Patents

Literature

120results about How to "Reduce manufacturing errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

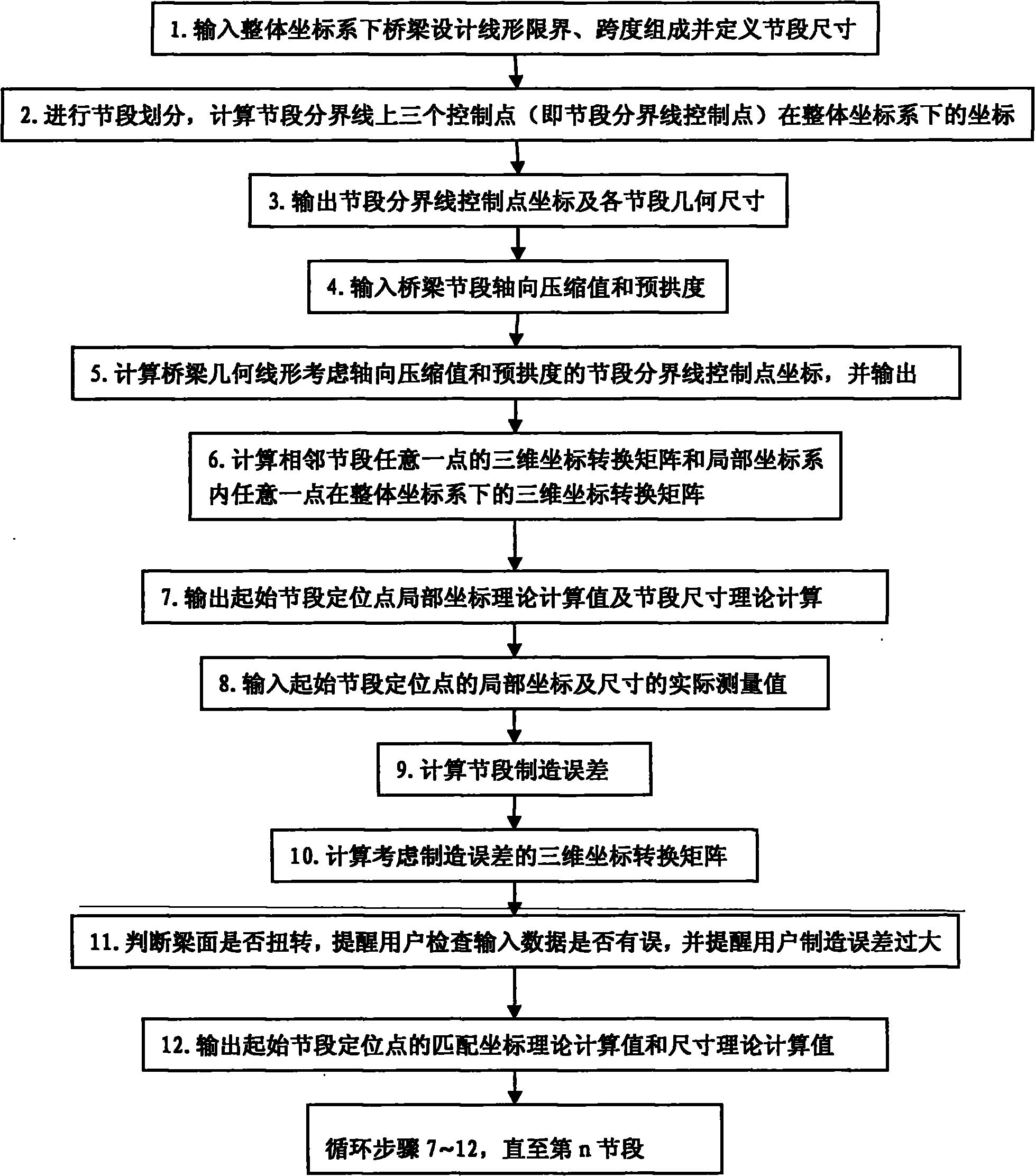

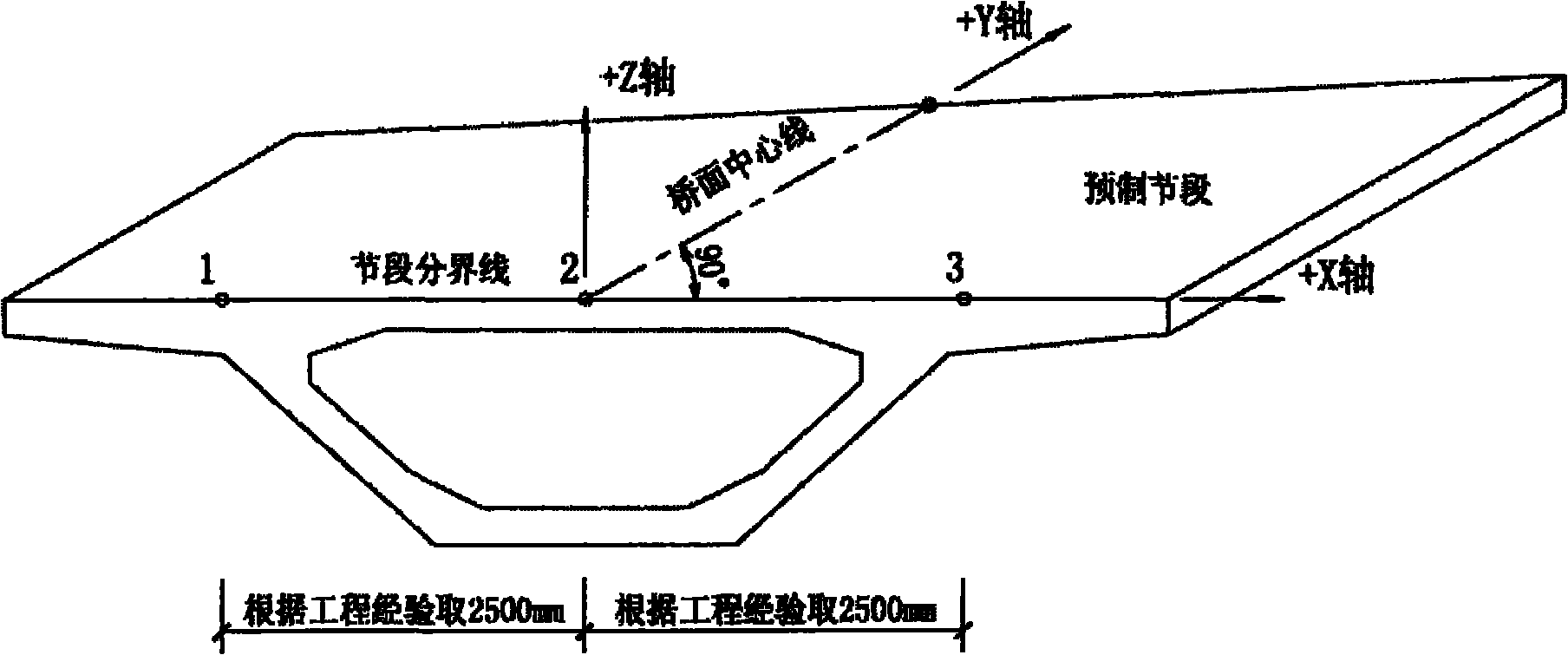

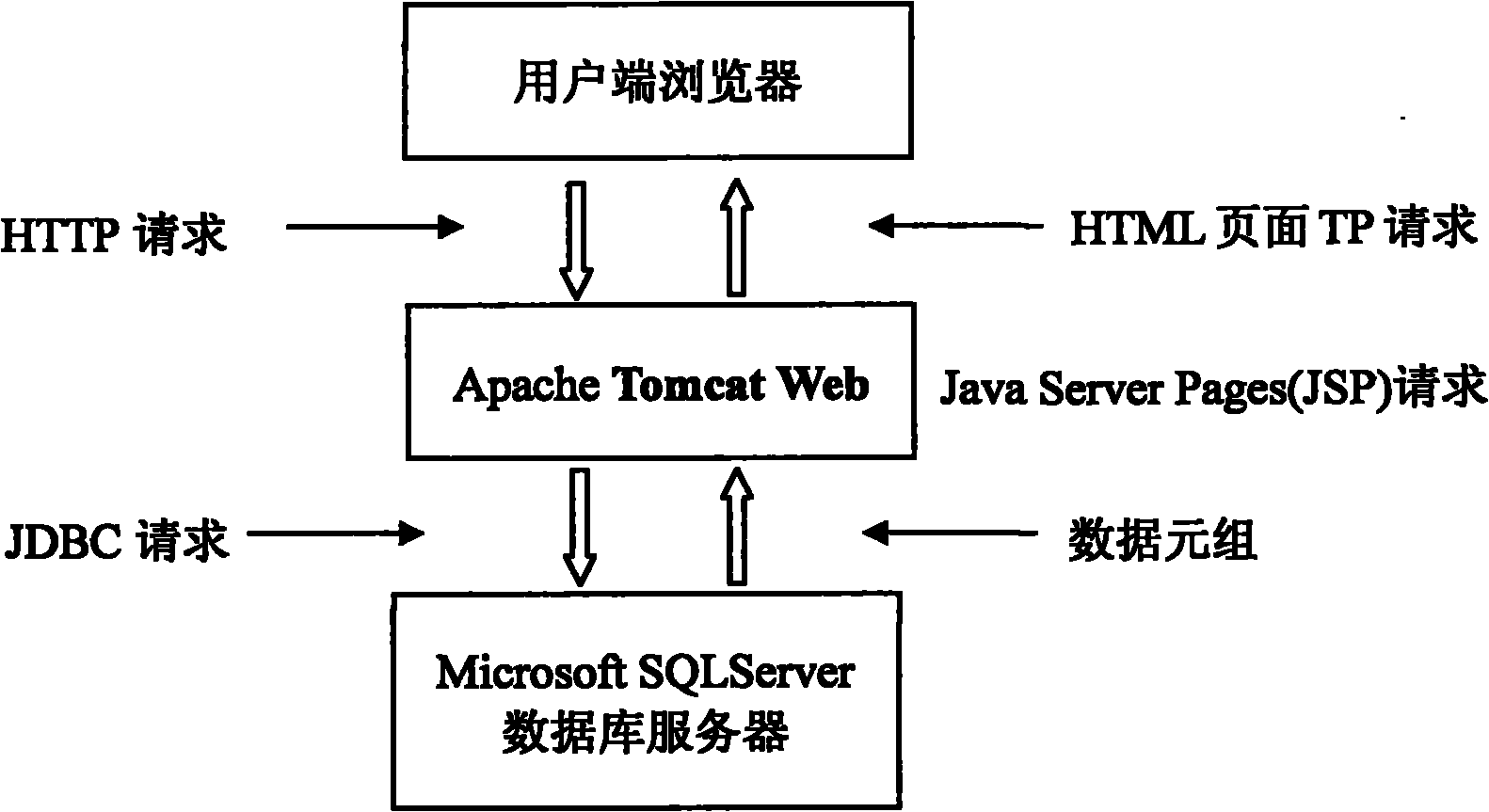

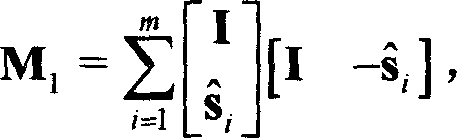

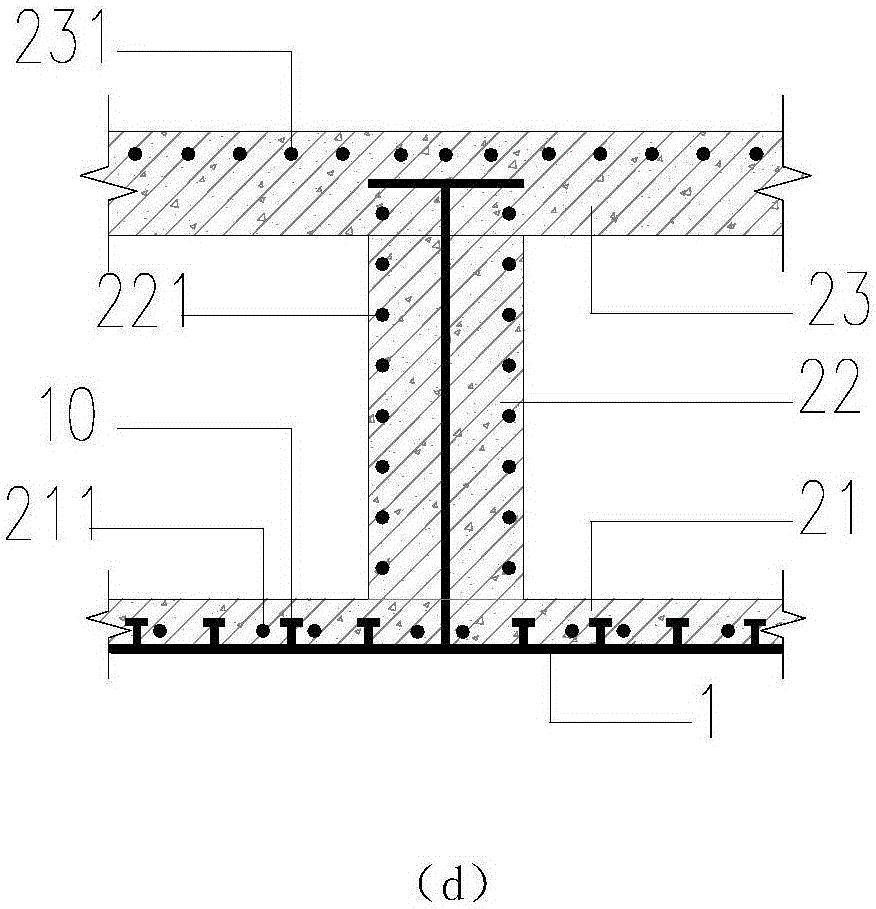

Three-dimensional numerical control method for bridge section precasting technology

ActiveCN101942805AReduce manufacturing errorsReduce Prefabrication DeviationsBridge erection/assemblyNumerical controlAxial compression

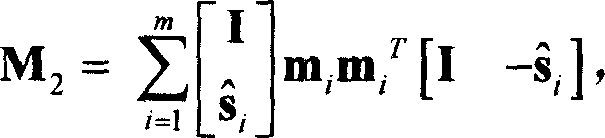

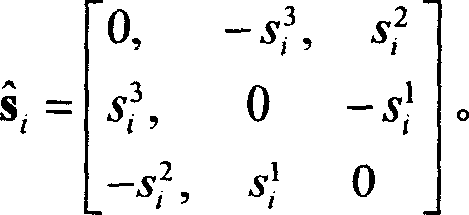

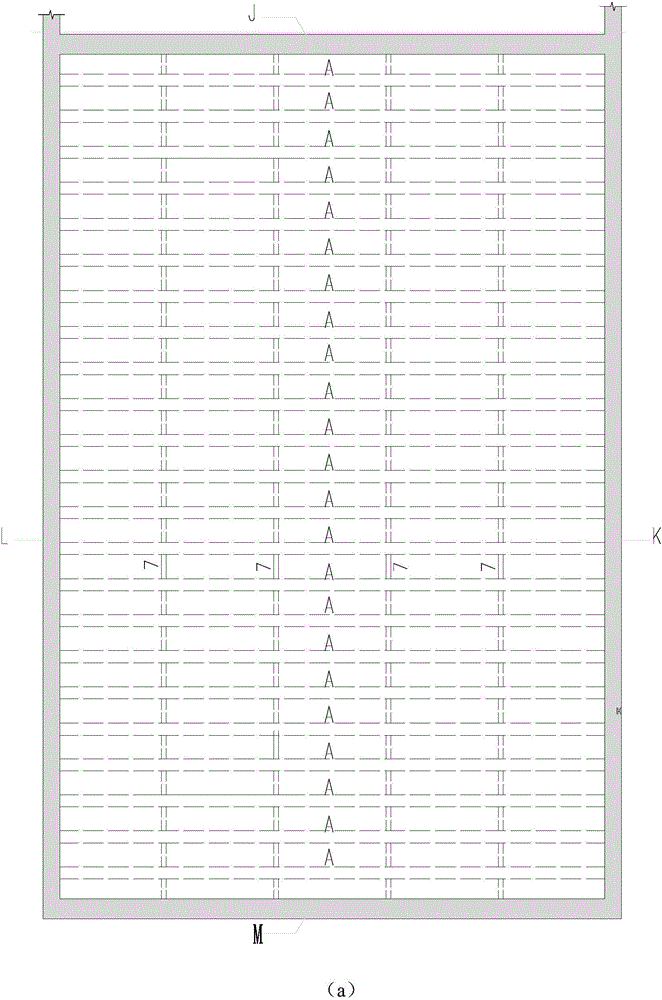

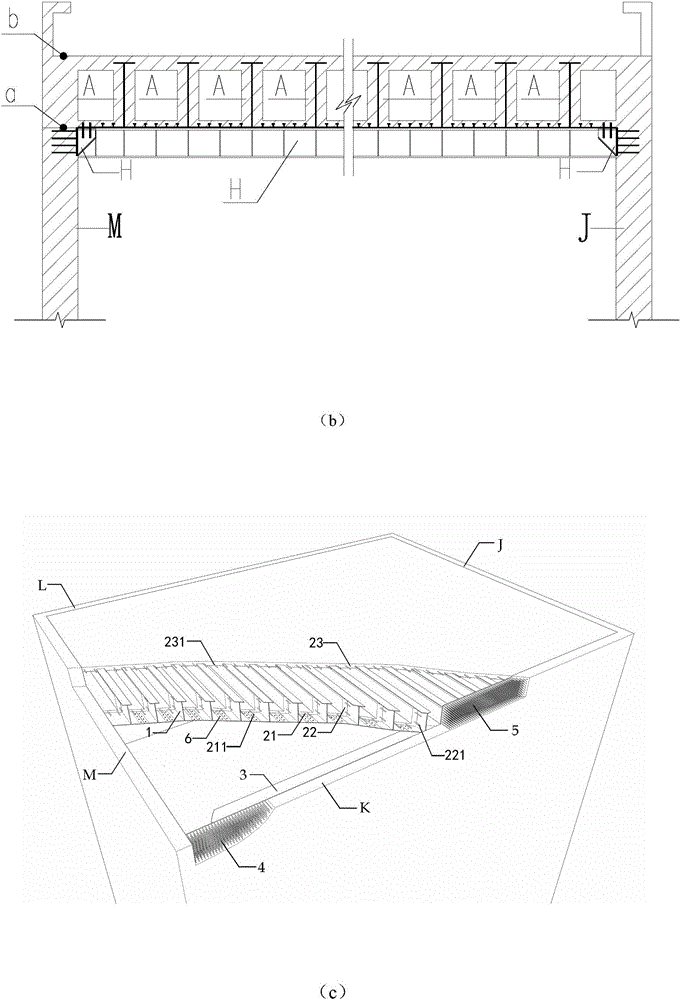

The invention discloses a three-dimensional numerical control method for a bridge section precasting technology, which comprises the following steps: dividing the bridge into sections; calculating the global coordinates of the section boundary control point and the geometric dimensions of each section; inputting the axial compression value and camber of the sections, correcting the global coordinates of the section boundary control point, and calculating new coordinates; calculating the three-dimensional coordinate transition matrix of any point of the adjacent sections; calculating manufacturing errors of the sections and adjustment quantities of the adjacent sections in six directions; calculating the three-dimensional coordinate transition matrix of any point of the adjacent sections after considering the section manufacturing errors; judging whether the beam surface is twisted according to the manufacturing errors of the sections; and according to the three-dimensional coordinate transition matrix of any point of the adjacent sections after considering the section manufacturing errors, outputting the theoretical calculation values of the matching coordinates of the initial section locating point, and the theoretical calculation values of the section dimensions. The invention realizes three-dimensional control on the geometric line shapes of the bridge sections, and reduces the manufacturing errors caused by the separate control on plane and facade line shapes.

Owner:瀚阳国际工程咨询有限公司

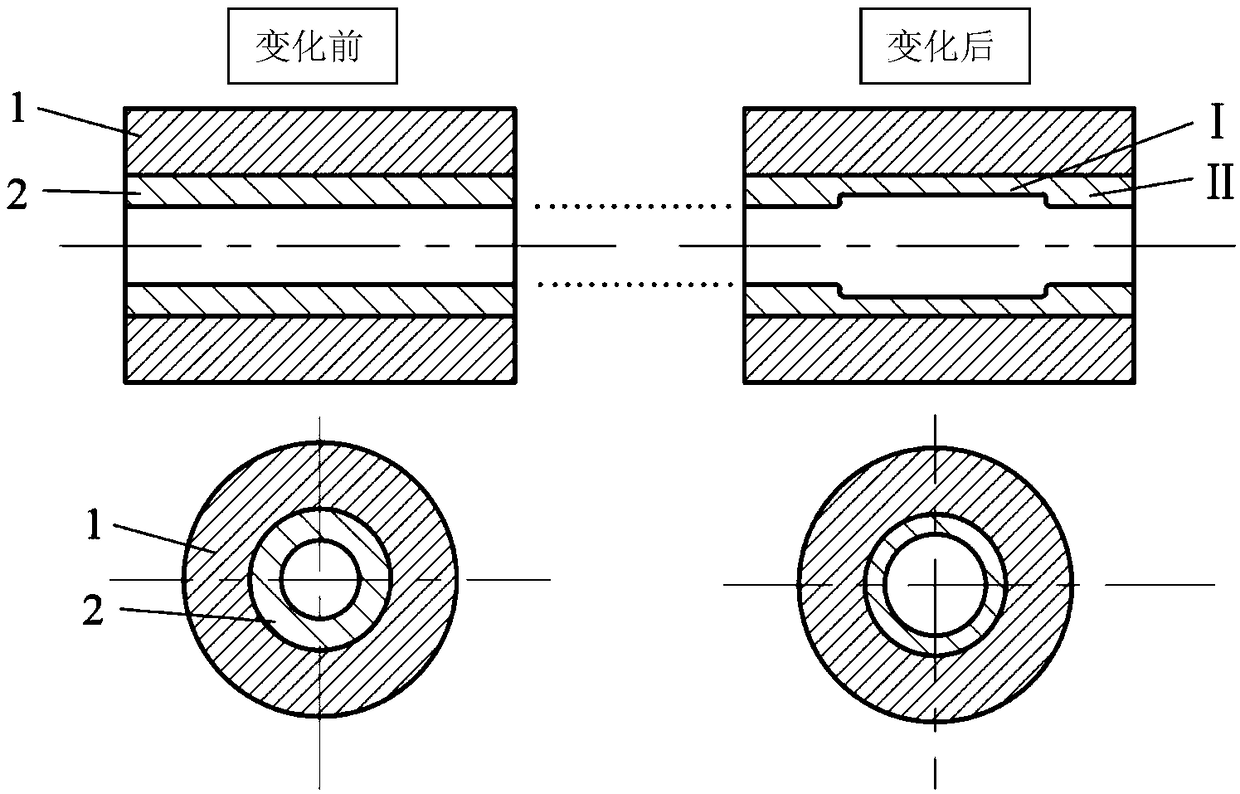

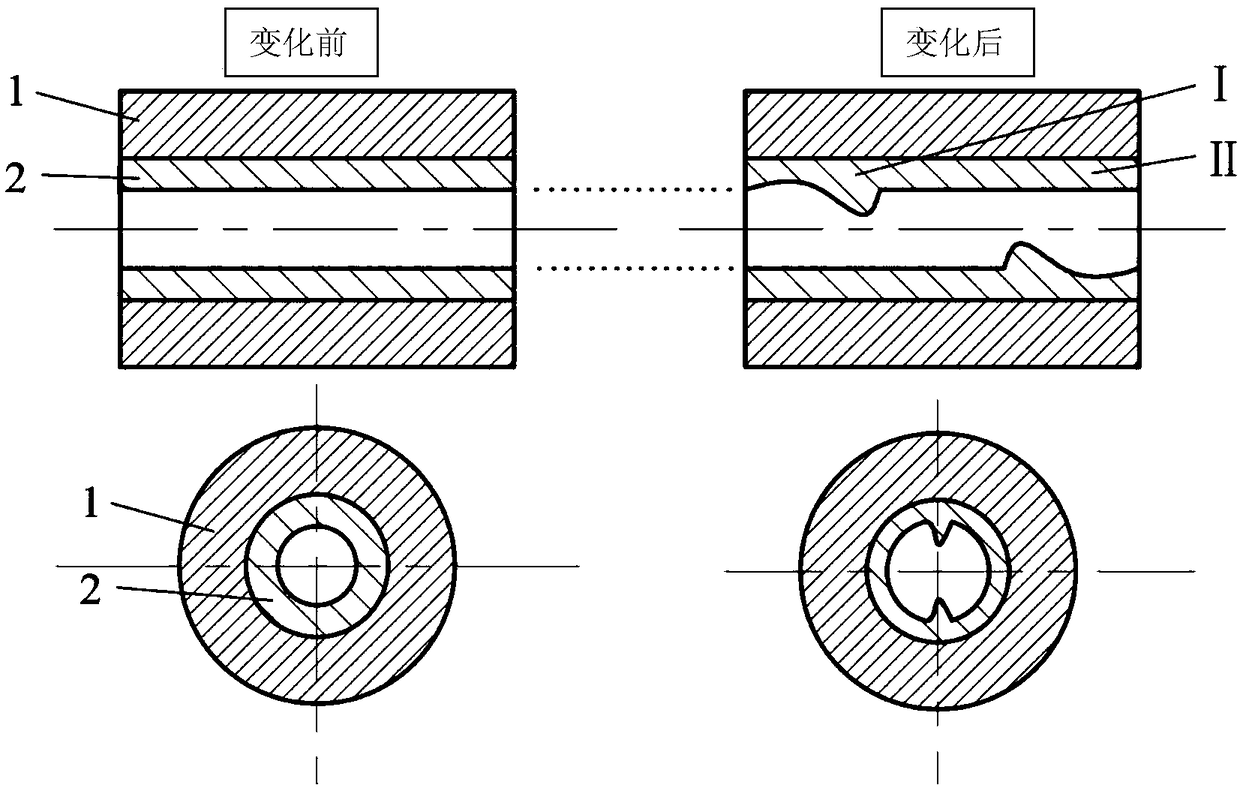

Intelligent conformal cooling channel of mold and manufacturing method thereof

InactiveCN108097953AUniform cooling effectImprove cooling effectAdditive manufacturing apparatusMetallic material coating processesShape changeCooling effect

The invention belongs to the field of mold cooling channels and discloses an intelligent conformal cooling channel of a mold and a manufacturing method thereof. According to the intelligent conformalcooling channel, a memory alloy coating layer is arranged on the inner wall of the conformal cooling channel; the coating layer senses the internal temperature of the conformal cooling channel and conducts shape change according to the temperature so as to make the flow, flow velocity and flow condition of cooling liquid in the cooling channel change. The invention further discloses the manufacturing method of the intelligent conformal cooling channel. Through the intelligent conformal cooling channel of the mold and the manufacturing method thereof, intelligent change of the internal shape ofthe cooling channel is achieved, accurate and high-efficiency cooling is achieved, the cooling efficiency is improved, and the overall cooling effect of the mold is uniform and rapid.

Owner:HUAZHONG UNIV OF SCI & TECH

Methods for installing and welding three-facet rubber tiles on liquidized natural gas ship

ActiveCN101028665AImprove production efficiencySave costsWelding/cutting auxillary devicesAssembly machinesPetroleum engineeringLiquefied natural gas

A technology for assembling and welding the triangular body used for the liquefied natural gas ship includes an assembling step and a welding step. For said assembling step, the 8 plates constituting said triangular body are supported by internal supporting plate and angular supporting plate to splice said triangular body. For said welding step, the diagonal cross welding is used in its 4 welding region.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

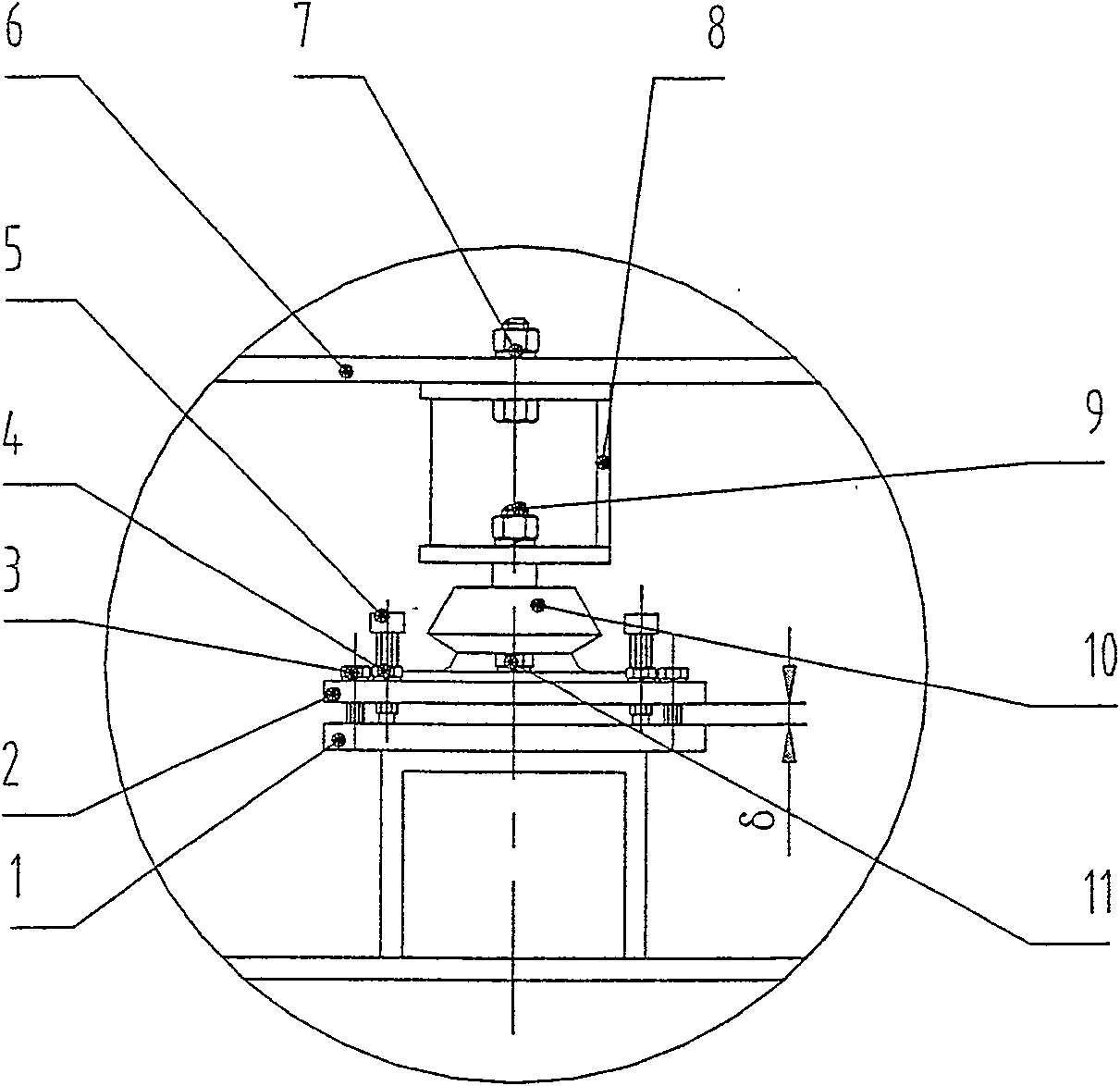

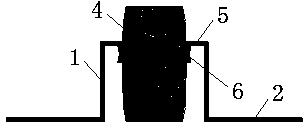

Adjustable elastic support structure

InactiveCN100555806CEliminate manufacturing errorsEliminate installation errorsSupports/enclosures/casingsCouplingEngineering

The invention relates to an adjustable elastic support structure, specifically for the support connection between rotary machines (screw compressors, motors, etc.) and machine bases, and belongs to the technical field of support devices. It mainly adopts the shock absorber to be connected with the bottom plate and the bracket respectively, the motor is connected with the bracket, the chassis is supported by the top screw, the nut locks the top screw, and the bottom plate and the chassis are connected by the connecting bolt. The invention has a simple, compact and reasonable structure; the elastic support can eliminate and reduce the transmission of motor vibration; the adjustable support can eliminate the manufacturing error and installation error of each component, so that each support point can obtain ideal support force and reduce additional vibration and noise ; It can reduce the additional bending moment on the connecting cylinder and the additional force of the connecting bolts, so as to ensure the smooth operation of the machine.

