Patents

Literature

85results about How to "Reduce block time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

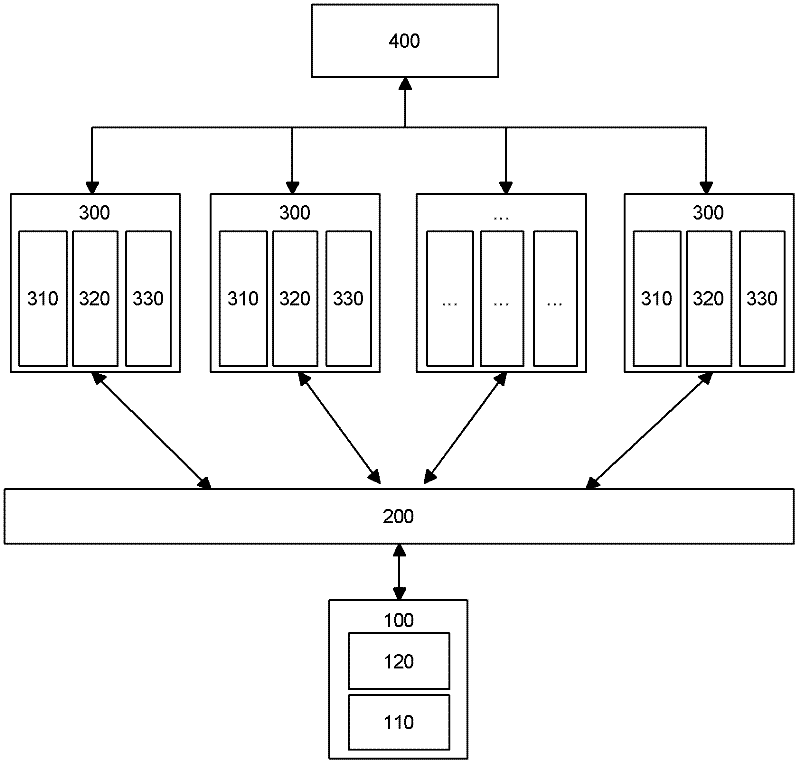

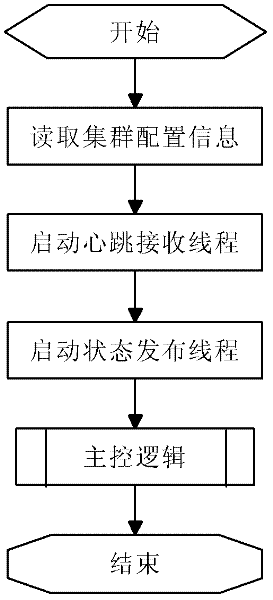

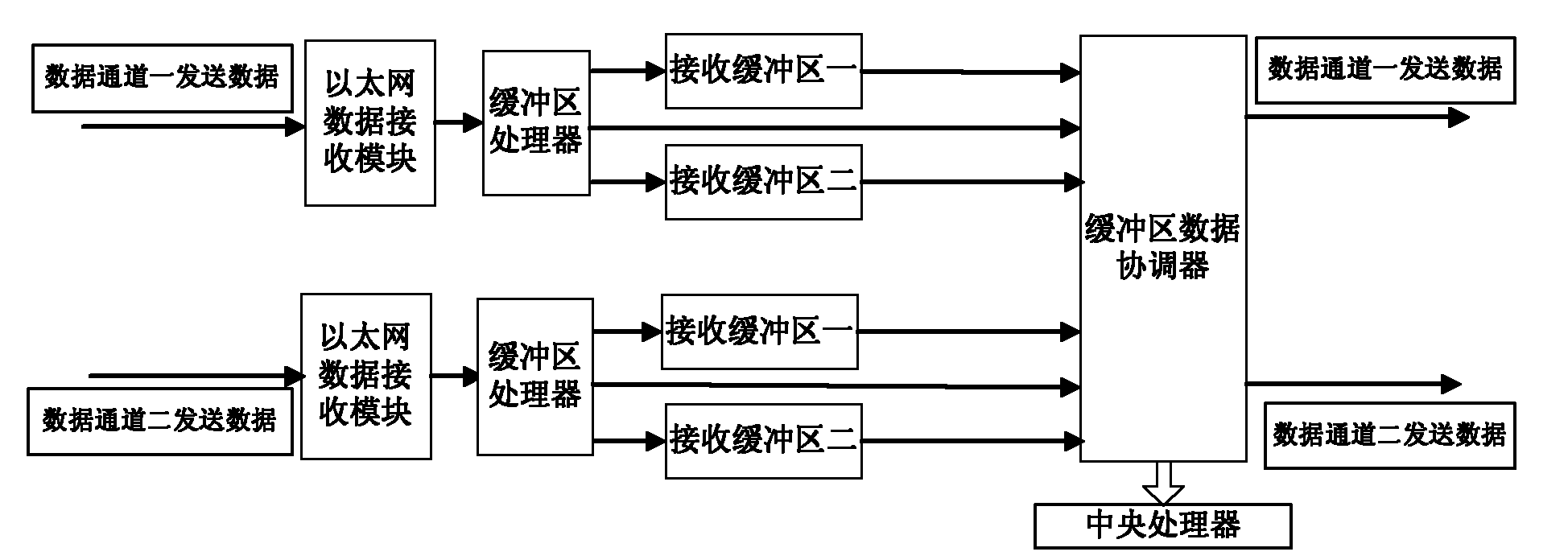

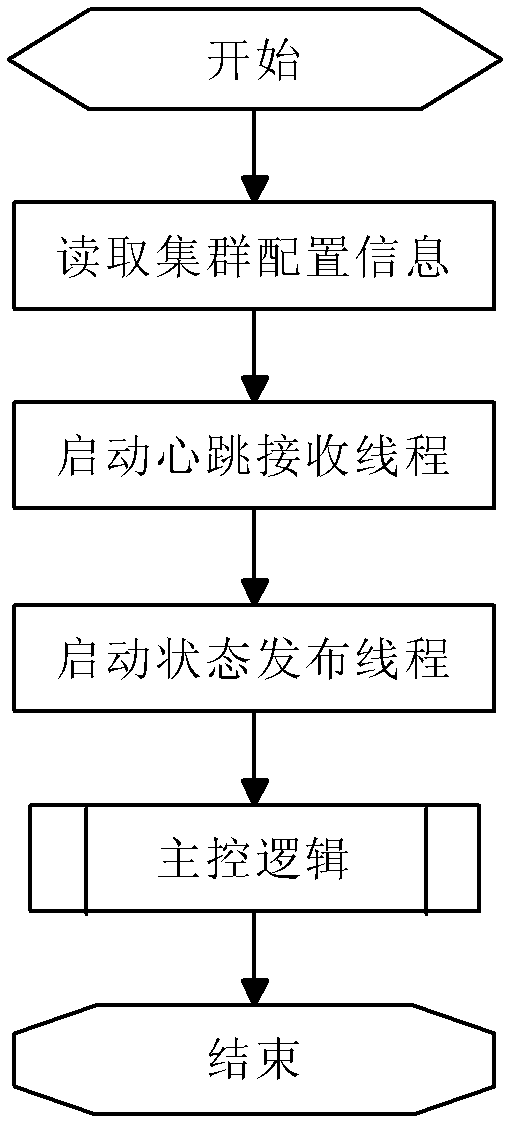

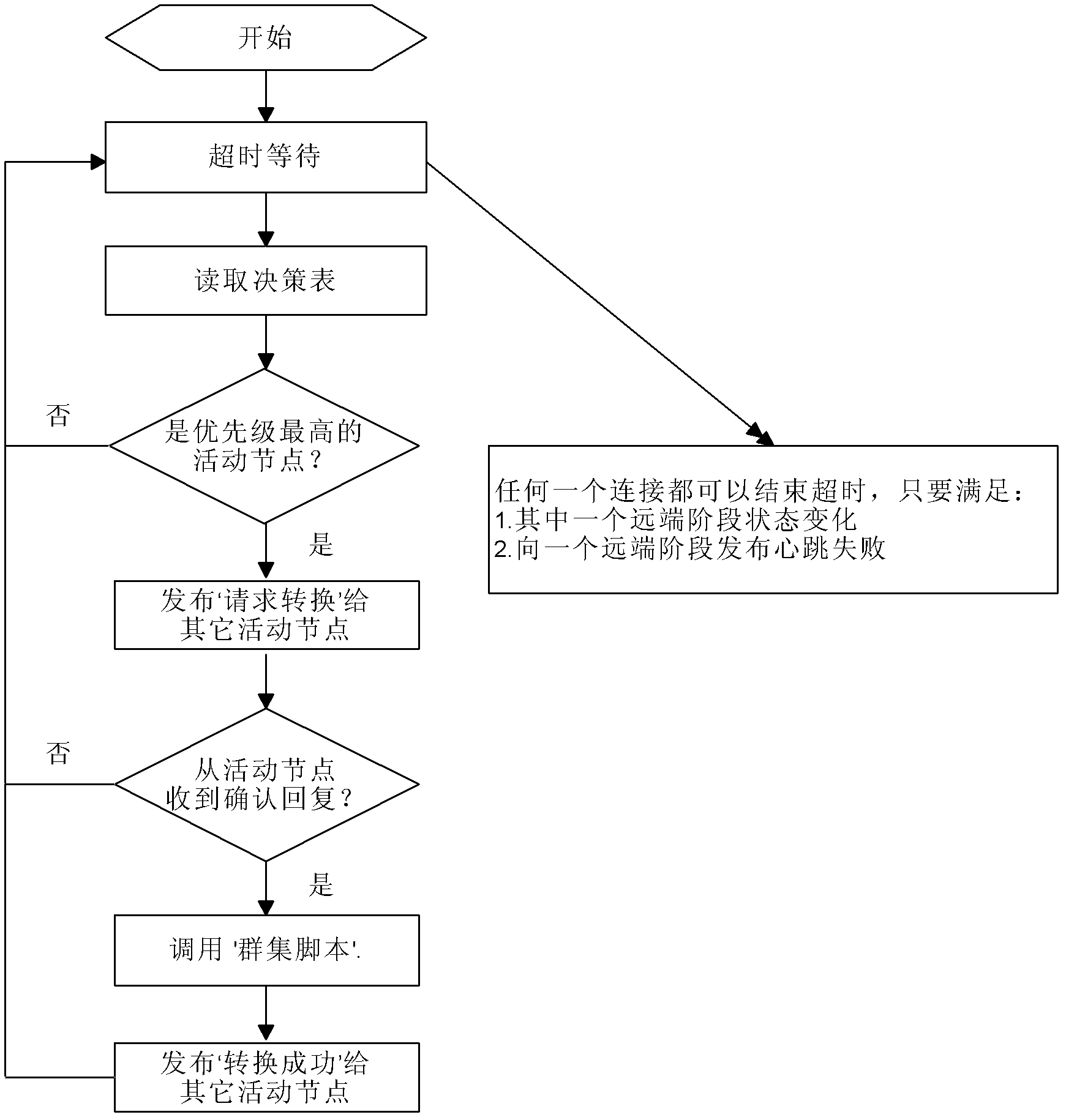

Intelligent dynamic load balancing method for high-speed real-time database

ActiveCN102404390AReduce block timeFlexible distributionTransmissionDynamic load balancingNetwork communication

The invention discloses an intelligent dynamic load balancing method for a high-speed real-time database. The method comprises the following steps of: configuring cluster arbitration tables with consistent content in each client and each cluster server node; dividing a background data storage module into different physical storage partitions; establishing communication and connection between the client and each cluster server node; maintaining the consistent content of the cluster arbitration tables in servers on respective cluster server nodes by respective cluster server nodes; receiving and processing a task sent by the client; initiating a data reading and writing request to a global virtual internet protocol (IP) address by the client; sending the request to a destination cluster server node by a network communication management module; and performing necessary verification by a target cluster server node after the request submitted by the client is received, and processing a legal request. According to the method, hardware and software resources of a plurality of server nodes are flexibly integrated and optimal utilization and scheduling of hardware platform recourses are realized.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

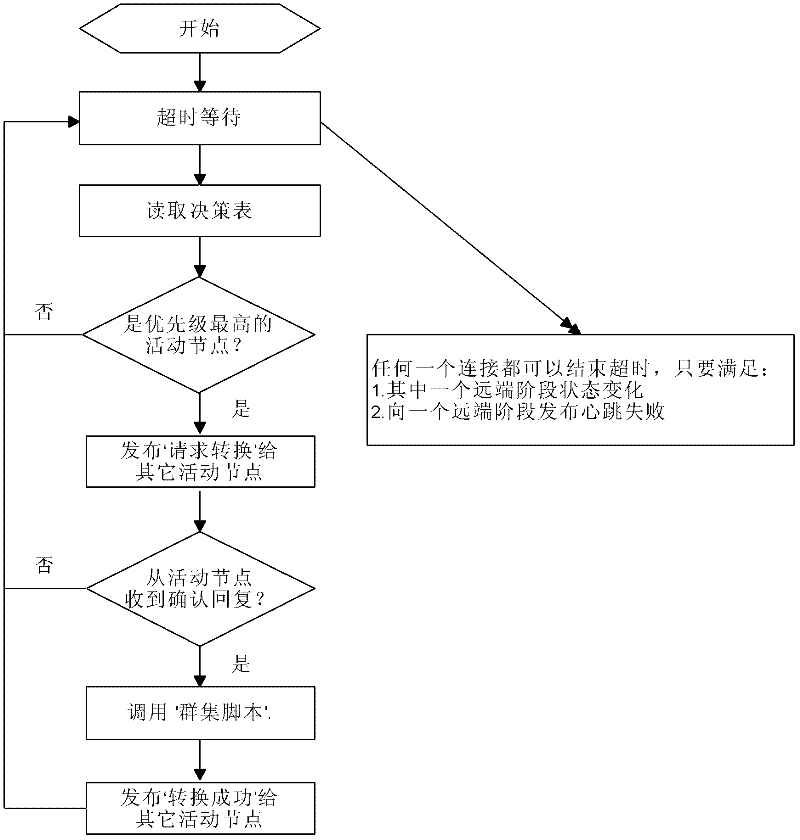

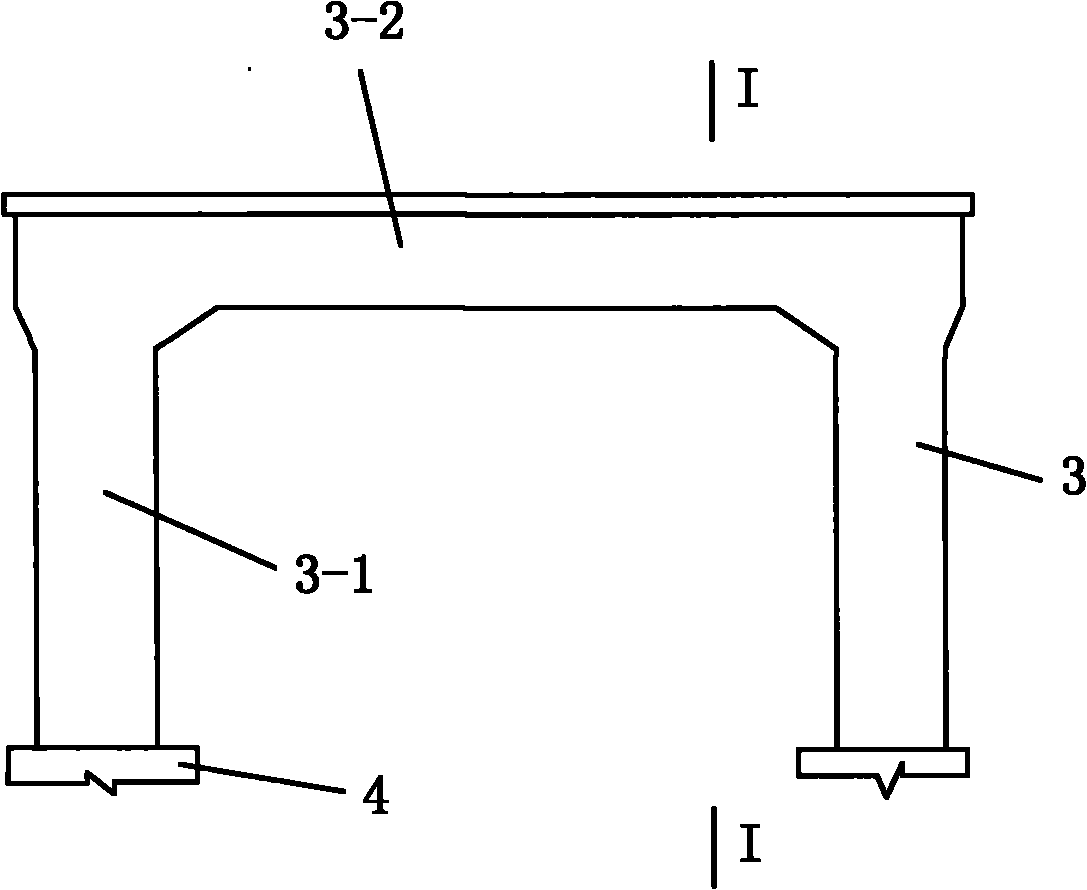

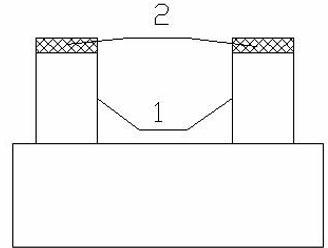

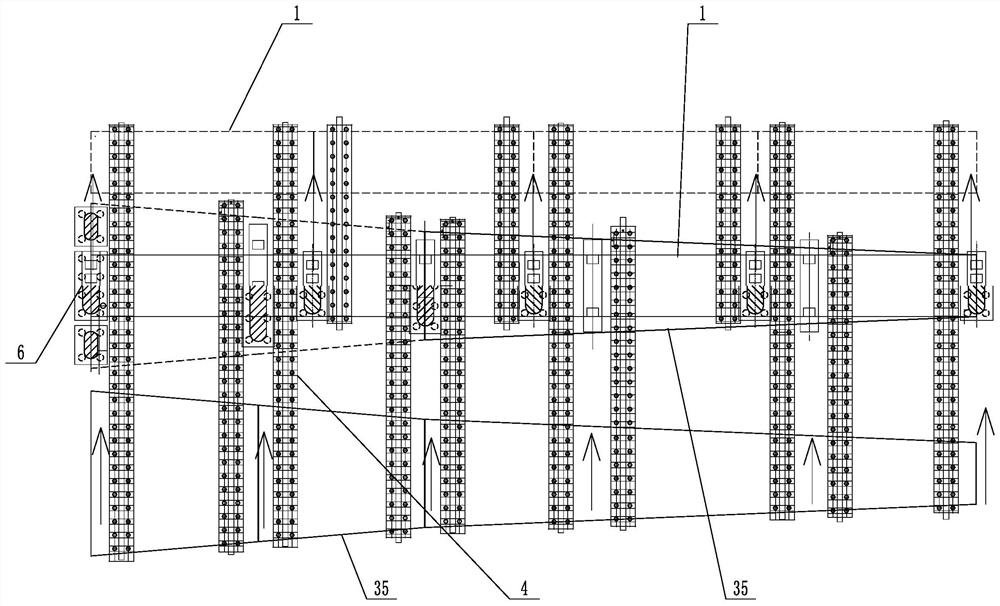

Double track bridge construction process crossing existing railway operational lines

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

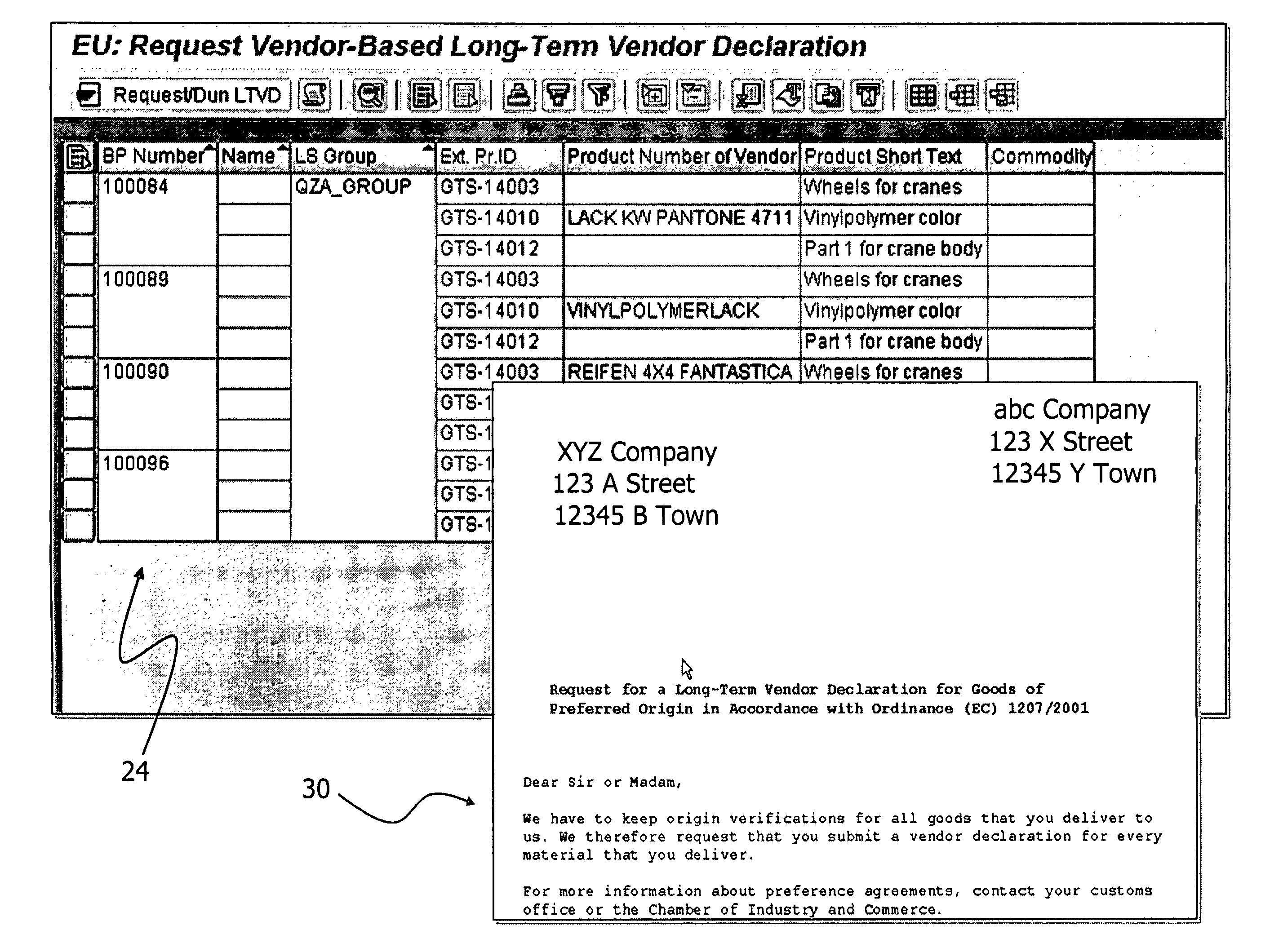

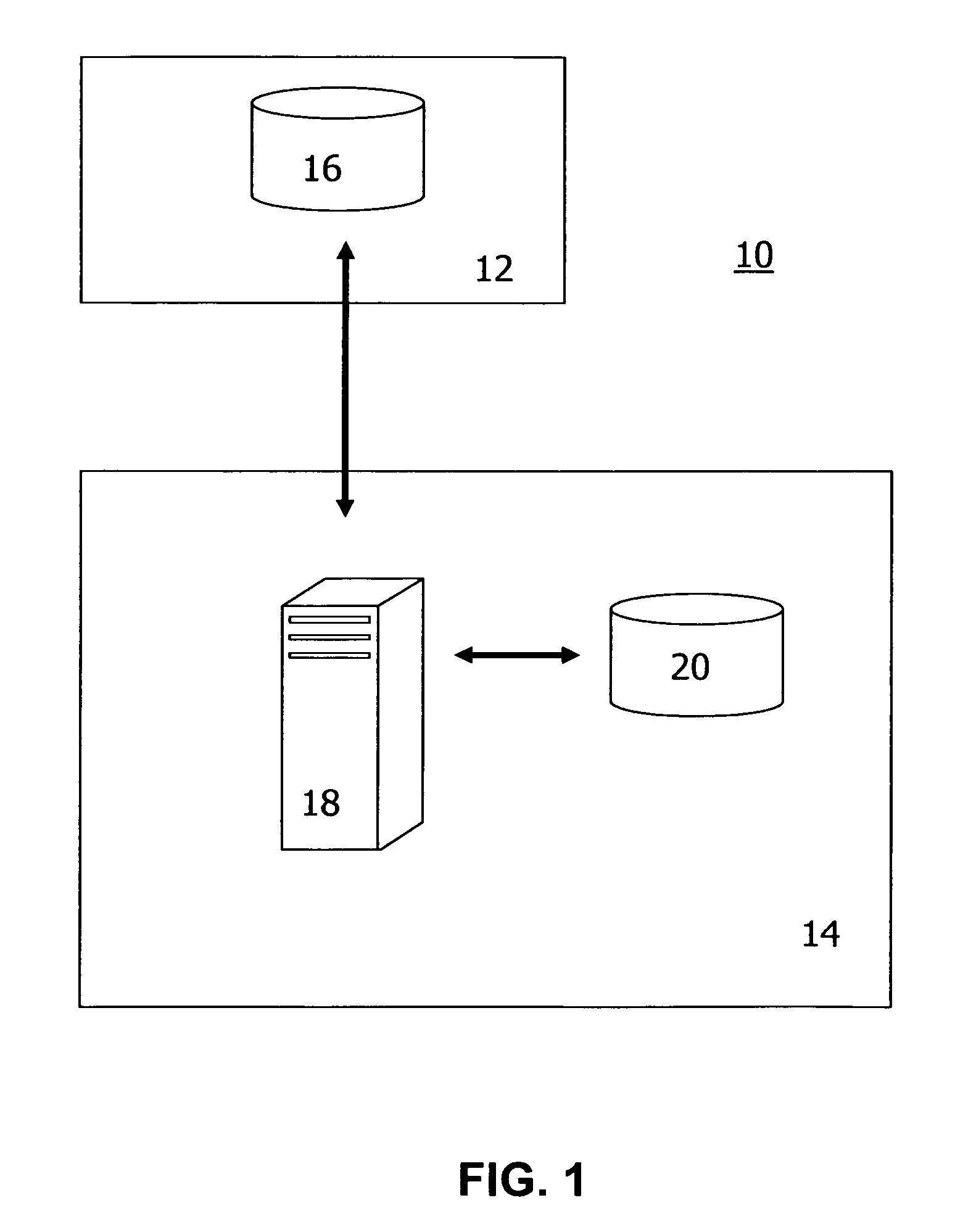

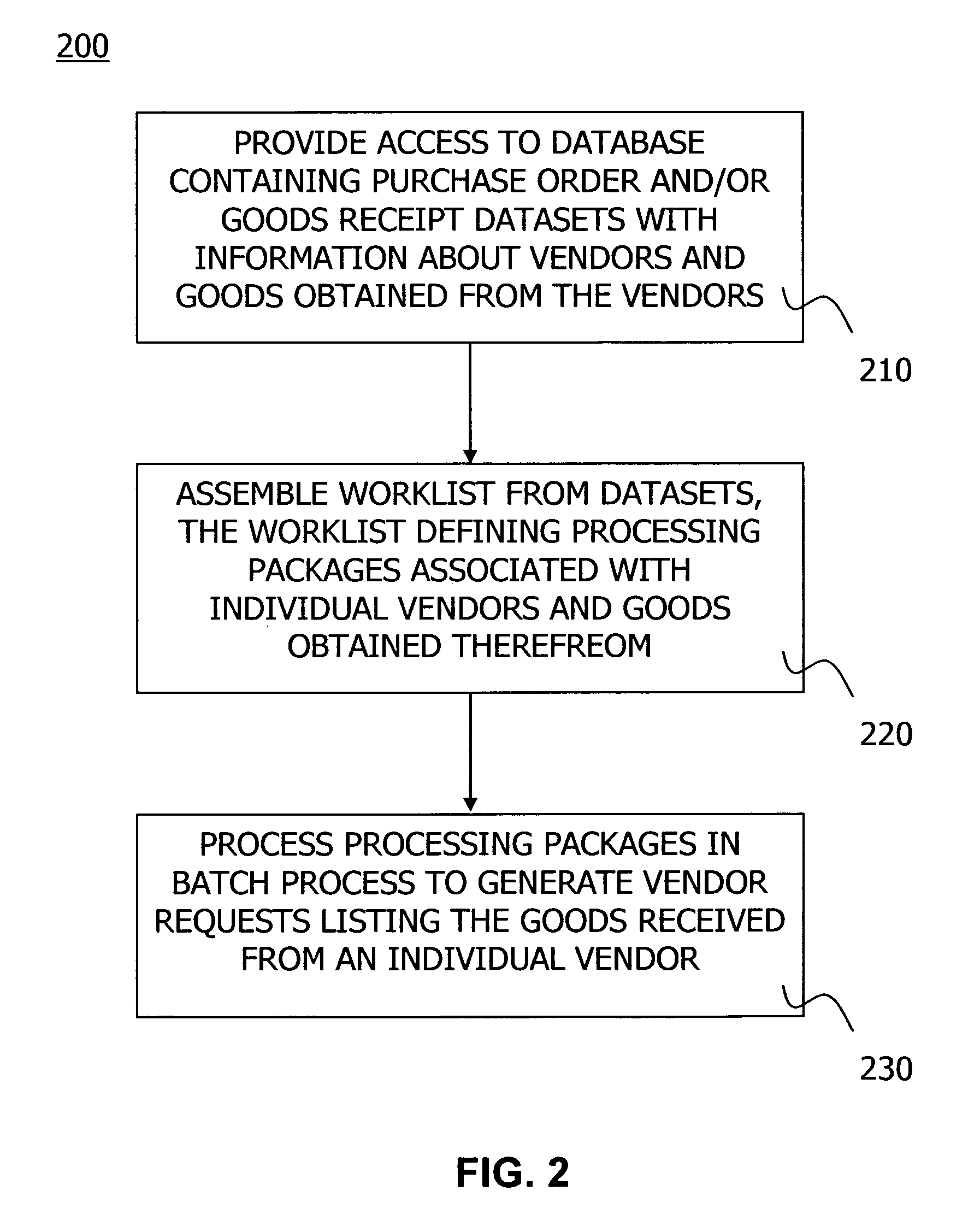

Methods and systems for mass data handling in a preference processing context

Methods and systems are provided for generating vendor declaration requests in a trade preference processing context. In one implementation, an electronic database is utilized that contains at least one of purchase order data sets and goods receipt data sets that include information about vendors and about goods purchased from the vendors. The electronic database may be accessed to assemble a worklist from the information included in the data sets. The worklist may define a plurality of processing packages associated with individual vendors and indicate the goods purchased from the vendors. The processing packages on the worklist may then be processed in a batch process to generate the vendor declaration requests.

