Secondary first-stage blade for transonic compressor on high-speed gas turbine

A gas turbine, transonic technology, applied to parts of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve the hidden dangers of compressor operation, low calculation and manufacturing accuracy, and large blade wear, etc. problem, to achieve the effect of improving efficiency, improving work efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

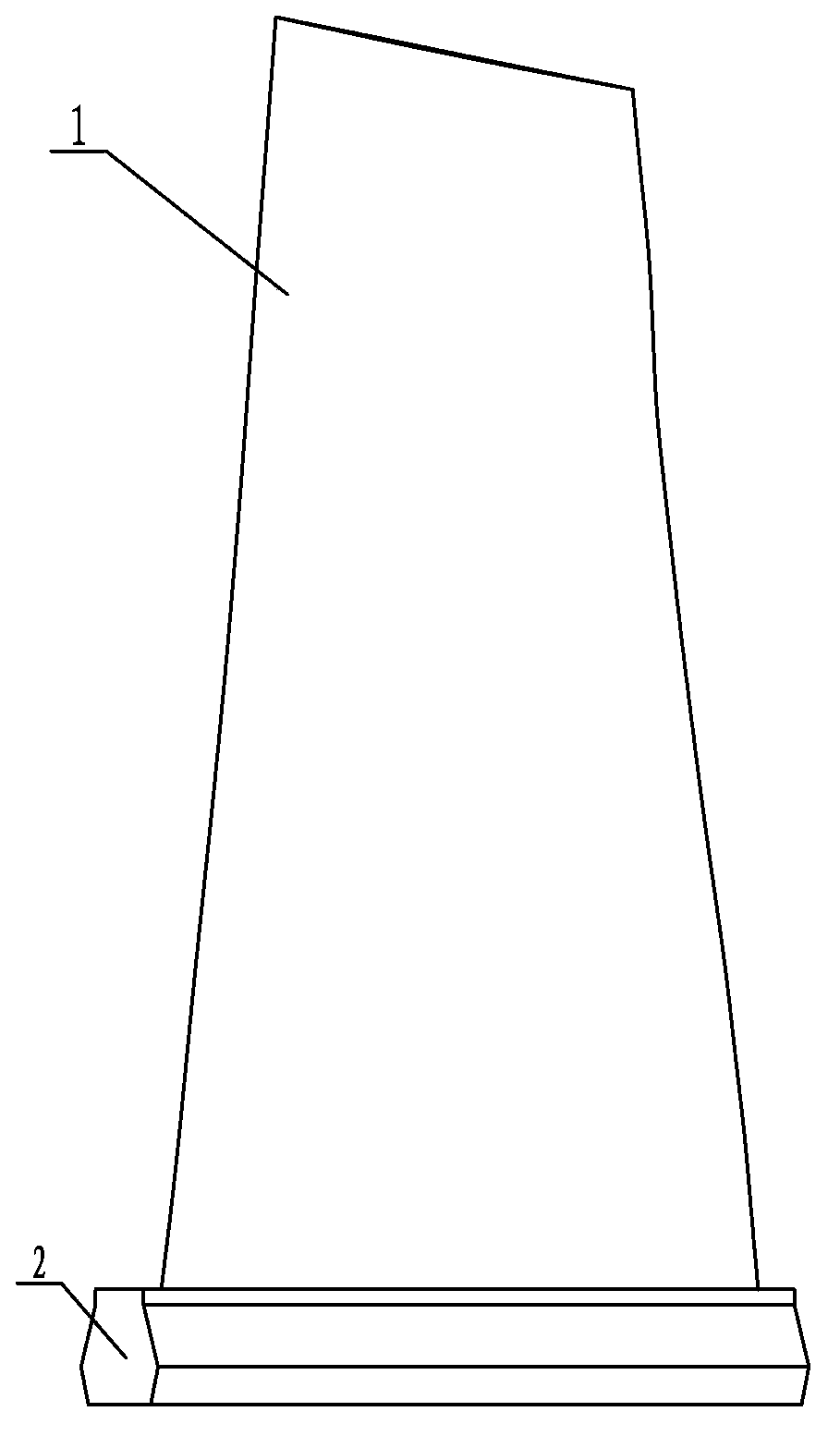

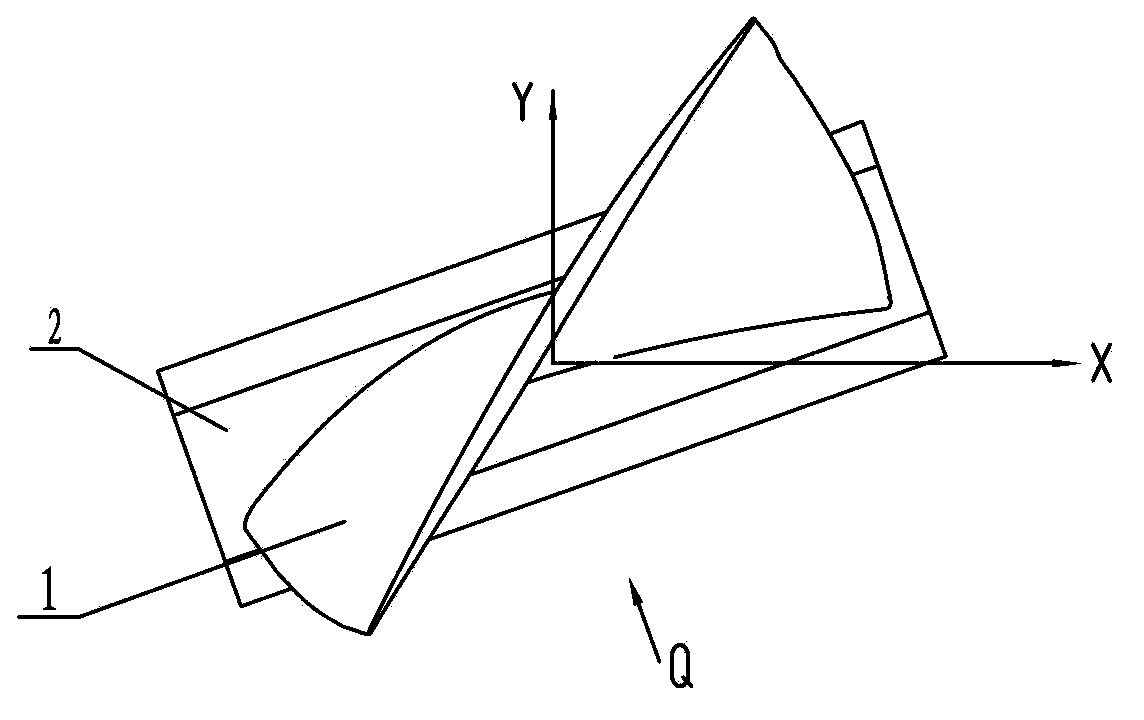

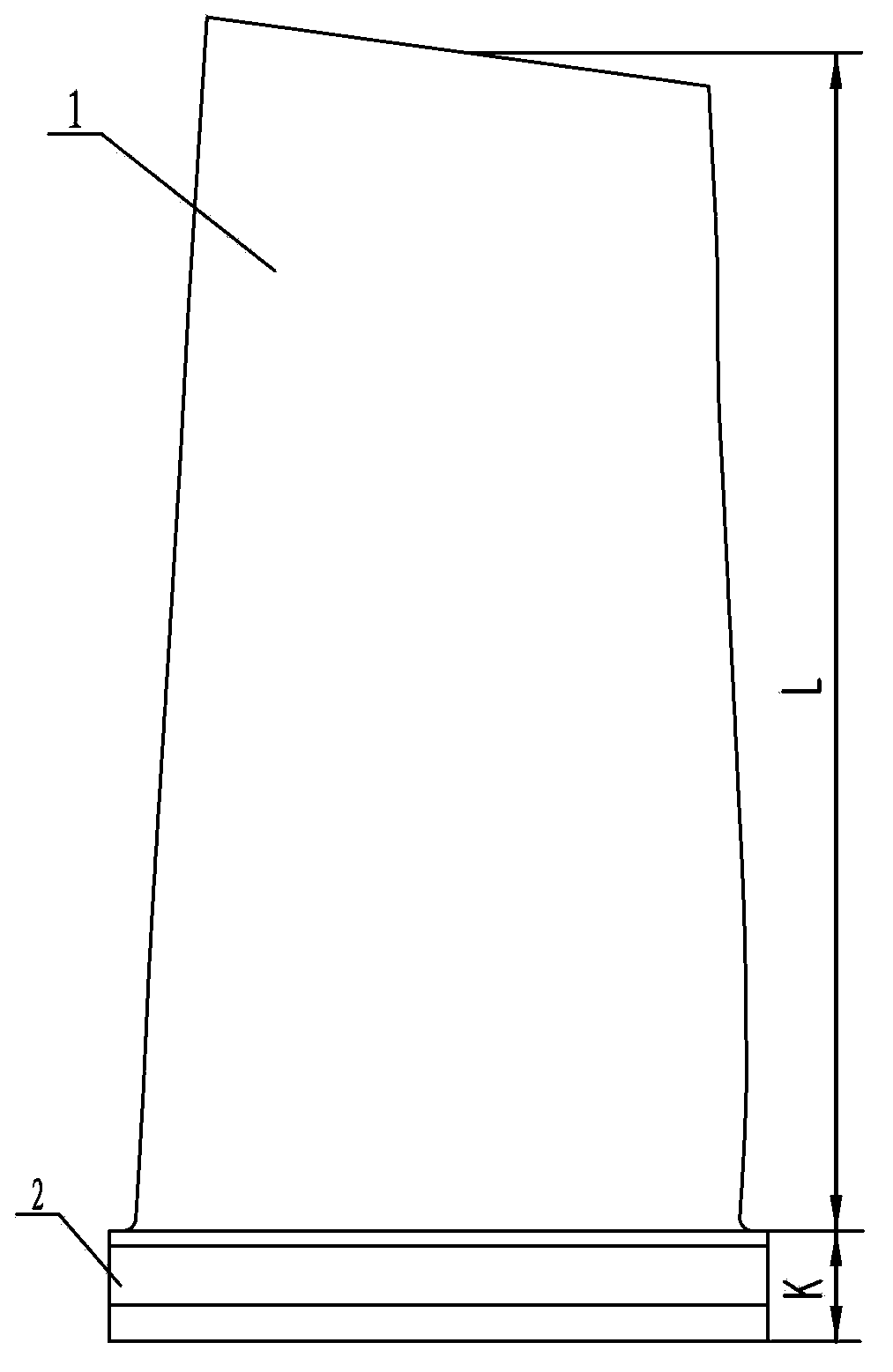

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 This embodiment is described. In this embodiment, a sub-first-stage blade for a transonic compressor on a high-speed gas turbine is described. The blade includes a blade working part 1 and a blade root 2, and the blade working part 1 and blade root 2 are composed of From top to bottom, the cross-sectional area of the blade working part 1 decreases