Owner:WUXI COMPRESSOR CO LTD

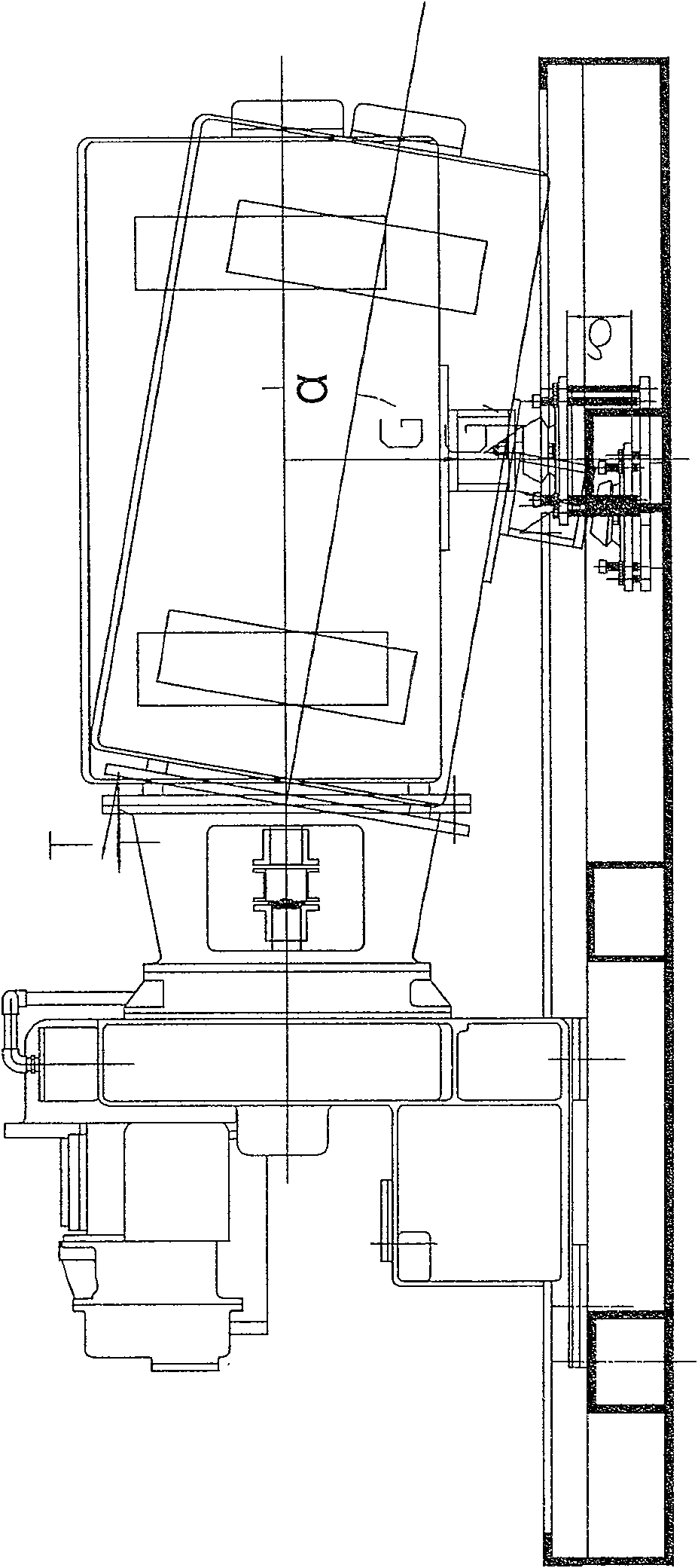

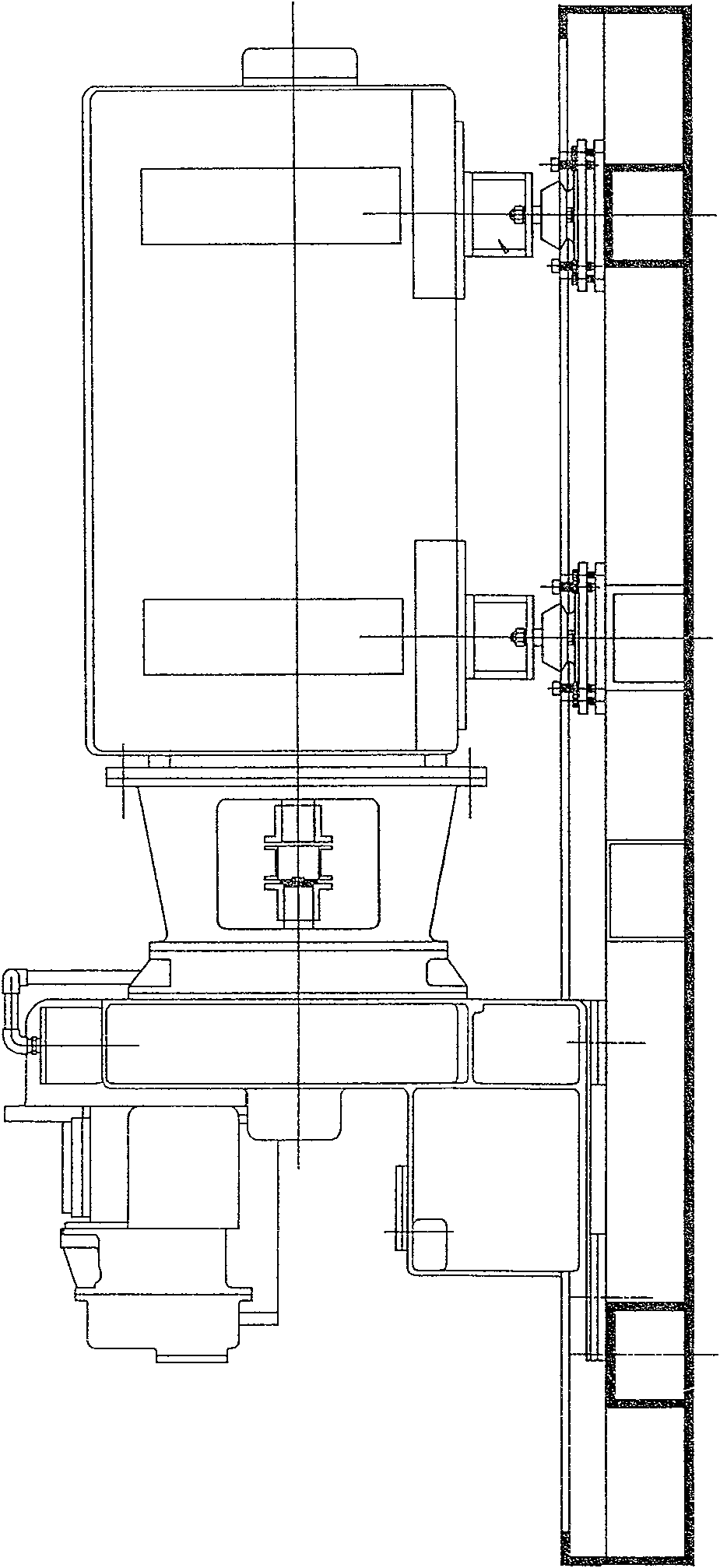

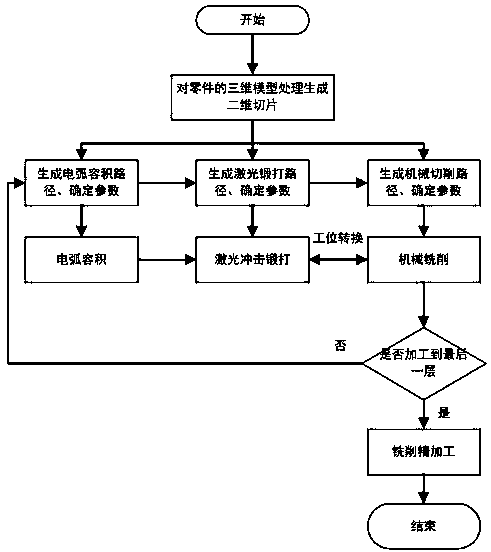

Wire material electric arc fused deposition and laser shock forging composite additive and subtractive manufacturing method and device

InactiveCN108817671AOvercome the shortcomings of poor manufacturing precisionReduce residual stressLaser beam welding apparatusMechanical millingSurface roughness

The invention relates to the technical field of additive and subtractive manufacturing methods and more specifically relates to a wire material electric arc fused deposition and laser shock forging composite additive and subtractive manufacturing method and device. The electric arc fused deposition technology, the laser shock forging technology and the mechanical milling technology are coupled; first, a cladding layer is formed by electric arc fused deposition; when the temperature sensor detects the temperature of the cladding layer to a set laser forging temperature, the laser forging and the electric arc fused deposition are simultaneously performed, and laser shock forging is performed on the molding region, which can reduce the manufacturing error during the wire accumulation processand the error caused by the surface roughness of the forging part, and improve the overall precision of the part. after the electric arc fused deposition and the laser shock forging are finished, parts are transferred to the milling station to mechanically mill the surface of the parts to improve surface accuracy, reduce the manufacturing error during wire stacking and the error caused by the surface roughness of the part forging, improve the overall accuracy of the parts and overcome the shortcomings of poor wire forming precision in electric arc fused deposition.

Owner:GUANGDONG UNIV OF TECH

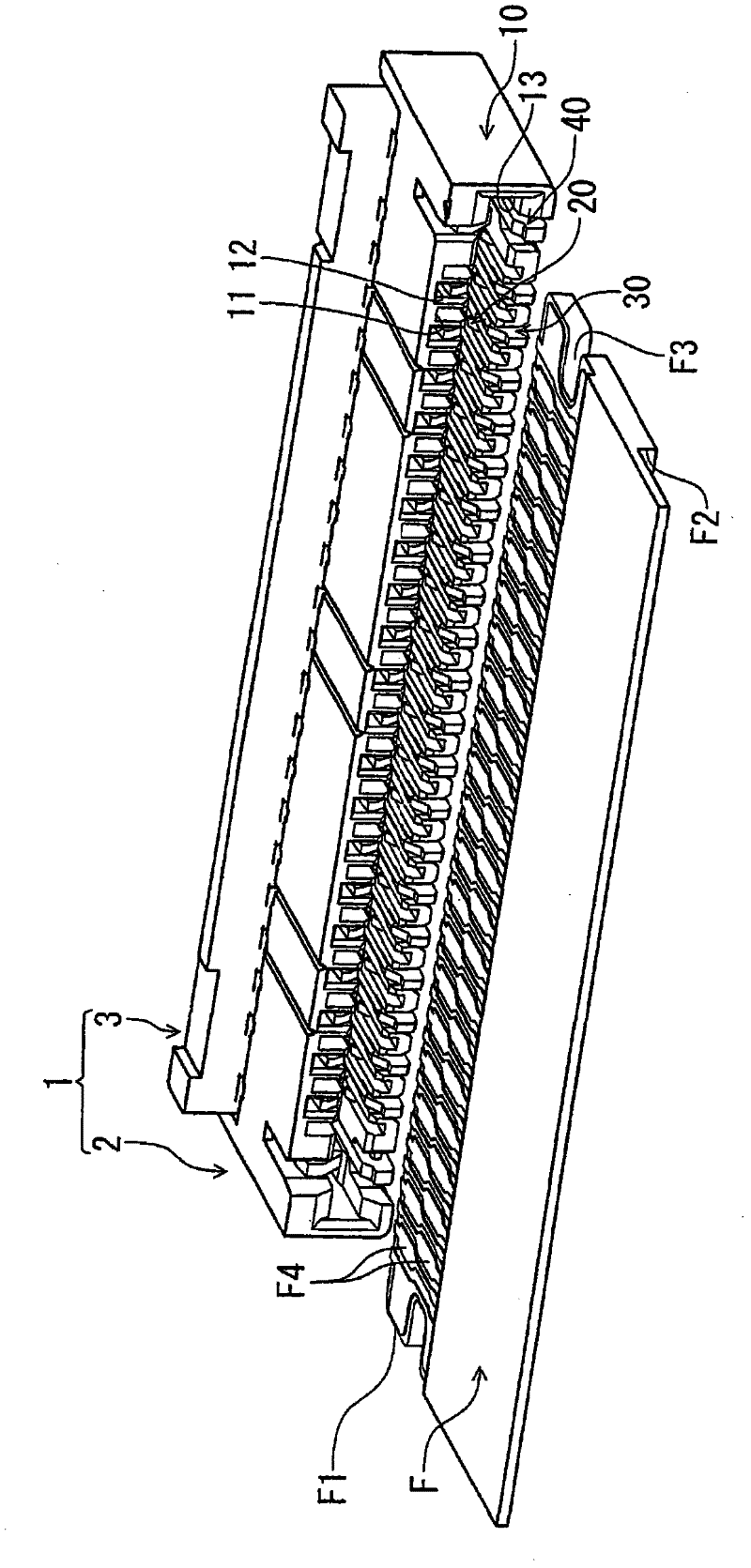

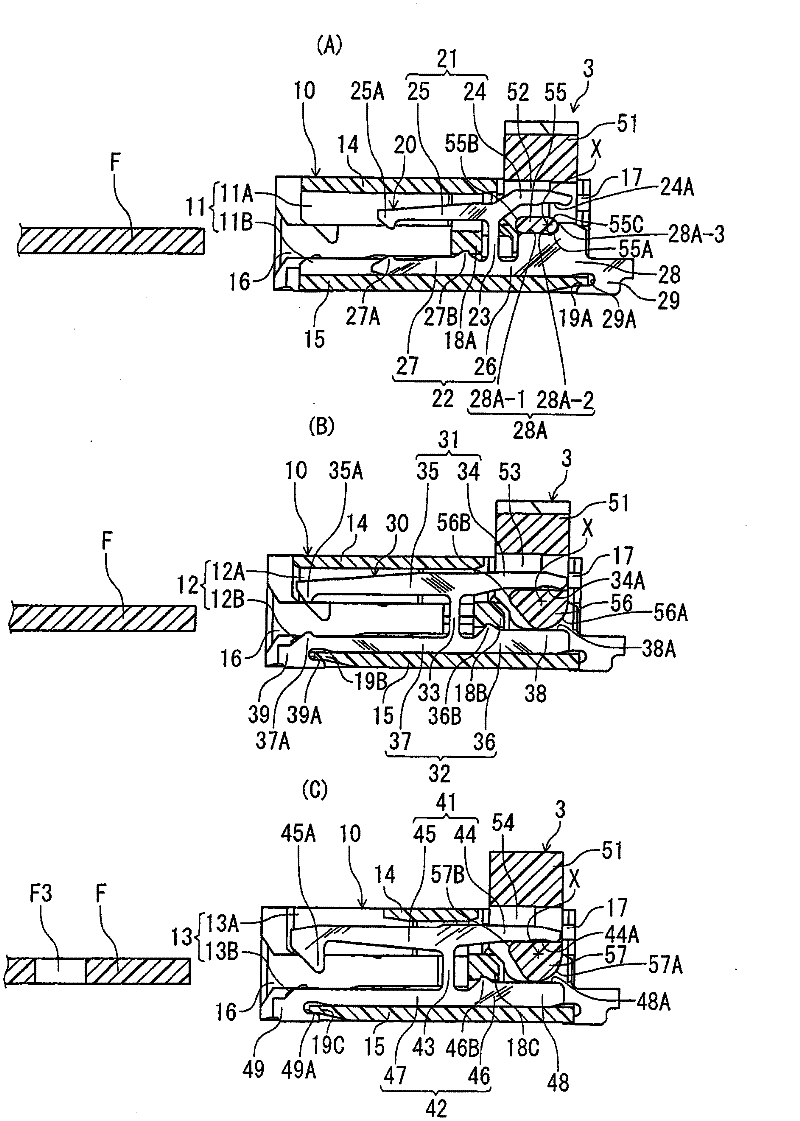

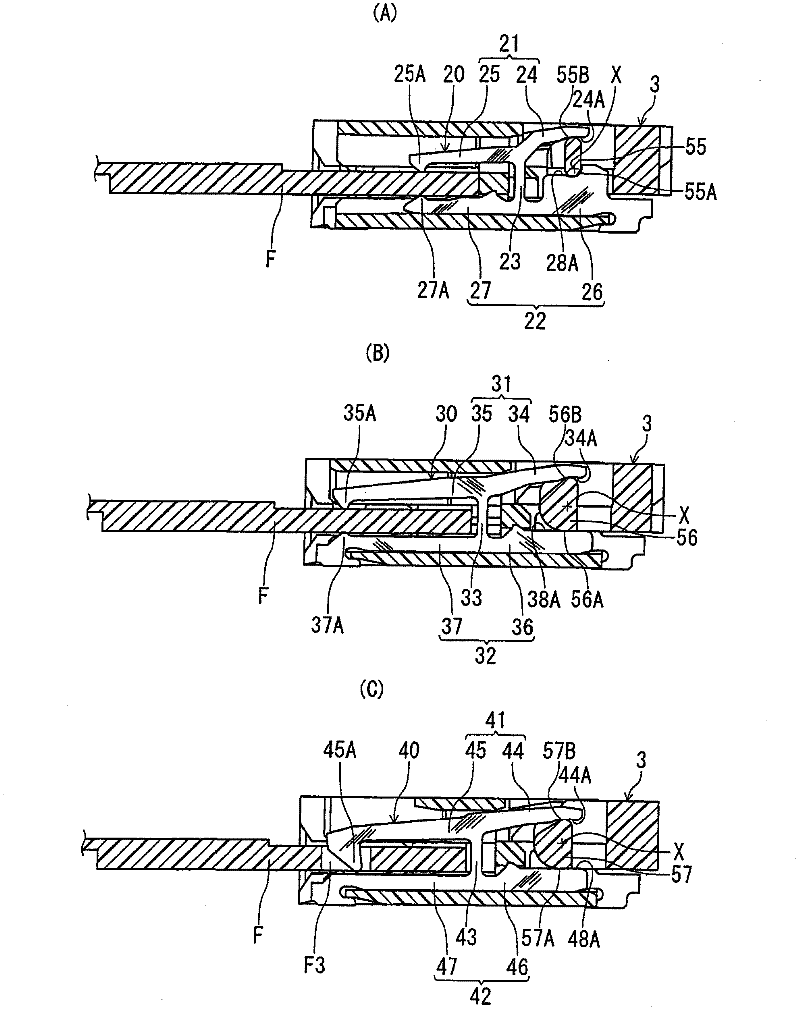

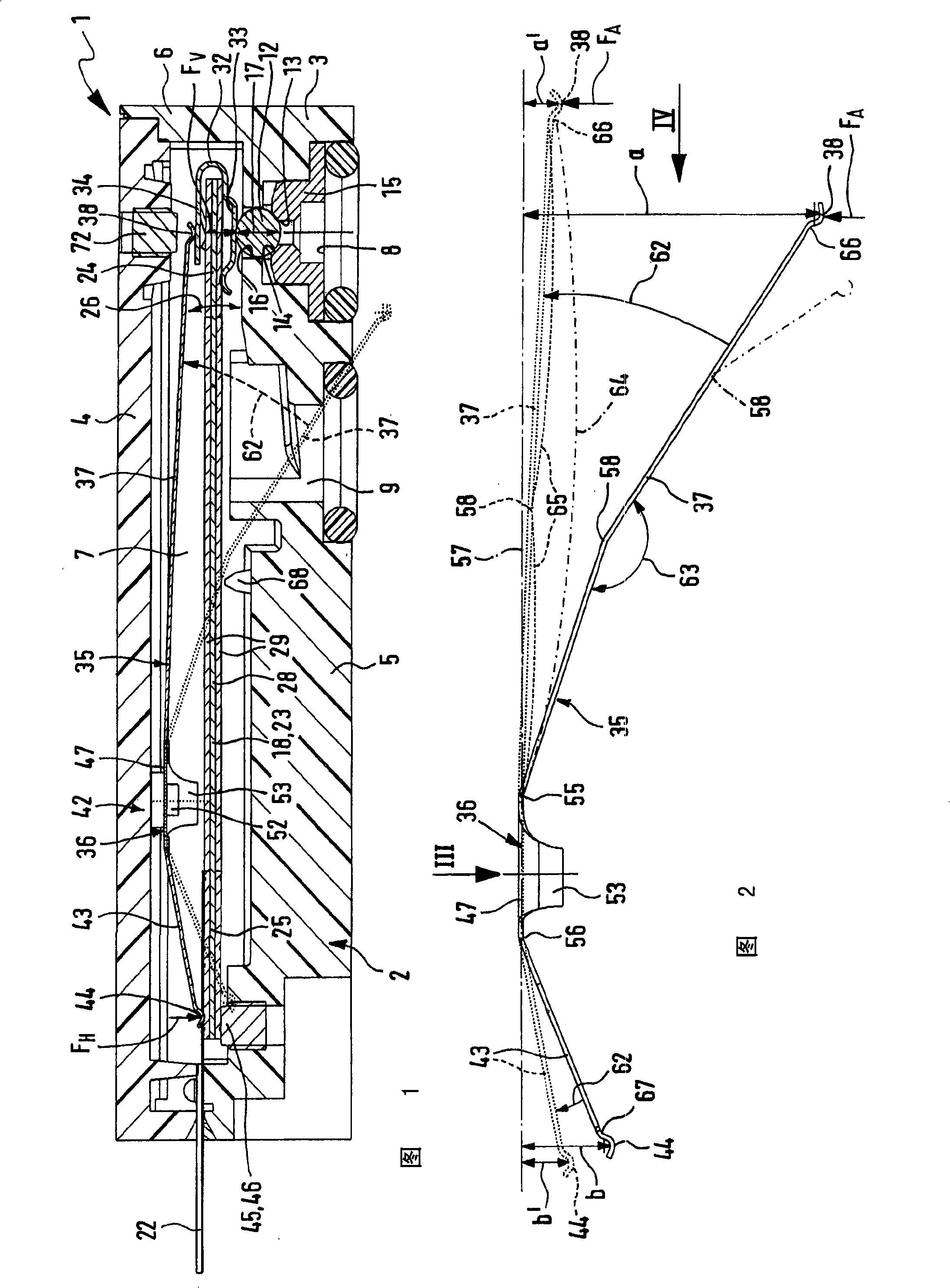

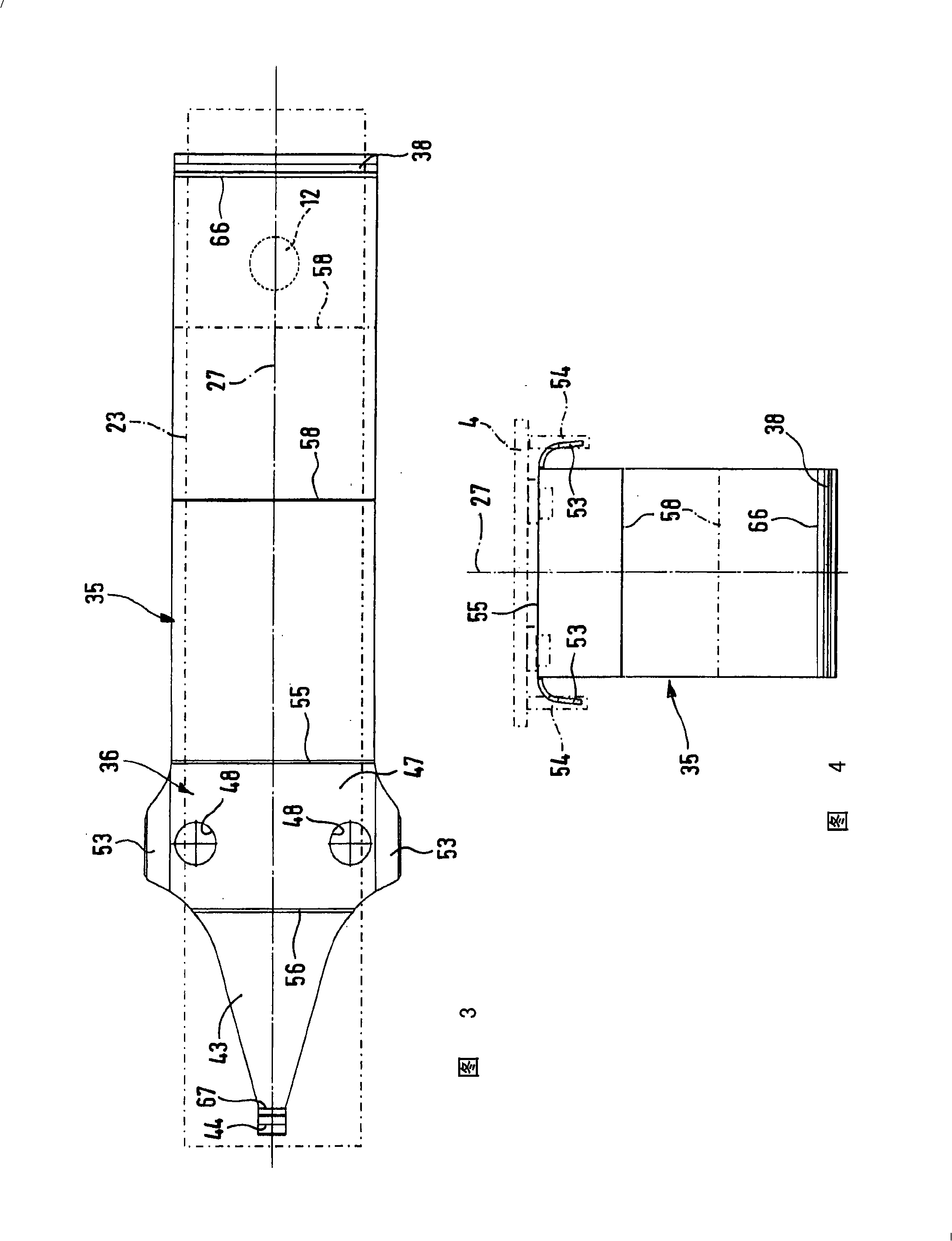

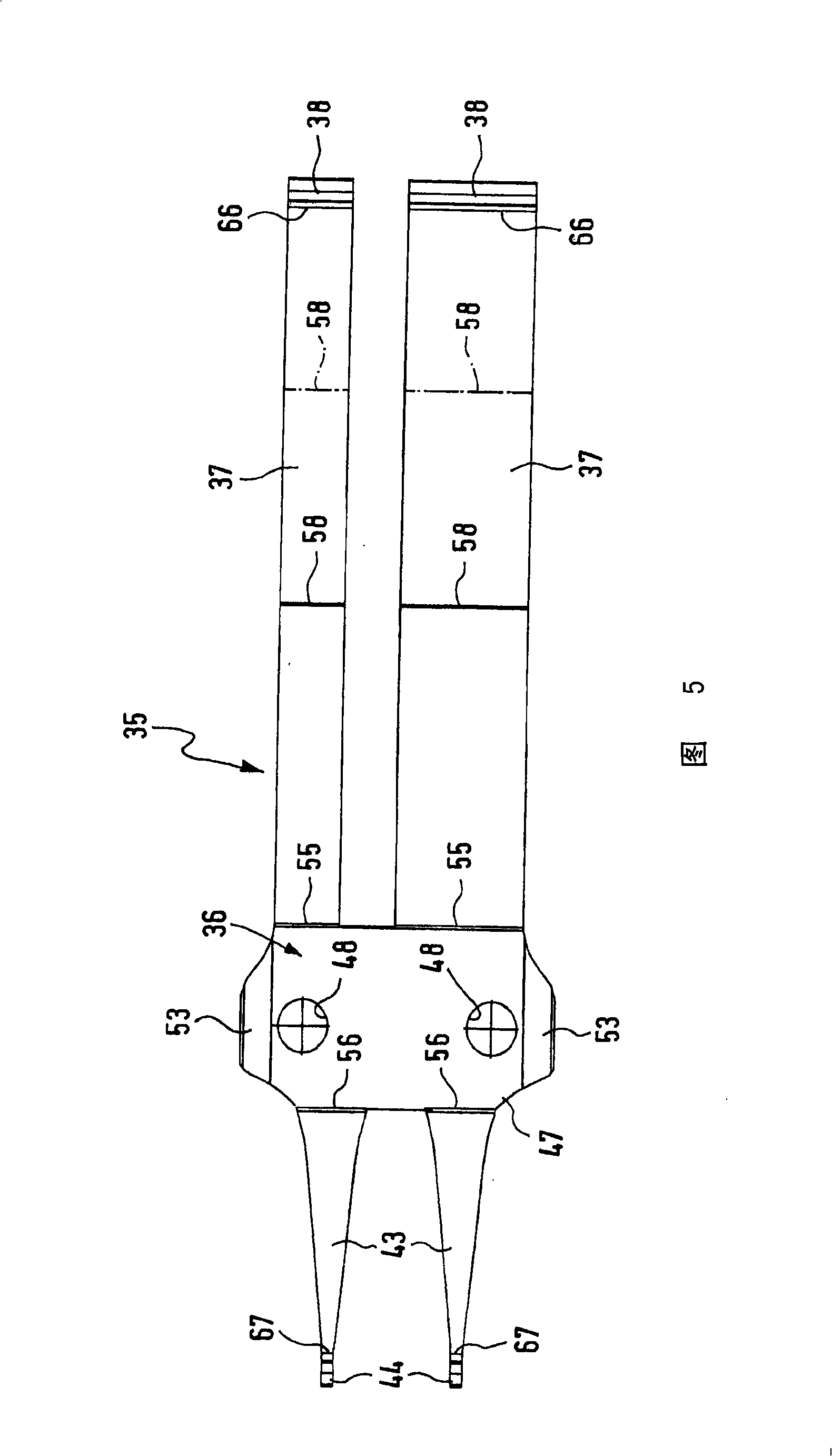

Electric connector for flat conductor

InactiveCN102332648AReduce manufacturing errorsReduce assembly errorsEngagement/disengagement of coupling partsCoupling contact membersElectrical conductorCam

An electric connector for a flat conductor comprises two kinds of terminals with different assembling directions towards a shell and can greatly reduce position error of cam parts. In the flat type electric connector for the conductor, an attaching part (38A) of a second terminal (30) attached with the cam is arranged at a position which is the same with a lower edge of a position limiting part (18B) or therebelow, an attaching part (28A) of a first terminal (20) is arranged above the attaching part (38A) of the second terminal (30), a first cam part (55) and a second cam part (56) of a movable construction member (3) can rotate around a common axes, the movable construction member (3) is provided with upper cam edges (55B), (56B) and lower cam edges (55A), (56A) which are abutted against upper arm parts and lower arm parts of the first terminal and the second terminal, the lower cam edges (55A), (56A) of the first cam part (55) and the second cam part (56) can form that when the movable construction member (3) turns towards a closed position, the difference of radius lengths of the cams which are movably contacted with the lower arm part within a movable contacting range and in the optional same angle positions is a fixed value.

