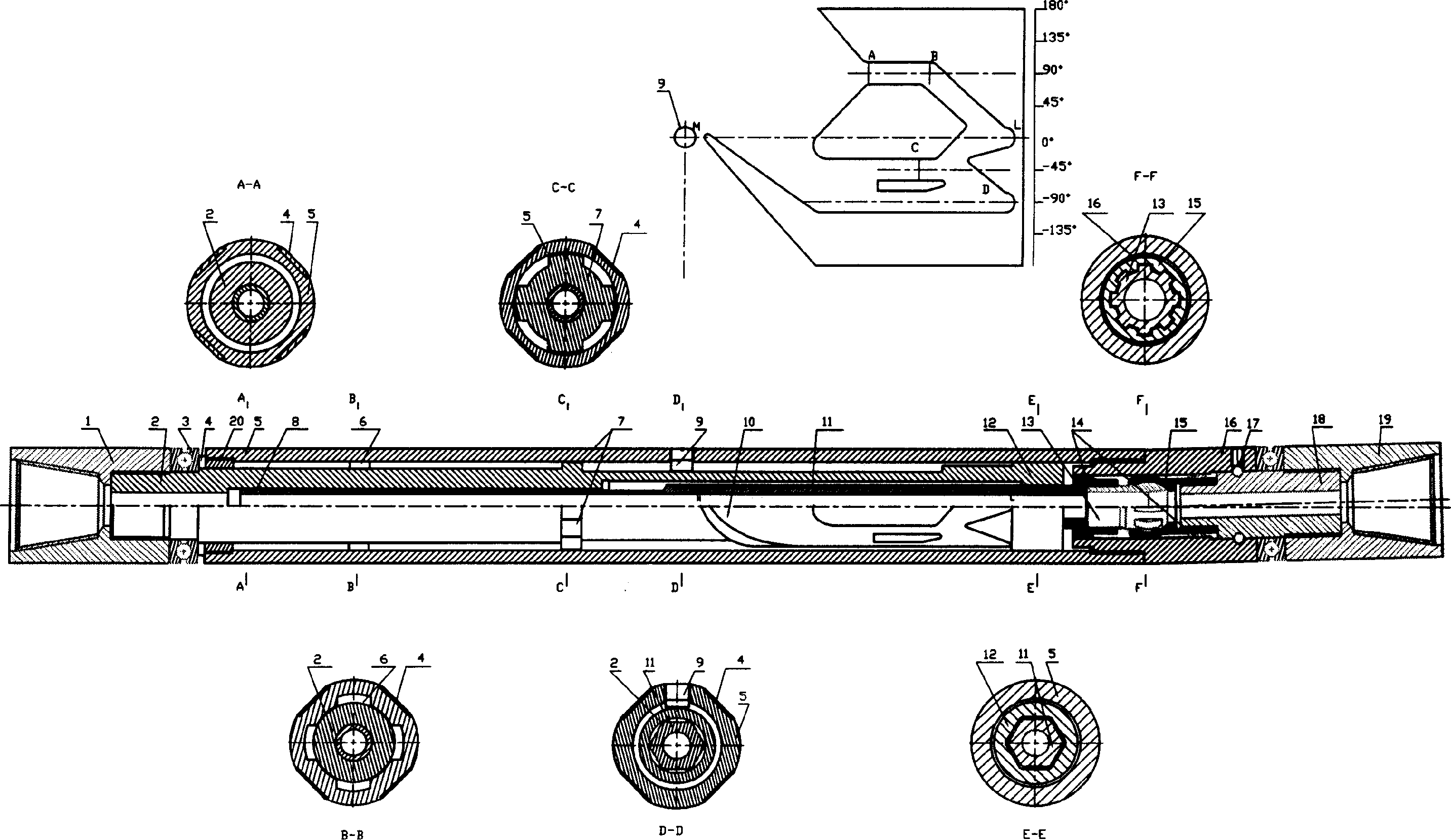

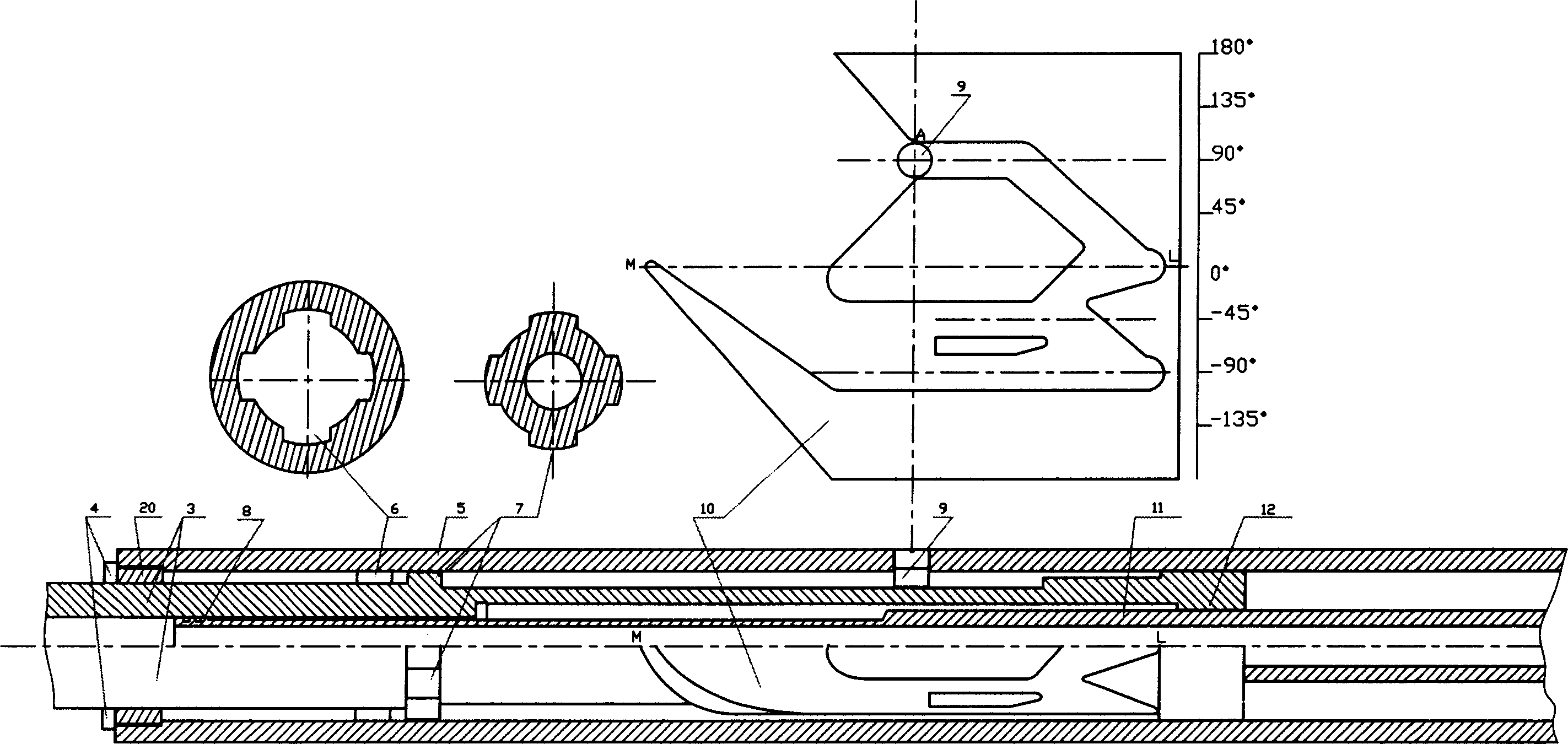

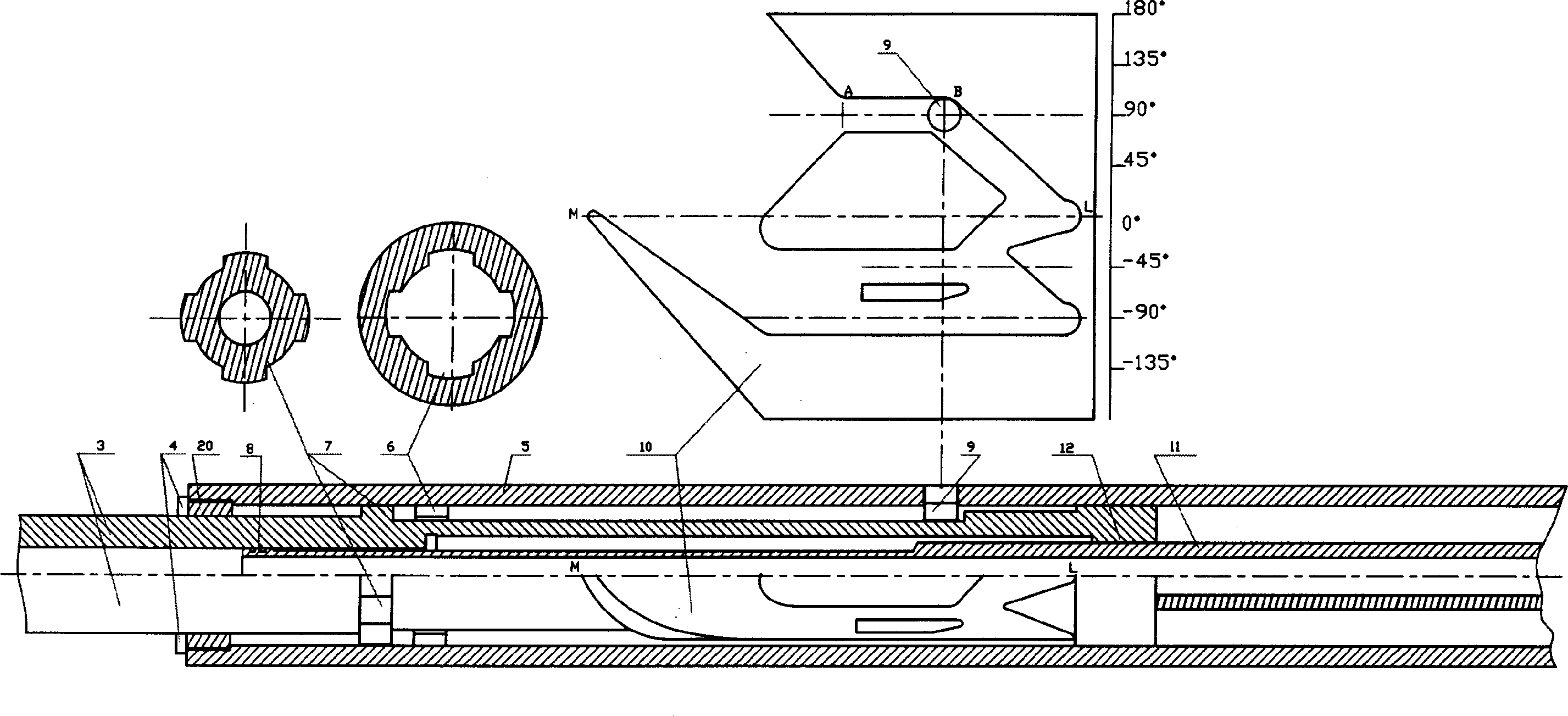

Guide rail spline oriented drilling tool

A guide rail spline orientation drill includes a shell, driving shaft, moving pin, moving seal, spring tab, driven shaft, bearing, gimbal joint and whipstock. There is guide rail on the out face of the driving shaft in a one-way circle shape. There is an inner spline on the inner wall of the shell with the same phase to the moving pin. There is an outer spline on the out face of the driving shaft. The inner spline and outer spline could get through the guide rail in case of interlace position, and will transmit drilling pressure in case of overlap position. The drill is driven by rotary disc and capable of substituting screw drill. The drill could work in two manners of angle building and angle holding by raise up or putting down it.

