Urban high-altitude hedge multi-surface integrated trimming robot and trimming method thereof

A technology for robots and hedgerows, applied in the field of machinery, can solve the problems of poor pruning quality, complicated traffic conditions and high pruning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

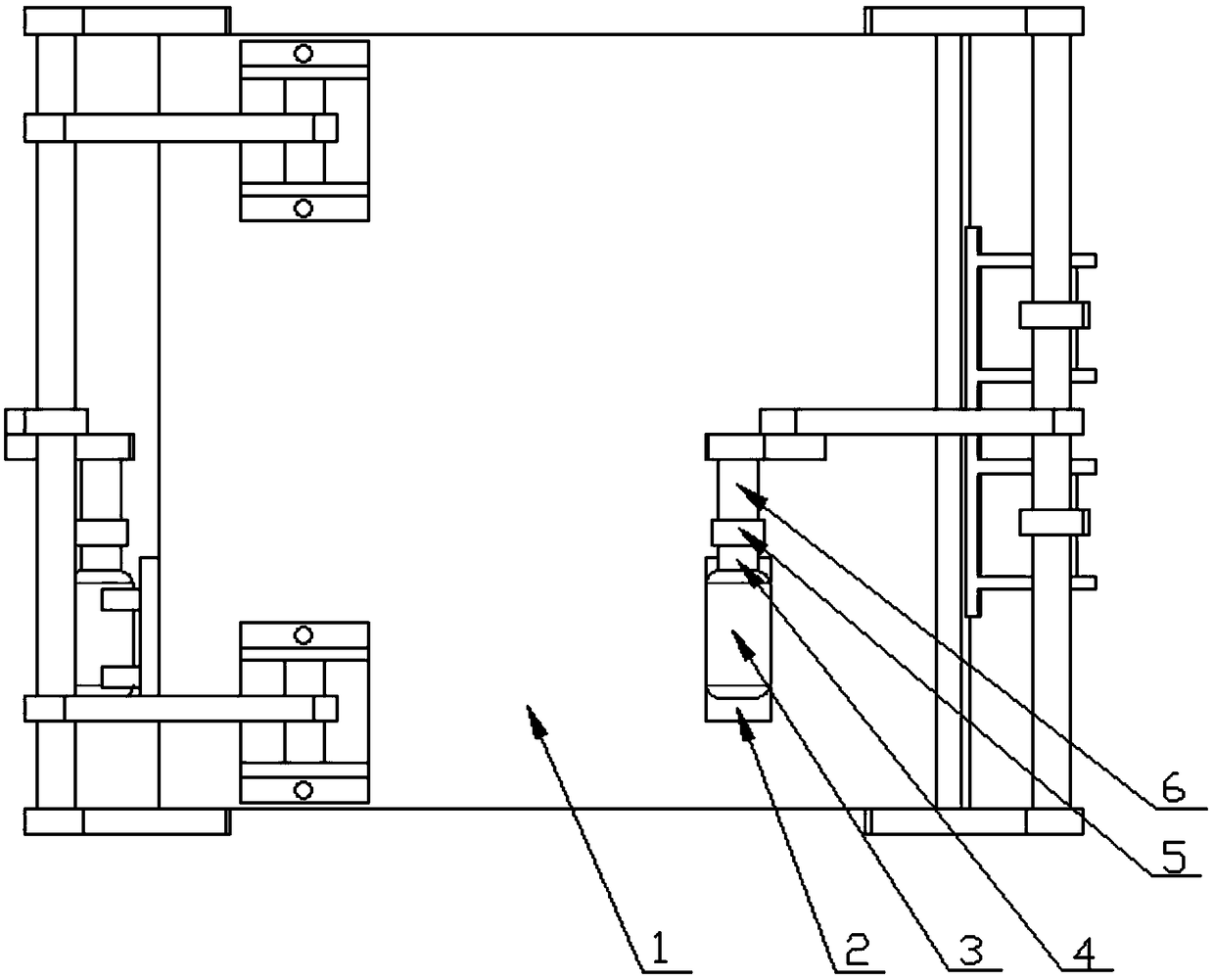

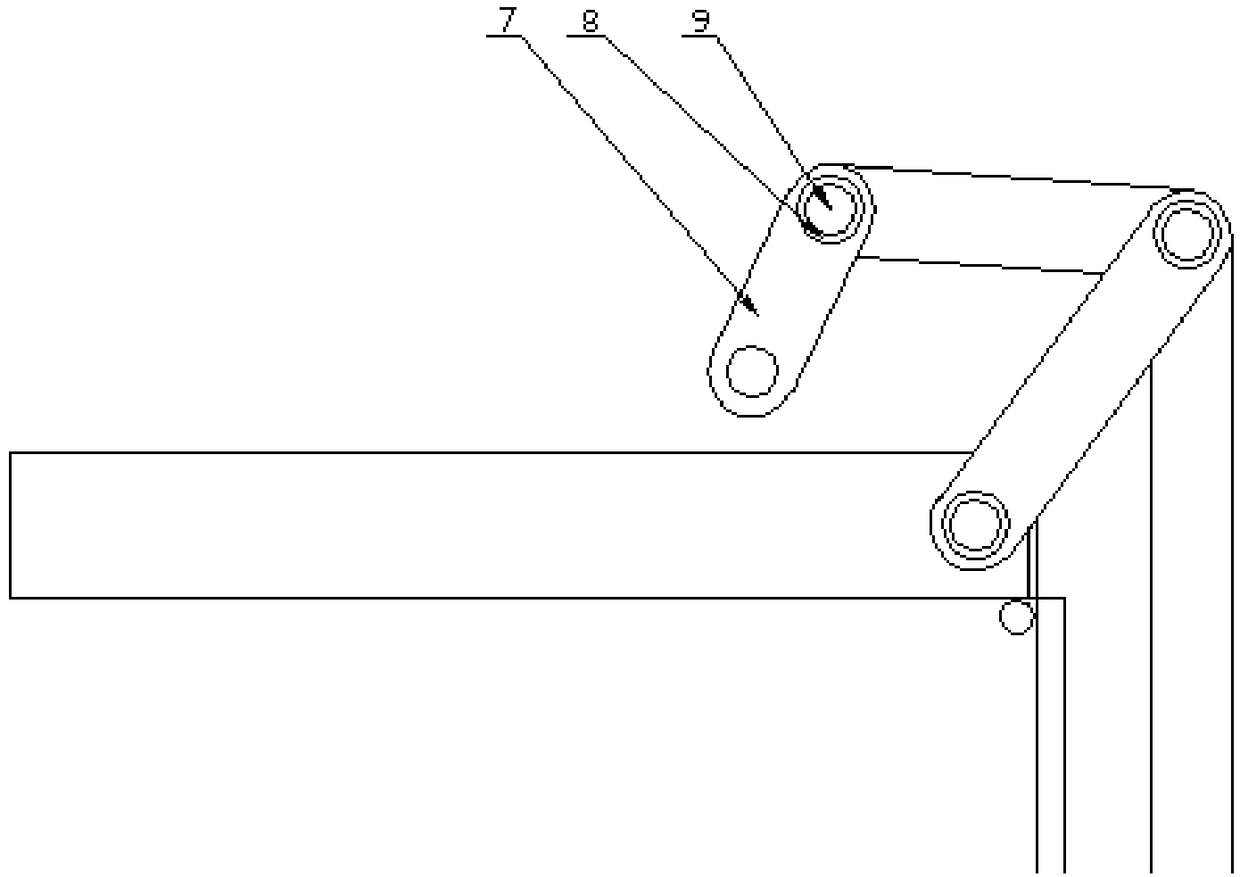

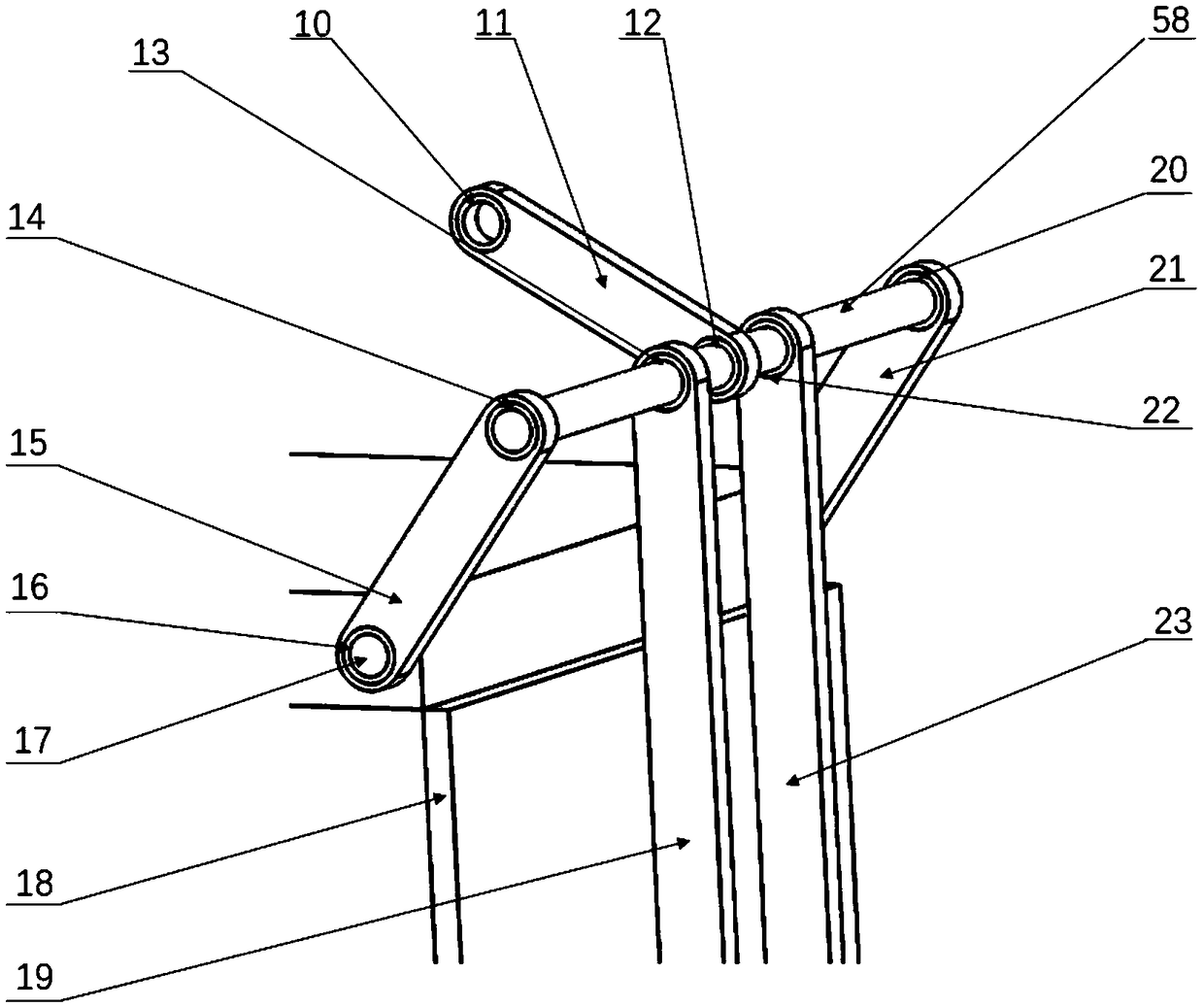

[0035] A multi-faceted integrated pruning robot for urban high-altitude hedges, such as Figure 8 As shown, it includes a baffle support mechanism, a crank rocker mechanism, a positioning wheel positioning mechanism, and a cutter mechanism; the baffle support mechanism is composed of four baffles, upper, lower, left, and right, and the adjacent baffles are connected by hinges. The baffle can rotate around the axis at a certain angle, and is mainly used to carry the crank rocker mechanism, the positioning wheel positioning mechanism and the tool mechanism; two sets of crank rocker mechanisms are located on the left and right sides of the upper baffle, and are used to control one part of the robot. The first-stage and second-stage deployments, the crank rocker mechanism part is used to transmit the movement, and the torque of the motor is transmitted to the rocker, which drives the baffle to move to the designated position; the positioning wheel positioning mechanism includes two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com