Owner:HIROSE ELECTRIC GROUP

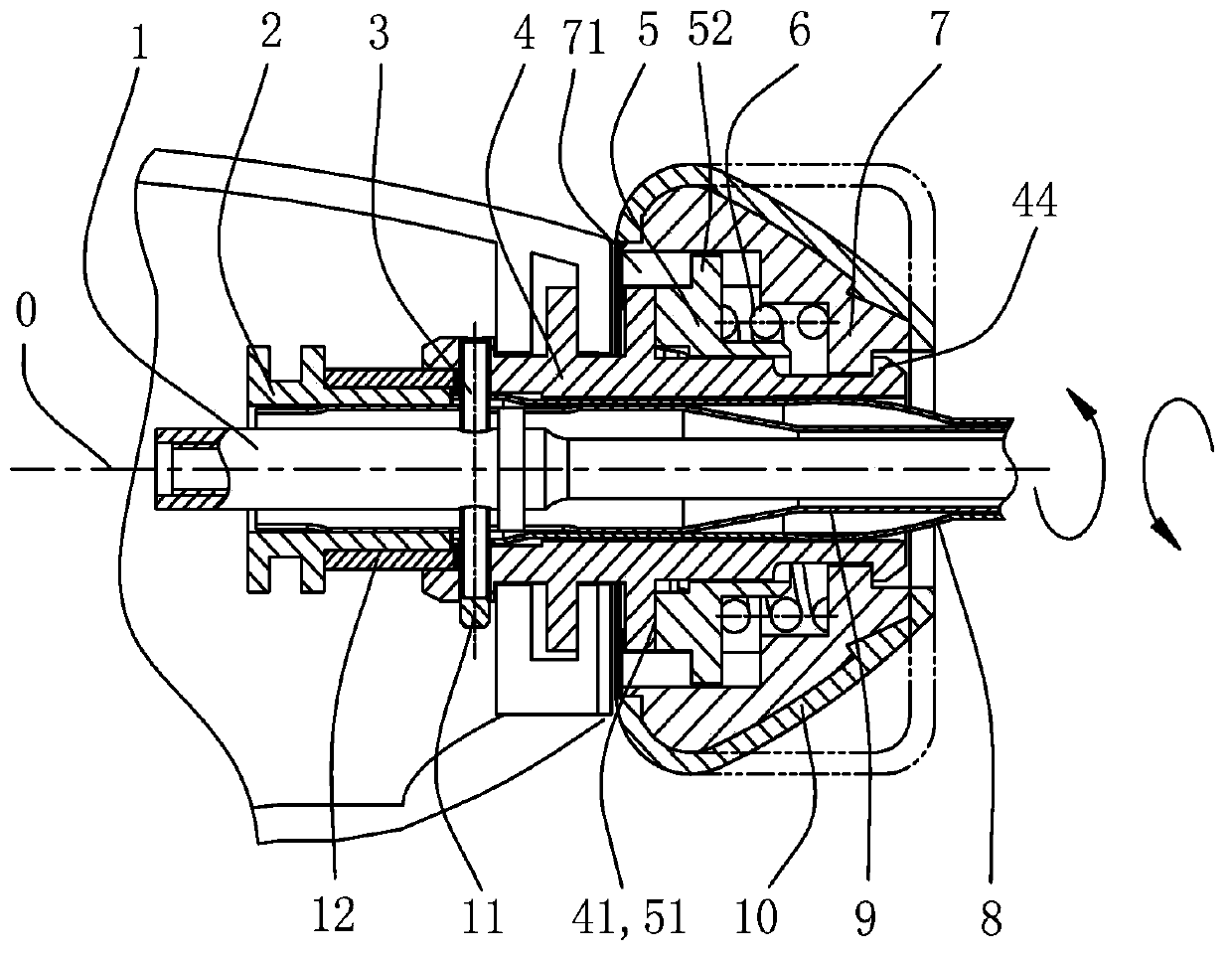

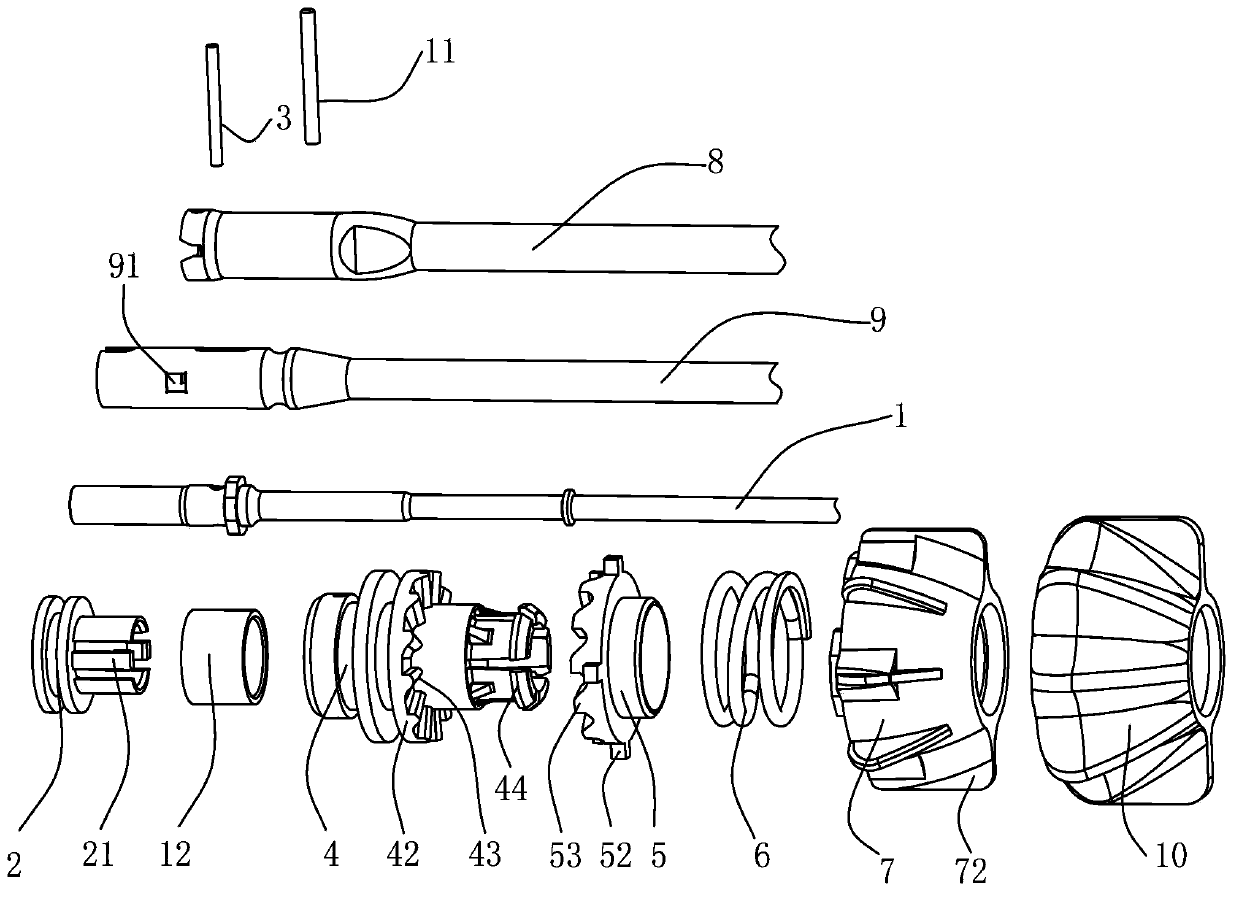

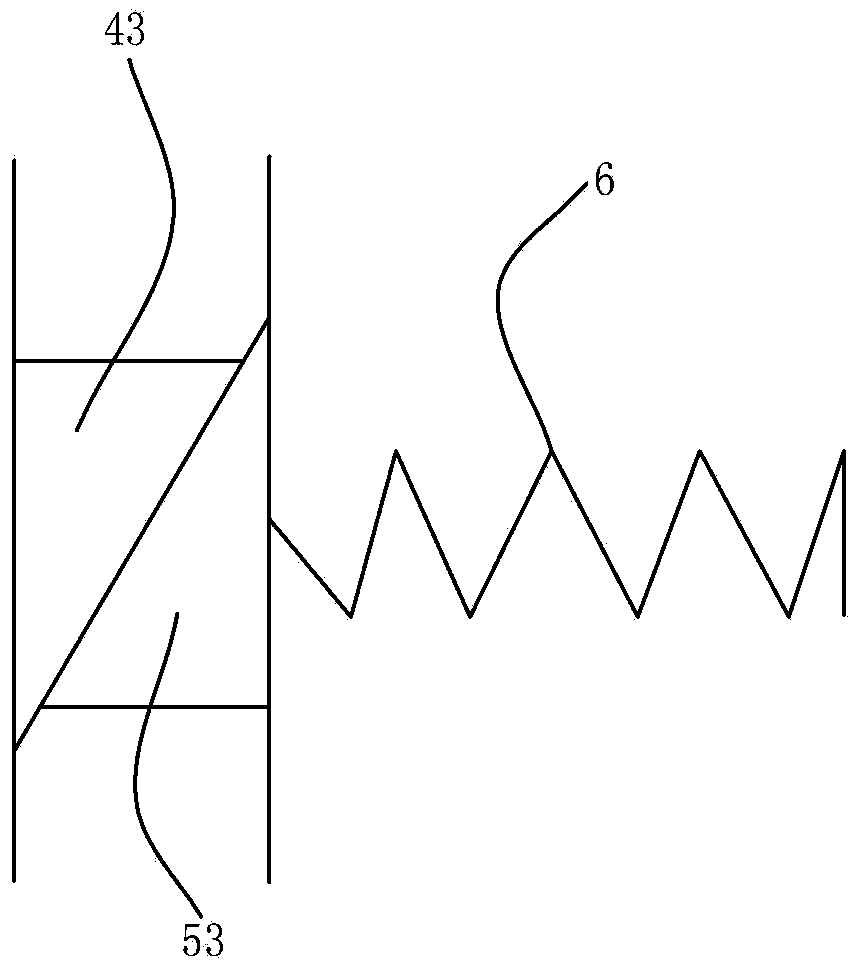

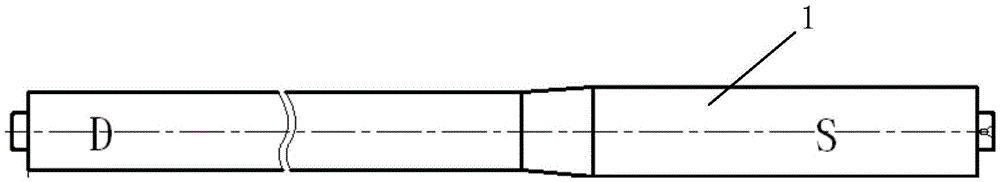

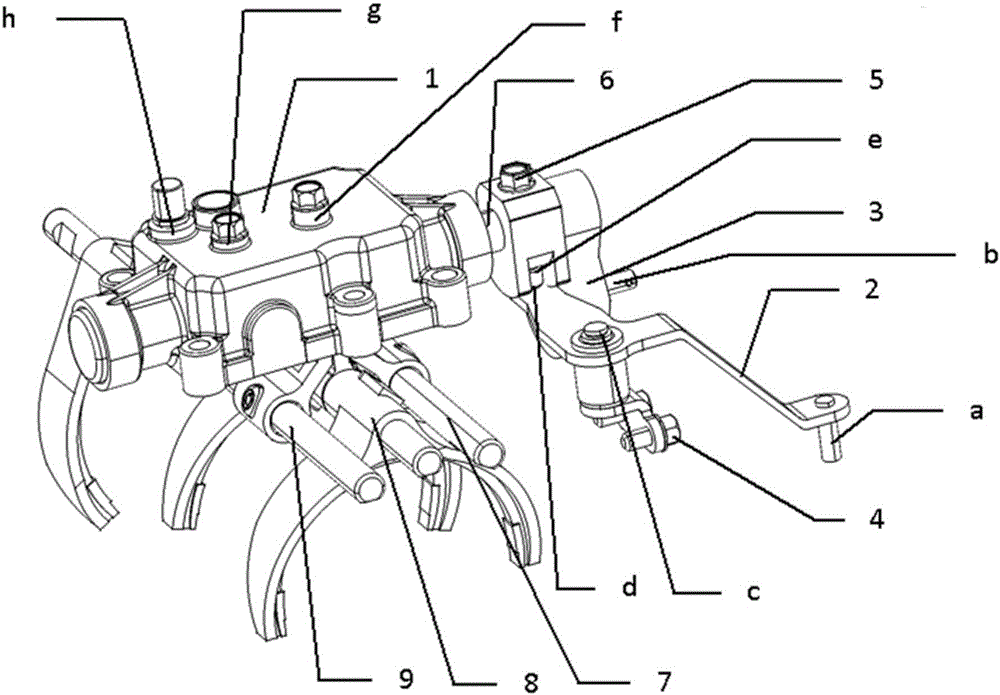

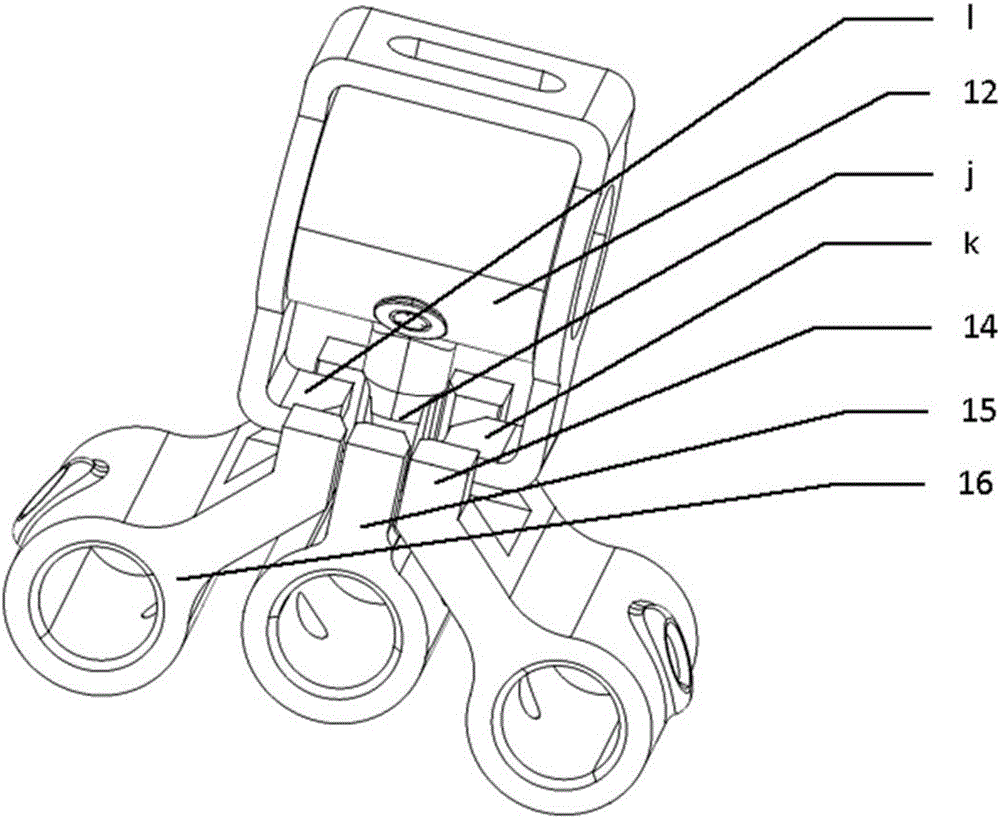

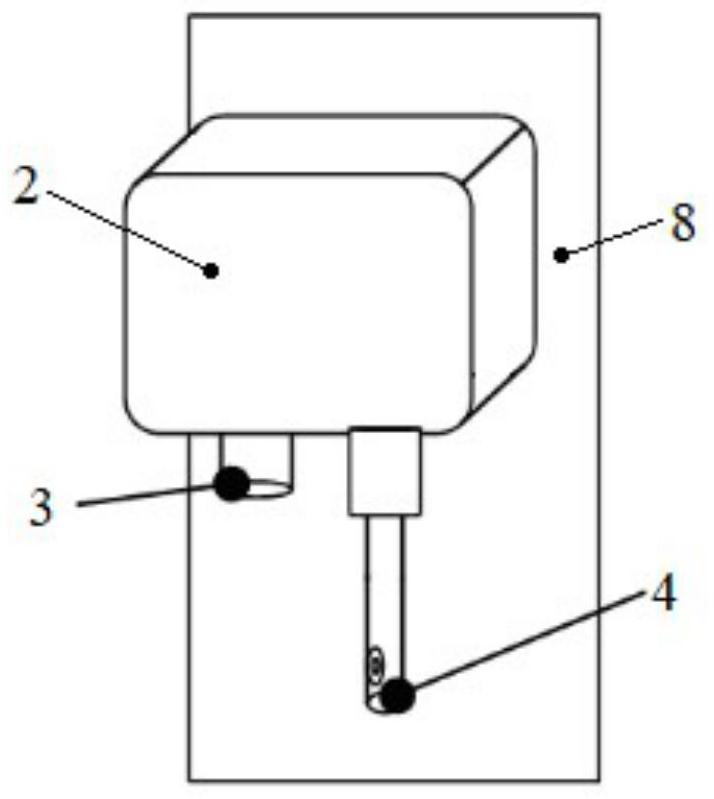

Ultrasound knife head and ultrasound knife

ActiveCN104173093AEasy to operateMaterial selection lowIncision instrumentsDiagnosticsBearing surfaceInteraction forces

Disclosed is an ultrasonic knife head (100), wherein a centre pole (1) of the ultrasonic knife head (100) can rotate around an axis and thread-connect to a driving handle (200), a power transmission device is fixedly connected to the centre pole (1), and the power transmission device has at least one bearing surface (41); the rotating device comprises a crowding mechanism and a rotation driving mechanism, wherein the rotation driving mechanism has at least one force applying surface (51), one bearing surface (41), wherein the force applying surface (51) is a surface which is not perpendicular to the axis, and the surfaces are capable of engaging with each other, and the crowding mechanism provides a thrust pressure to press the rotation driving mechanism against the power transmission device, thereby engaging the force applying surface (51) with the bearing surface (41), and the thrust pressure is set to be the thrust pressure the rotation driving mechanism can overcome when the interaction force between the force applying surface (51) and the bearing surface (41) is greater than the predetermined value, disengaging the force applying surface (51) and the bearing surface (41). As long as the thrust pressure is set reasonably, the set torque can be delivered, and when the torque is greater than the set value, the rotation driving mechanism will overcome the thrust pressure and slip, thereby limiting the delivery of the torque and providing protection. The present invention also provides an ultrasonic knife comprising the ultrasonic knife cutting head (100).

Owner:REACH SURGICAL

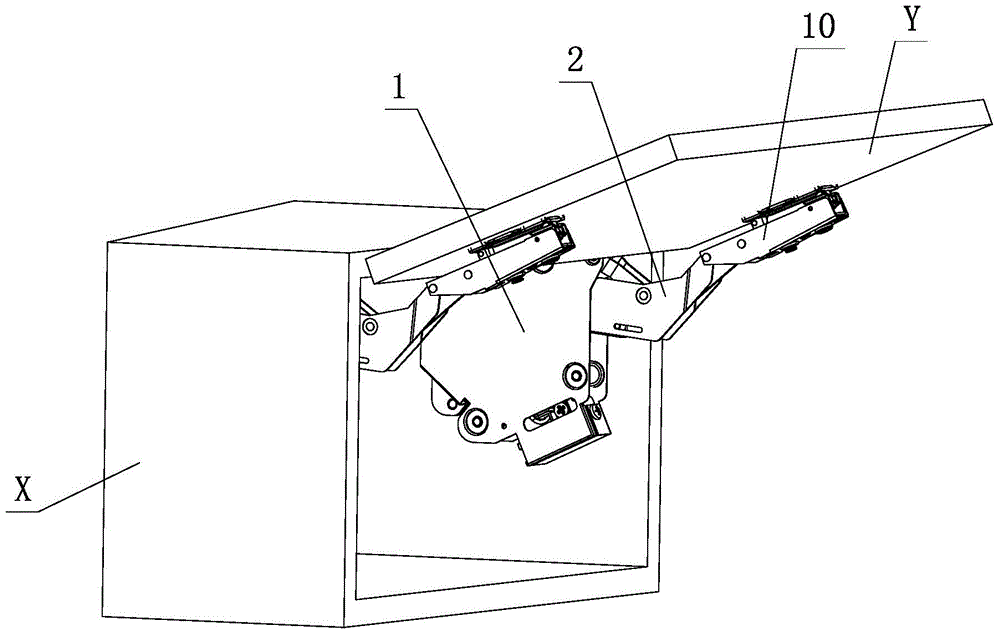

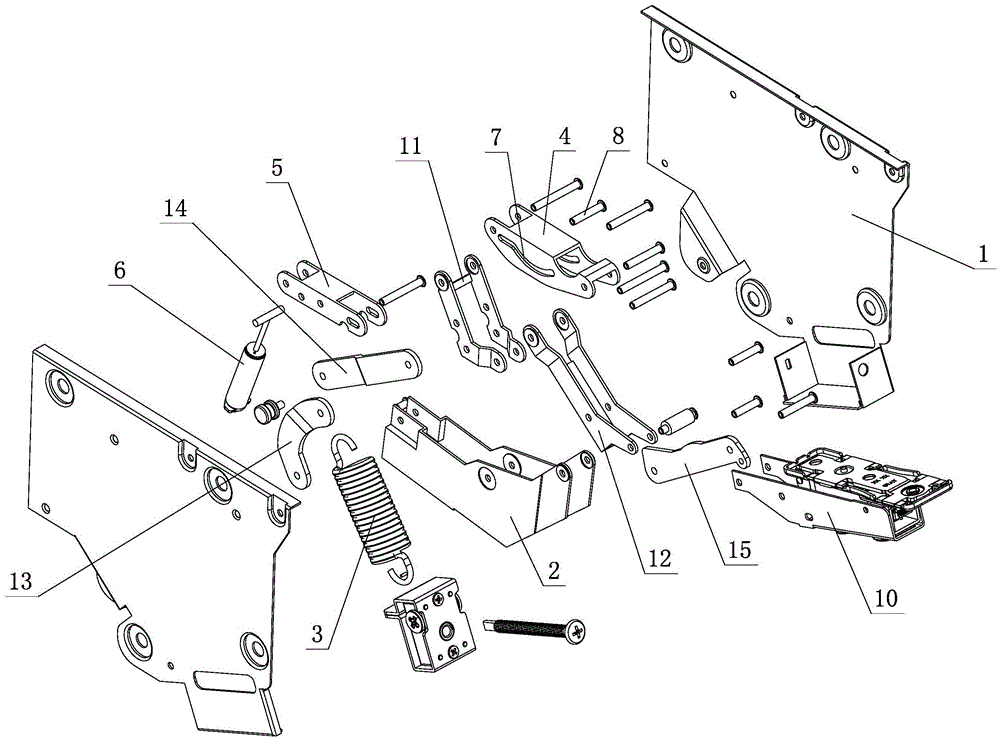

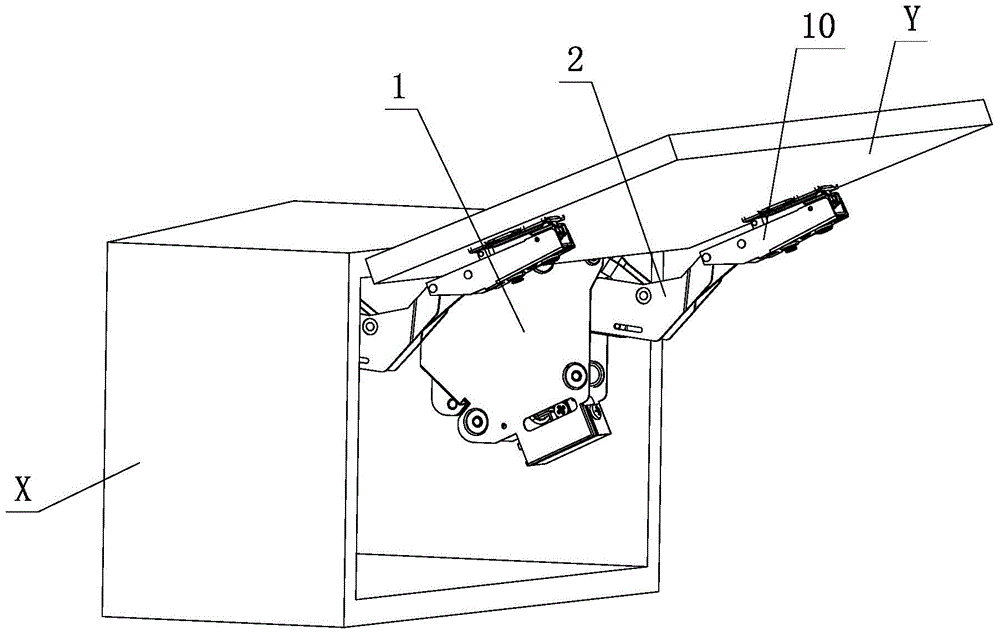

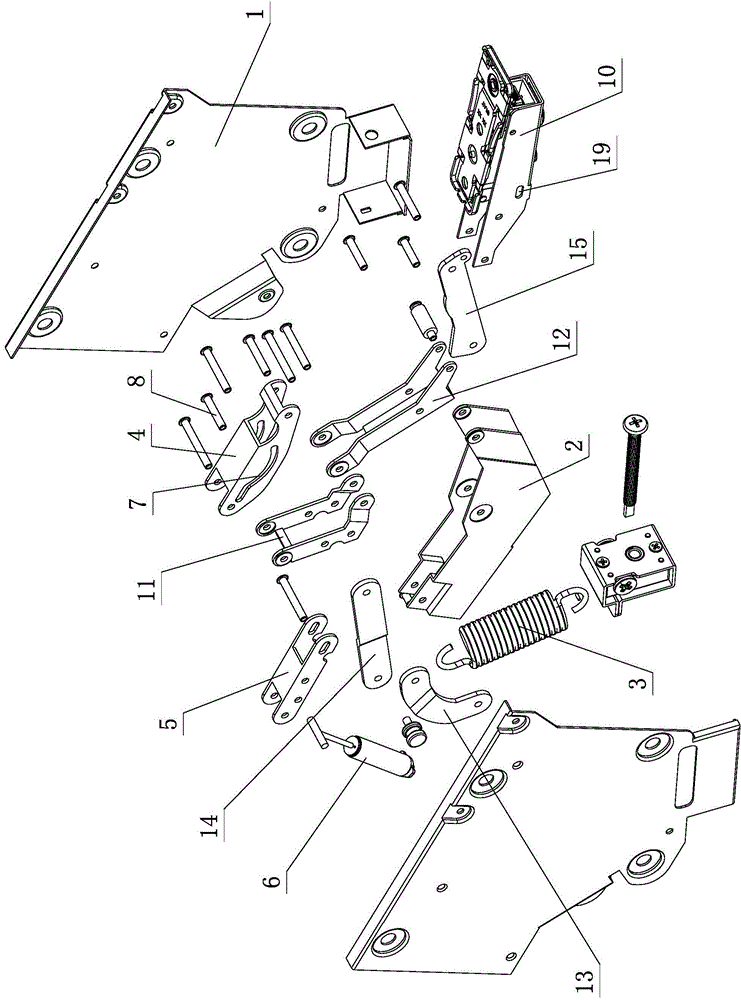

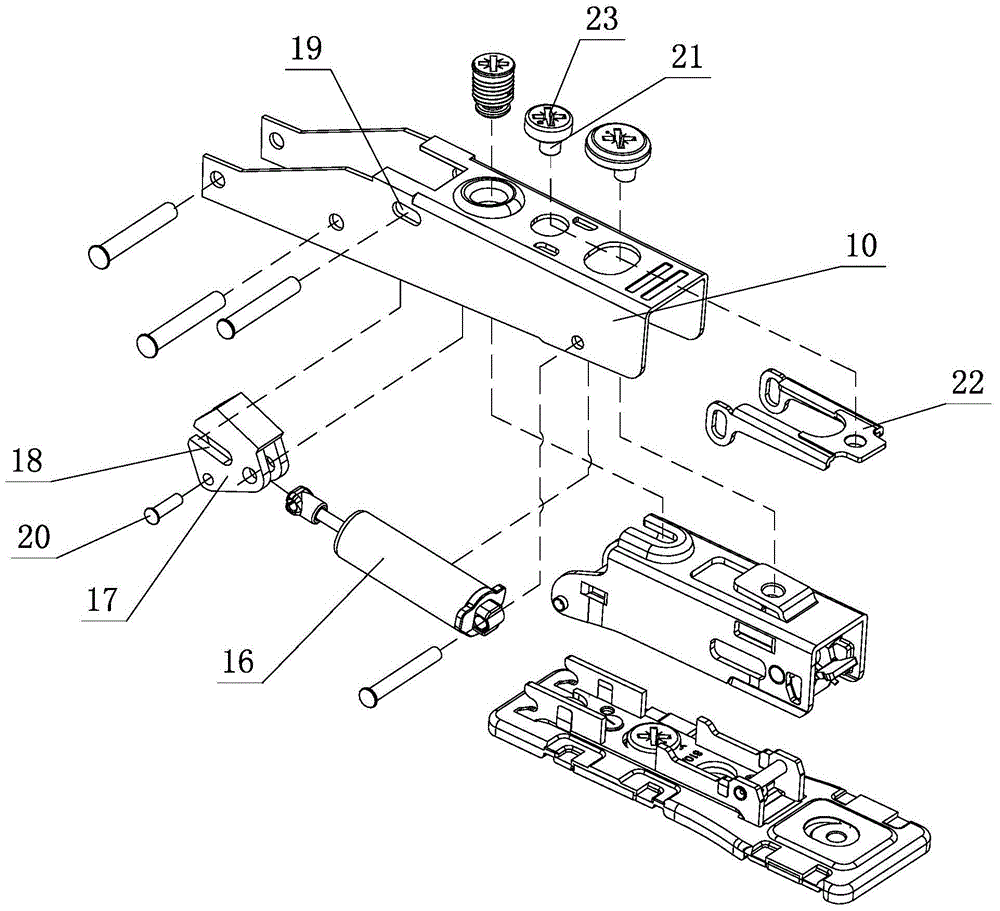

Damping and hovering structure of furniture tilt-up door

ActiveCN104912421ANo damping forcePrecise positioningBuilding braking devicesPin hingesAcute angleControl theory

A damping and hovering structure of a furniture tilt-up door comprises a fixing seat, a spring, a connecting arm component and a retaining element. The connecting arm component at least comprises a first connecting arm, a second connecting arm and a middle arm; the first connecting arm and / or the second connecting arm is hinged to the fixing seat, the middle arm is hinged to the fixing seat and / or the retaining element, and the retaining element is opened and closed on the fixing seat in a turnover manner under the action of the spring; a damping and hovering unit is arranged on the retaining element and comprises a hovering damper and a pushing element; when the retaining element is opened and closed within a certain acute angle range, the hovering damper is at the initial position and basically does not generate damping force; when the retaining element is opened and closed beyond the certain acute angle range, the middle arm acts on the hovering damper through elasticity of the spring and / or loading capacity of the retaining element, the hovering damper generates damping force, and elasticity of the spring and / or loading capacity of the retaining element is offset through the damping force, so that the retaining element can hover anytime when being opened and closed beyond the certain acute-angle range.