Owner:杜炊

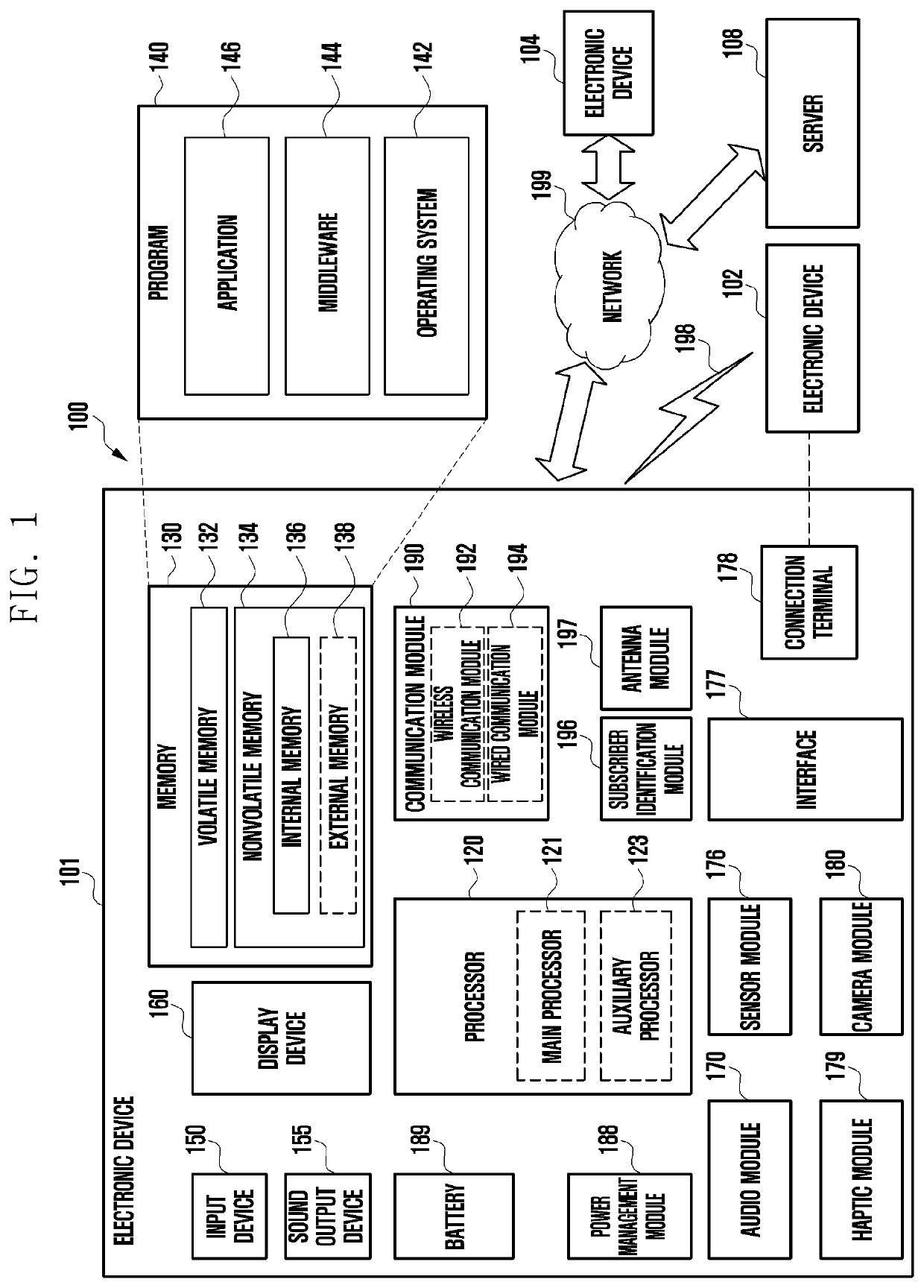

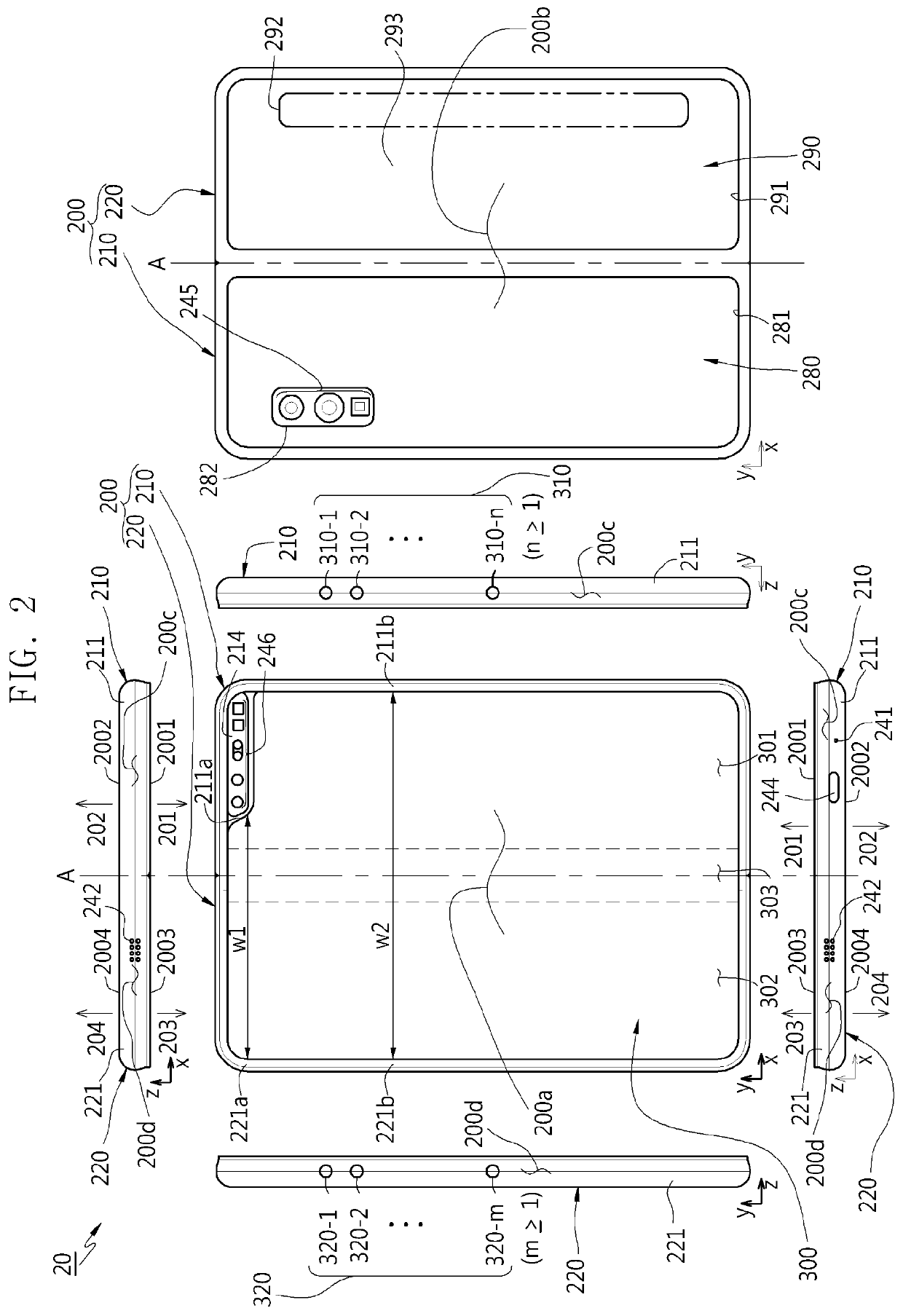

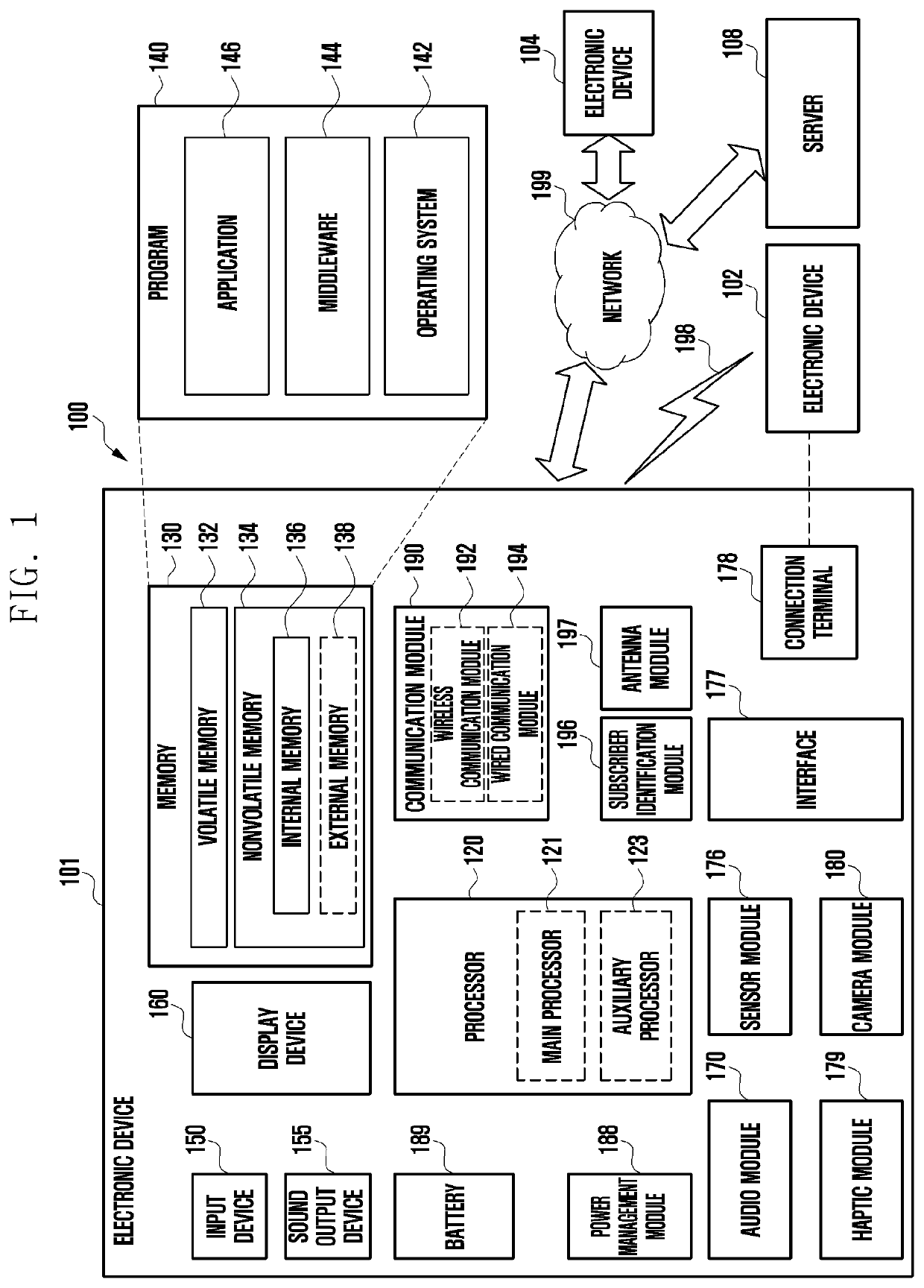

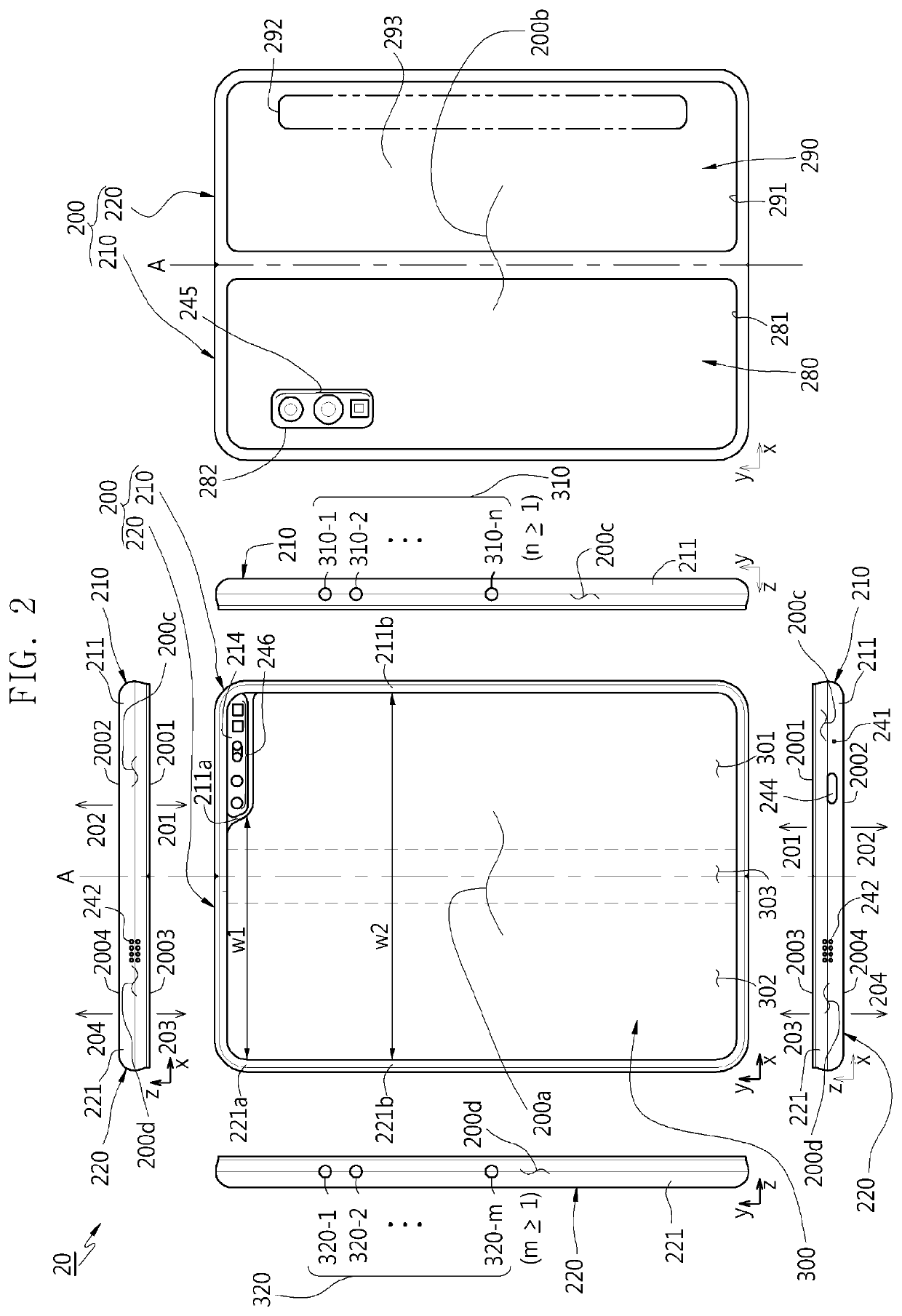

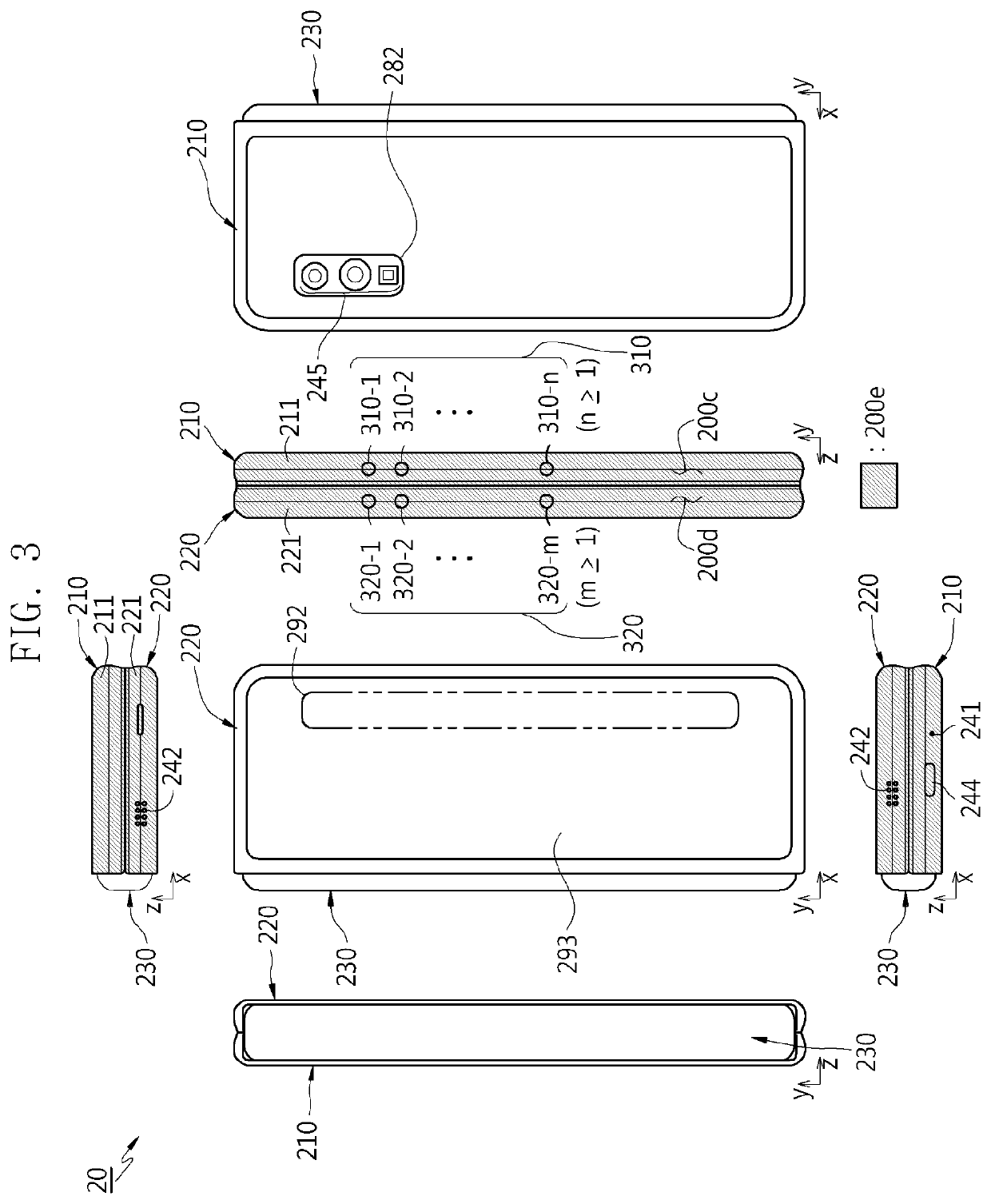

Foldable electronic device

ActiveUS20210152678A1Reduce constraintsProvide user experienceDetails for portable computersPivotal connectionsDisplay deviceEngineering

Provided is a foldable electronic device. The electronic device may include: a foldable housing including: a hinge structure; a first housing structure including a first surface, a second surface, and a first side surface; and a second housing structure including a third surface, a fourth surface, and a second side surface, and foldable with the first housing structure with the hinge structure, wherein, in a folded state, the first side surface and the second side surface are aligned; a flexible display; first side keys including a first sensing panel reflecting a change in force applied to the first side surface; second side keys including a second sensing panel reflecting a change in force applied to the second side surface; and a sensor generating a signal based on a change in the force detected by the first sensing panel or the second sensing panel. It is possible to provide other embodiments.

Owner:SAMSUNG ELECTRONICS CO LTD

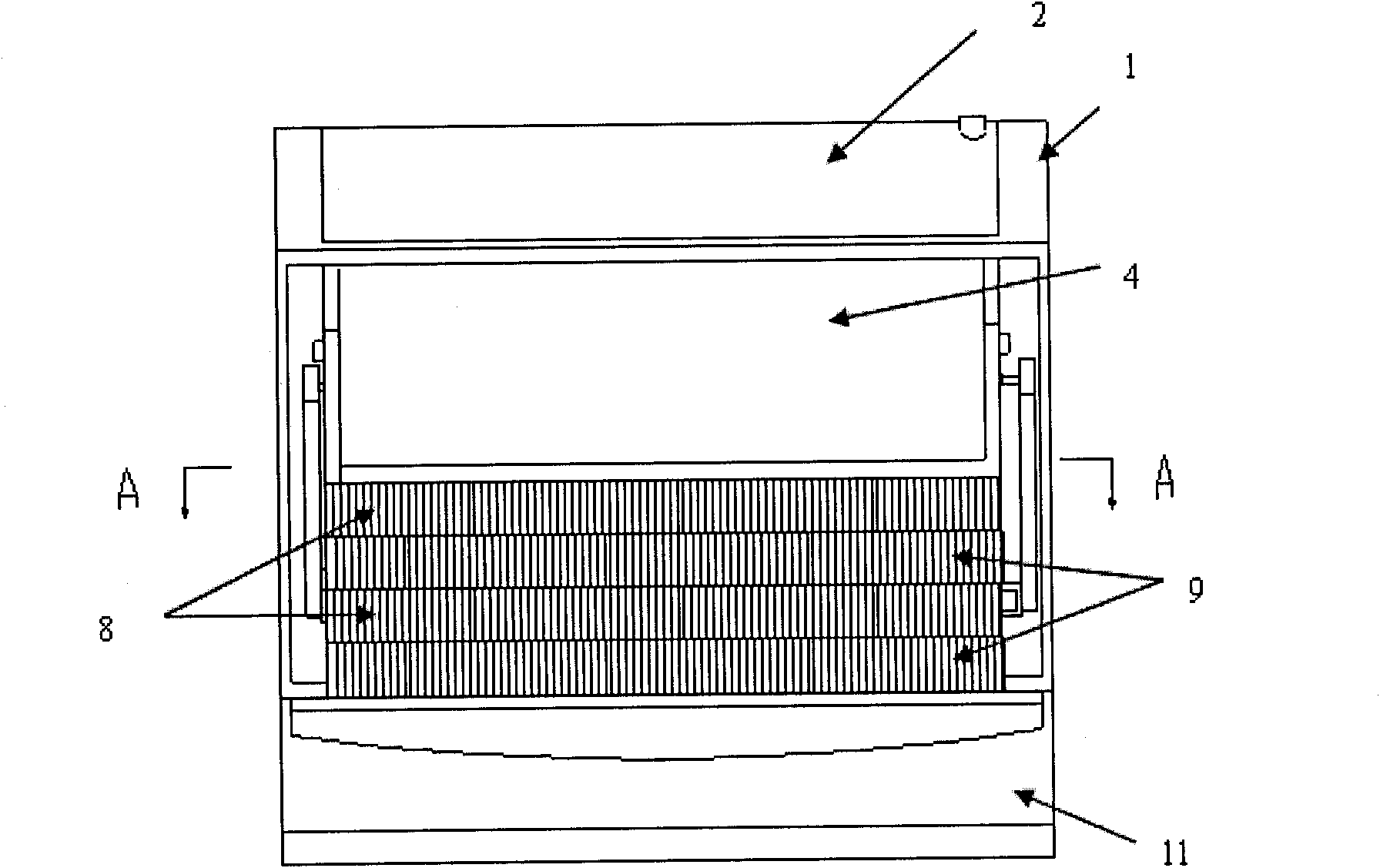

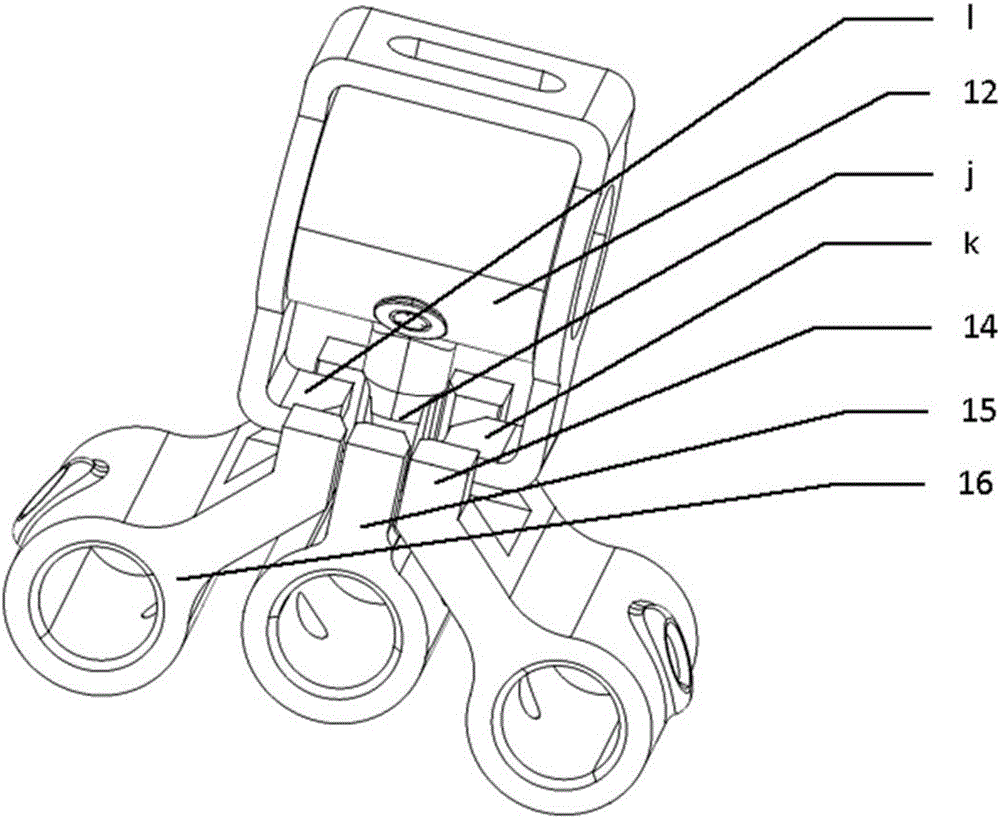

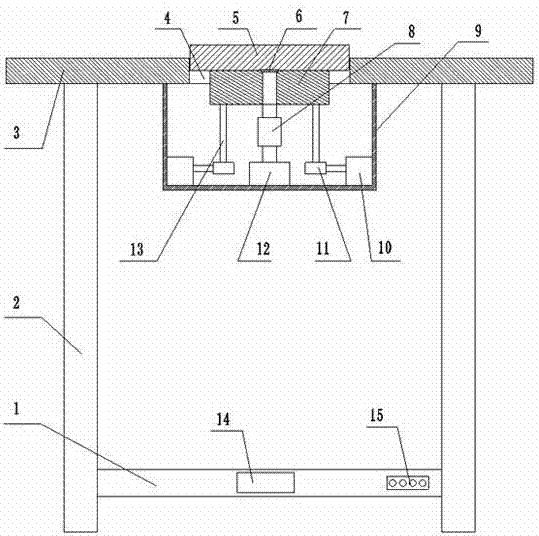

Portable mechanical type junk advertisement paper cleaner

InactiveCN101869898AEasy to cleanStable collectionCleaning using toolsCleaning using liquidsChinese charactersEngineering

The invention relates to a portable mechanical type junk advertisement paper cleaner. A cleansing liquid applying mechanism, a chipping mechanism and a chippings recycling mechanism are fixed in a box shell; a water tank of the cleansing liquid applying mechanism is fixed to the topside in the box shell; a water absorbing roller is fixed under the water tank by a roller support bracket, and both ends of the water absorbing roller are respectively provided with an elliptic groove; sawteeth which are distributed in a row are arranged on a sliding rack of the chipping mechanism; the front end of a connecting rod is provided with a roller follower, and the roller follower is installed in the elliptic groove; the other end of the connecting rod is in clearance fit with a sliding rod of the roller support bracket by a sliding sleeve in a shape like the Chinese character hui and meanwhile is connected with one end of an oscillating bar trough a rotating pair; the other end of the oscillating bar is connected with the sliding rack by a rotating pair; the back of the sliding rack is provided with a groove and forms a moving pair with the front end of the roller support bracket; a shovel-shaped tray of the chippings recycling mechanism is connected with the guide column moving pair of the box shell; and a reset spring is positioned between a guide column and the shovel-shaped tray. The invention has mechanical type, environmental-protection, sanitary and simple structure, small size, light weight and convenient carrying and use.

Owner:EAST CHINA JIAOTONG UNIVERSITY

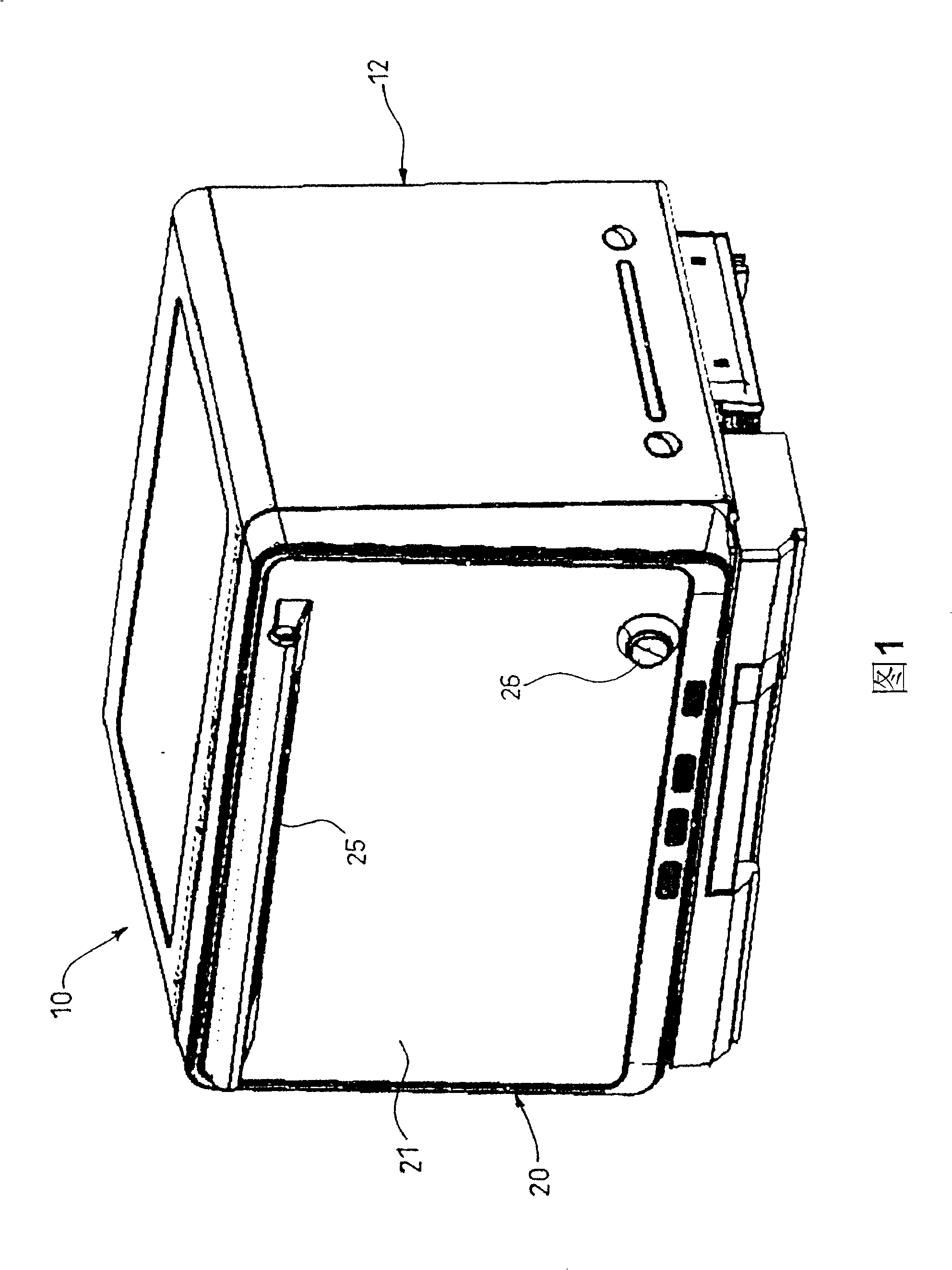

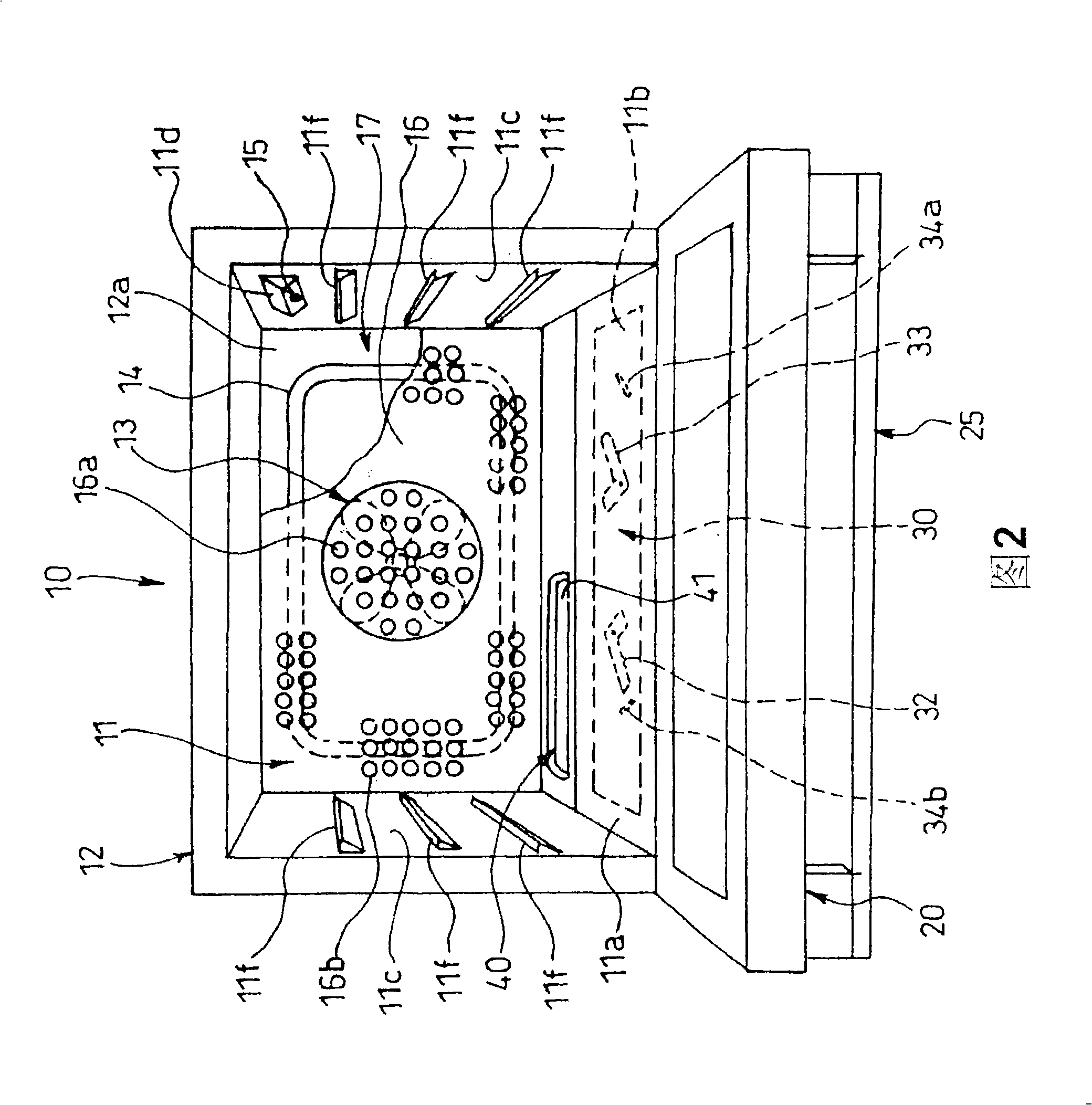

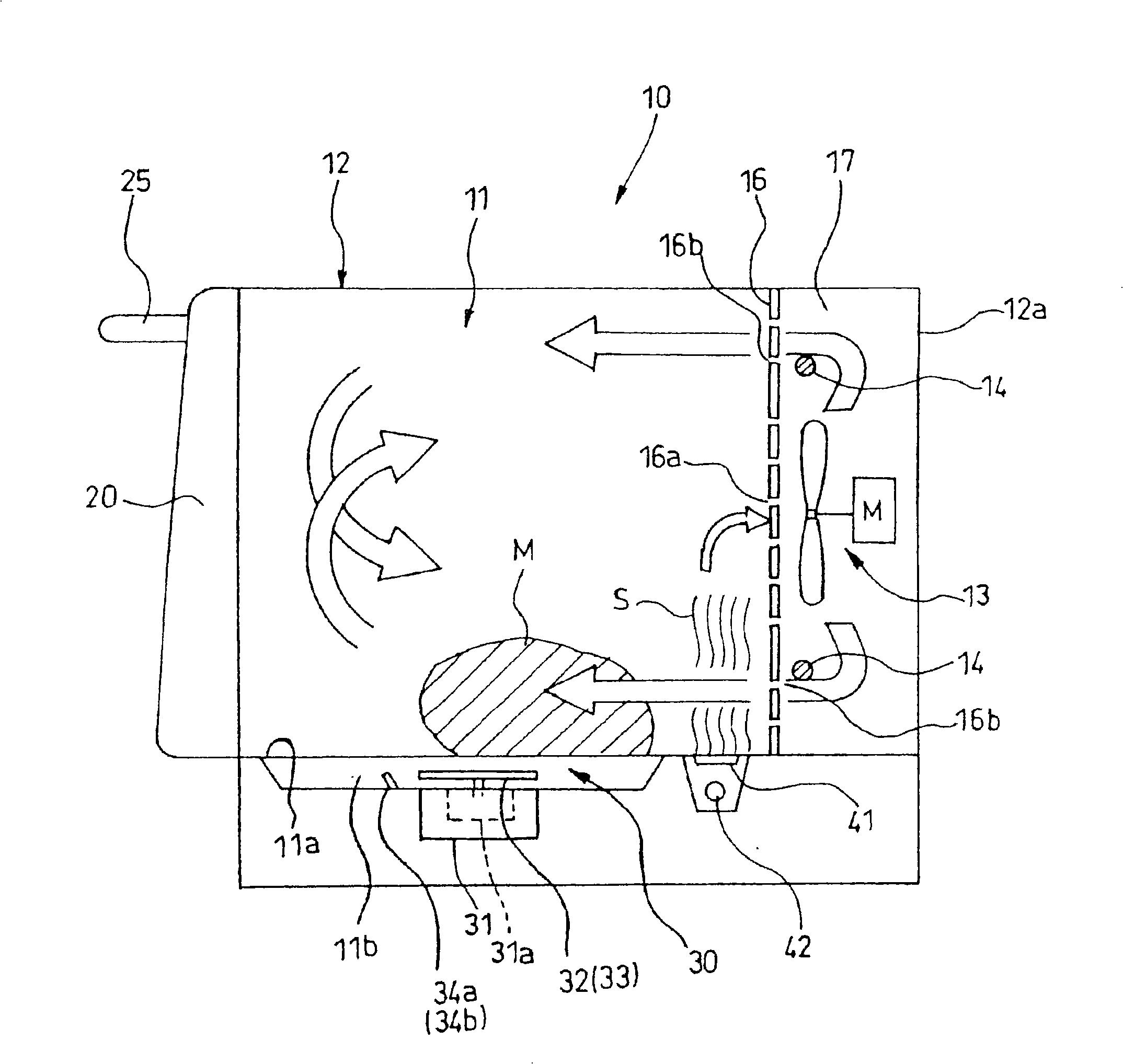

Heating cooker

InactiveCN101261015AHigh strengthImprove bending strengthDomestic stoves or rangesDoors for stoves/rangesFlexural strengthEngineering

The invention provides a heating cooker which ensures leak tightness between a machine door and a machine body by enhancing intensity of the machine door, increases heating efficiency and improves appearance. Nearly a whole front surface of the machine door (20) for opening / closing an opening of a heating chamber (11) of the machine body (12) is covered with one glass board (21), so anti-twisting intensity and anti-bending strength of the machine door (2) are increased, leak tightness of the machine body (12) to the machine door (20) is increased, and heating efficiency is increased. In addition, because the front surface is covered with one glass board, design is more fluency and appearance beauty is increased.

