Variable displacement swash plate compressor

A swash plate and variable displacement technology, applied in the field of compressors, can solve the problems of increased manufacturing cost, complex structure and process, complex structure, etc., and achieve the effects of reduced processing and assembly precision, low cost, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

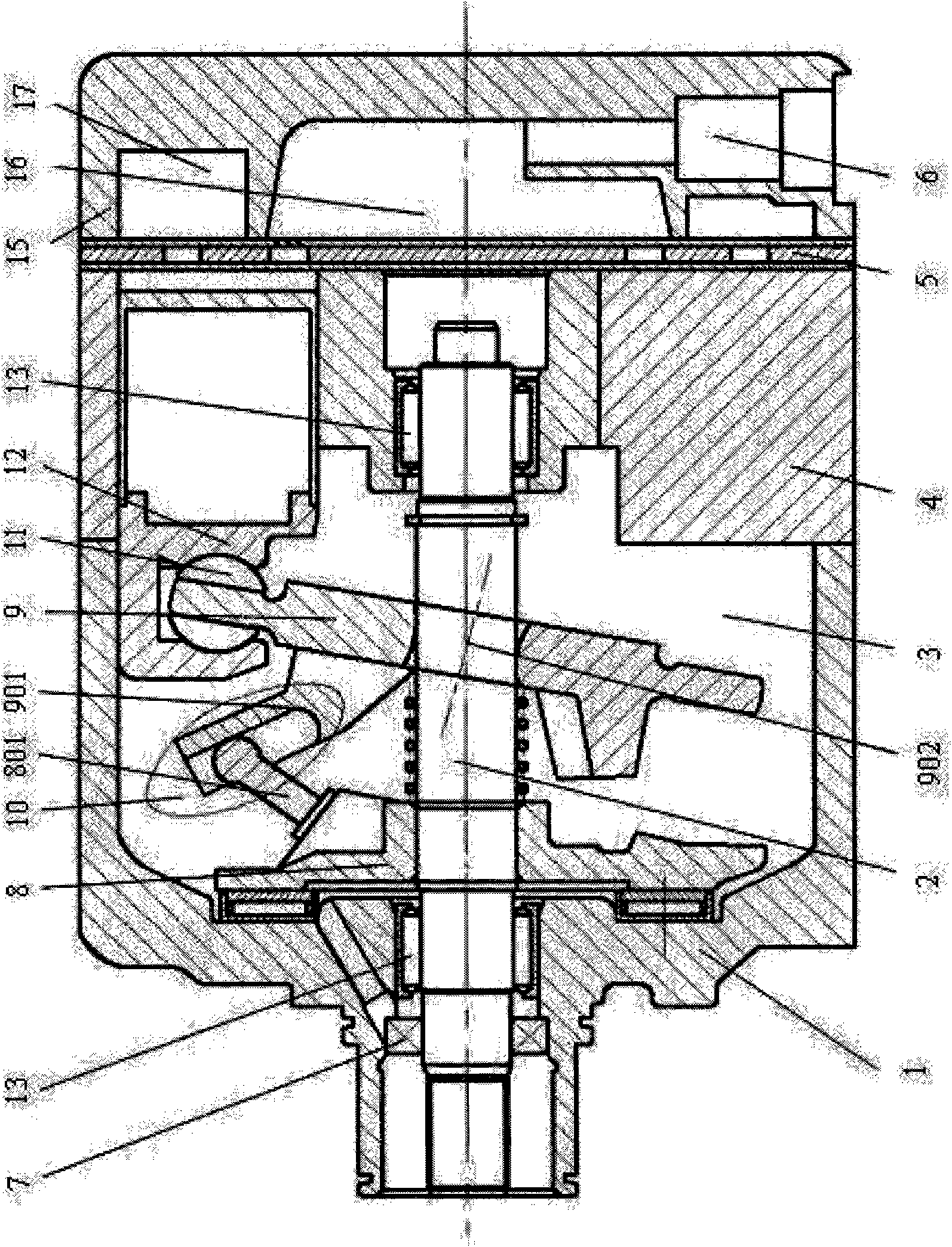

[0019] Embodiment: A variable displacement swash plate compressor, including a swash plate 9 and a cylinder block 4 , an end cover 1 is provided at one end of the cylinder block 4 , and a crank chamber 3 is formed.