Owner:伍志勇

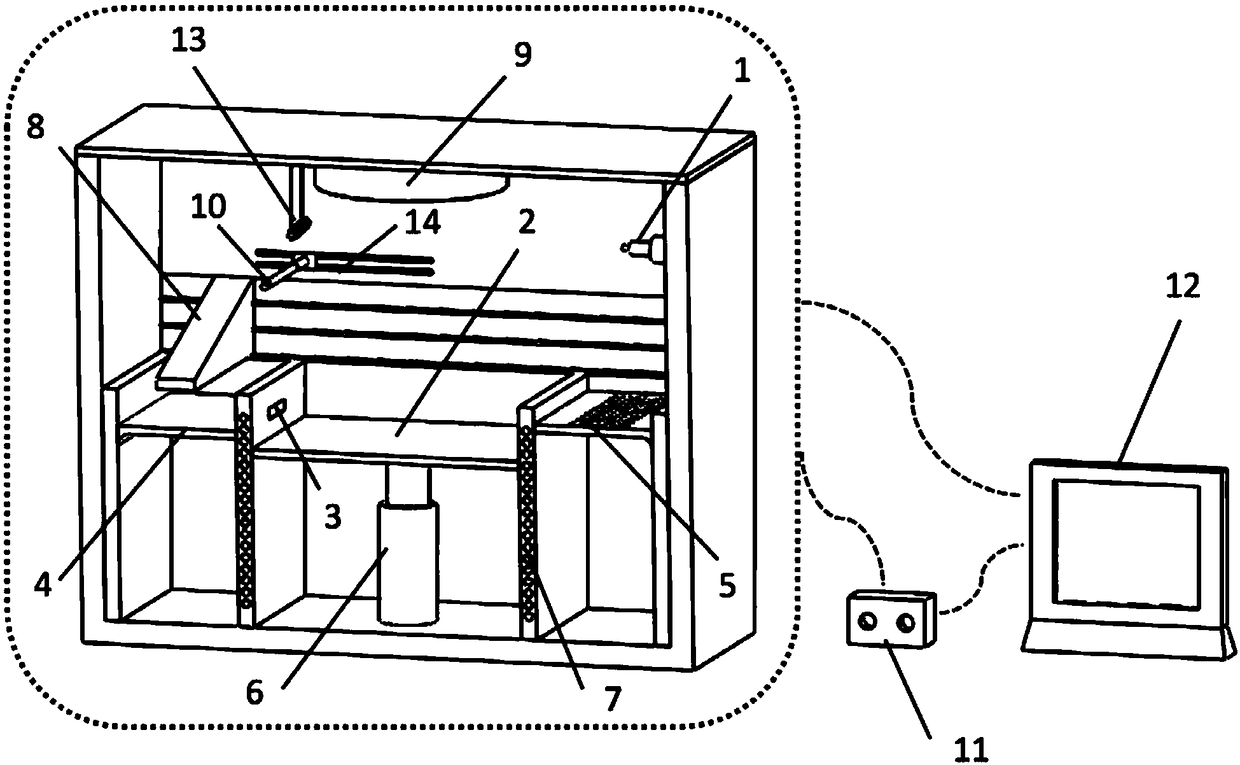

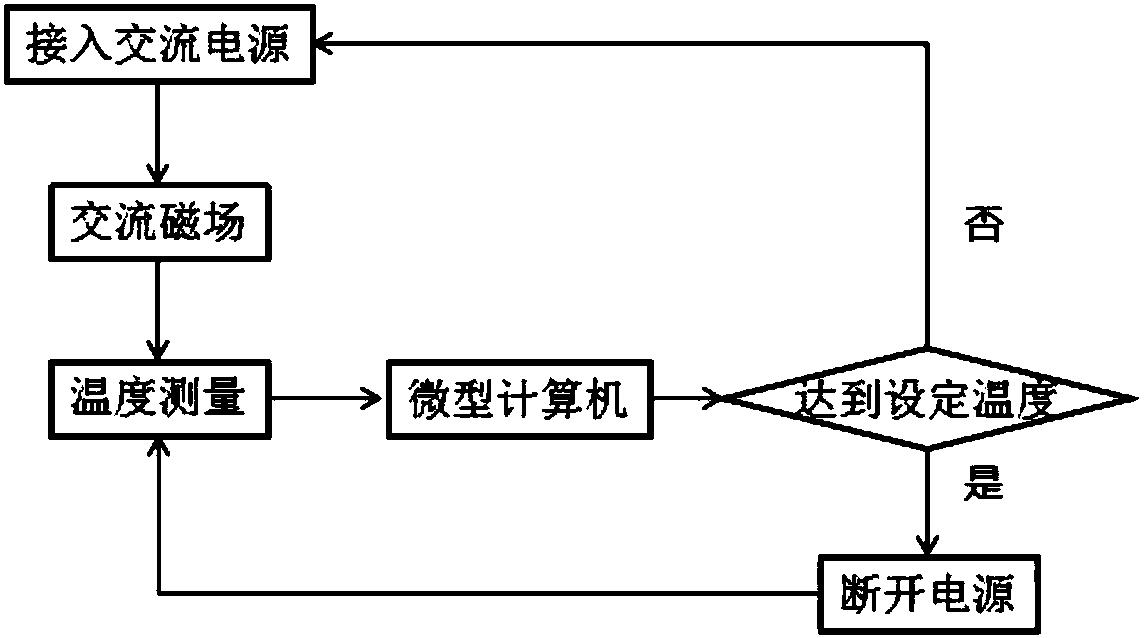

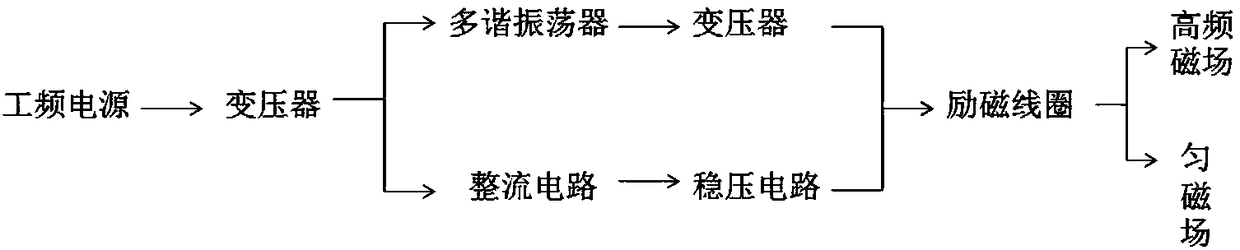

Thermo-magnetic coupling field cooperated selective laser-melting device and heating method thereof

ActiveCN108421976AImprovement is difficult to control, and there are defects such as coarse dendritesImprove the mechanical properties of defectsAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a thermo-magnetic coupling field cooperated selective laser-melting device and a heating method thereof. The thermo-magnetic coupling field cooperated selective laser-melting device is characterized in that a magnetic field generator is introduced on the basis of conventional laser selective sintering and heating; during normal printing, a control system controls the magnetic field generator to generate stable static magnetic fields; the static magnetic fields provide lorentz force to change flow field distribution, in a workpiece printing process, of a molten pool; when a workpiece is printed and accumulated to certain thickness, the magnetic field generator is controlled to generate alternating magnetic fields for heating, tempering and thermally treating the workpiece, and then naturally cooling the workpiece to the room temperature; and workpiece printing is continued according to the method until workpiece printing is ended. In a printing process, an unevenworkpiece effect generated by the Marangoni effect can be reduced, various defects caused by the printing process further can be eliminated, crystalline grains are refined, segregation is eliminated,and internal stress is reduced, so that the structure and the performance of the workpiece are more uniform, and therefore, growth of a metallographic structure of a printing material is promoted, and hardness and strength of the workpiece are improved.

Owner:湖南珞佳智能科技有限公司

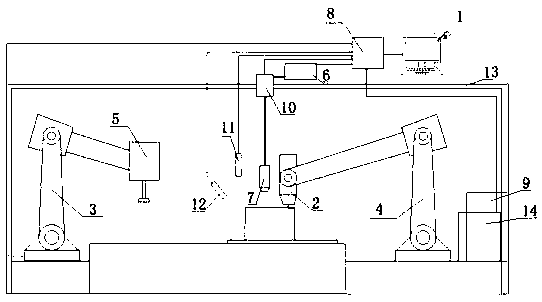

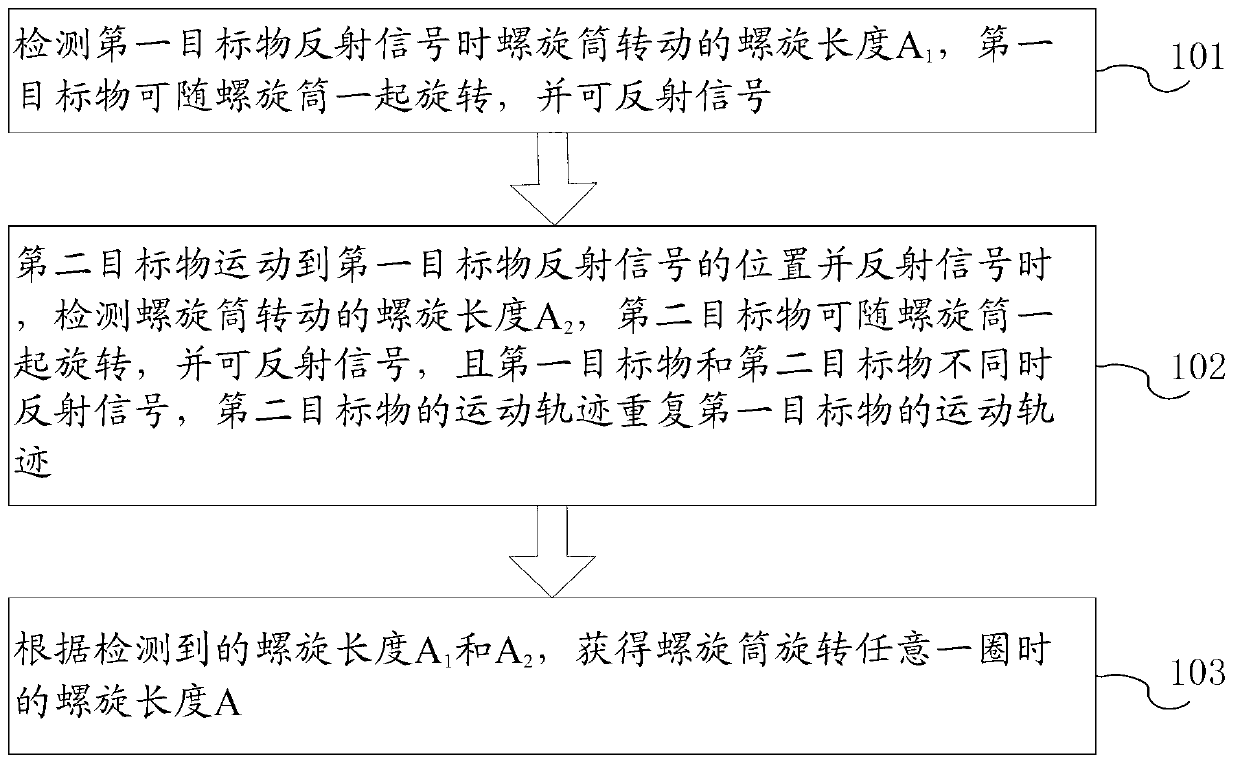

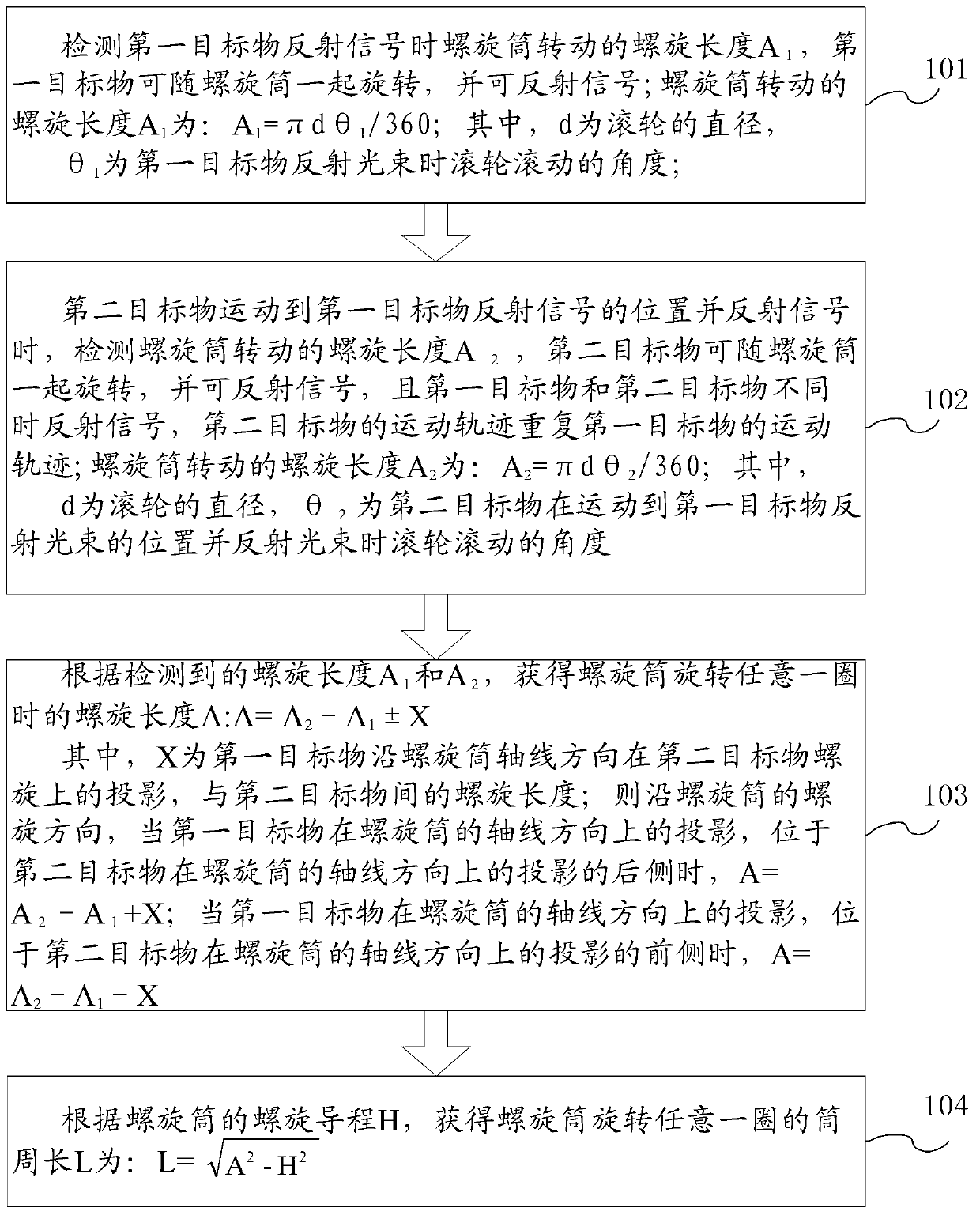

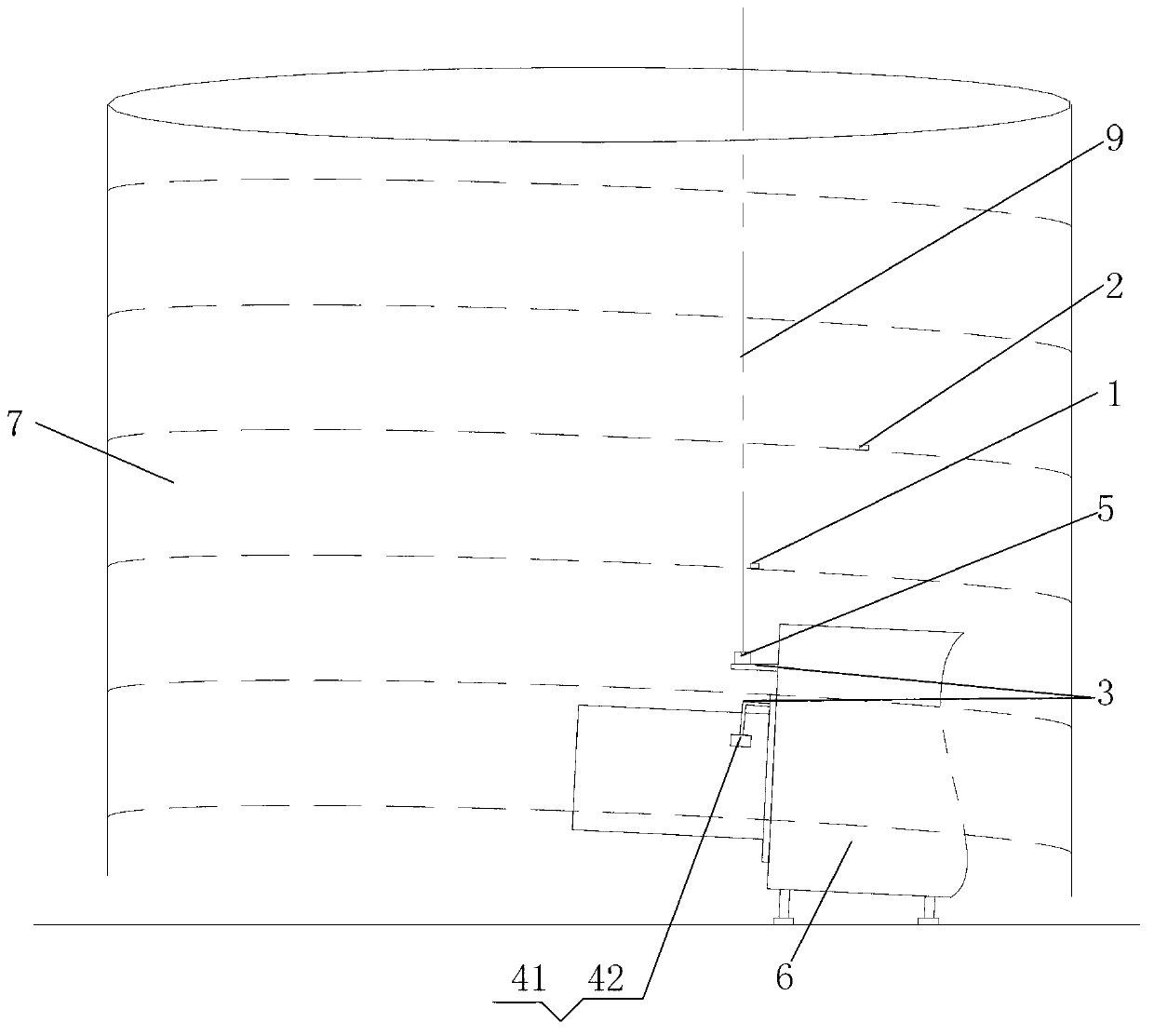

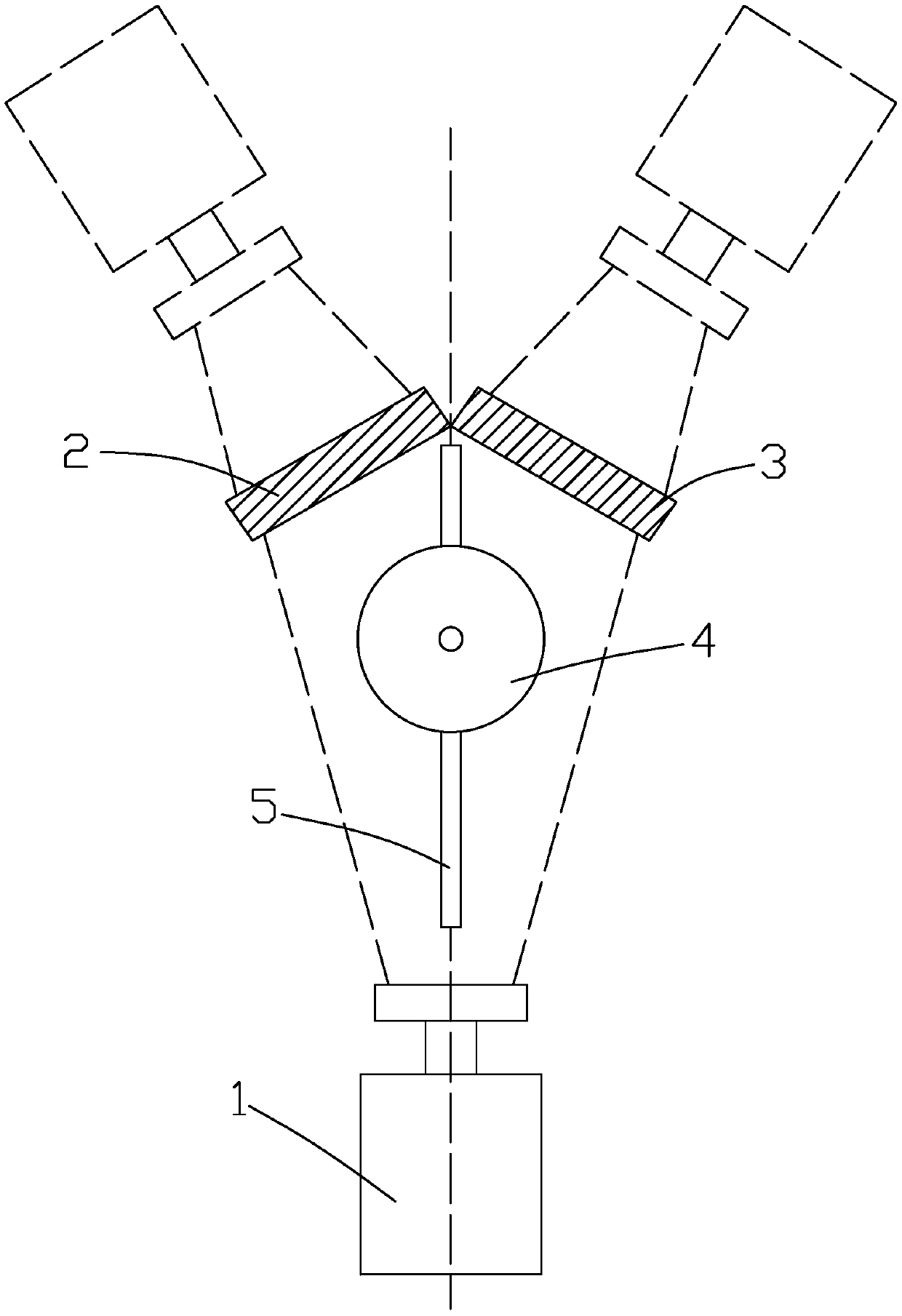

Circumference measurement method and device of spiral tube

ActiveCN102997851AMeasuring DynamicsAccurate measurementUsing optical meansMeasurement deviceEngineering

The invention provides a circumference measurement method and device of a spiral tube. The circumference measurement device comprises a detection device, a signal transmission device, a first target object, a second target object and a controller. The detection device can detect the spiral length of the spiral tube during rotation and is connected with the controller. The signal transmission device can transmit a signal. The first target object and the second target object are arranged on the wall of the spiral tube, can rotate along with the spiral tube, and respectively reflect the signal. The controller can obtain the spiral length and the tube circumference of the spiral tube rotating for any circle according to the spiral length of the spiral tube detected by the detection device when the first target object and the second target object respectively reflect the signal. By means of the technical scheme, circumference parameters such as the circumference, the diameter and the circumference error of the spiral tube can be measured accurately in a real-time and online mode, so that timely adjustment can be performed on a manufacture device of the spiral tube, installation errors can be eliminated, and manufacture accuracy of the spiral tube can be improved.

Owner:CHINA POWER IND INTERNET CO LTD

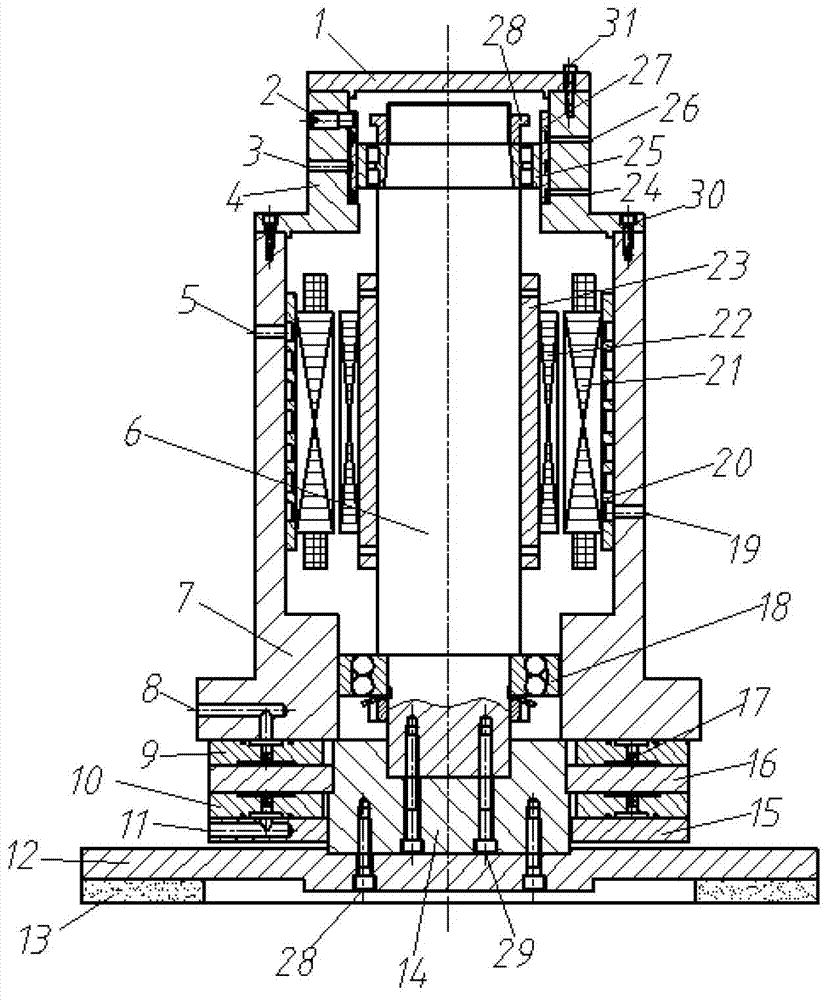

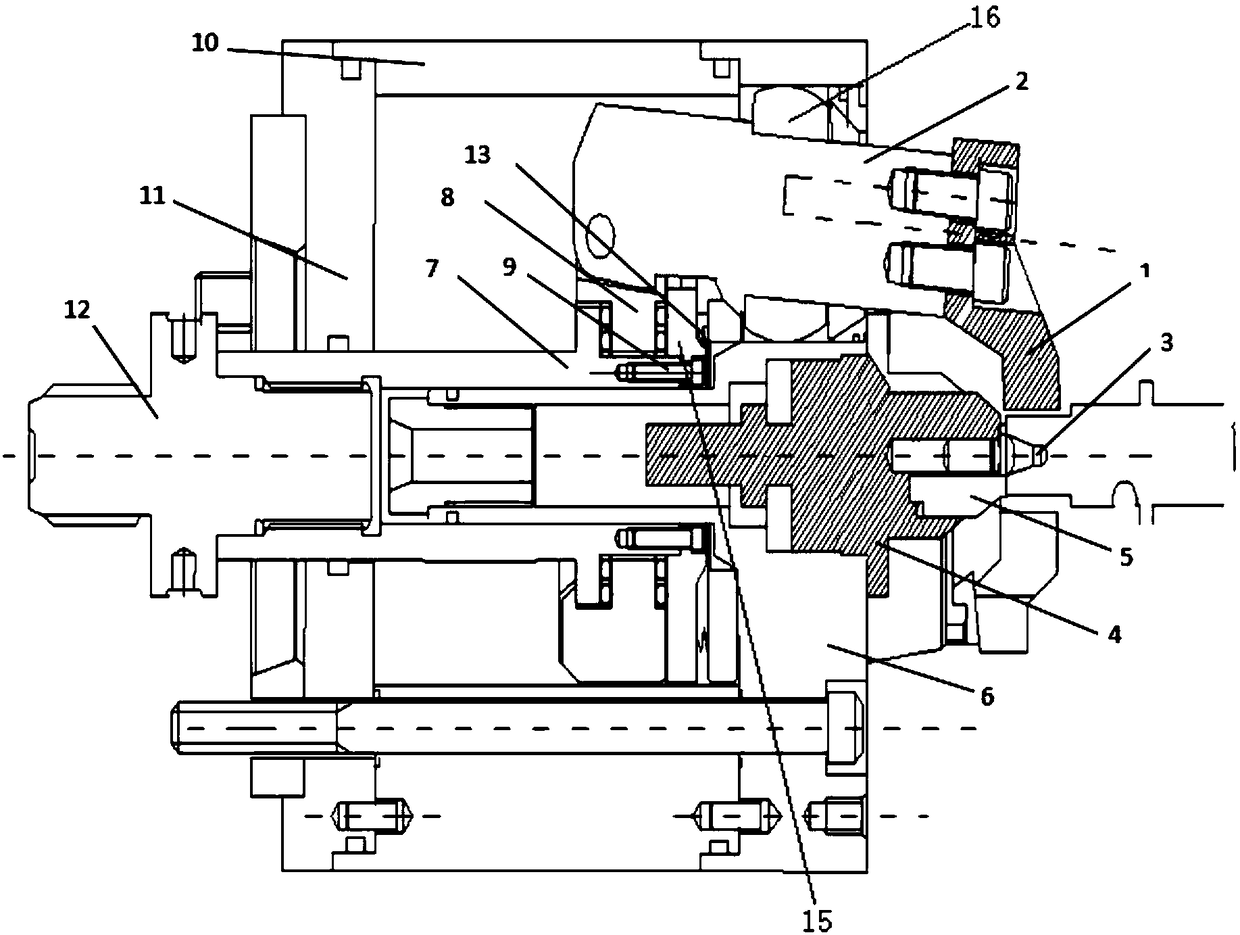

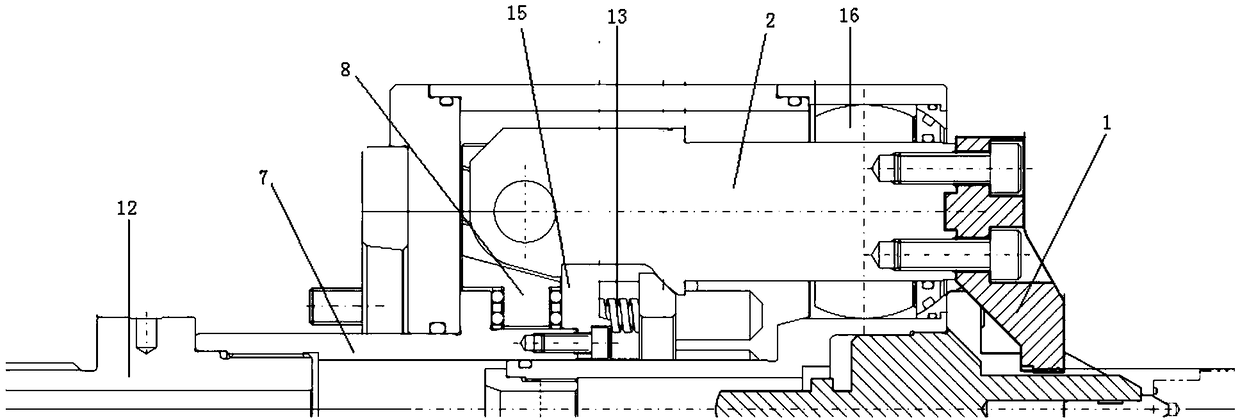

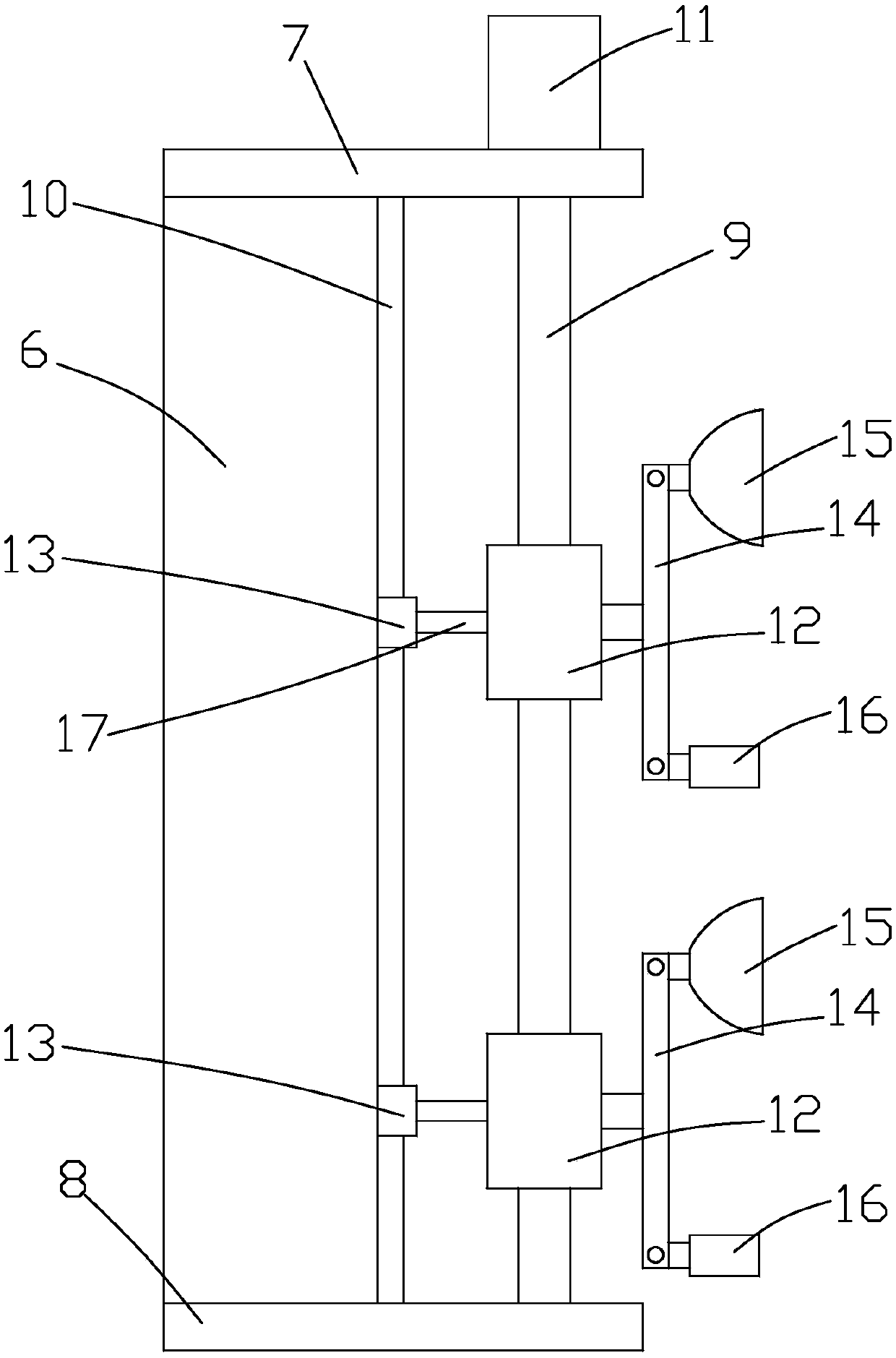

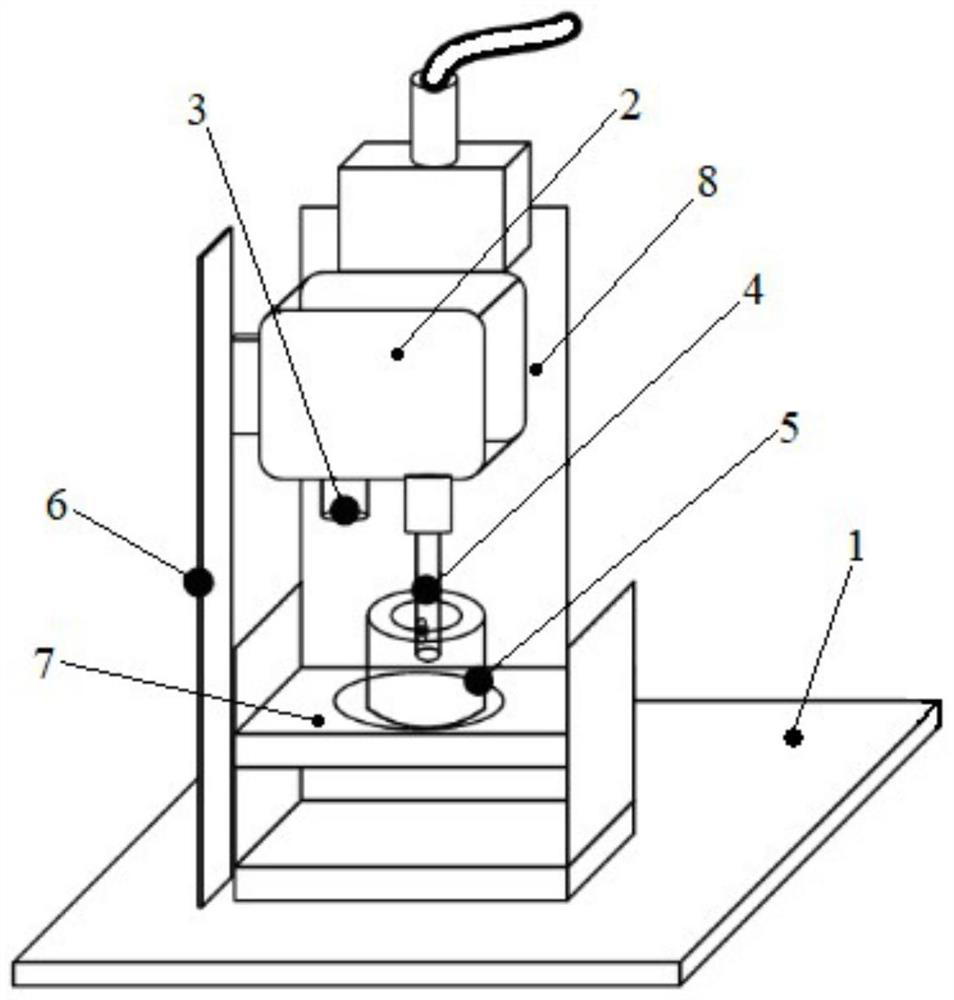

Large-size end surface processing electric spindle for mixed support of hydrostatic bearing and rolling bearing