Owner:PANASONIC CORP

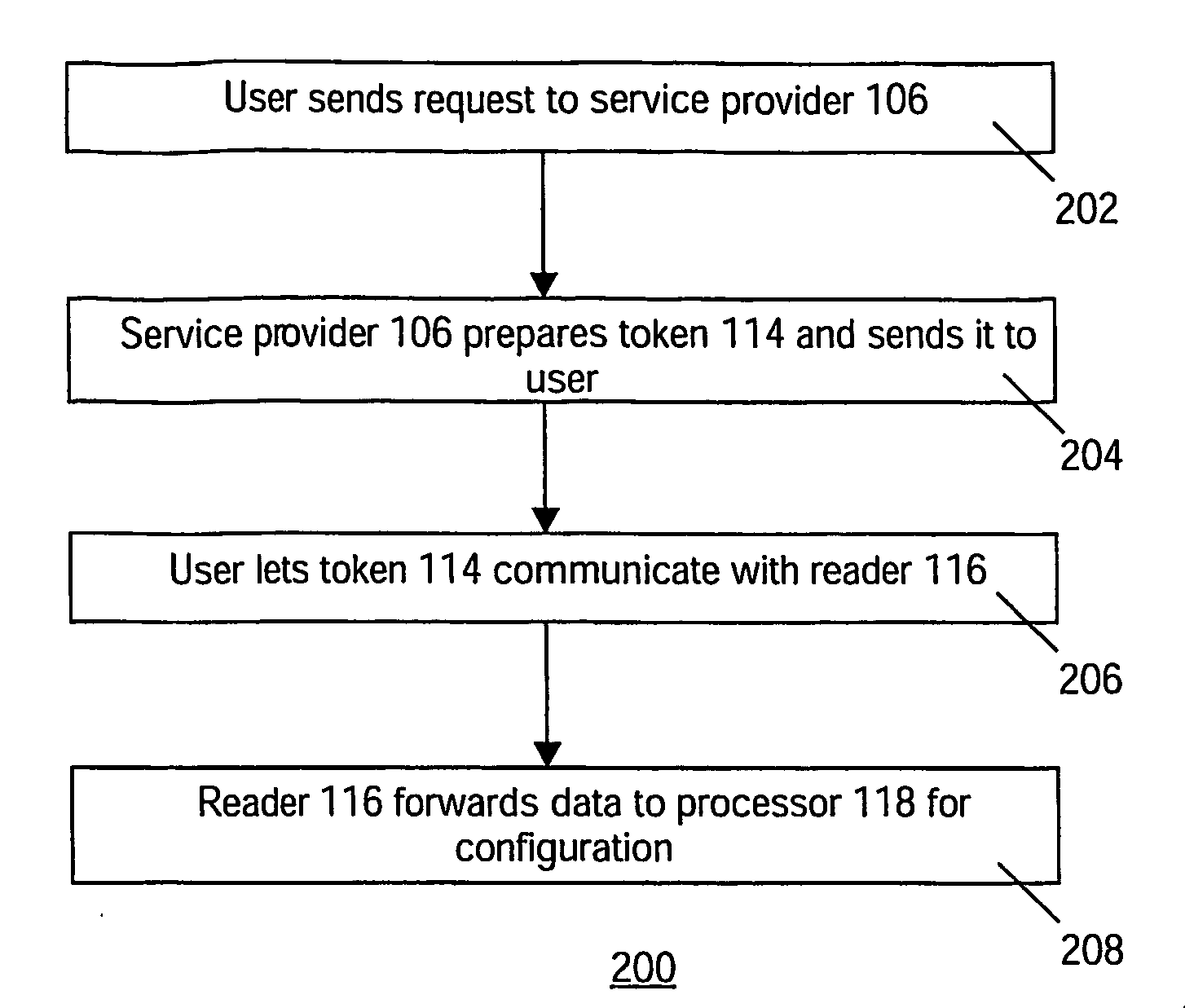

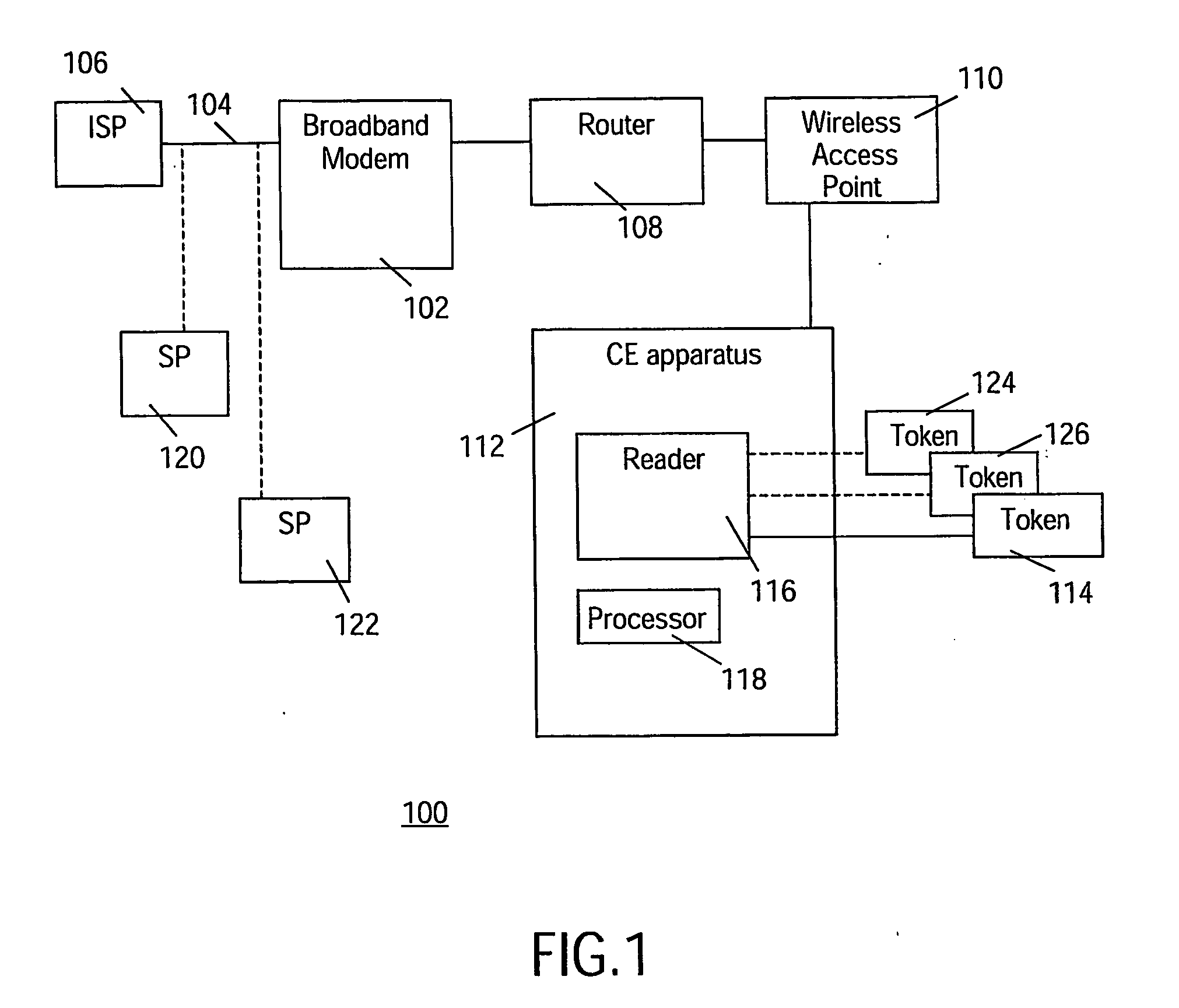

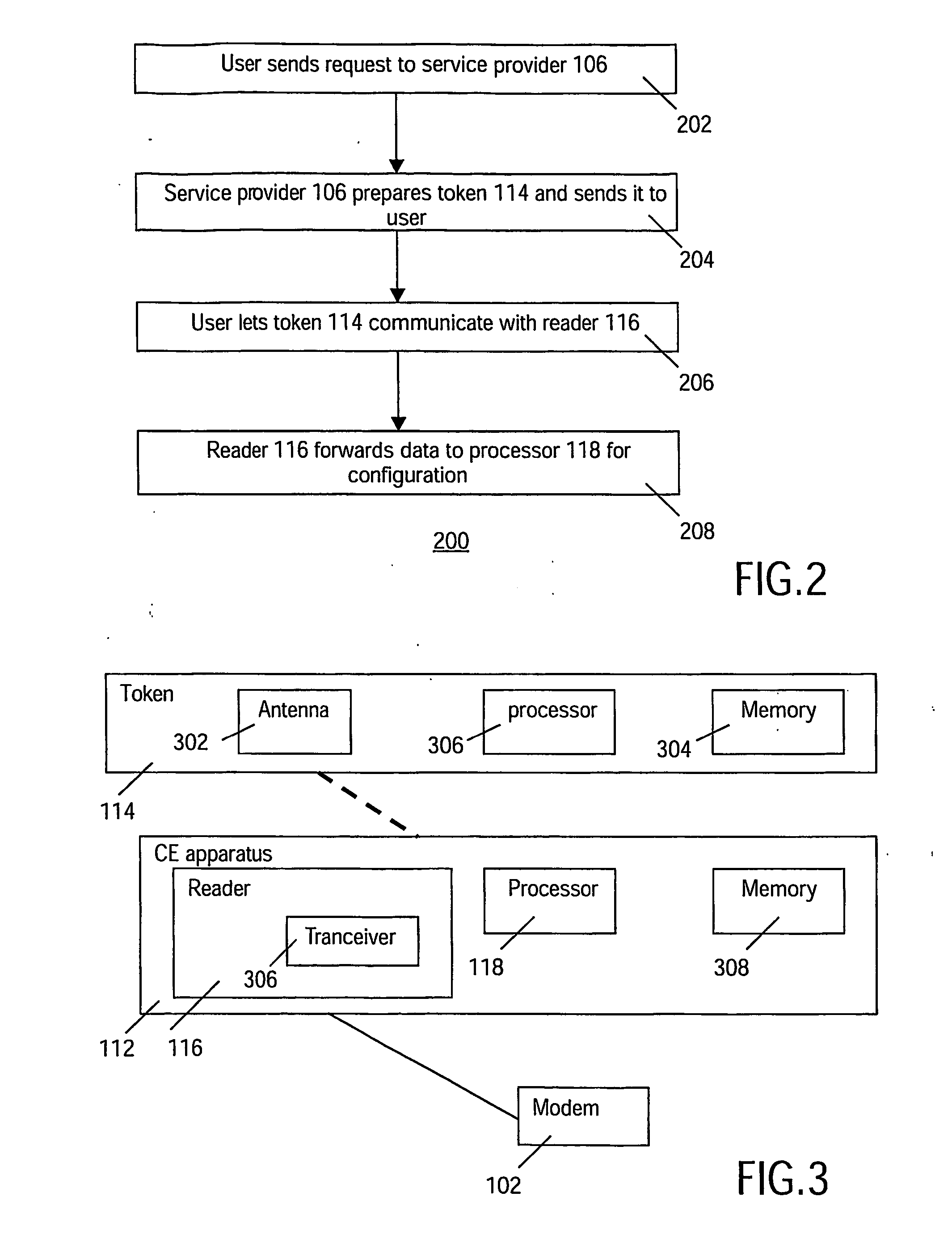

Configuring network interface on home network

InactiveUS20070115822A1OptimizationReduce needError preventionTransmission systemsData processing systemNetwork communication

A CE data processing system is configurable to communicate via a particular one of multiple data network environments. The system comprises a receiver for receiving configuration data from a physical token for configuring the system. The system comprises an appliance for data network communication via a network interface. The appliance accommodates the receiver for receiving the configuration data for configuring the network interface. The token and the receiver communicate in a wireless fashion.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

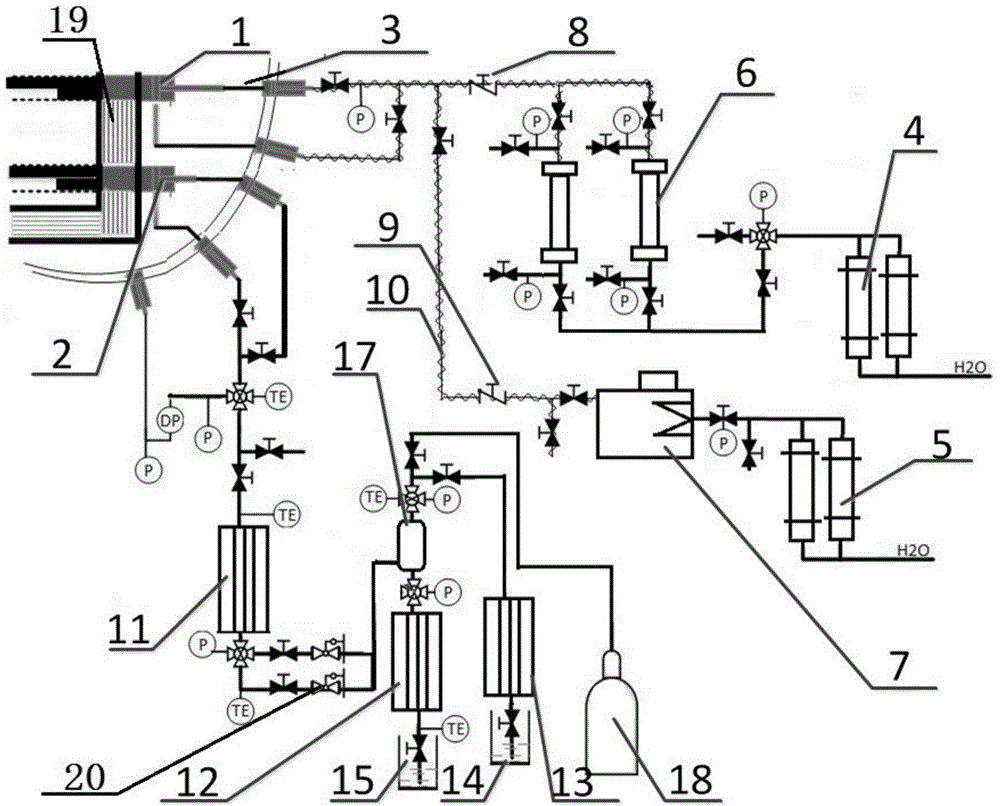

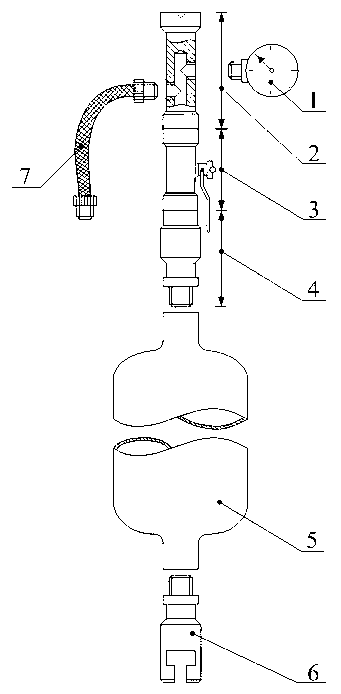

Solvent-assisted SAGD three-dimensional physical simulation experiment method and device

ActiveCN104948153ASteady injectionStable pressureFluid removalVapor–liquid separatorProcess engineering

The invention provides a solvent-assisted SAGD three-dimensional physical simulation experiment method and device. The device comprises an injection device, a simulated oil reservoir model and a recycling device, a first pump unit in the injection device is communicated with a piston container unit, a second pump unit is communicated with a steam generator, the piston container unit and the steam generator are communicated with a gas injection well of the simulated oil reservoir model respectively, one end of a first condenser of the recycling device is communicated with a production well of the simulated oil reservoir model while the other end of the same is communicated with a feeding port of a gas-liquid separator, a second condenser is communicated with a liquid outlet of the gas-liquid separator, a third condenser is communicated with a gas outlet of the gas-liquid separator, a raw oil and water collection container is connected with the second condenser, and a solvent recycling container is connected with the third condenser. By the method and the device, mining conditions of solvent-assisted SAGD technology can be simulated, and mechanism of solvent in the process of SAGD can be studied so as to optimize and improve existing solvent-assisted SAGD technology according to oil reservoir conditions.

Owner:PETROCHINA CO LTD

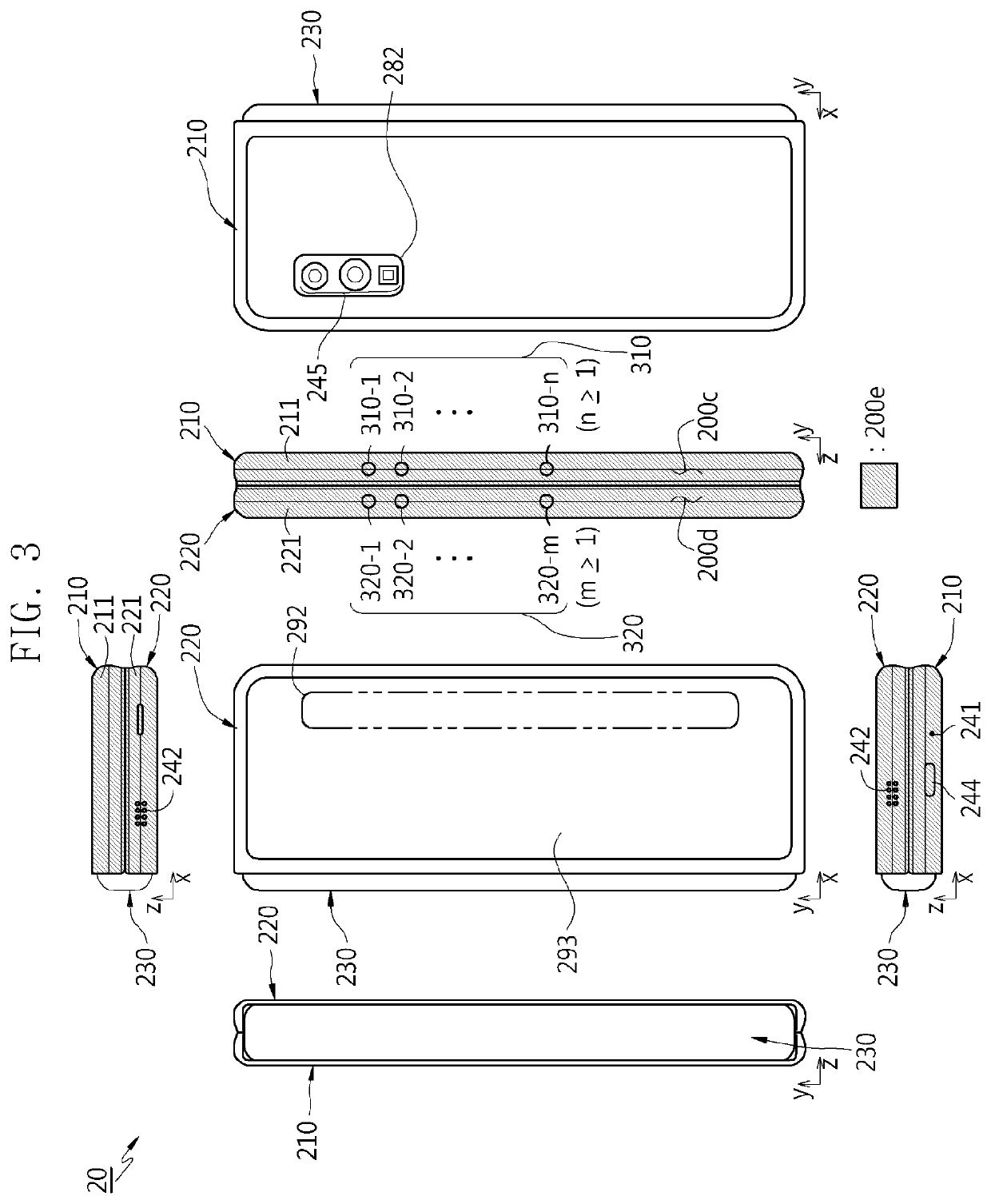

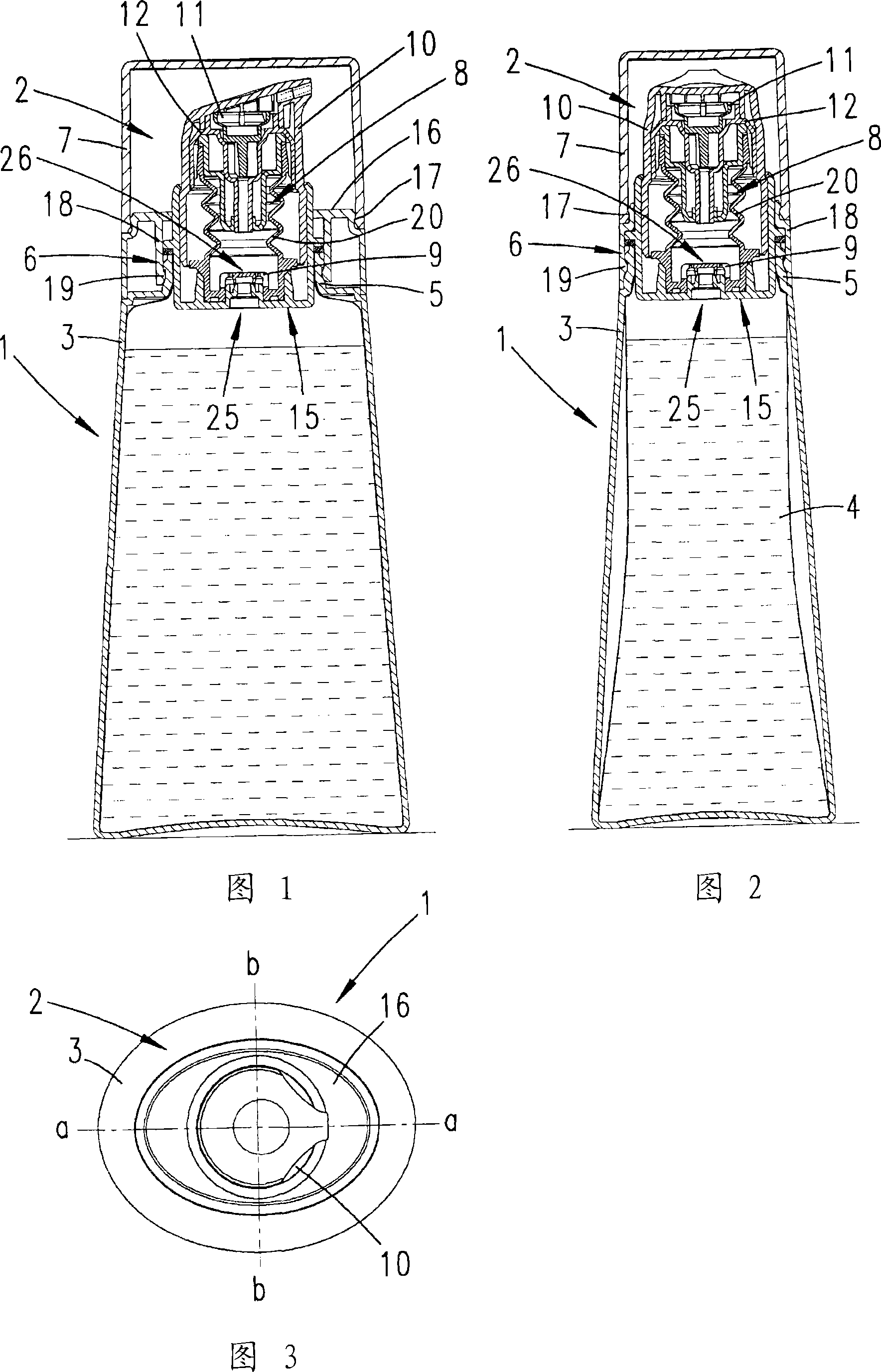

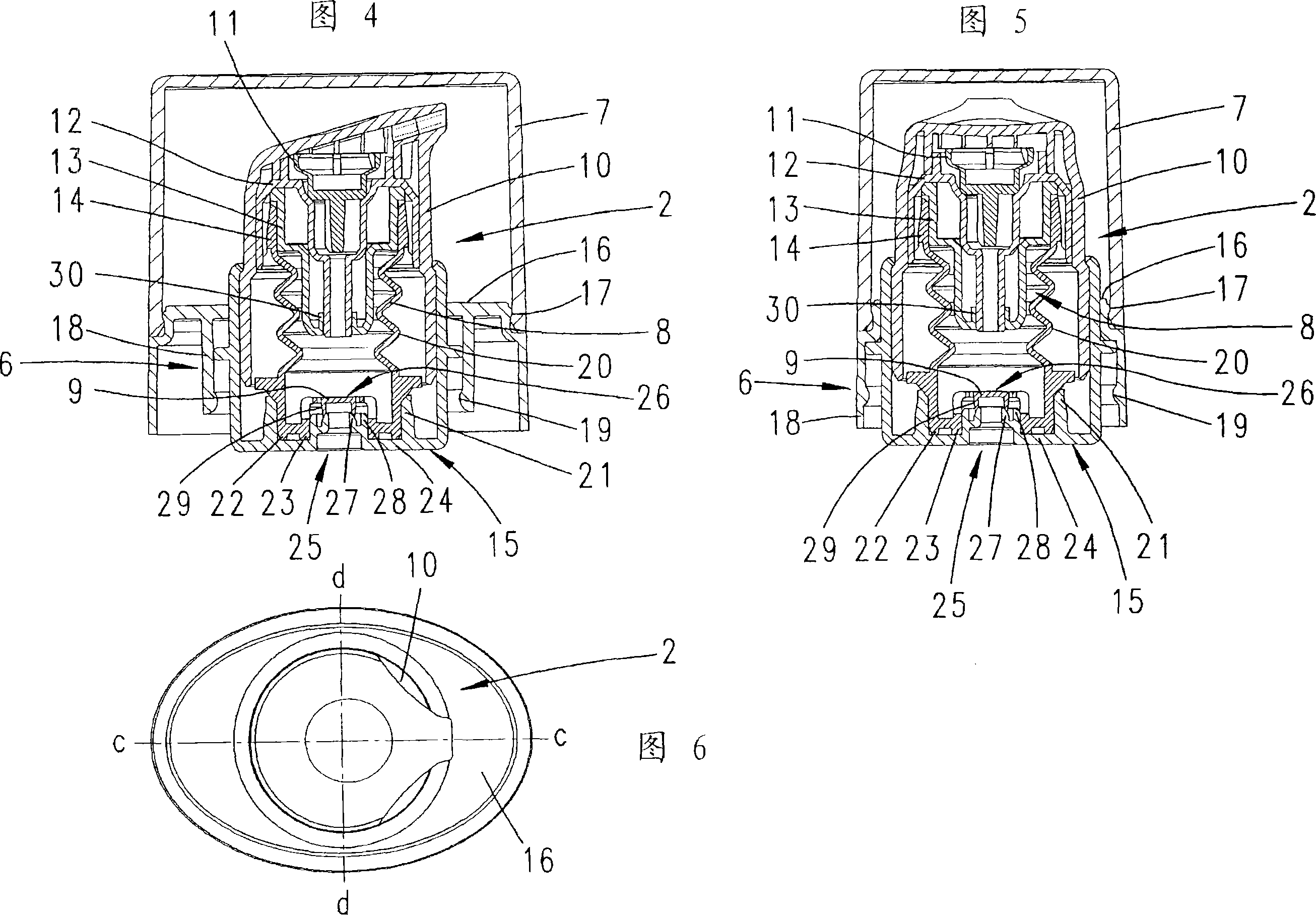

Dispenser for discharging liquid to pasty materials

InactiveCN101160179AAvoid pressure fluctuationsSmooth designSingle-unit apparatusLiquid statePump chamber

The present invention relates to a dispenser (1) for discharging liquid state or slurry-shaped material. The dispenser (1) includes a pump head (2) and a pump chamber (8) which comprises a pump chamber wall (20) arranged in the pump chamber, an inlet valve (26) and an outlet valve (11). The dispenser (1) also includes a storing container (3) which is accommodated with a storing bag (4) that can reduce the dimension for discharging. The pump chamber wall (20) of the pump head (2) is formed with a flexible mode to obtain a design which has an advantage at vibrating or pressure abrupt increasing aspect.