Owner:SAP AG

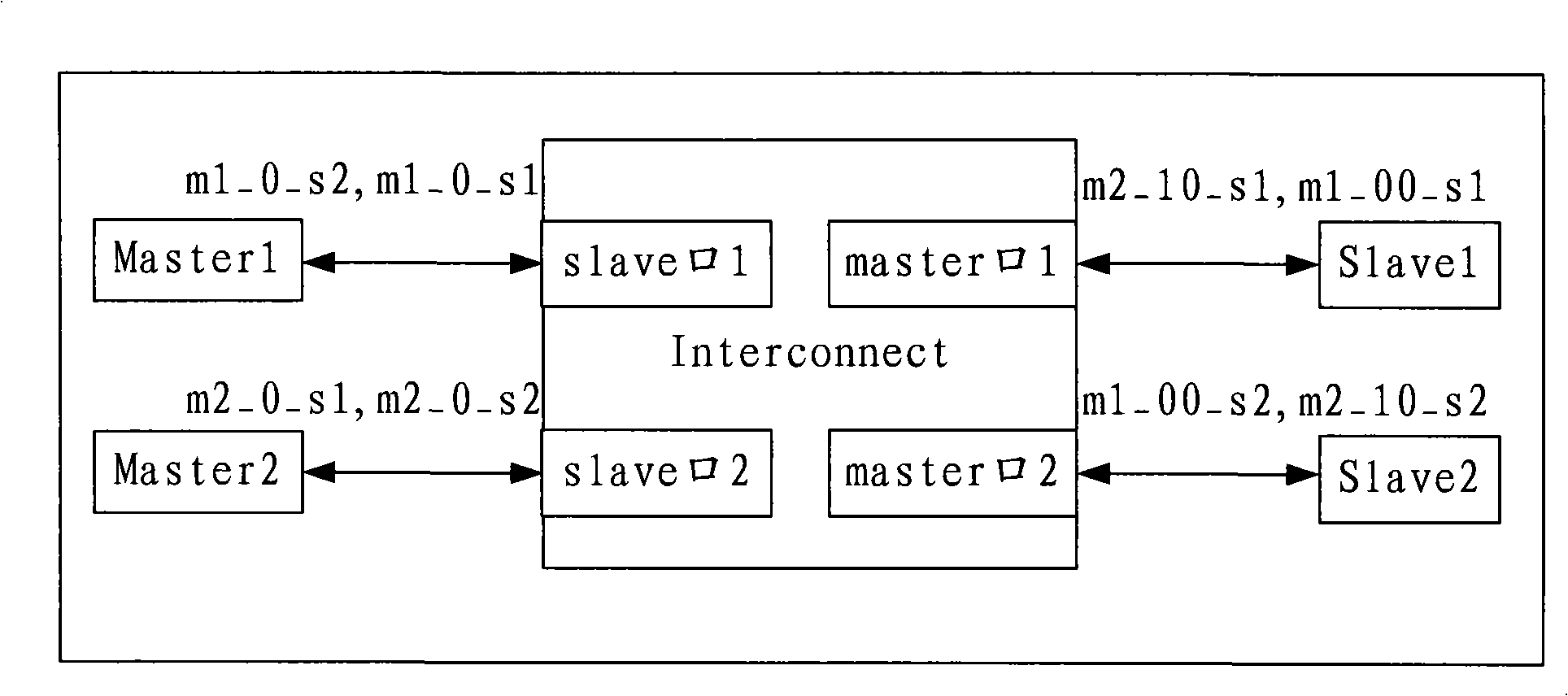

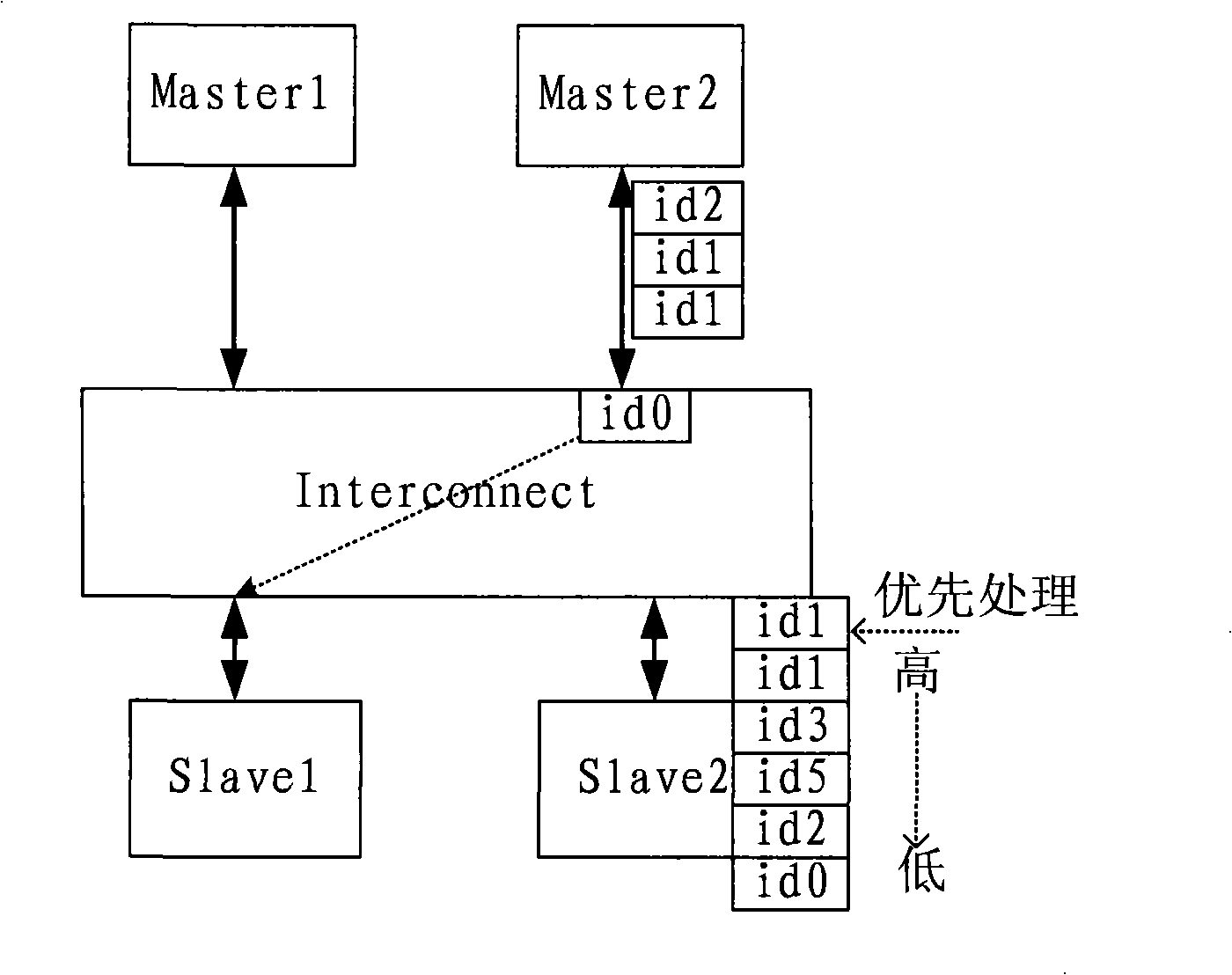

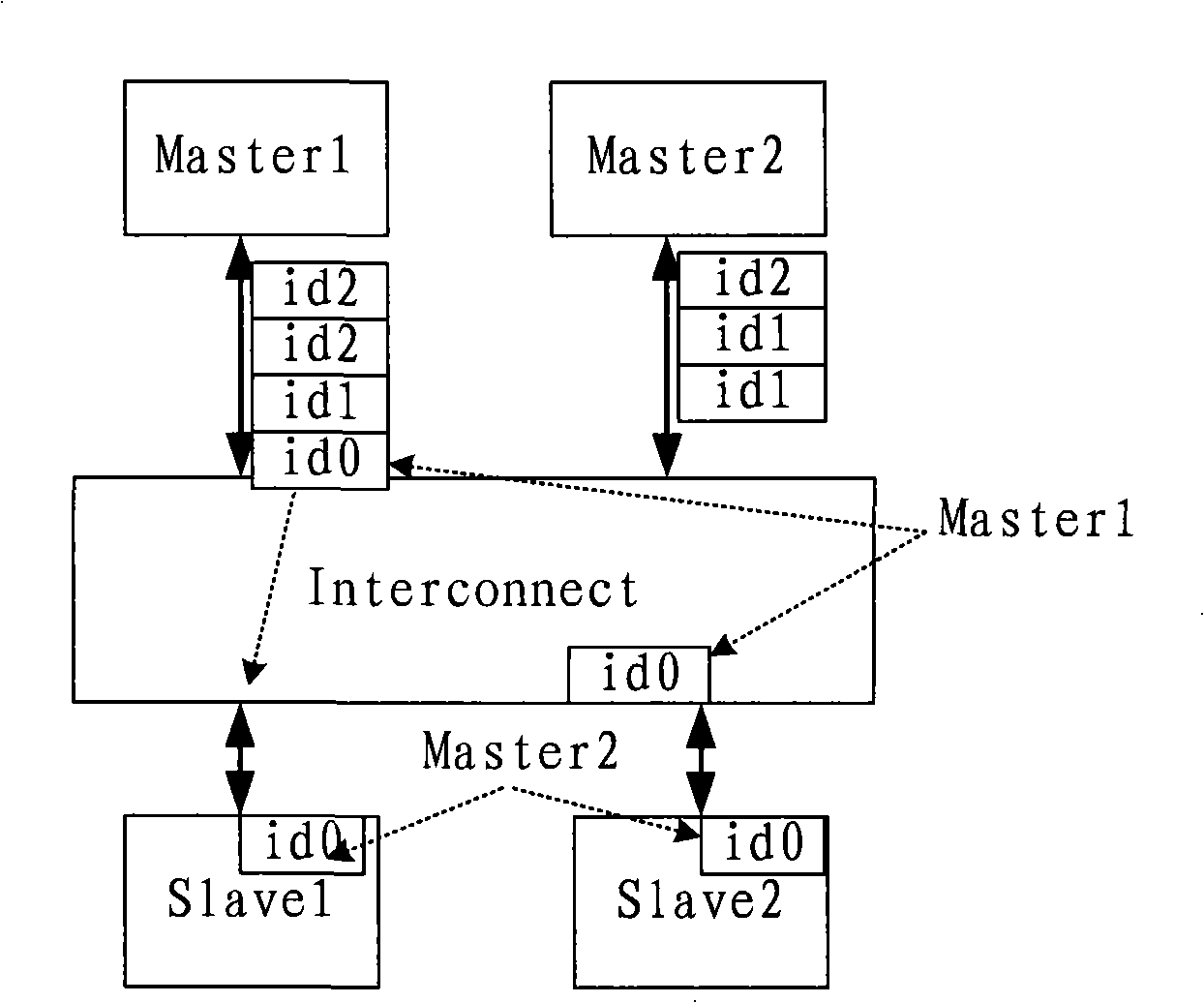

System bus deadlock prevention method, device and on-chip system

ActiveCN101308477AProcessing speedGuaranteed processing speedElectric digital data processingEmbedded systemDeadlock

An embodiment of the invention discloses an anti-deadlock method, a device and an on-chip system of a system bus and relates to the on-chip system technical field to solve the problem that the existing deadlock prevention technology can affect the performance of the system bus to a greater extent. The embodiment of the invention blocks the operations which can possibly cause deadlock, and by sending a priority improving command, the embodiment helps the equipment to speed up the processing speed of the previously sent operation command which causes deadlock root. The embodiment of the invention is mainly used in the bus-required systems or equipment, such as AXI system bus.

Owner:HONOR DEVICE CO LTD

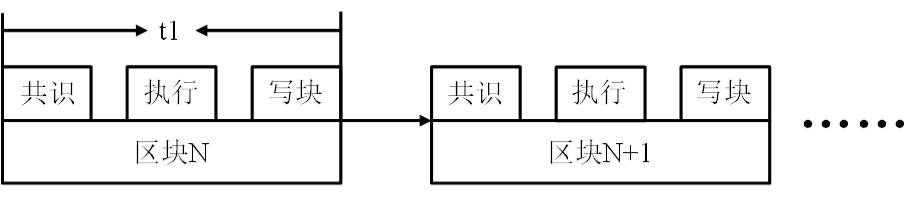

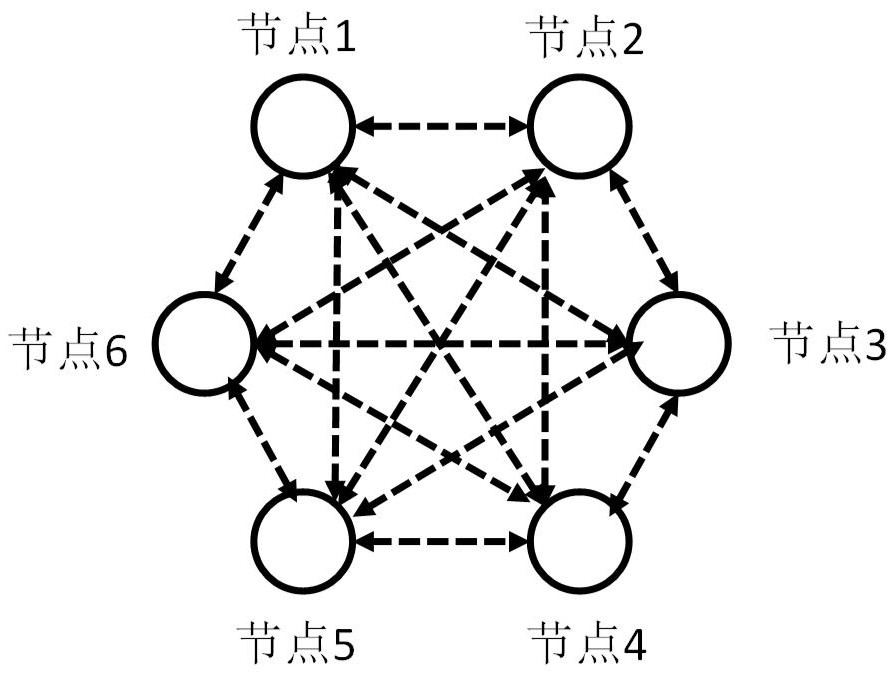

New construction of block chain and its consensus algorithm

The invention discloses a novel block chain structure and a consensus algorithm thereof, which relates to the technical field of the bottom layer of the block chain and is used for solving the problems of slow block efficiency and insufficient security of the existing block chain, comprising a plurality of nodes; And generating a plurality of blocks numbered sequentially N; The invention is characterized in that: the node comprises a block-out node and a verification node; The out-block node is used for receiving and buffering the signatures of other nodes to the previous block (number N-1); The verification node verifies the received transaction information and signs and broadcasts the verified transaction. The node alternately generates blocks in sequence, and if the node is unable to generate blocks, the number of the blocks is skipped. Using the characteristics of block chain to improve the BFT class consensus algorithm, both the security and efficiency are improved.