InactiveCN102814733AExtended service lifeReduce manufacturing errorsGrinding machine componentsRotational axisBall bearing

The invention relates to a large-size end surface processing electric spindle for mixed support of a hydrostatic bearing and a rolling bearing. The electric spindle comprises a rotating shaft (6), double rows of cylindrical roller bearings (25), an extrusion oil film damper (27), an aligning ball bearing (18), a first static pressure thrust bearing (9), a first static pressure thrust bearing (10), a thrust disc (16), a rotor (14), a motor shell (7) and an upper shell (4), and is characterized in that the rotating shaft (6) is a stepped shaft, the aligning ball bearing (18) is arranged on the lower part of the rotating shaft (6), and an outer ring of the aligning ball bearing (18) is in clearance fit with the motor shell (7); and a large axial carrying capacity is obtained by the electric spindle, high-precision manufacture with the entire support of the hydrostatic bearing is avoided, the processing cost is reduced, and the service life of the rolling bearing is prolonged.

Owner:SOUTHEAST UNIV

Adjustable damping hovering structure of flap-up door of furniture

The invention discloses an adjustable damping hovering structure of a flap-up door of furniture. The adjustable damping hovering structure comprises a fixing seat, a spring, a connecting arm assembly and a stopping and butting element. The connecting arm assembly at least comprises a first connecting arm, a second connecting arm and a middle arm; the first connecting arm and / or the second connecting arm are hinged to the fixing seat, the middle arm is hinged to the fixing seat and / or the stopping and butting element, the stopping and butting element can be opened or closed on the fixing seat under the effect of the spring, a damping hovering device is arranged on the stopping and butting element, the stopping and butting element can be hovered at any time when the damping hovering device carries out opening and closing activities outside a certain acute angle range, an adjusting assembly is arranged on a displacement element, and the displacement element can be repositioned relative to the stopping and butting element by the aid of the adjusting assembly, so that damping force of a hovering damper can be ultimately adjusted. The adjustable damping hovering structure has the advantages that the improved adjustable damping hovering structure is simple, reasonable, safe and reliable, is easy to manufacture and implement, convenient to operate, wide in service range, low in noise and high in practicality, can be quickly adjusted, can be opened and closed smoothly and is low in collision when opened and closed, and the like.

Owner:伍志勇

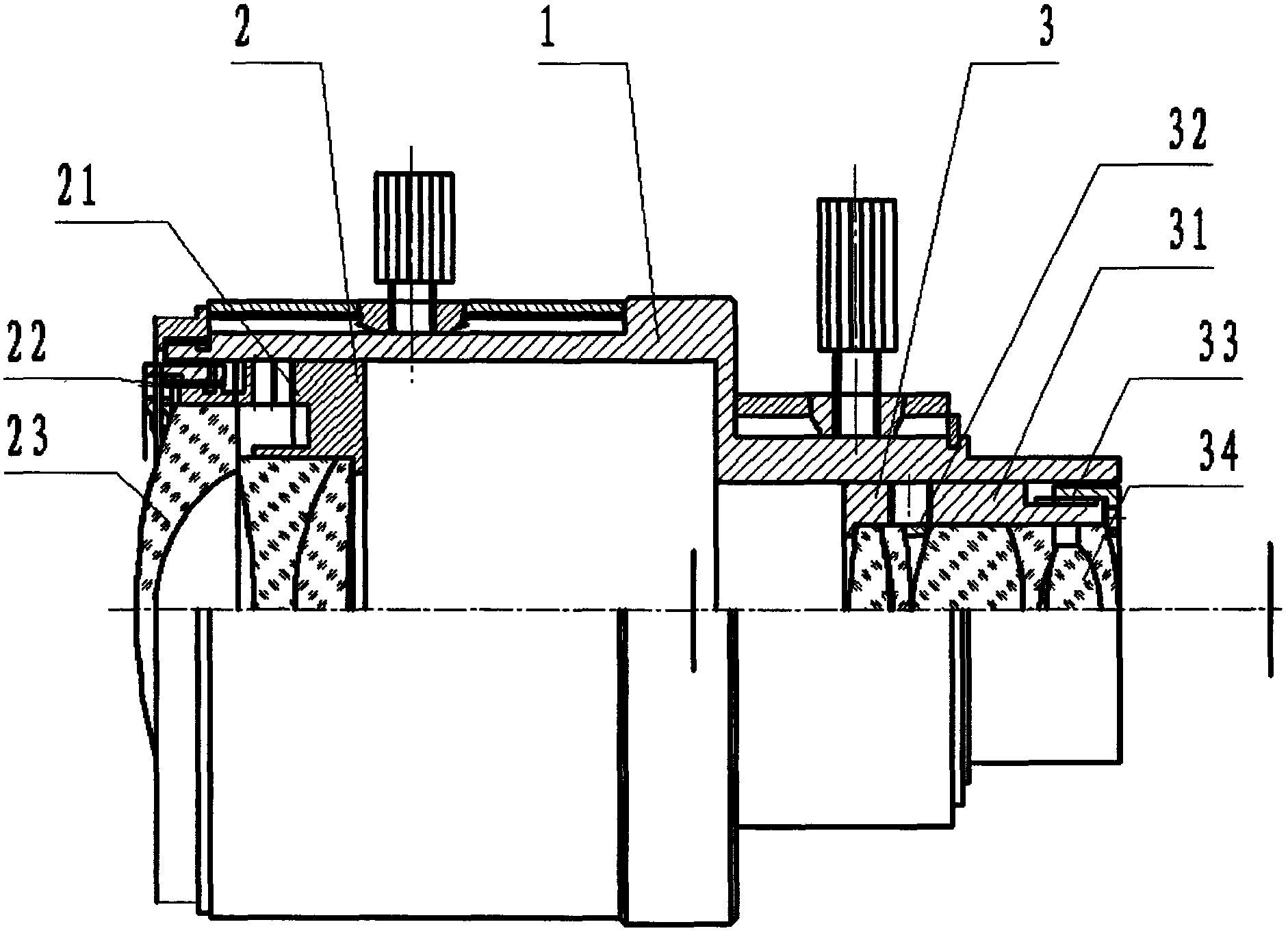

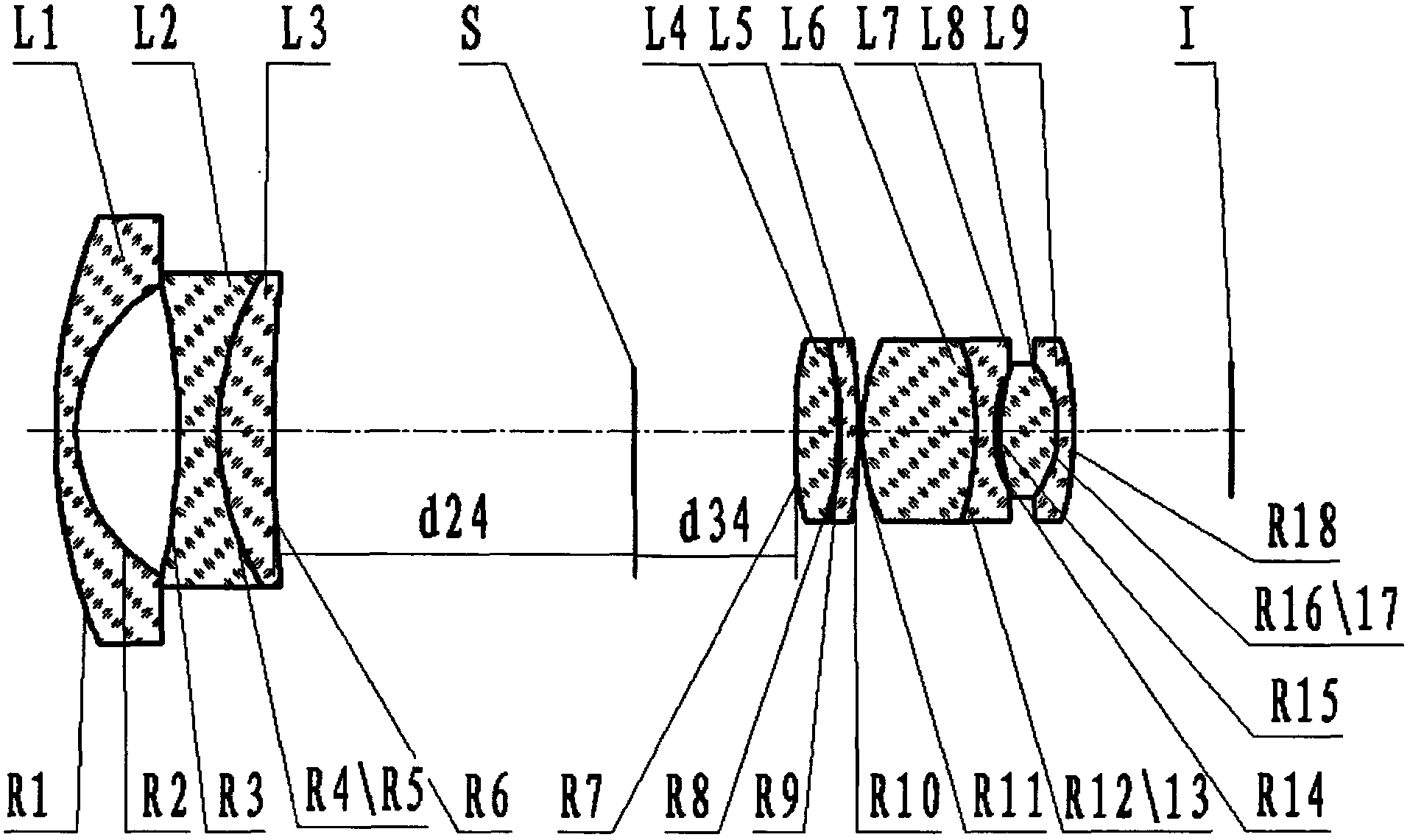

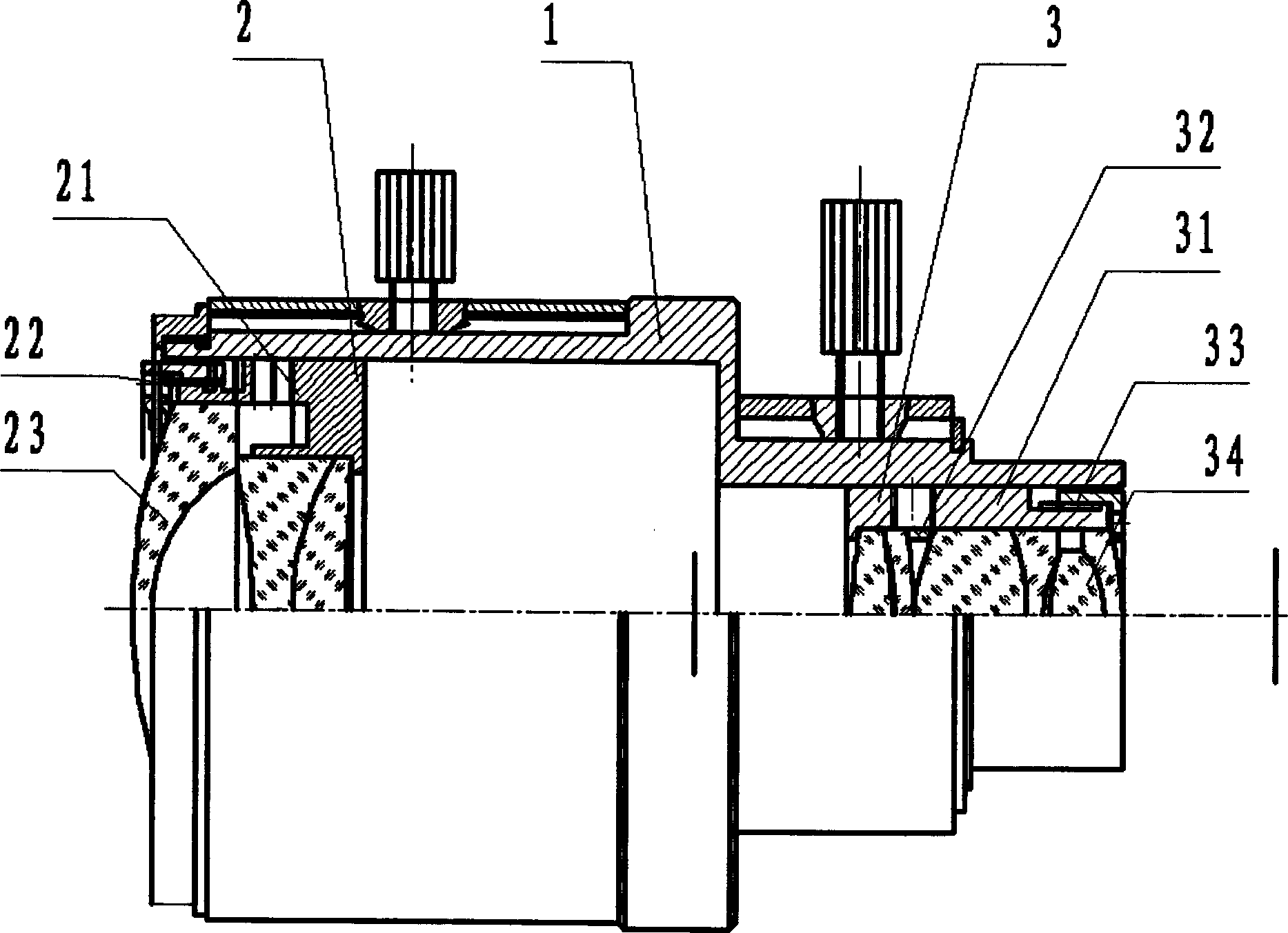

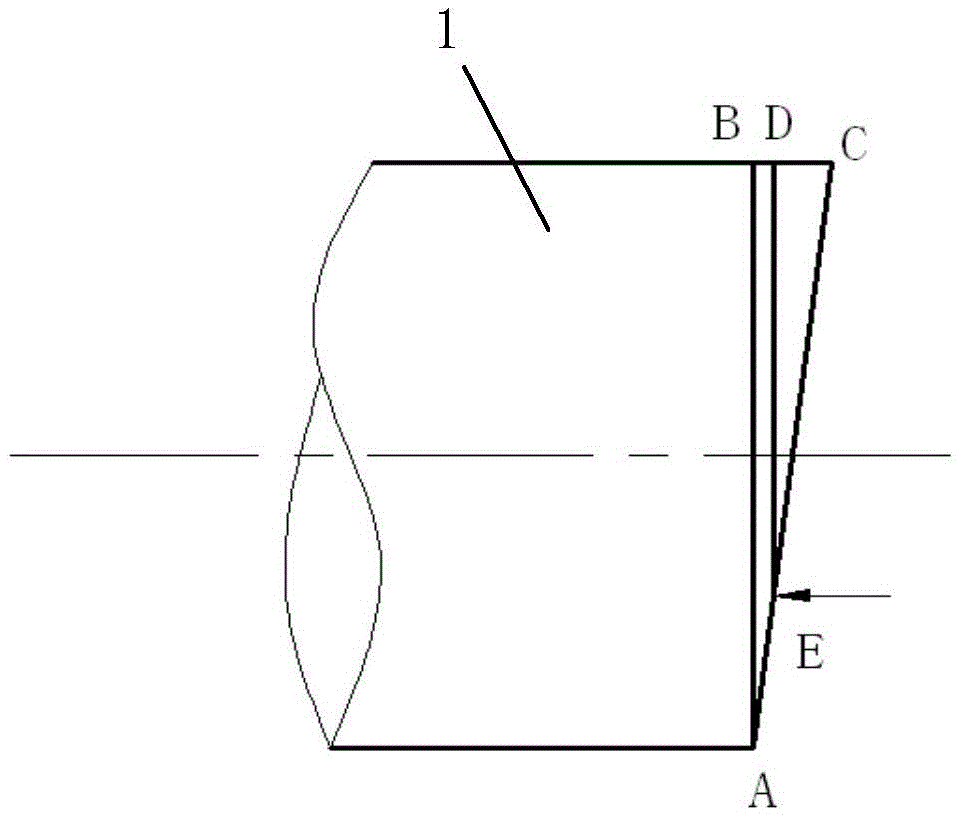

Two-constituent optical compensation zoom lens

InactiveCN102707409AReduce manufacturing errorsImprove efficiencyDiffraction gratingsMountingsCamera lensImaging quality

The invention discloses a two-constituent optical compensation zoom lens comprising a main cylinder component, a front component and a rear component, wherein the front component comprises a front lens tube, a front press ring and a compensation lens group; and the rear component comprises a rear lens tube, space rings, rear press rings and a zoom lens group. The compensation lens group and the zoom lens group have nine lenses which comprise at least three balsaming lenses. The total focal power of the compensation lens group is negative, and the total focal power of the zoom lens group is positive. The front component and the rear component move in the main cylinder component, so that the focal range changes of the complete lens can be adjusted by changing the opposite positions of the compensation lens group and the zoom lens group and mutually compensating image surfaces. An assembling method of the two-constituent optical compensation zoom lens in the invention comprises the following nine steps: assembling six optical lenses; assembling two the space rings, and assembling two press rings. Compared with the same class of the lens, the assembling steps of the two-constituent optical compensation zoom lens are reduced to be nine steps, so that the efficiency is doubled, the manufacturing error is reduced, the optical stability is improved, the image quality yield is greatly improved, and the application range is wide.

Owner:FUZHOU DEV ZONE HONGFA OPTOELECTRONICS TECH

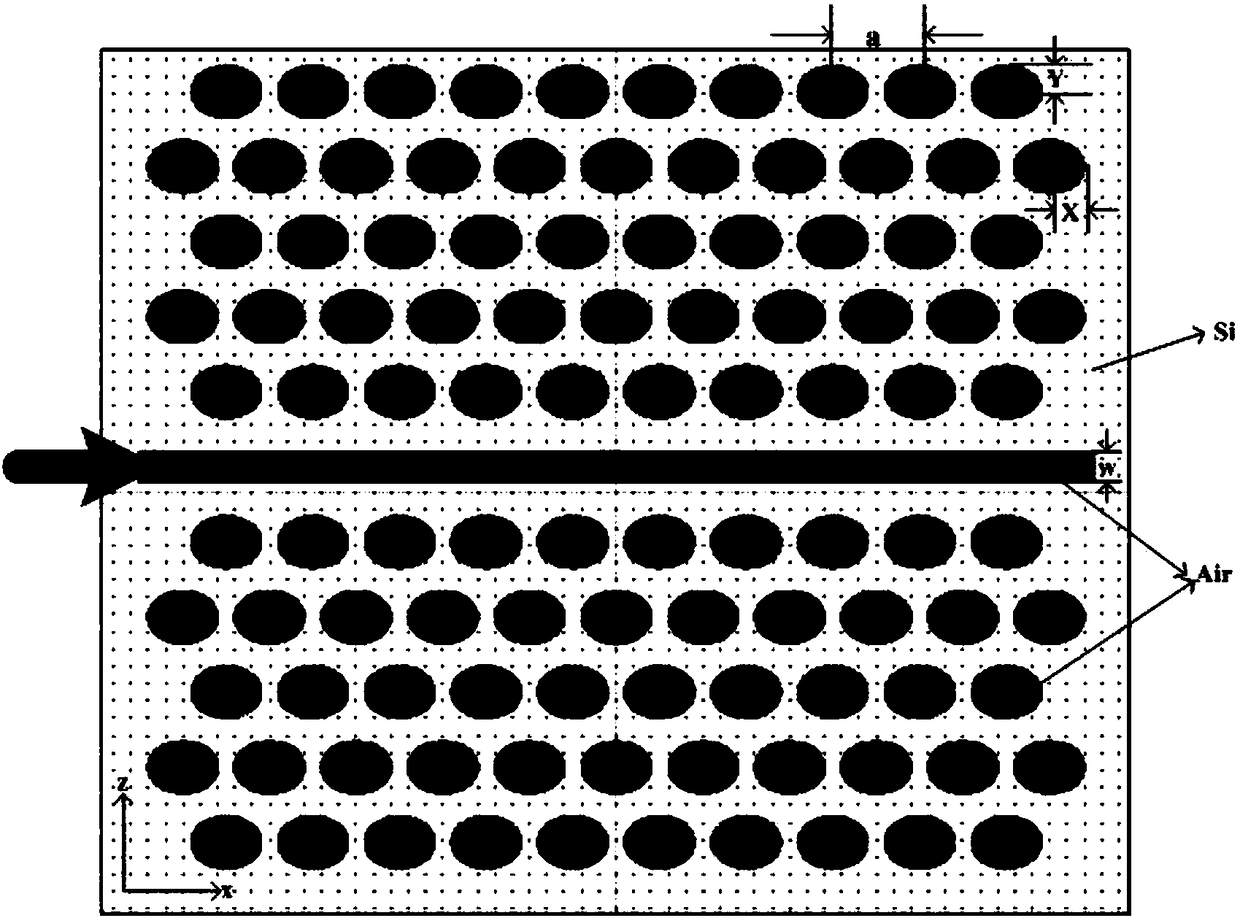

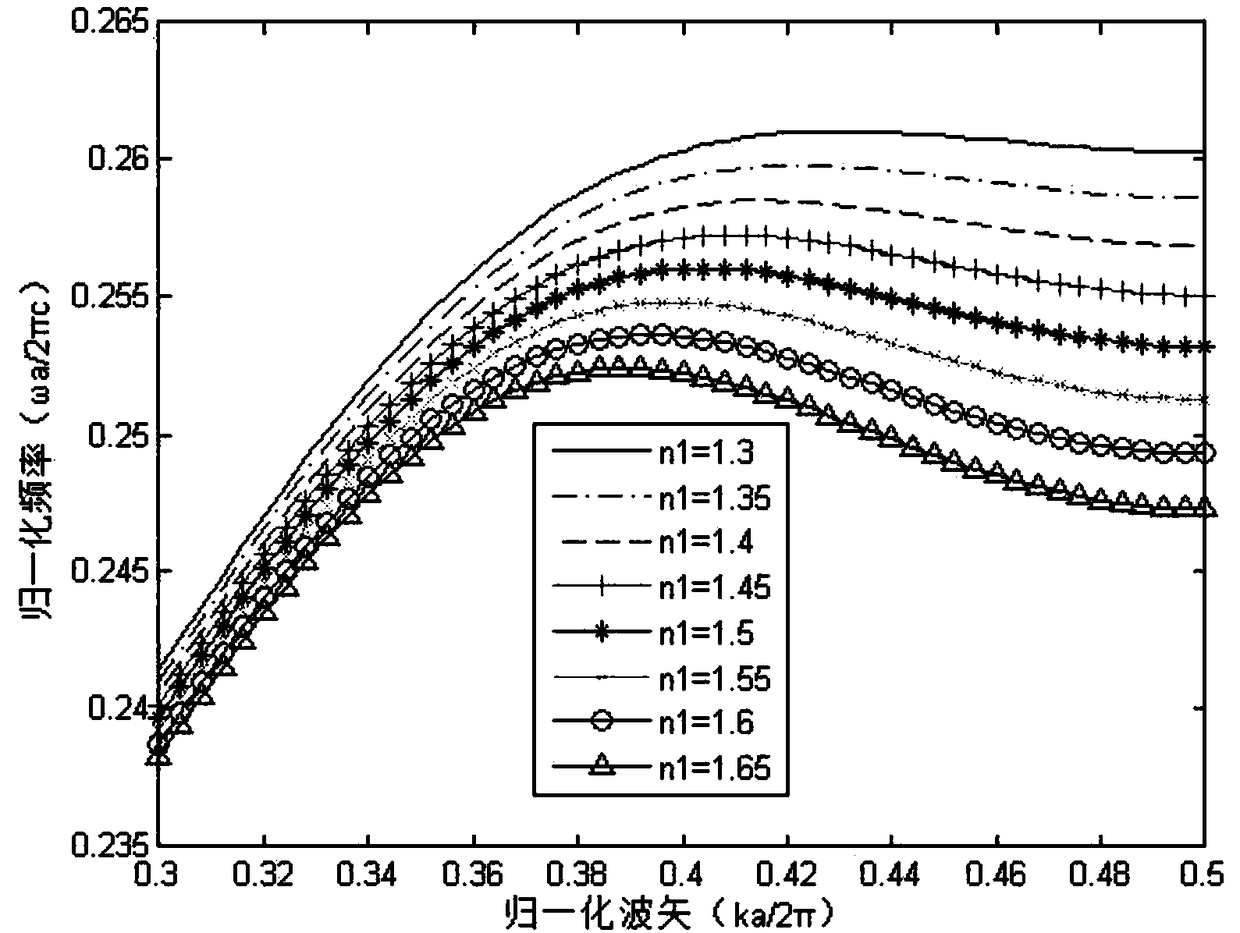

Optimization method for slow light characteristics of elliptical-hole photonic crystal Slot waveguide

InactiveCN109425930AReduce complexitySimple methodOptical light guidesSlot-waveguideGroup velocity dispersion

The invention discloses an optimization method for slow light characteristics of an elliptical-hole photonic crystal Slot waveguide. The optimization method realizes the slow light characteristics oflarge broadband and low group velocity dispersion through filling the first row of air holes close to an air slot with a liquid with the refractive index being n1 and filling the second row of air holes with a liquid with the refractive index being n2 in the elliptical-hole photonic crystal Slot waveguide and adjusting the refractive index of the liquids according to the slow light effect. According to the optimization method provided by the invention for the slow light characteristics of the elliptical-hole photonic crystal Slot waveguide, the elliptical-hole photonic crystal Slot waveguide can be reutilized, liquids with different refractive indexes can be filled in the same photonic crystal Slot waveguide according to practical application requirements so as to realize different slot light characteristics, and the utilization rate of the photonic crystal Slot waveguide is improved.

