Patents

Literature

33 results about "Multiscale entropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

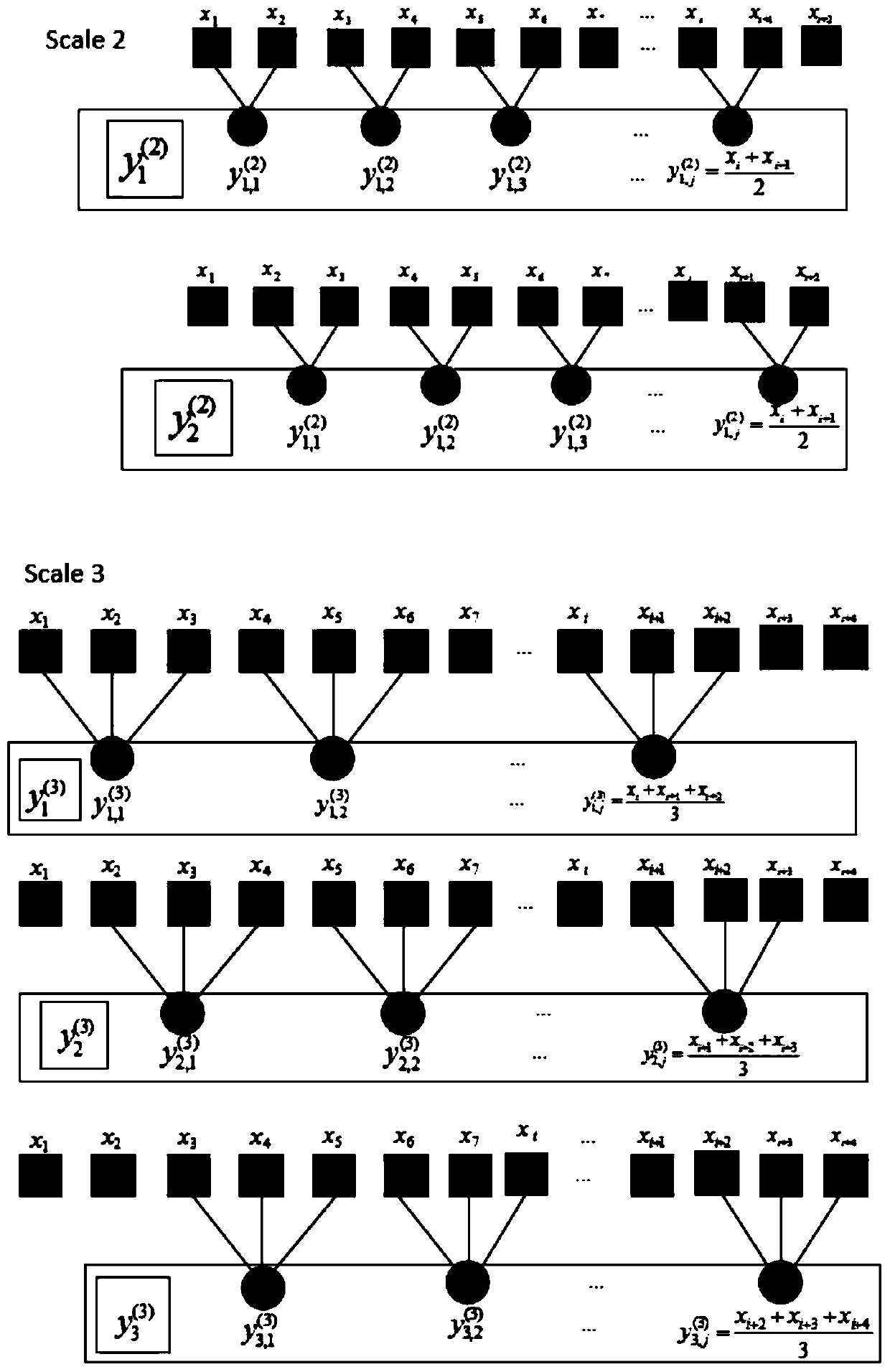

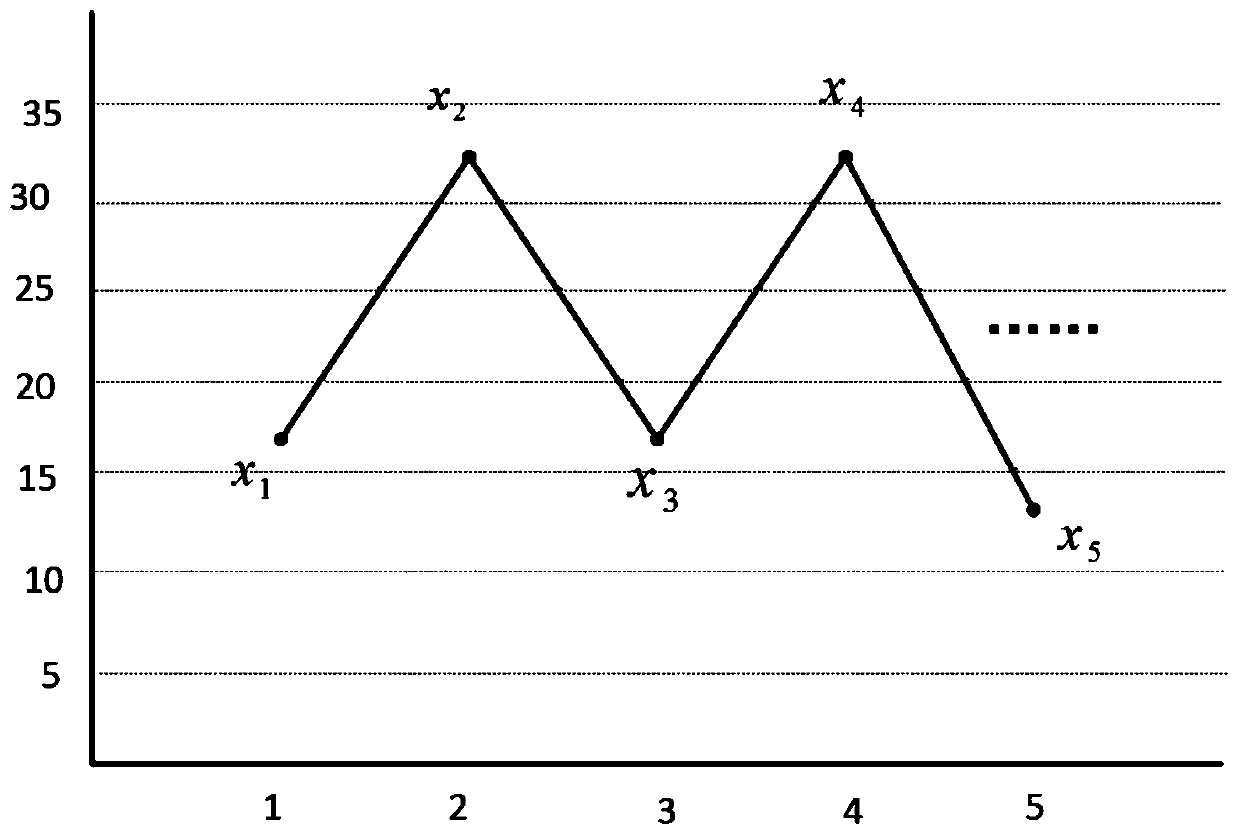

Multiscale entropy (MSE) provides insights into the complexity of fluctuations over a range of time scales and is an extension of standard sample entropy measures described here. Like any entropy measure, the goal is to make an assessment of the complexity of a time series.