Owner:夸克链科技(深圳)有限公司

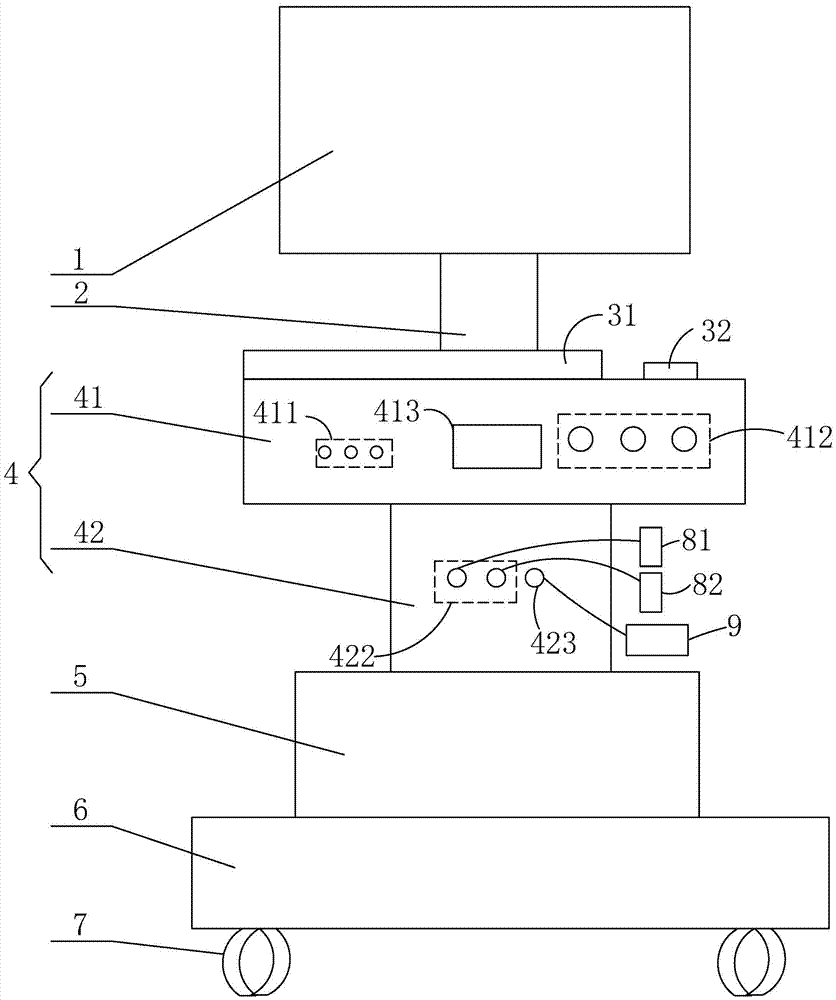

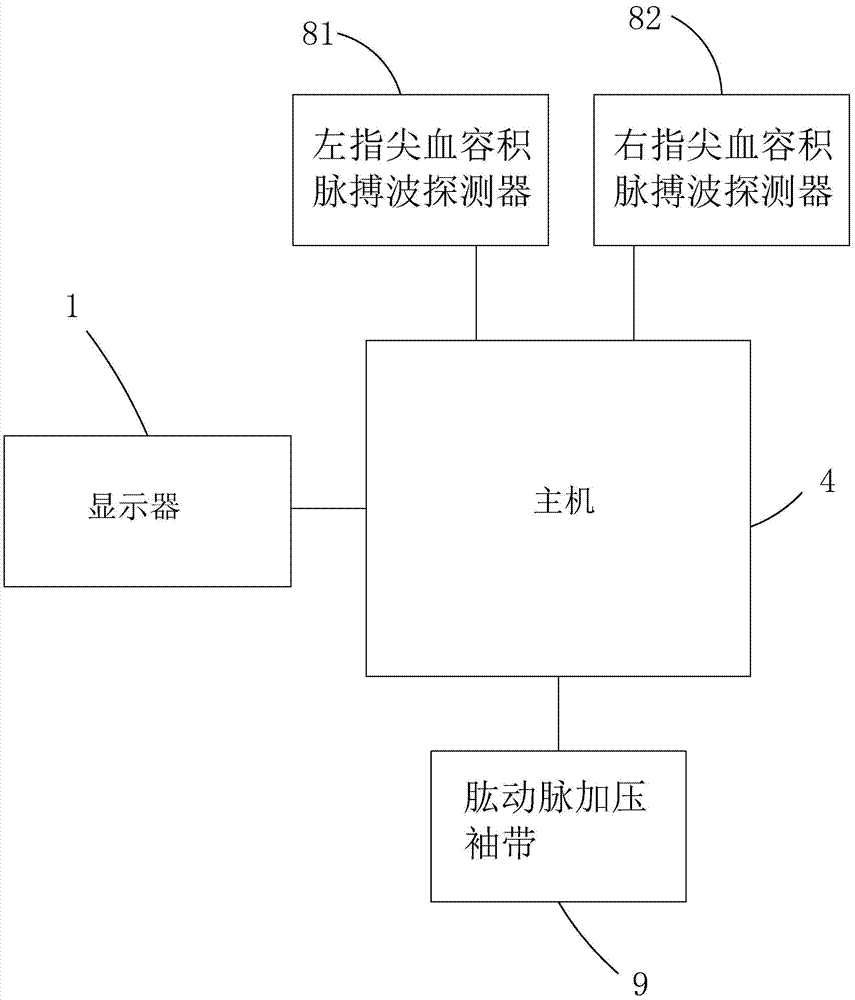

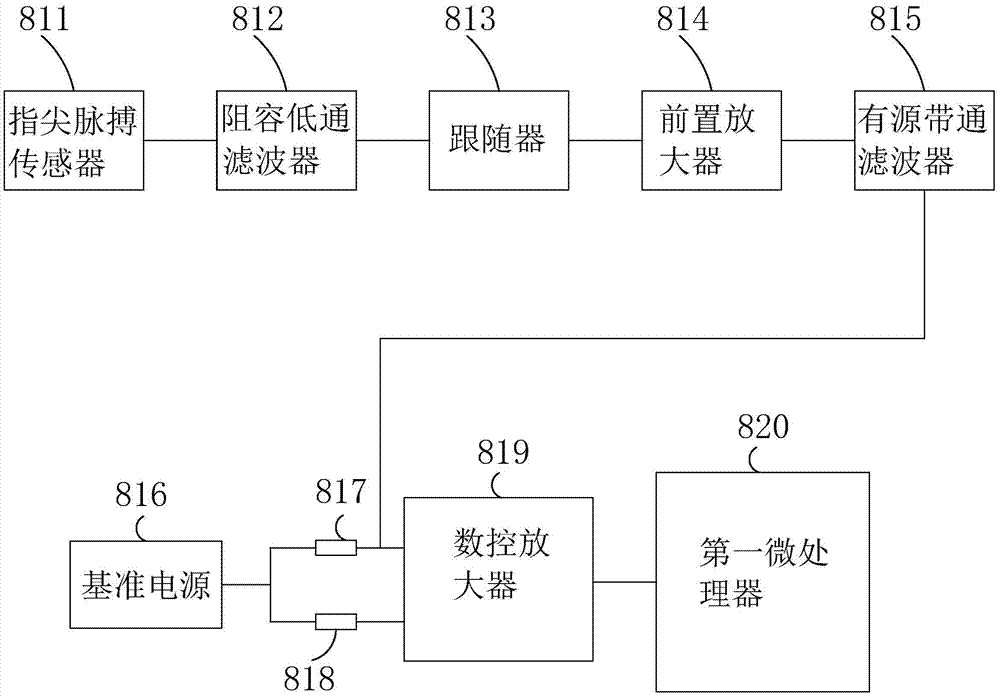

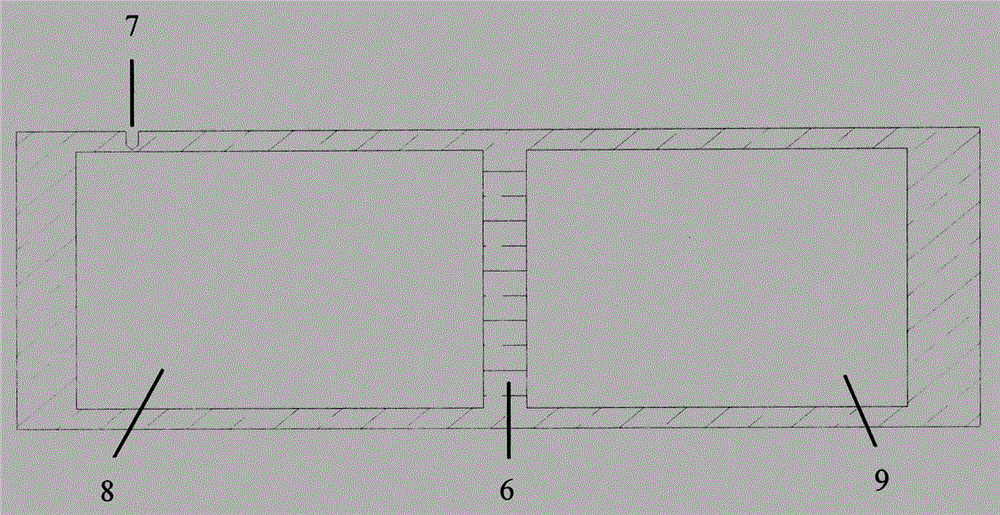

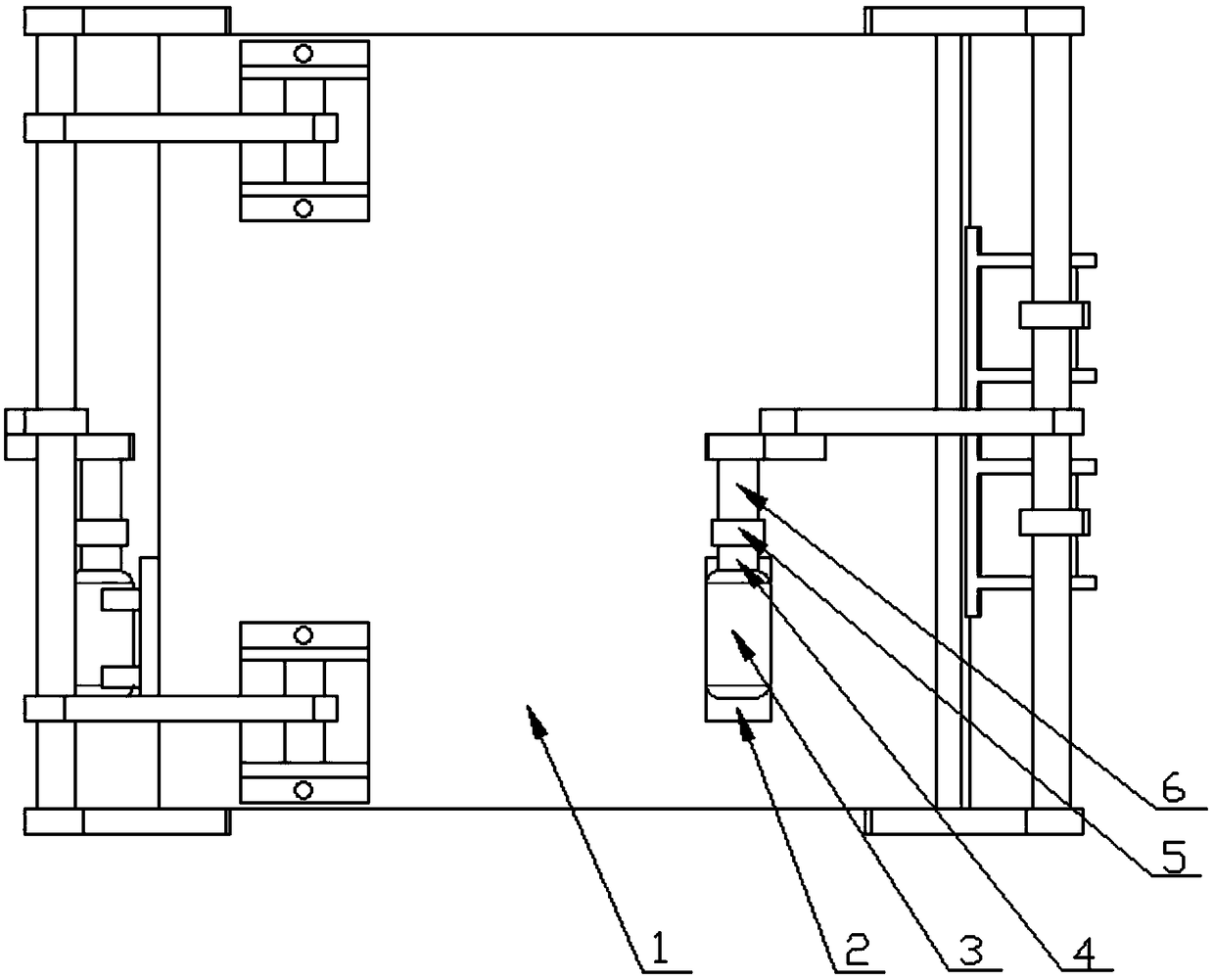

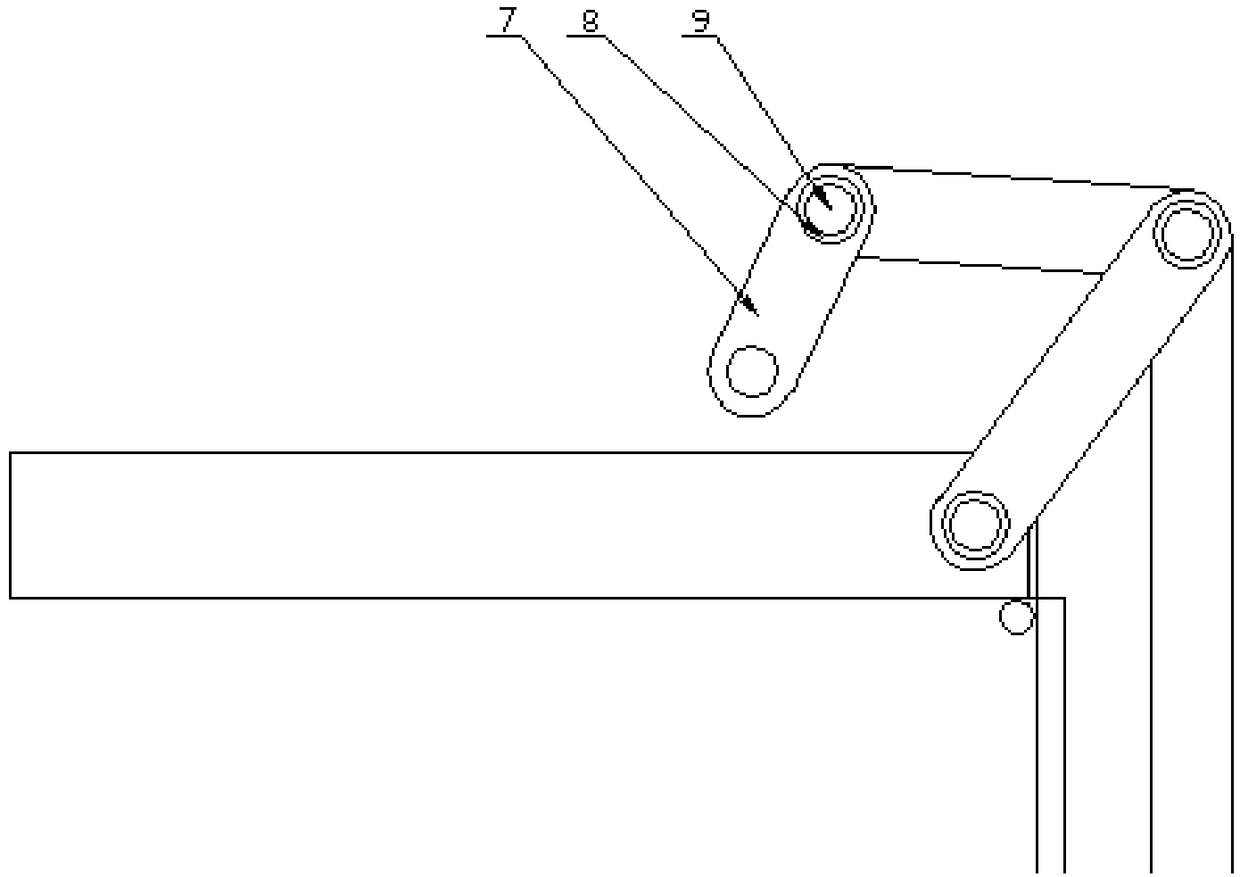

Vascular endothelial function evaluation and detection system and method based on FMD

InactiveCN105433985AShorten block timeReduce manufacturing costHeart/pulse rate measurement devicesDiagnostic recording/measuringBlood circulationBrachial artery

The invention provides a vascular endothelial function evaluation and detection system and method based on the FMD. The blood volume pulse wave of a left fingertip and the blood volume pulse wave of a right fingertip are collected through a left fingertip blood volume pulse wave detector (81) and a right fingertip blood volume pulse wave detector (82) respectively. Pressurization is conducted on the brachial artery of a left arm or a right arm through a brachial artery pressurization cuff (9) so that blood circulation of the left arm or the right arm can be blocked. A host (4) calculates the vascular endothelial function situation index according to the changes of the left fingertip blood volume pulse wave area and the right fingertip blood volume pulse wave area before and after pressurization blocking of the brachial artery, the vascular endothelial function can be comprehensively evaluated, the blocking time of the brachial artery is shortened, and the system production cost is reduced.

Owner:SHENZHEN QIANHAI SHENGYEER MEDICAL ELECTRONICS BIOTECH CO LTD

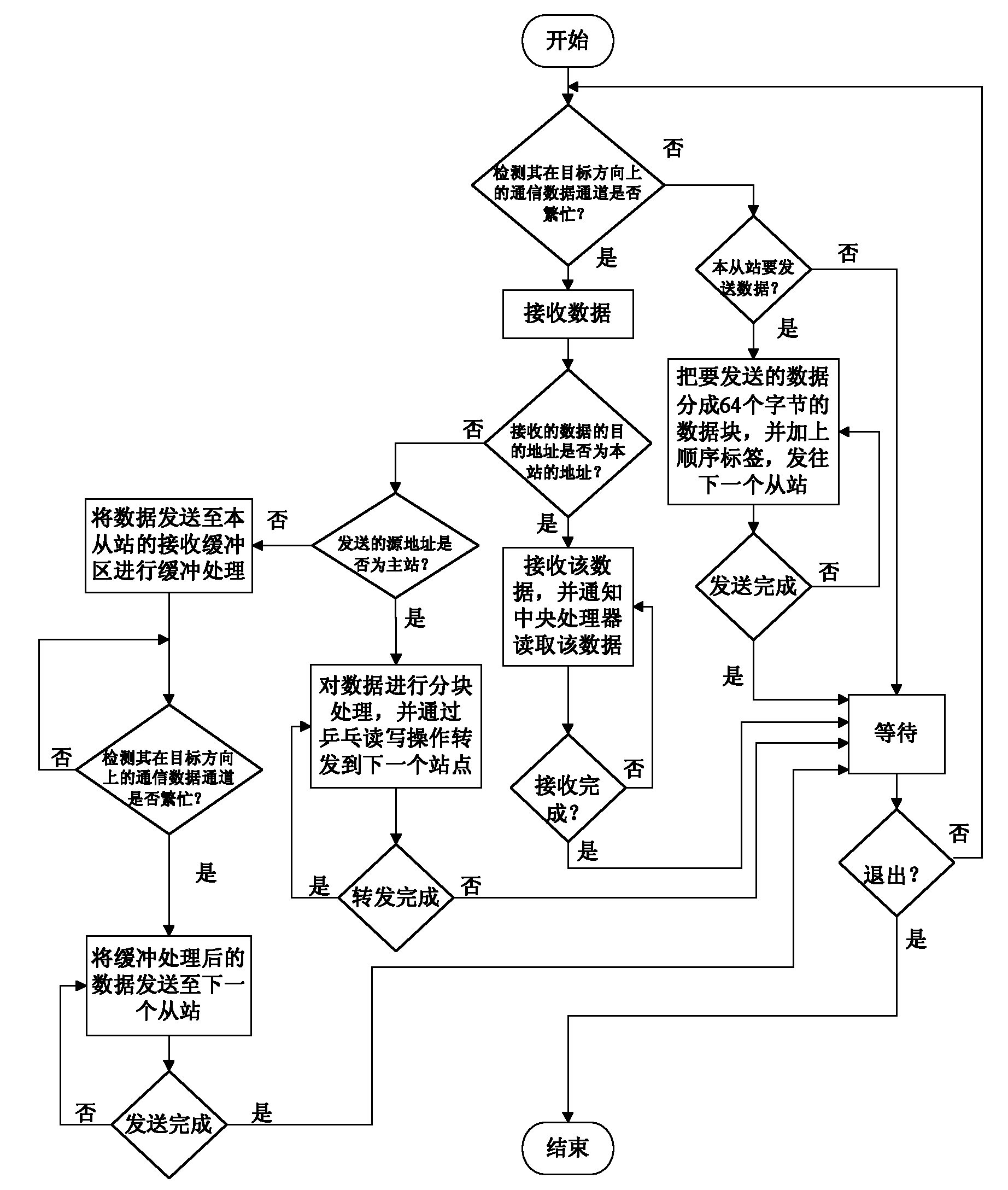

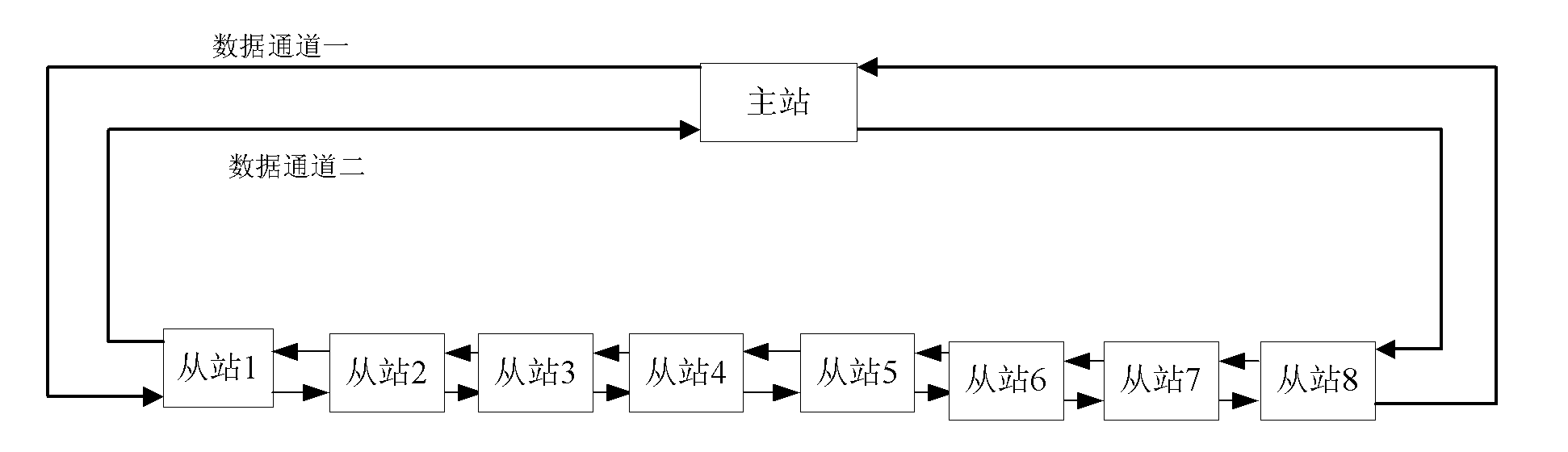

Method for implementing mutual communication of slave stations of high-speed field bus

ActiveCN101945031AImprove data exchange speedEasy data collectionError preventionBus networksCommunications systemWait state

The invention provides a method for implementing mutual communication of slave stations of a high-speed field bus. The method comprises the following steps of: (1) detecting whether a communication data channel of a slave station in the target direction is busy or not by the slave station; if so, receiving data transmitted on the communication data channel, and processing the data, otherwise, performing the next step; (2) judging whether the slave station transmits data thereof or not, if so, performing the next step, otherwise, entering a waiting state; (3) segmenting the data to be transmitted by the slave station, and transmitting the data to the next slave station; and (4) judging whether the data of the slave station is transmitted or not, if so, entering the waiting state, otherwise, continuously transmitting the data until the data is completely transmitted. The invention also provides a mutual communication system for the slave stations of the high-speed field bus for implementing the method. The invention can support direct mutual communication among the slave stations, and can greatly improve the data switch speed among the slave stations.

Owner:GSK CNC EQUIP

Water pressure composite quick blocking method applied in drilling and blasting

The invention discloses a water pressure composite quick blocking method applied in drilling and blasting. The quick blocking comprises a water bag, a dynamite roll, a water bag and a high-molecular resin sealing bag. the water bag of the first segment is placed at the bottom of a hole opening; the dynamite roll of the second segment is closely connected with the water bag in series; the water bag of the third segment is placed behind the dynamite roll of the second segment; the high-molecular resin material of the fourth segment is placed in a drilling after kneading, squeezing and foaming; the high-molecular resin material flows out as liquid and penetrates into the space among the dynamite, the water bags and socks; quick solidification is performed and blast holes are blocked. the viscosity of the high-molecular resin material with rocks is larger than that of traditional stemming. the impact wave produced by the explosion of the dynamite is directly applied on rocks through the water bag installed at the bottom of the blast hole and therefore the explosive energy consumption is reduced and blast hole utilization is increased. The water bags in the blast hole generates water atomization effect during explosion which can reduce air impact wave, absorb explosive dust and dilute poisonous gases.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

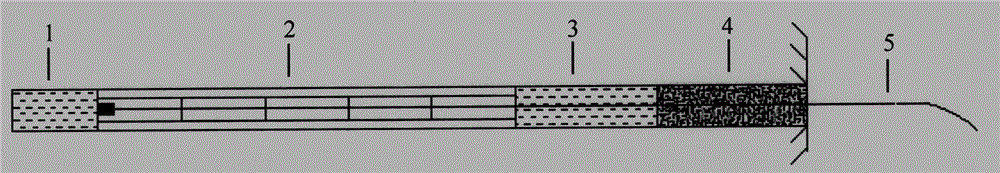

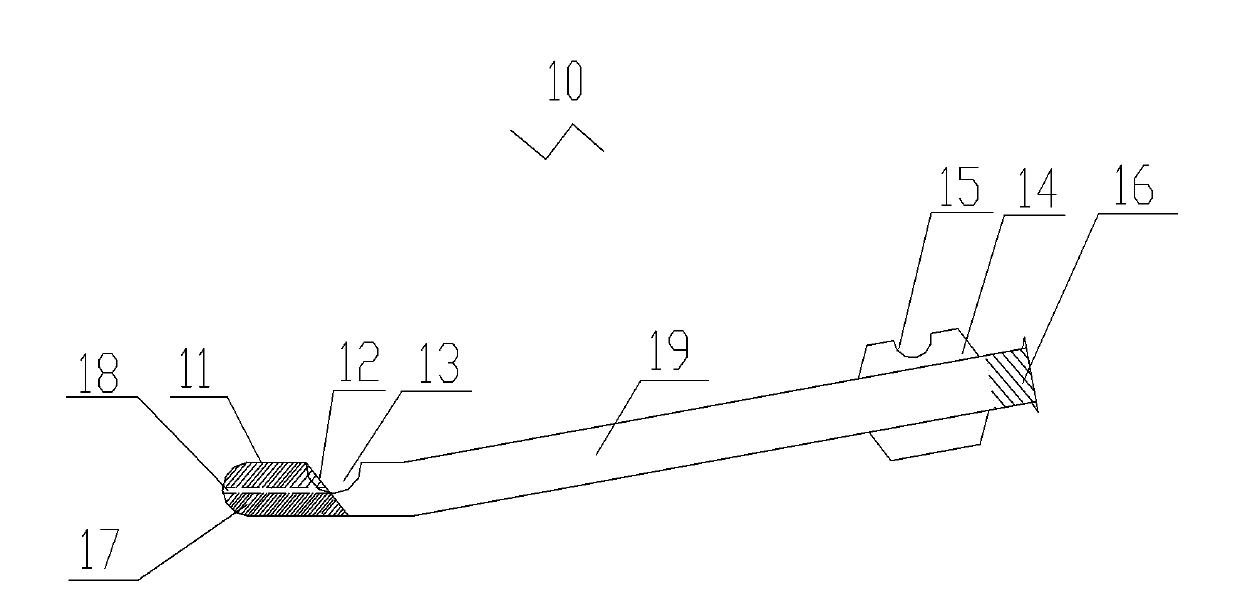

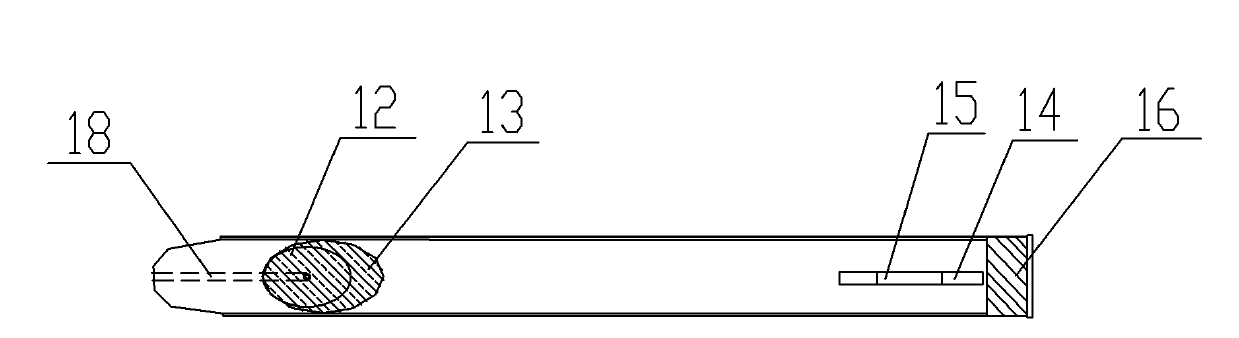

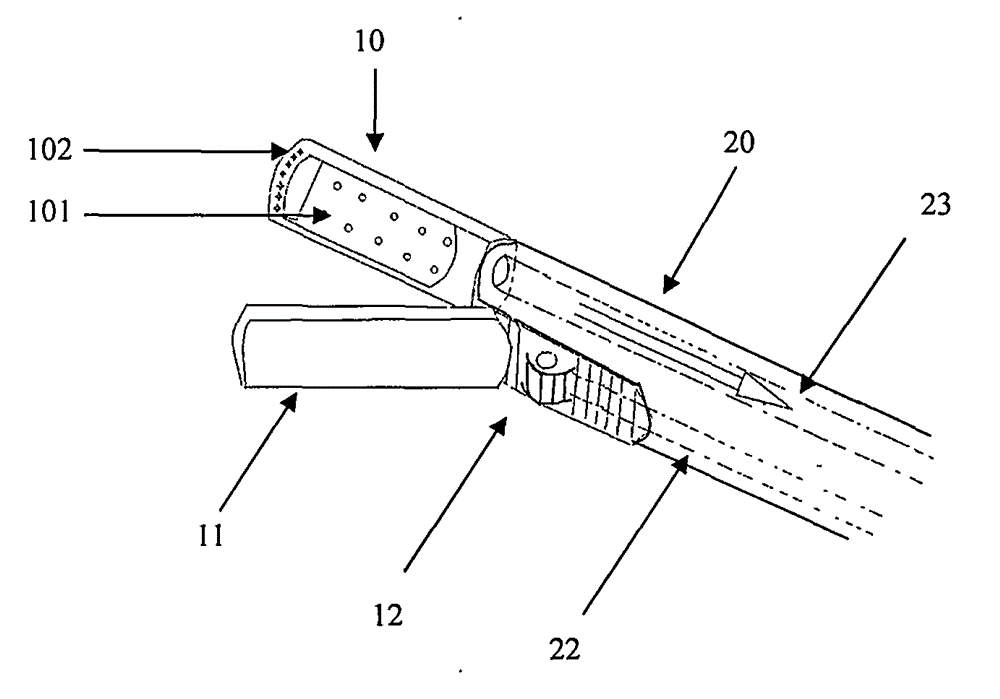

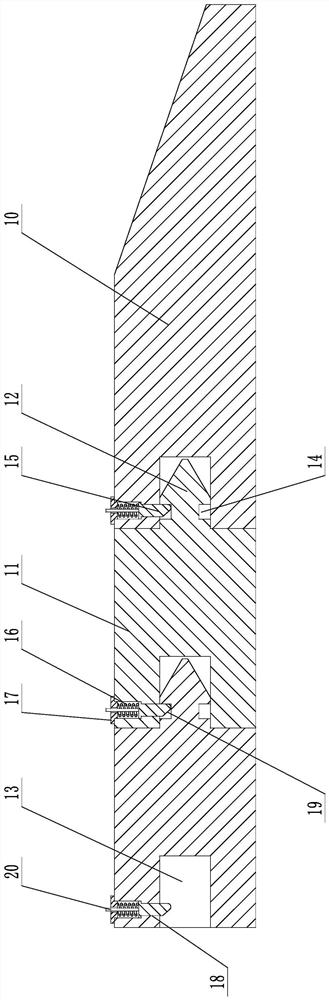

Occluder intervention conveying device

The invention discloses an occluder intervention conveying device, which comprises an outer sheath, an outer sheath inner core, an inner sheath and a hemostasis valve, wherein the outer sheath comprises an outer sheath head end, an outer sheath body and a tail end opening; the outer sheath head end is provided with a side opening; an inner structure of the part over against the side opening is a turning inclined surface; the inner sheath is inserted in the outer sheath body and penetrates through the side opening to be turned; the hemostasis valve is used for being connected with the tail endopening of the outer sheath in a buckling manner; and the outer sheath inner core is used for being placed in the outer sheath body as a support when the outer sheath is punctured. According to the occluder intervention conveying device disclosed by the invention, the occluder conveying operation can be realized by ultrasonic guidance, the operation process has no radioactive wound and drug injury on staffs without radiography, the outer sheath with a turn angle leads to the inner sheath to make a turn in the heart, the punctured part does not need to be oppressed and braked to stop bleeding,the post-operative patient can walk immediately, the post-operative recovery speed is quick and the operation pathway is short; in addition, the occluding steps are simplified, the occluding time is saved, the occluding firmness and stability can be guaranteed, the radioactive radiography equipment is not needed and the medical cost is low.

Owner:SHANGHAI MICROPORT RHYTHM MEDTECH CO LTD

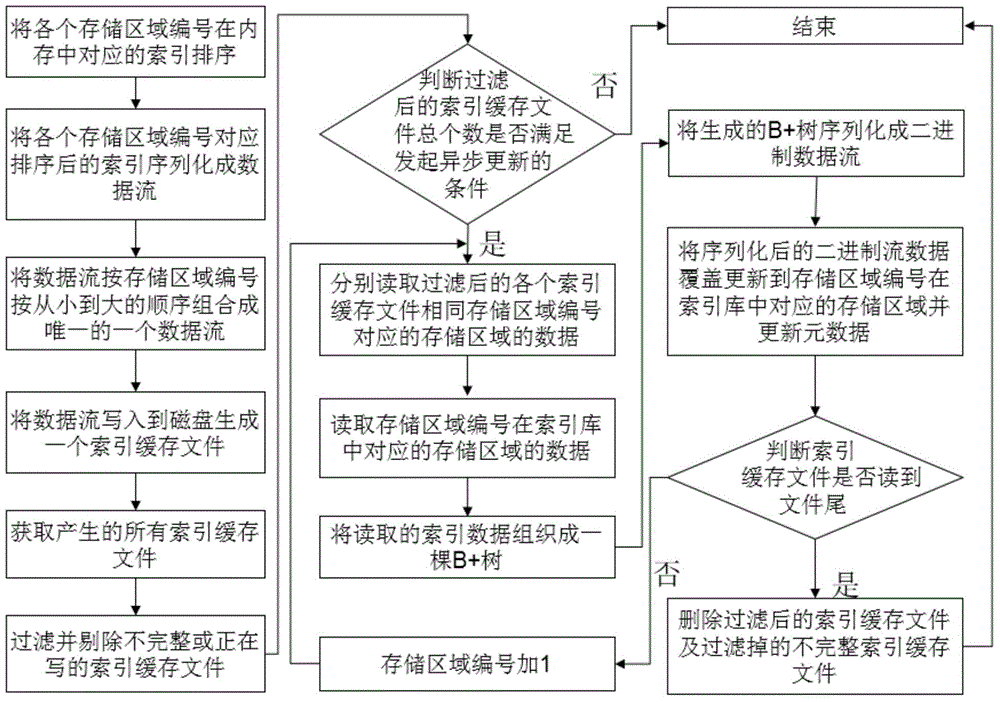

Read optimization method for asynchronously updating indexes based on B+ tree

ActiveCN104408128AReduce data volumeImprove query performanceSpecial data processing applicationsOperating systemB+ tree

The invention relates to a read optimization method for asynchronously updating indexes based on a B+ tree. The read optimization method comprises the steps of 1) generating index cache files, 2) obtaining all the index cache files, 3) filtering and removing incomplete or being-written index cache files, 4) determining whether the condition of initiating asynchronous update is satisfied, and if so, continuing the performing of the step 4), 5) reading index data in memory areas corresponding to the same memory area number of each filtered index cache file, respectively, 6) reading index data in memory areas corresponding to memory area numbers in an index library, 7) organizing the index data into a B+ tree according to the rule of the B+ tree, 8) serializing the B+ tree generated in the step 7) into a binary system stream, and 9) performing coverage and update of the data processed in the step 8) into the memory areas corresponding to the memory area numbers in the index library. Compared with the prior art, the read optimization method for asynchronously updating the indexes based on the B+ tree has the advantage of reducing the index data size inquired and read from mass index records each time.