Owner:NANJING UNIV OF SCI & TECH

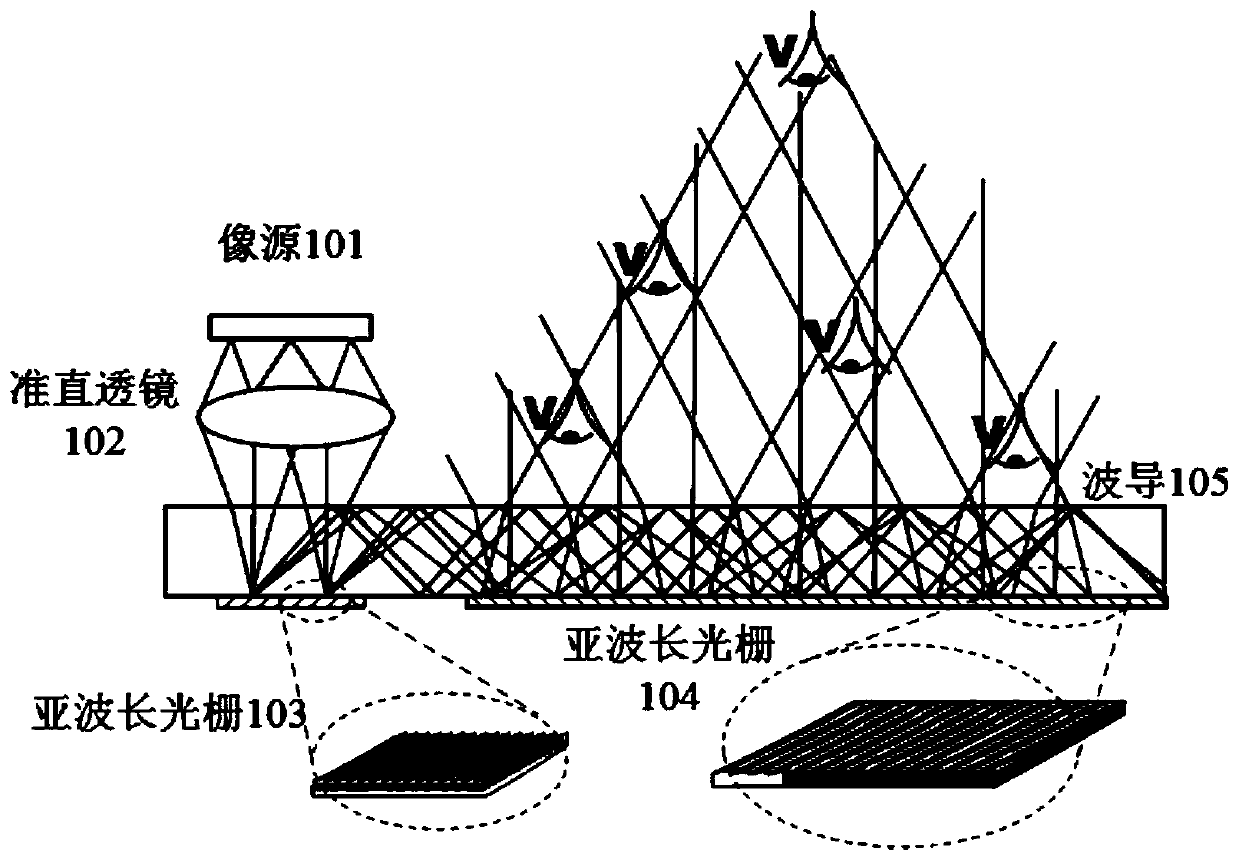

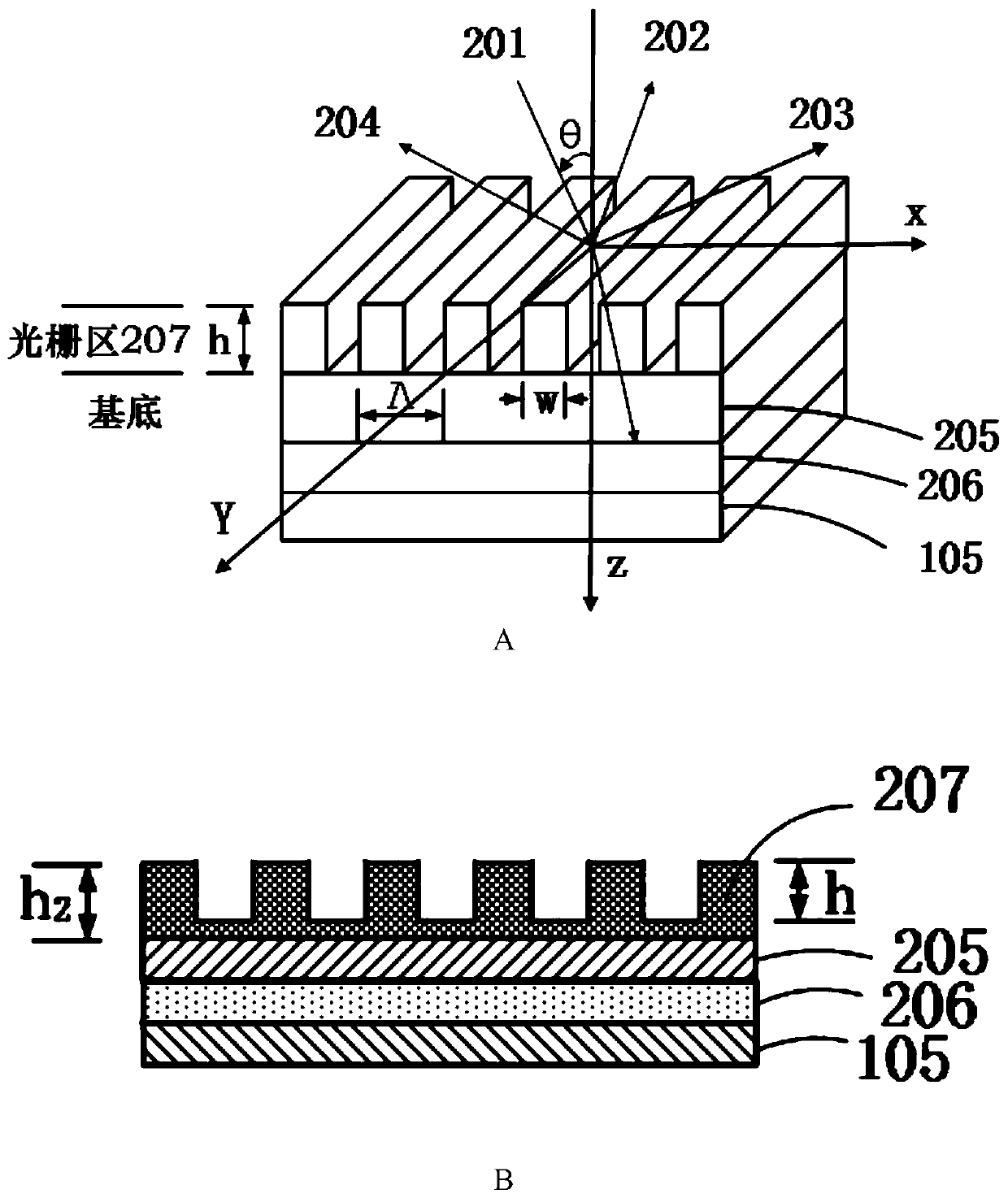

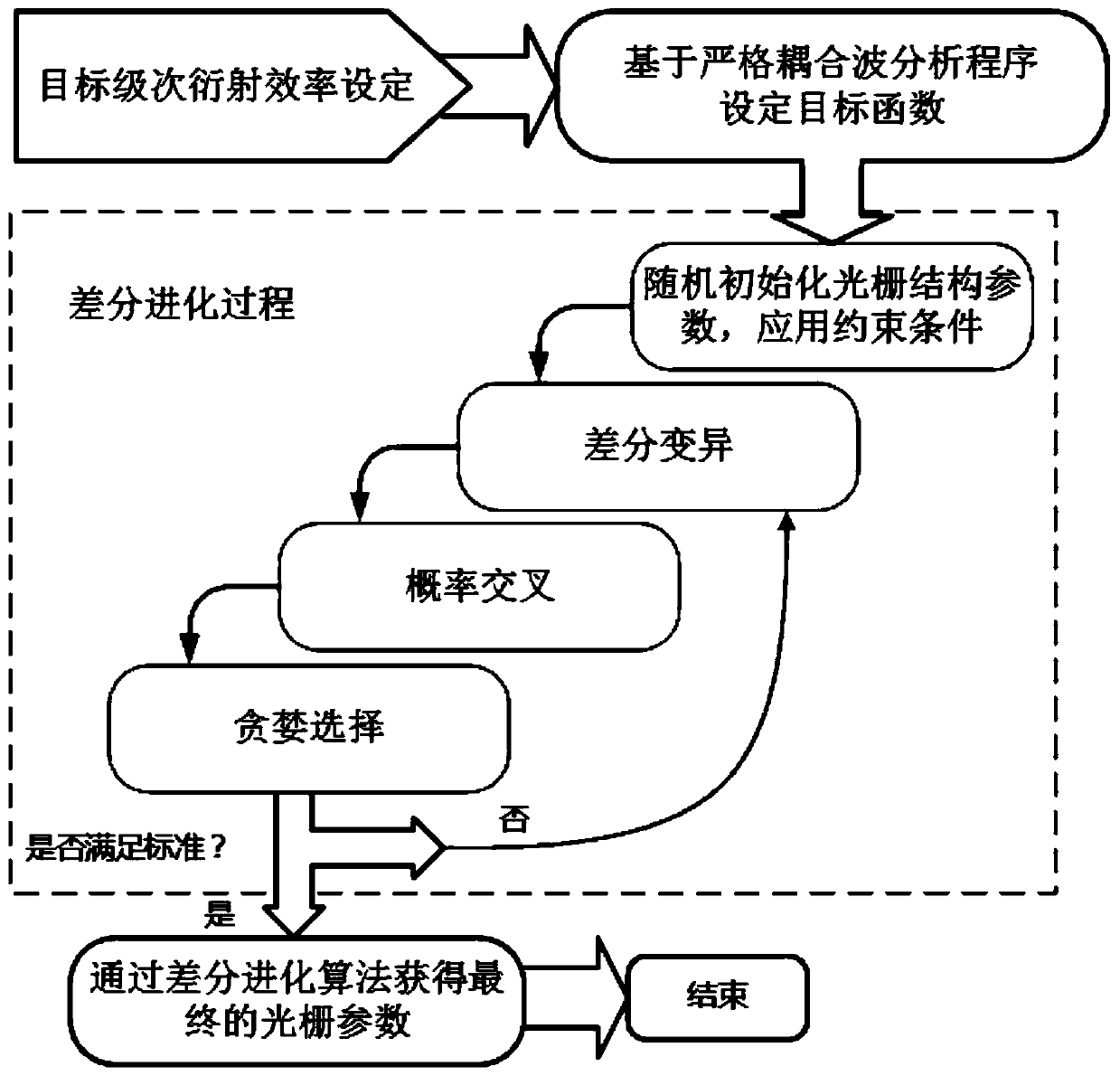

Design and optimization method of waveguide display sub-wavelength diffraction grating

InactiveCN110764255AImprove rationalityImprove reliabilityOptical elementsAngle of incidenceRefractive index

The invention relates to a waveguide display sub-wavelength diffraction grating. The sub-wavelength diffraction grating used for a waveguide display system is designed in order to provide an optimization algorithm which does not require gradient calculation, has multidimensional real number optimization, is discontinuous, does not need to be differentiable, and can be changed with time. A design and optimization method of the waveguide display sub-wavelength diffraction grating comprises the following steps that a grating substrate material, the number of film layers, and the refractive indexof a coating material are determined, and grating parameters involved in optimization are selected; a strict coupled wave analysis theory is adopted to calculate the diffraction efficiency and is combined with a differential evolution algorithm to determine that an evaluation function is the variance of the reflection diffraction first-order diffraction efficiency and the target order diffractionefficiency within the range of a required wavelength or an incident angle; the target order diffraction efficiency is set; and the differential evolution algorithm is used for optimization. The designand optimization method of the waveguide display sub-wavelength diffraction grating is mainly applied to occasions of design and manufacturing of diffraction gratings.

Owner:TIANJIN UNIV

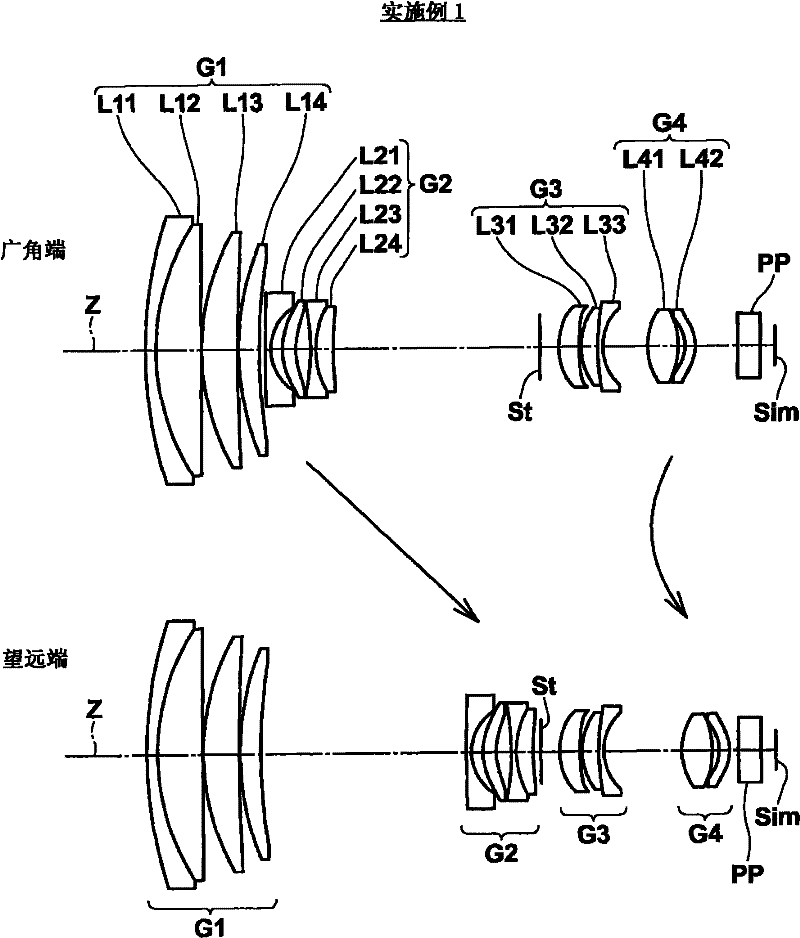

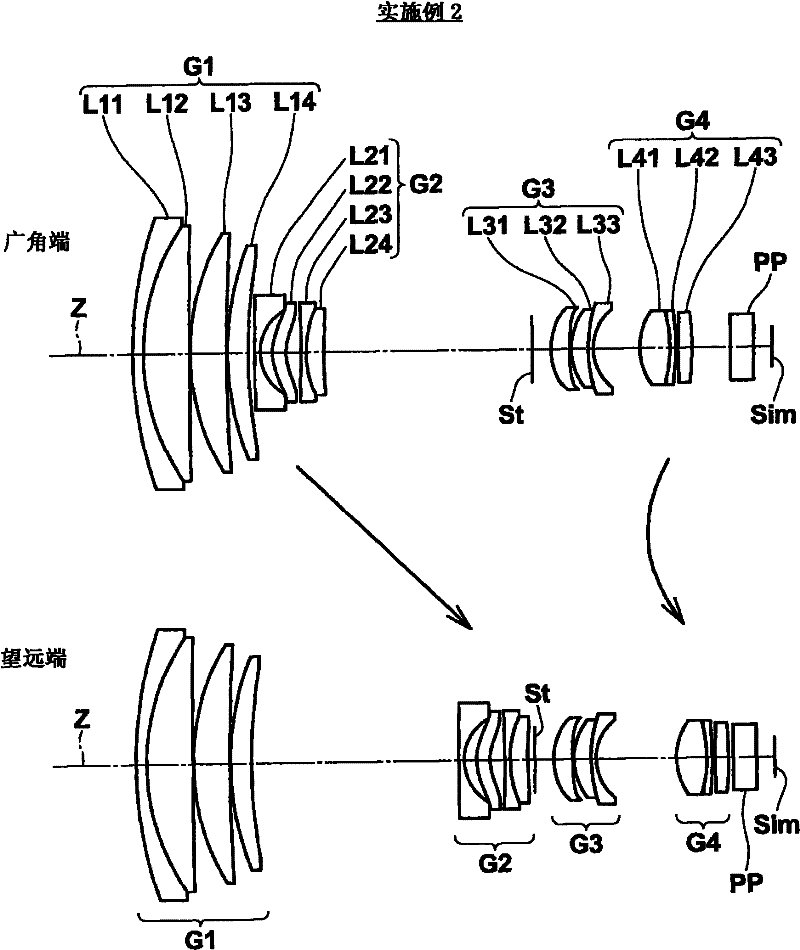

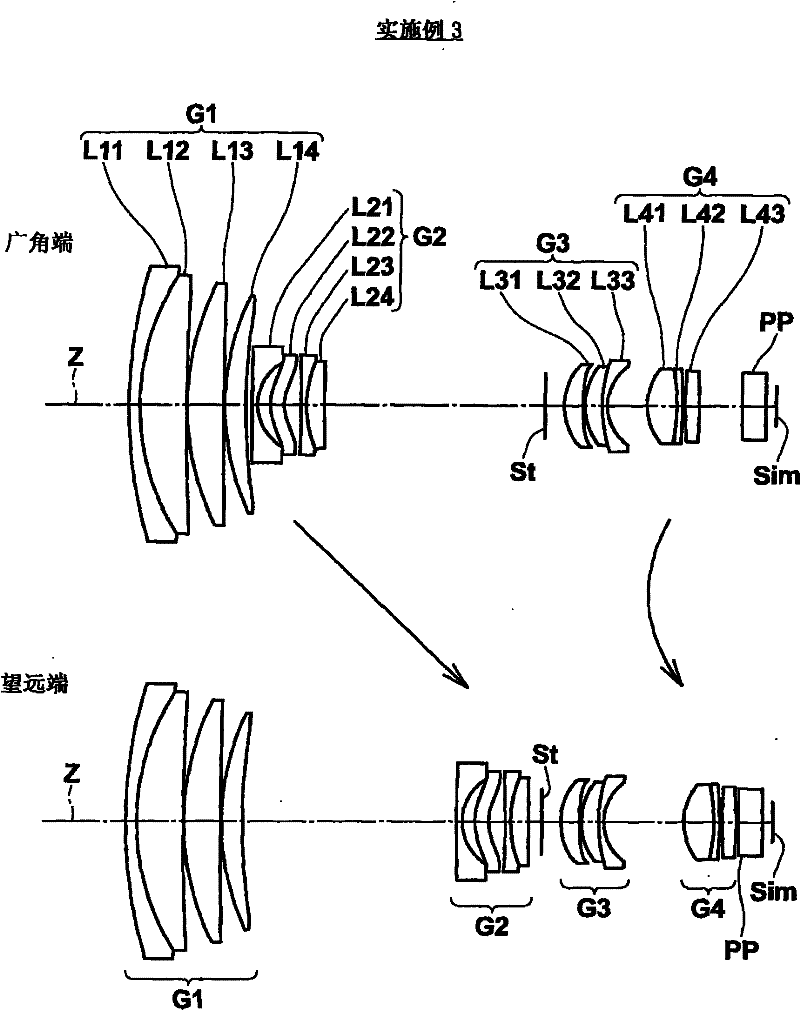

Zooming lens and camera device

InactiveCN101750722AGood optical performanceReduce manufacturing errorsTelevision system detailsColor television detailsPhysicsFocal length

The invention provides a zooming lens, which is small-sized and has good optical performance, and has little performance deterioration of the manufacture error or the assembly error even the focal power of a second lens group. The zooming lens, from the objective side, has, in order, a positive first lens group (G1), a negative second lens group (G2) moving to zoom, a diaphragm, a positive third lens group (G3), and a positive fourth lens group (G4) for performing the correction and focusing of the image position with the zooming. The second lens group (G2), from the objective side, has, in order, a first negative lens (L21), a curved moon-shaped lens (L22) with a convex surface toward the objective side, a second negative lens (L23), and a positive lens (L24). The focal length of the curved moon-shaped lens (L22) is f22, the focal length of the second lens (G2) is f2, thus the formula (1) is satisfied: the absolute value of f22 / f2 is more than 5.0 (1).

Owner:FUJIFILM CORP

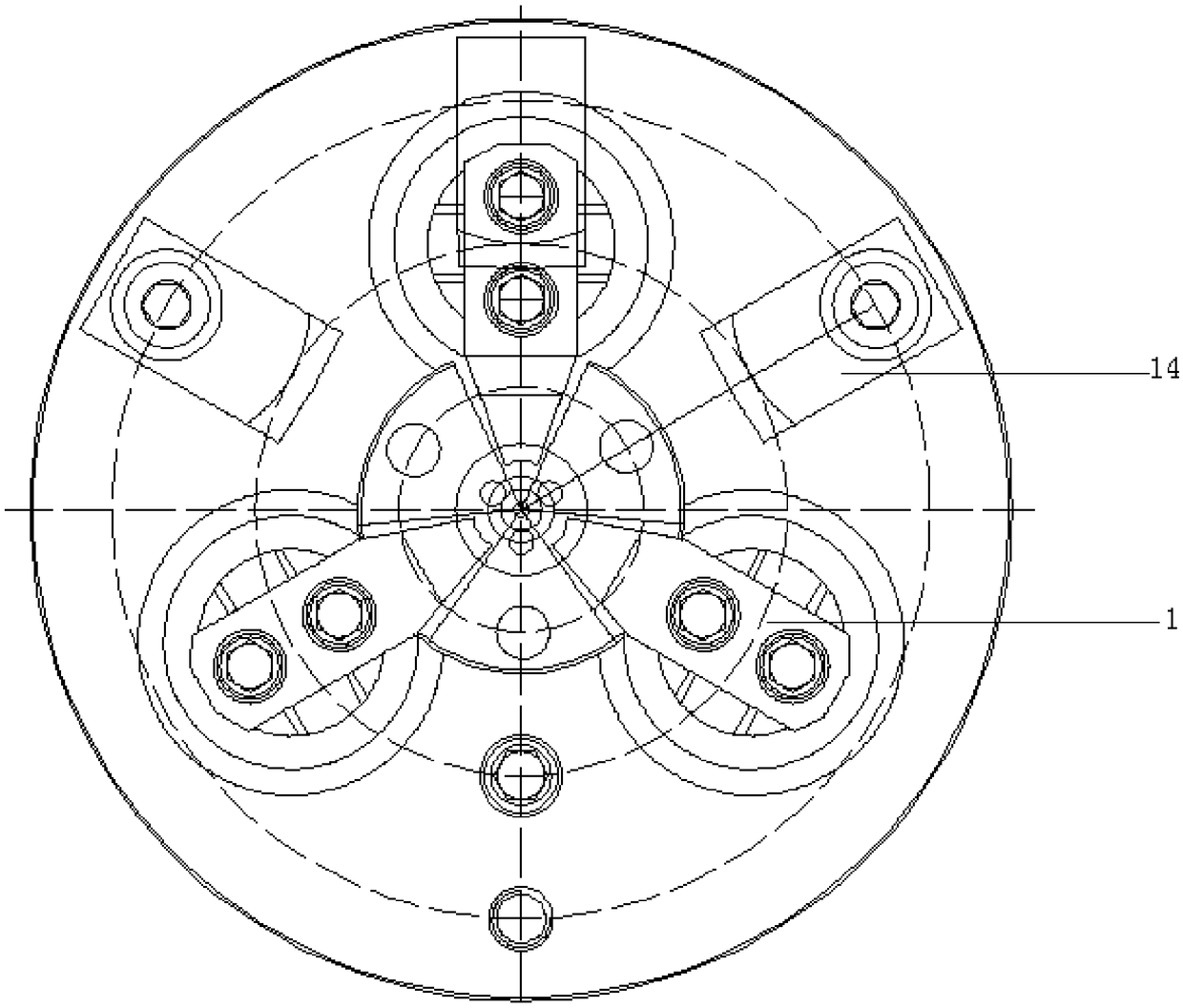

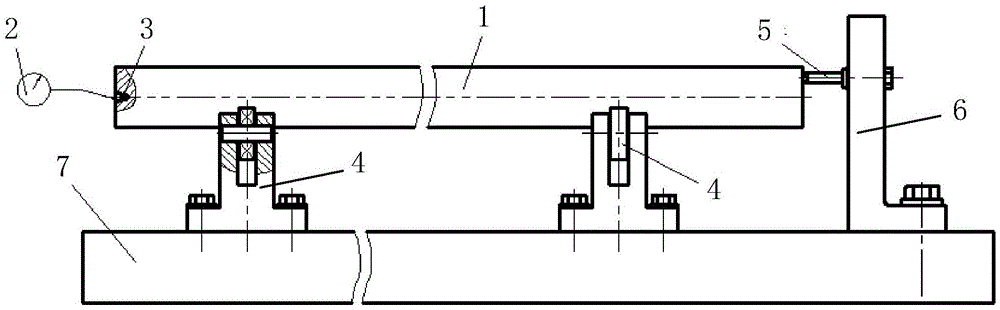

Production fixture of automobile engine balance shaft

ActiveCN109128948AAvoid Inconsistent Positioning DatumsReduce manufacturing errorsPositioning apparatusMetal-working holdersBalance shaftEngineering

The invention relates to a production fixture of an automobile engine balance shaft. The production fixture is used for clamping and fixing the automobile engine balance shaft during processing and production. The production fixture comprises a fixture body; a chuck is fixedly installed at one end of the fixture body; an end face driver is fixedly installed on the chuck and fixedly provided with acentre for centering a center hole of the balance shaft; and a plurality of extensible clamping claws for fixing the periphery of the balance shaft are arranged on the outer side of the chuck. Compared with the prior art, the centre of the end face driver can be jacked into the center hole of the balance shaft to maintain centering reference consistency, high torque needed for rough turning operation can be transmitted through combination of clamping force provided by the three clamping claws and holding force provided by the end face driver, and the end face driver can complete machining ofall outer circles once being clamped, so that the balance shaft production efficiency is improved, and coaxiality and production precision are ensured.

Owner:SHANGHAI UNIV OF ENG SCI

Center hole radial circle run-out detection tool and batch detection method

ActiveCN105571471ASimple structureReasonable designMechanical counters/curvatures measurementsPetroleum engineering

Owner:XIAN HUASHAN TUNGSTEN PROD CO LTD

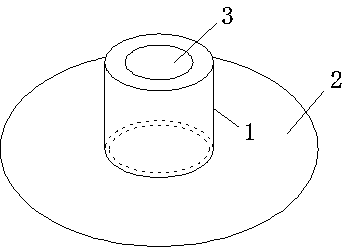

Foot-pedal type compaction fixing device of soil-sample saturator

InactiveCN103471891AEasy to operateSimple structurePreparing sample for investigationSheet steelBiomedical engineering

The invention relates to a foot-pedal type compaction fixing device of a soil-sample saturator, belongs to the technical field of geotechnical test instruments and equipment and is designed for solving the problems that soil-sample manufacture and compacting operation is complex, the saturator is hard to fix and forming quality of a soil sample is poor. The foot-pedal type compaction fixing device mainly comprises a saturator fixing sleeve and a ring-shaped foot pedal, wherein each of the saturator fixing sleeve and the ring-shaped foot pedal is formed by machining a steel plate which is 3mm thick; the saturator fixing sleeve is a semi-closed hollow steel cylinder with an opening in one end and a round hole in the center of the other end, and is 80mm in outer diameter and 56mm in height, and the diameter of the opening in the semi-closed end is 50mm; the ring-shaped foot pedal is welded at the bottom end of the opening of the saturator fixing sleeve and is 400mm in outer diameter. The foot-pedal type compaction fixing device has the advantage that the structure is simple, the cost is low, the operation is convenient, the practicability is strong, and not only the labor is saved, but also the soil-sample manufacturing quality can be effectively improved.