Owner:大型塑胶制品两合公司

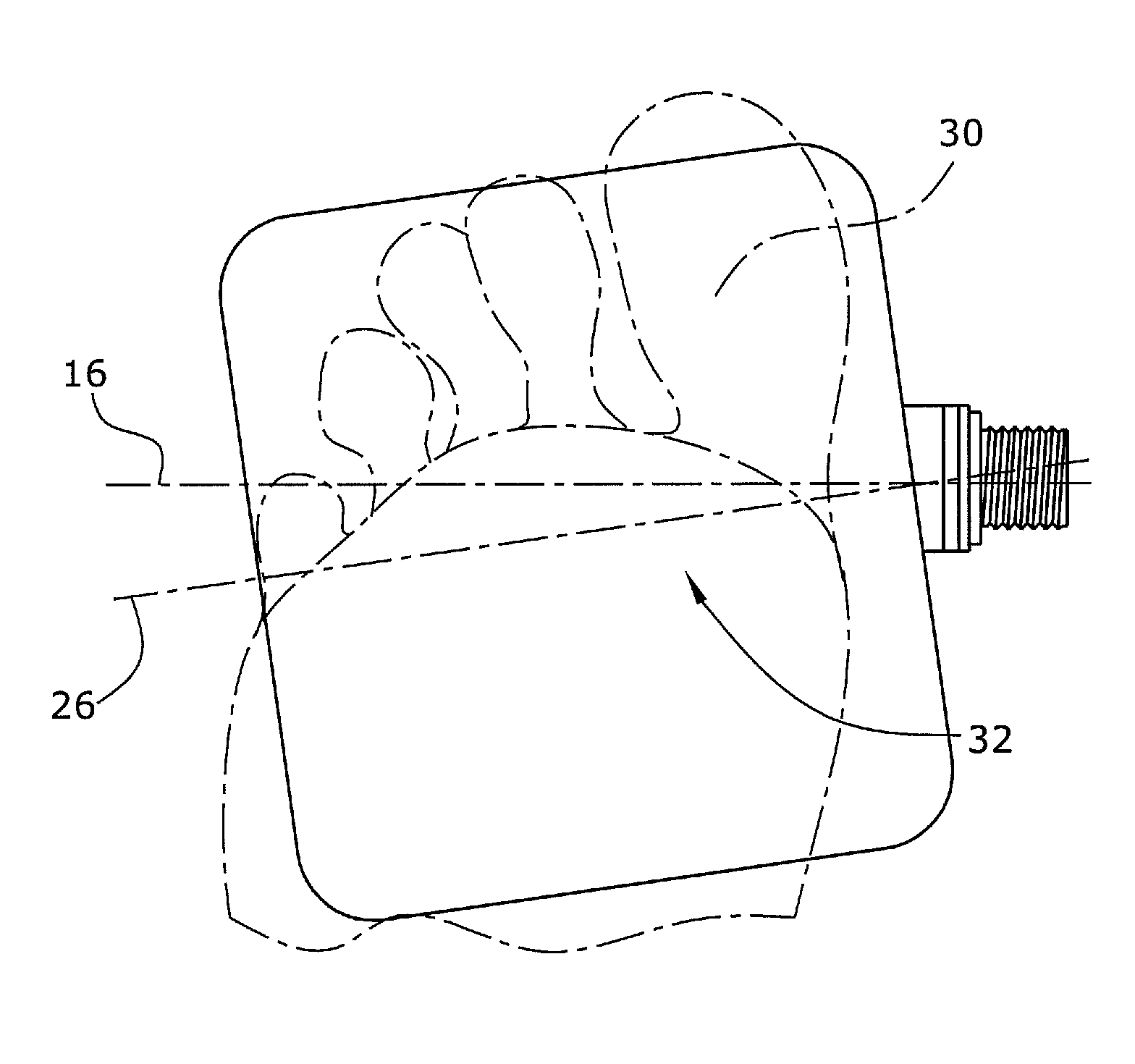

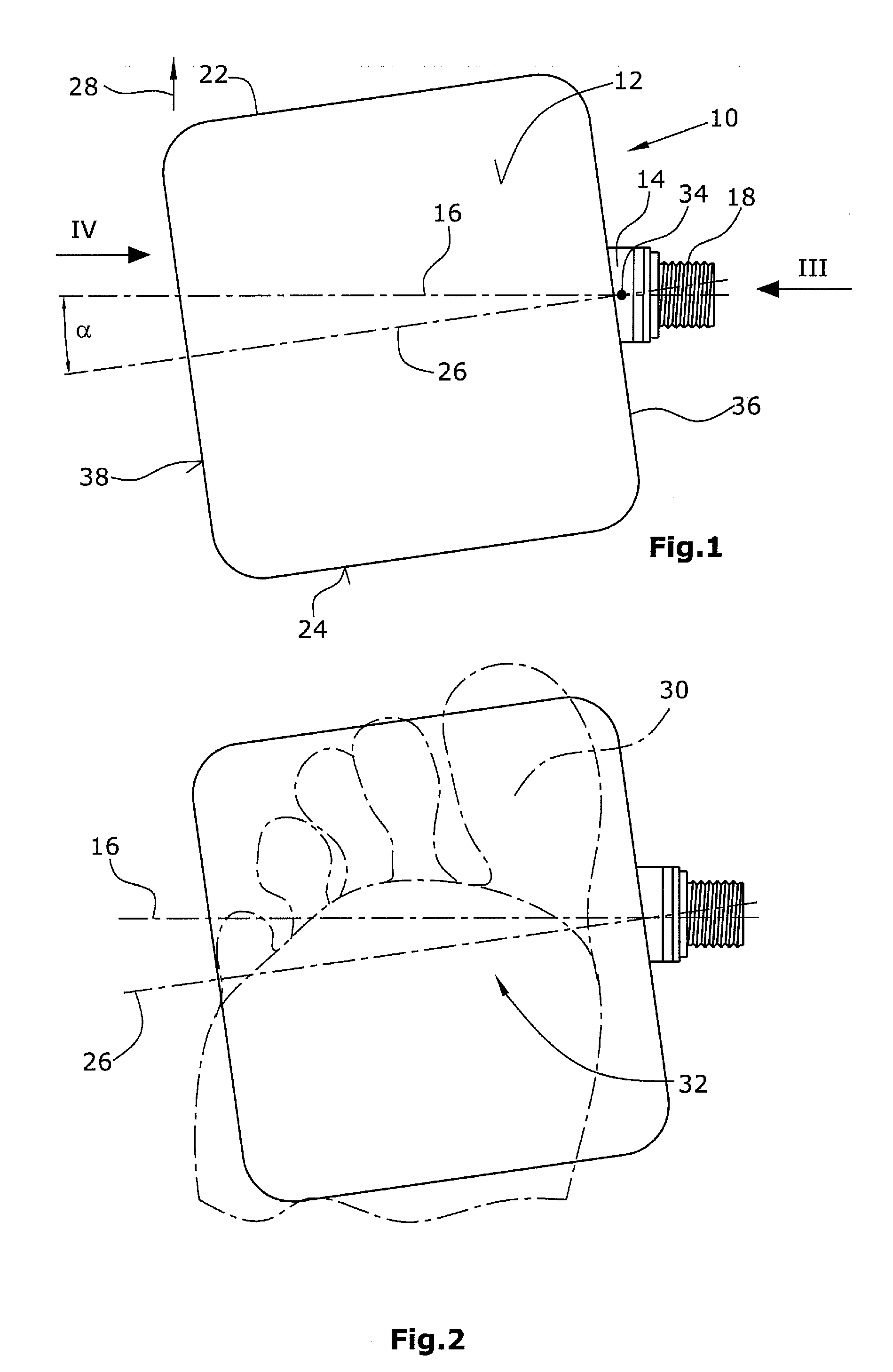

Bicycle pedal

InactiveUS20120060646A1Improve positioningPositive effectMechanical apparatusVehicle cranksEngineeringTreadle

A bicycle pedal comprises a pedal body having a support surface and a pedal axle rotatably supporting the pedal body. The pedal is characterized in that the support surface has a recess extending substantially across the entire width of the pedal, the deepest portion of the recess being offset from the pedal axle.

Owner:RTI SPORTS VERTRIEB VON SPORTARTIKELN

Manufacturing method of composite material pressure container

InactiveCN103016950AReduce self-tightening pressureSelf-tightening pressure is metPressure vesselsInternal pressureFree cooling

The invention relates to a manufacturing method of a composite material pressure container, which comprises the following steps: 1, connecting an inflating and pressure-maintaining tooling with a lining, inflating the lining with air having a certain pressure to enable the lining to be subjected to swelling deformation, and calculating to determine the internal pressure of the inflated metal lining according to a formula; 2, keeping the lining in a pressure-maintaining state, and performing twisting processing of fibrous composite materials; 3, after the twisting operation is finished, transferring into a curing oven, and performing rotary hot curing; and 4, after the curing operation is finished, naturally cooling, and slowly releasing the internal air to relieve the pressure, thereby ensuring that the elastic contraction of the lining counteracts the compression stress in the twisting process and the curing contraction of the composite material and the lining can be peeled and separated from the composite material layer. According to the invention, the internal stress required in the self tightening process can be reduced, and the swelling deformation rate of the composite material layer can be reduced, thereby lowering the fiber breakage rate of the composite material layer and ensuring high overall performance of the composite material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

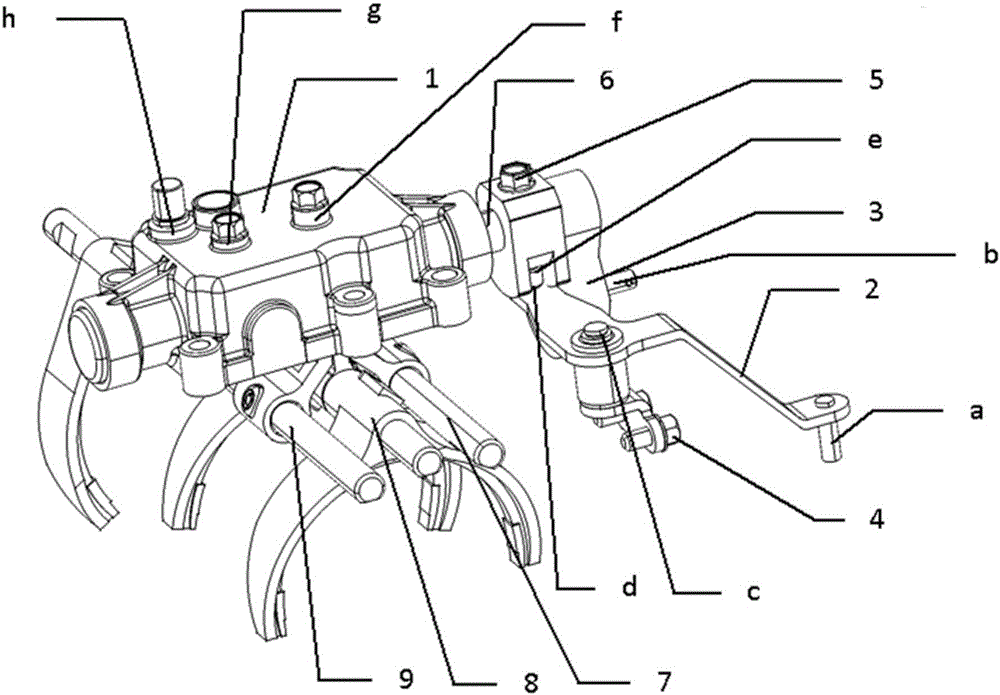

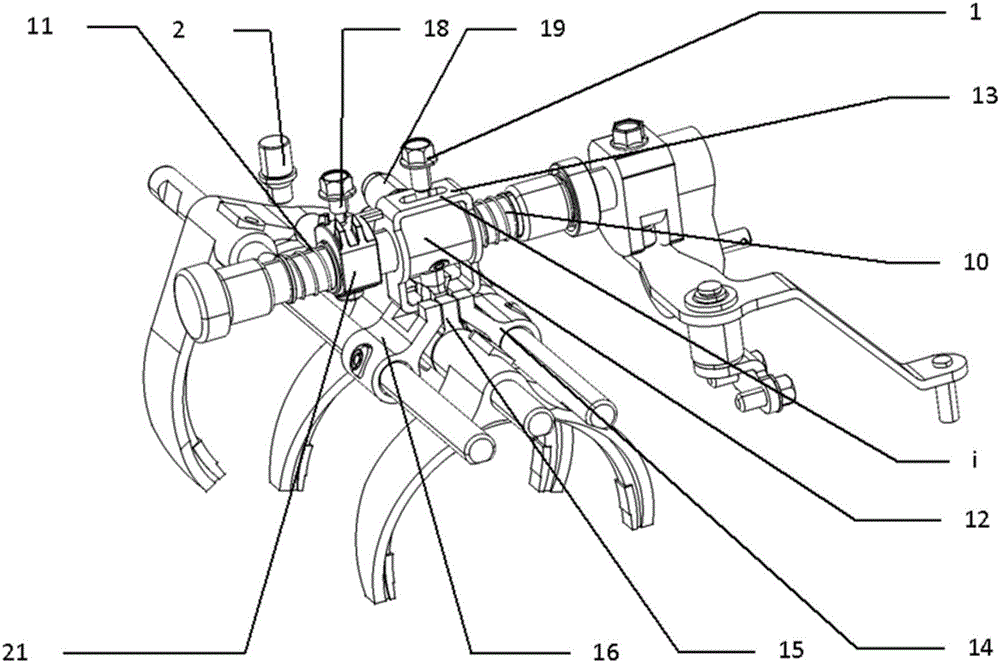

Gear-shifting control mechanism assembly of transmission

InactiveCN106481801ASimple structureImprove return performanceControlled membersGearing controlChinese charactersControl system

The invention relates to a gear-shifting control mechanism assembly of a transmission. The assembly comprises a gear selecting and shifting base, a gear selecting rocker arm, a gear shifting rocker arm, a gear selecting and shifting shaft, a first gear and second gear shifting fork combination part, a third gear and fourth gear shifting fork combination part, a fifth gear and R gear shifting fork combination part, a first gear selecting return spring, a second gear selecting return spring, a gear selecting and shifting push block, a gear shifting interlocking plate, a first gear and second gear shifting push block, a third gear and fourth gear shifting push block, a fifth gear and R gear shifting push block, a gear selecting guide bolt, a gear shifting guide bolt, a gear shifting locating pin and a guide block with a groove shaped like a Chinese character 'wang'. According to the technical scheme, in a control system, the gear shifting locating pin is added, and therefore the gear shifting suction feeding can be improved; the guide block with the groove shaped like the Chinese character 'wang' is designed, and therefore gear shifting can be smooth, the gear shifting track can be uniform and the gear shifting quality can be improved; the gear shifting interlocking plate is adopted, and therefore the design of a box body and a shifting fork shaft can be simplified, and the assembly technology can be simplified; and a compression spring is adopted for gear selecting returning and has the advantages that the manufacturing errors are small and the gear selecting returning effect is good compared with a traditional torsion spring.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

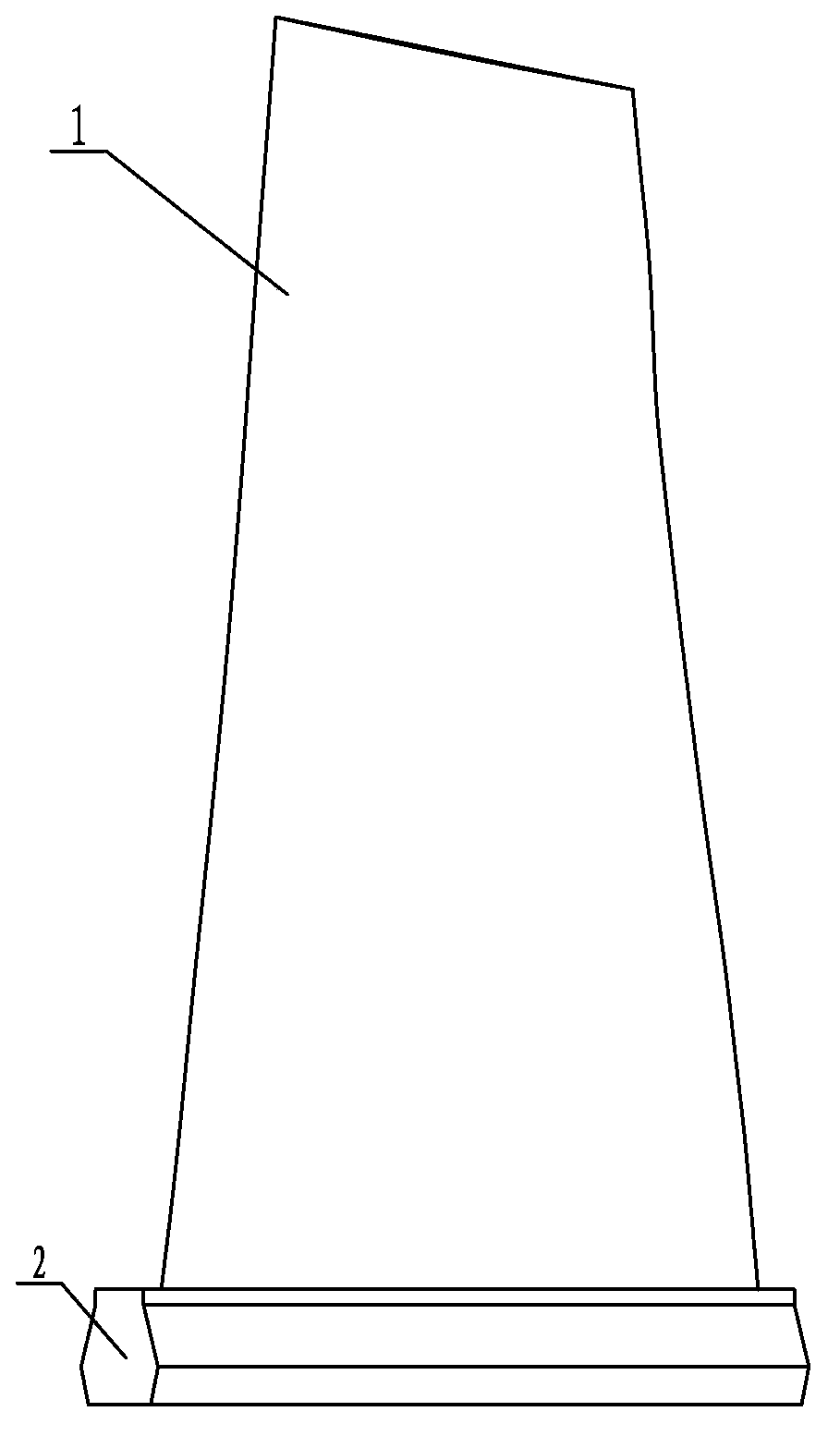

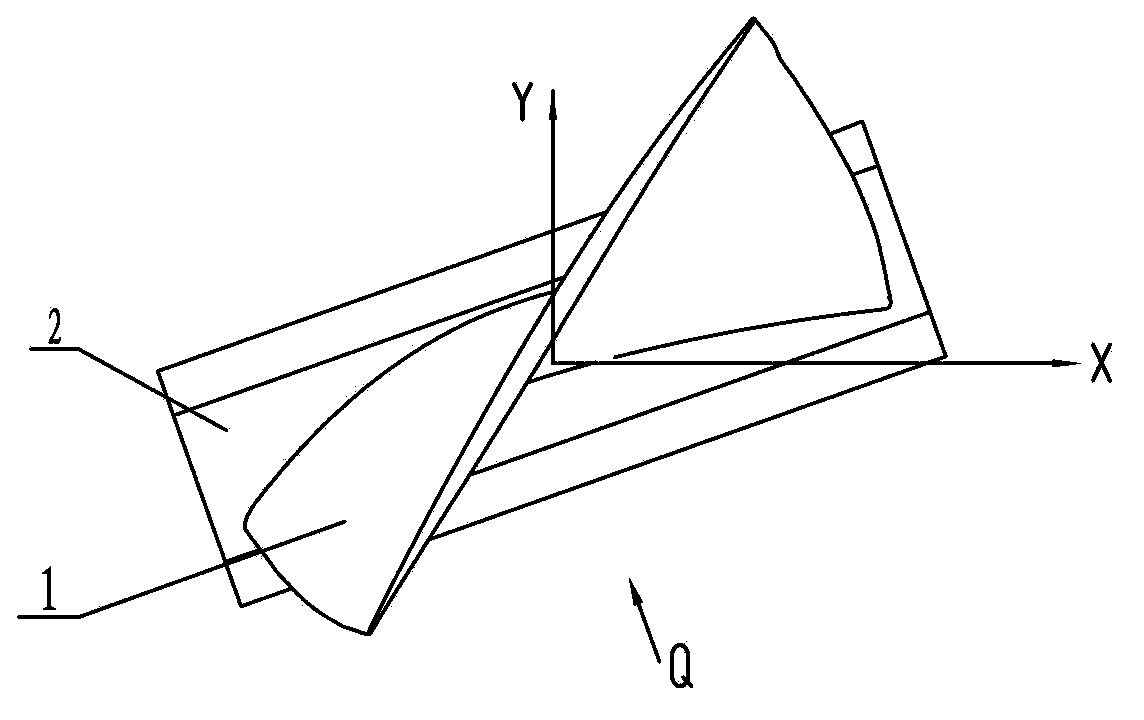

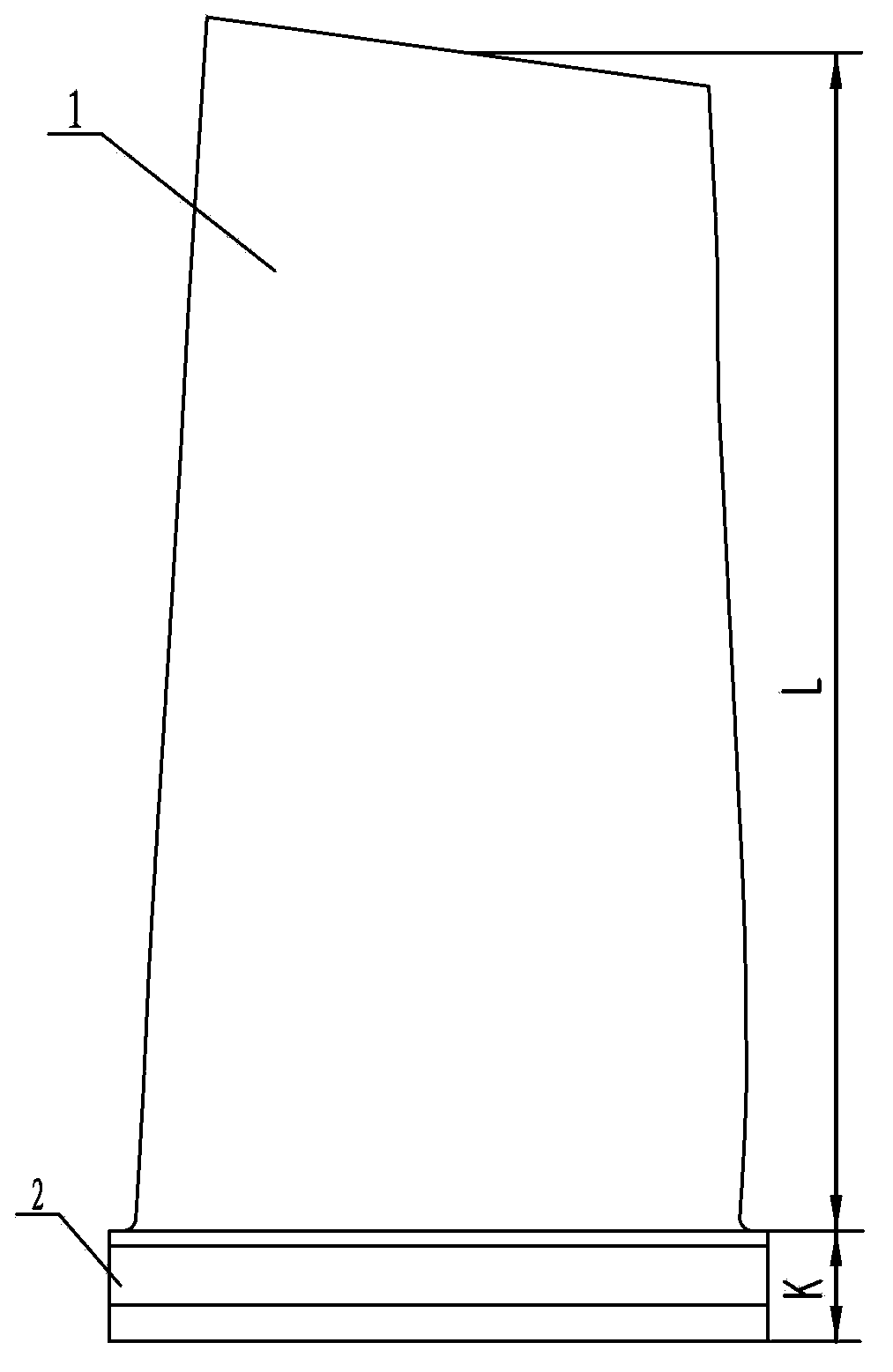

Secondary first-stage blade for transonic compressor on high-speed gas turbine

InactiveCN103423193AReduce wearExtended service lifePump componentsPumpsTurbine bladeTransonic compressor

The invention belongs to the field of gas turbine blades, and relates to a secondary first-stage blade for a transonic compressor on a high-speed gas turbine. The problems that due to computing and manufacturing accuracy, a secondary first-stage blade of a transonic compressor for an existing high-speed gas turbine is high in wear, low in working efficiency and short in service life and causes security risk to running of the compressor are solved. A blade working portion and a blade root are made into a whole from top to bottom, the overall height L of the working portion is 146.22mm, the axial width B of the root of the blade working portion is 70.46mm, a variation range of the axial width B of the blade working portion is within 71.12mm-40.06mm, a variation range of chord length b of a cross section of the blade working portion is within 74.55mm-79.72mm, a variation range of a bending angle alpha is within 17.667 degrees-59.508 degrees, a variation range of the maximum thickness Dmax of a profile is 8.46-2.38mm, and the thickness DE of the position, 0.7mm away from an air outing edge, of the air outing edge is 1.59-0.34mm.