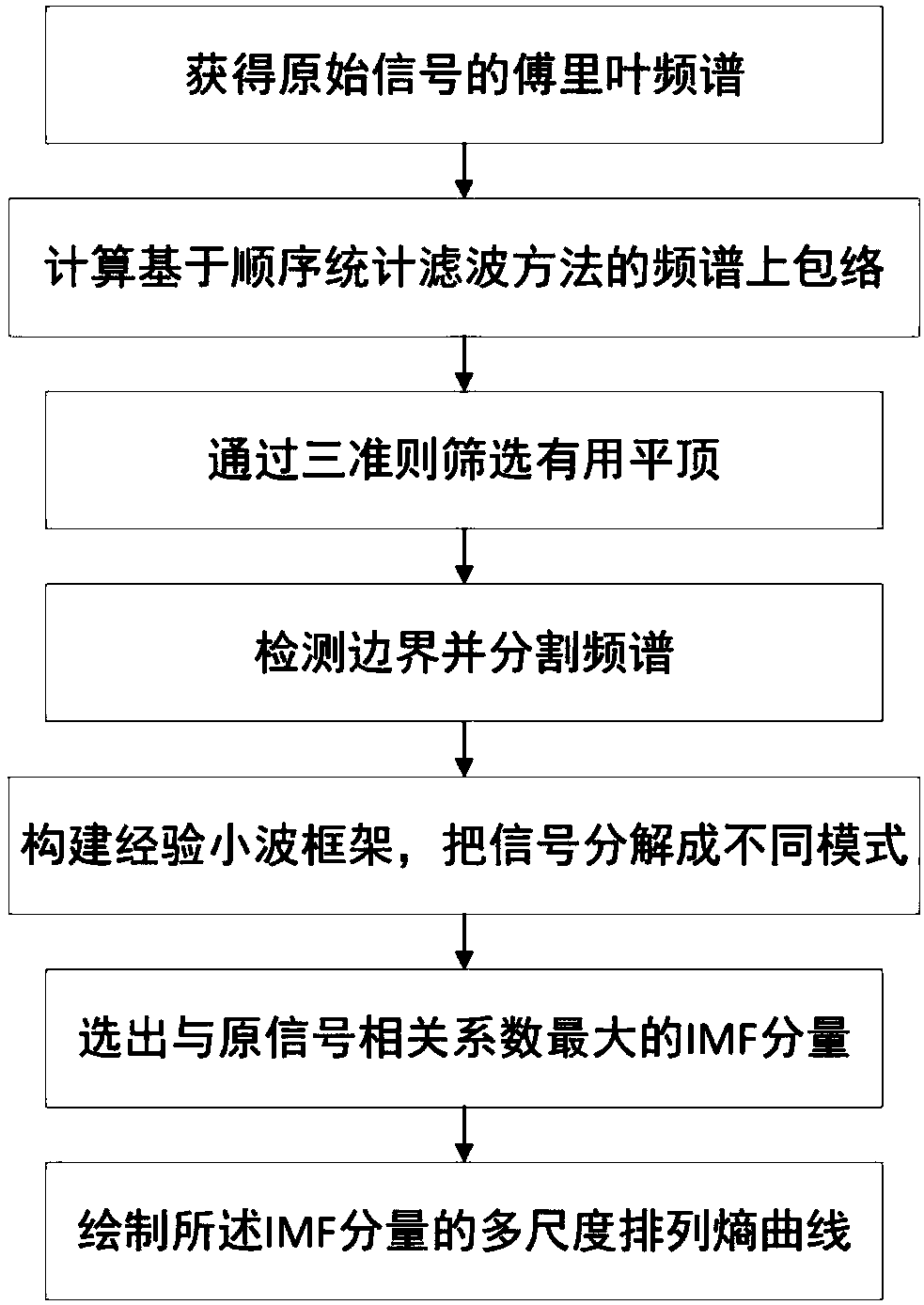

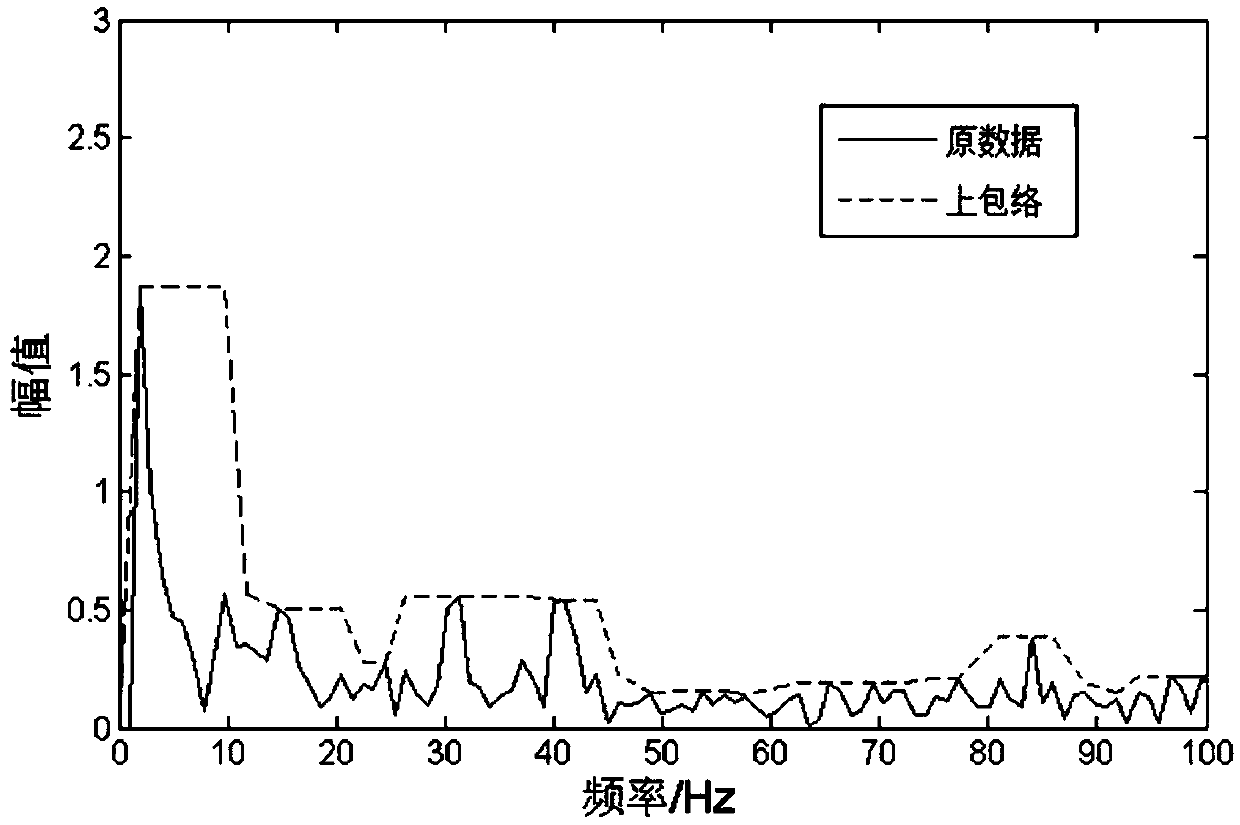

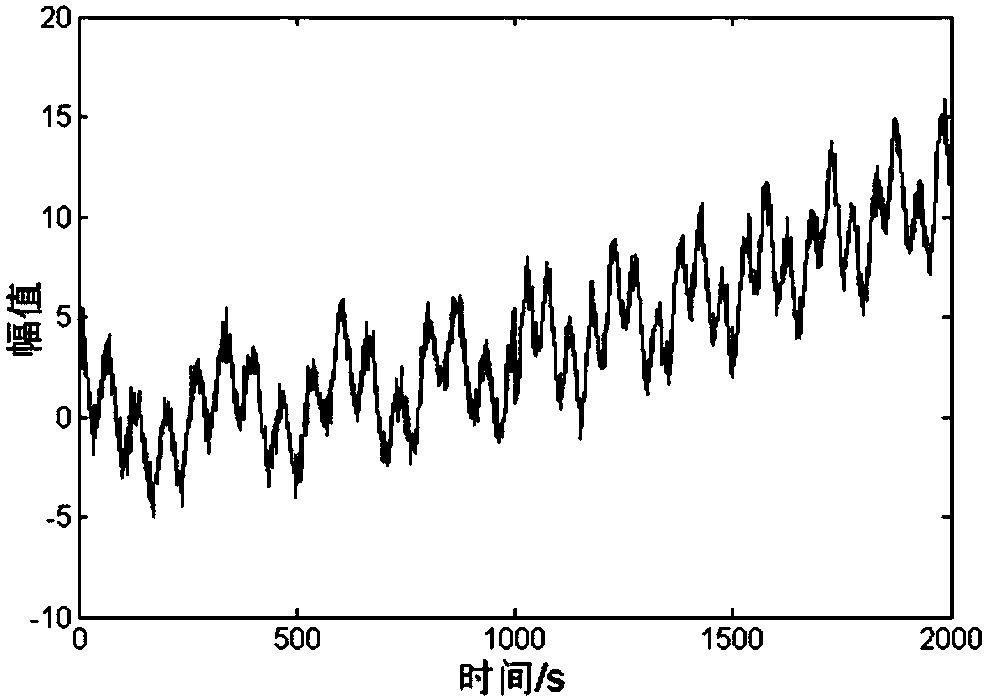

Bearing fault diagnosis method and system device based on improved empirical wavelet transform

