Double track bridge construction process crossing existing railway operational lines

A technology of existing railways and construction technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high safety risk, difficult construction, short construction period, etc., to reduce safety risks, shorten construction period, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

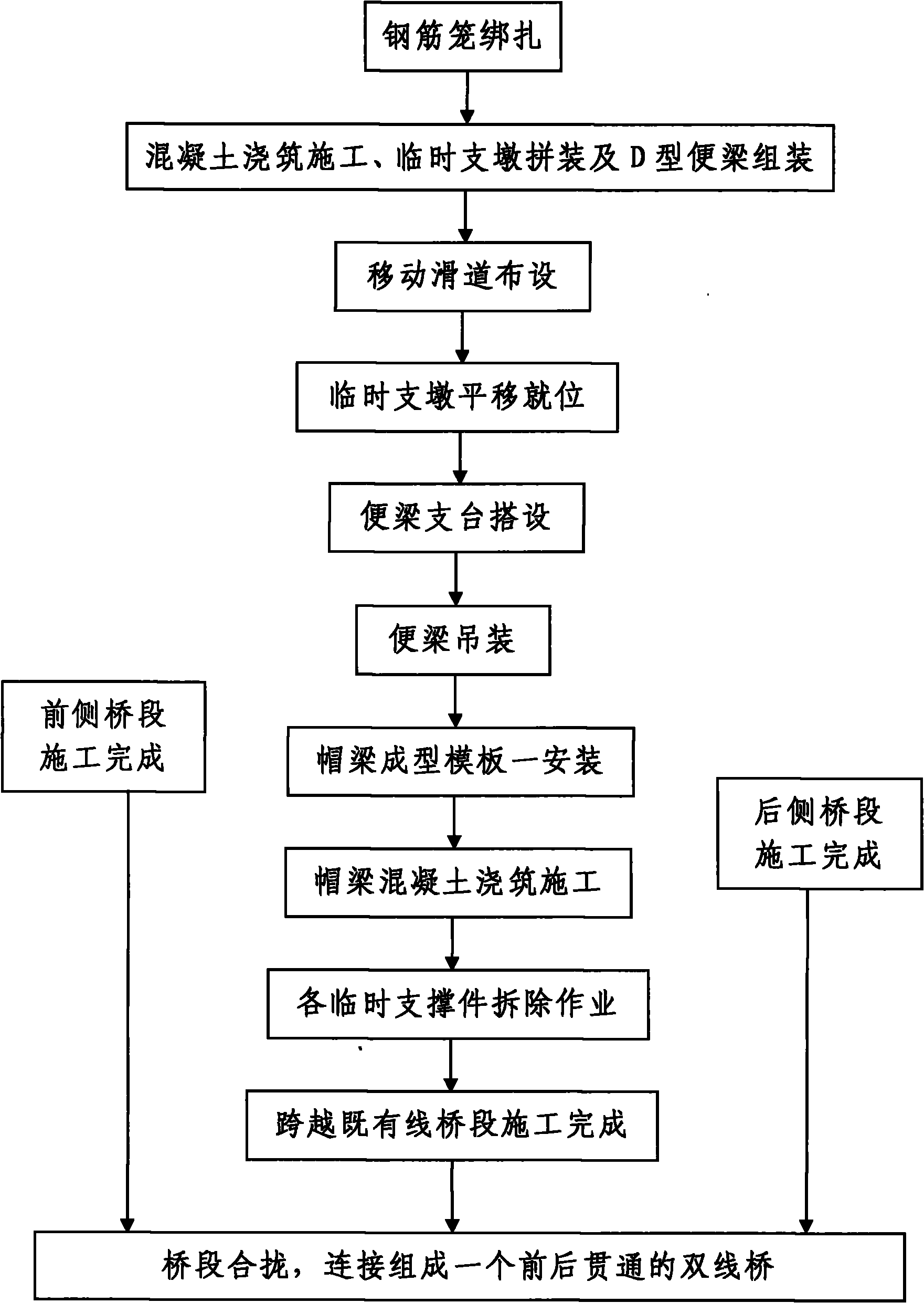

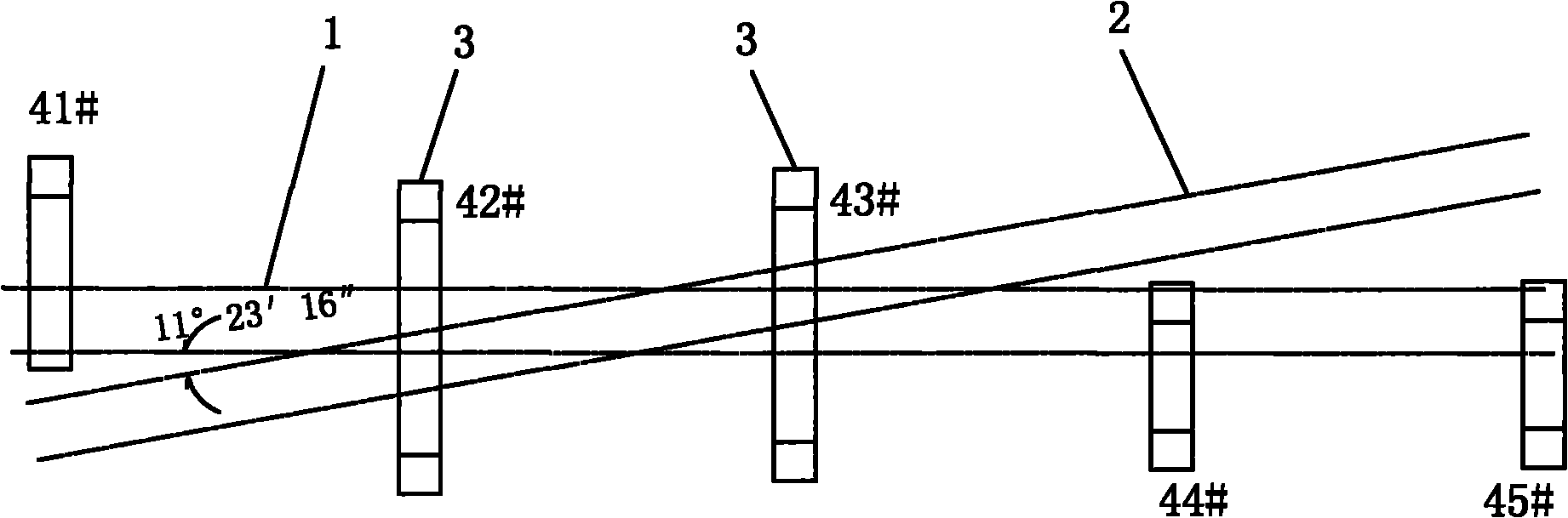

[0070] Such as figure 1 Shown is a double-line bridge construction process spanning the existing railway operating line, the constructed double-line bridge 1 includes a bridge section spanning the existing railway operating line 2 and a bridge section before and after the bridge section spanning the existing