Owner:HARBIN TURBINE

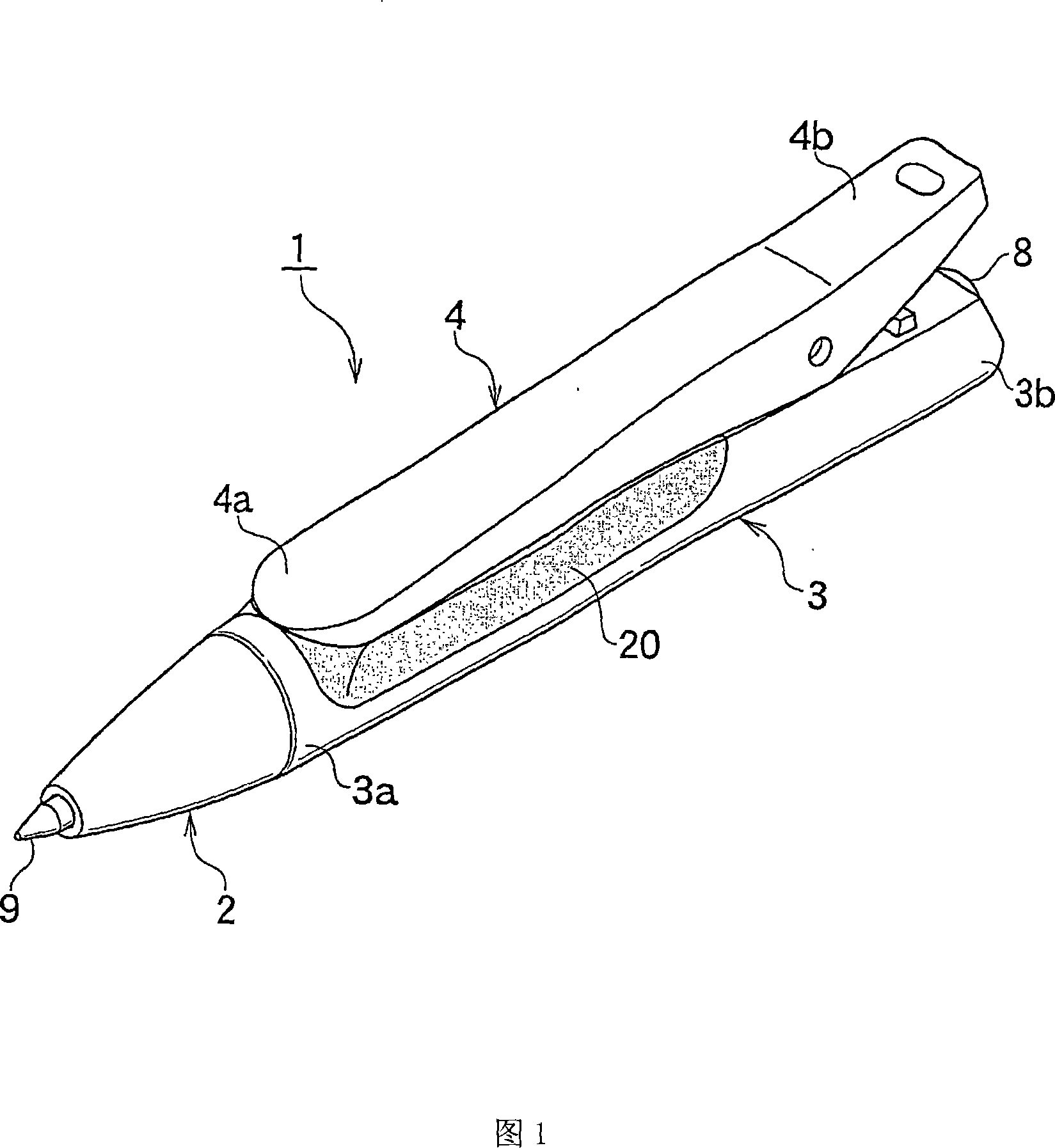

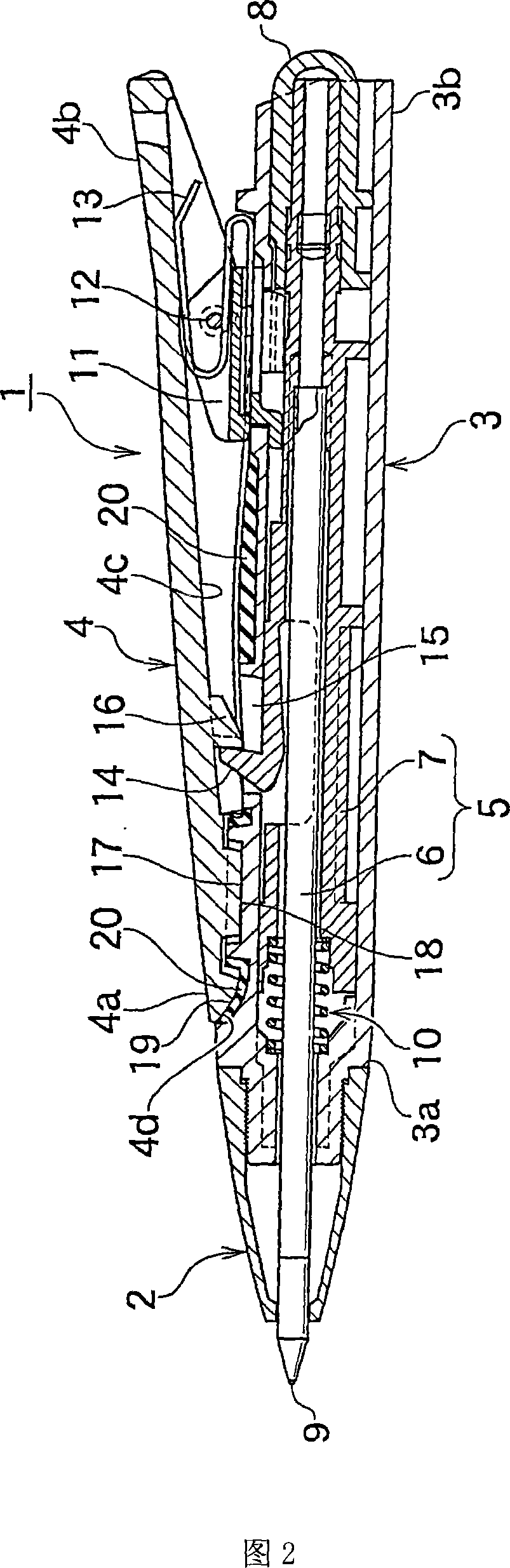

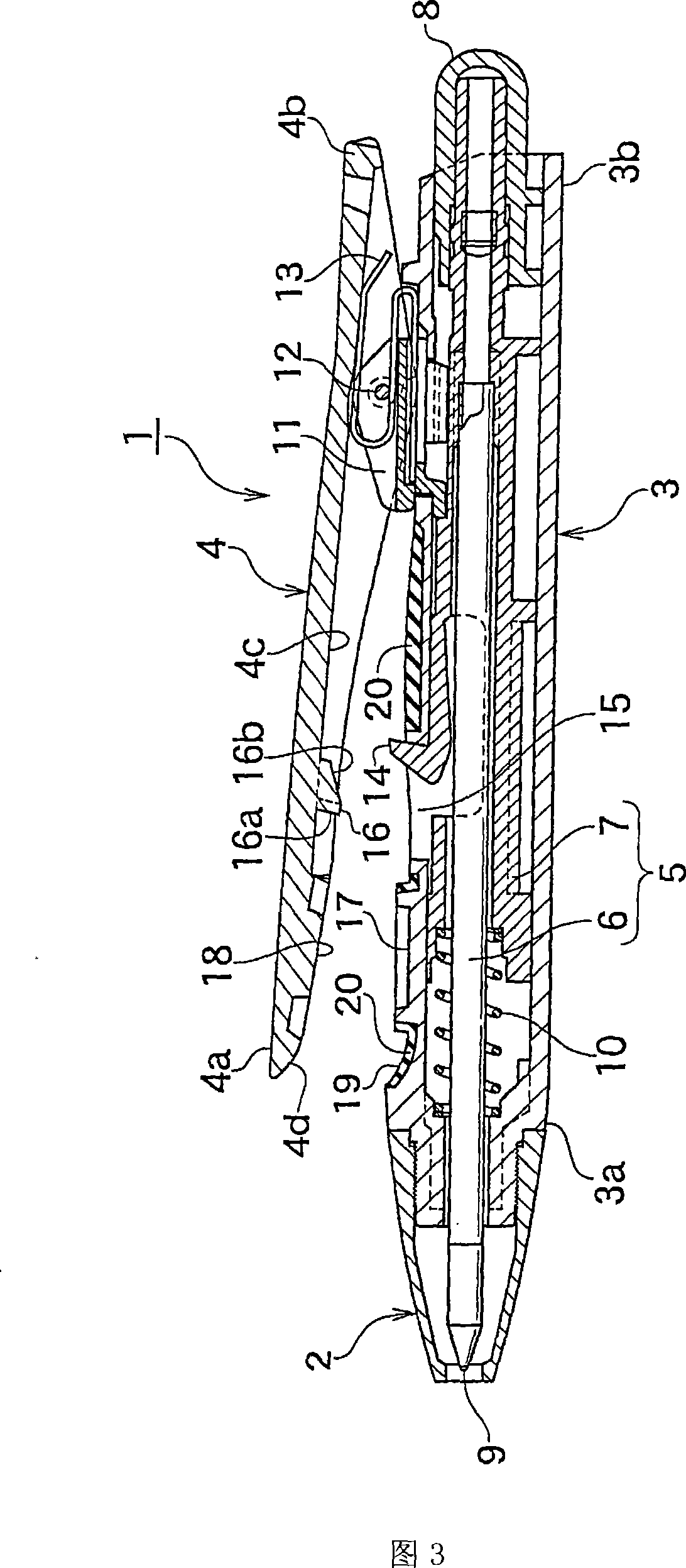

Writing instrument

Owner:TOMBOW PENCIL CO LTD

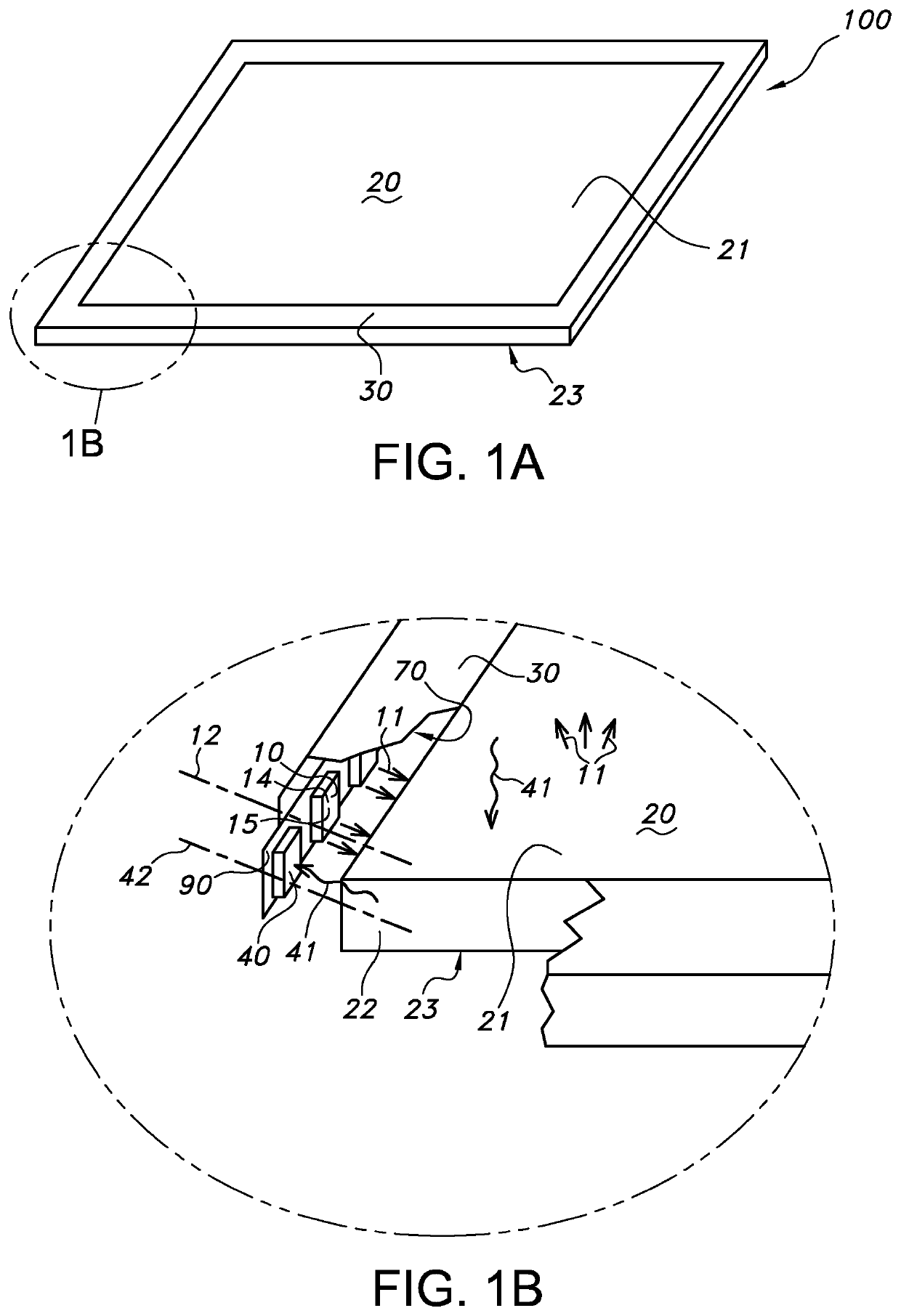

Integrated ir receiver in side-lit panels

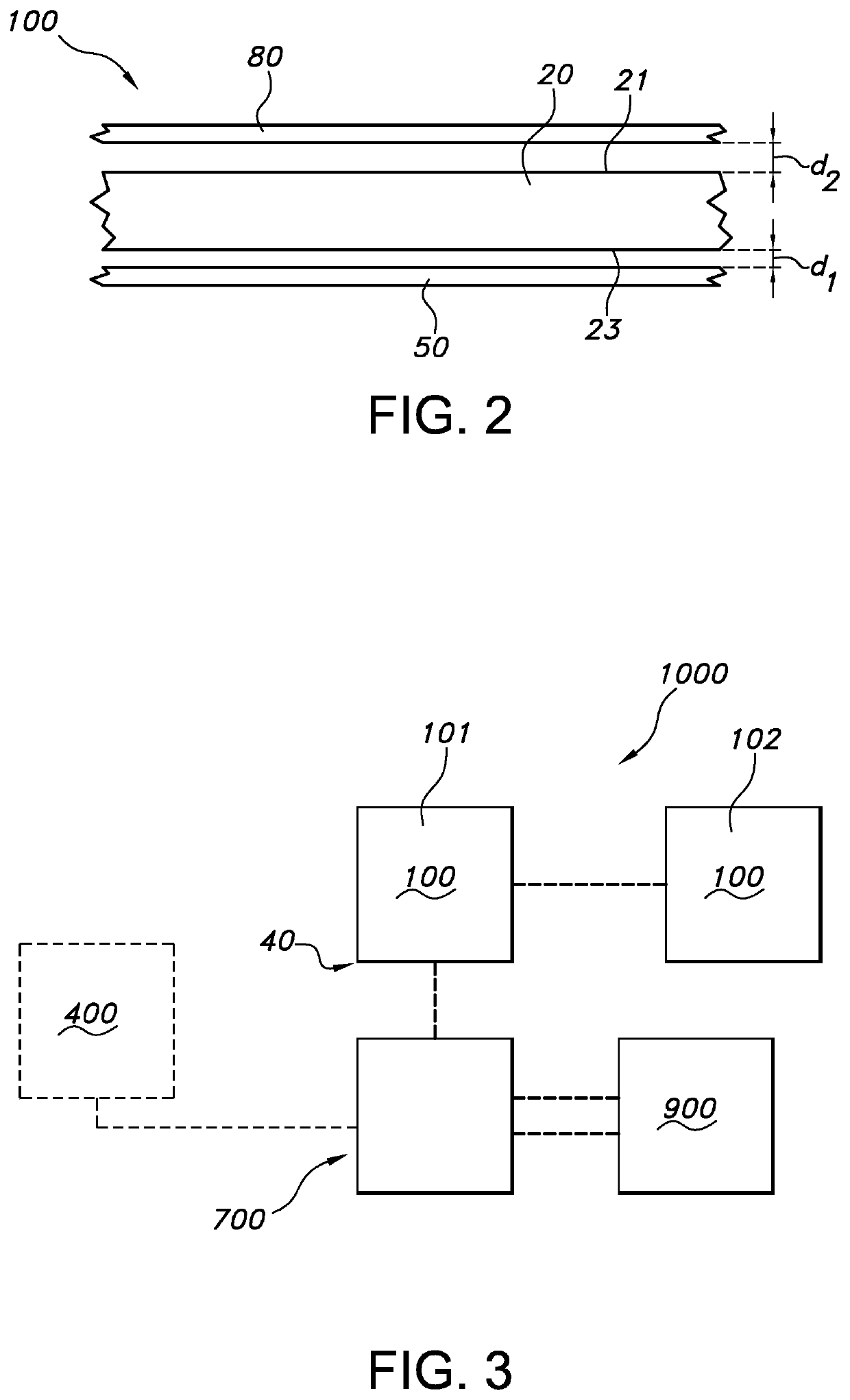

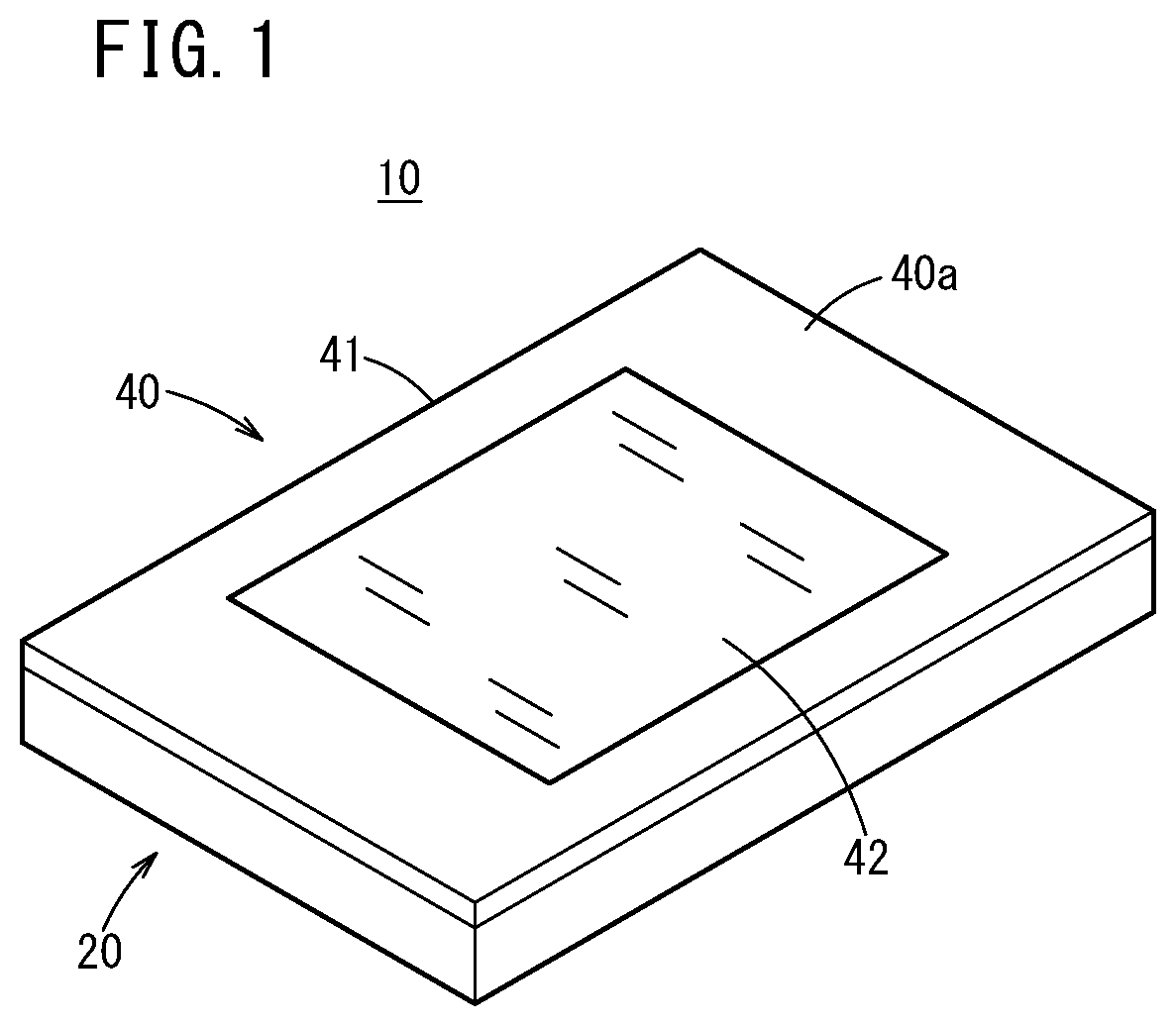

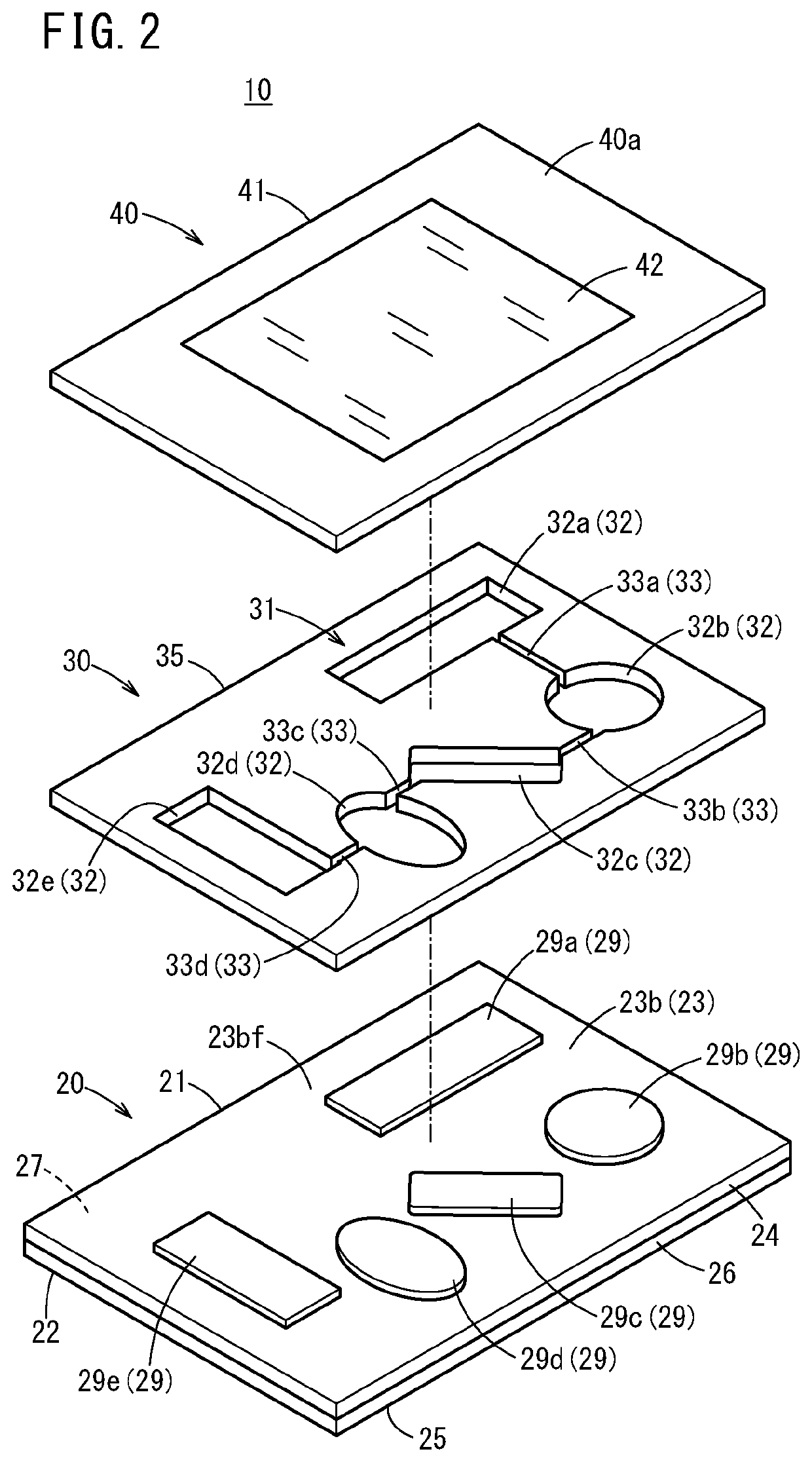

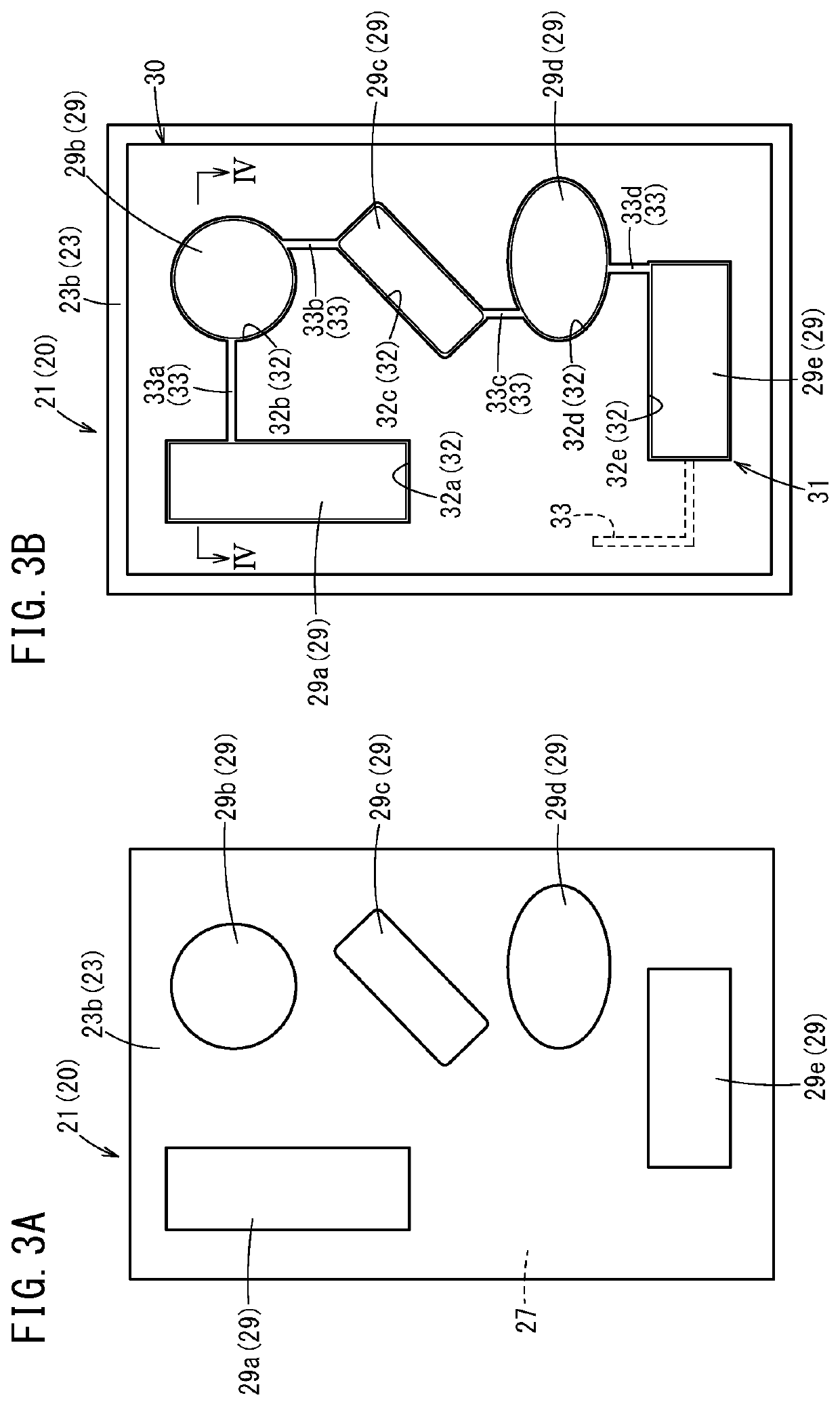

ActiveUS20200124263A1Smooth designPrevent escapeMechanical apparatusElectric circuit arrangementsLight guideEngineering

The invention provides a lighting device (100) comprising a plurality of light sources (10), a light guide plate (20), a rim (30), and an IR sensor (40), wherein: (i) the light sources (10) are configured to provide light source light (11), and wherein the light sources (10) are configured in an edge-lighting configuration with the light guide plate (20); (ii) the light guide plate (20) comprises a circumferential edge (22) of which at least part is 5 configured as light incoupling face for the light source light (11), and a first face (21) of which at least part is configured as light outcoupling face; (iii) the rim (30) comprises the plurality of light sources (10) and the IR sensor (40); and (iv) the IR sensor (40) is configured to sense IR radiation (41) via the light guide plate (20).

Owner:SIGNIFY HLDG BV

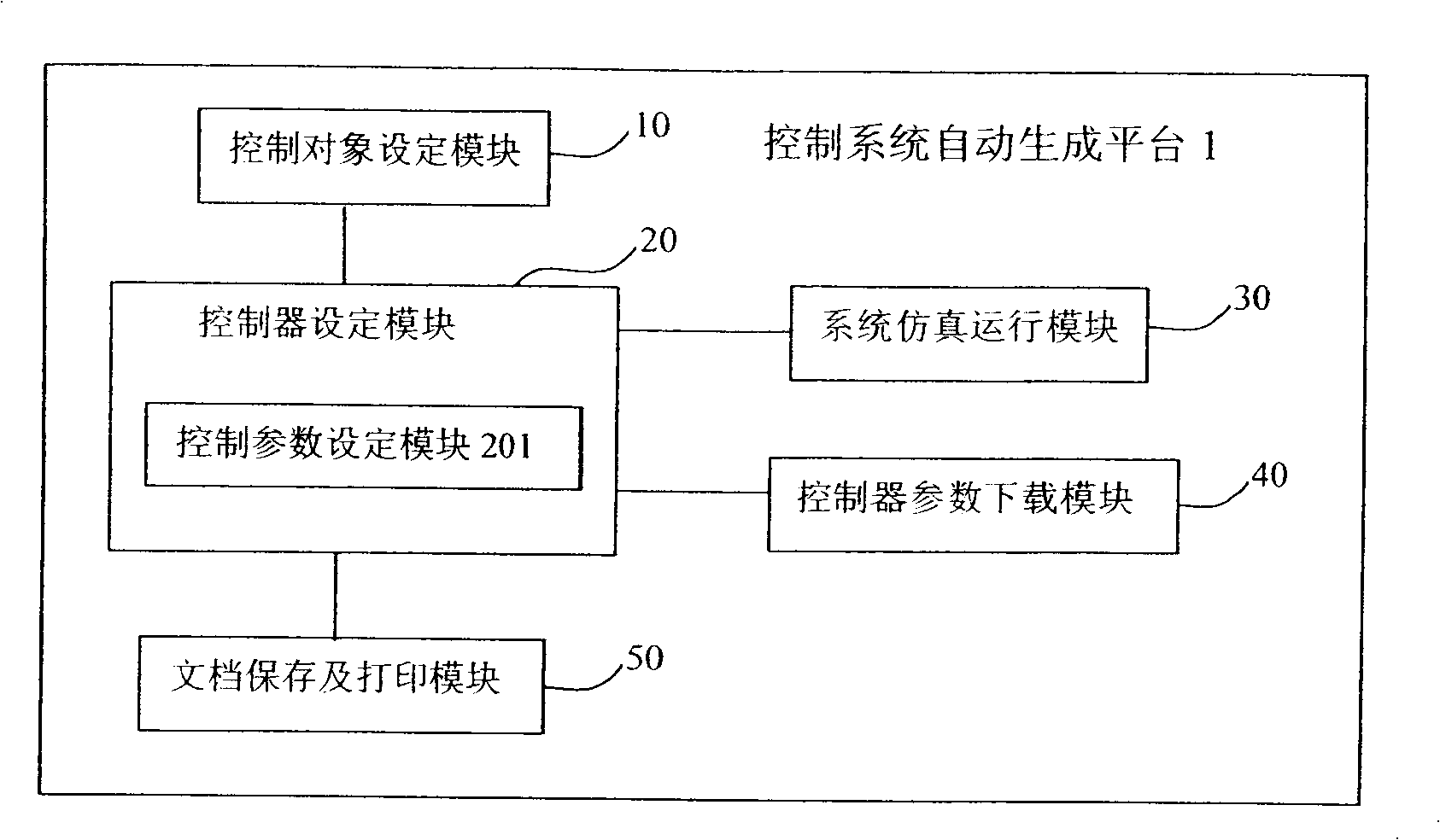

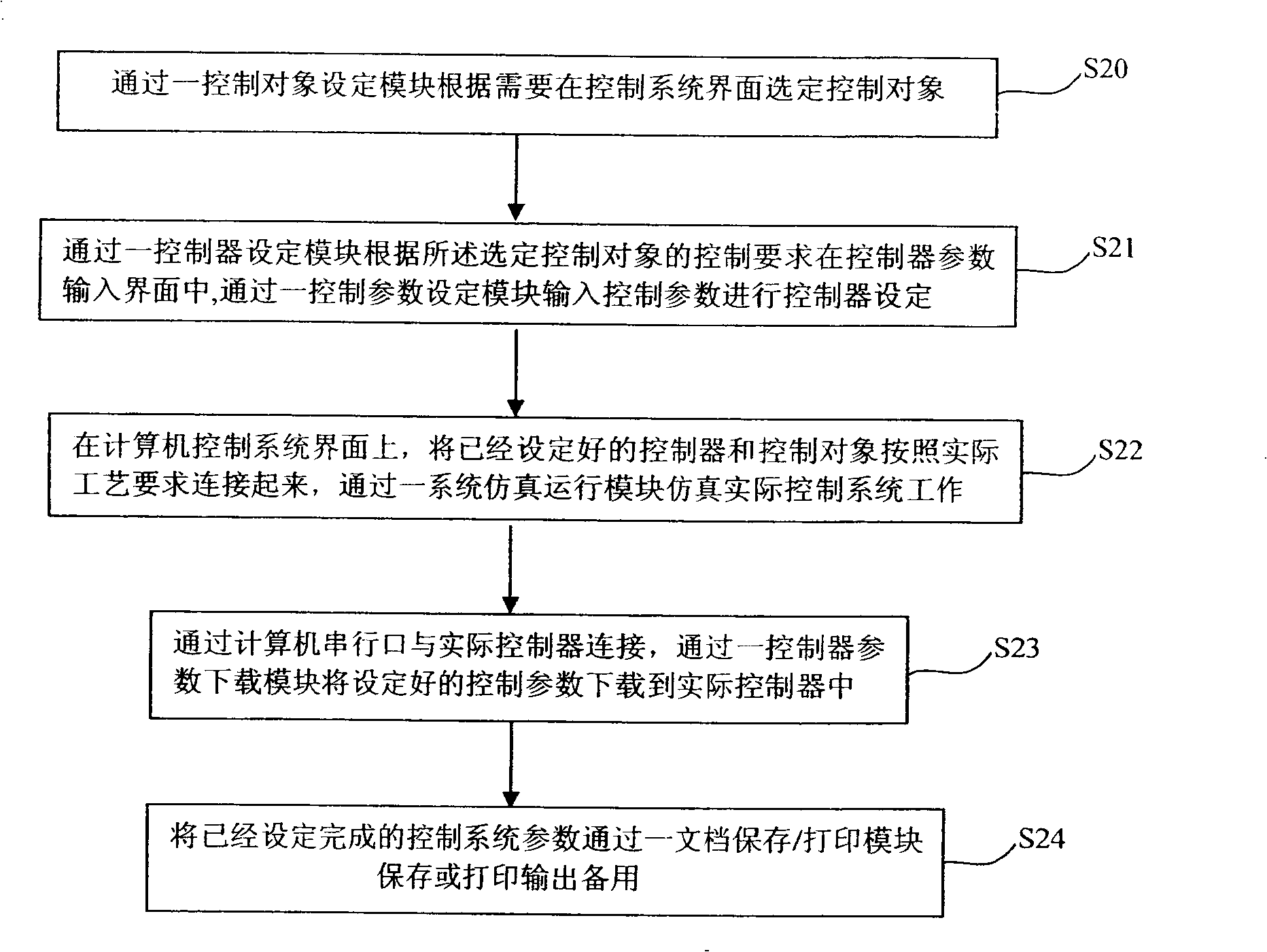

Automatic generating platform of control system and method thereof

InactiveCN101354571AEasy designSmooth designElectric programme controlControl systemControl software

The invention discloses a control system automatic generation platform and a method thereof. The control system automatic generation platform is provided with a control software automatic generation program and a controller driver in advance, and comprises a controlled object set module which is used to select a controlled object inside an interface of the control system according to requirements; a controller set module which is used to input a control parameter for controller set inside a parameter input interface of the controller according to the control requirements of the controlled object, as well as a controller parameter download module which is used to download the set control parameter into the controller via a computer serial port.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Electric heating tea table with rotatable elevation