Owner:EISOO SOFTWARE

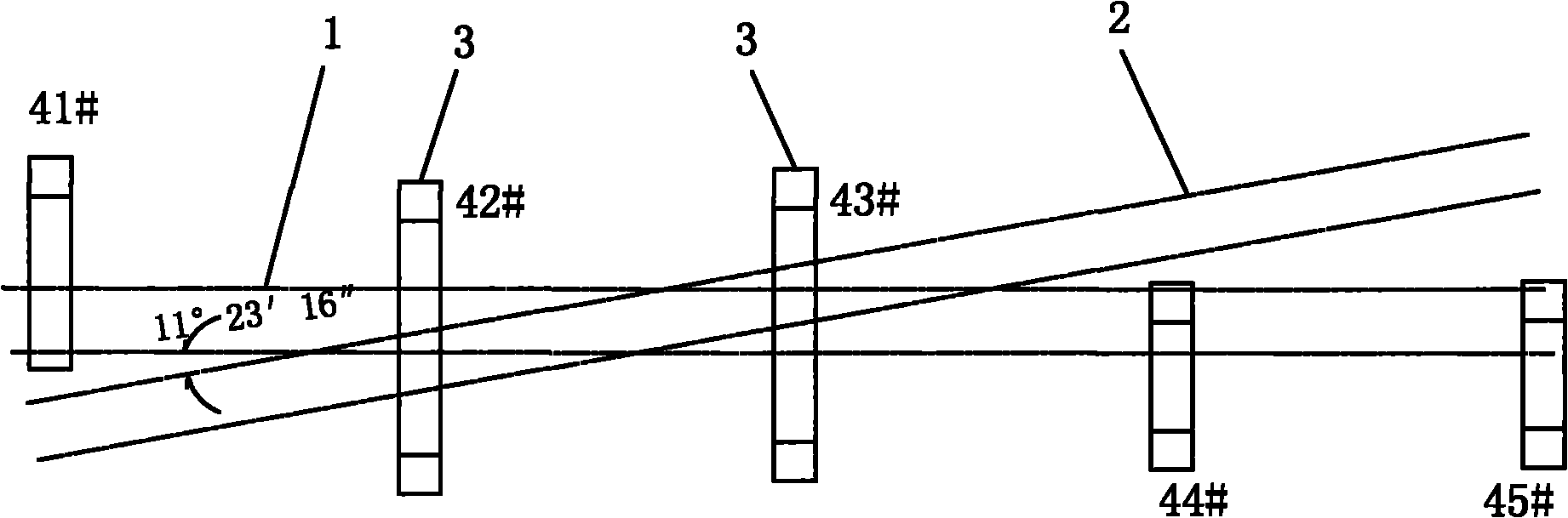

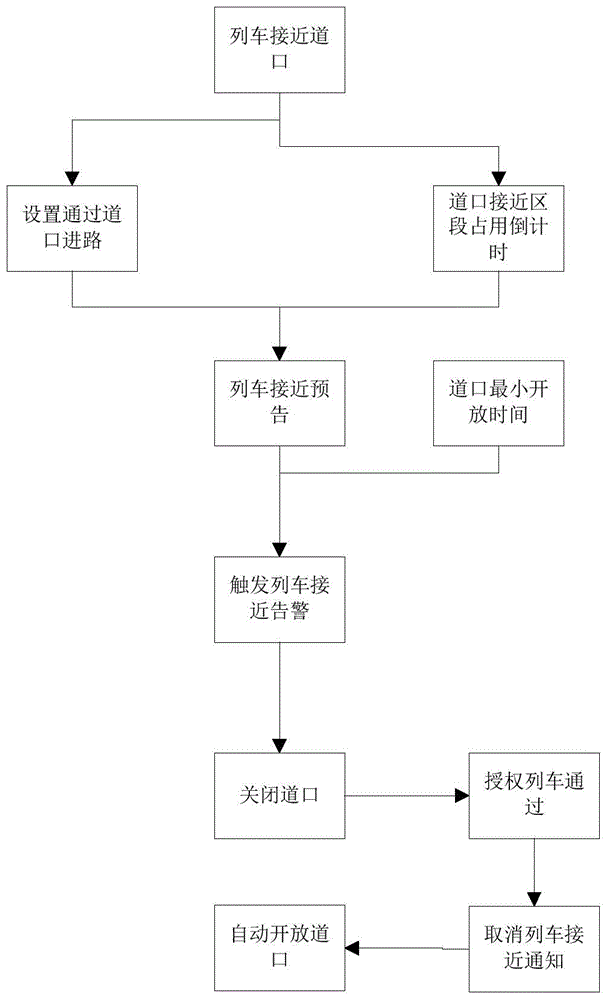

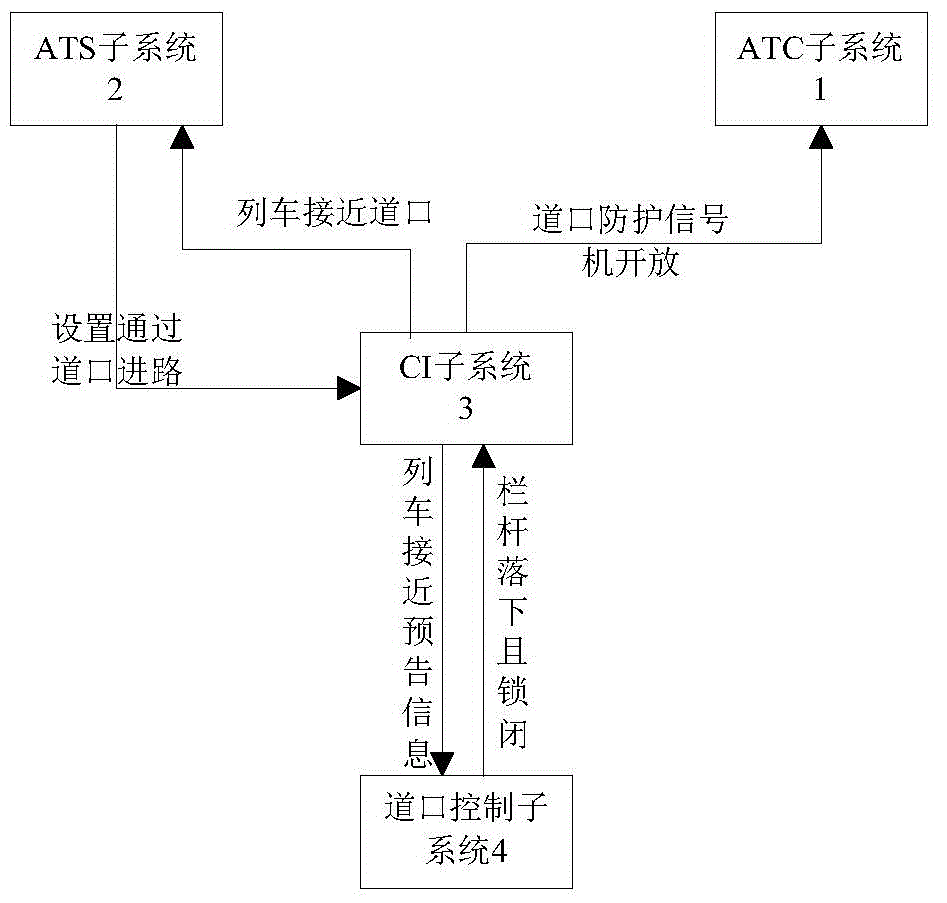

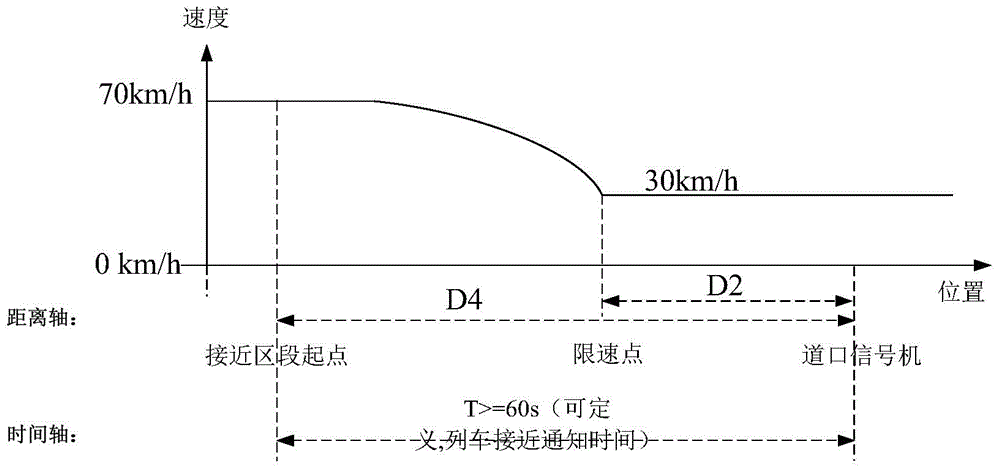

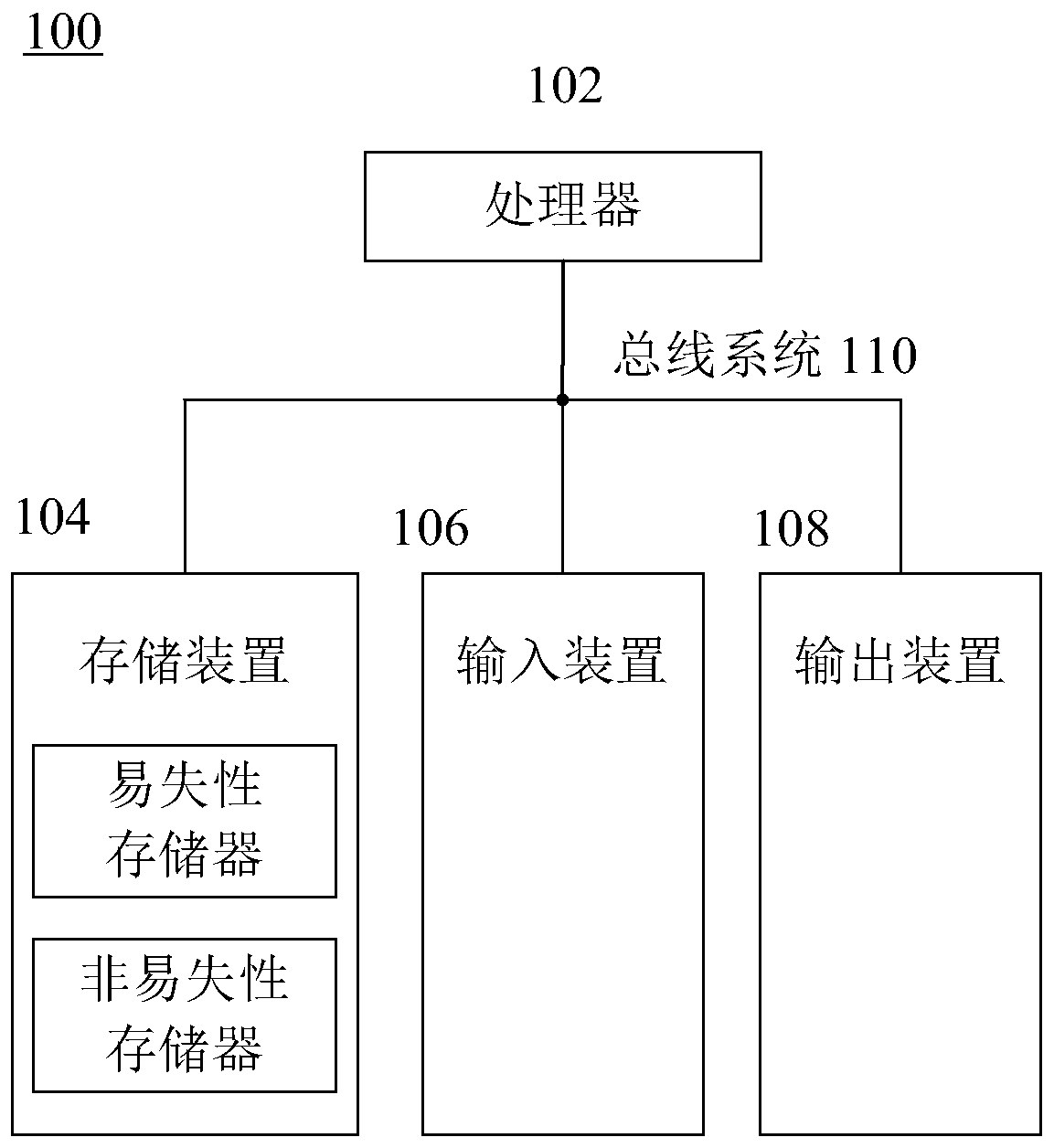

Crossing control method and system for urban rail transit

The invention relates to a crossing control method for an urban rail transit. The method comprises the steps of 1) when a train is close to a crossing, an ATS subsystem sending a setup instruction of entering a path through the crossing to a CI subsystem; 2) after the crossing occupied by the train is judged to be close to a section and the condition that a delay timer counts to zero, sending a train approaching message; 3) closing a road annunciator, meanwhile prompting a crossing terminal to close a rail, and lowering the rail after the crossing terminal confirms that the crossing is clear; 4) lowering the rail and sending a closing message to the CI subsystem; 5) automatically starting a crossing protection annunciator; 6) authorizing the train to pass the crossing after an opening message from the crossing protection annunciator; 7) after the train passes the crossing, removing the train approaching message and sending to the crossing control subsystem; and 8) lifting the rail. Compared with the prior art, the crossing control method for the urban rail transit has the advantages of precisely locating the position of the approaching triggering informing point, optimizing the crossing occupation time of the rail transit train, automatically managing the crossing informing messages and the like.

Owner:CASCO SIGNAL

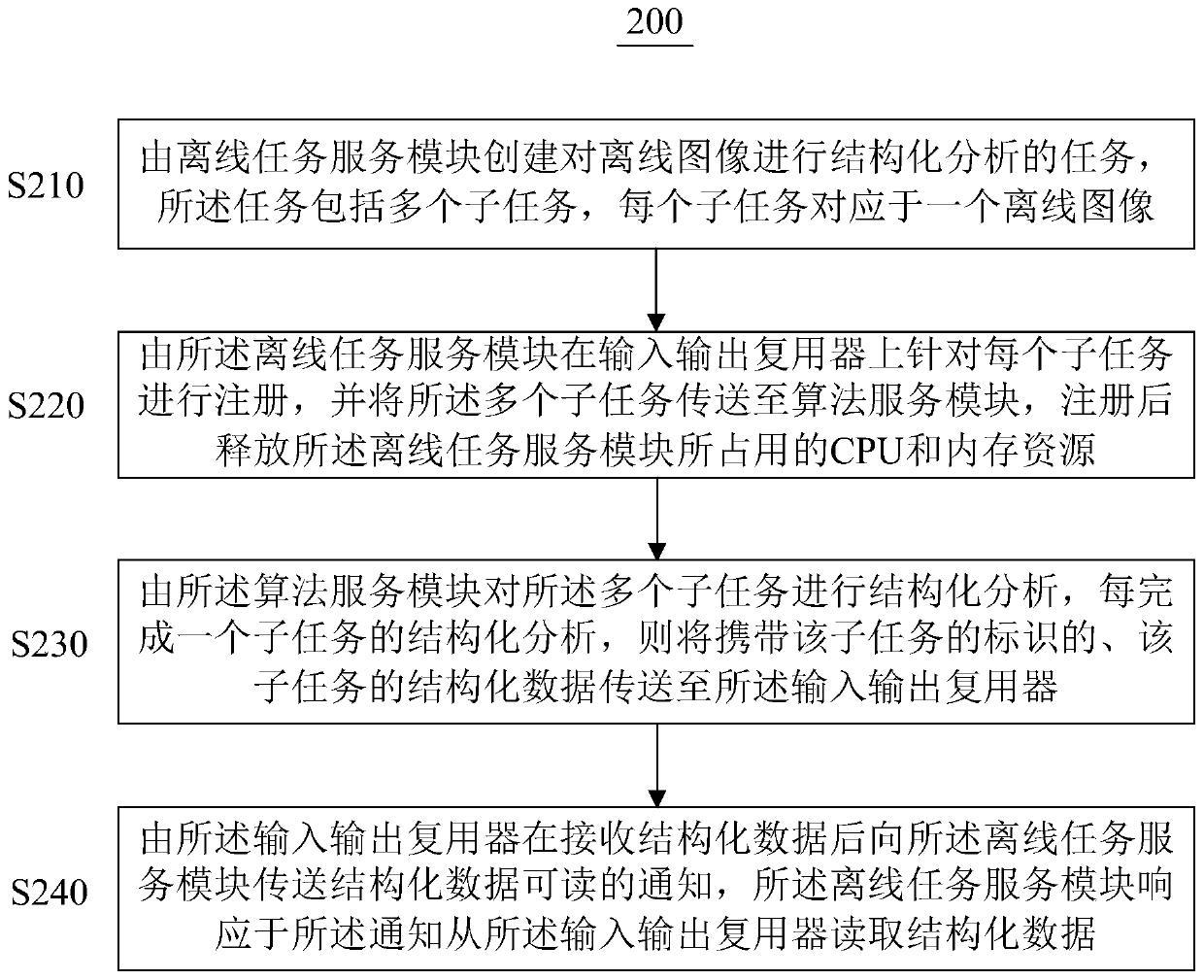

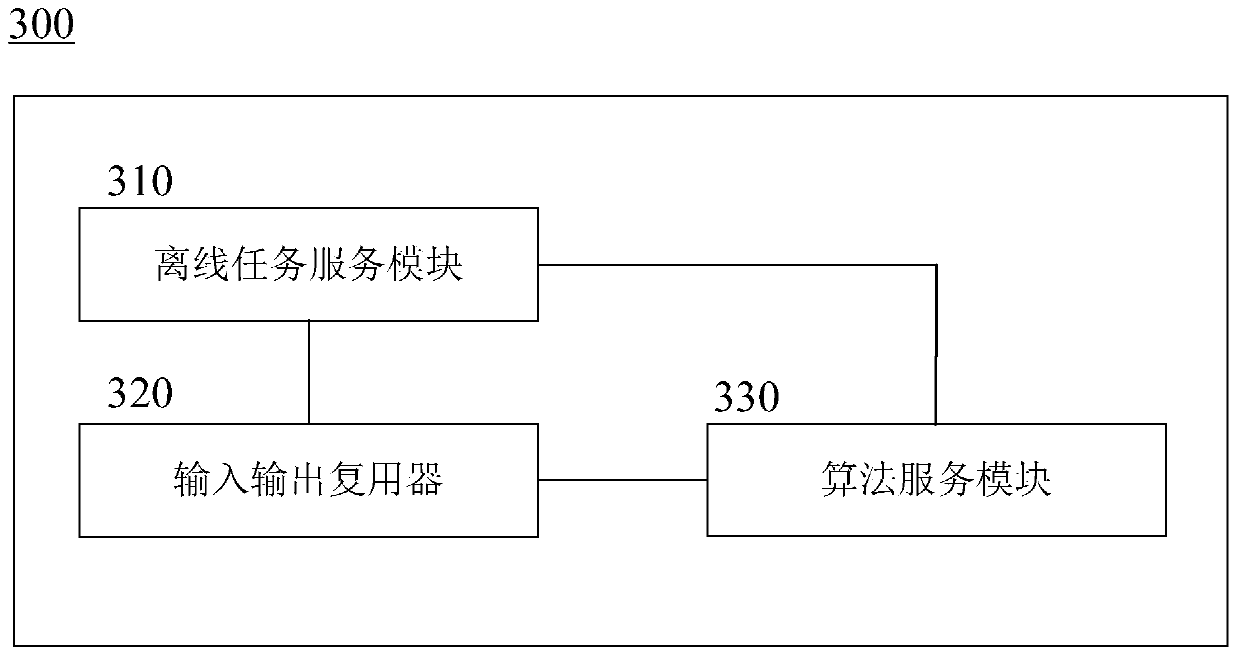

Offline image structured analysis method, device, system and storage medium

ActiveCN110413822AIncrease profitReduce block timeDigital data information retrievalProcessor architectures/configurationMultiplexerStructural analysis

The invention provides an offline image structured analysis method, a device, a system and a storage medium. The method comprises the steps that an offline task service module creates a task for performing structural analysis on an offline image; the offline task service module registers each subtask on the input / output multiplexer, transmits the plurality of subtasks to the algorithm service module, and releases CPU and memory resources after registration; the algorithm service module carries out structural analysis on a plurality of subtasks, and transmits structural data of the subtasks carrying identifiers of the subtasks to the input and output multiplexer every time the structural analysis of one subtask is completed. After receiving the structured data, the input / output multiplexertransmits a notification that the structured data is readable to an offline task service module, which reads the structured data from the input / output multiplexer in response to the notification. According to the offline image structural analysis scheme, IO blocking time is shortened, and the performance of a structural analysis task is optimized.

Owner:BEIJING KUANGSHI TECH

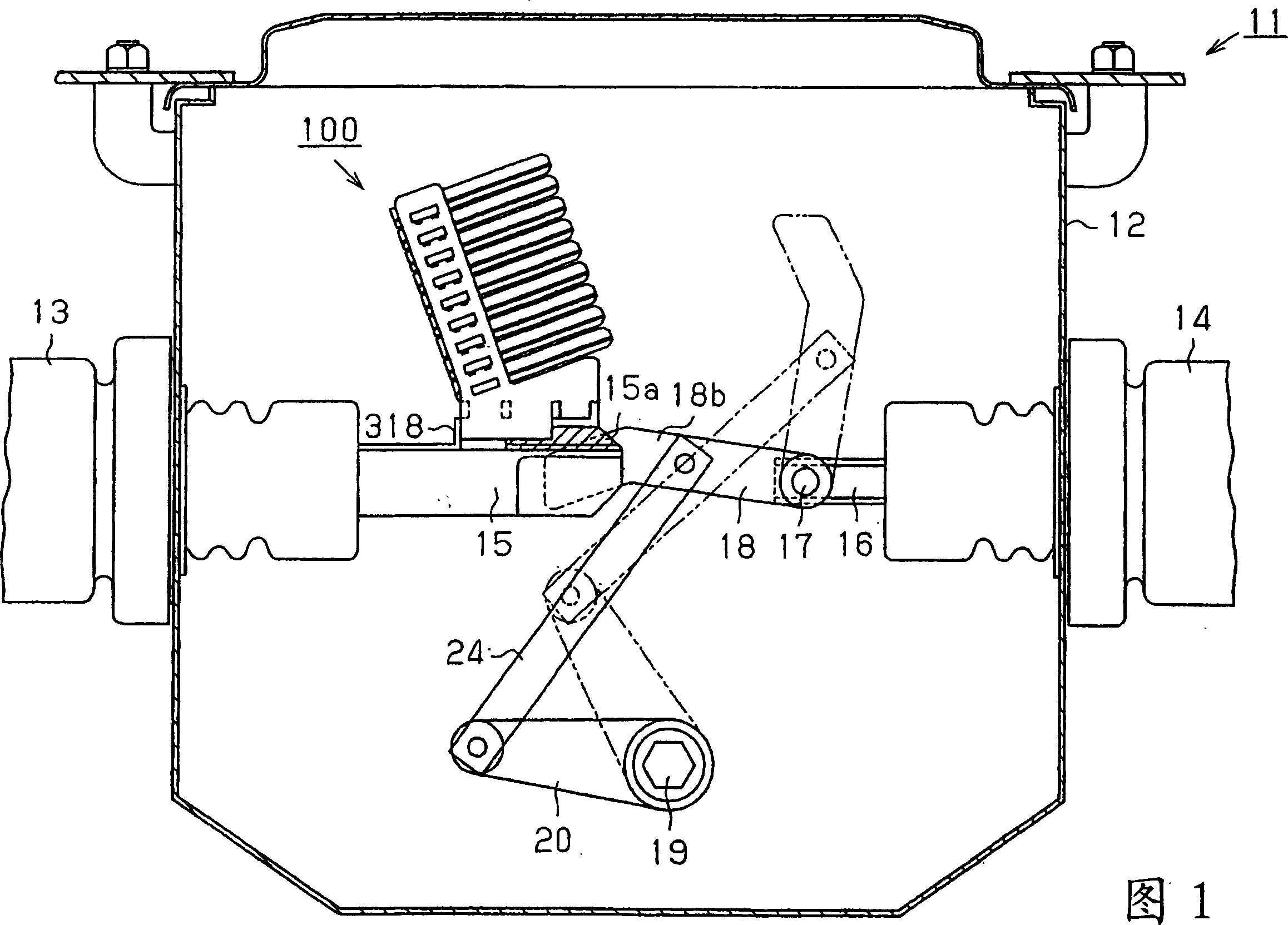

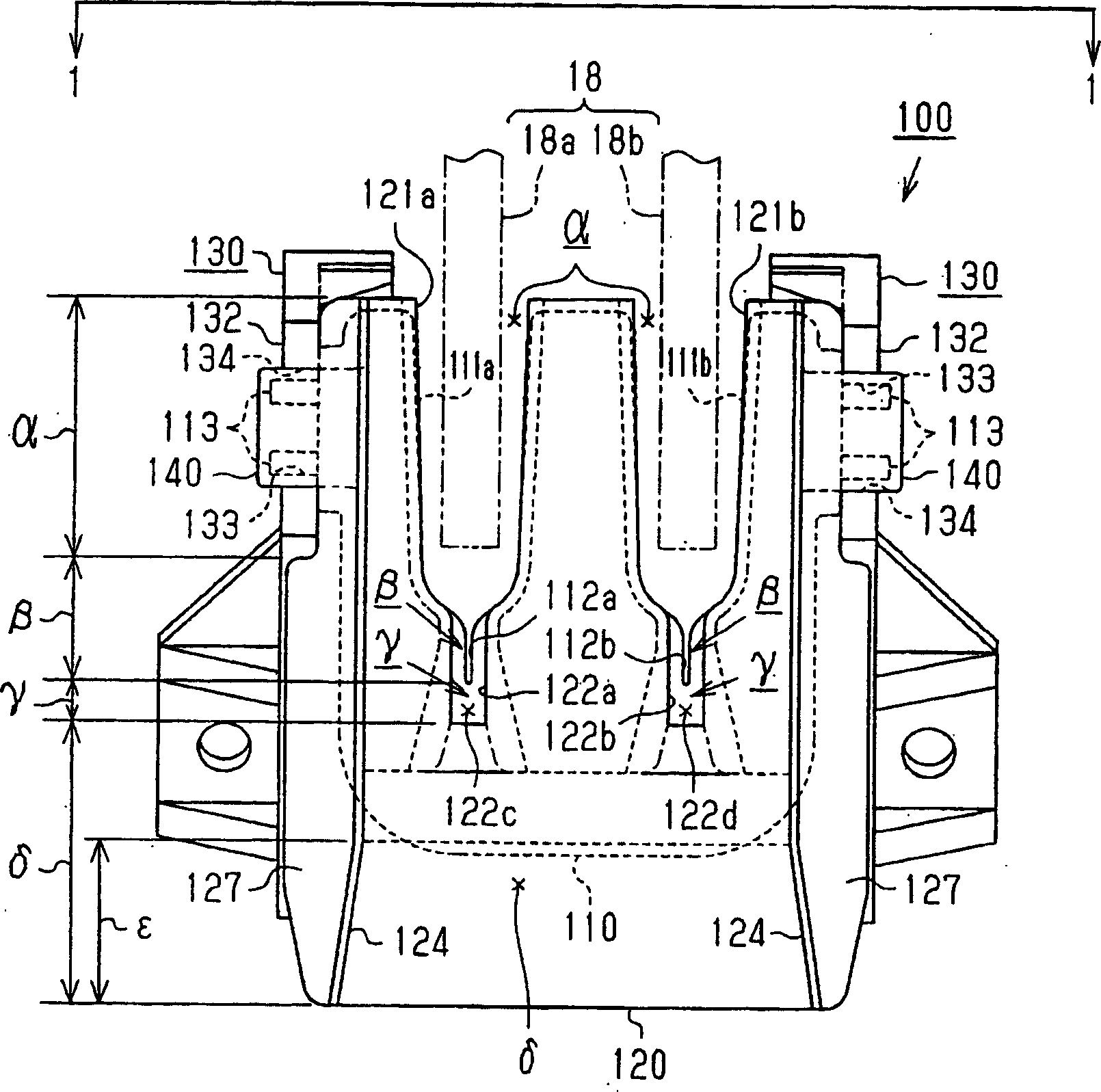

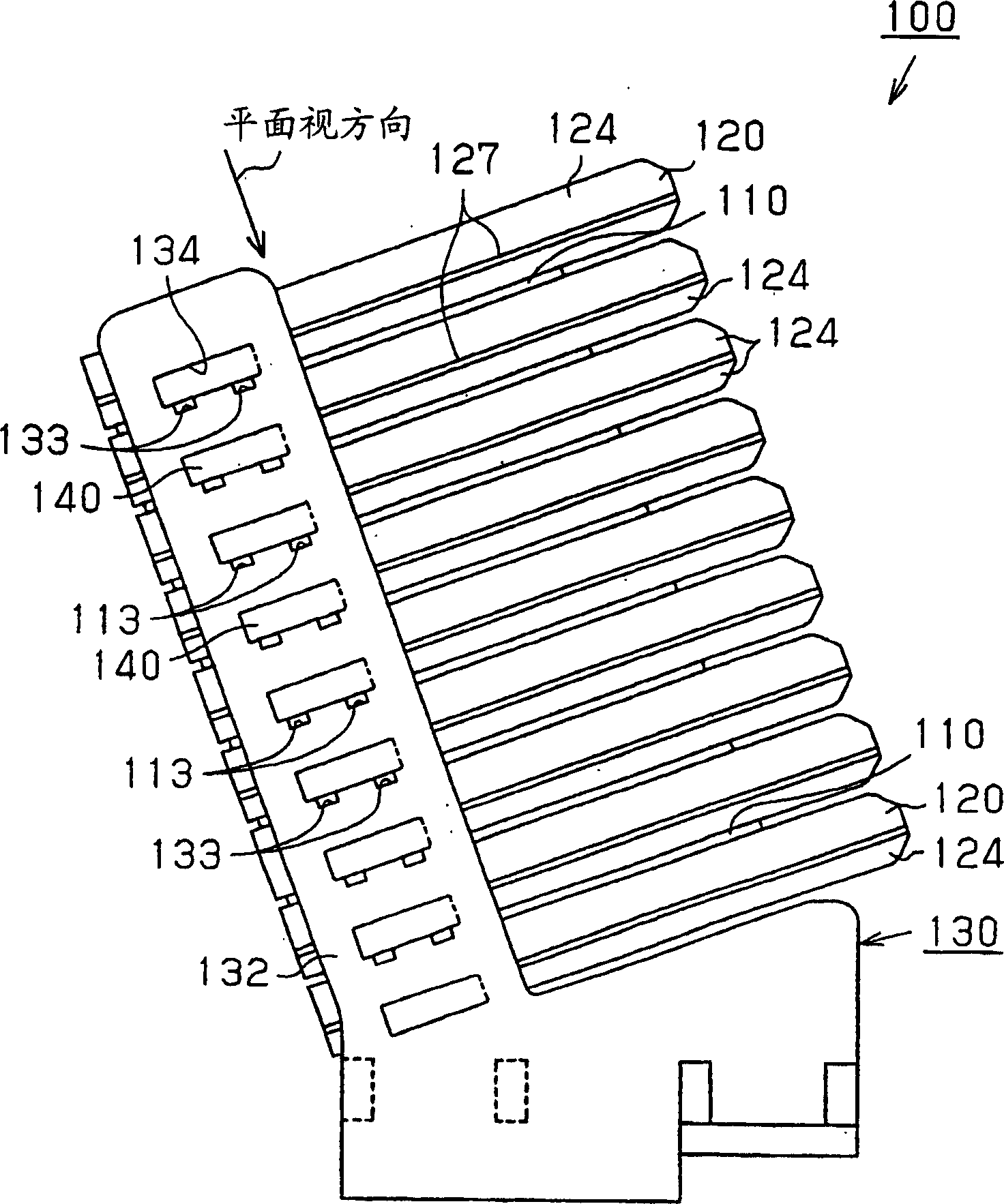

Arc arrester and switch having same

InactiveCN1499552AEliminate arcing in high and low current rangesImprove the performance of arc suppressionHigh-tension/heavy-dress switchesAir-break switchesContact timeElectric arc

Provided is an arc extinguishing device capable of extinguishing an arc not only at a high-current zone but also at a low-current zone by improving an arc extinguishing performance. A grid 110 having grid channels 111a, 111b and an arc extinguishing member 120 having arc extinguishing member channels 121a, 121b are alternately arrayed at a given interval in a moving direction of a movable electrode. The movable electrode is made to pass the grid channels 111a, 111b and the arc extinguishing member channels 121a, 121b sequentially at open channels. Narrow grooves 112a, 112b are formed at the innermost part of the grid channels 111a, 111b. When the channels are opened, the arc is attracted and fixed to (restrained by) the narrow grooves 112a, 112b. Especially, by restraining the arc of the low-current zone in the circuit interrupter 100, a contact time of the arc with an arc extinguishing decomposition gas generated from the arc extinguishing member 120 is secured. As a result, an arc of the low current zone can also be promptly extinguished.

