Heating cooker

A technology for cooking utensils and heating chambers, applied to electric heating fuel, lighting and heating equipment, household heating, etc., can solve the problems of poor heating efficiency, easy gaps, hot air leakage, etc., and achieve enhanced twist resistance and Effects of flexural strength, heating efficiency improvement, and airtightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

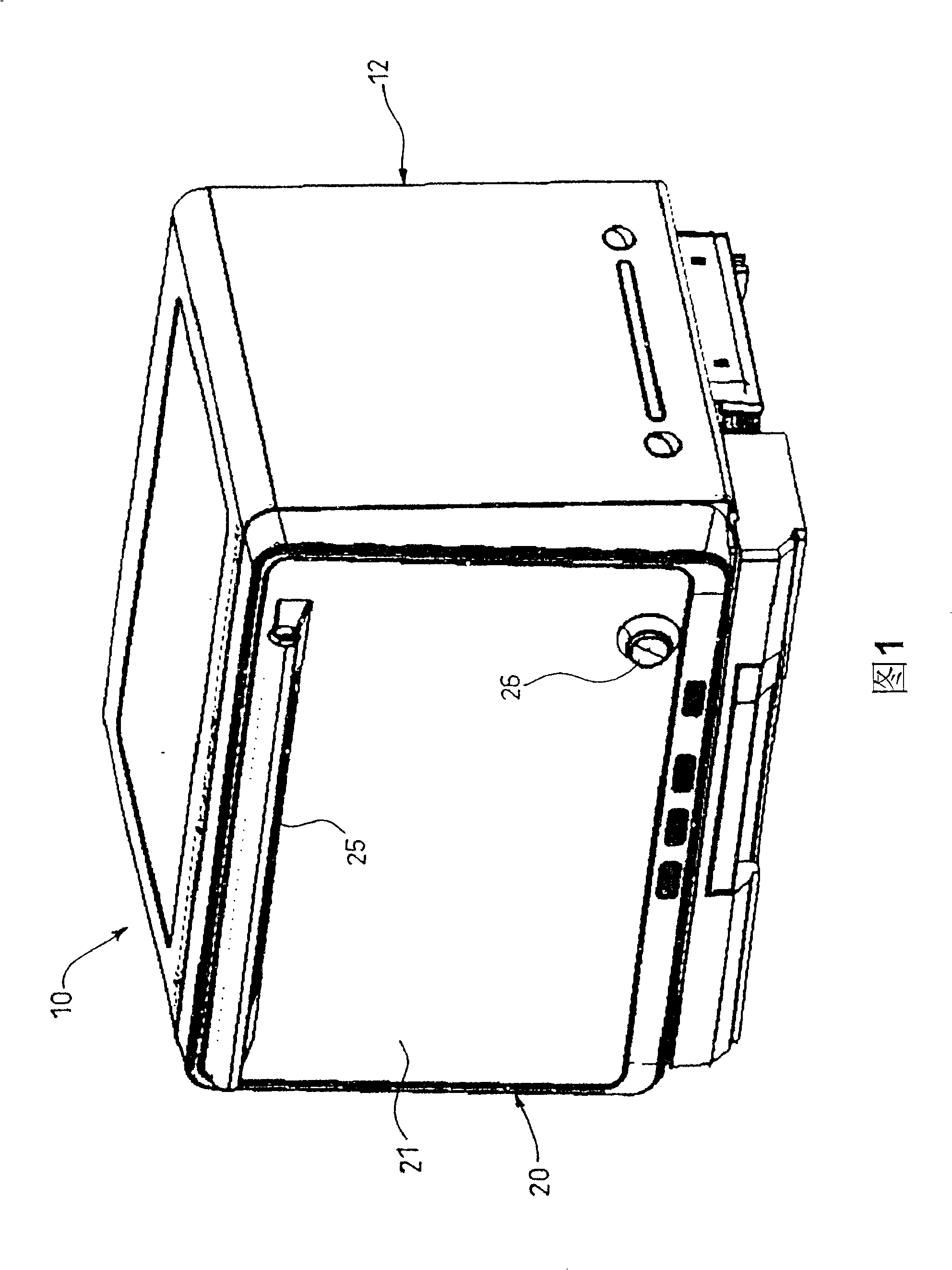

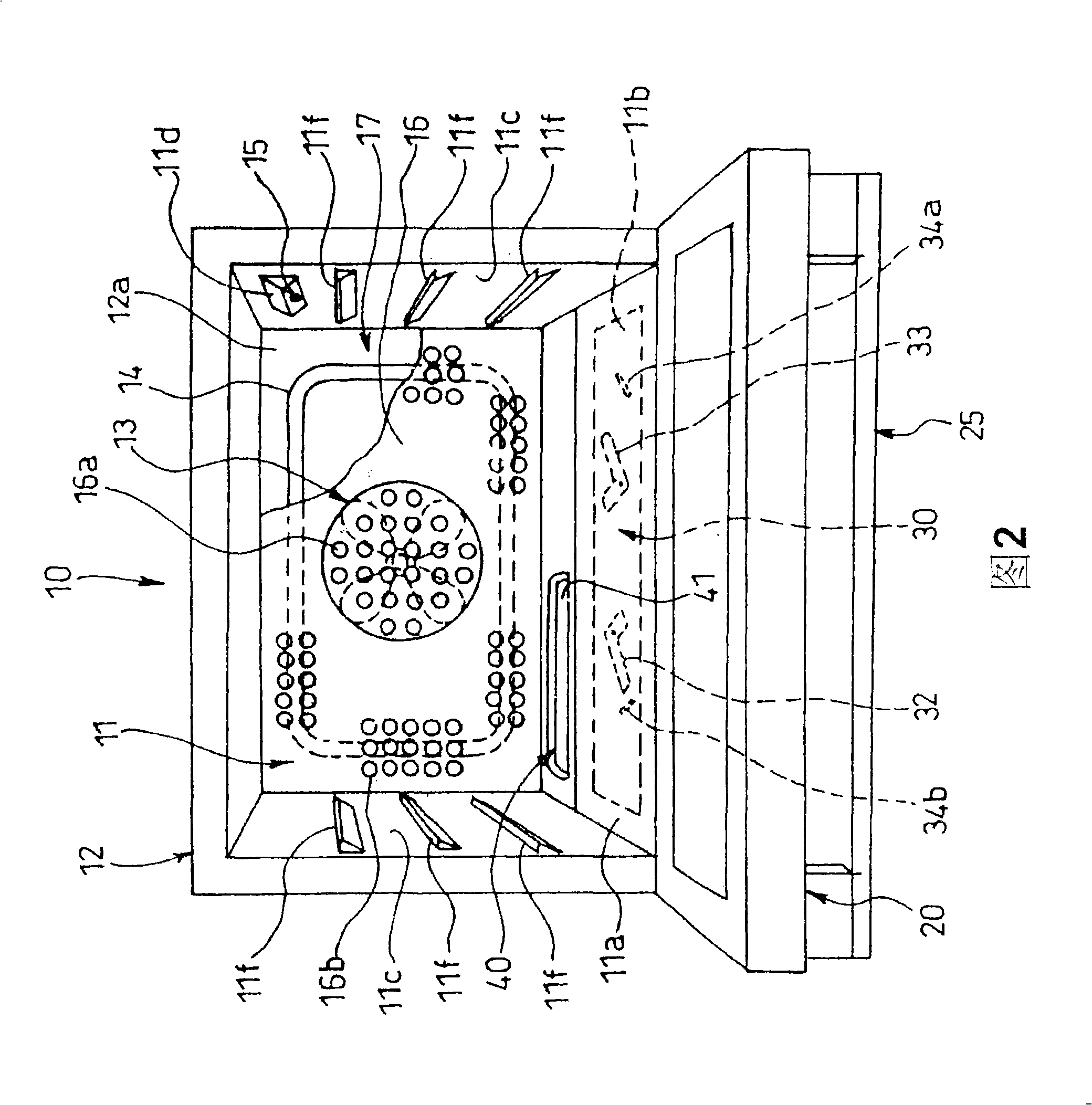