InactiveCN108375472AImprove the shortcomings of unreasonable segmentationAvoid mode aliasingMachine bearings testingCharacter and pattern recognitionCorrelation coefficientFrequency spectrum

The invention provides a bearing fault diagnosis method and system device based on improved empirical wavelet transform. The method comprises: step one, collecting different fault bearing signals as analysis signals and converting a time domain waveform into a frequency domain waveform; step two, drawing an upper envelope of a frequency spectrum and transforming a frequency peak with a tight support into a flat top; step three, screening flat tops in the frequency domain based on criteria, removing meaningless flat tops, and keeping a main frequency; step four, using a minimum value between adjacent flat tops as the boundary of spectrum segmentation; step five, establishing wavelet filters respectively for segmented frequency spectrums and decomposing the signals into N mode components; step six, calculating similarity values between mode components and the original signals by using a cross-correlation coefficient and selecting a component with the highest similarity value; and step seven, taking a fault sample, calculating an IMF component with the largest correlation coefficient of the sample, calculating a multi-scale entropy of the IMF component, and drawing the multi-scale entropy curve of the sample to realize fault classification.

Owner:WUHAN UNIV OF SCI & TECH

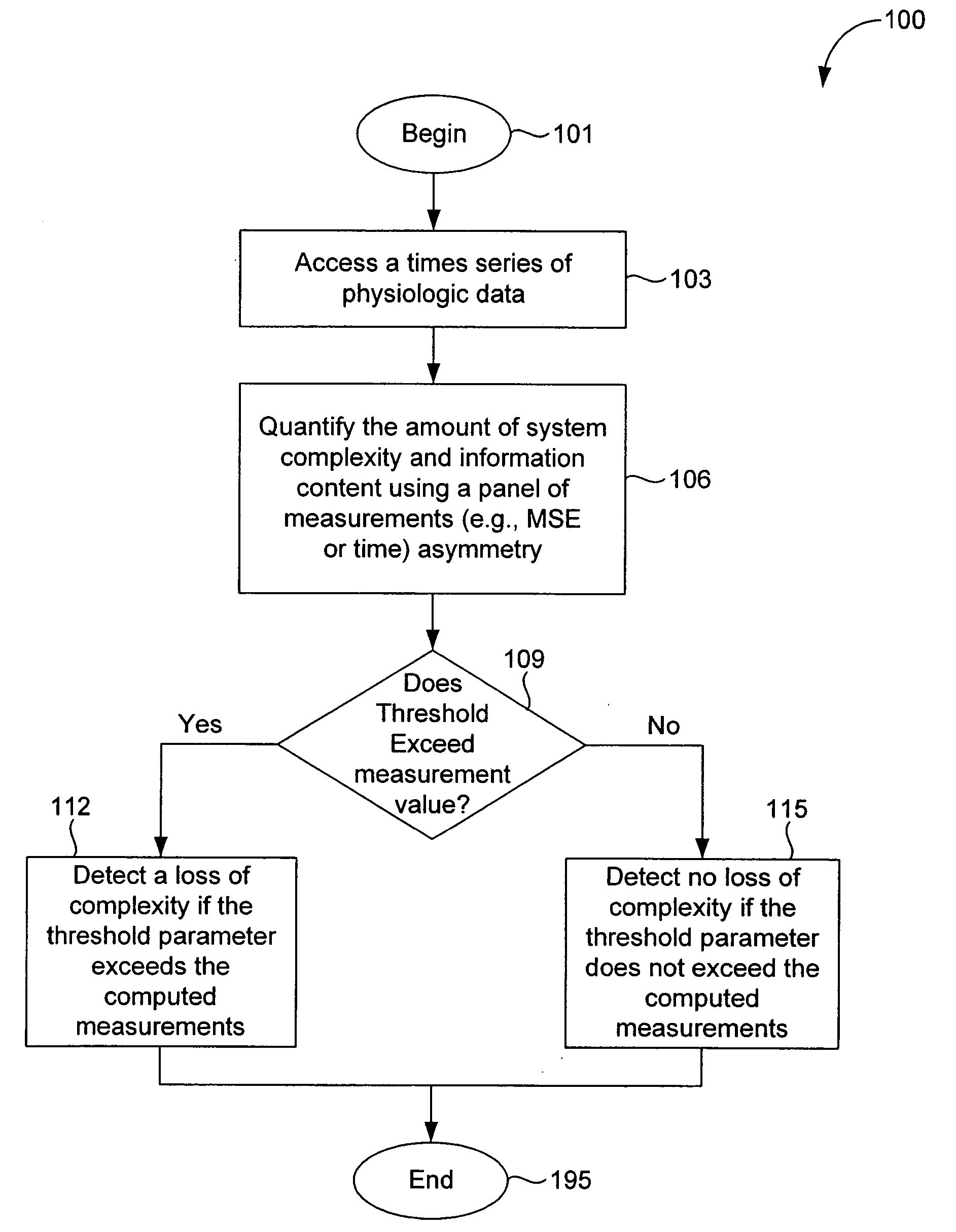

Complexity-based dynamical analysis of a network

InactiveUS20070066906A1ElectroencephalographyElectrocardiographyClinical psychologyBiological network