gradually from the root to the top. The profile of the blade working part 1 is a twisted blade with variable cross-section. The total height L is 146.22 mm, the axial width B of the blade working part 1 varies from the root of the blade working part 1 to the top of the blade working part 1, and the variation range is 71.12 mm to 40.06 mm, and the chord length of the cross section of the blade working part 1 is It is b, the variation range of b is 74.55mm~79.72mm, the bending angle is α, the variation range of α is 17.667°...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 To illustrate this embodiment, the section heights H of the blade working part 1 described in this embodiment are 38.75mm, 79.39mm, 122.57mm, and 151.83mm respectively, and the corresponding axial widths B of the blade working part 1 are respectively 62.35mm and 53mm respectively. . The maximum thickness Dmax of the molding line is 8.30mm, 5.15mm, 2.69mm, 2.38mm, and the corresponding thickness DE of the air outlet edge at the distance F from the air outlet edge is 1.05mm, 0.61mm, 0.41mm, 0.34mm. The above structure is adopted Parameters, while ensuring that the shape and size of the blade meet the design requirements, it can also make the blade easy to assemble, and other components and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 , figure 2 with image 3 Describe this embodiment, the total height of the blade root 2 in this embodiment is K, K=13.67mm, the blade root 2 is a helical fir tree-shaped blade root, and the axial width of the blade root 2 is W, W=81.53mm , with the above-mentioned structure, the blade can be firmly loaded into the rim, and the assembly is stable, safe and reliable, and the other components and connections are the same as those in the first embodiment.

[0010] The specific parameters of each section are as follows:

[0011] section

[0012] B——B0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com