Owner:ENERGY SUPPORT CORP

Self-blocking descender-belay device

Owner:ETAB LUDGER SIMOND

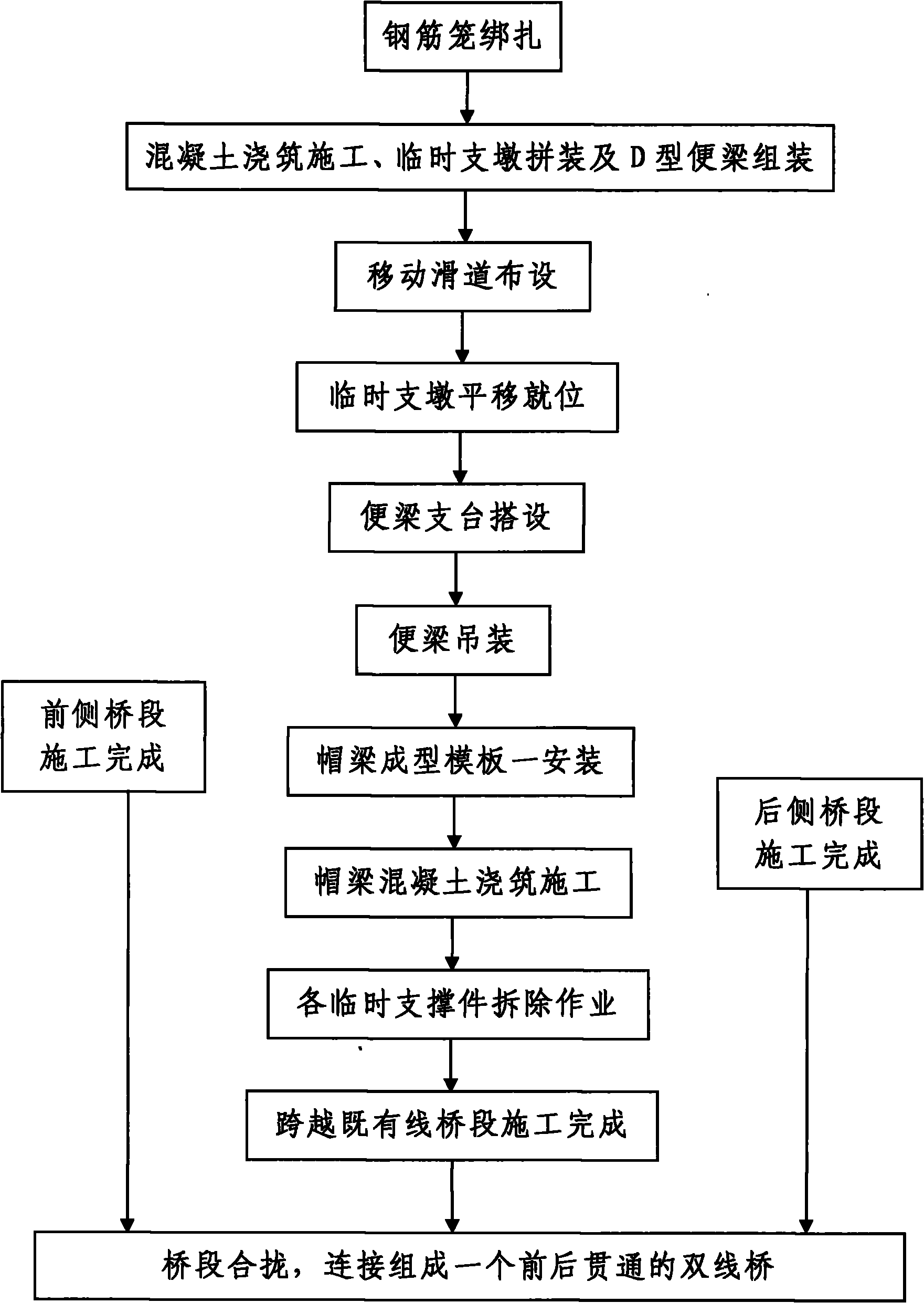

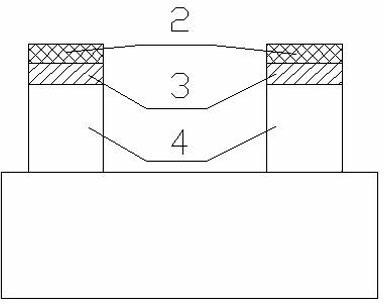

A construction method for reconstruction of old bridge piers

ActiveCN102286940AReduce the impactLow costBridge erection/assemblyBridge strengtheningSocial benefitsMechanization

The invention relates to a construction method and in particular relates to a construction method for remoulding old pier columns of bridges. The construction method at least comprises the following steps: cutting and removing column bodies at the top end parts of the old pier columns, sleeving steel boxes at the upper ends of the old pier columns from which the column bodies at the top end partsare removed, packaging cover plates at the openings on the steel boxes and grouting the gaps between the cover plates and the top ends of the old pier columns via reserved grouting holes on the coverplates. The construction method has the following advantages: the degree of mechanization is high, thus accelerating the construction progress and shortening the blockage time; therefore the construction method has obvious social benefits; and steel boxes are adopted to remould the existing piers, thus meeting the precision requirement and lowering the construction cost, therefore the construction method has obvious social benefits and higher popularization and application values.

Owner:CHINA RAILWAY 24TH BUREAU GRP

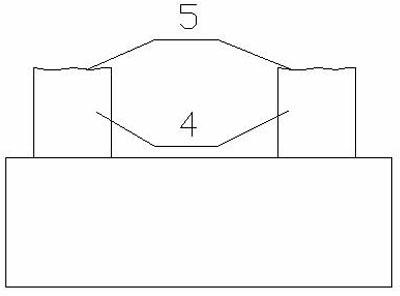

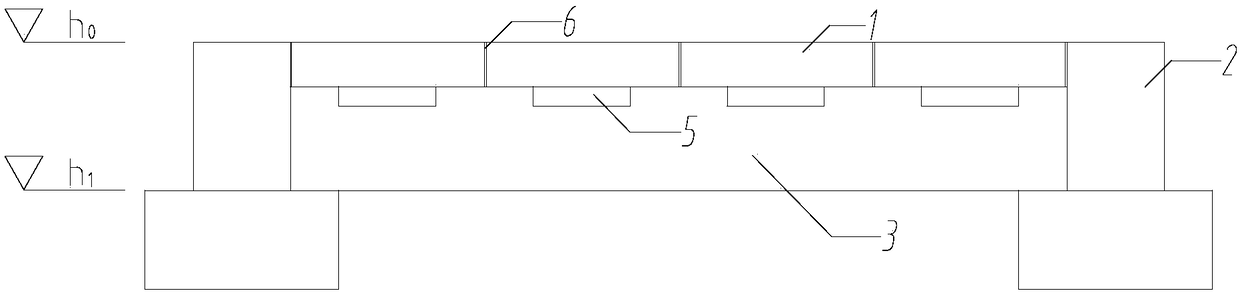

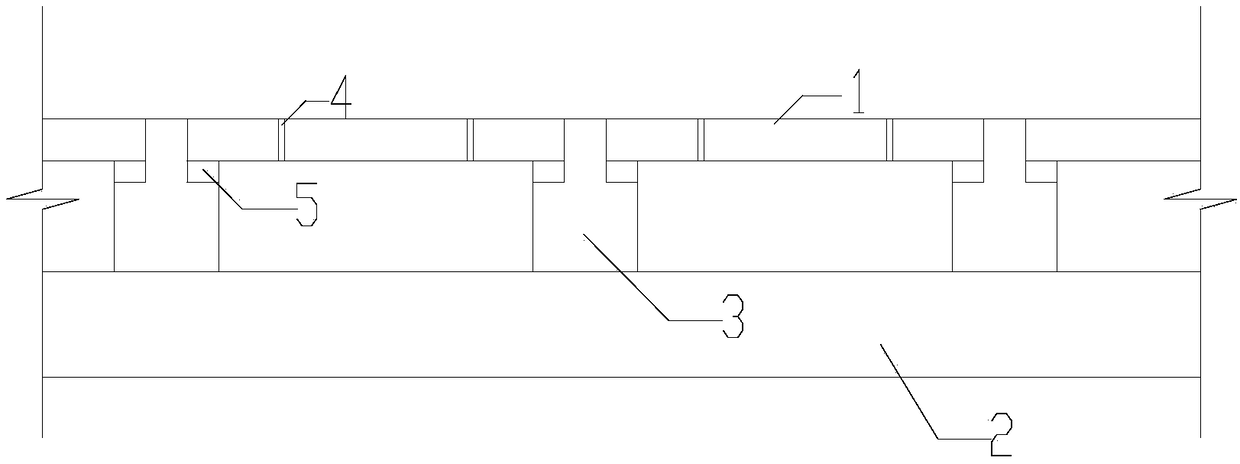

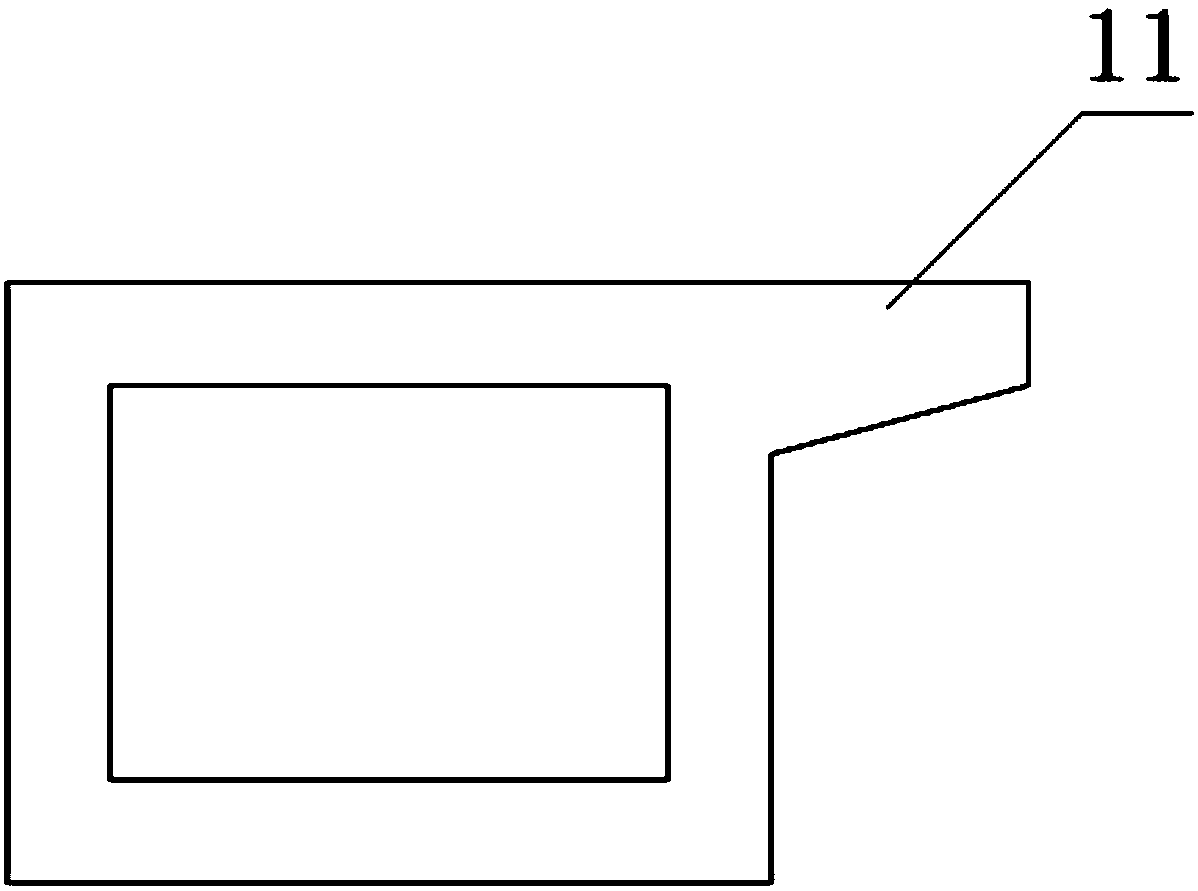

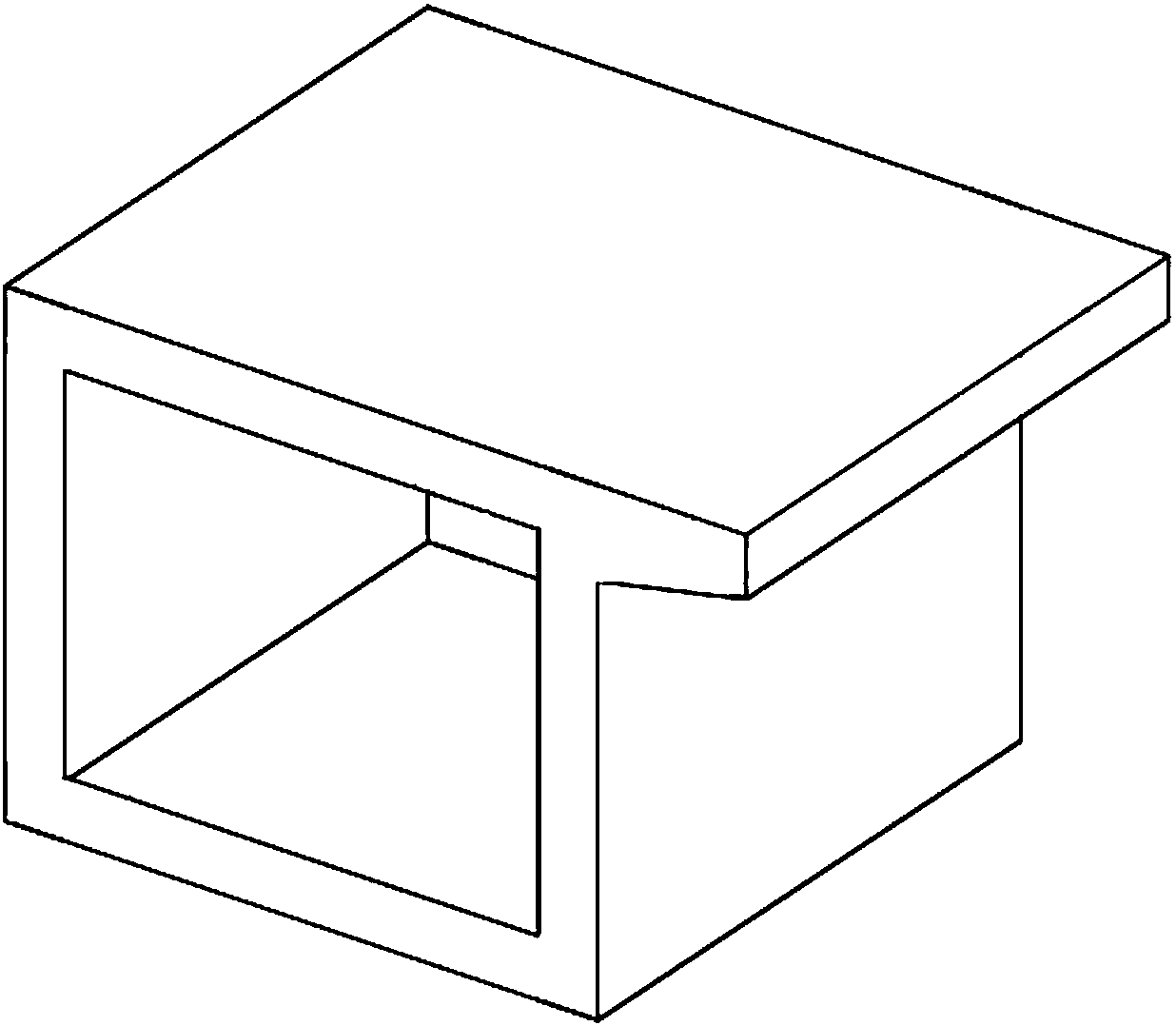

Assembly type concrete beam plate and installation and maintenance method

PendingCN108625284AAvoid displacementExtended service lifeBridge structural detailsBridge erection/assemblyConcrete beamsBridge deck

The invention discloses an assembly type concrete beam plate and an installation and maintenance method. The assembly type concrete beam plate comprises a plurality of prefabricated bridge deck slabsand longitudinal beams; the prefabricated bridge deck slabs are arranged in a parallel mode and erected on the upper surfaces of the longitudinal beams; the prefabricated bridge deck slabs and the longitudinal beams are fixed through clamping structures; each clamping structure is formed by a rib-plate clamped in a clamping groove; each rib-plate is arranged at the end of the lower surface of thecorresponding prefabricated bridge deck slab; and each clamping groove is formed in the position, corresponding to the rib-plate, on each longitudinal beam. The prefabricated bridge deck slabs with the rib-plates are connected with the longitudinal beams with the clamping grooves, and therefore the displacement generated when the prefabricated bridge deck slabs are subjected to the dynamic load effect of vehicles is overcome; construction is convenient; and meanwhile, the service life of the bridge floor is prolonged and maintenance cost is lowered due to the fact that rigidly connected positions are segregated by flexible materials and the buffering effect is played. Hoisting holes formed in the upper surface of the prefabricated bridge deck slabs are used for convenient replacing, so that no large area damage occurs on the bridge floor structure, and time of traffic obstruction is shortened.

Owner:JSTI GRP CO LTD +1

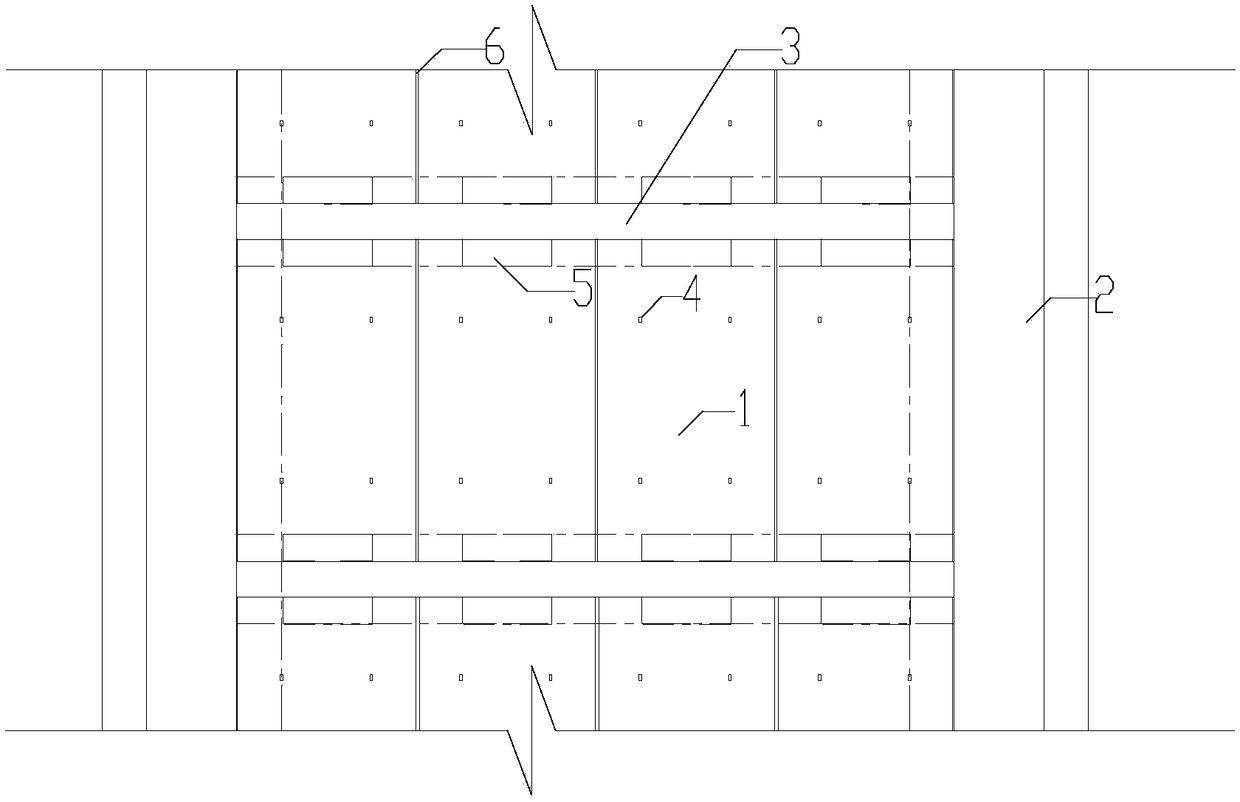

Method for constructing or reconstructing assembled platform and special prefabricated module group

PendingCN108547198ASimple construction processShorten the construction periodPaving gutters/kerbsClimate change adaptationRebarCushion

The invention aims at providing a method for constructing or reconstructing an assembled platform and a special prefabricated module group. According to the method for constructing or reconstructing the assembled platform, the efficiency of the platform constructing or reconstructing project can be comprehensively enhanced, the platform constructing or reconstructing project quality can be comprehensively improved, the construction is simple and flexible, manpower and material resources are saved, the influences on running and transportation are small, the method is safe and time-saving, and the potential safety hazard in the later period is reduced. The method for constructing or reconstructing the assembled platform comprises the specific construction steps of 1, preparing a prefabricated module group with a reinforced concrete structure; 2, mounting the prefabricated module group to a designated position by using a hoisting appliance; treating a foundation of a new platform and filling anti-freezing sand first, and then mounting prefabricated modules after pouring a concrete strip-shaped foundation; 3, binding reinforcing meshes on the prefabricated modules and pouring a concrete cushion; 4, comprehensively laying pipelines; and 5, after the concrete cushion reaches the strength, continuing to lay a slope making layer, a leveling layer and a sand cushion; and laying a platform cap-beam, a safety line, blind bricks and pavement bricks to finish the construction.

Owner:沈阳铁道工程建筑集团有限公司

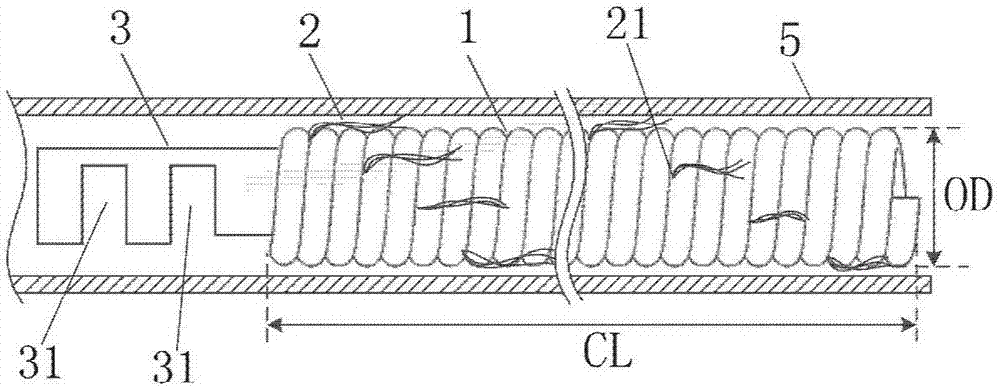

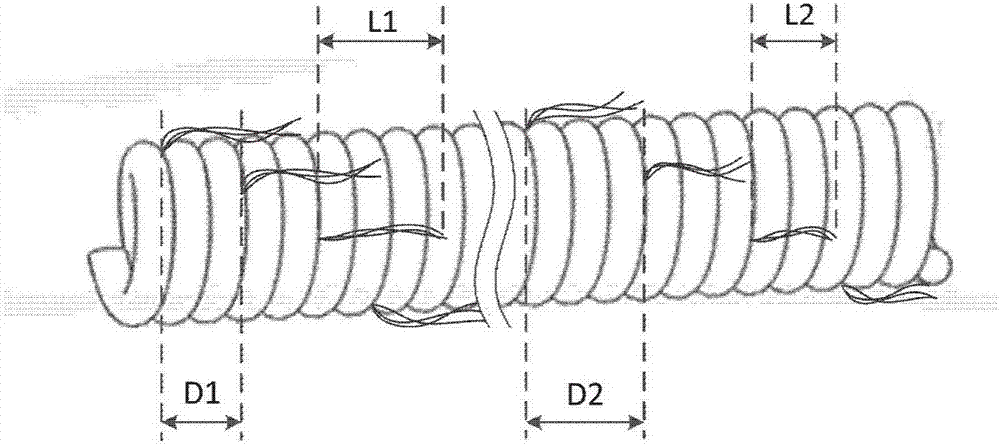

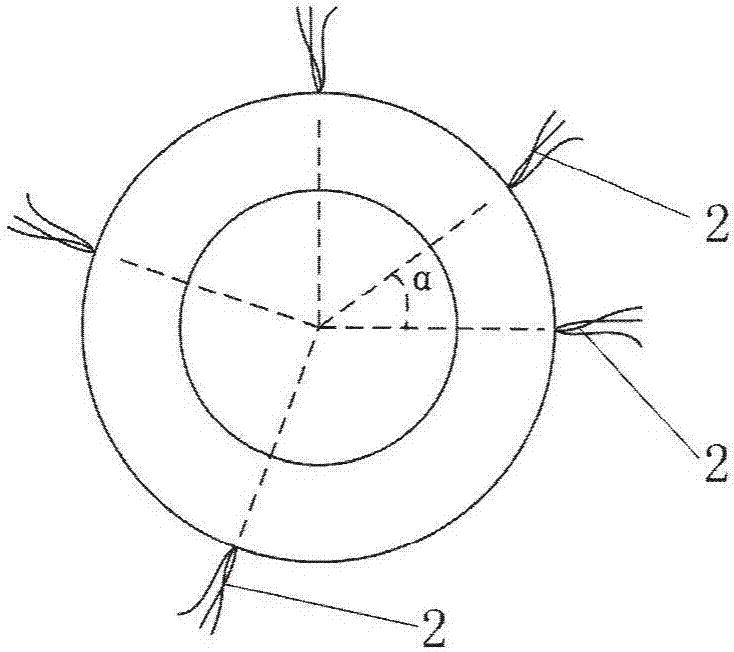

Spring ring

The invention discloses a spring ring. The spring ring comprises a spring ring body and a fiber bundle fixedly connected to the spring ring body. The spring ring has the following beneficial effects: according to the structure design of the provided spring ring, the applied friction force in a conveying pipe is lower while the spring ring is released; and the pushing force is more easily and better transmitted along the axial direction of the spring ring, and the stacking situation of the spring ring cannot be produced, so the operation difficulty of an operator is reduced, and the aneurysms rupture risk is reduced.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