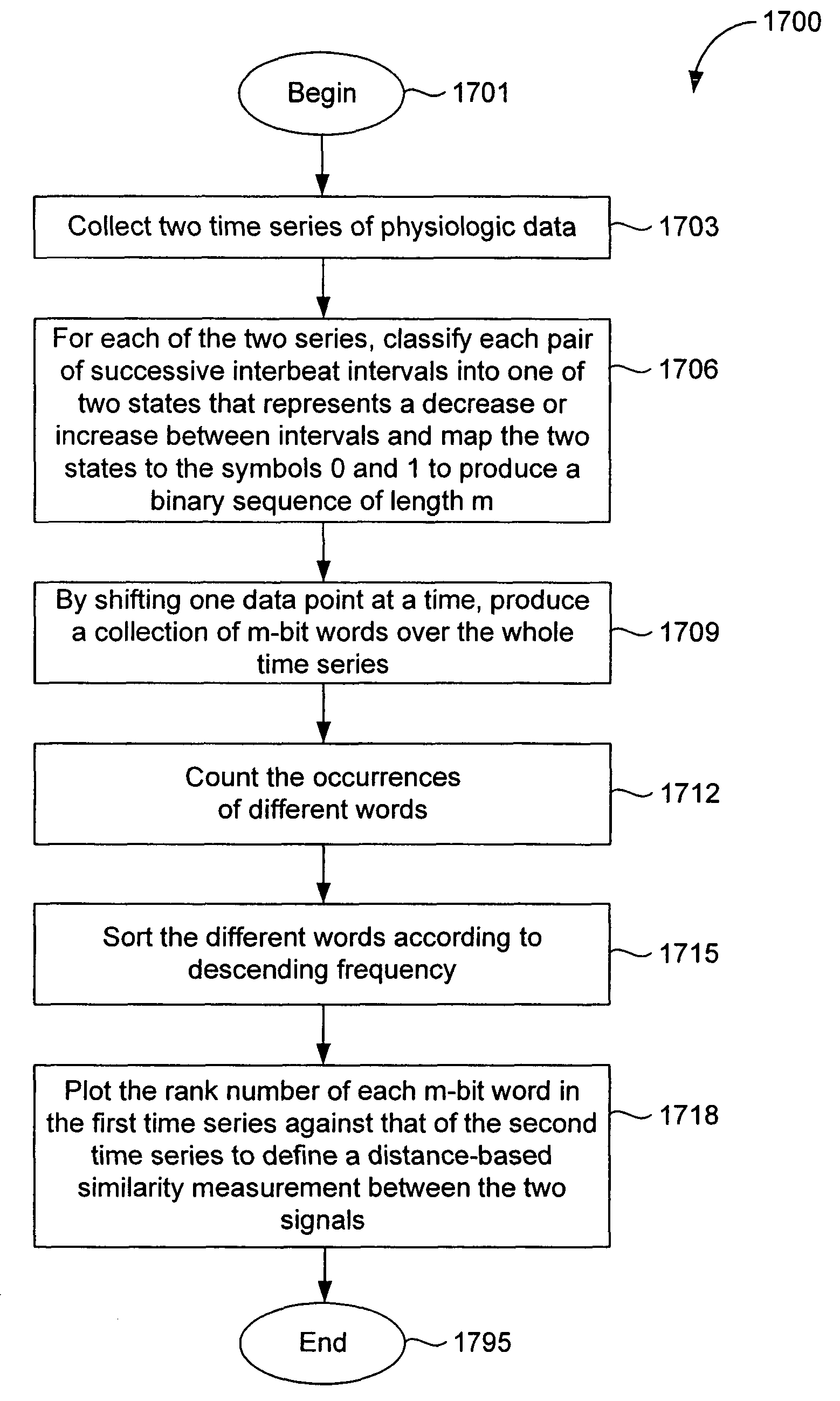

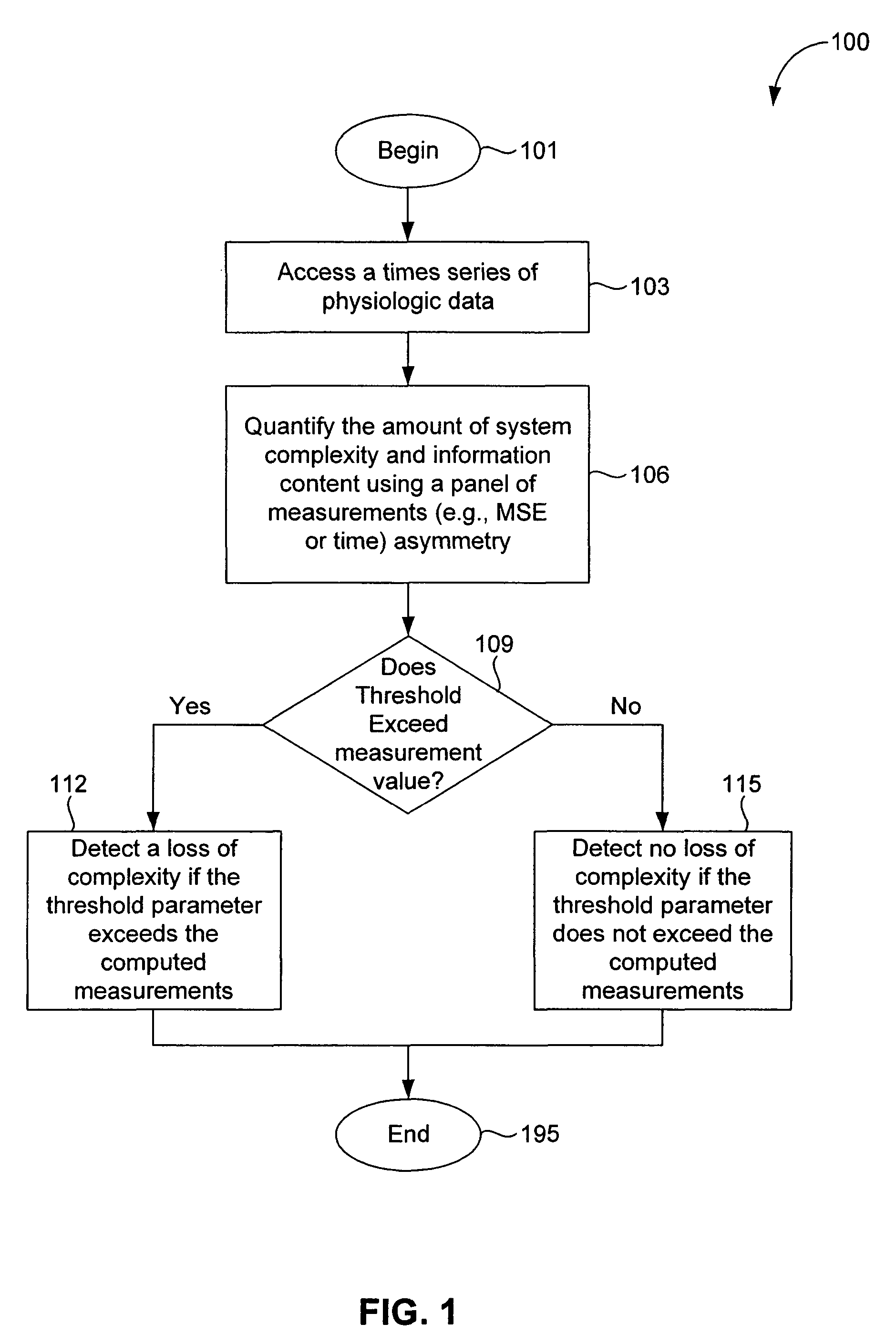

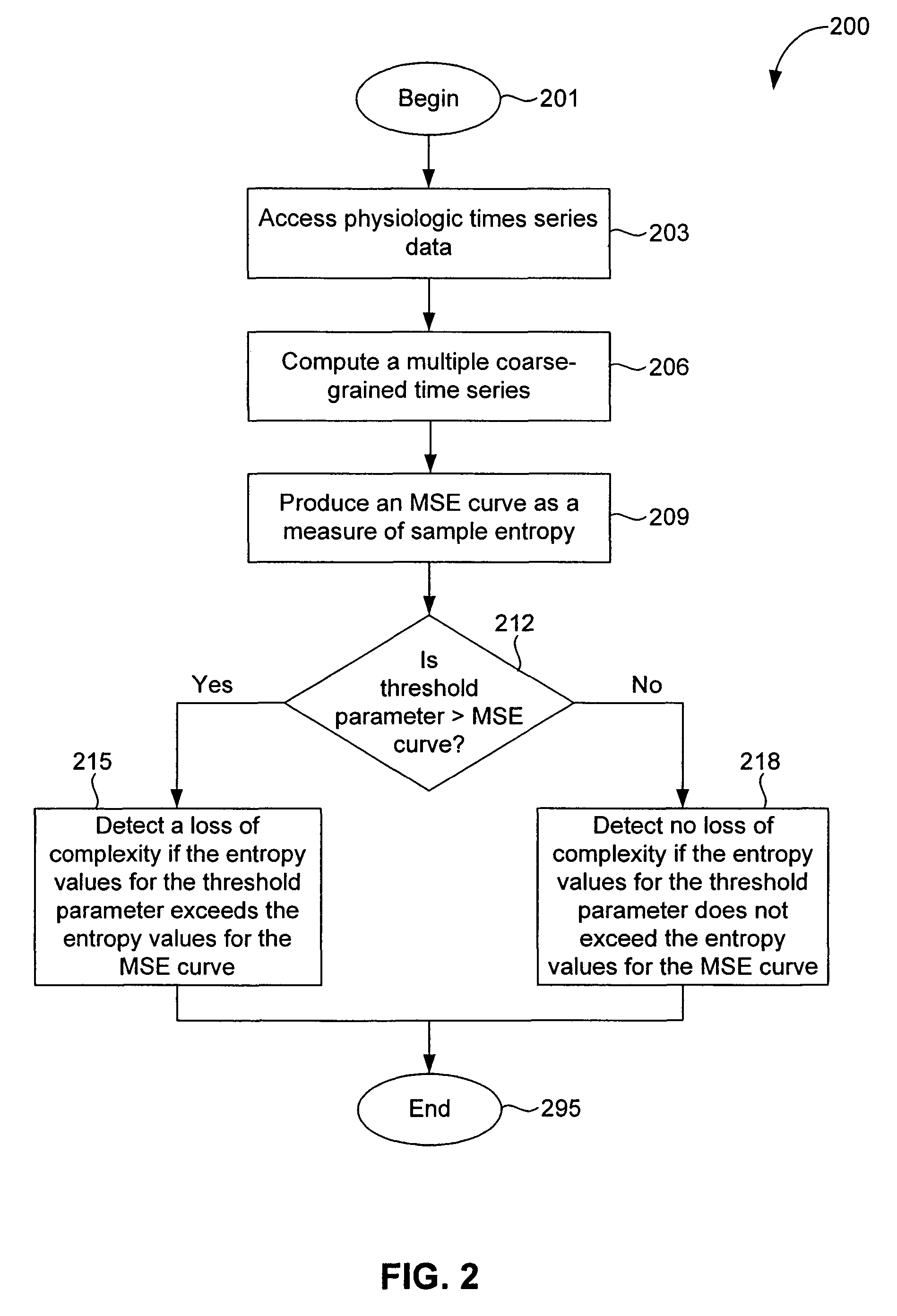

In a subject undergoing therapeutic intervention, efficacy of the therapeutic intervention is assessed based on a series of physiologic data associated with the subject. The series of physiologic data is analyzed to produce a measure of complexity. The complexity measure is then compared to a control. The efficacy of the therapeutic intervention is assessed based on the comparison of the complexity measure to the control. The control may be, for example, a complexity measure taken prior to initiation of the therapeutic intervention, a complexity measure taken from a different subject, or a predetermined threshold value. The measure of complexity is generated using, for example, a multiscale entropy measurement (MSE), a time asymmetry measurement, and / or an information-based similarity measurement. An increase in complexity indicates a positive effect of the therapeutic intervention, while a decrease in complexity indicates a negative effect of the therapeutic intervention. Stability of a non-biologic network, such as a computer network, communications network or transportation network can also be assessed.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