Owner:SHANDONG UNIV OF SCI & TECH

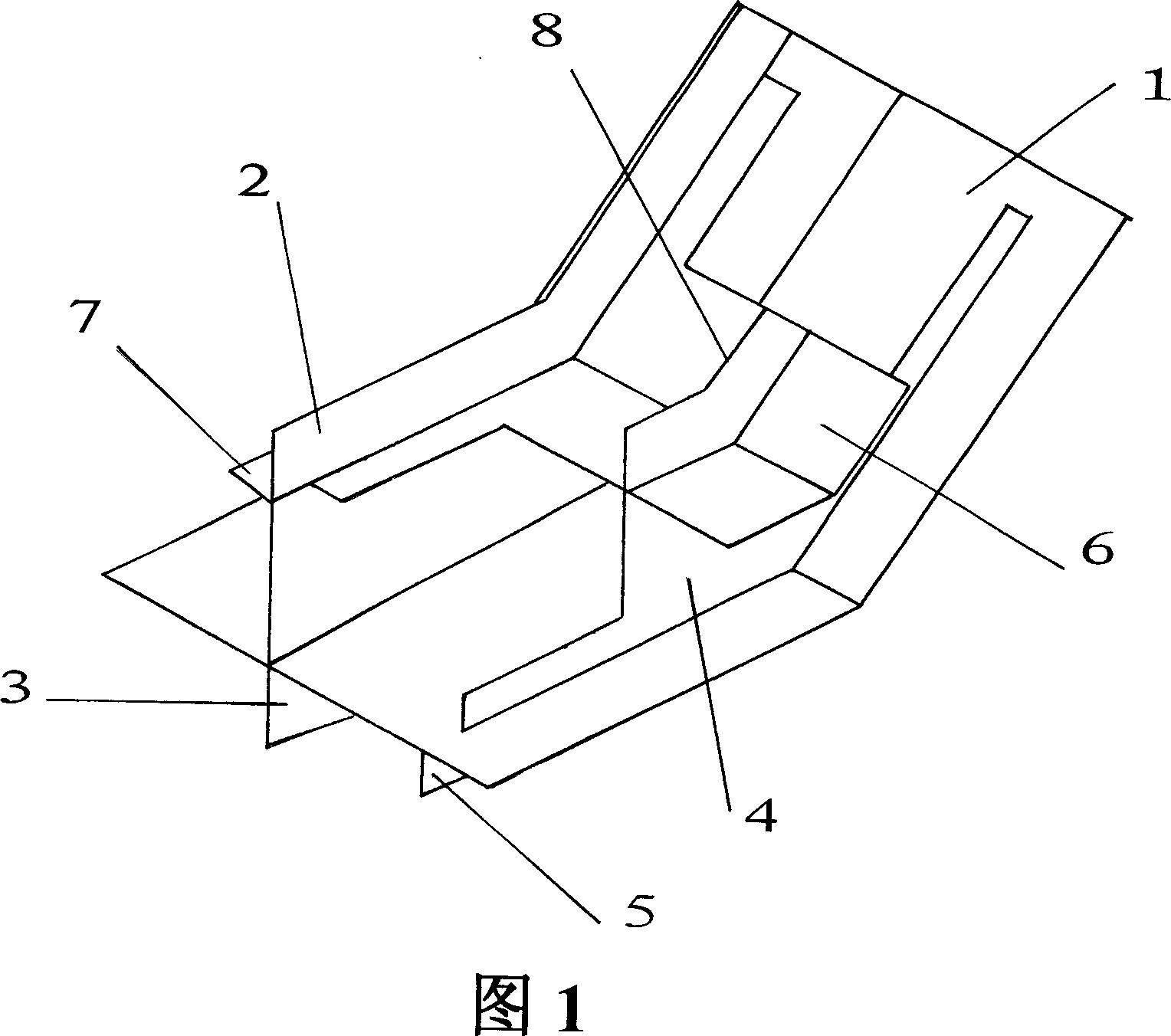

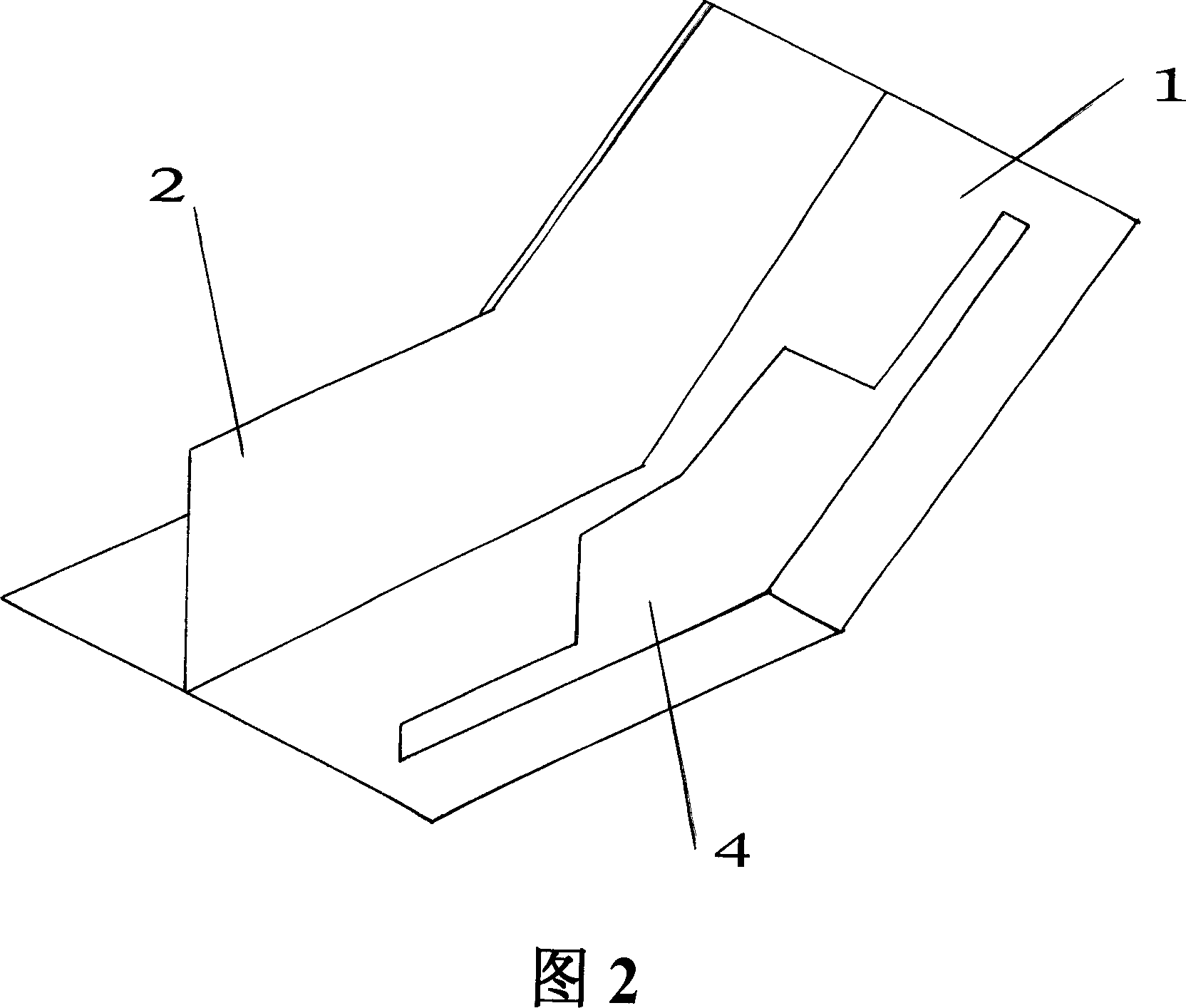

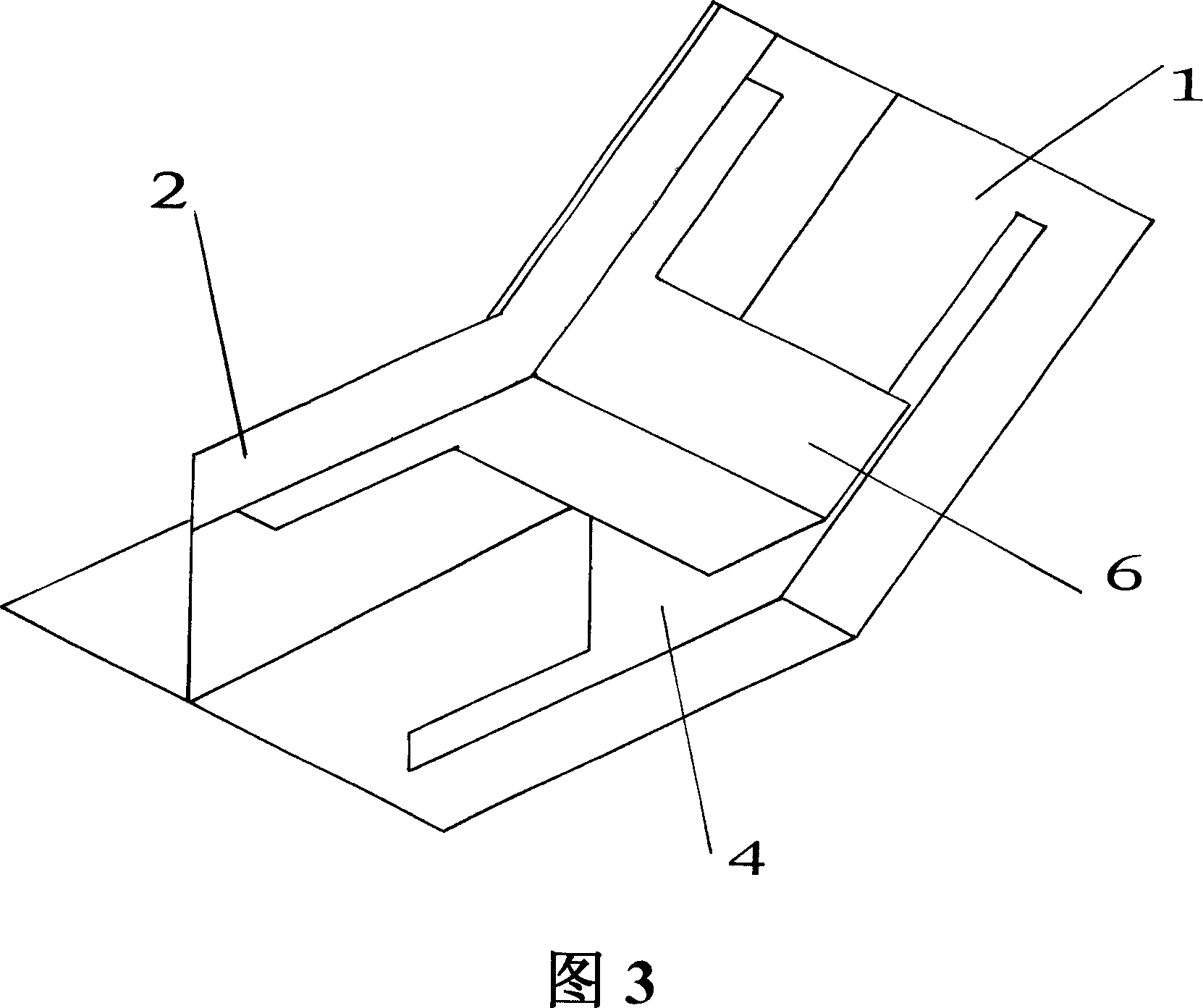

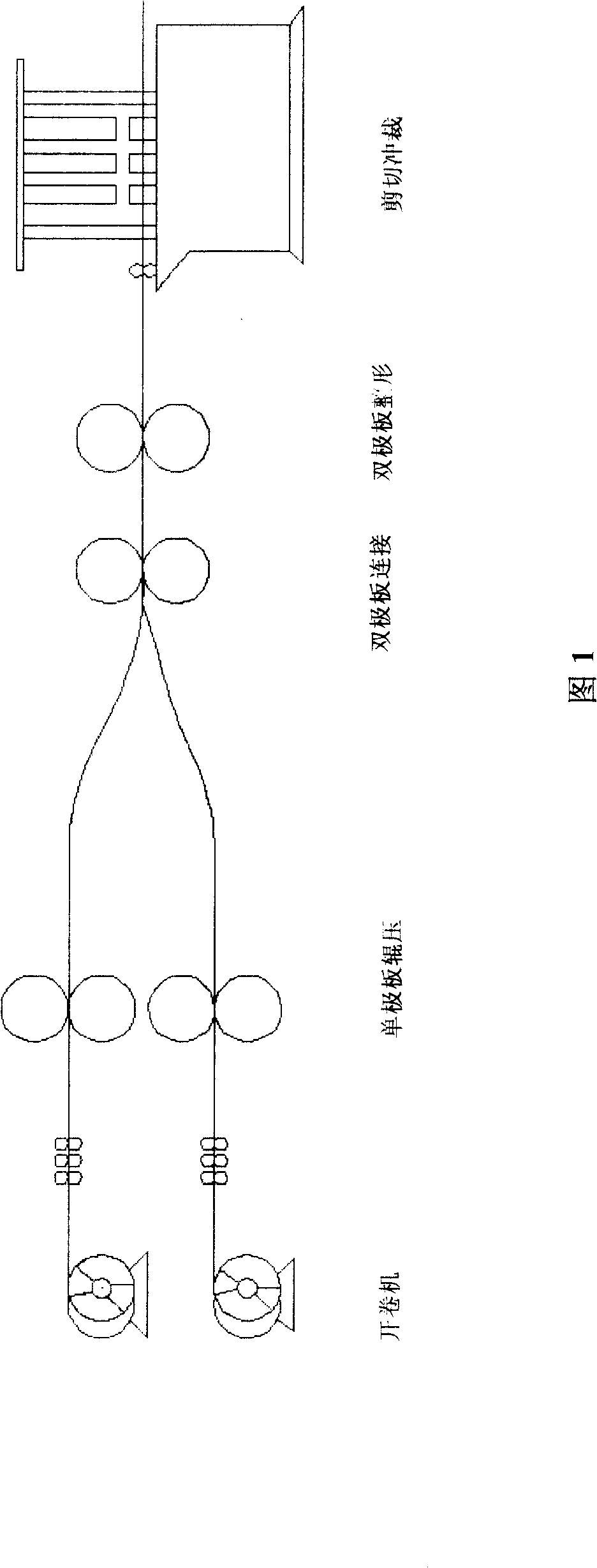

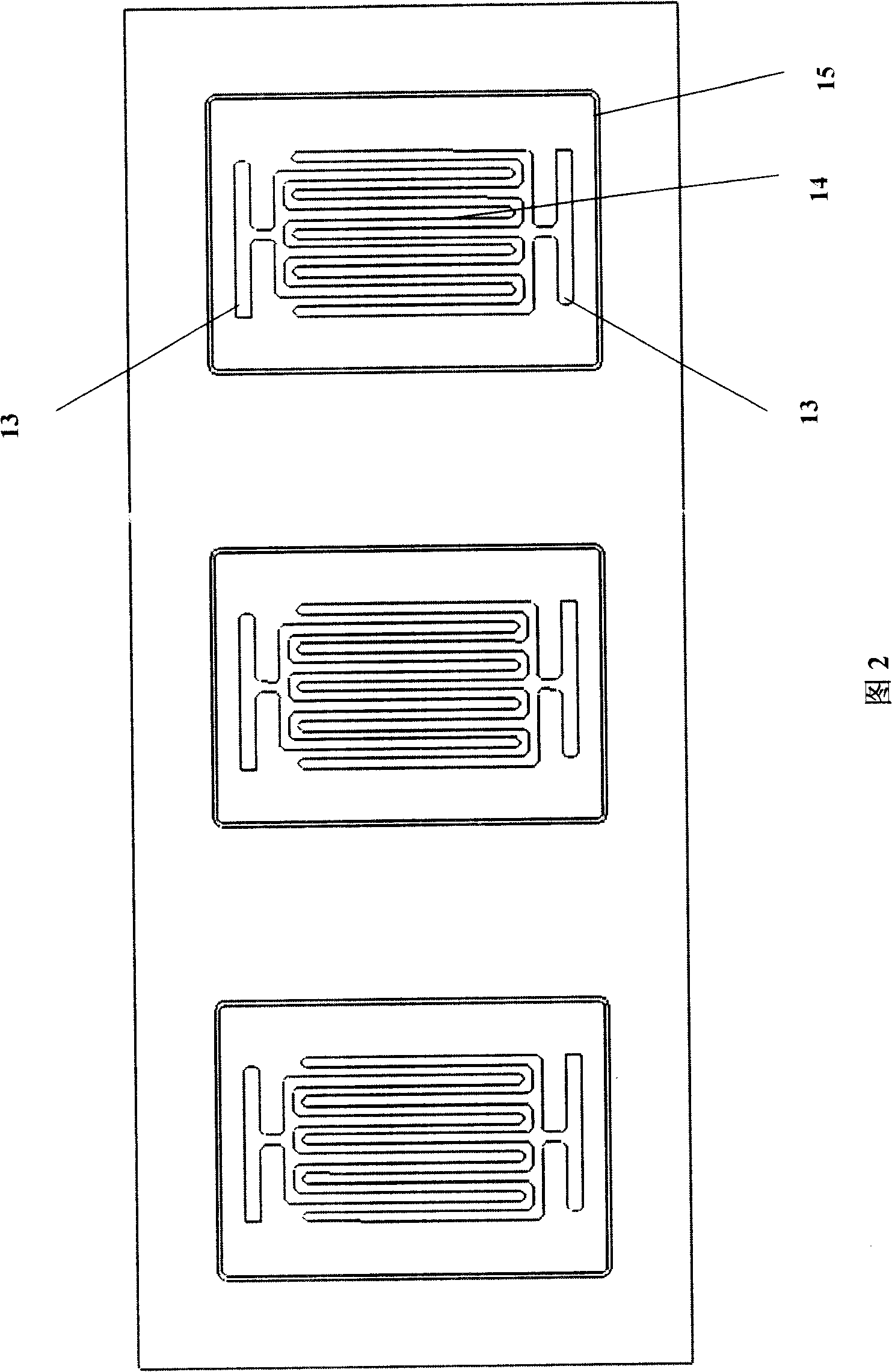

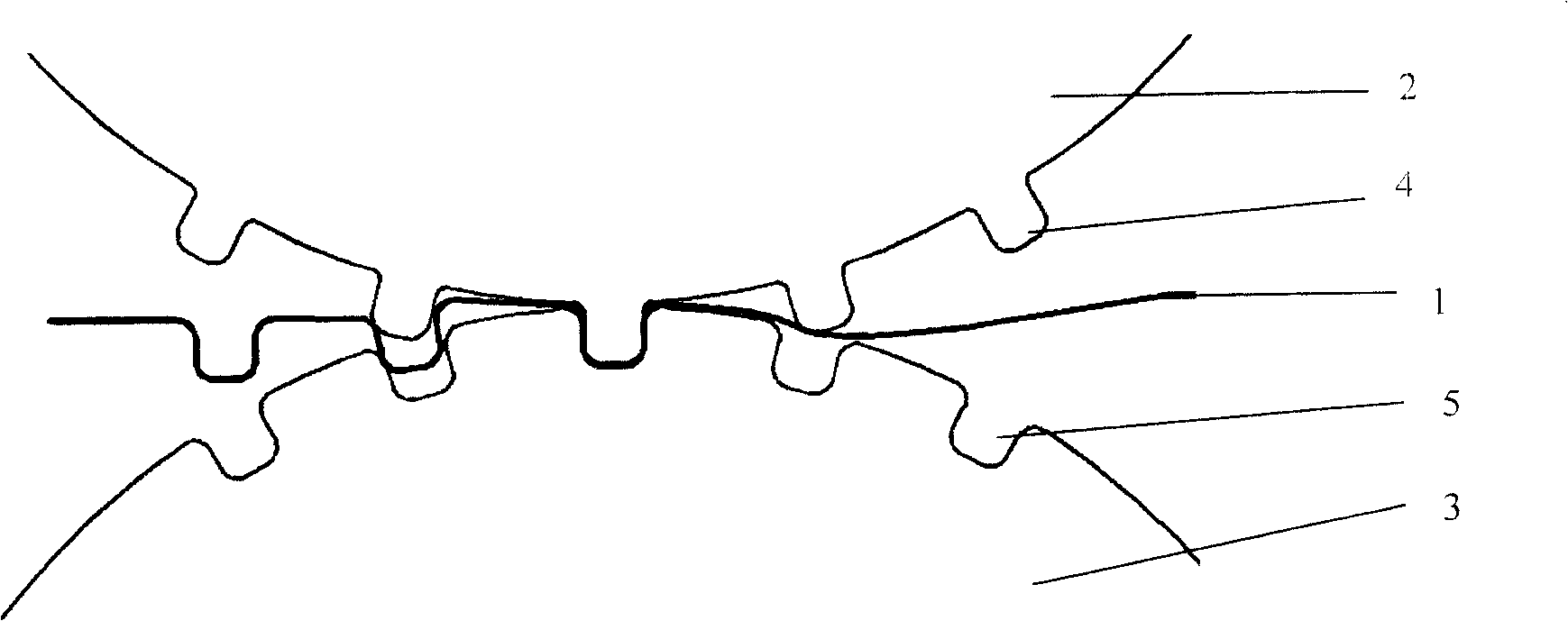

A rolling formation based manufacture method for metal bipolar plate of proton exchange membrane fuel cell

InactiveCN100423331CReduce manufacturing costQuality improvementShaping toolsCell electrodesProduction lineSingle plate

The related metal bipolar plate manufacture method for proton exchange film fuel cell comprises: based on rolling shape, manufacturing all roller couples for target form included single-plate rolling roller couple, bipolar plate connection roller couple and the shaping roller couple; using single-plate rolling roller couple to roll the plate from top and bottom positions simultaneously; using bipolar plate connection roller couple to connect two independent single plates; then, using the shaping roller couple for shaping; finally, cutting and blanking. This invention can reduce both cost and manufacture error.

Owner:SHANGHAI JIAOTONG UNIV

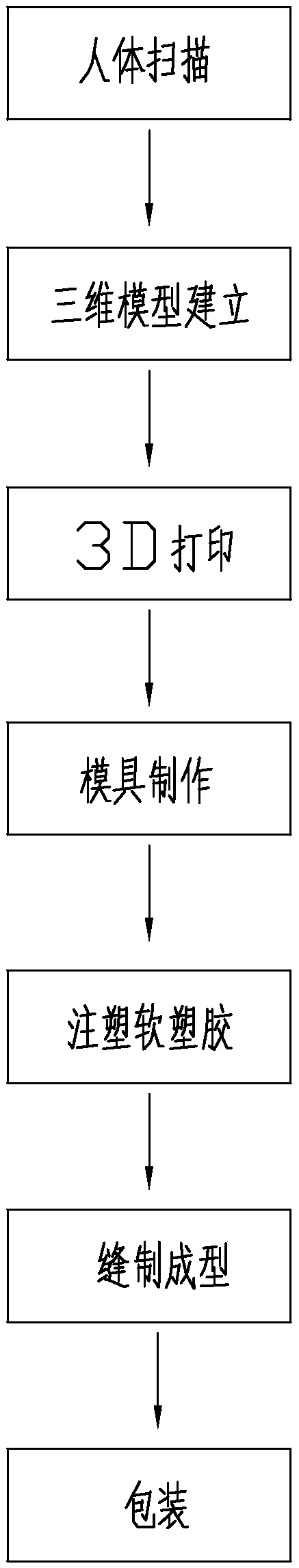

3D light thin breathable athletic undergarment manufacturing method

InactiveCN107811331AReduce manufacturing errorsAdjustable spacingBrassieresCorsetsProduction lineInjection molding machine

The invention discloses a 3D light thin breathable athletic undergarment manufacturing method which comprises the following steps: 1) scanning a human body; 2) establishing a three-dimensional model;3) 3D printing; 4) manufacturing a mould; 5) injection molding soft plastic; 6) sewing and forming and 7) packaging. The manufacturing method disclosed by the invention has simple technological steps;by means of a production technology in which 3D printing and laminating injection molding are combined, fondness of different customers can be met to perform athletic undergarment framework customization; furthermore, production cost is effectively reduced, production line production is facilitated, burrs generated by directly utilizing 3D printing to manufacture frameworks are effectively avoided, technological processes are simplified, and athletic undergarment processing quality is improved.

Owner:季孝伟

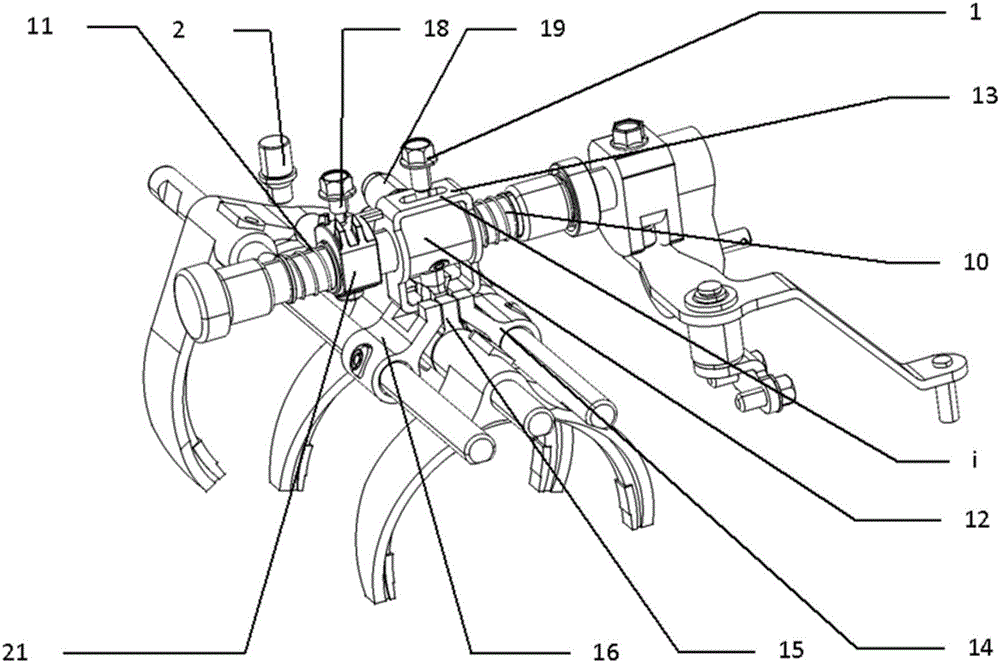

Gear-shifting control mechanism assembly of transmission

InactiveCN106481801ASimple structureImprove return performanceControlled membersGearing controlChinese charactersControl system

The invention relates to a gear-shifting control mechanism assembly of a transmission. The assembly comprises a gear selecting and shifting base, a gear selecting rocker arm, a gear shifting rocker arm, a gear selecting and shifting shaft, a first gear and second gear shifting fork combination part, a third gear and fourth gear shifting fork combination part, a fifth gear and R gear shifting fork combination part, a first gear selecting return spring, a second gear selecting return spring, a gear selecting and shifting push block, a gear shifting interlocking plate, a first gear and second gear shifting push block, a third gear and fourth gear shifting push block, a fifth gear and R gear shifting push block, a gear selecting guide bolt, a gear shifting guide bolt, a gear shifting locating pin and a guide block with a groove shaped like a Chinese character 'wang'. According to the technical scheme, in a control system, the gear shifting locating pin is added, and therefore the gear shifting suction feeding can be improved; the guide block with the groove shaped like the Chinese character 'wang' is designed, and therefore gear shifting can be smooth, the gear shifting track can be uniform and the gear shifting quality can be improved; the gear shifting interlocking plate is adopted, and therefore the design of a box body and a shifting fork shaft can be simplified, and the assembly technology can be simplified; and a compression spring is adopted for gear selecting returning and has the advantages that the manufacturing errors are small and the gear selecting returning effect is good compared with a traditional torsion spring.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

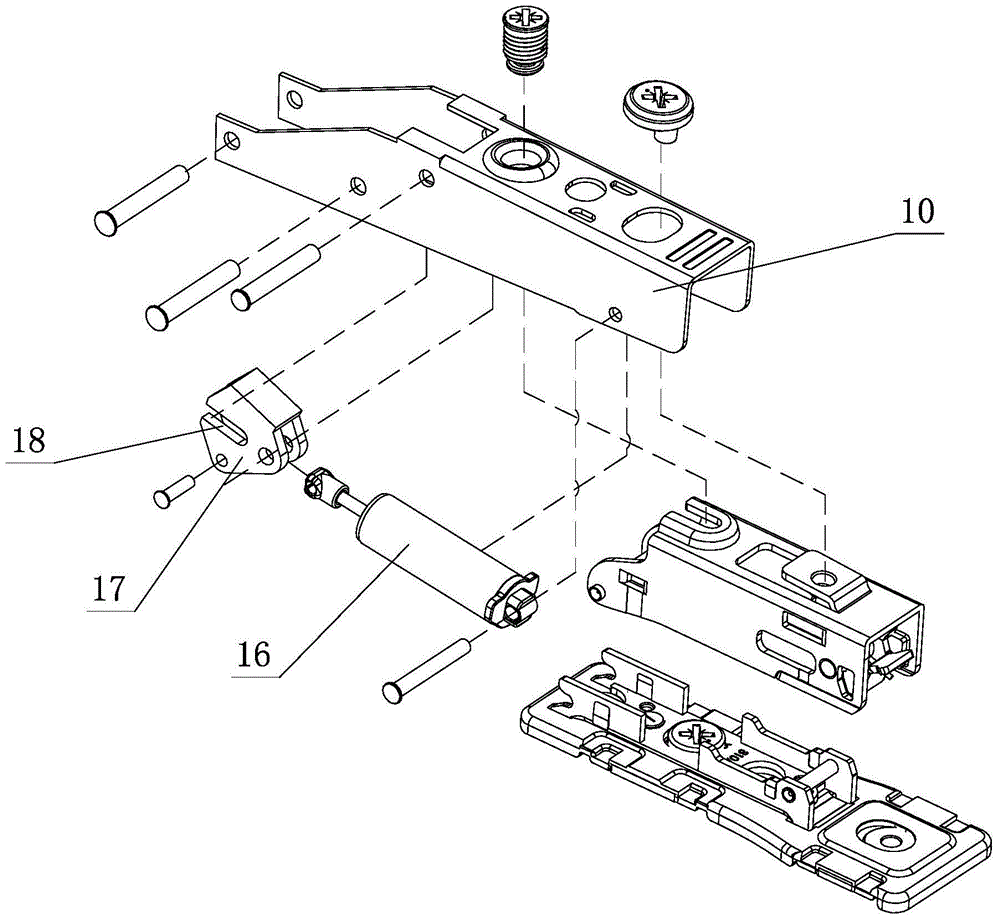

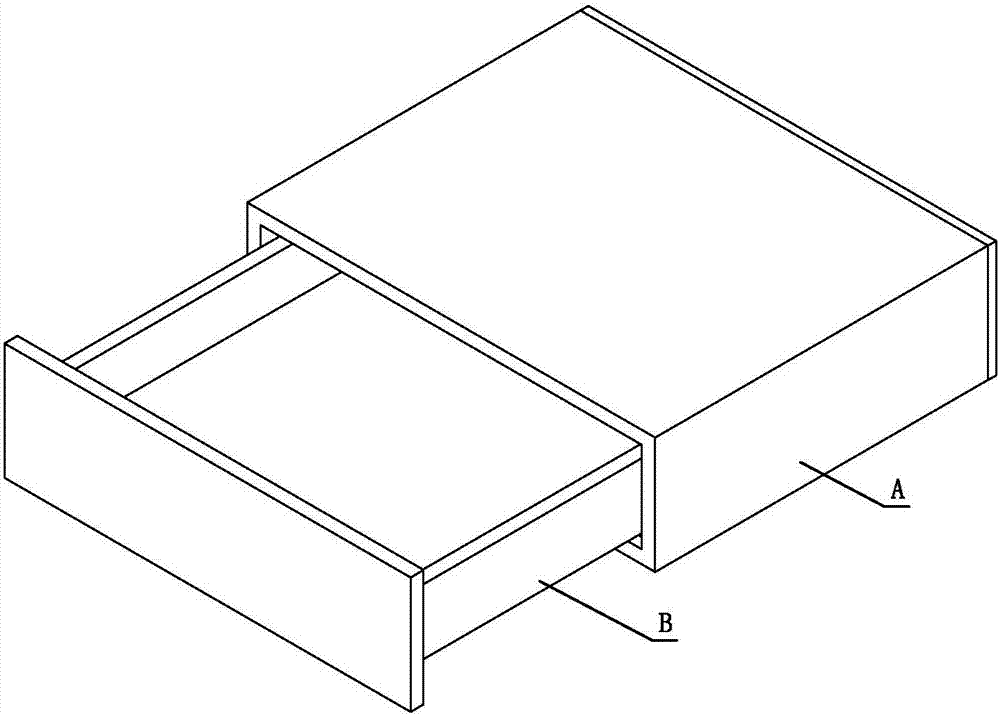

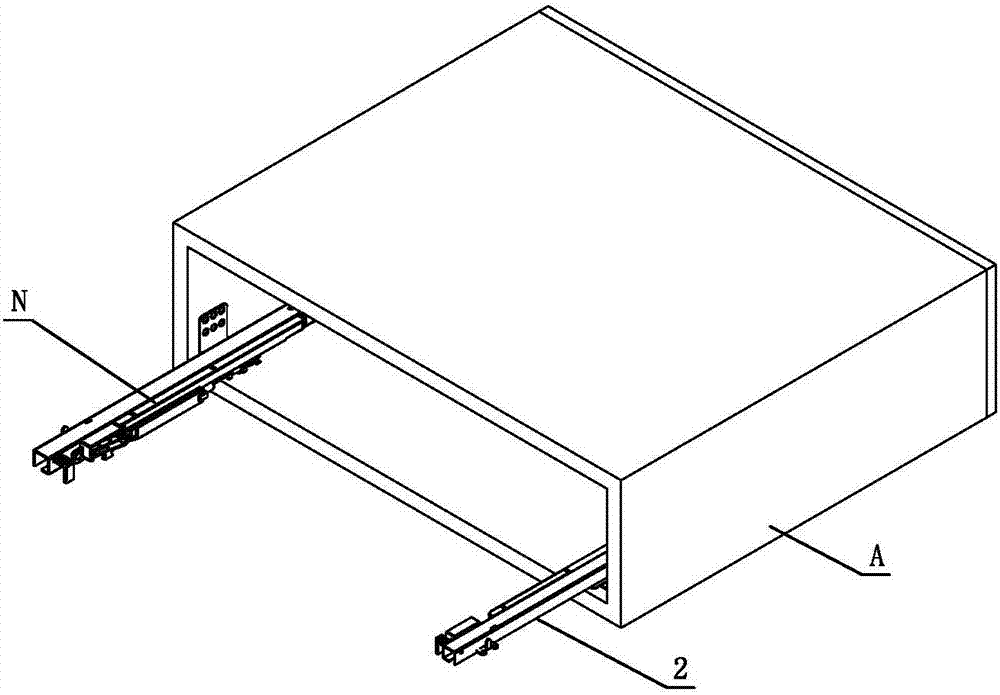

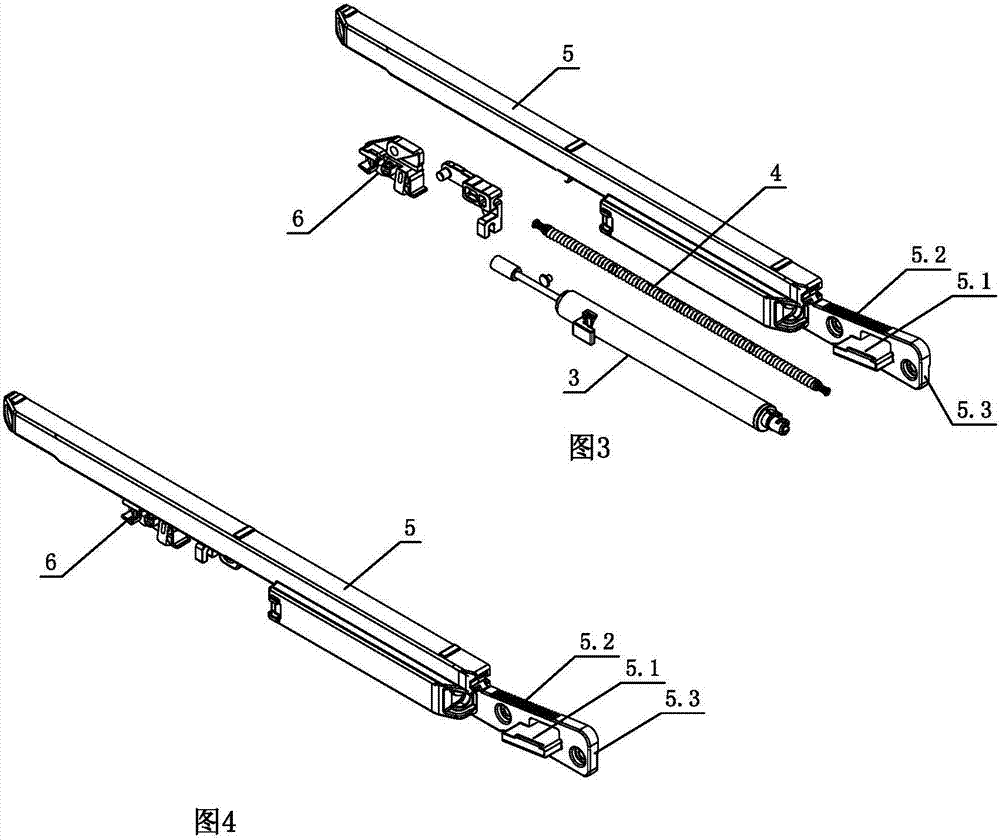

An adjustment and locking mechanism for drawer slide rails

An adjustment and locking mechanism for a drawer slide rail, comprising a slide rail assembly and a damping device, at least when the slide rail assembly is closed, the damping device is used to generate a buffered closure; the bracket seat is provided with an adjustment and locking device, and the adjustment and locking device is provided with a support part, guide part and locking part, the bracket base is provided with a guide fitting part and a tooth part, the guide part is sleeved on the guide fitting part, the locking part acts on the tooth part, and the adjustment of the locking device is limited by the cooperation between the guide part and the guide fitting part. The position slides on the bracket seat, and the adjustment locking device slides on the bracket seat through tools or manual action, so that the support part of the adjustment locking device and the upper wall of the moving rail form a height difference, so as to realize the height difference between the adjustment locking device and the upper wall. Level positioning adjustment. The guiding part of the present invention is set separately from the tooth position, and the tooth position is elastically engaged with the tooth part, so that the mutual elastic sliding is smooth and can be locked at any time, and effectively prevents abdication, and realizes step-by-step adjustment between the adjustment locking device and the cabinet body.

