Mechanical replacement and laying construction method for ballast turnout

A construction method and technology for turnouts, which are applied to roads, tracks, ballast layers, etc., can solve the problems of irreversible permanent deformation of turnout rails, unguaranteed construction accuracy, time-consuming and labor-intensive, etc. Adjusted workload, effect of shortening welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

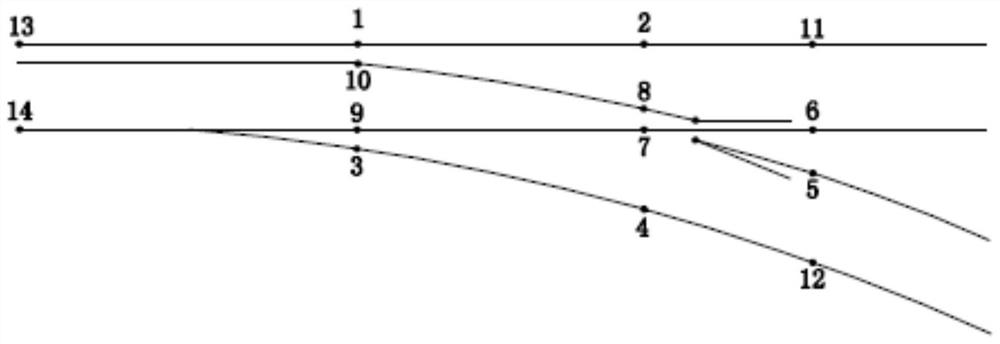

[0047] Combine below figure 1 Describe in detail the preferred technical scheme of the ballasted turnout mechanized pavement replacement construction method:

[0048] A construction method for ballasted turnout mechanized resurfacing, comprising a turnout resurfacing equipment, the turnout resurfacing equipment comprising a unit composed of several upper computers and a plurality of lower computers with crawler walking platforms, the turnout resurfacing The equipment completes the dismantling and flipping of the whole set of old turnouts and the laying of new turnouts through the cooperation of the upper and lower computers. It is characterized in that it includes the following steps:

[0049] Step 1: The overall pre-paving construction and assembly process, including the following steps: the first step, the preparation of the assembly platform; the second step, lifting and unloading all rail parts; the third step, placing and adjusting the switch sleeper of the movable frog p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com