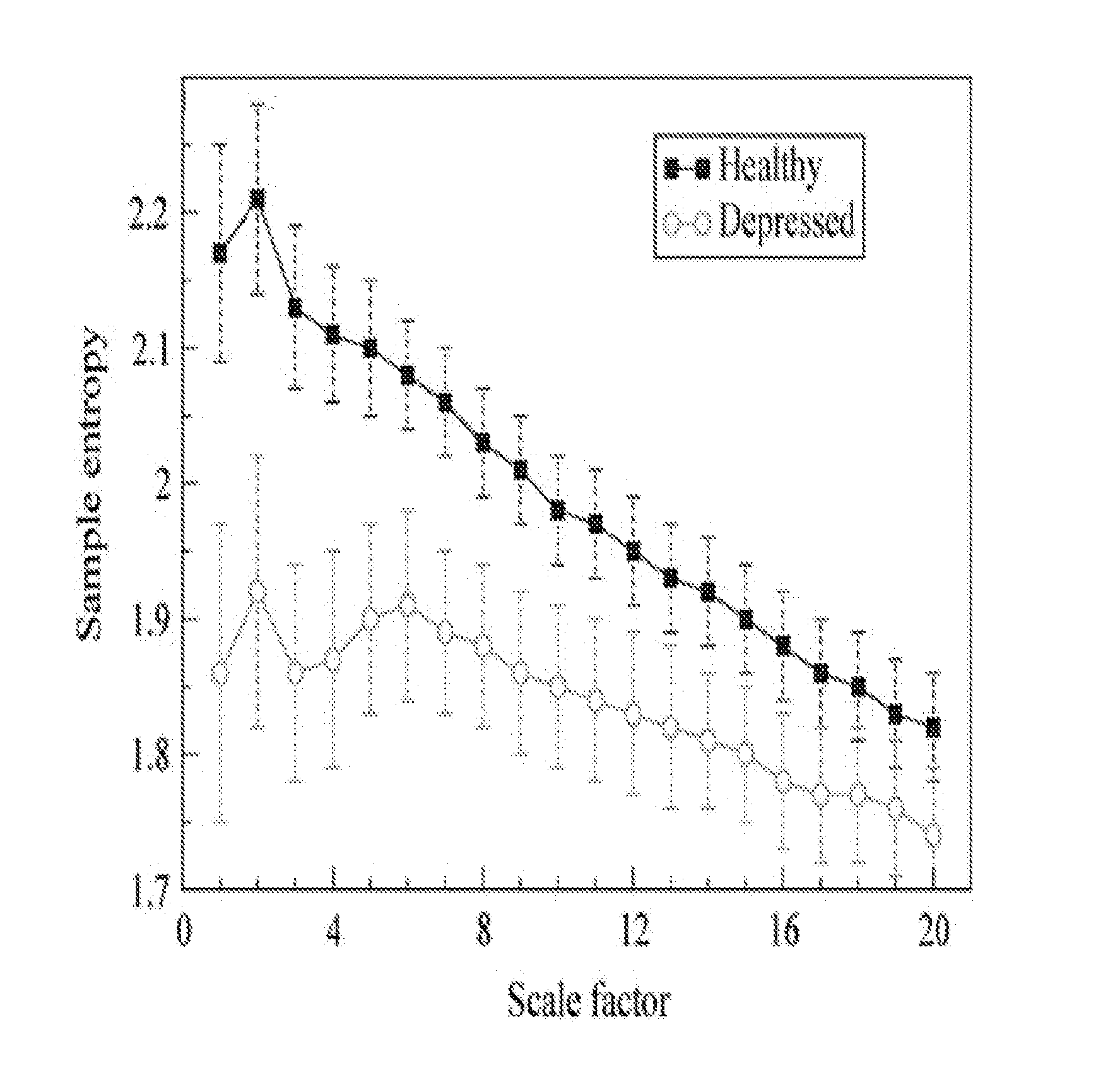

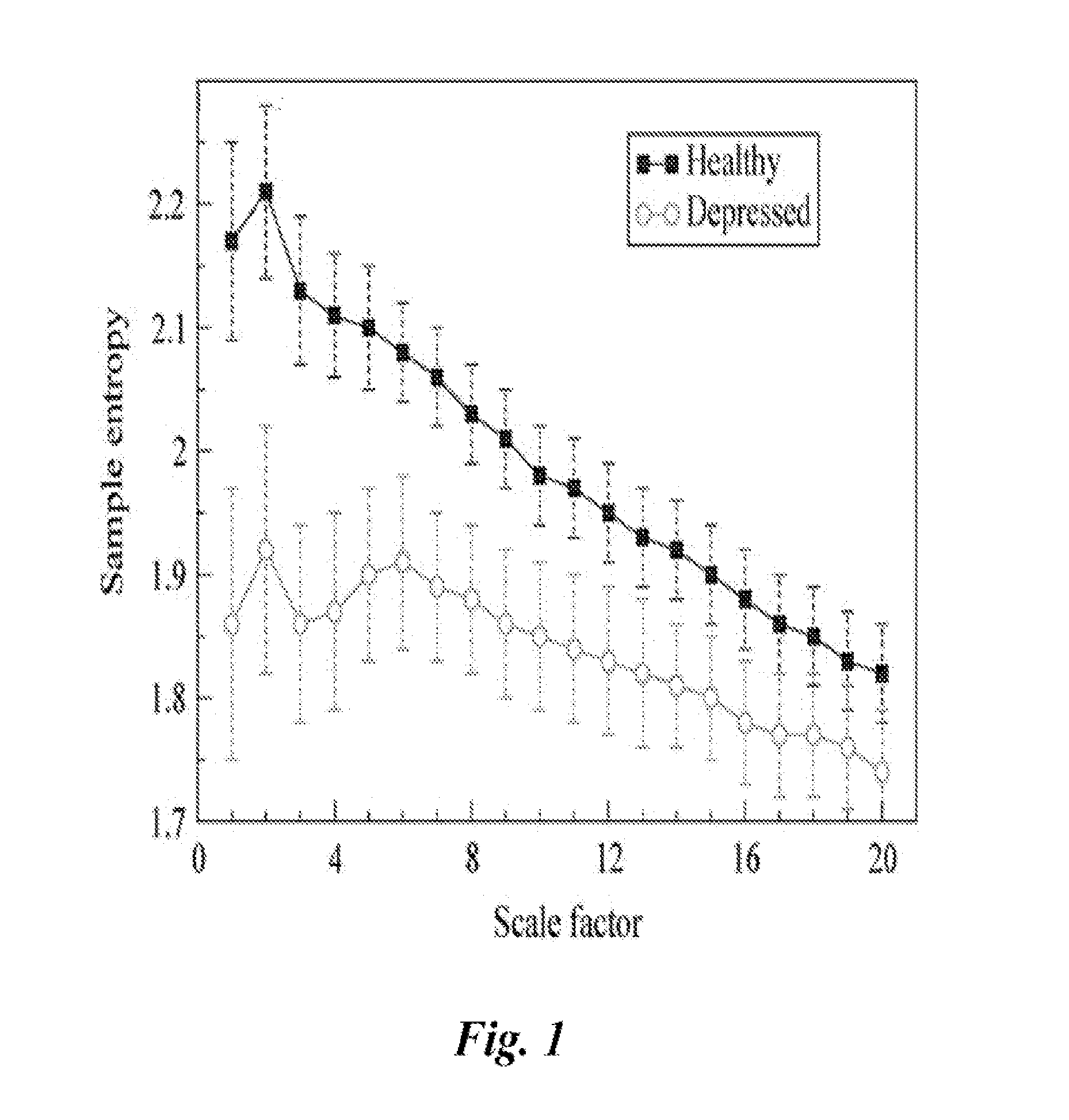

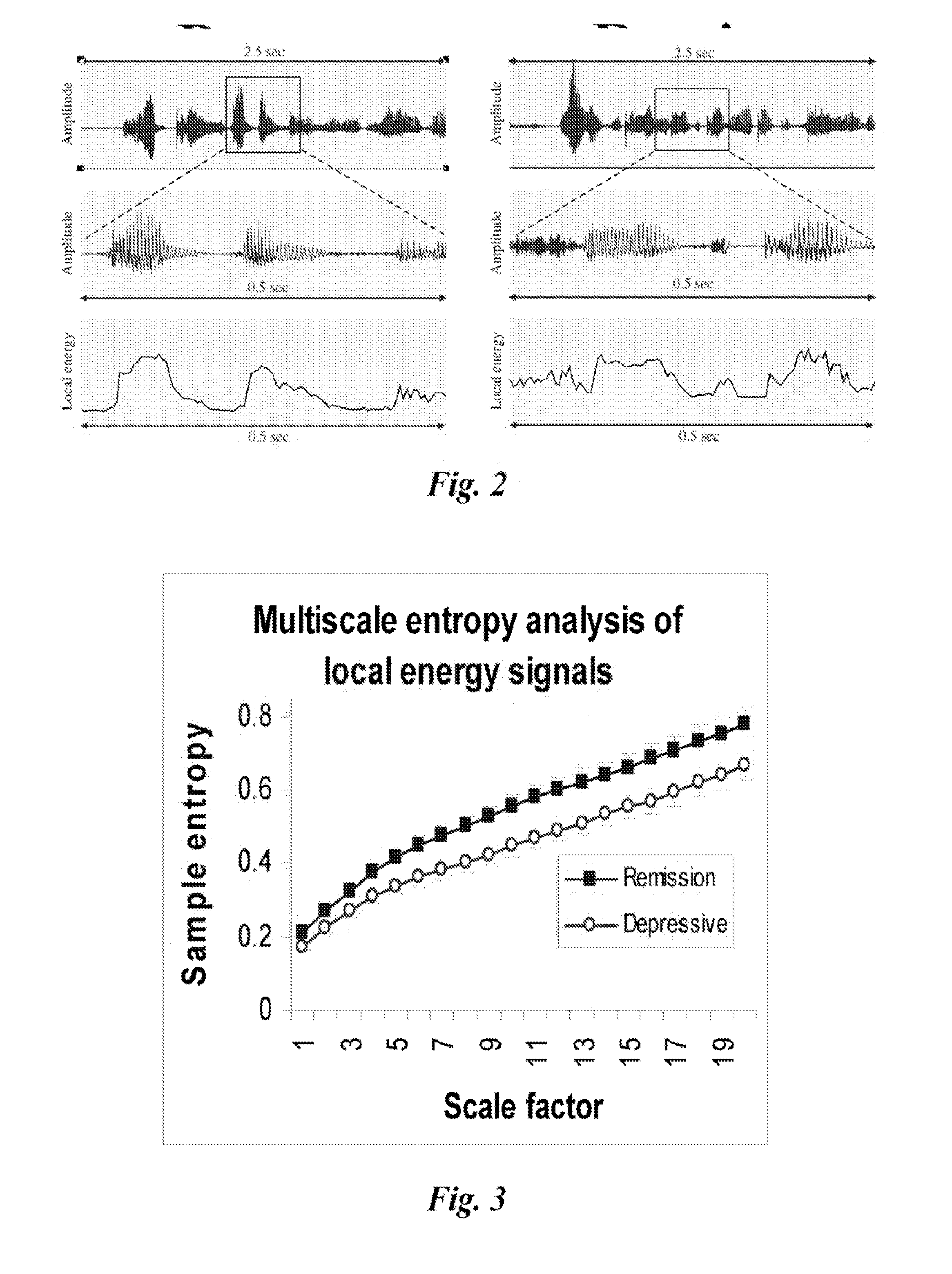

Complexity based methods and systems for detecting depression

Major depression can affect multiple physiologic systems. Analysis of signals that reflect integrated function may be useful in probing dynamical changes in this syndrome. Complex variability can be used as a marker of healthy, adaptive control mechanisms and dynamical complexity decreases with aging and disease. The heart rate (HR) dynamics in non-medicated, young to middle-aged males during an acute major depressive episode exhibit lower complexity compared with healthy counterparts. By analyzing HR time series, a neuroautonomically regulated signal, during sleep, using the multiscale entropy method, a measure of complexity of HR dynamics can be determined. The complexity of the HR dynamics is significantly lower for depressed than for non-depressed subjects for the entire night and combined sleep stages 1 and 2, providing an indication of depression. These complexity signals, individually, or in combination with the complexity of other physiologic signals, can be used to define novel dynamical biomarkers of depression.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