Owner:伍志勇

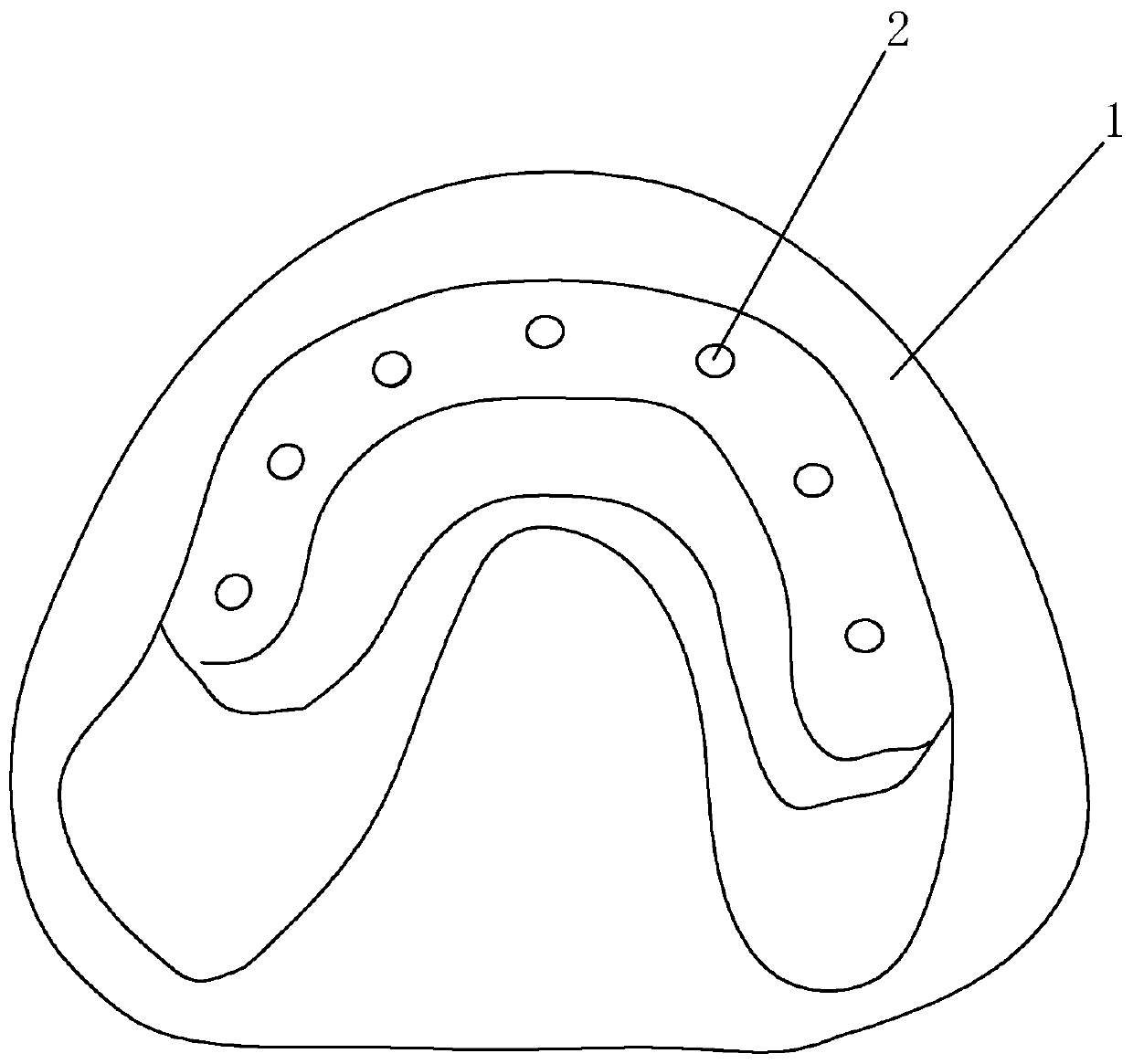

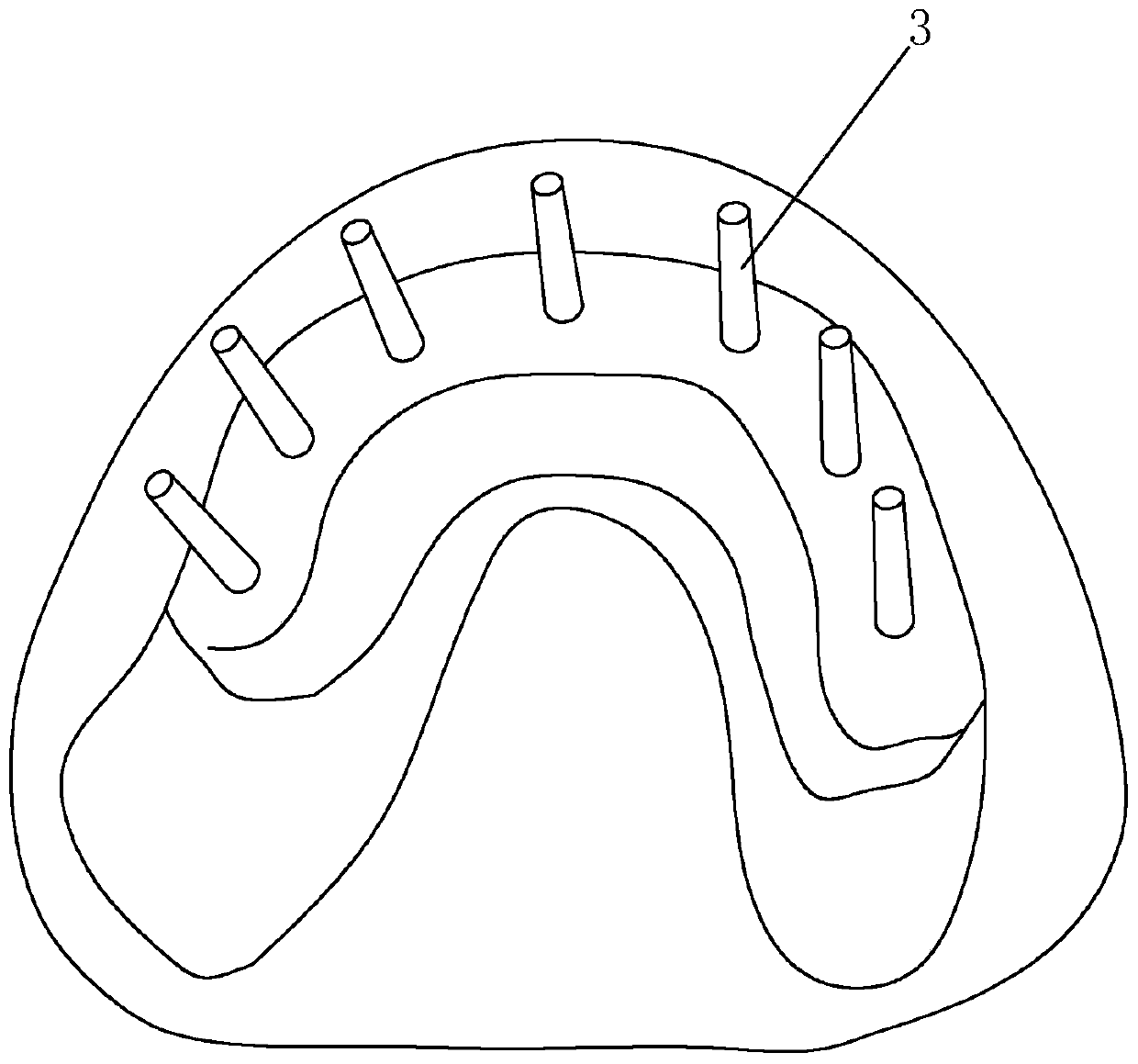

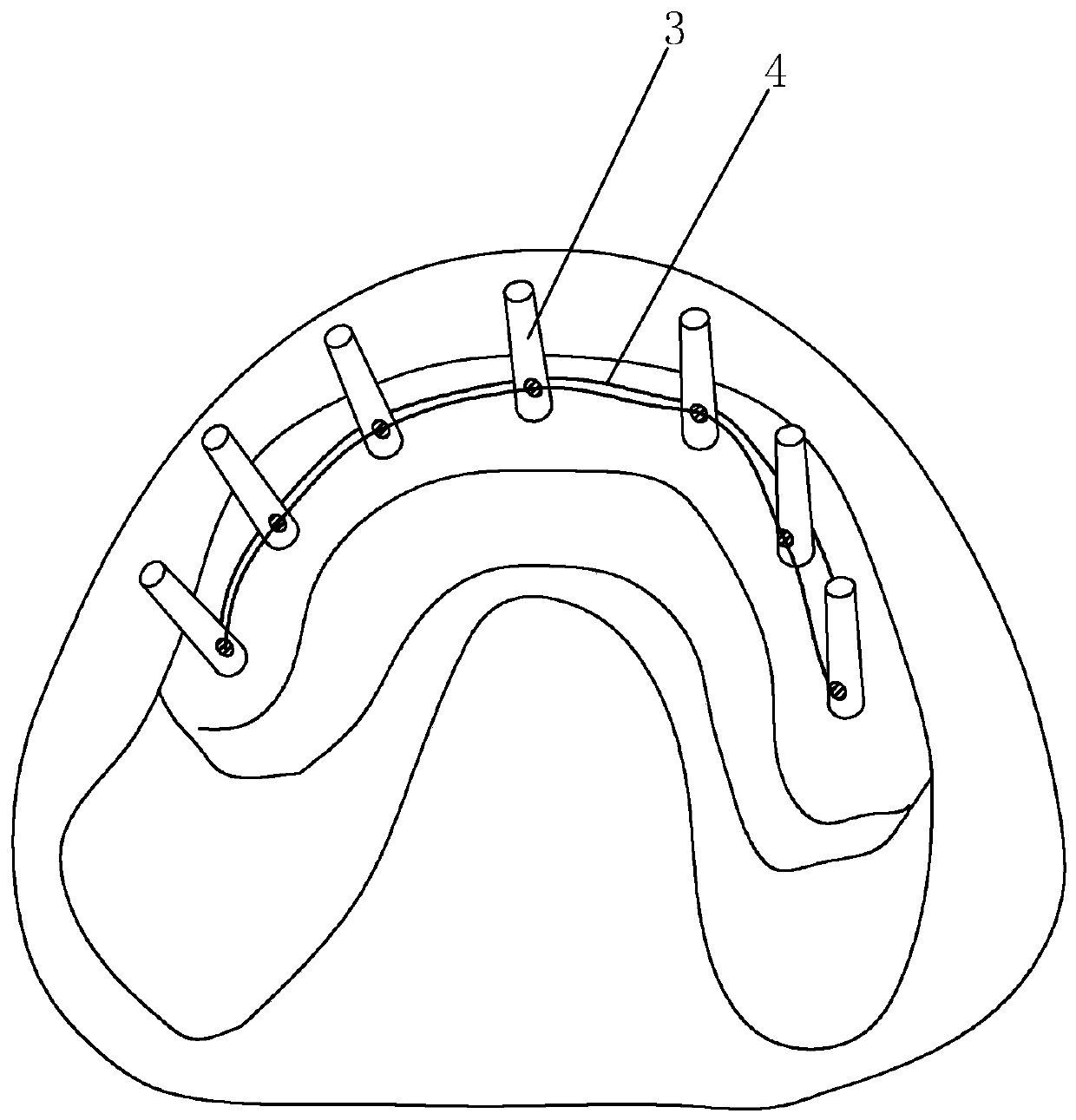

Making method of edentulous jaw precise tooth transfer model

InactiveCN110251254AHigh precisionReduce manufacturing errorsDental implantsDental articulatorsTransfer modelEngineering

The invention discloses a making method of an edentulous jaw precise tooth transfer model. The making method includes following steps: step 1, modeling for the first time: using a tray and silicone rubber, and adopting a windowing modeling method to acquire a patient tooth matching relationship; step 2, pouring a tooth gypsum model on a solidified silicone rubber impression, and obtaining a preliminary model; step 3, mounting transfer rods on the tooth gypsum model in situ; step 4, arranging a position fixing device between each two adjacent transfer rods; step 5, cutting one position fixing device to form an incision; step 6, trying the transfer rods connected with the position fixing devices on in the mouth of a patient according to an arranging sequence, and adjusting positions of the transfer rods; step 7, adopting a curing agent to reconnect the position fixing devices which are cut open at the incisions; step 8, adopting the windowing modeling method for second-time modeling; step 9, pouring a tooth gypsum model on a silicone rubber impression obtained by second-time modeling, and obtaining a final model. By the making method, making accuracy of tooth gypsum models for edentulous jaw patients can be improved effectively.

Owner:福州众升成功医疗科技有限公司

Layout planing method for positioning unit of precise clamp

InactiveCN1687936AWell formedImprove computing efficiencySpecial data processing applicationsFloating searchEngineering

The invention is a precision clamp locating cell laying-out method, selecting characteristic points and directional vectors on a workpiece to define an error tolerance index according to the manufacture task, thus deriving locating error control index as design optimizing target function, using the density data points obtained by scattering reference surface of the workpiece as a candidate set of clamp locating cells, and letting initial solution set of locating cells be a null set, applying the floating search method to select a point from the candidate set each time to supplement it into the solution set, and simultaneously conditionally deleting the selected bad points, so circulating until six locating cells are screened, and thus laying out the optimum locating cells. The said locating error tolerance index has a geometrical meaning related with the manufacture task but is irrelated with the selection of the reference frame, neither is the derived locating error control index. The invention can reduce the precision requirement for clamp locating cells and reference surface of a workpiece on the premise of meeting the workpiece manufacturing accuracy, thus reducing the manufacturing cost.

Owner:SHANGHAI JIAO TONG UNIV

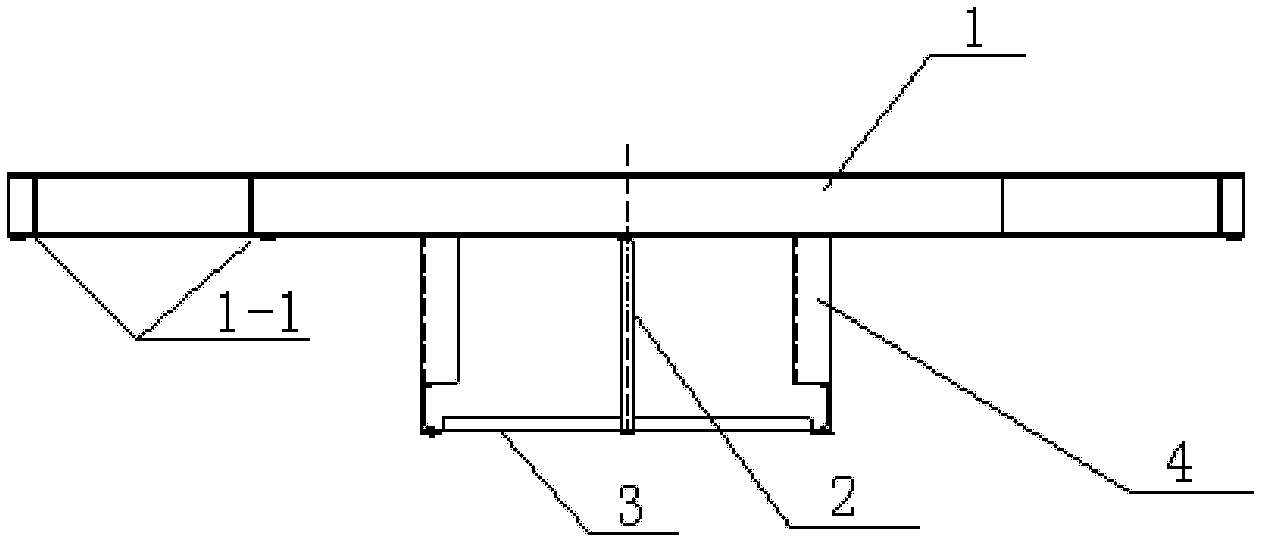

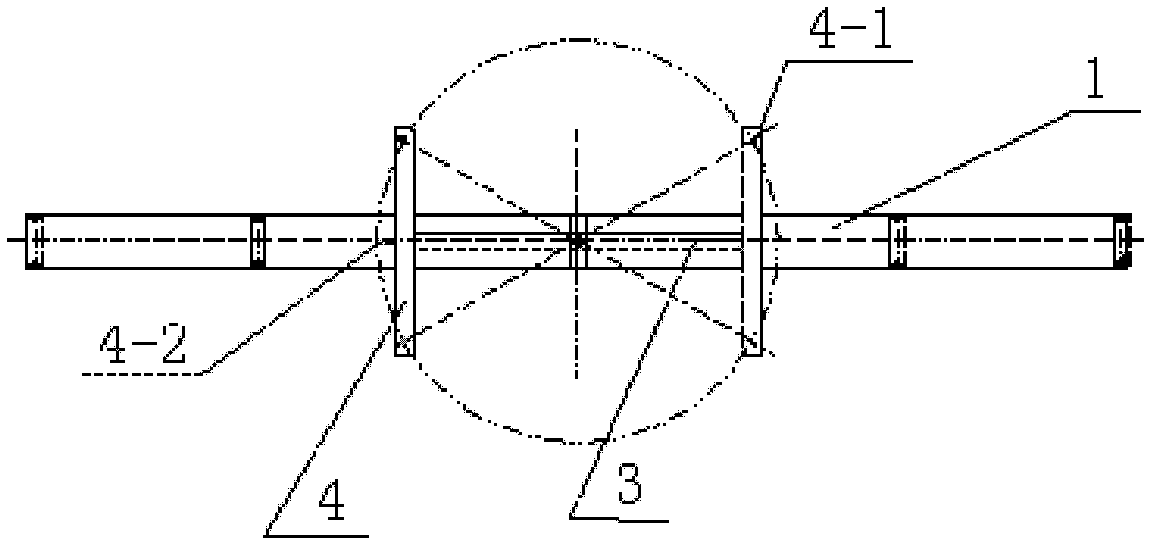

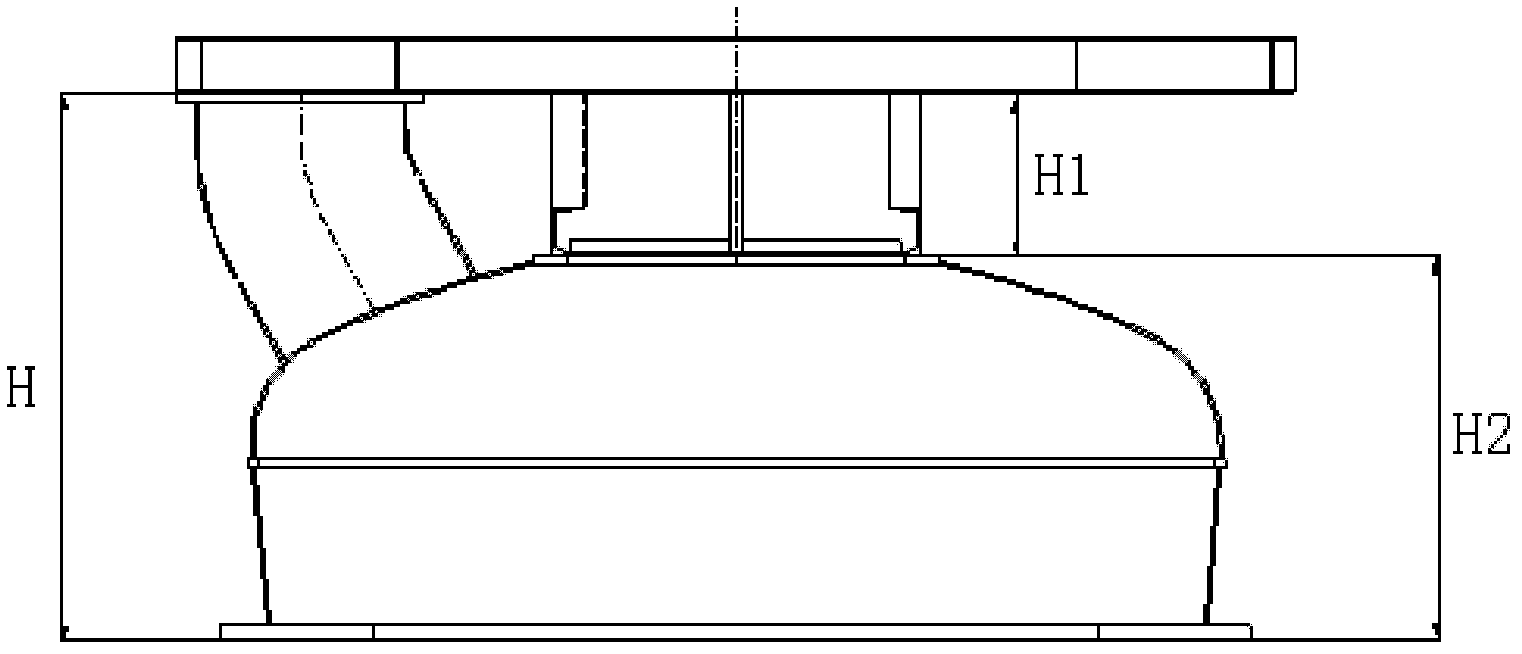

Single side steel plate concrete hollow combined roof construction method

ActiveCN106499195AGuarantee the construction qualityPlay a closed roleFloorsBuilding material handlingReinforced concreteNuclear power

A single side steel plate concrete hollow combined roof construction method belongs to the field of modular construction of large-span large-space roofs and floor systems of nuclear power plants. The construction method includes: manufacturing a steel skeleton module and a support module, and hoisting all the modules in a non-device hoisting opening; constructing a temporary maintenance structure in a device hoisting opening; manufacturing roof reinforced concrete in the non-device hoisting opening on site; constructing a single side steel plate concrete hollow combined roof in the device hoisting opening; and temporarily drilling holes in the roof in service. The method can meet an assumed structure stress state during designing of the single side steel plate concrete hollow combined roof, i.e., the roof is hinged to a side wall during construction so as to seal the plant; in normal use, the roof is connected to a fixing end of a wall, and plays a role in whole structure seismic resistance of the plant; and the construction method can avoid cross-operation between device installation and roof civil construction, can lower the safety risk of high-altitude construction, and can effectively shorten the total construction period.

Owner:CHINERGY CO LTD

Positioning die for arranging elbow pipe on powder concentrator shell

InactiveCN102248350AGuaranteed installation accuracyReduce difficultyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringConcentrator

The invention discloses a positioning die for arranging an elbow pipe on a powder concentrator shell. The positioning die comprises an upper die plate, a core rod and a lower die plate, wherein one end of the core rod is vertically connected with the upper die plate, and the other end of the core rod is vertically connected with the lower die plate; and a positioning device for fixing the elbow pipe is arranged on the upper die plate. By the positioning die, the installation accuracy of the elbow pipe on the powder concentrator shell is ensured, and the measurement positioning difficulty and manufacturing error of the elbow pipe during weld positioning are reduced effectively. In addition, the manufacturing accuracy is ensured while the work efficiency is improved during batch production, and the positioning die is easy and convenient to operate.

Owner:江苏羚羊机械有限公司

Valve

ActiveCN101328987AEasy to hangGuaranteed torque balanceOperating means/releasing devices for valvesLeaf springsEngineeringVALVE PORT

The present invention relates to a valve with a valve member prestressed to an initial position through a bearing spring (35). The prestressing is generated by a reed (37) which is deflected to a prestressed working position from a neutral position without prestressing relative to a retaining segment (36) along a deflecting direction (62). The reed (37) is provided with at least one inflexion (58), so the reed is bended little although big deflection exists, and therefore only little installation space is required.

Owner:FESTO AG & CO KG

Cylindrical part inner wall defect size three-dimensional measurement system and measurement method thereof

PendingCN114279361AReduce manufacturing errorsRobustOptically investigating flaws/contaminationUsing optical meansThree dimensional measurementEngineering

The invention discloses a cylindrical part inner wall defect size three-dimensional measurement system. A multi-degree-of-freedom displacement mechanism, a part fixing table and an observation structure supporting frame are arranged on a stable measurement platform; an observation mechanism is arranged on the observation structure supporting frame, and an observation module and a measurement sensor are arranged on the observation mechanism; and the cylindrical part is fixed on the part fixing table. The invention further discloses a measuring method of the three-dimensional measuring system. According to the technical scheme, non-contact measurement is adopted, and manufacturing errors of a traditional contact type measuring instrument and reading errors caused by human factors are reduced; model fitting is carried out based on the RANSAC algorithm, the robustness is high, and the efficiency is higher; high-precision multi-angle displacement driving is adopted, vertical lifting and 360-degree all-dimensional inductive triggering are achieved, integrated automatic execution is achieved, and the working efficiency is improved.

Owner:哈尔滨工业大学芜湖机器人产业技术研究院

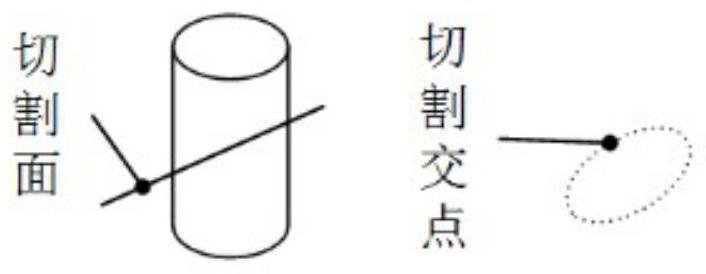

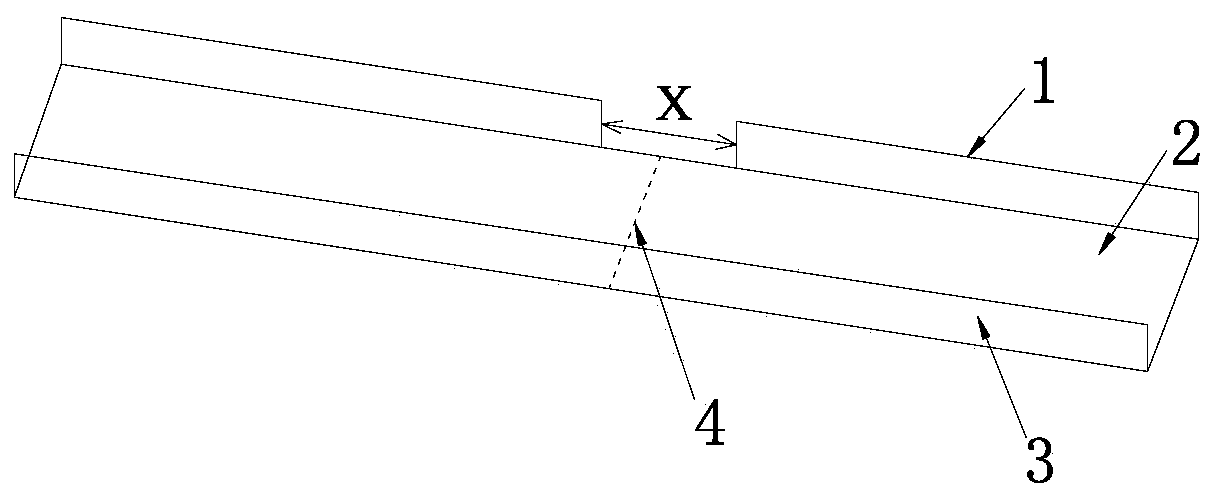

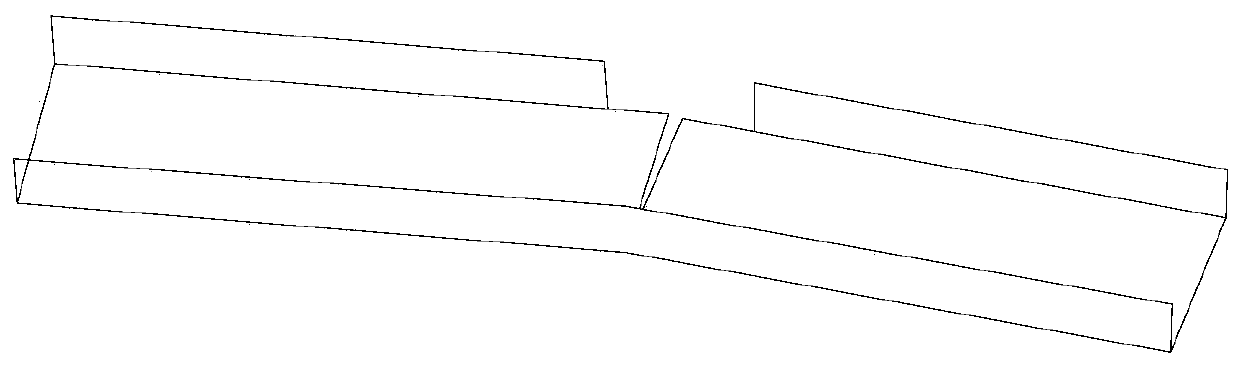

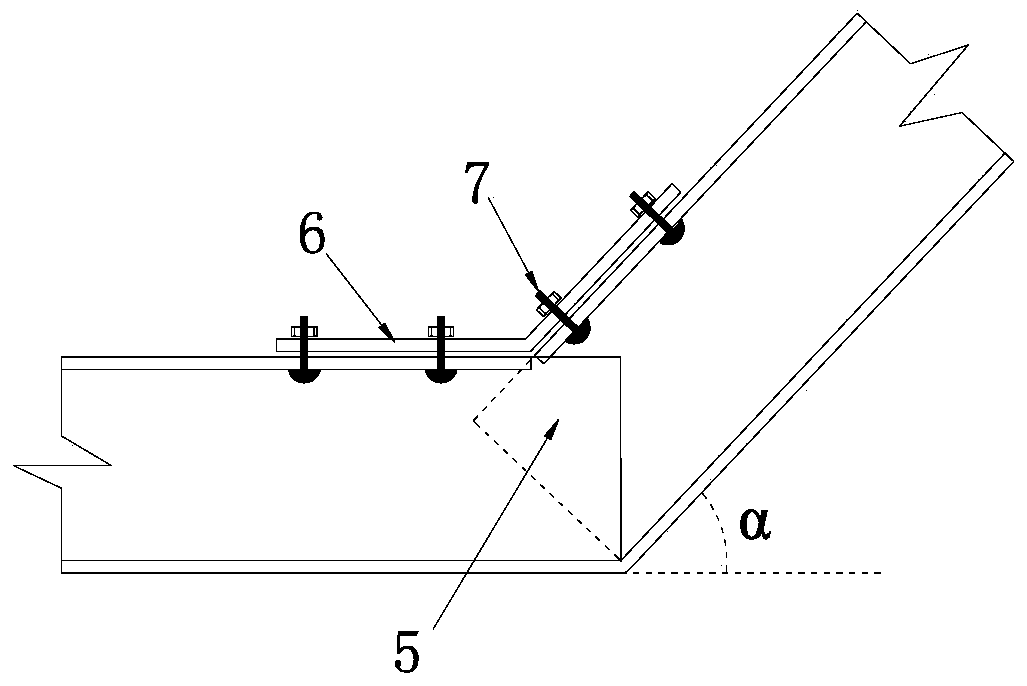

Groove-type cable bridge frame horizontal bend manufacturing method

InactiveCN110429534AGood for healthWon't breakOther manufacturing equipments/toolsCable installation apparatusCable trayAngle alpha

The invention provides a groove-type cable bridge frame horizontal bend manufacturing method. The method comprises the following steps of 1, measuring two bridge frames which needs to set bend connection so as to determine a pre-made horizontal bend angle alpha; 2, calculating a cutting length x of a side edge of each bridge frame, wherein x = 2b* tgalpha, and the b is a bridge frame width; 3, cutting and removing a x length on an inner side edge of each bridge frame, taking an x area as a bottom to make a midperpendicular on a bottom surface of each bridge, then cutting along a drawing line,and only cutting the bottom surface of each bridge frame to protect the outer side edge of the bridge frame; 4, folding the outer side edge of each bridge frame at a vertex of a vertical line so thatthe bottom surfaces of the two sides of a cutting seam overlap, and a cut gap portion of the inner side edge is completely closed; and 5, drilling holes in the overlapped bottom surface, fixing with agalvanized square neck bolt, and installing a connecting plate at a folded corner formed by folding of the inner side edges so as to complete fixing of a horizontal bend. In the method, electrowelding is not needed, an anti-corrosion layer of a bridge frame material is not damaged, a cutting work amount is reduced, the method is simple and easy to operate, and a construction period is effectivelyshortened.

Owner:CHINA 22MCC GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com