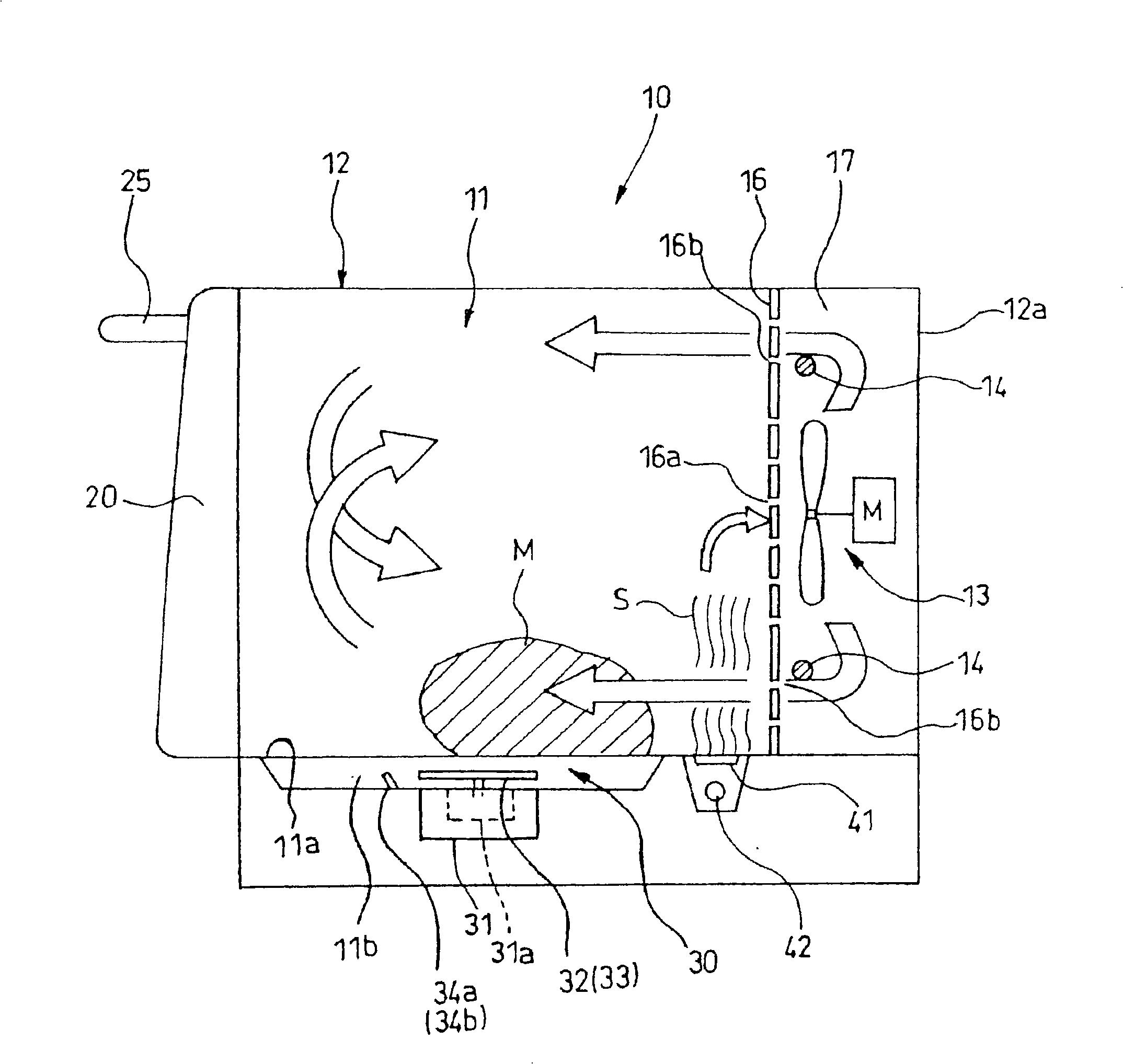

[0032] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] As shown in Figures 1 to 3, the heating and conditioning device 10 of the present invention is a heating and conditioning device with a steam generating device, which has a rectangular box-shaped body 12 with an opening on the front surface, and a The machine door 20 of the opening part on the body 12. The inside of the body 12 is provided with a heating chamber 11 for heating objects M to be loaded into. As shown in Figure 2, the heating chamber 11 is provided with: a circulating fan 13 for stirring the air in the heating chamber 11 and circulating the air in the heating chamber 11; a convection heater for heating the circulating air in the heating chamber 11 14; and an infrared sensor 15 provided on the side wall 11c of the heating chamber 11 for detecting the temperature in the heating chamber 11. The center of the bottom plate 11a of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com