Railway temporary-beam quick mounting-dismounting complete apparatus

A technology of a complete set of devices and convenient beams is applied in the field of rapid loading and unloading complete sets of railway conveyor beams, which can solve the problems such as the need to block the section for more than one hour or even two hours, reduce the number of trains running, and achieve economic losses in railway transportation. The effect of light weight, reduced blockage time, and reduced economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

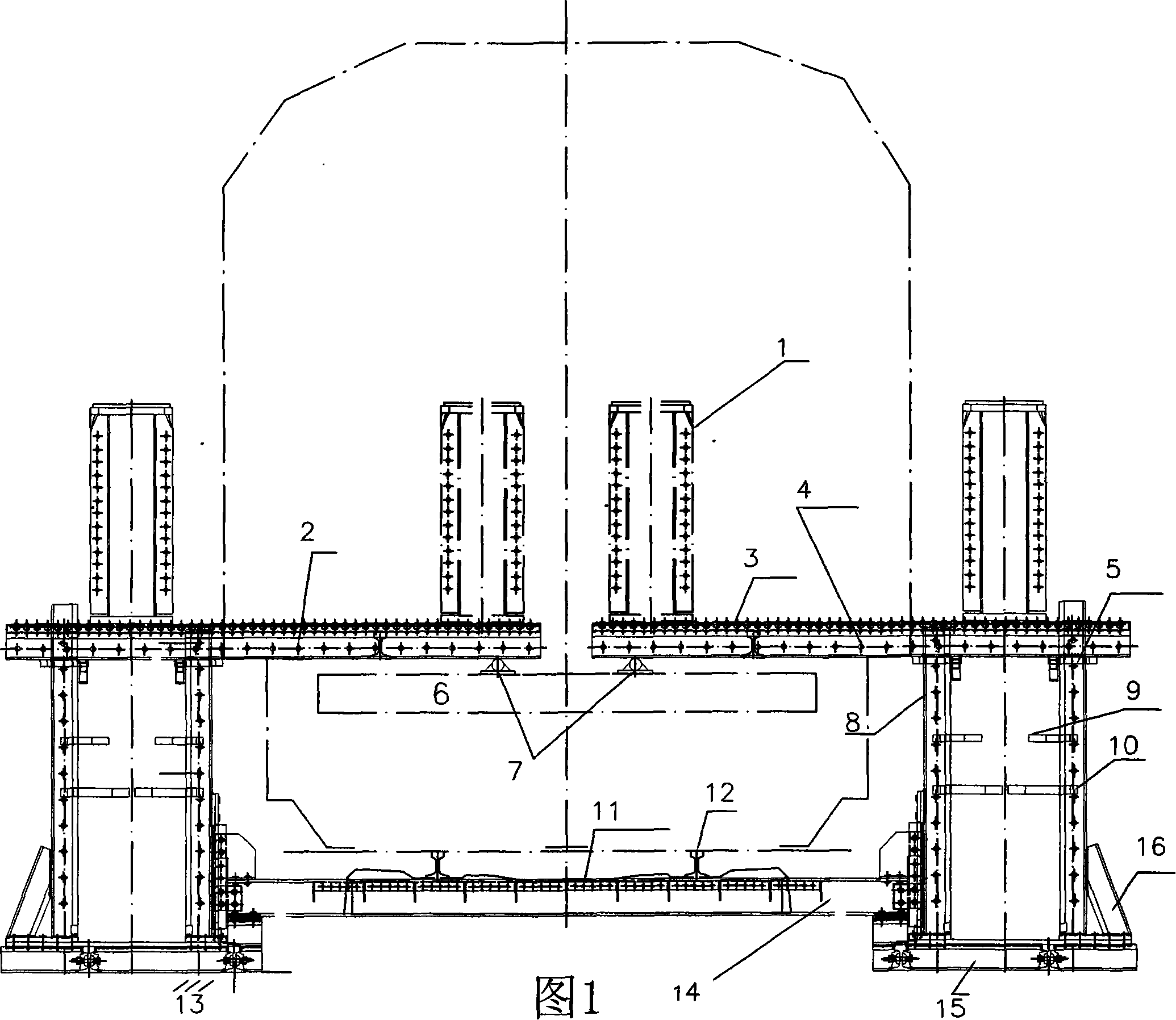

