Turnout beam replacement construction method

A construction method and technology of turnout beams, which are applied to bridges, bridge materials, bridge maintenance, etc., can solve the problems of large impact on normal traffic and long replacement time of turnout beams, and achieve short replacement operation time, shorten blockage time, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

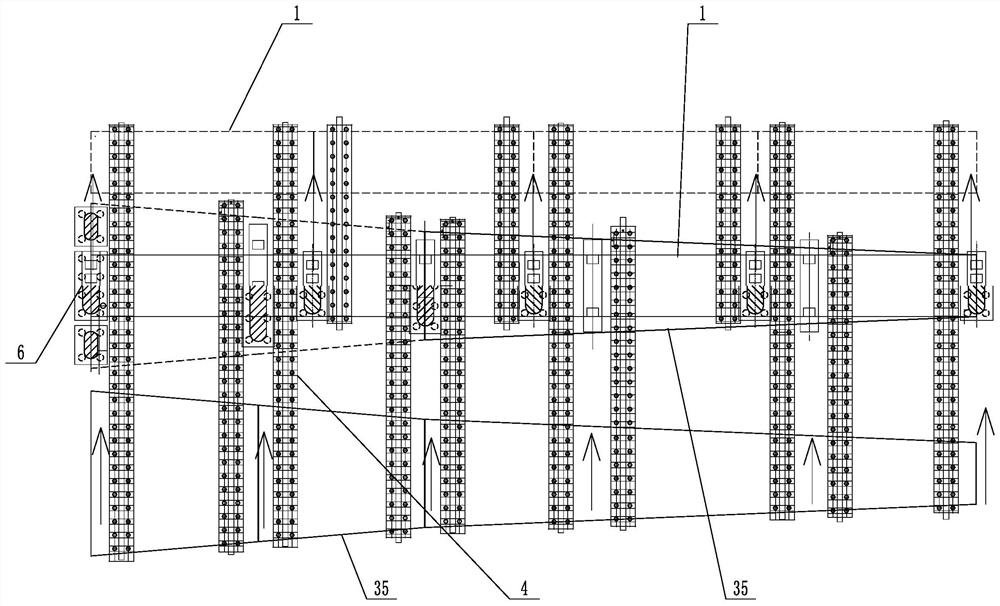

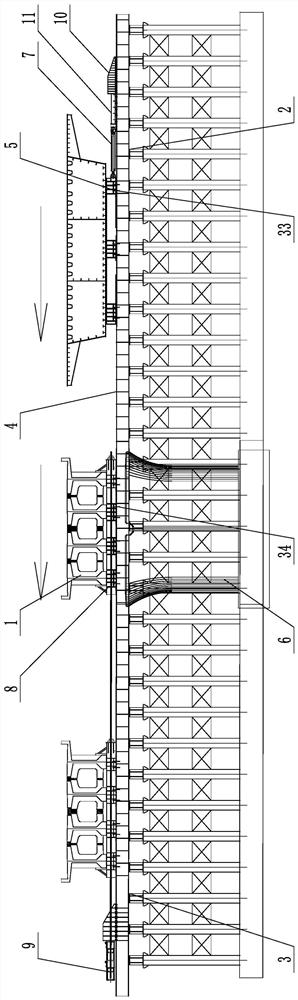

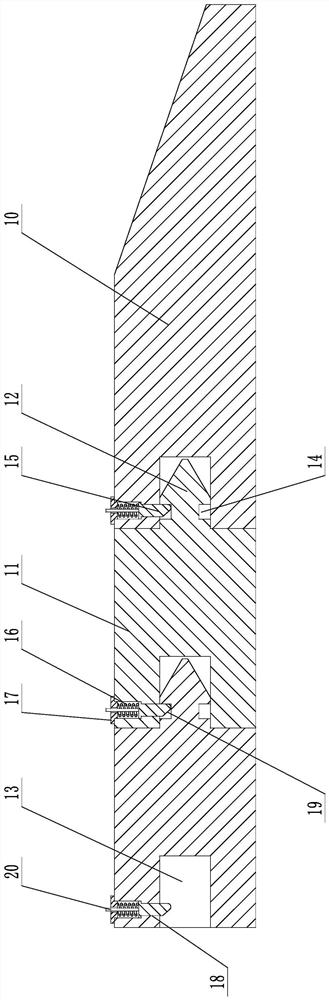

[0025] Embodiment: A kind of turnout beam replacement construction method (see attached figure 1 to attach Figure 4 ), including the following steps: a. Site layout, respectively laying out turnout beam platform 2 and existing beam storage platform 3 on both sides of existing beam 1; turnout beam platform and existing beam storage platform are set on the combined support On the steel pipe pier, the composite support steel pipe pier adopts φ529×10mm steel pipe. Double I36b I-beams are installed at the top of the steel pipe columns, and I20b I-beam diagonal braces are arranged between the columns. There are channel steel distribution beams and 6mm steel plates on it. The steel plate goes along the cross bridge to the steel sleeper. The bottom formwork of the beam is laid directly on the steel sleeper. In order to reduce the settlement of the assembly site, the foundation reinforcement area at the platform of the turnout beam system adopts bored piles with a diameter of 1.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com