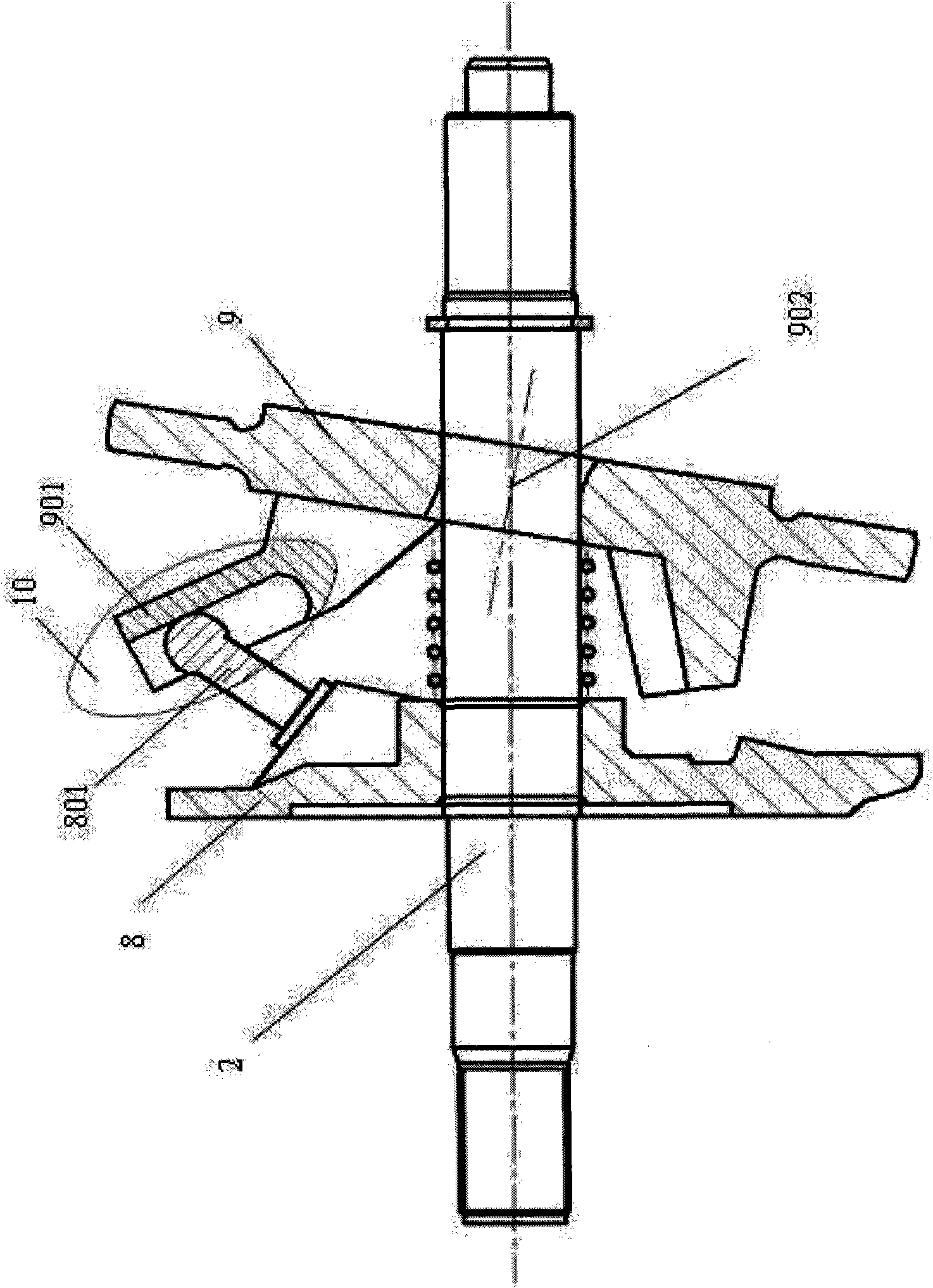

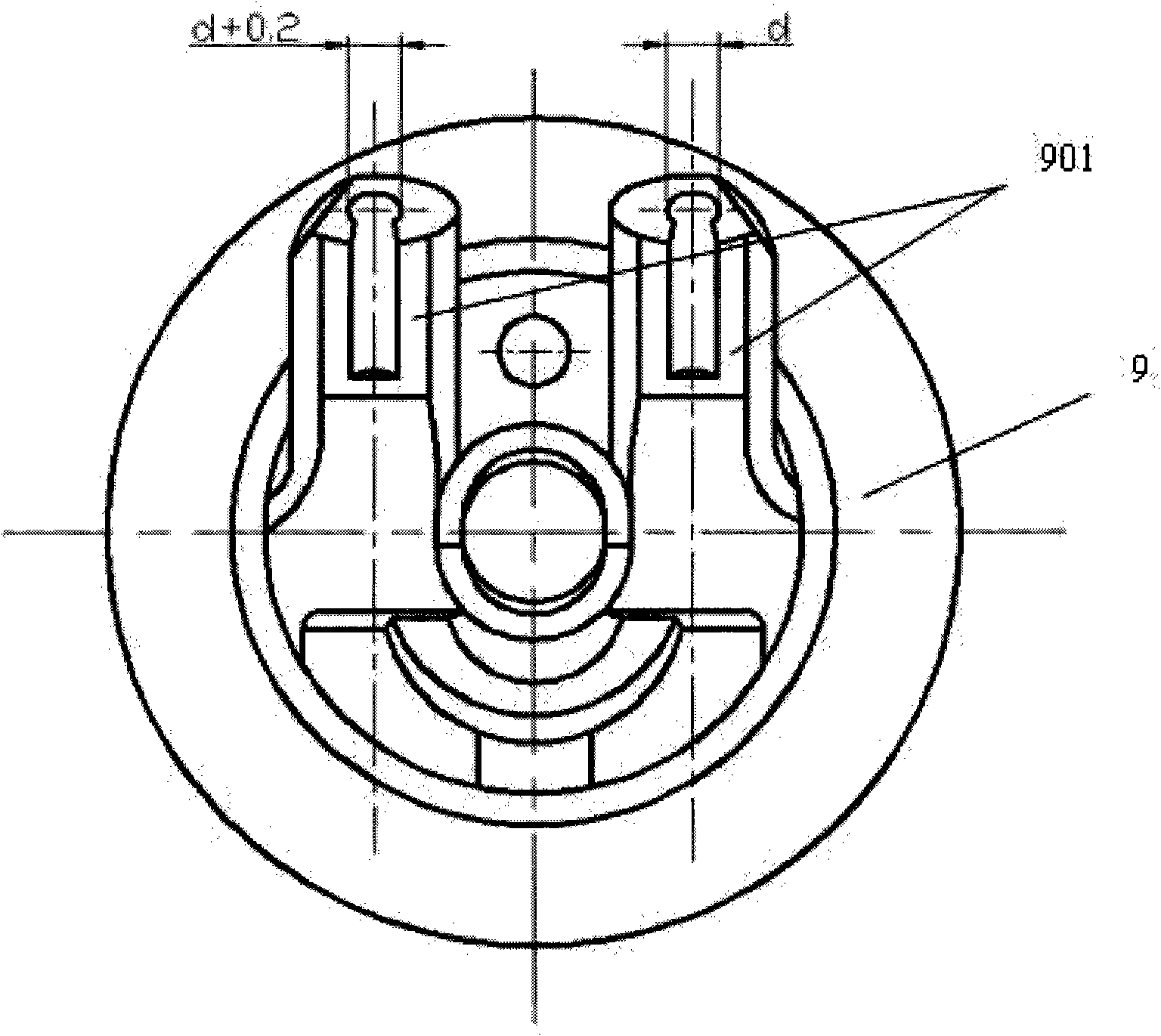

[0020] Both the cylinder block 4 and the end cover 1 are provided with a rolling bearing 13, the rolling bearing 13 is provided with a main shaft 2, the main shaft 2 is fixedly connected with a driving disc 8, and the driving disc 8 is provided with a pair of cylindrical guide pins 801 with spherical heads, One end of the main shaft 2 is provided with a shaft seal 7, and the shaft seal 7 is connected with the main shaft 2 in a movable seal. The main shaft 2 is driven by external power such as an automobile engine or an electric motor.

[0021] The main shaft 2 passes through the waist-shaped hole 902 provided on the swash plate 9 . The swash plate 9 can slide forward and backward on the main shaft 2 to change its inclination angle with the main shaft 2 , and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com