PendingCN107095453AThe rotation process is stableReasonable designFurniture partsServing tablesElectric heatingElectricity

The invention discloses an electric heating tea table with rotatable elevation. The tea table comprises a tea table body, wherein the tea table body comprises a panel, a base board, and multiple support columns arranged between the panel and the base board, circular through holes are arranged in the center position of the panel, a rotating desktop is arranged in the circular through holes, the rotating desktop and the size of the circular through holes arranged in center location of the panel are matched, the upper surface of the desktop and the panel are levelly arranged, a rotating and lifting device is arranged on the back, the rotating or up and down movements of the rotating desktop around the panel can be achieved by the rotating and lifting device. By the adoption of the electric heating tea table, by the arrangement of the rotating and lifting device on the back of the rotating desktop, the rotating or up and down movements of the rotating desktop around the panel can be achieved by the rotating and lifting device. The electric heating tea table with rotatable elevation has the advantages of being reasonable in design, simple in structure, ease of use in operation, good in stability, flexible in rotation, high in reliability and the like.

Owner:ZUNYI BAOJINGYUAN SCI & TECH CO LTD

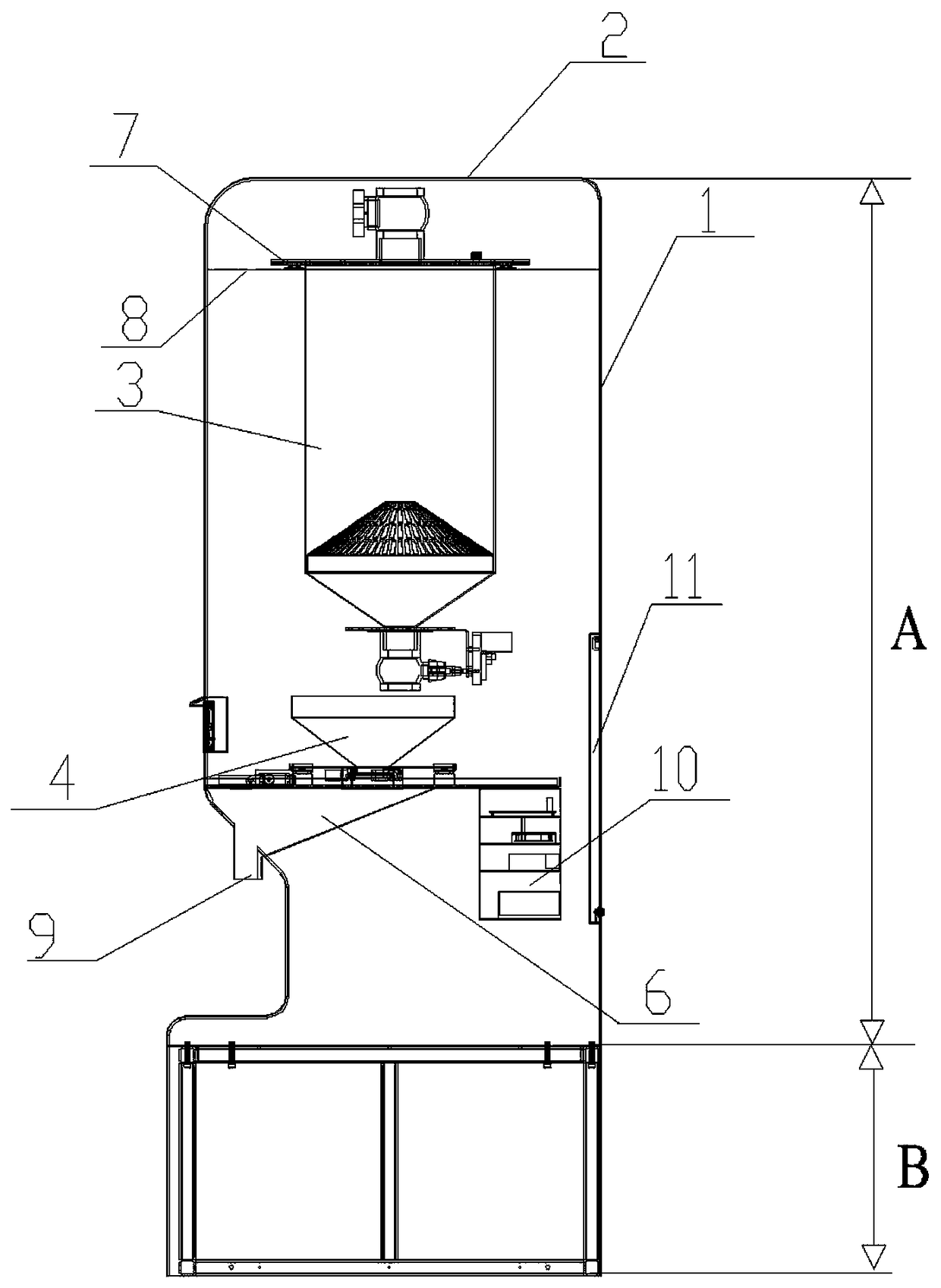

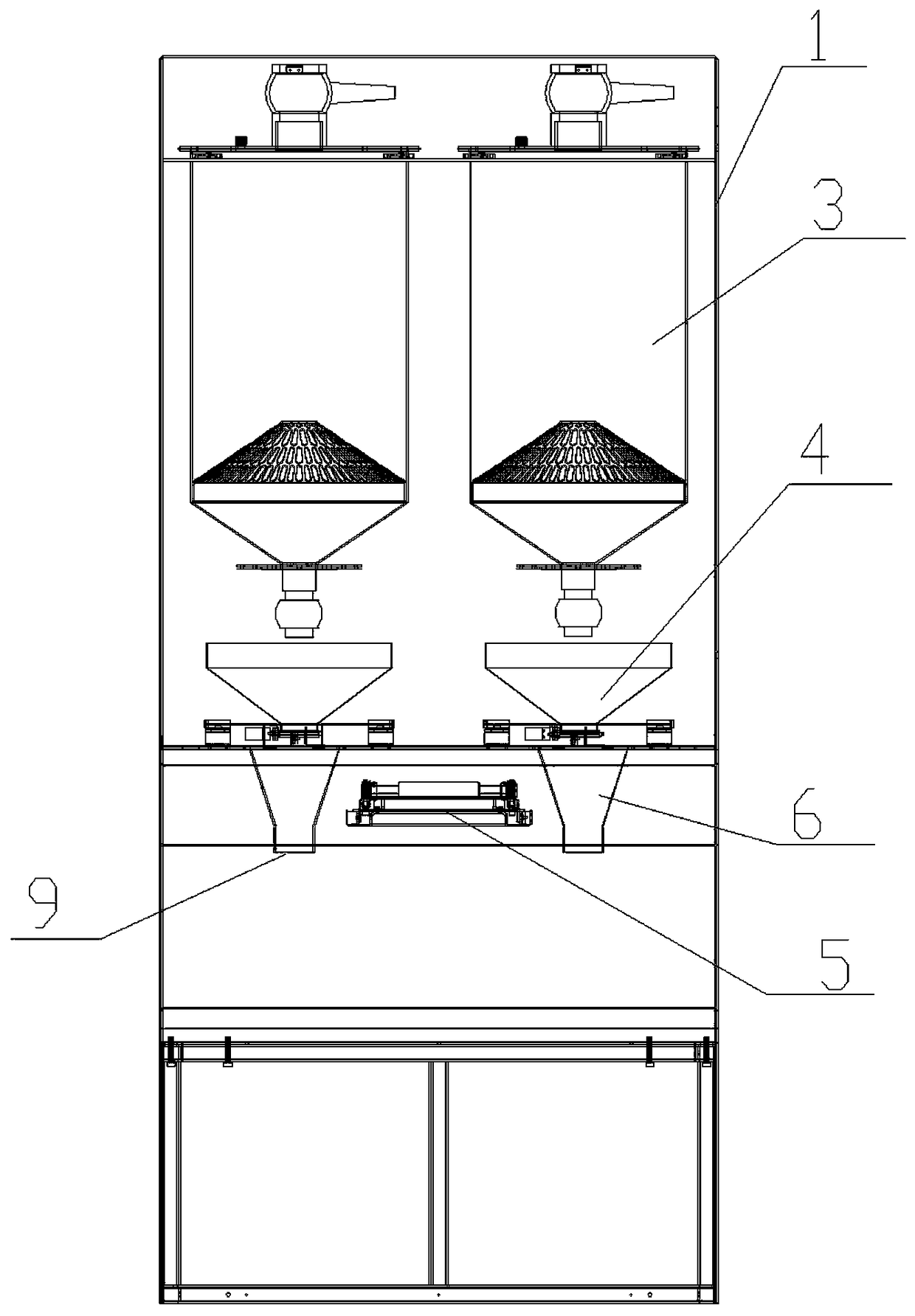

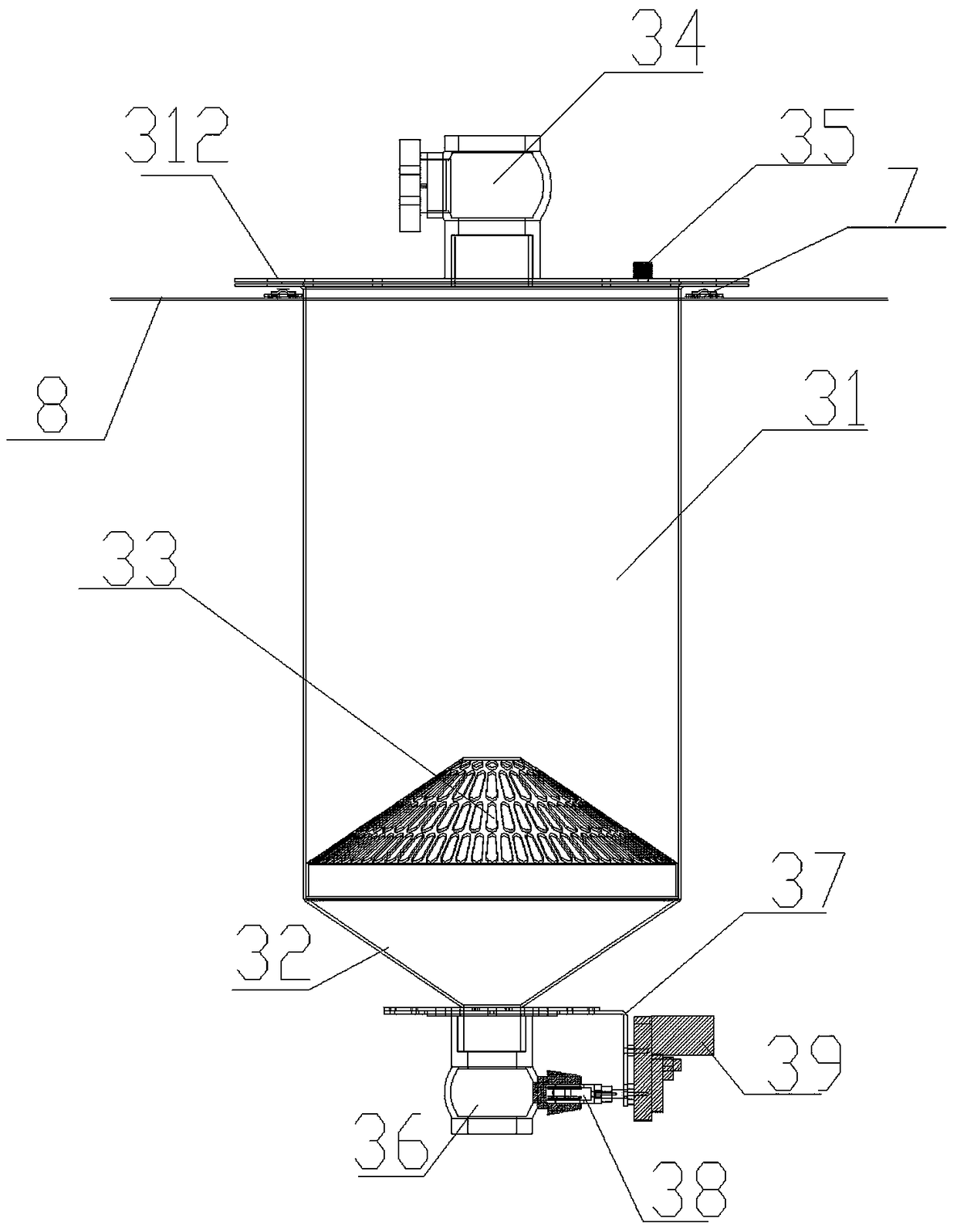

Portable grain vending machine

PendingCN108922040AControl the discharge situationPrevent moisture deteriorationApparatus for dispensing fluids/granular materialsGrain storageComputer engineering

The invention discloses a portable grain vending machine. The portable grain vending machine comprises a computer case; a top cover is arranged at the upper end of the computer case; a shopping bag extracting device and at least a grain storage bin are arranged in the computer case; a shopping bag extracting mouth and a grain taking mouth as many as the grain storage bin are arranged at the frontside of the computer case; and the downside of the outputting mouth of each grain storage bin is correspondingly communicated with a grain taking mouth through each obliquely arranged discharging channel. The portable grain vending machine is simple in structure, convenient to install, easy to transport, small in volume and more practical.