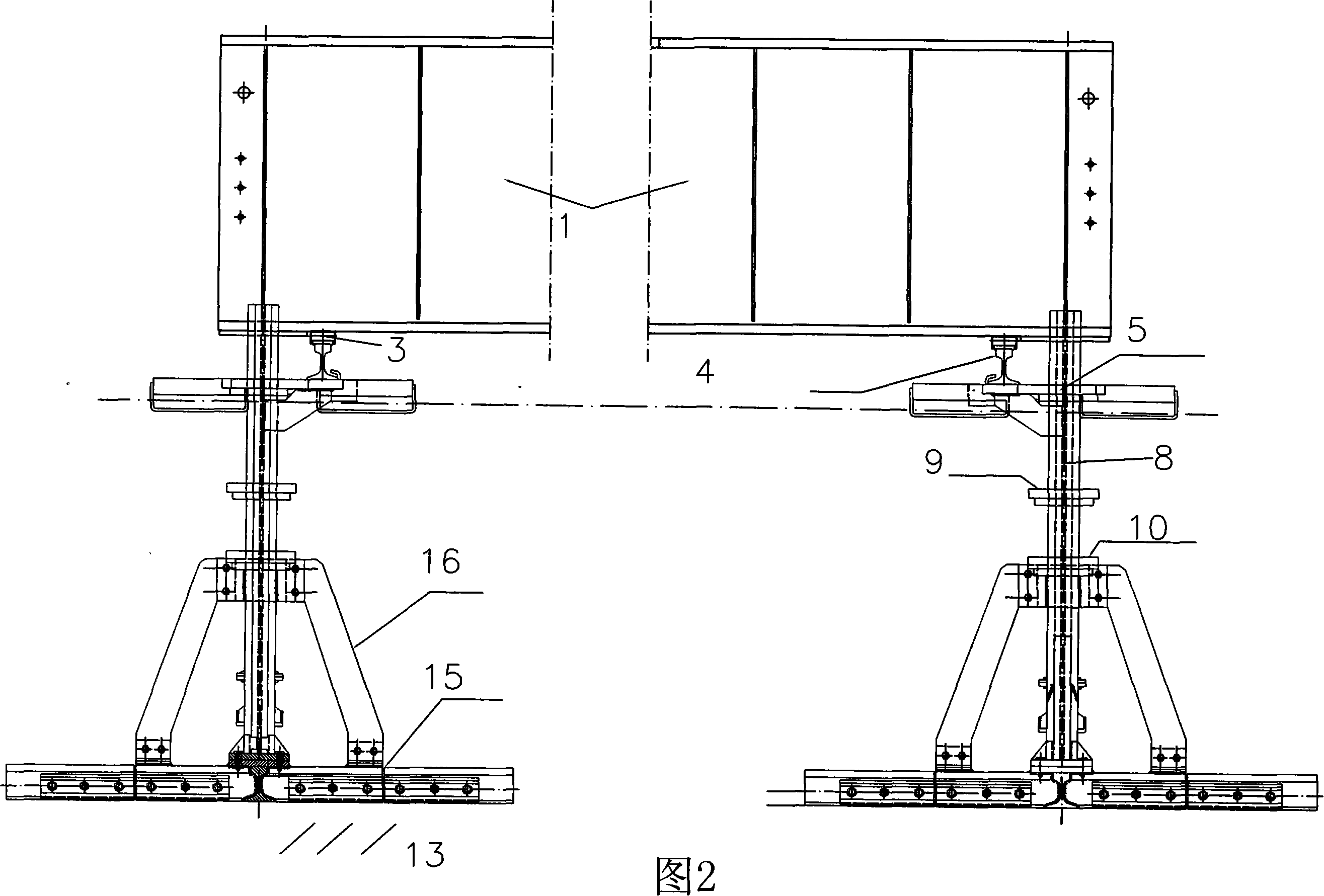

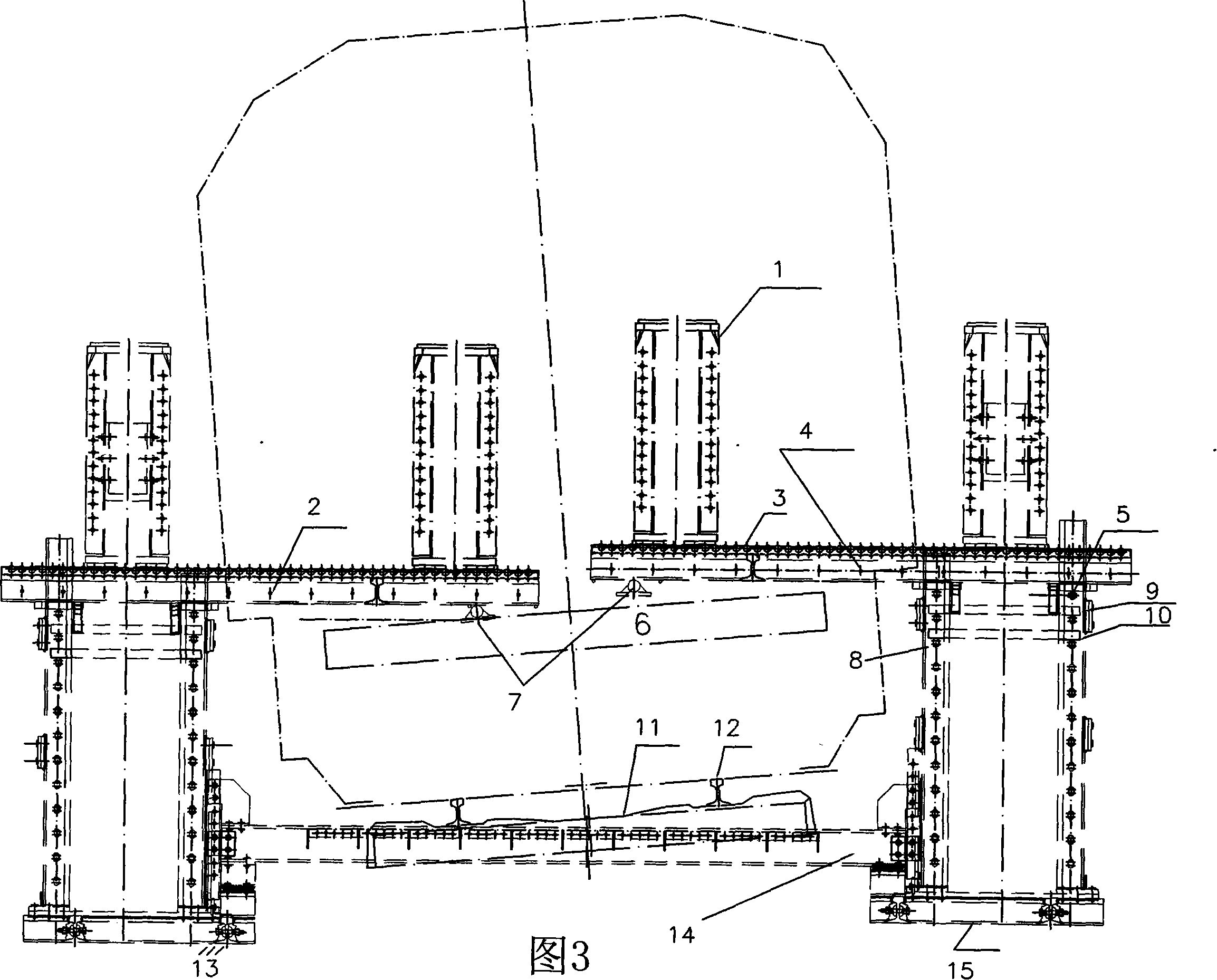

[0043]With reference to Fig. 1-shown in Fig. 8, the complete set of fast loading and unloading of railway beams according to the present invention includes four sets of beam lifting devices respectively arranged on both sides of the railway track, and two sets of beam lifting devices opposite to each other on both sides of the railway pass through the rail 12 The fixed I-beams 14 at the bottom are connected together; each group of beam lifting devices includes three sets of work platforms and a pair of lifting column guide rails 8 on both sides of the work platform for sliding up and down. And the bottom is drilled with equal height round pin holes at a certain distance, the round pin holes are pierced with positioning pins to support the working platform that is lifted to this position, and the bottom of the guide rail of the lifting column is provided with a gap for pulling out the working platform; The upper part of the convenience beam lifting device is equipped with a roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com