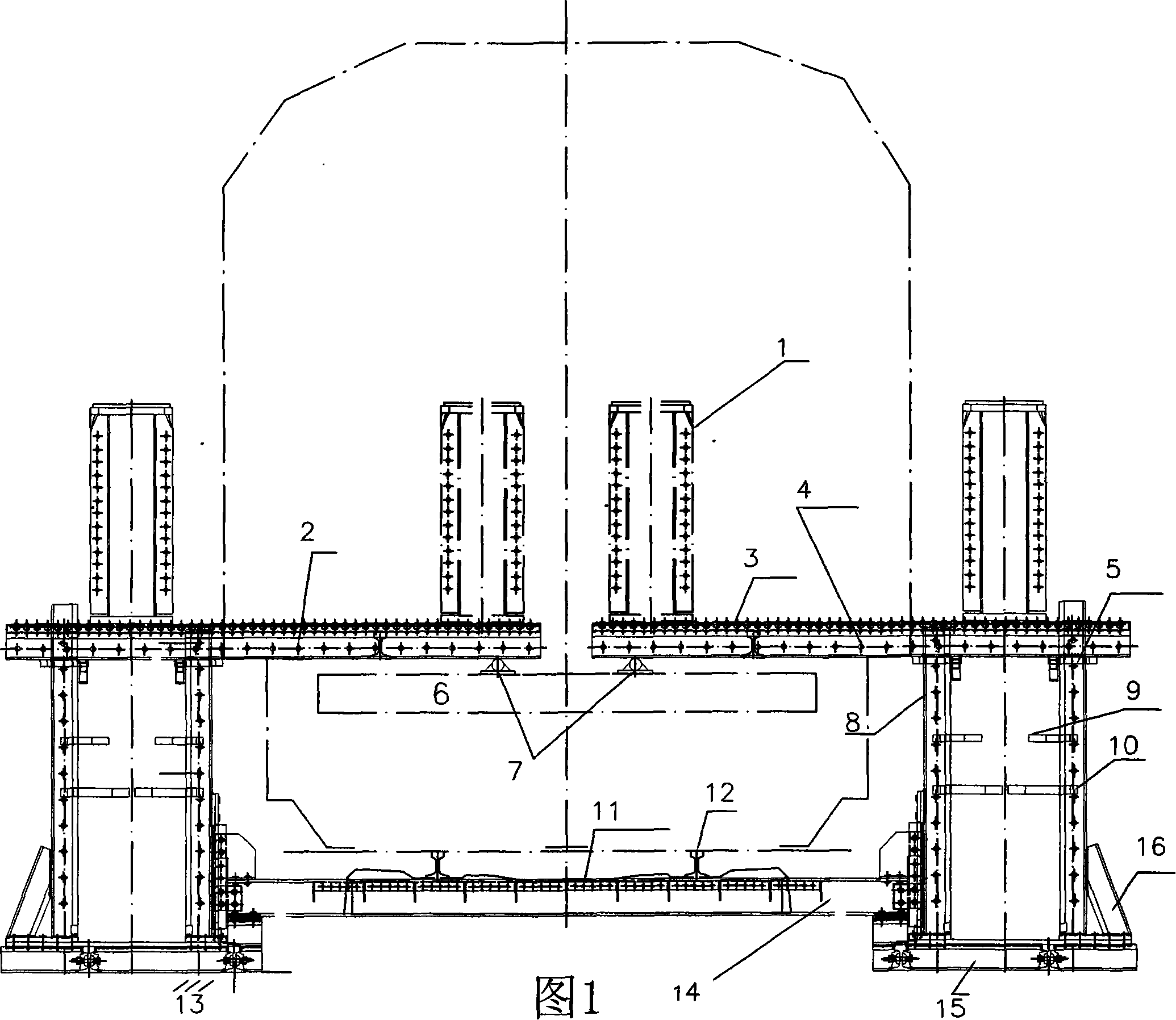

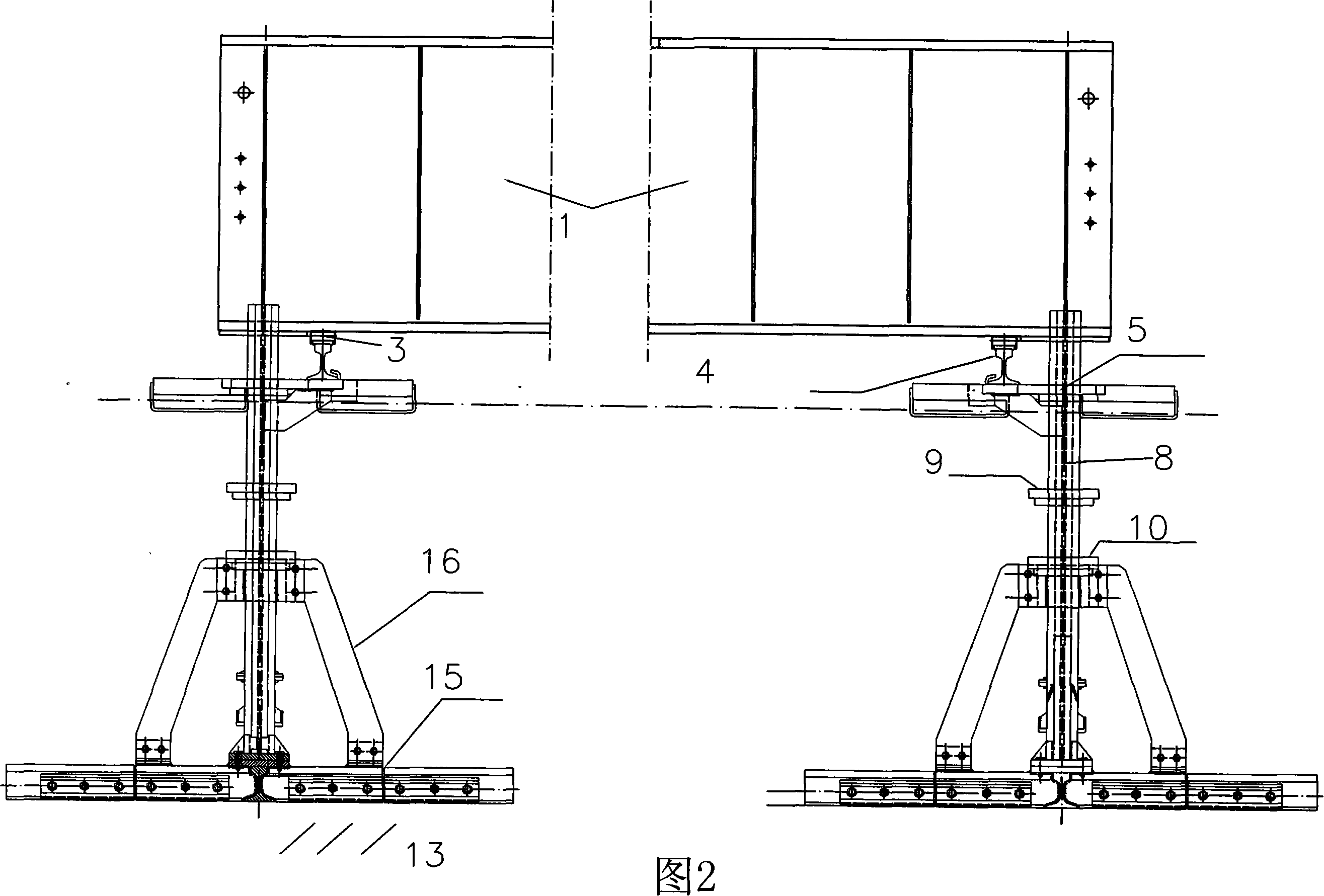

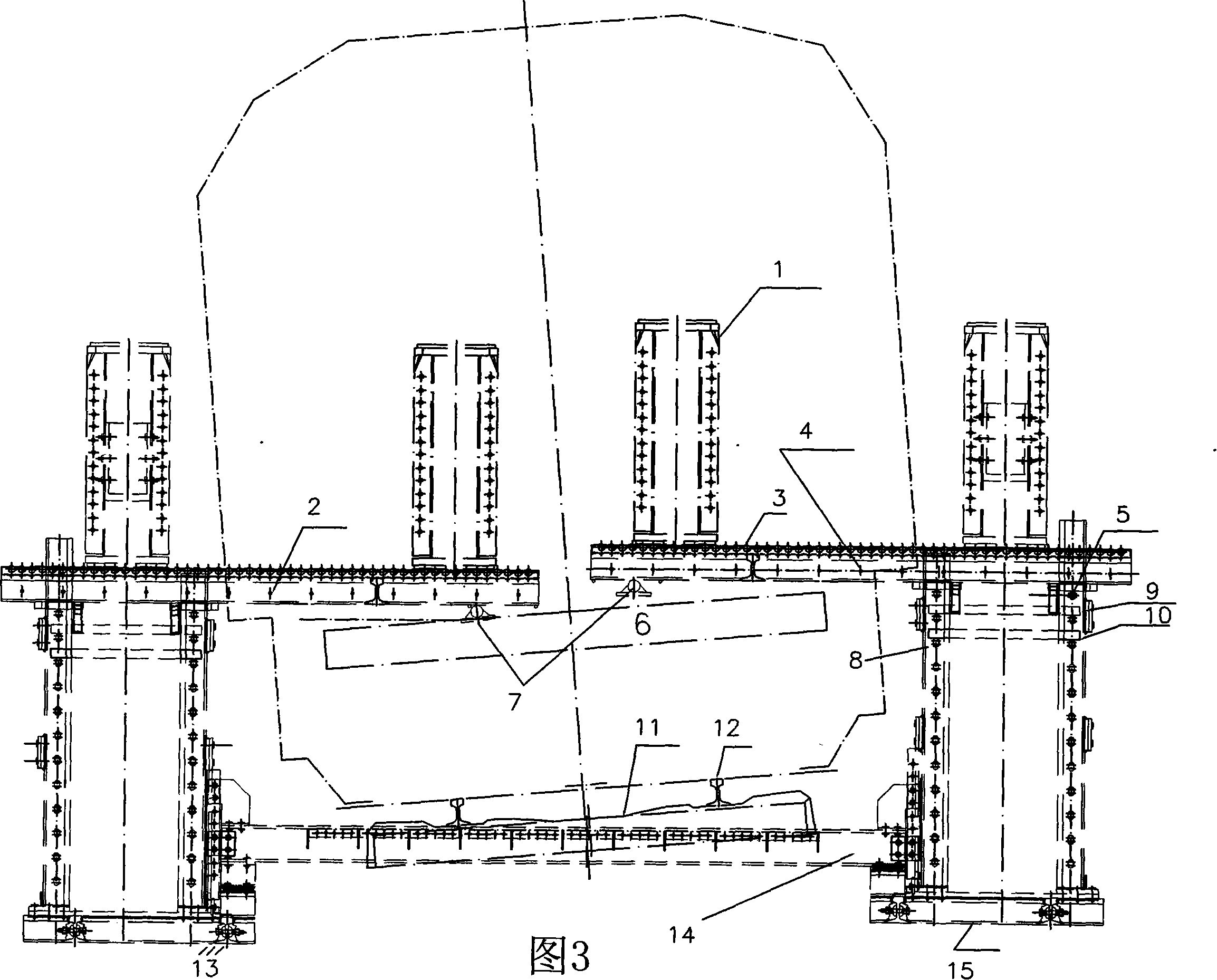

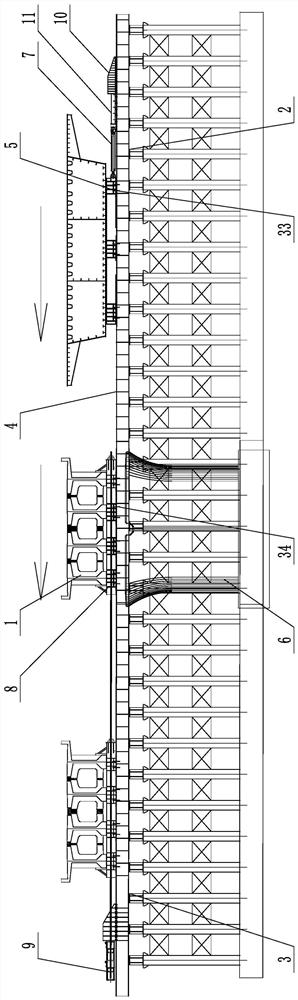

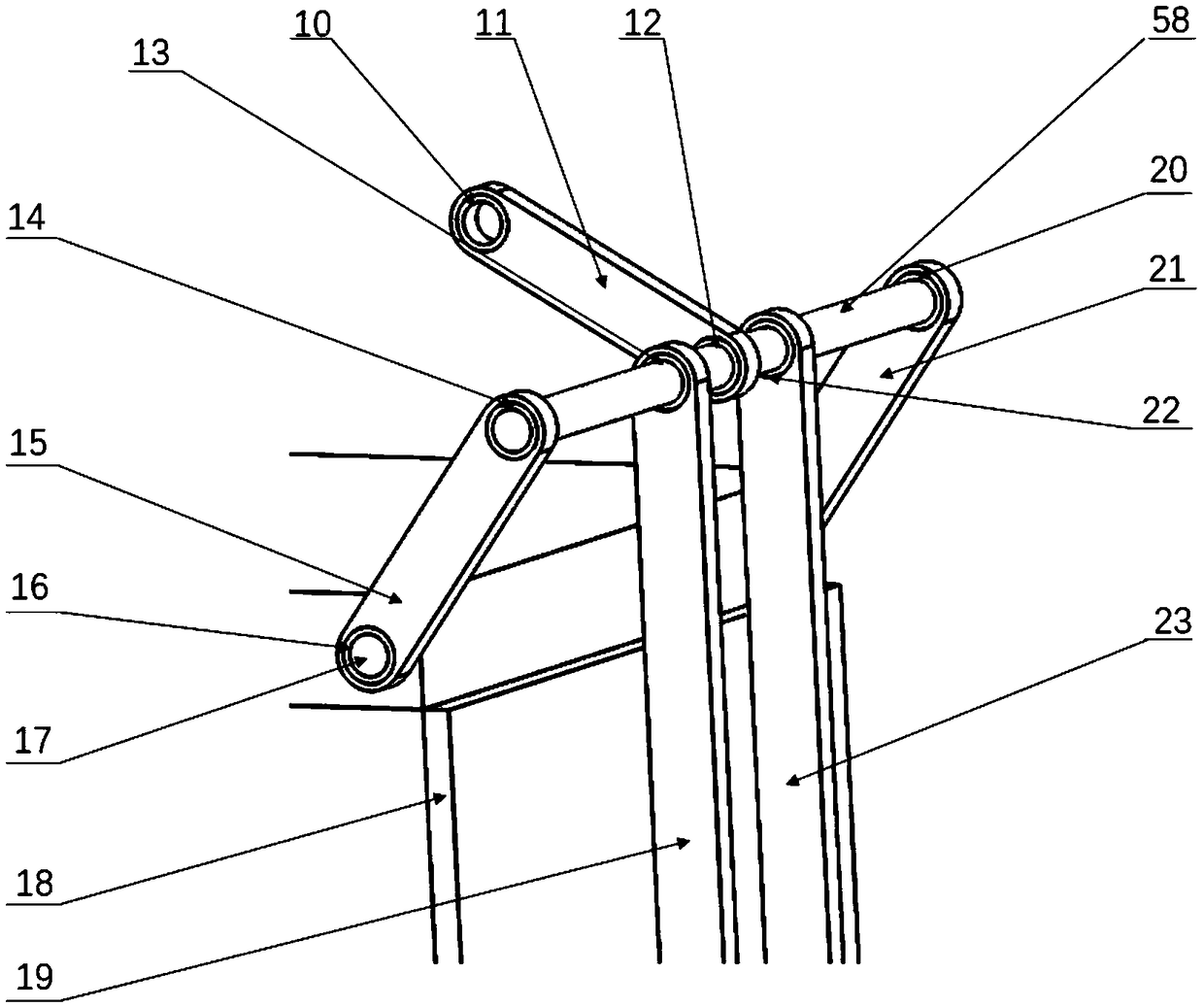

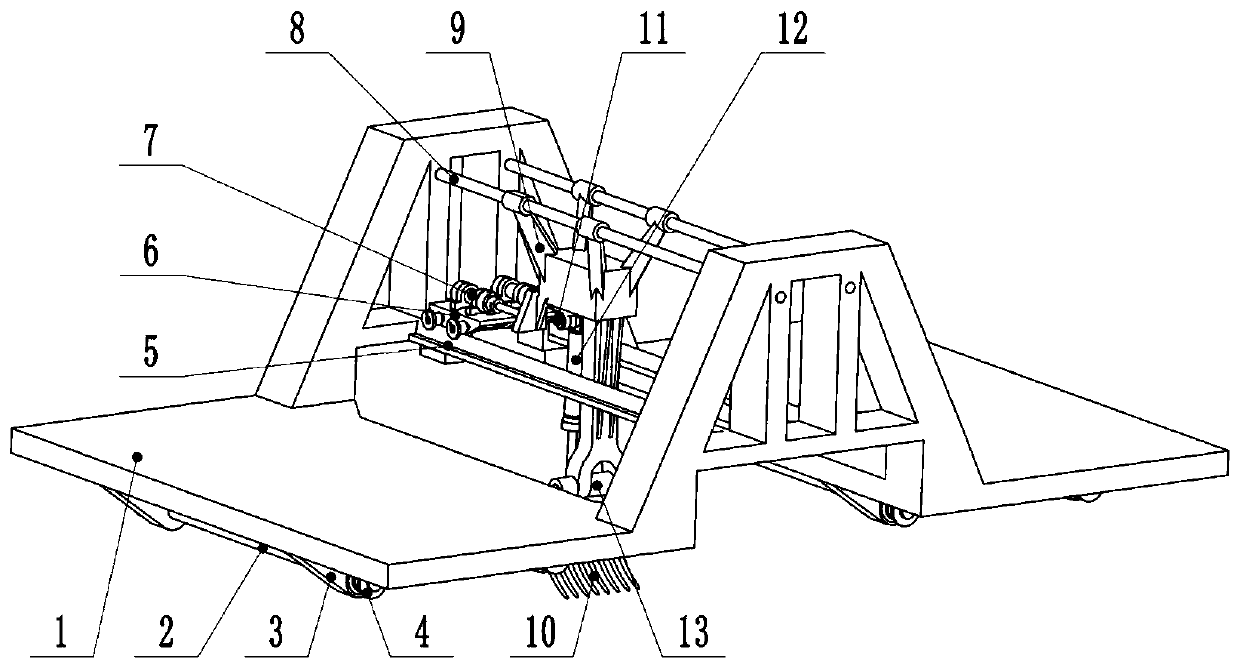

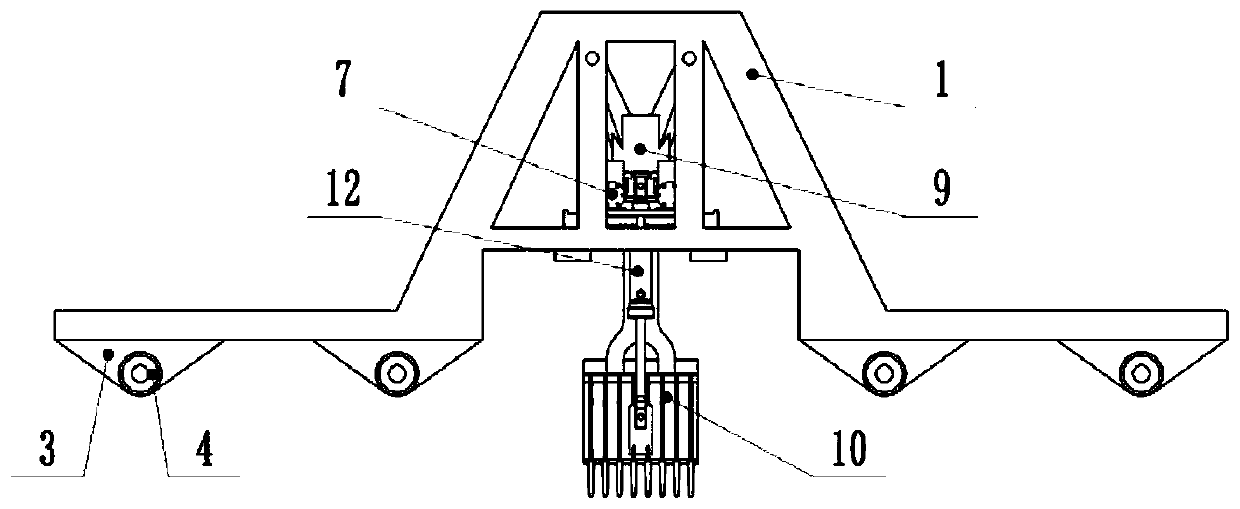

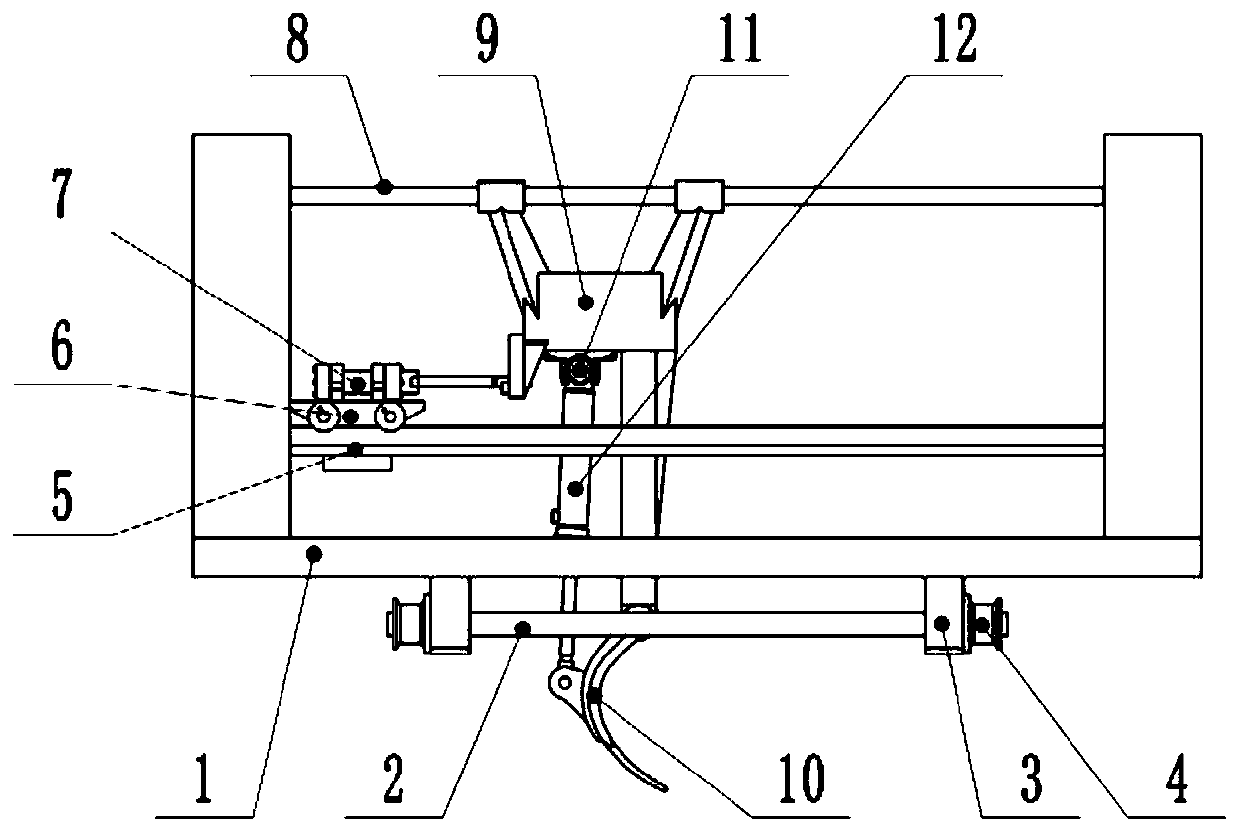

Railway temporary-beam quick mounting-dismounting complete apparatus

InactiveCN101070690AReduce weightFast, safe and secure loading and unloadingRailway track constructionBogieEngineering

The invention involves a rapid loading and unloading railroad beam sets devices. It includes four groups landing device on both sides of the beam, the landing devices on both side of rail through a fixed device connect with I-beam; each beam landing installations include three groups of working platform, a pair of movements column guide rail at the bottom of which has a gap for draw up work platform; beam devices and track movements through the roller row flatbed truck and rail link springboard; orbit flatbed tricycle along the length of the table with two sets of two-way adjustable level of frame, each with bogies on the beam quick slingers; also has crowbar,jack level adjustment, and track adjustment pad . This device can secure move the beam from orbit flatbed truck unloaded on the shoulders of the railway quickly safe, the railway or road shoulders of the beam on track flatbed truck loaded, so as to shorten the time interval blockade to reduce train plug, a little late.

Owner:福州汇和商贸有限公司

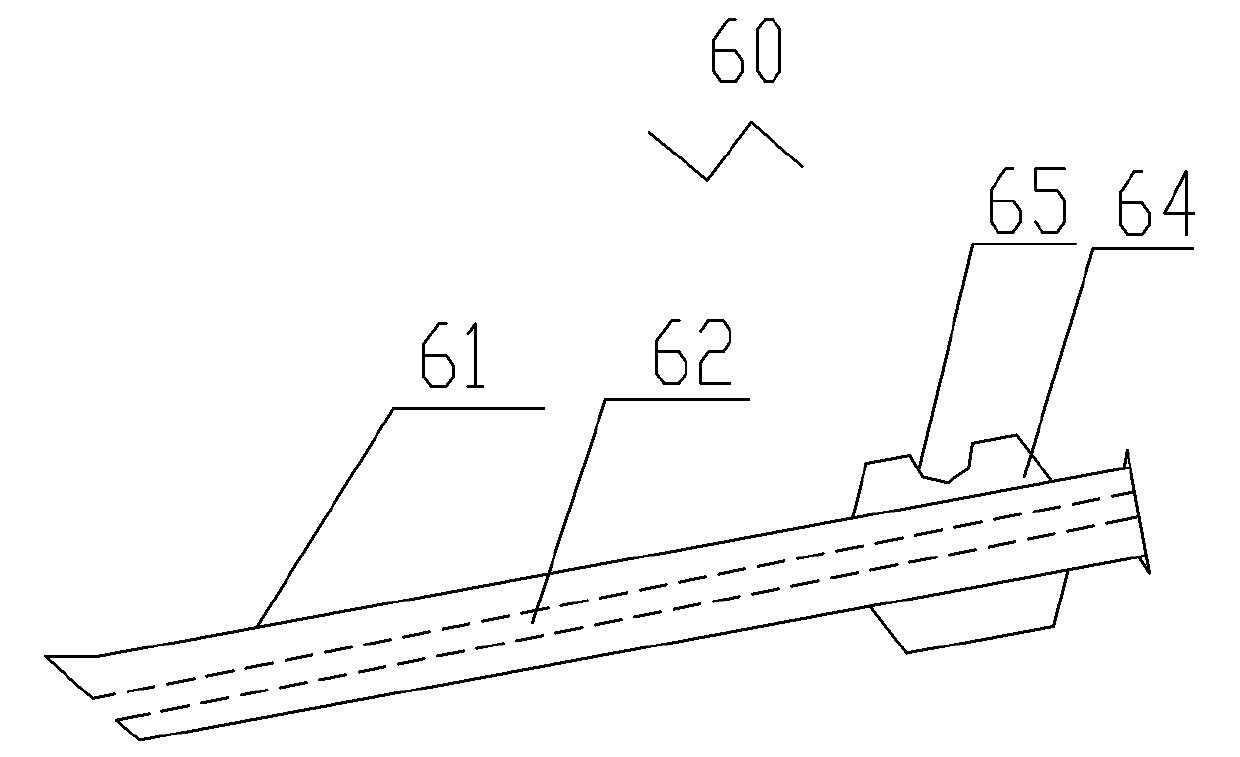

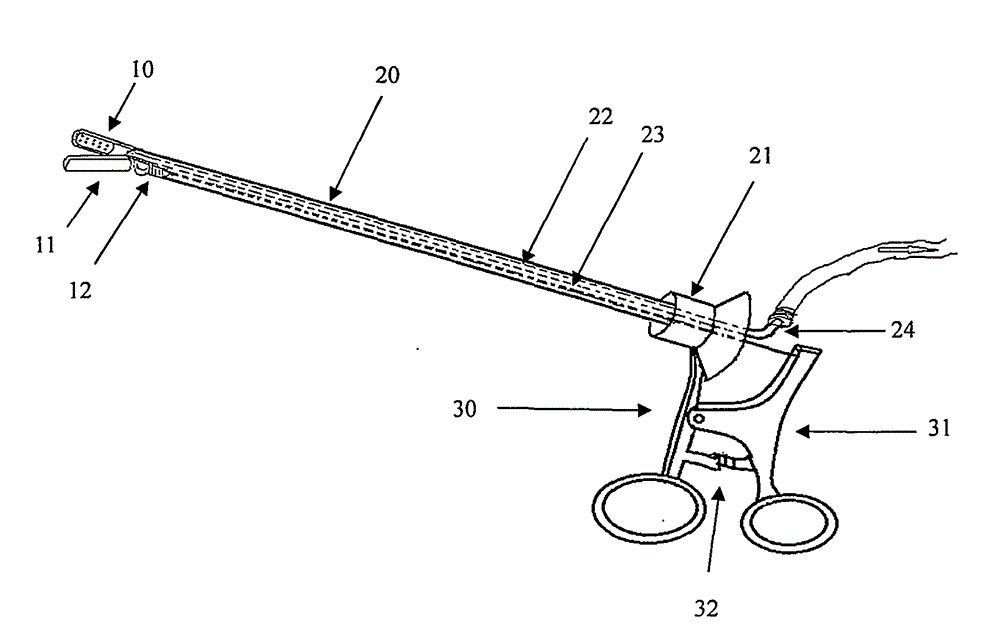

Portal vein thrombus taking-out clamp for laparoscopic surgery

The invention belongs to the field of medical apparatuses and instruments, and relates to a clamp device for clamping portal vein tumor thrombus or thrombus in laparoscopic surgery. The device is characterized by comprising a clamp portion, a casing pipe, a handheld handle, a solid pull rod and a hollow connection pipe, and the solid pull rod and the hollow connection pipe are arranged in the casing pipe and used for connecting the clamp portion with the handheld handle. The clamp portion comprises an opening and closing device, a clamp head A and a clamp head B, wherein the clamp head A and the clamp head B are symmetrical in size and shape, and the inner side of each clamp head is a semi-arc concave face. The clamp head A is of a solid structure, the inner wall of the concave face is smooth, and the clamp head A is connected with the pull rod through the opening and closing device. The clamp head B is of a hollow structure, the concave face of the clamp head B is provided with tiny holes, and the inner space of the clamp head B is connected with an aspirator through the hollow connection pipe to transfer negative pressure. When the handheld handle is tightened, the pull rod closes the clamp head A and the clamp head B through the opening and closing device, and the semi-arc hollow concave faces of the inner sides are oppositely combined to form a closed thrombus taking-out cavity. The portal vein thrombus taking-out clamp for laparoscopic surgery can effectively and safely take out portal vein tumor thrombus, is easy to design and manufacture and has a wide market prospect.