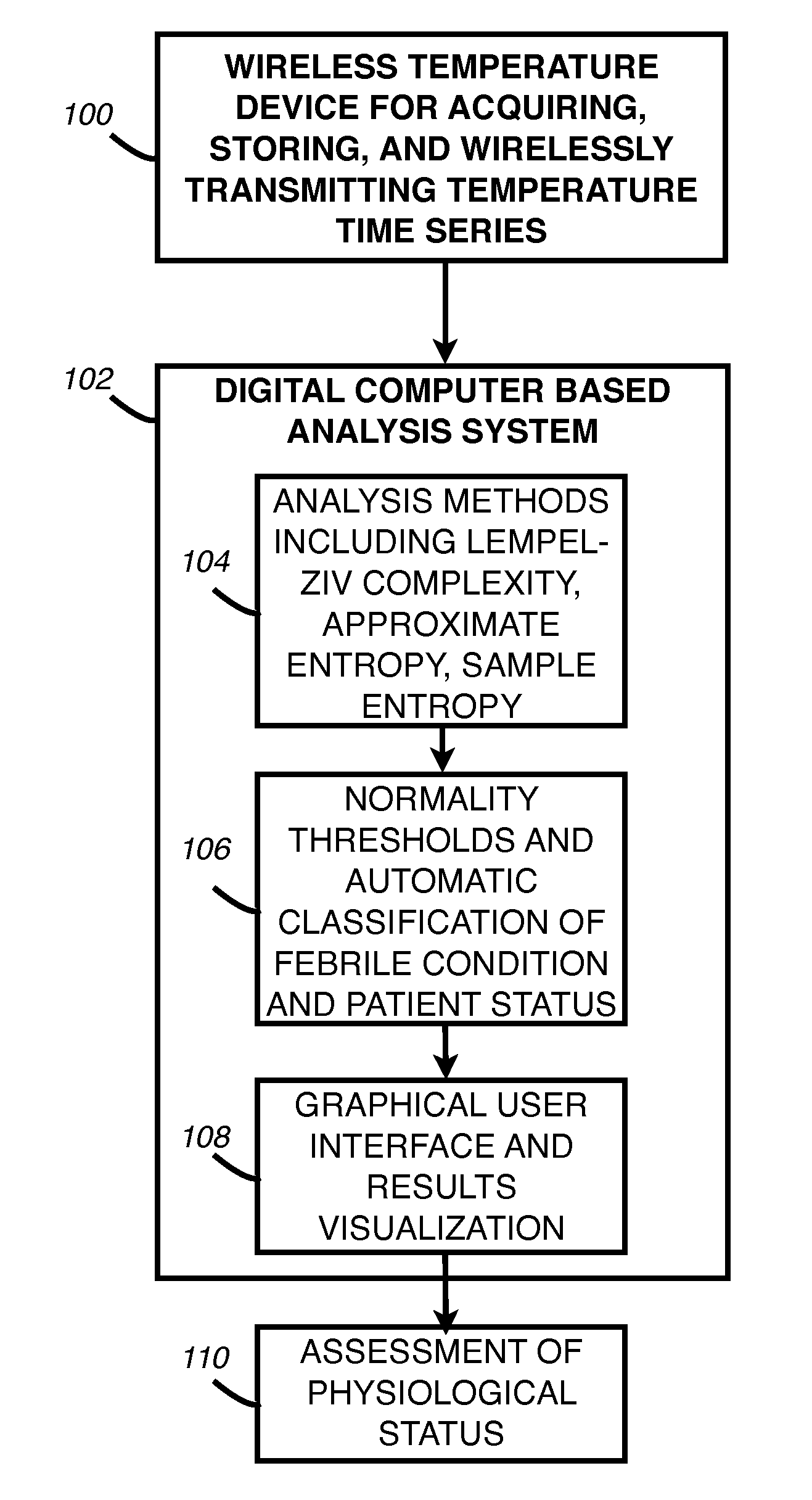

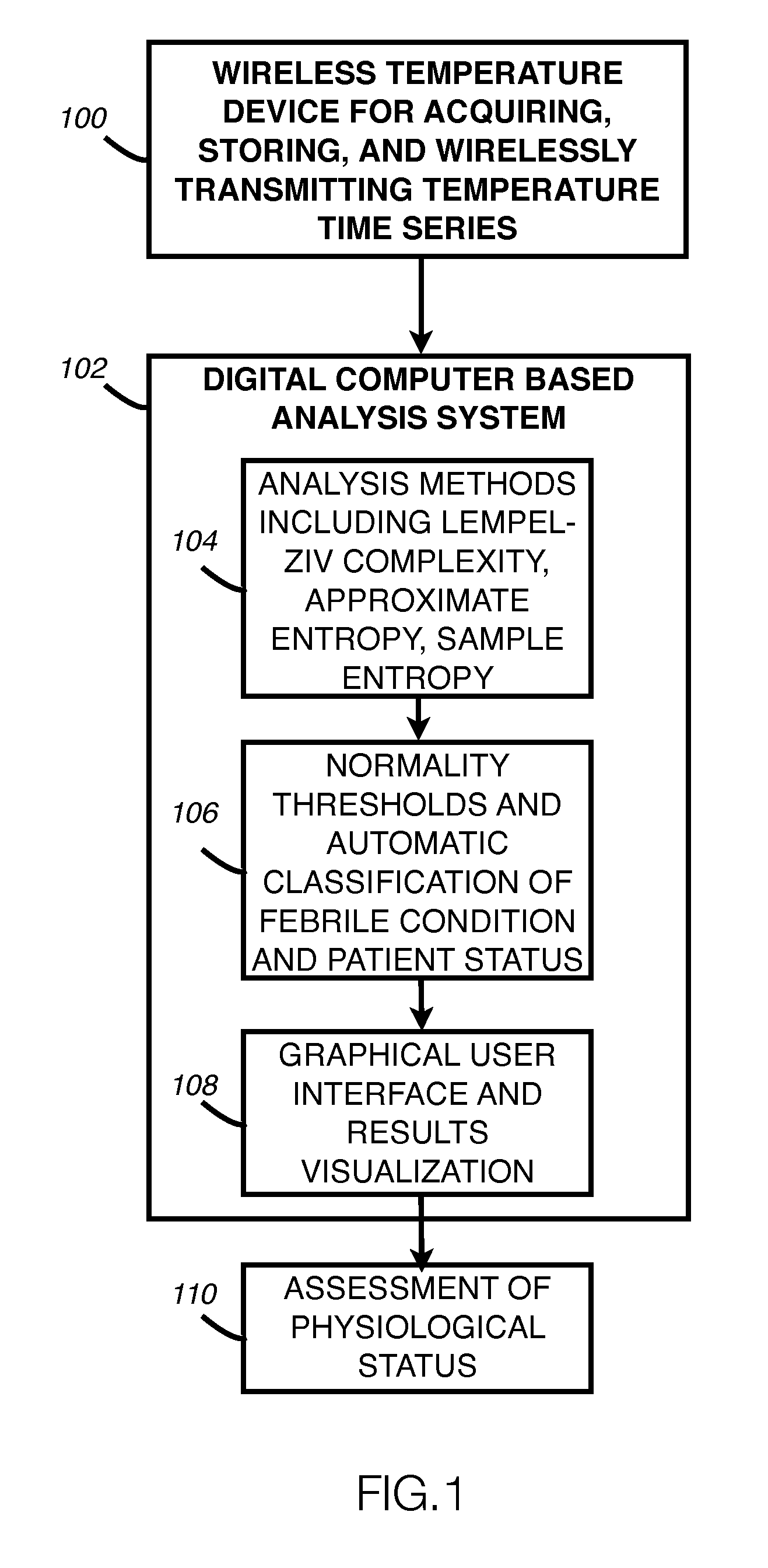

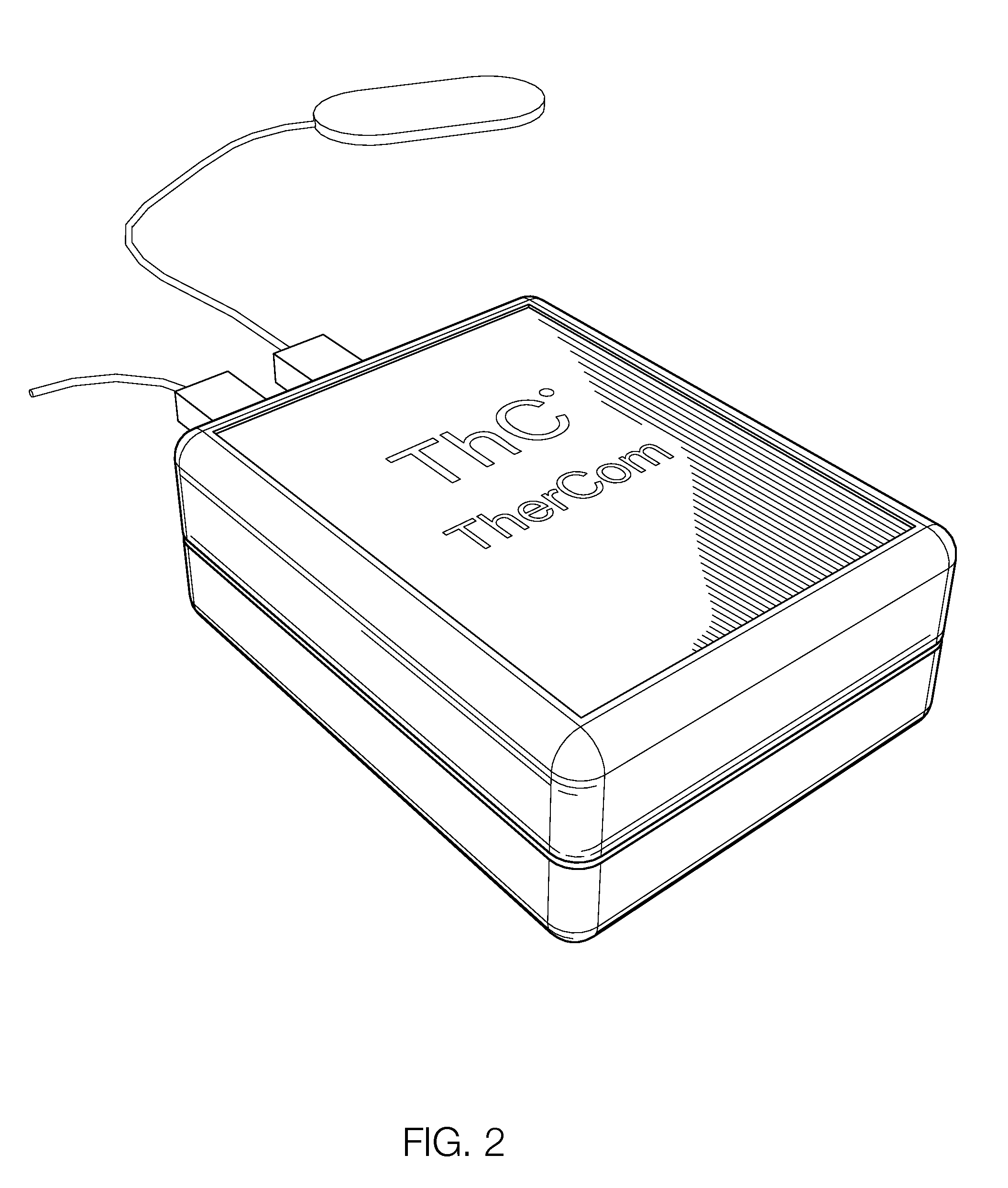

System and apparatus for wireless high-frequency temperature acquisition and analysis

InactiveUS20100042013A1Thermometer detailsThermometers using material expansion/contactionMulti methodSample entropy

We disclose a system, an apparatus, and a method for high frequency temperature monitoring and analysis. According to a disclosed embodiment the system comprises: (a) a wireless temperature acquisition and logging device especially designed for multi-day, high-frequency, and high-resolution temperature sampling; and (b) an analysis system implemented in a digital computer with one or more processors in order to analyze and characterize said temperature using a plurality of methods including complexity analysis techniques such as Lempel-Ziv complexity, Approximate Entropy, Sample Entropy, Multiscale Entropy, and Detrended Fluctuation Analysis; and other statistical time-series analysis techniques. According to one embodiment the temperature monitoring system is designed to capture the dynamic aspects of temperature in order to enable researchers and clinicians to study temperature regulation, thermal physiology, and clinical thermometry.

