Single side steel plate concrete hollow combined roof construction method

A steel plate concrete and construction method technology, applied in building structure, floor slab, building, etc., can solve the problems of shortening the critical path construction period, failing to meet the functional requirements of the reactor building, and reducing the safety risk of high-altitude construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The construction method of a single-sided steel plate concrete hollow composite roof proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

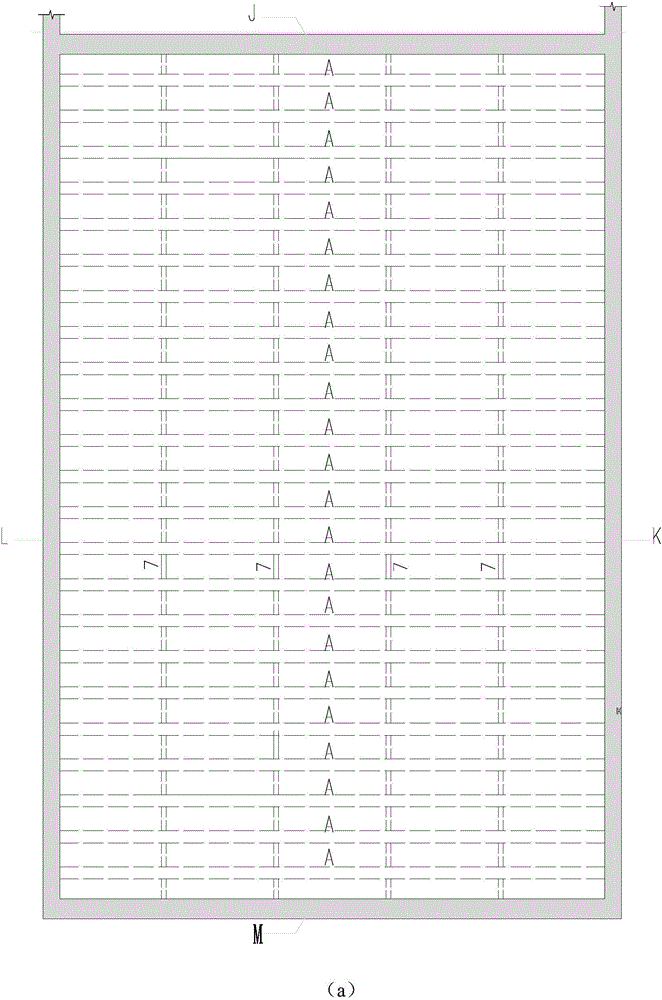

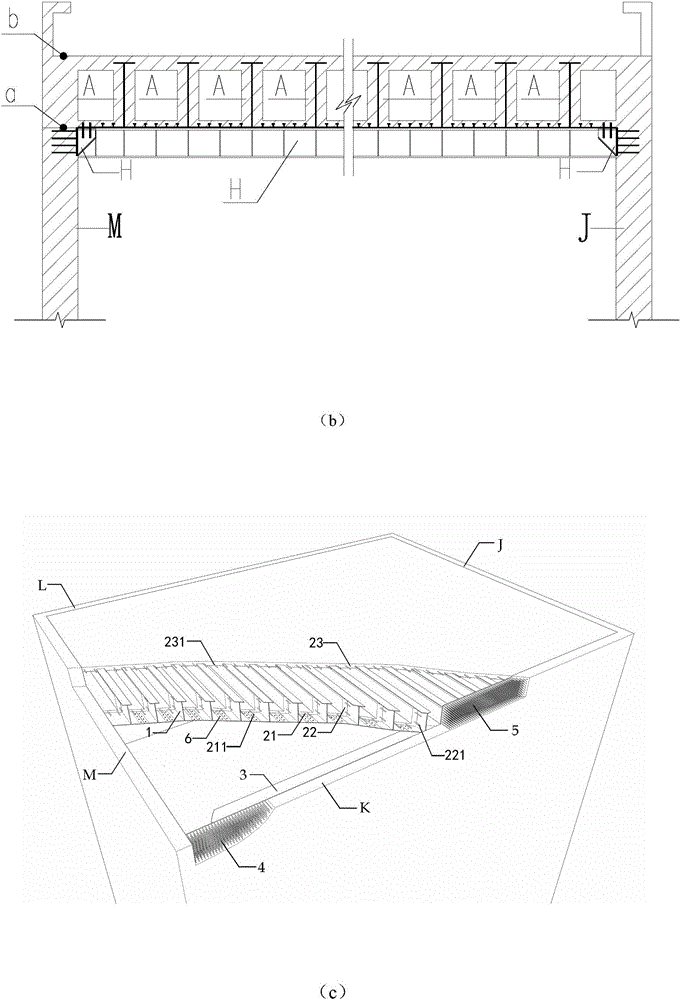

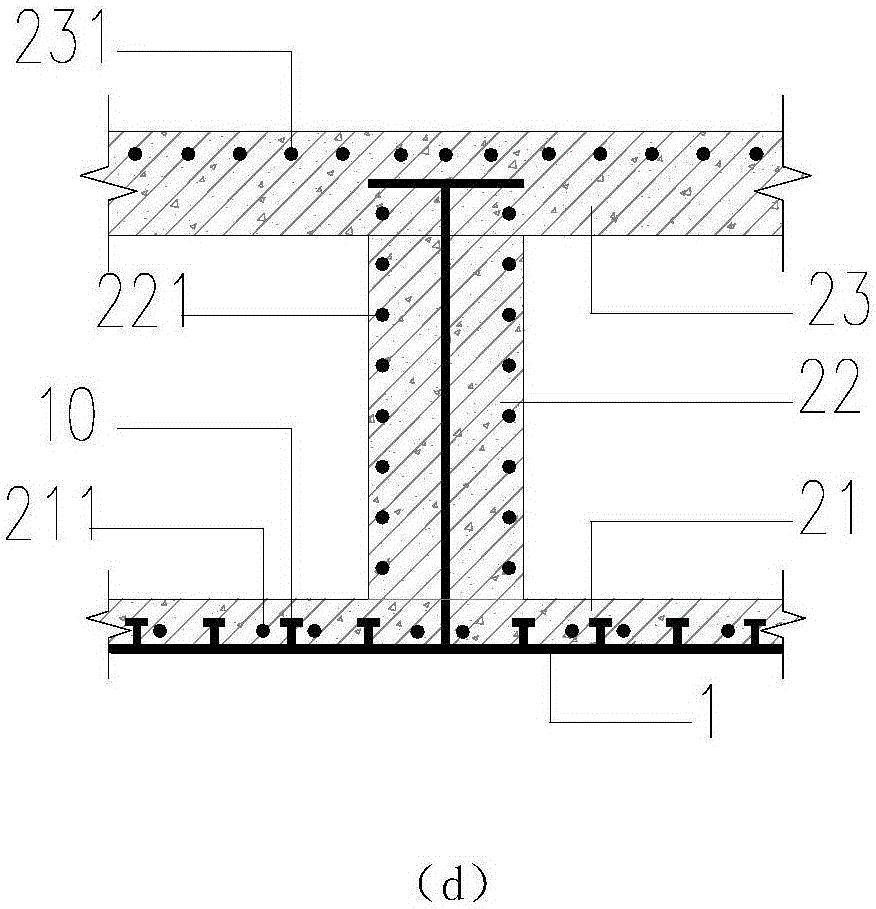

[0068] The present invention adopts a single-side steel plate concrete hollow composite roof according to the characteristics, project progress and functional requirements of the roof of the high-temperature gas-cooled reactor nuclear power plant. The plane layout, main section and three-dimensional diagram of the single-sided steel plate concrete hollow composite roof are as follows: figure 1 As shown in (a), 1(b) and 1(c), the roof includes several steel skeleton modules and I-shaped reinforced concrete 2 on them, and the whole is in the shape of a flat rectangular box with multiple hollows in the middle Structure, the roof is fixed on the surrounding walls of the reactor building through the support module H; the steel skeleton module is connected by se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com