Owner:卫旭彪

Turnout beam replacement construction method

ActiveCN111926721AShort replacement operation timeDoes not affect normal operationBridge erection/assemblyBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a turnout beam replacement construction method, and aims to overcome the defects of long turnout beam replacement time and great influence on normal driving. In the turnout beam replacement construction process, the steel box beam is assembled on the turnout beam manufacturing platform, an existing beam can normally run in the assembling process, and normal running of an existing line is not affected. After the steel box girder is assembled and the existing girder is jacked up, the existing girder is pulled by a traction jack while a new turnout girder is pushed by a pushing jack, and the operations of the existing girder and the new turnout girder are synchronously carried out, so that the existing line blocking time is favorably shortened. The existing beam movesto the existing beam storage platform under the traction of the traction jack, the turnout beam moves to the position above the bridge pier under the pushing effect of the pushing jack, and beam falling is conducted through the beam falling jack after adjustment is conducted in place, so that a new turnout beam is erected on the bridge pier, and replacement construction is completed. And then thenew turnout beam is connected with the original beam, so that the normal traveling crane can be prevented from being blocked, and the influence on the normal traveling crane is small.

Owner:CHINA RAILWAY 24TH BUREAU GRP ZHEJIANG ENG CO LTD +1

BLOCK GENERATION METHOD, device, APPARATUS, AND STORAGE MEDIUM

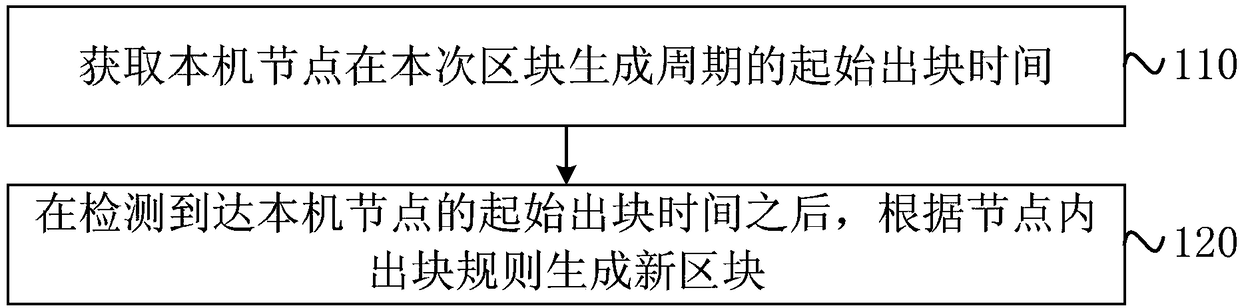

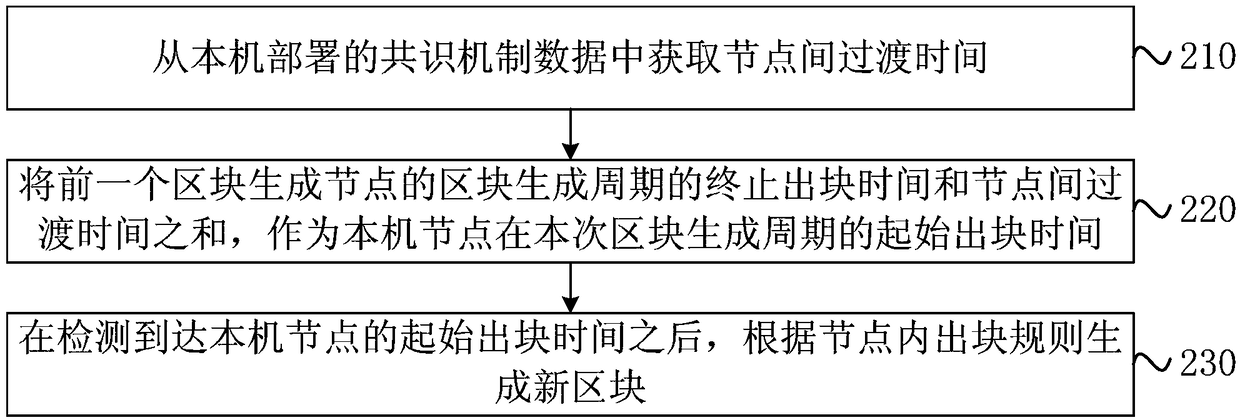

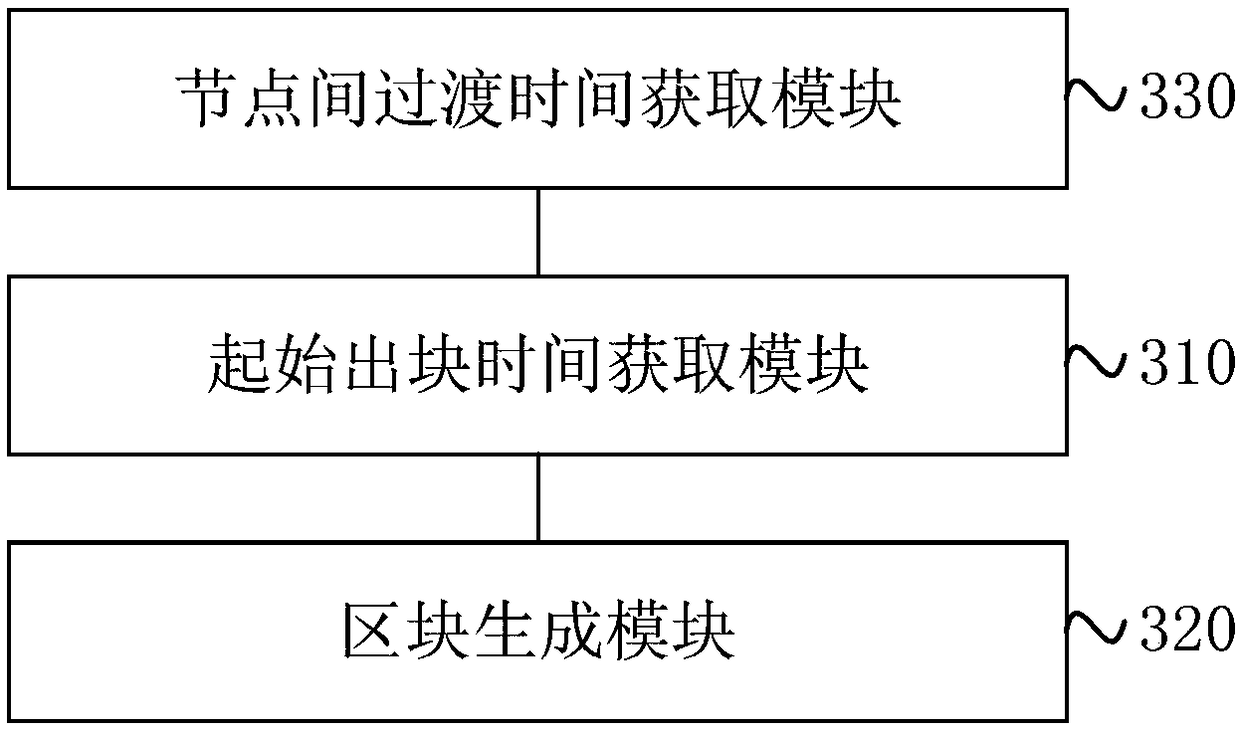

ActiveCN109344630AReduce the probability of blockchain forksAvoid being discardedDigital data protectionChain networkBlockchain

The embodiment of the invention discloses a block generation method, a device, an apparatus and a storage medium. The method comprises the following steps: obtaining the starting block-out time of thelocal node in the current block generation cycle, wherein the starting block-out time is determined according to the block generation cycle of the previous block generation node and the transition time between nodes; After detecting the start block-out time to the local node, a new block is generated according to a block-out rule within the node. At that time of handover of the block generation node, for the node transition time between adjacent handoff nodes is increased, so that even if the chunk-out time in the node is shortened according to the chunk-out rule in the node, The invention also provides sufficient time for the generation of tail blocks in the previous block generation node and the transmission to the block chain network, reduces the probability of the block chain bifurcation under the condition of shortening the block-out time of the node and improving the block acknowledgement speed, and avoids the tail blocks in the previous block generation node from being discarded.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

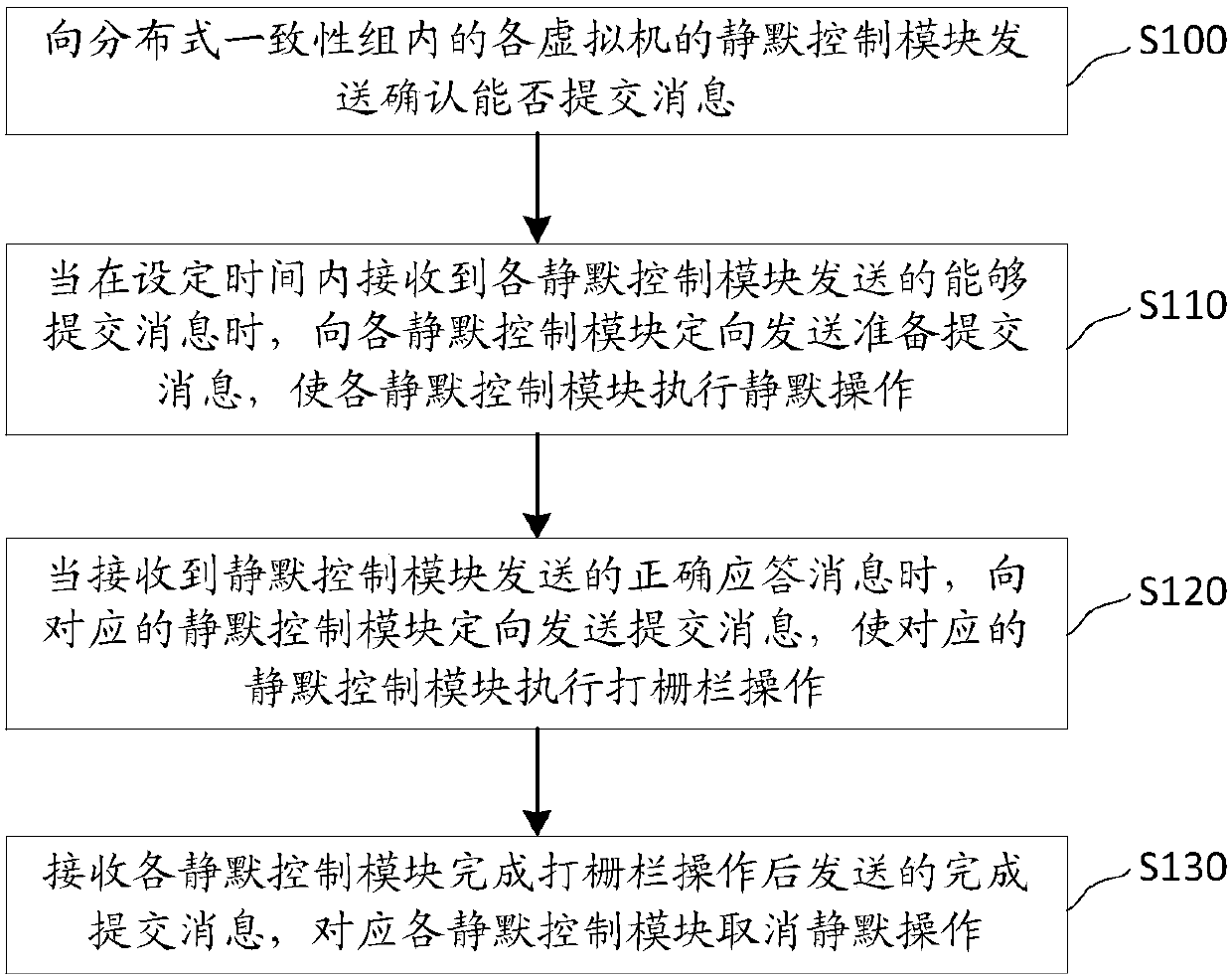

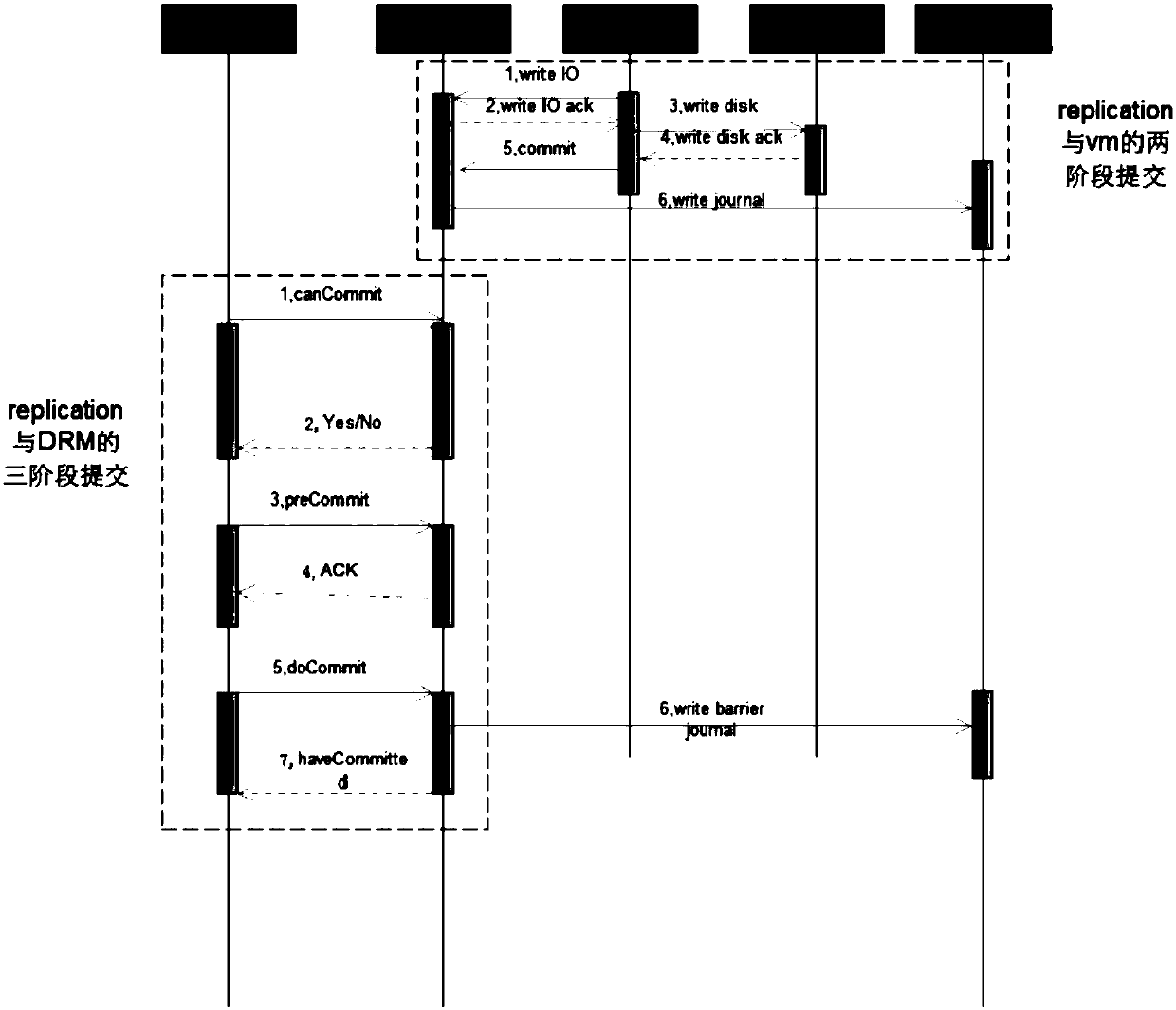

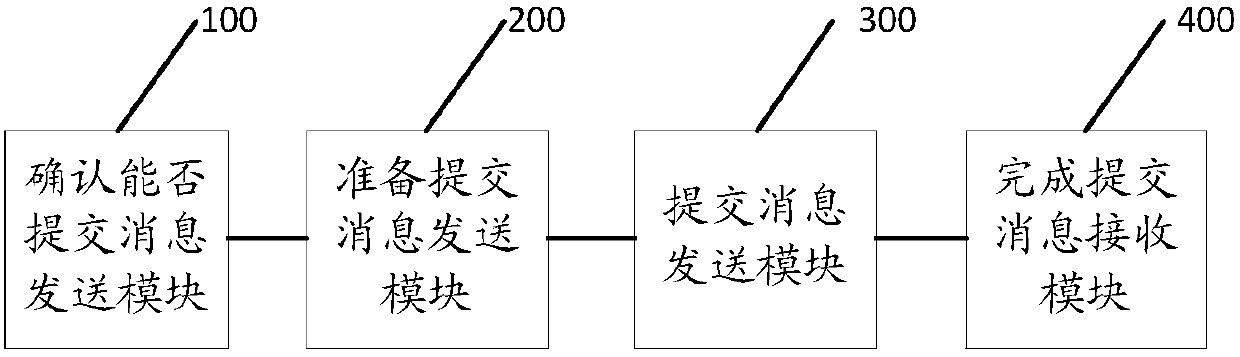

Implementation method and device of distributed consistency group and DRM equipment

PendingCN110442475ALittle impact on performanceReduce block timeError prevention/detection by using return channelProgram controlVirtual machineSetting time

The invention discloses an implementation method and device of a distributed consistency group. The method comprises the following steps: sending a message for confirming whether a message can be submitted or not to a silence control module of each virtual machine in the distributed consistency group; when messages which can be submitted and are sent by all the silence control modules are receivedwithin set time, directionally sending messages to be submitted to all the silence control modules, and making all the silence control modules to execute silence operation; when a correct response message sent by the silence control module is received, directionally sending a submission message to the corresponding silence control module, so that the corresponding silence control module executesa fence hitting operation; receiving a completion submission message sent by each silence control module after completing the fence hitting operation. According to the method, on the basis of ensuringthe consistency of the distributed consistency group, the blocking time is reduced. The invention further discloses an implementation device of the distributed consistency group, DRM equipment and acomputer readable storage medium, which have the above beneficial effects.