Owner:河南省天天粮仓科技有限公司

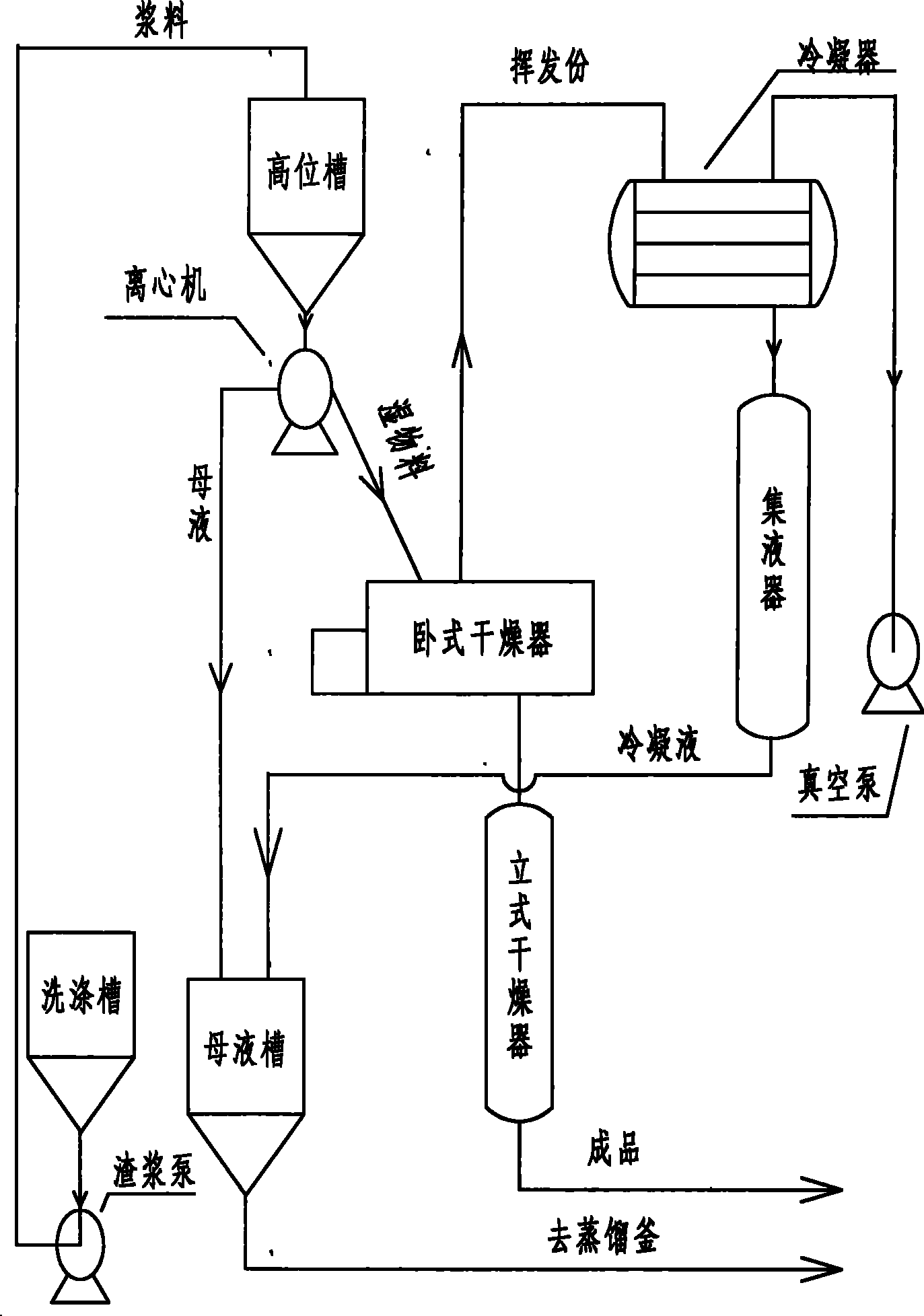

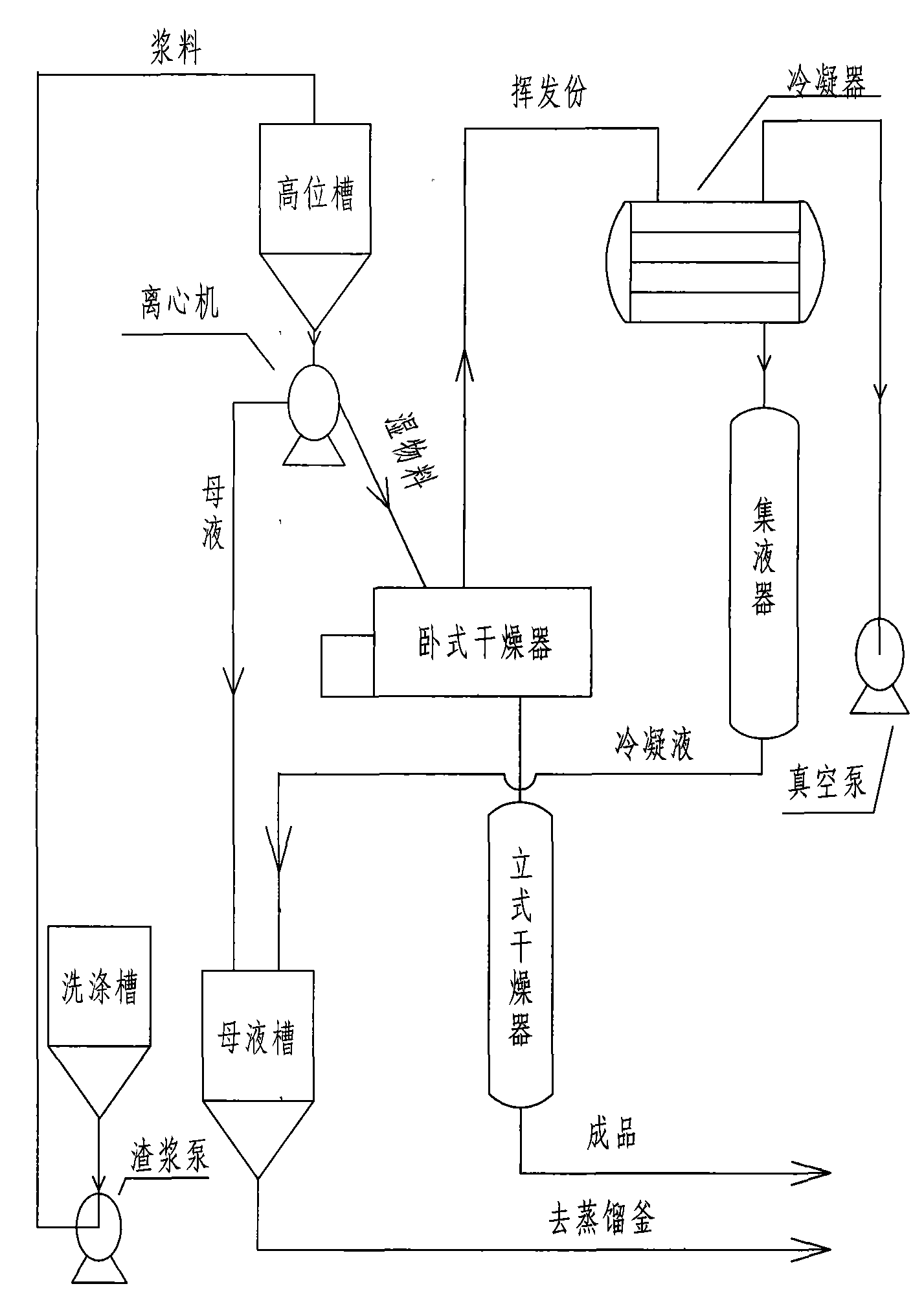

Desolution, centrifugation and drying integrated process of poly (propylene carbonate) industrial production

ActiveCN101456946BSolving industrialization problemsContinuous processChemical industryComing outCentrifugation

The invention relates to the exsolution, centrifugation and drying integrated technology in the industrial production of poly propylene carbonate, which belongs to the technical field of the synthesis of the industrial production of the poly propylene carbonate and the post treatment of the product. The technology comprises: injecting the poly propylene carbonate slurry continuously into a sealedelevated tank by a slurry pump; entering a centrifuge after leaving the elevated tank; putting the slurry continuously into the centrifuge to be centrifugalized to ensure that the moisture content (weight) of the wet material is less than 50 percent; putting the wet material coming out of the centrifuge into a horizontal drier to be dried for 1-6 hours and putting mother liquor into a mother liquor tank; putting the solids with less than 1 percent of moisture content (weight) coming out of the horizontal drier continually into a vertical drier to be dried for 1-4 hours to ensure the moisture content (weight) is less than 0.2 percent after drying; obtaining the ultimate solid which is the finished product of the poly propylene carbonate; and condensing and recovering the fugitive constituents to be led into the mother liquor tank. The technology of the invention has the advantages of complete sealed entire process, complete liquid constituent recovery, continuous technological process,smooth and integrated design, simple equipment and low production and labor cost, which is particularly suitable for industrial production.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

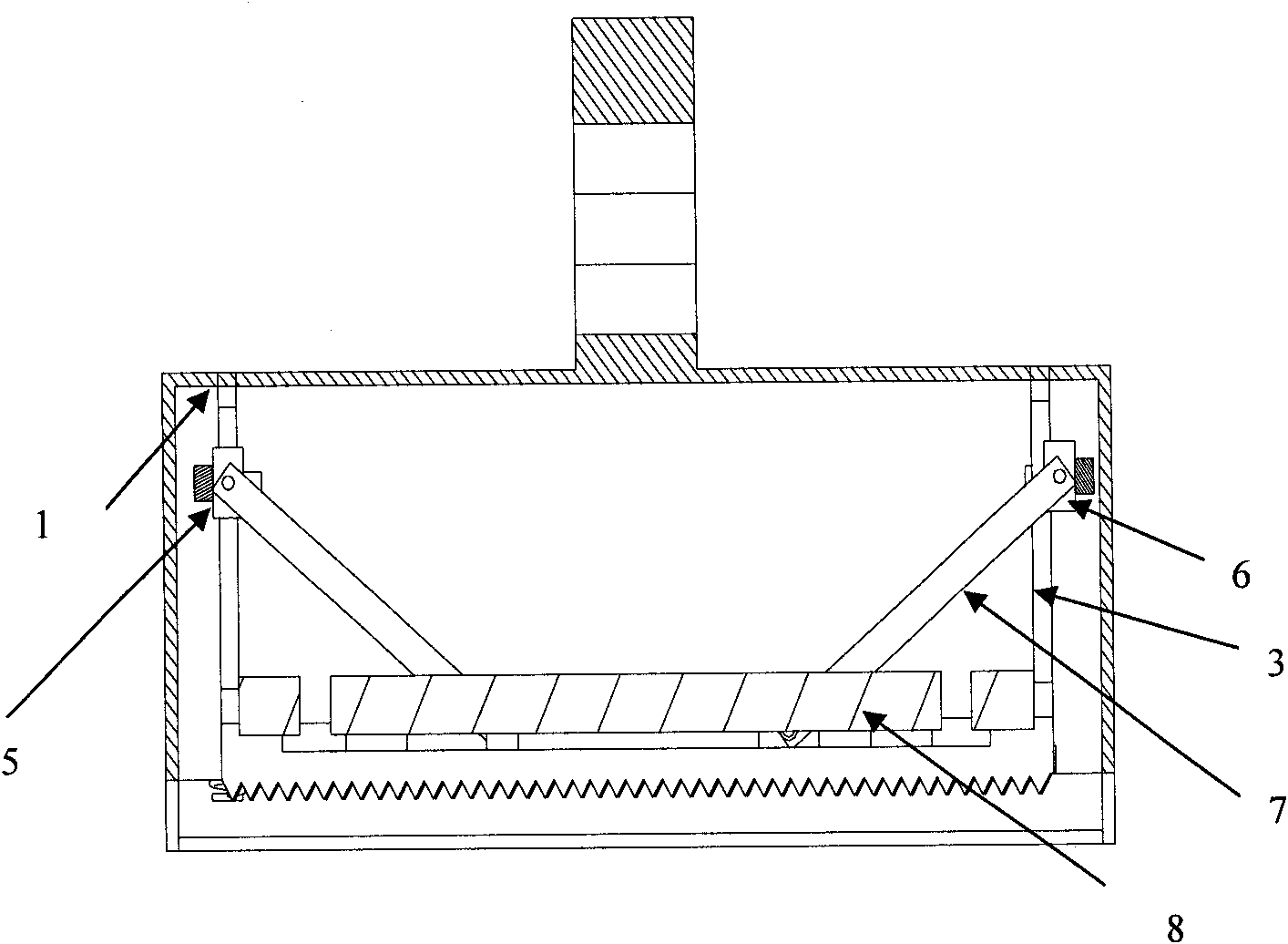

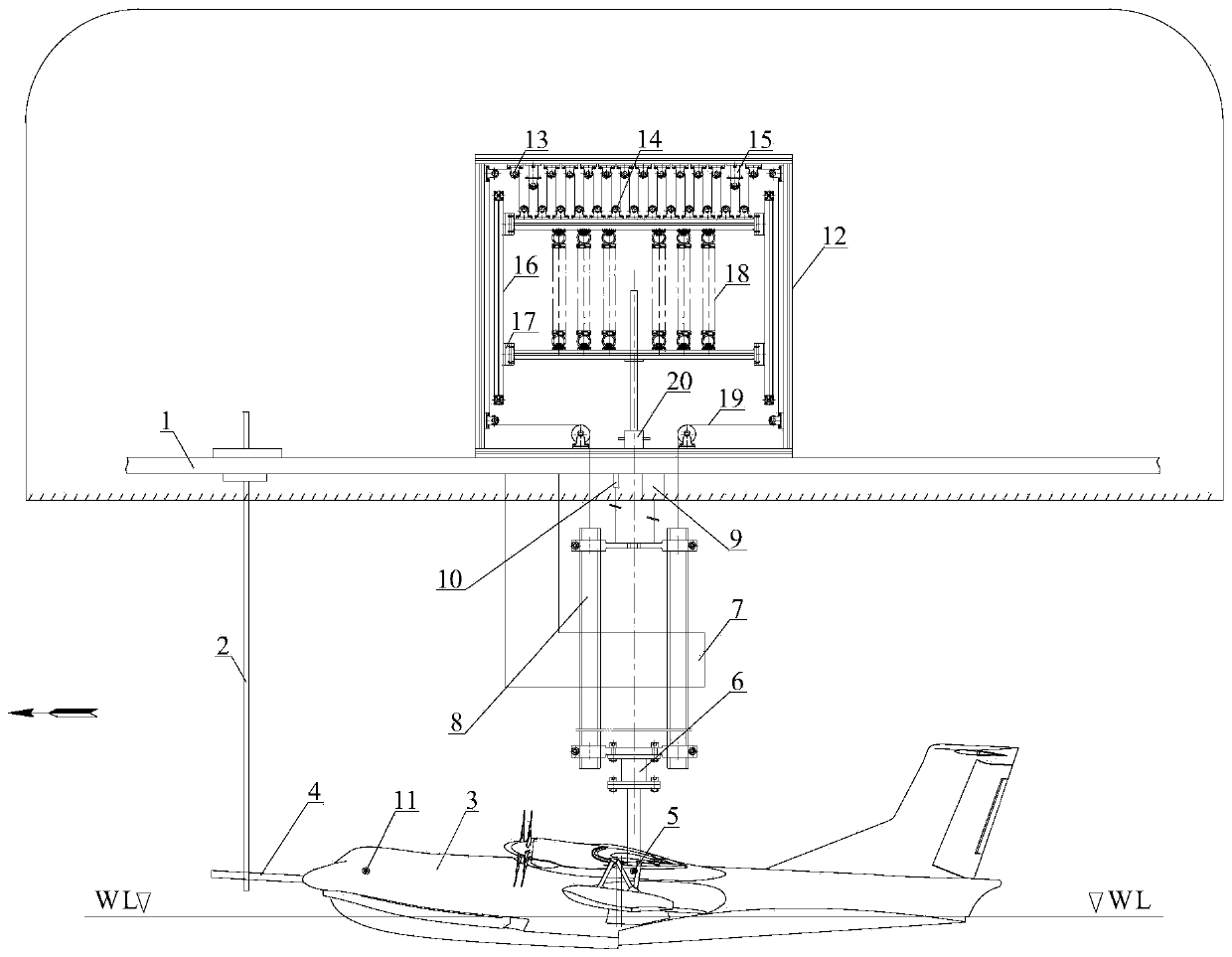

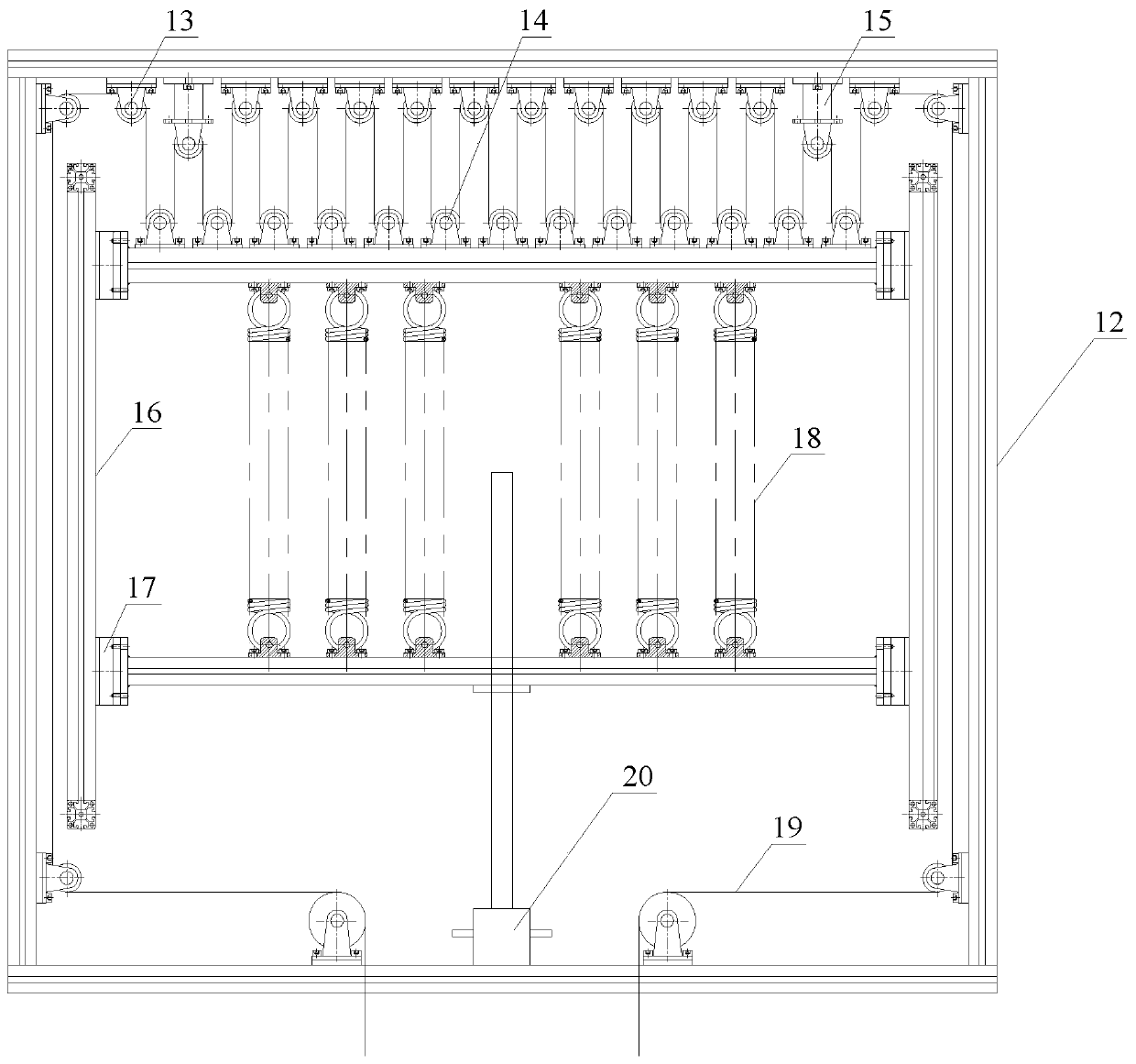

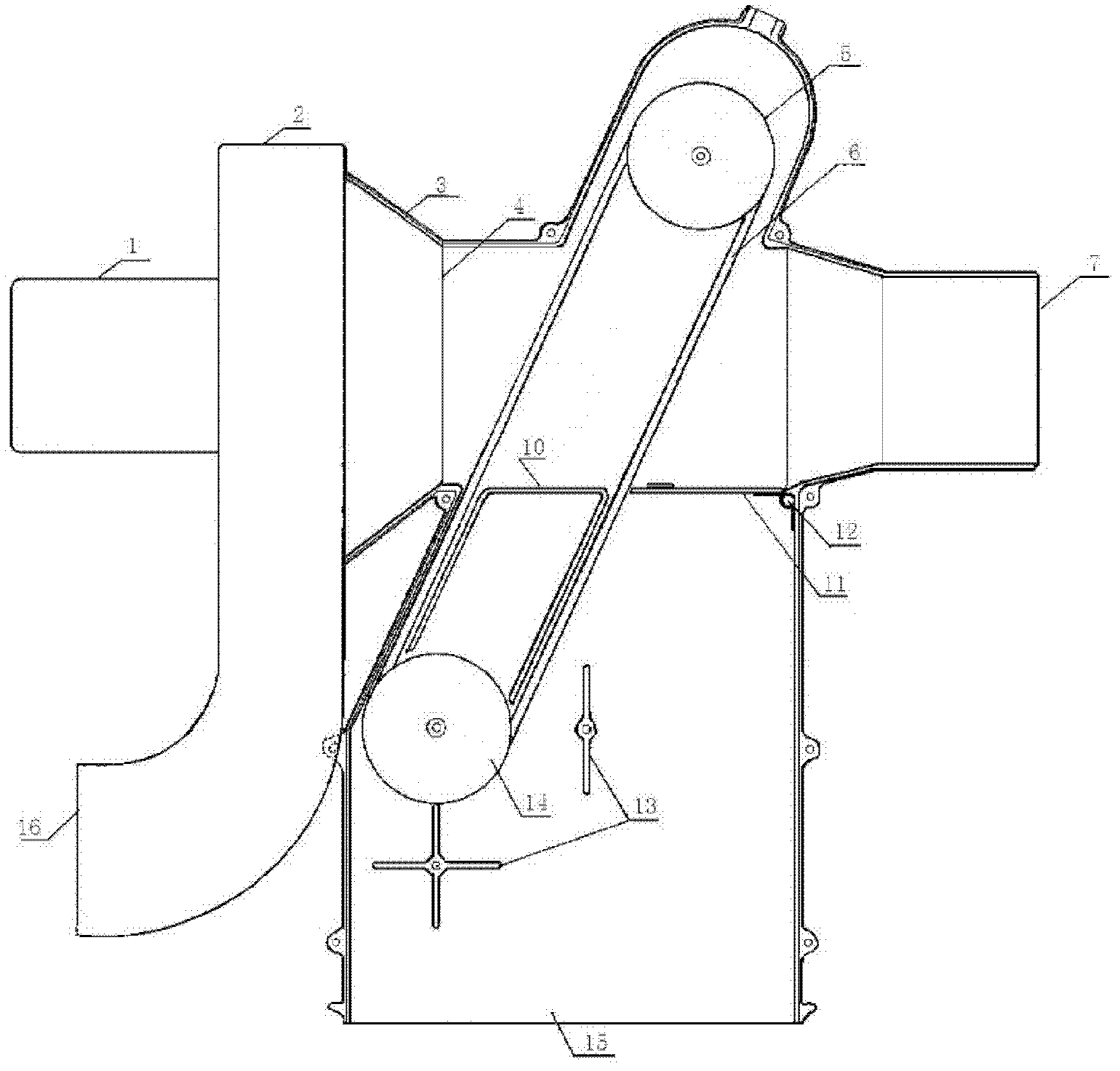

Water surface aircraft seakeeping test constant force unloading device and method

ActiveCN111056043AReducing the technical risk of seakeeping testSolve technical difficulties in seakeeping researchAircraft components testingMarine engineeringFlight vehicle

The invention belongs to the field of water surface aircraft seakeeping tests, and provides a water surface aircraft seakeeping test constant force unloading device and method. The constant force unloading device comprises a trailer measuring bridge, a navigation rod, a model, a navigation piece, an angle sensor, a resistance sensor, a limiting guide rail, a heaving rod, a remote control electrichoist, a displacement sensor, an overload sensor, a fixed frame, a fixed pulley, a movable pulley, a tension sensor, a linear sliding rail, a sliding block, a spring, a Kevlar rope and a rocker. A relatively constant simulated aerodynamic lift force can be provided for a full-aircraft unpowered model and a single-hull model seakeeping test of a water surface aircraft; a test technical method withhigher reliability and more accurate model test data are provided for real seakeeping prediction of the water surface aircraft, quick and efficient test verification is performed on feasibility of a water surface aircraft seakeeping design scheme, and technical guarantee is provided for seakeeping design and research of the water surface aircraft.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Foldable electronic device

ActiveUS11064060B2Provide user experienceSmooth designDetails for portable computersPivotal connectionsDisplay deviceStructural engineering

Provided is a foldable electronic device. The electronic device may include: a foldable housing including: a hinge structure; a first housing structure including a first surface, a second surface, and a first side surface; and a second housing structure including a third surface, a fourth surface, and a second side surface, and foldable with the first housing structure with the hinge structure, wherein, in a folded state, the first side surface and the second side surface are aligned; a flexible display; first side keys including a first sensing panel reflecting a change in force applied to the first side surface; second side keys including a second sensing panel reflecting a change in force applied to the second side surface; and a sensor generating a signal based on a change in the force detected by the first sensing panel or the second sensing panel. It is possible to provide other embodiments.

