Water pressure composite quick blocking method applied in drilling and blasting

A hydraulic composite and rapid technology, applied in the field of geotechnical engineering, can solve problems such as the difficulty in guaranteeing the plugging effect of blastholes, low energy utilization rate of explosives, and low cohesion of rocks, so as to improve the utilization rate of blastholes and increase the explosion energy Utilization rate, effect of improving blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] For above-mentioned blast hole, the specific implementation mode of the inventive method is as follows:

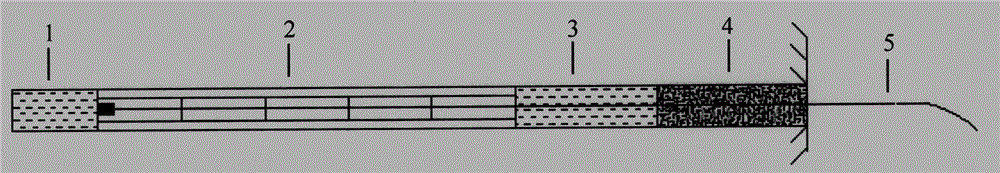

[0028] (1) A water-saving bag 1 is loaded into the bottom of the blast hole. The water bag that this concrete implementation adopts is every joint long 200mm, and diameter is 35mm, and bag thickness is 0.8mm, is the cylindrical shape that common polyethylene plastics is made.

[0029] (2) The explosive 2 is loaded into the blast hole, closely connected with the water bag 1, and the nonel tube 5 is pulled out of the orifice. The explosive used in this specific implementation is an emulsion explosive, and the total length of the charge is 2.8m.

[0030] (3) The four water bags 3 are packed into the blast hole, and are closely connected with the explosives 2.

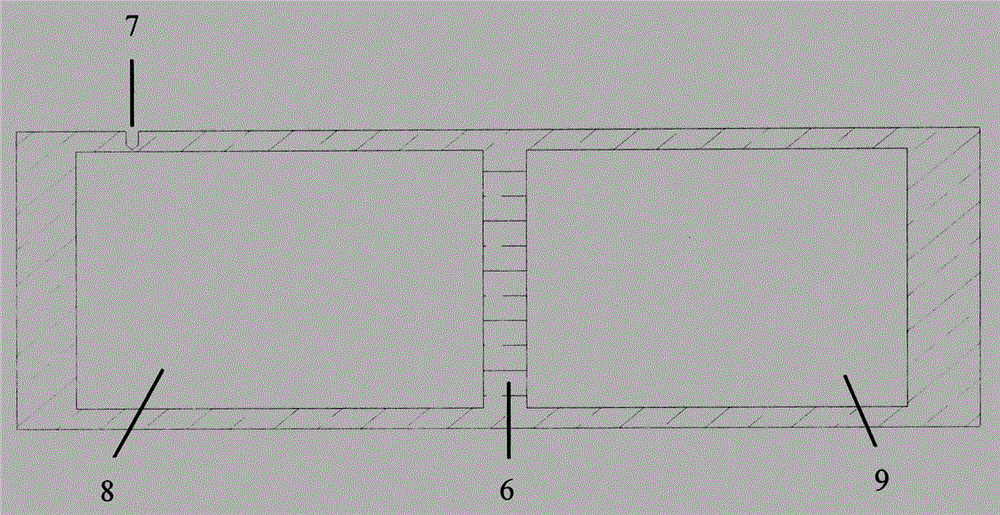

[0031] (4) Knead and squeeze the bag containing polymer resin black material 8 and white material 9, squeeze out the middle indentation 6, and fully mix and react the black material 8 and white material 9; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com