Owner:SANGFOR TECH INC

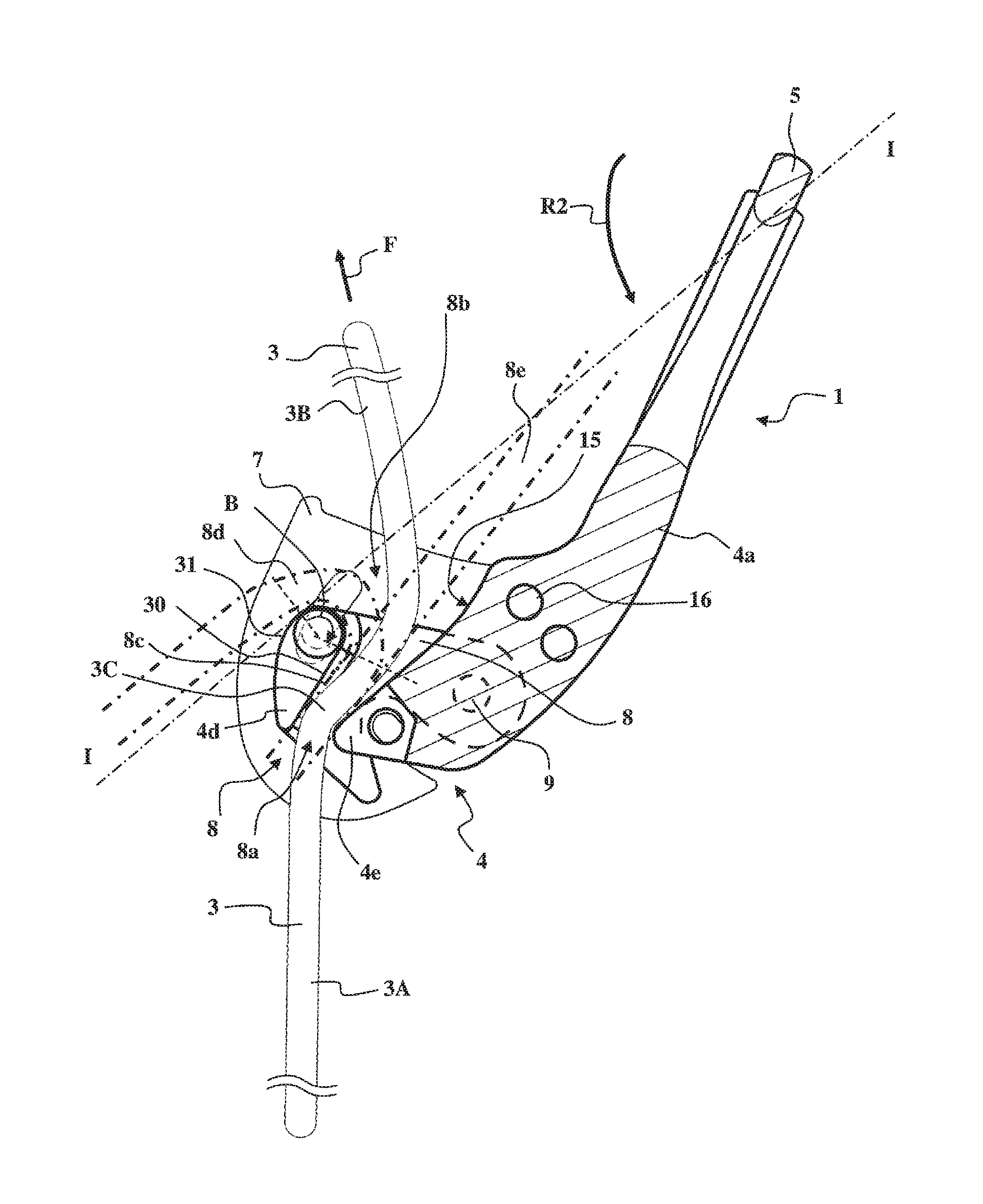

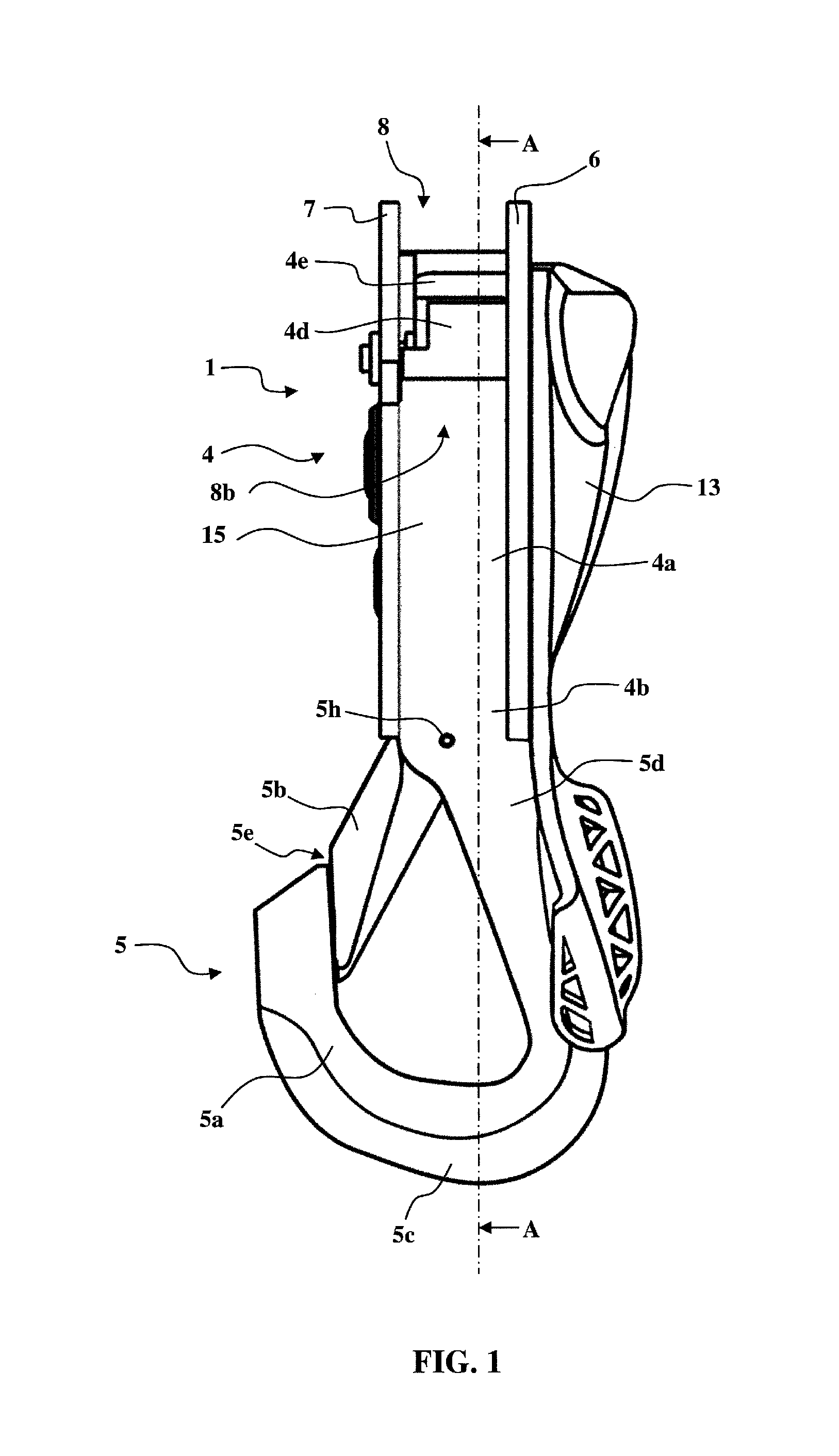

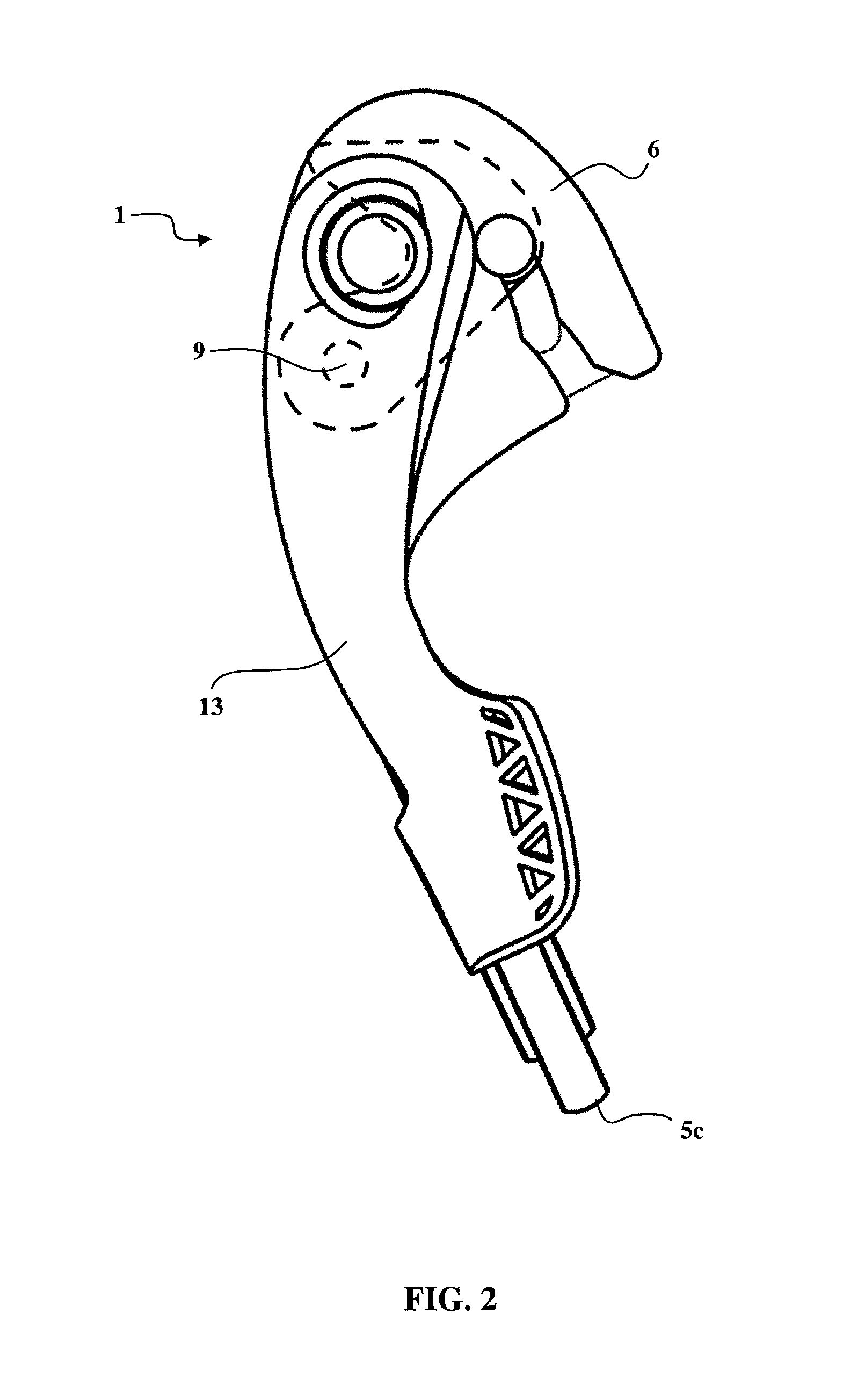

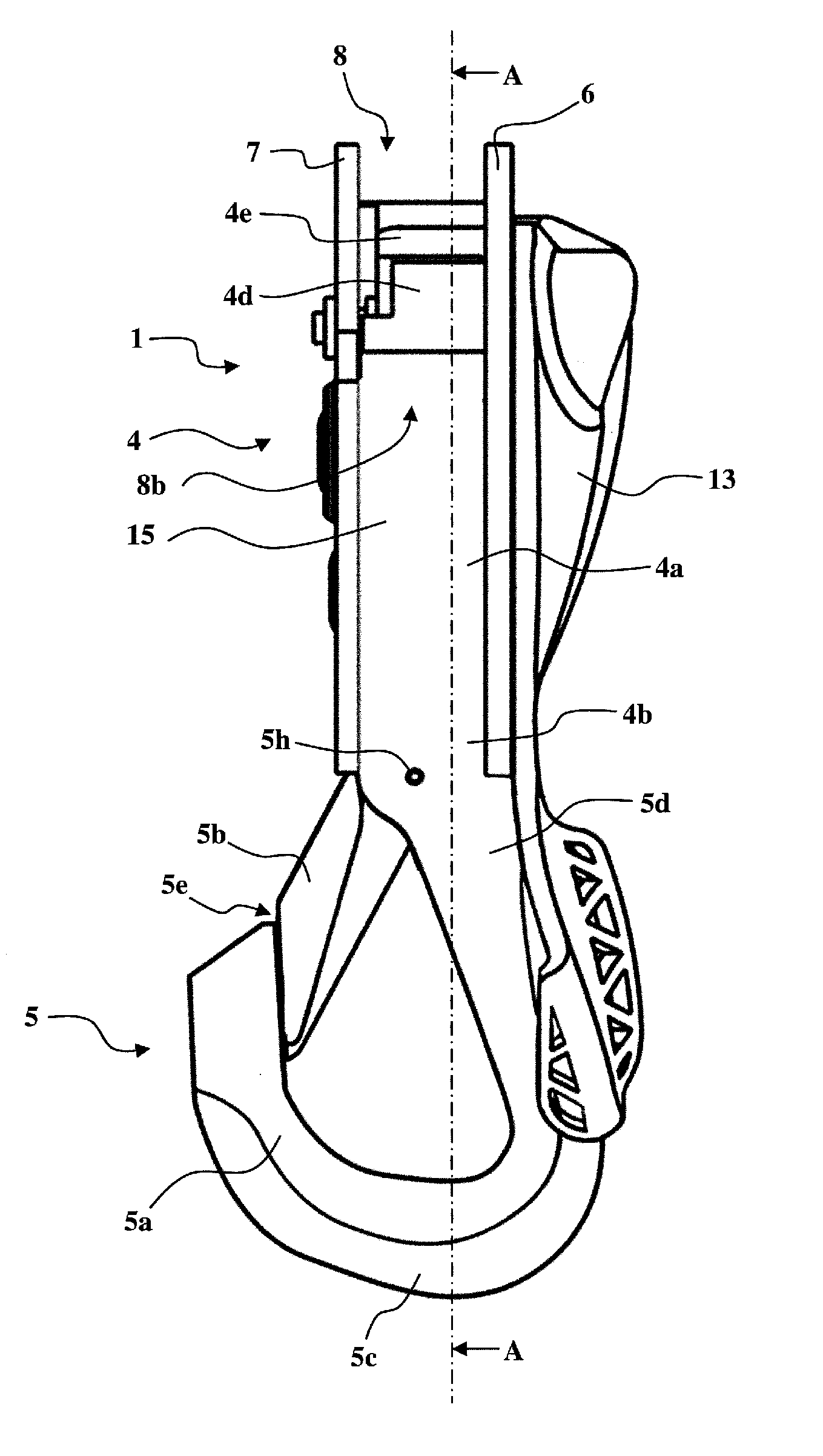

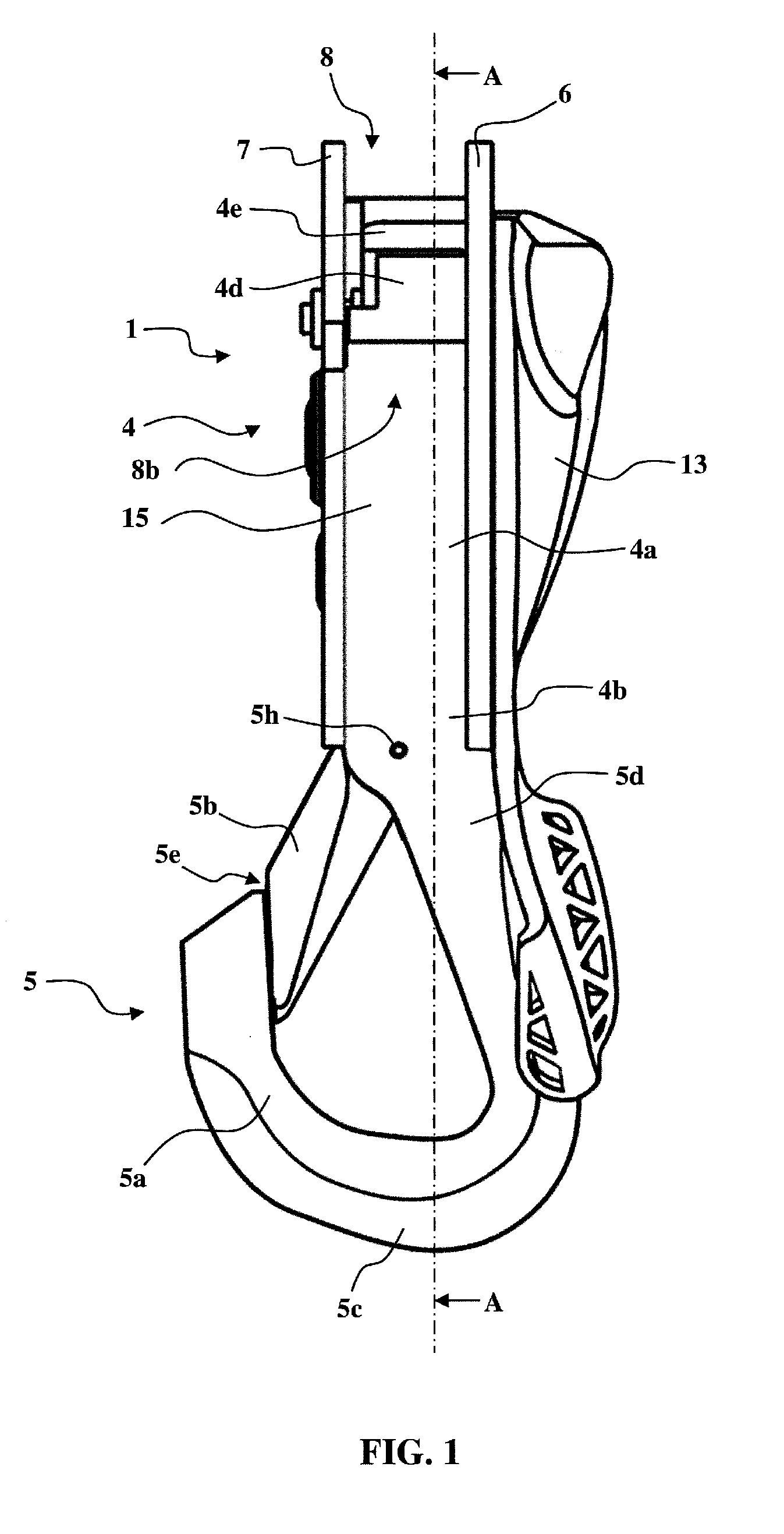

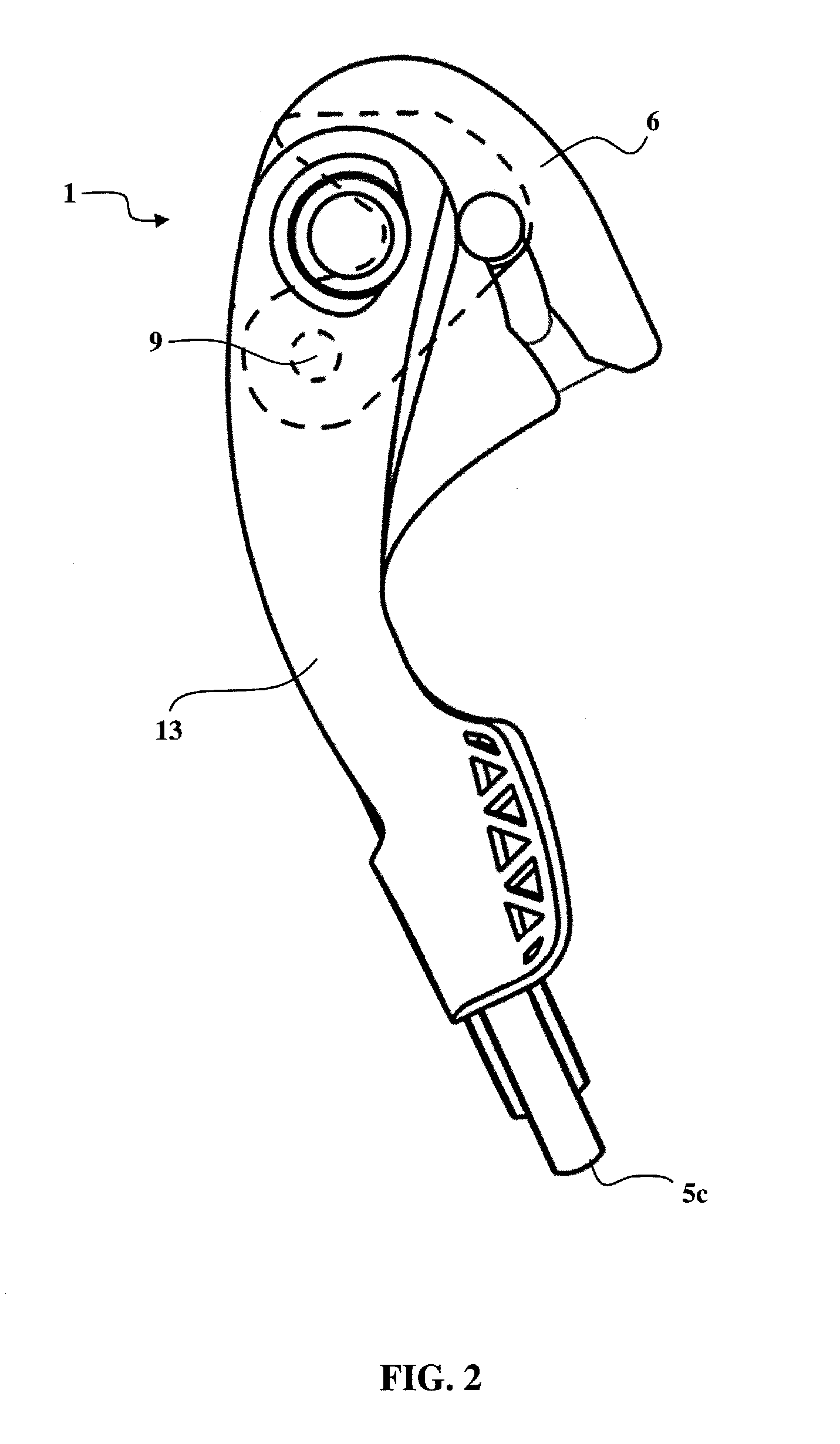

Self-blocking descender-belay device

InactiveUS20150096838A1Large spacingEase of displacementMountaineeringBuilding rescueEngineeringDescender

The self-blocking descender-belay device (1) according to the invention comprises:a first lateral guide flange (6) for the rope, comprising a braking nose (4e),a second lateral guide flange (7) for the rope, which is separated from the first flange (6) by a transverse gap (8) for passage of the rope, and can be displaced between a spaced position for putting into place and removal of a rope, and a closed position in which the rope is trapped in the transverse gap (8) for passage of the rope,a cam (4d) which is engaged between the first and second flanges (6, 7) and is mobile towards and away from the braking nose (4e), and is thrust towards the braking nose (4e) by a cam return spring,the transverse gap (8) for passage of the rope extending between a rope input in the vicinity of the braking nose (4e), and a rope output opposite,the rope output having a large opening such as to permit free orientation of the rope output end between a blocking orientation in which the rope surrounds the cam (4d), and a release orientation in which the rope passes through the transverse gap (8) for passage of the rope directly, and without thrusting the cam (4d) towards the braking nose (4e).

Owner:ETAB LUDGER SIMOND

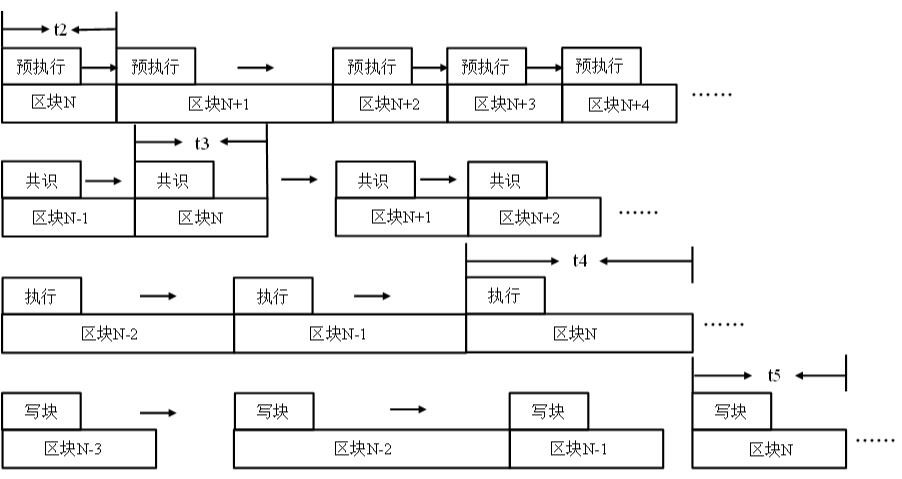

Method and device for executing transaction in block chain

ActiveCN113744063AReduce block timeIncrease profitFinanceDigital data protectionParallel computingFinancial transaction

The invention provides a method and a device for executing a transaction in a block chain, which are applied to a block chain node. The method comprises: receiving a plurality of first transactions belonging to a first block, and pre-executing the plurality of first transactions to obtain a pre-execution read-write set of the plurality of first transactions, wherein the pre-execution read-write set is used for grouping the plurality of first transactions; carrying out consensus on second blocks in parallel in the pre-execution process of the multiple first transactions; the second block is a block before the first block.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

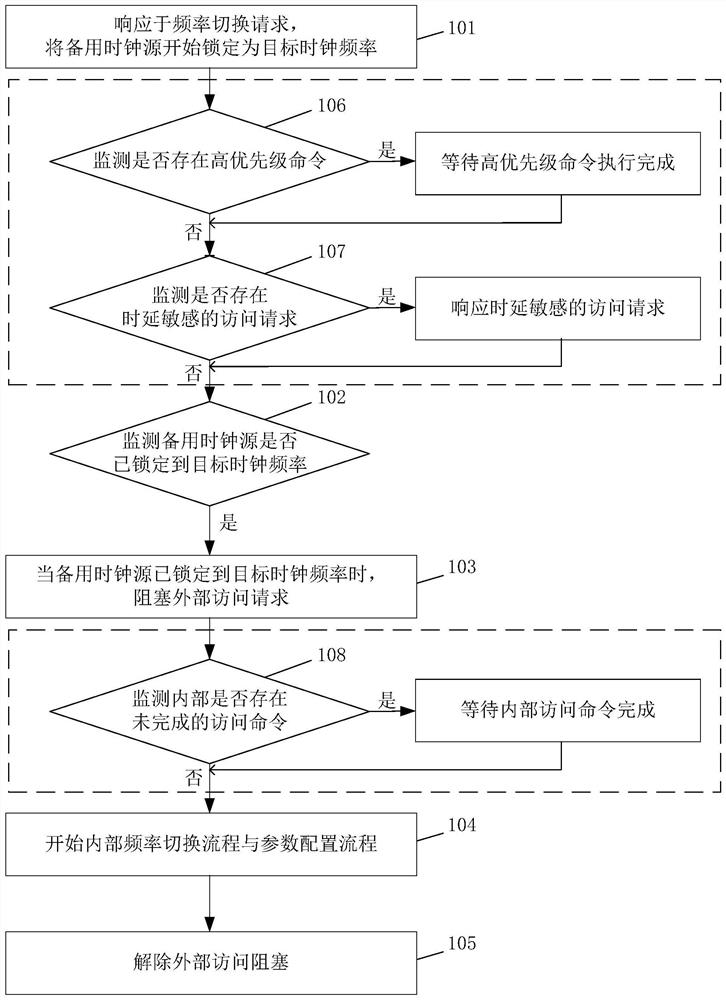

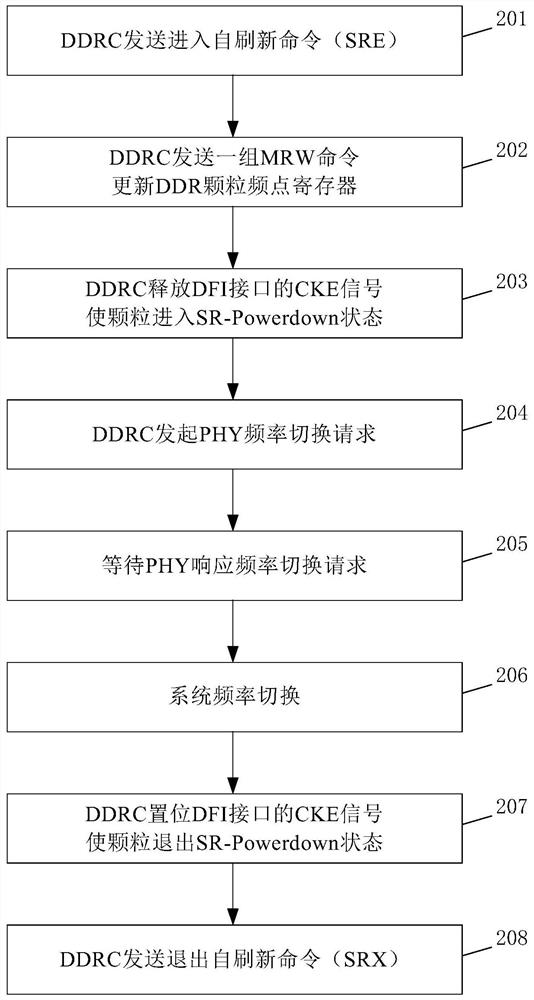

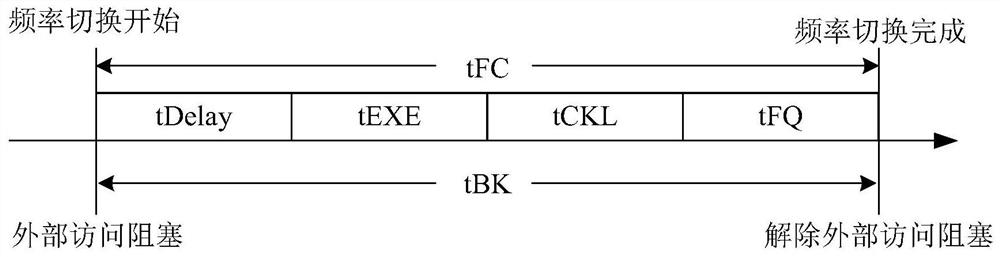

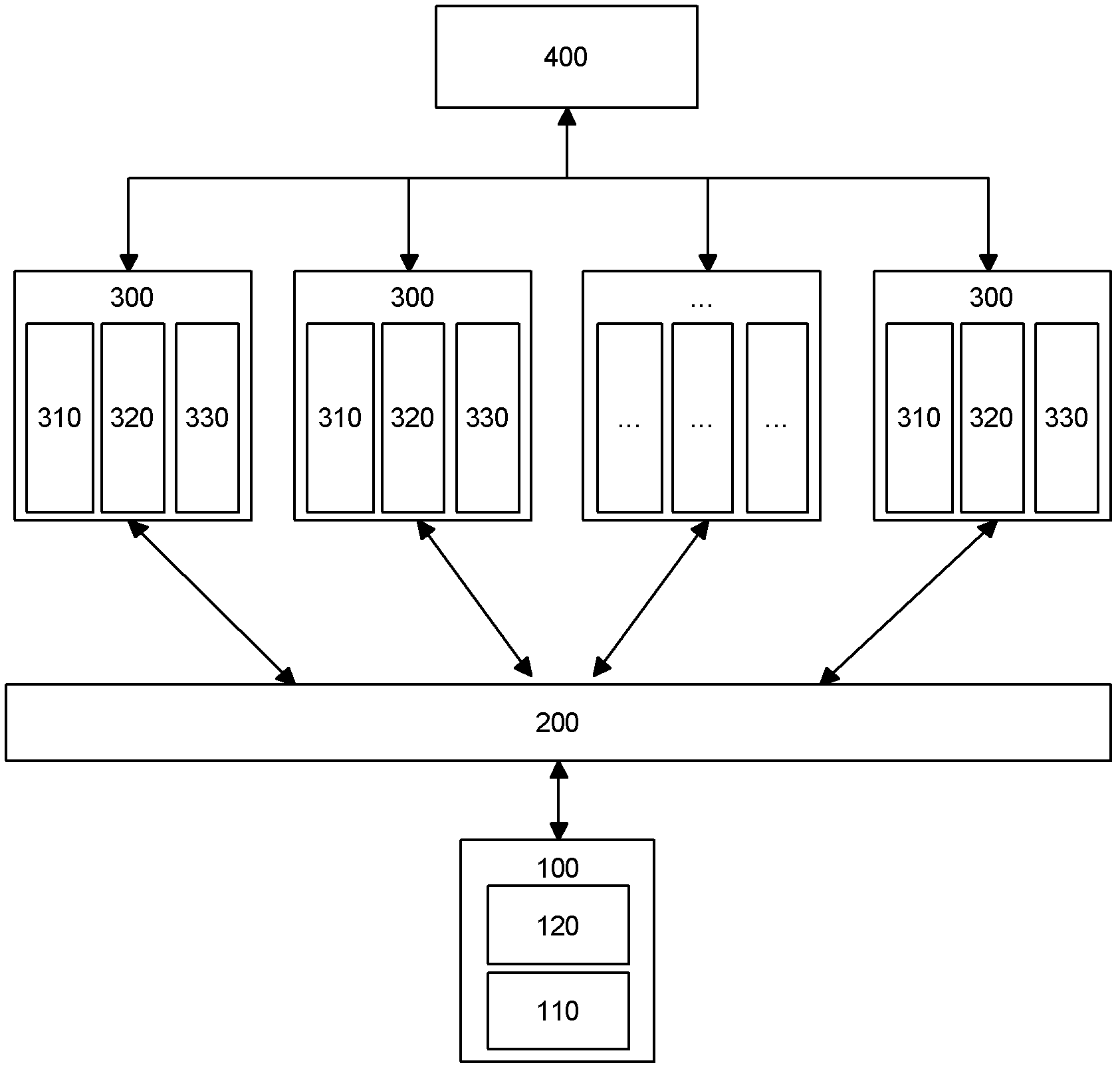

Control method, device and system for synchronous storage device

PendingCN112581994AShorten the timeReduce performance bandwidth impactDigital storageElectric digital data processingClock rateEmbedded system

The invention provides a control method, device and system of a synchronous storage device. The method comprises the following steps: in response to a frequency switching request, starting to lock a standby clock source as a target clock frequency; monitoring whether the standby clock source is locked to the target clock frequency or not; when the standby clock source is locked to the target clockfrequency, blocking external access; starting an internal frequency switching process and a parameter configuration process; and removing external access congestion. According to the method, the timerequired by the frequency switching process of the synchronous storage device can be reduced, and the external access blocking time is reasonably and effectively reduced, so that the influence of thefrequency switching process on the performance bandwidth of the whole chip is effectively reduced.

Owner:JLQ TECH CO LTD

Intelligent dynamic load balancing method for high-speed real-time database

ActiveCN102404390BReduce block timeFlexible distributionTransmissionDynamic load balancingNetwork communication

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Urban high-altitude hedge multi-surface integrated trimming robot and trimming method thereof

ActiveCN109479551ARealize all-in-one trimmingAchieve one-piece pruningHedge trimming apparatusCuttersAgricultural engineeringSelf adaptive

The invention discloses an urban high-altitude hedge multi-surface integrated trimming robot and a trimming method thereof. The robot comprises a baffle plate supporting mechanism, crank rocker mechanisms, a positioning wheel positioning mechanism and a cutter mechanism; the baffle plate supporting mechanism comprises an upper baffle plate, a lower baffle plate, a left baffle plate and a right baffle plate; two sets of the crank rocker mechanisms are respectively positioned at the left side and the right side of the upper baffle plate and used for controlling the first-stage unfolding / first-stage folding and the second-stage unfolding / second-stage folding of the robot; the positioning wheel positioning mechanism comprises two positioning wheels, which are mounted on the lower baffle plateand are contacted with a middle plane of a hedge table base through self-adaptive motion for positioning; the cutter mechanism comprises an upper cutter, a lower cutter and a left cutter, and the upper cutter, the lower cutter and the left cutter are used for trimming three sides the hedge. The trimming robot can simultaneously perform multi-surface trimming and mechanical operation, and has goodtrimming quality, thereby effectively avoiding the phenomenon of uneven pruning of the existing trimming device.

Owner:SOUTH CHINA AGRI UNIV

Railway switch slag stone cleaning robot

The invention discloses a railway switch slag stone cleaning robot and relates to the field of railway slag stone cleaning. The railway switch slag stone cleaning robot comprises an underframe, a railpulley, a supporting seat, a sliding guide rail, a sliding platform, a guide rod, a mechanical arm, an excavating shovel, a hydraulic cylinder A and a hydraulic cylinder B; the underframe is a firmware support for the robot; the supporting seat, a pulley connecting shaft and the rail pulley are mounted on the bottom surface of the lower part; the sliding guide rail is fixedly connected to the upper part of the underframe and slidingly connected with the sliding platform; a differential heavy-load hydraulic cylinder A is placed on the sliding platform; the mechanical arm on the guide rod is connected with the excavating shovel; and the earring-shaped hydraulic cylinder B is mounted on the mechanical arm. An operator moves the robot to a switch slag stone cleaning position, the hydraulic cylinder B pushes the excavating shovel to excavate slag stones, the hydraulic cylinder A pushes the mechanical arm to realize a transporting action, and the slag stones are cleaned to a corresponding location. According to the railway switch slag stone cleaning robot, the operation is simple and convenient, the time and labor are saved, the labor cost is greatly reduced, and the slag stone cleaningefficiency is enhanced.

Owner:王昕

Mechanical replacement and laying construction method for ballast turnout

InactiveCN112878120AImprove shop qualityHigh degree of mechanizationRail switchesBallastwayArchitectural engineeringStructural engineering

The invention relates to a mechanical replacement and laying construction method for a ballast turnout. The method comprises the steps of selecting a turnout pre-laying position, transporting the turnout, replacing and laying the turnout within blocking time, treating new and old stone ballasts, welding the turnout and the like. According to the method, the whole set of turnouts are pre-laid outside the blocking time, and the method is implemented within the blocking time as follows: the whole set of turnouts are transported to the vicinity of a turnout replacing and laying area by adopting turnout replacing and laying equipment, old turnouts are dismantled and moved away, ballast beds are excavated, old stone ballasts are removed and transferred, the ballast beds are leveled, new turnouts are laid, tamping and stabilizing are performed, the turnouts are finely adjusted, and finally turnout welding is completed until a line is opened. According to the invention, the turnout changing and paving quality is improved, the overall construction time is saved, the blocking construction frequency is reduced, the construction can be flexibly carried out according to the blocking time, the mechanization degree is improved, the construction safety risk and the labor intensity are reduced, meanwhile, the material and manpower consumption is reduced, and the cost is saved for the turnout changing and paving construction.

Owner:CRCC HIGH TECH EQUIP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com