Owner:SAMSUNG ELECTRONICS CO LTD

Disk brake

ActiveUS8042656B2High strengthAvoid deformationAxially engaging brakesSlack adjustersUltimate tensile strengthMechanical engineering

The strength and rigidity of pad springs are increased with a simple structure to prevent deformation and so forth of the pad springs caused by external force. A mounting member is provided with pad springs for resiliently supporting friction pads. Each pad spring has guide plates, a connecting plate, an engagement plate, radially urging portions, circumferentially urging portions, reinforcement, etc. The reinforcement includes a rectilinear reinforcement formed on a flat plate portion of the connecting plate by embossing, for example, and oblique reinforcements formed on joint portions of the connecting plate. Thus, the joint portions and so forth of the pad springs can be prevented from being deformed by external force when the brake is activated or during assembling operation, for example, and hence it is possible to prevent positional displacement of the guide plates, etc. that would otherwise be caused by the deformation of the joint portions.

Owner:HITACHI ASTEMO LTD

Backpack type electric airflow picking machine for cotton fruits and method for same

The invention relates to the technical fields of harvesting and picking devices for cotton crop fruits, in particular to a backpack type electric airflow picking machine for cotton fruits. The backpack type electric airflow picking machine comprises a direct current motor structure, a rectifying fan structure, cotton pulling wheels, a structure of a driving wheel capable of driving a chain belt type filter screen to rotate, a structure of the chain belt type filter screen and an adjusting wheel rotating along with the driving wheel. The backpack type electric airflow picking machine is characterized by comprising an entire machine casing, and a direct current motor, a rectifying fan, a chain belt type filter screen device, upper and lower cotton pulling wheels, an inverted U-shaped wind shield and an elastic wind shield which are arranged in the entire machine casing as well as an aspirated-air type cotton picking manipulator connected onto an air cotton interface on the casing. The backpack type electric airflow picking machine disclosed by the invention has the advantages of reliability, portability, simpleness and convenience for repairing, maintaining and charging, small size, light weight, lightness and flexibility for operation, reliability and durability for use, continuousness in picking, high quality of picked cotton and high grade of the obtained cotton.

Owner:徐森良

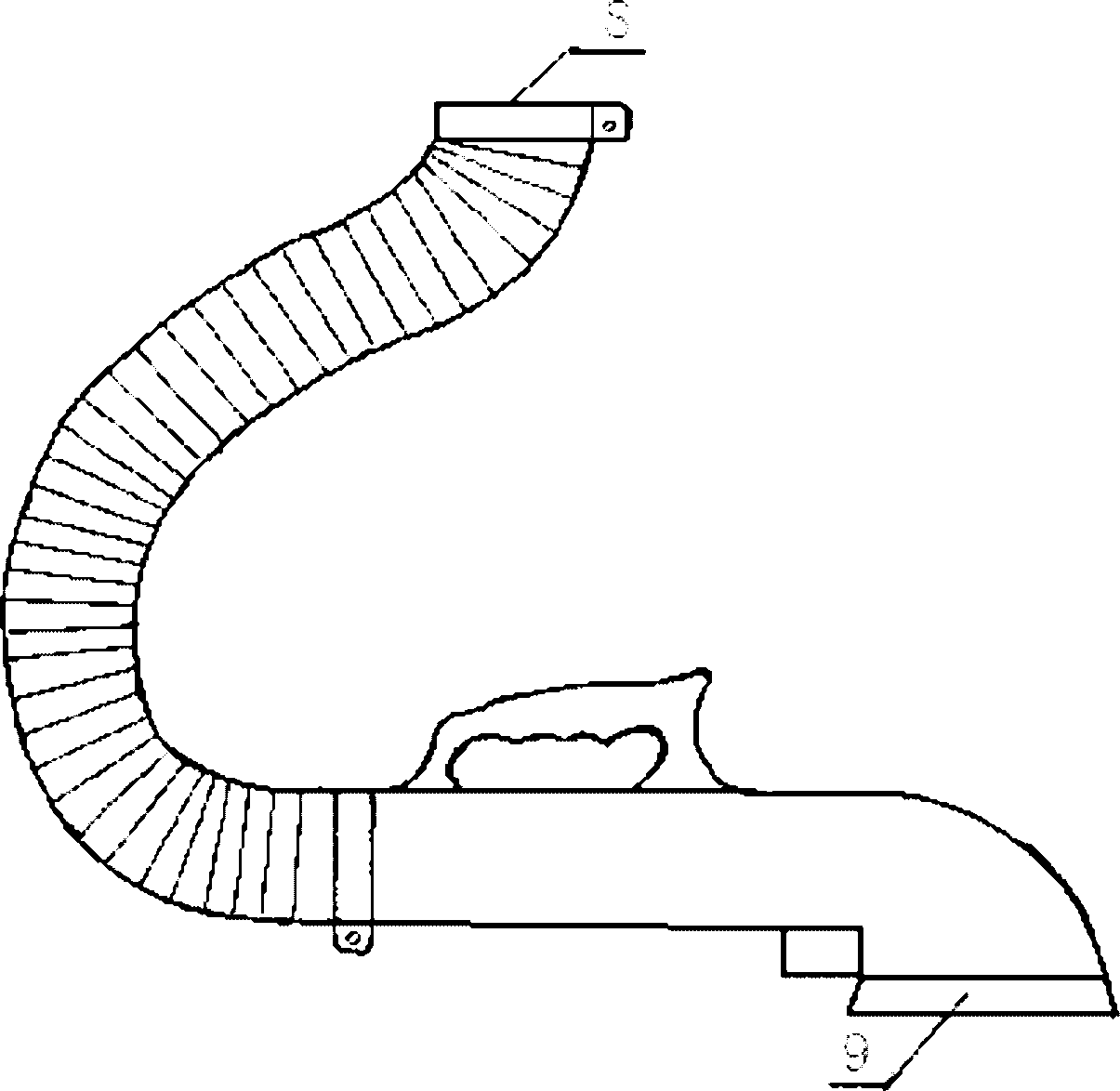

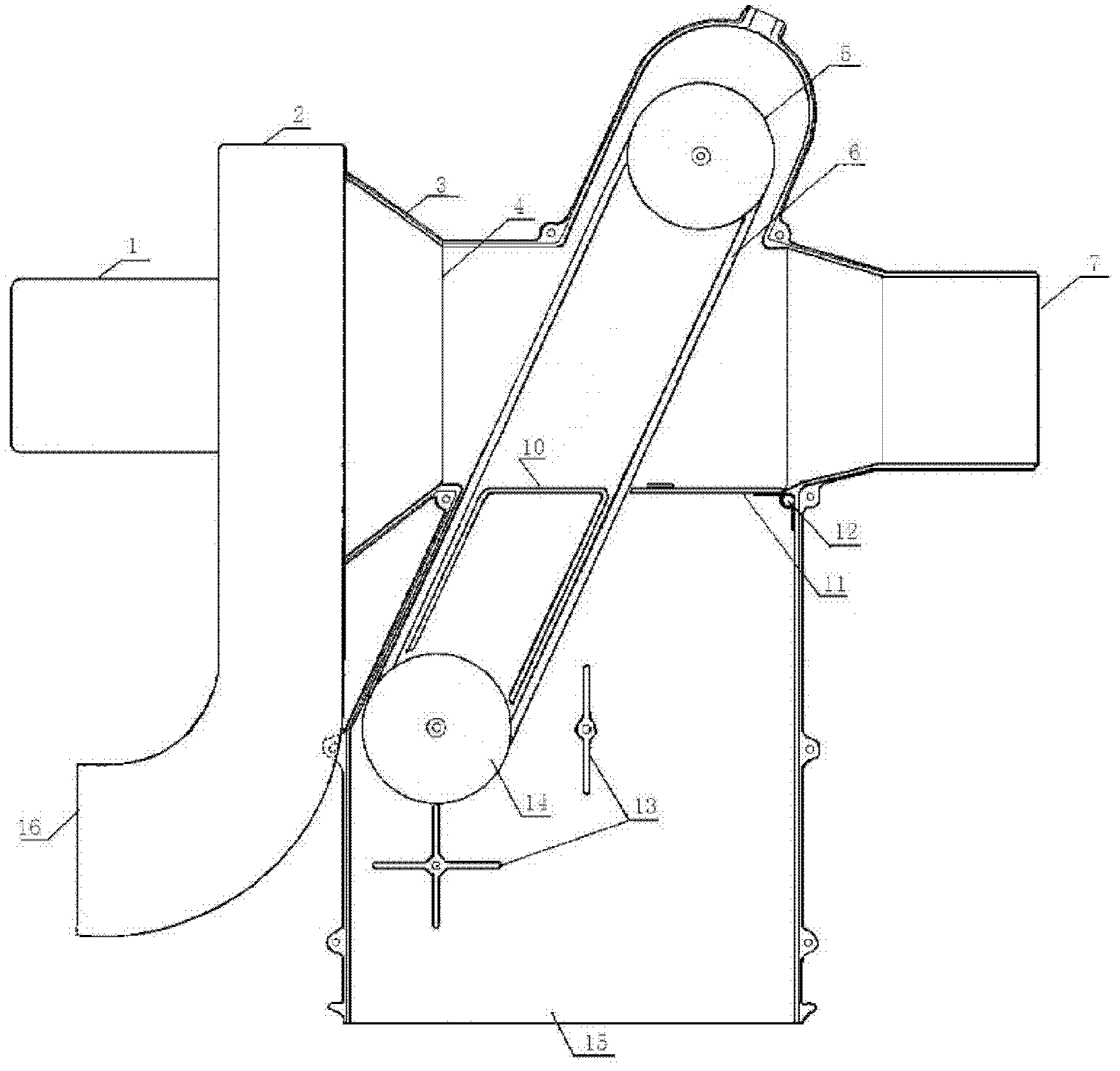

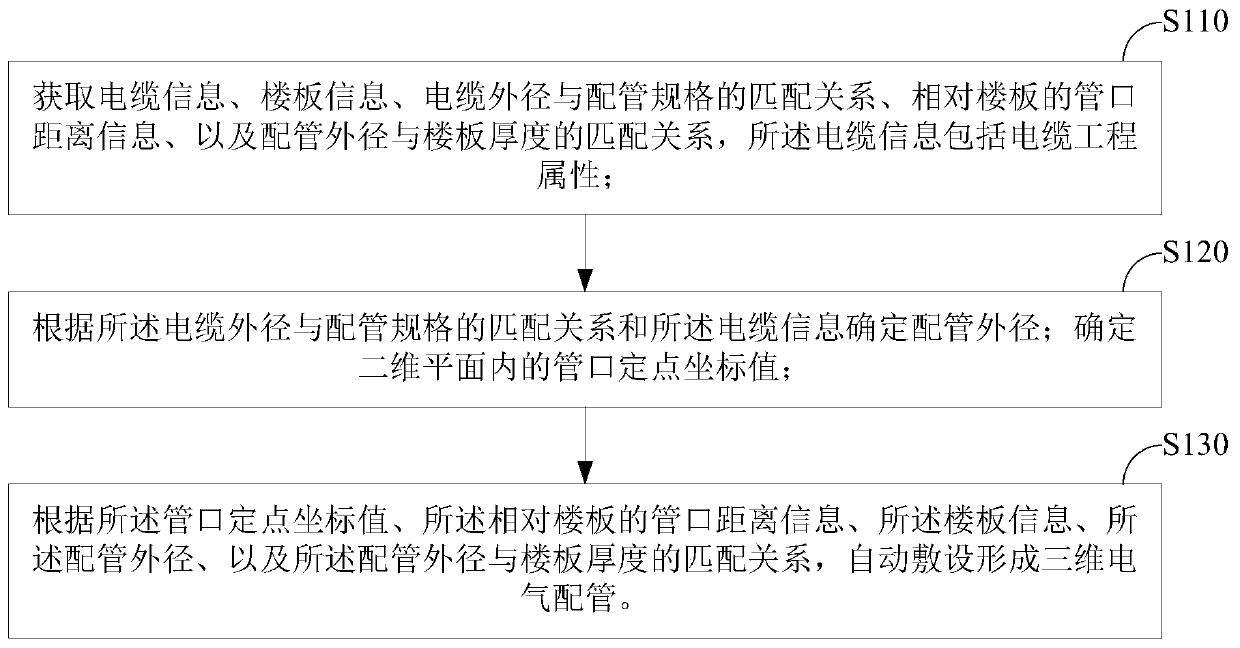

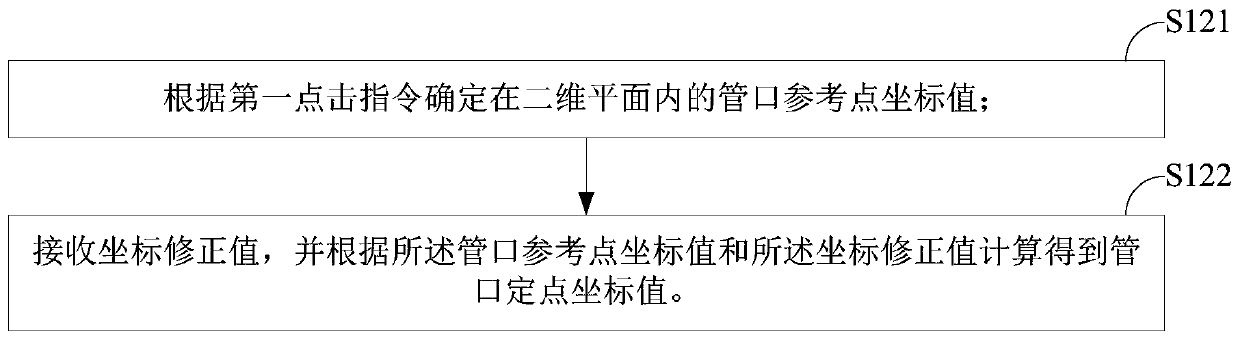

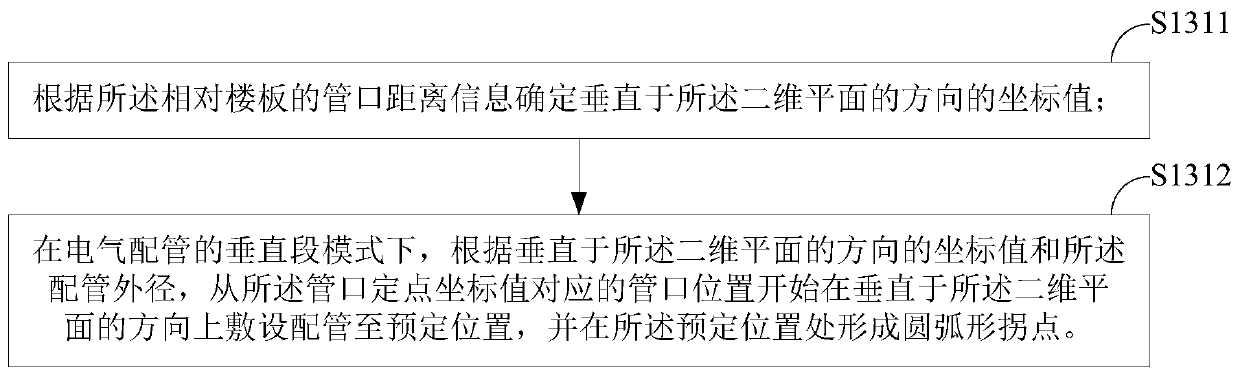

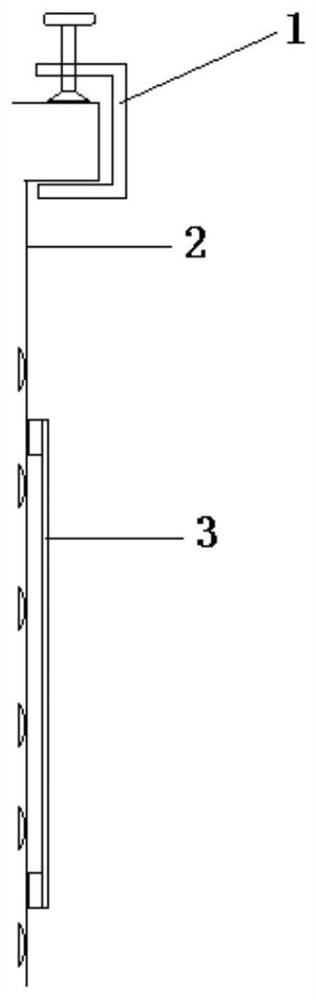

A computer-aided drawing method and device for electrical piping

ActiveCN109766601ASmooth designImprove design efficiencyData processing applicationsSpecial data processing applicationsFloor slabComputer-aided

The invention provides a computer-aided drawing method and device for electrical piping, and the method comprises the steps of obtaining the cable information, the floor information, the matching relationship between the cable outer diameter and the piping specification, the pipe orifice distance information relative to the floor, and the matching relationship between the piping outer diameter andthe floor thickness, wherein the cable information comprises the cable engineering attribute; determining the outer diameter of the piping according to the matching relation between the outer diameter of the cable and the specification of the piping and the cable information; determining a fixed-point coordinate value of the pipe orifice in the two-dimensional plane; and according to the pipe orifice fixed-point coordinate value, the pipe orifice distance information of the relative floor slab, the floor slab information, the piping outer diameter and the matching relation between the pipingouter diameter and the thickness of the floor slab, automatically laying to form the three-dimensional electrical piping. According to the scheme, the three-dimensional tubing design efficiency can beimproved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

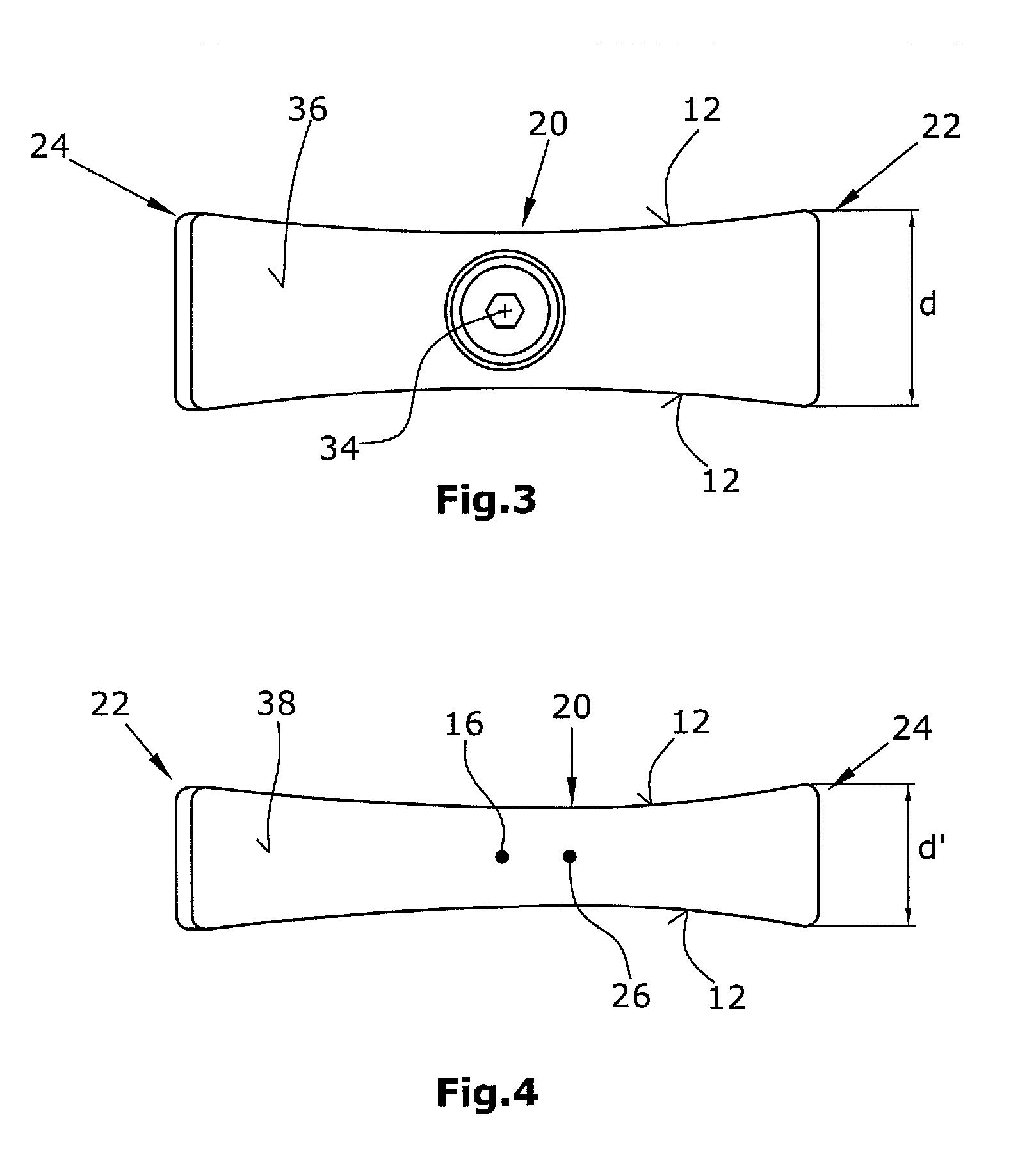

Teaching aid for displaying polynomial function and display method thereof

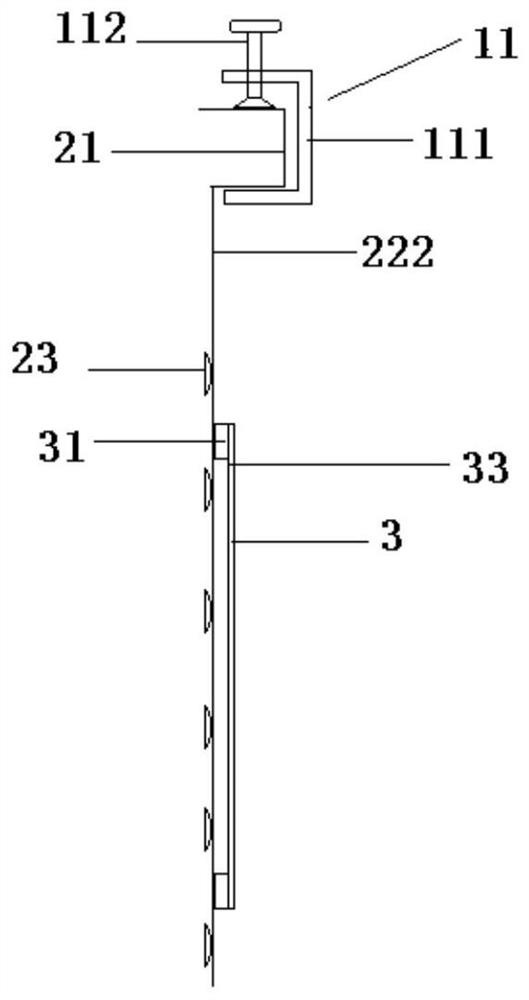

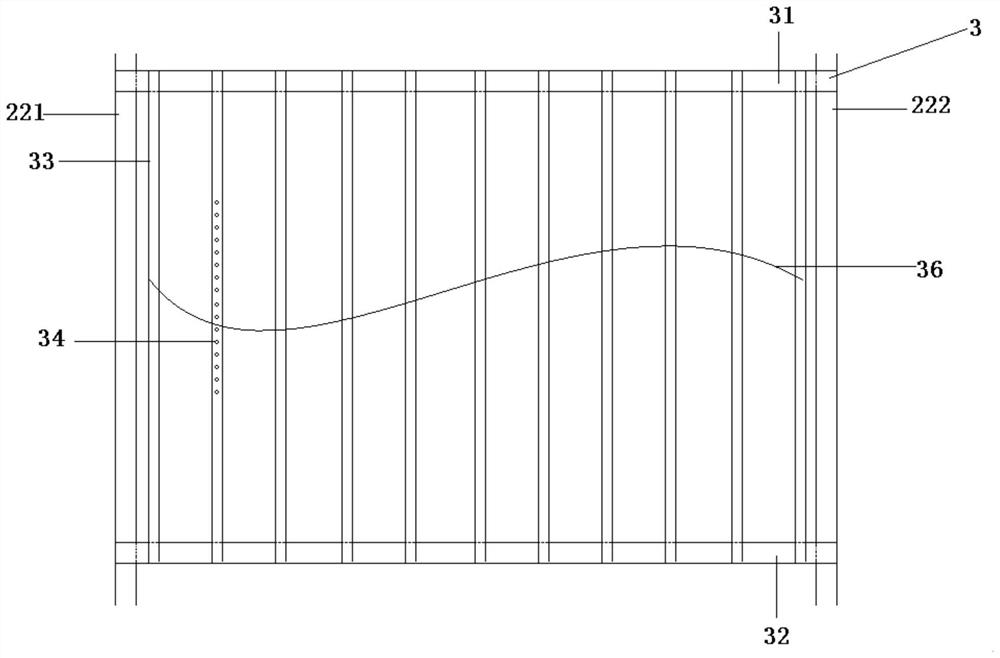

The invention discloses a teaching aid for displaying a polynomial function. The teaching aid comprises a fixing part (1), a hoisting piece (2) and a demonstration part (3), wherein the fixing part comprises a left fixing part (11) and a right fixing part (12); the hoisting piece comprises a buckling part (21), a body part (22) and a sucking disc (23); and the demonstration part comprises an upper rod (31), a lower rod (32), a longitudinal rod (33), a longitudinal rod hole (34), an intersection piece (35), an intersection needle (351), an intersection fork (352), a polyester piece (36), a white board part (37) and a magnetic piece (38). The invention discloses a polynomial function display method, which is carried out by utilizing a teaching aid and comprises a teaching aid assembly step, a polynomial function selection and calculation step, a coincidence calculation step and a display step.

Owner:临沂职业学院

Molded product

ActiveUS20200001570A1Design quality can be deterioratedQuality improvementLayered productsFilm/foil adhesivesComposite materialPolymer chemistry

A molded product includes a body including a flat part and a projection protruding from the flat part, a design member including a design surface, and an adhesive member sticking the design member to the body. The adhesive member includes a buffer portion formed by cutting off a part of the adhesive member at a position corresponding at least to the projection. Thus, the adhesive member negates differences in level on the body, allowing the design surface to be smooth.

Owner:HONDA MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com