Gear-shifting control mechanism assembly of transmission

A technology of operating mechanism and transmission, applied in the direction of instruments, controlled components, mechanical equipment, etc., can solve the problems of low precision of gear selection and return force, poor shifting clarity, complex interlock structure, etc., and achieve smooth gear shifting. , Enhance the effect of shifting suction and simplify the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

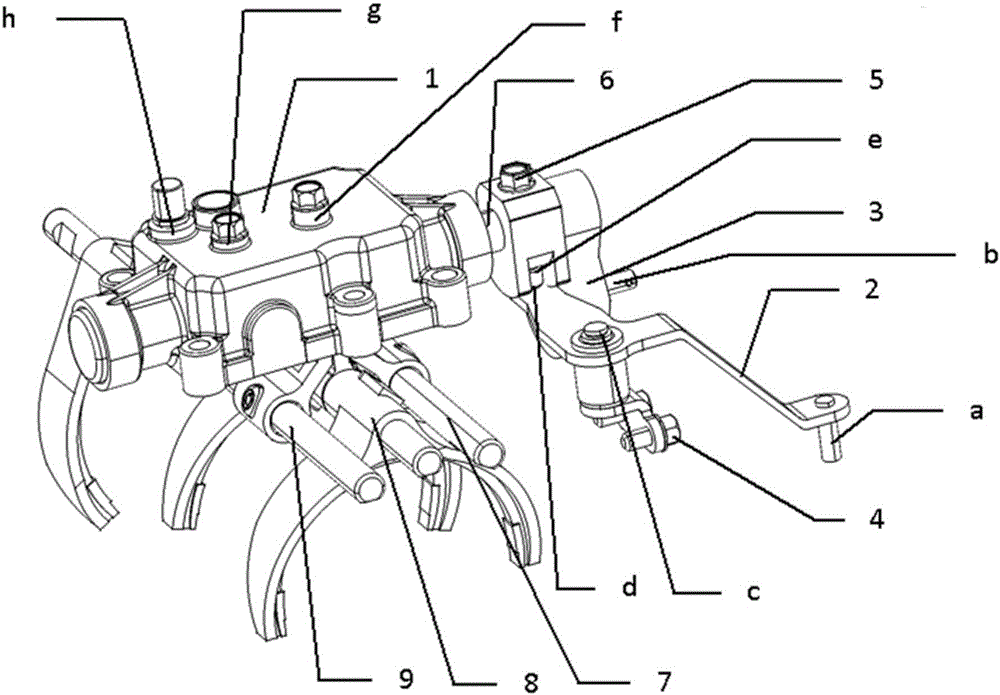

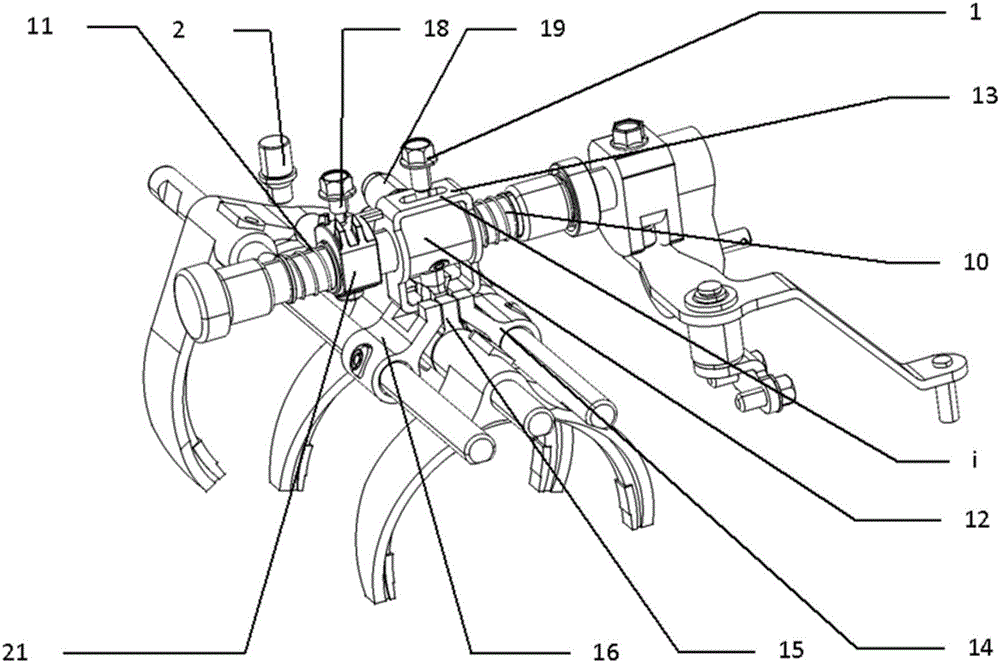

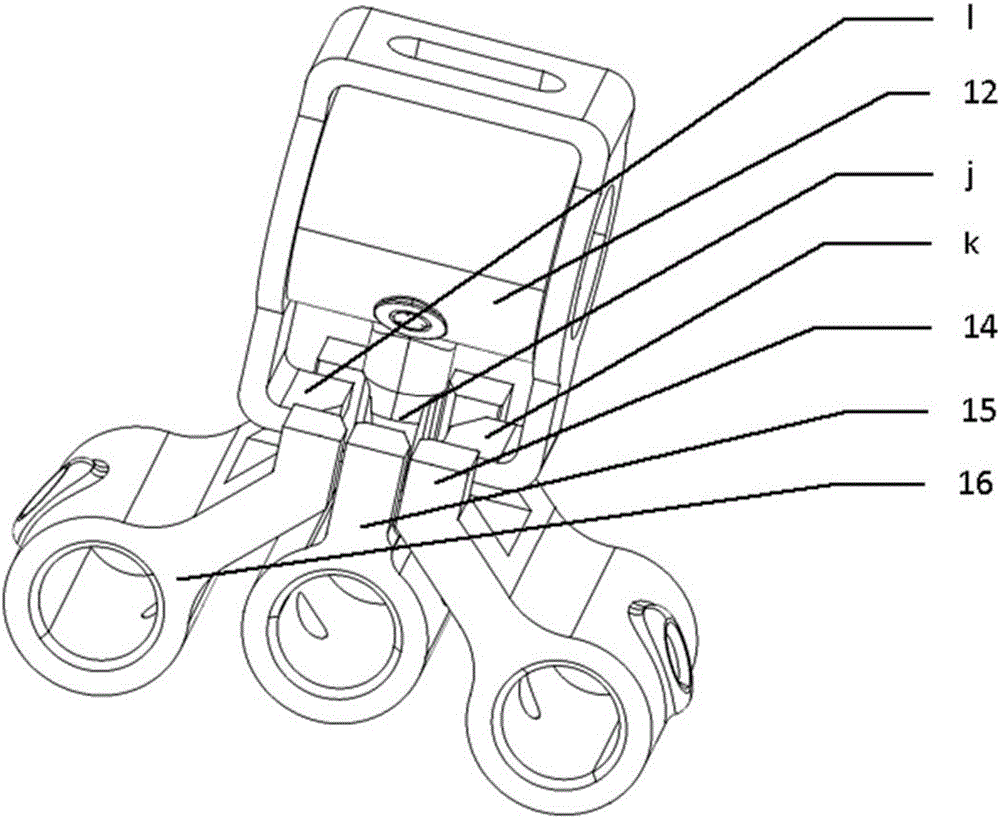

[0037] The present application provides a transmission shifting mechanism assembly, such as Figure 1 to Figure 5 As shown, it includes the gear selection seat 1, the gear selection rocker arm 2, the gear shift rocker arm 3, the gear selection shaft 6, 1, the 2nd gear shift fork assembly 7, 3, the 4th gear shift fork assembly 8, 5, R gear shift fork assembly 9, first gear select return spring 10, second select select return spring 11, select shift dial 12, shift interlock plate 13, 1, 2 shift shift dial 14, 3, 4 gear shift paddles 15, 5, R gear shift paddle 16, gear selection guide bolt 17, shift guide bolt 18, shift positioning pin 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com