railway line. The front side bridge section and the rear side bridge section connected at the ends, the front side bridge section, the bridge section spanning the existing line and the rear side bridge section are connected to form a double-line bridge that runs through the front and back. The process includes the following steps:

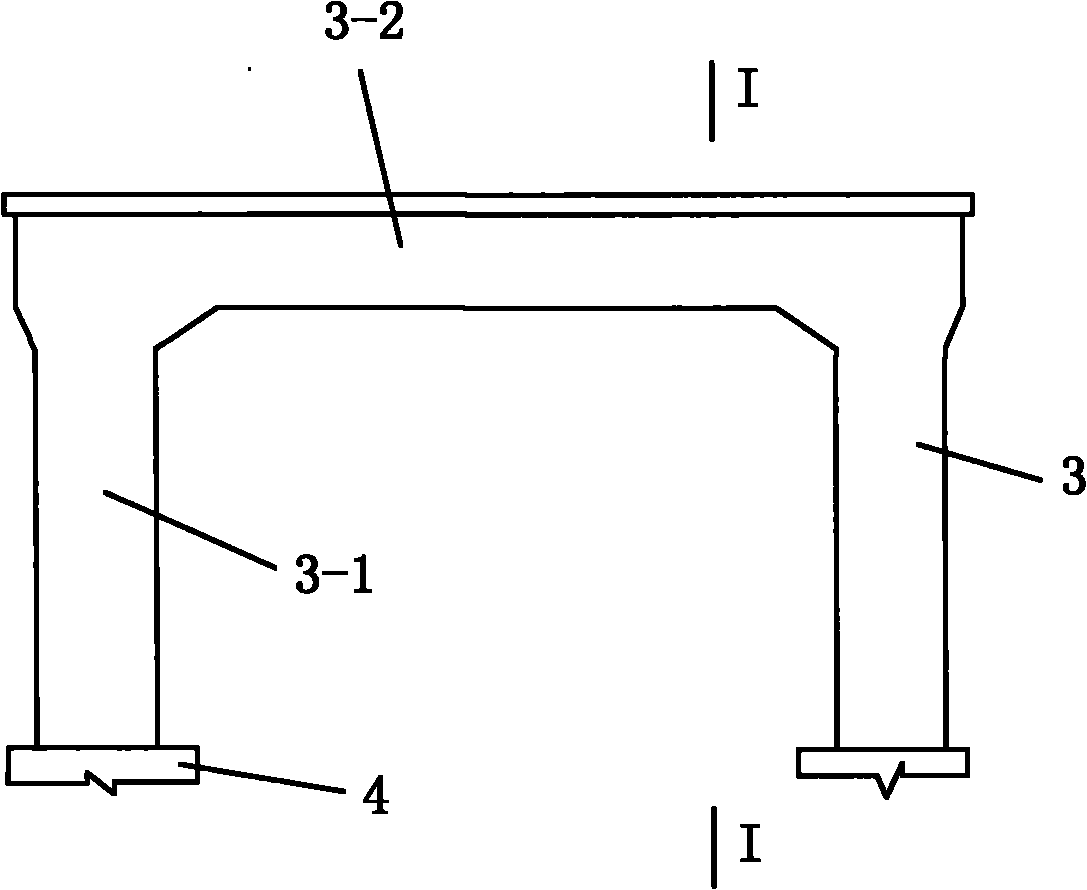

[0071] Step 1. Simultaneous construction of the front bridge section, the bridge section spanning the existing line and the rear bridge section: the bridge section spanning the existing line includes an upper girder section spanning the existing railway operation line 2 and two pairs of the upper girder section respectively Supporting portal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com