Owner:INNOVATEC

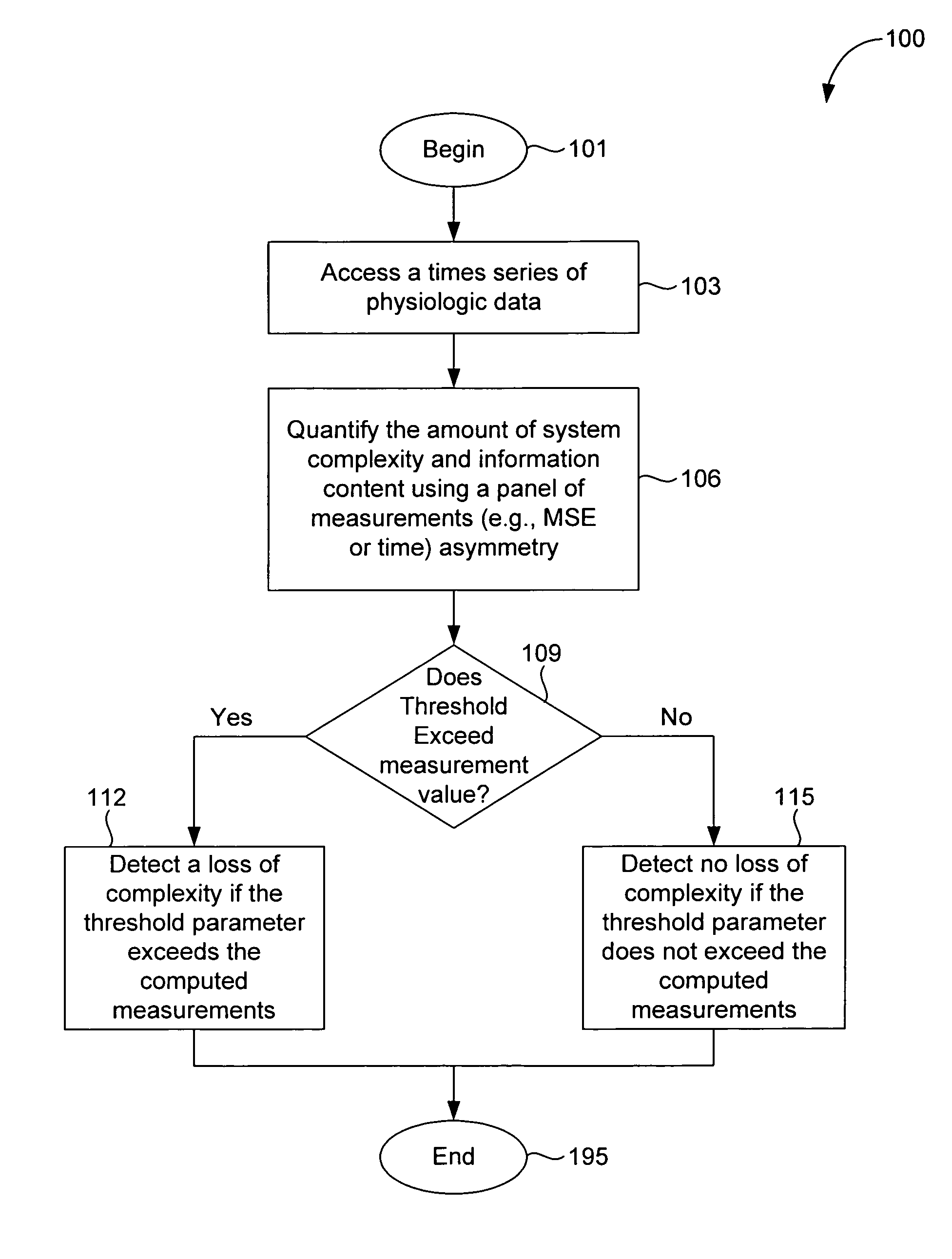

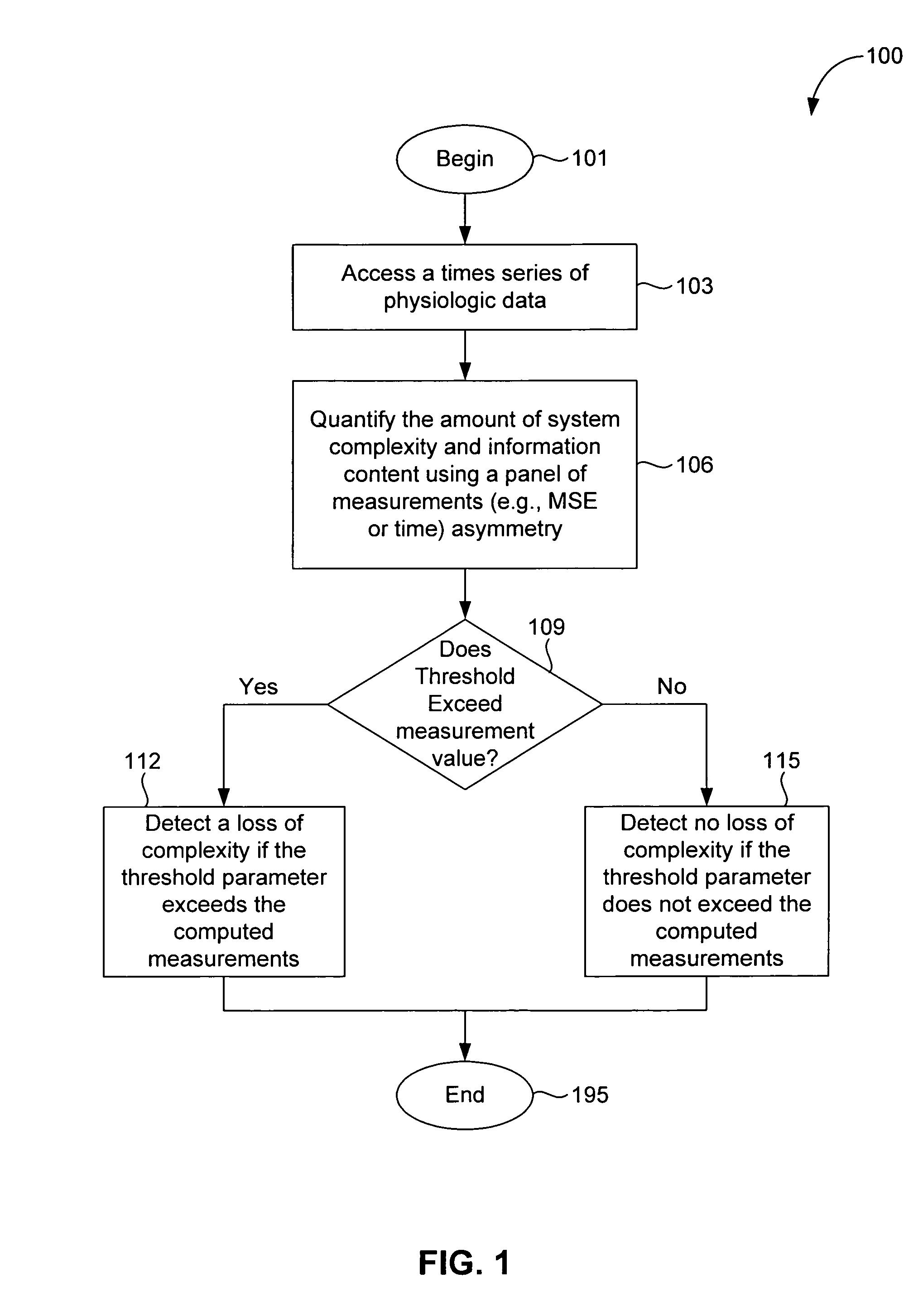

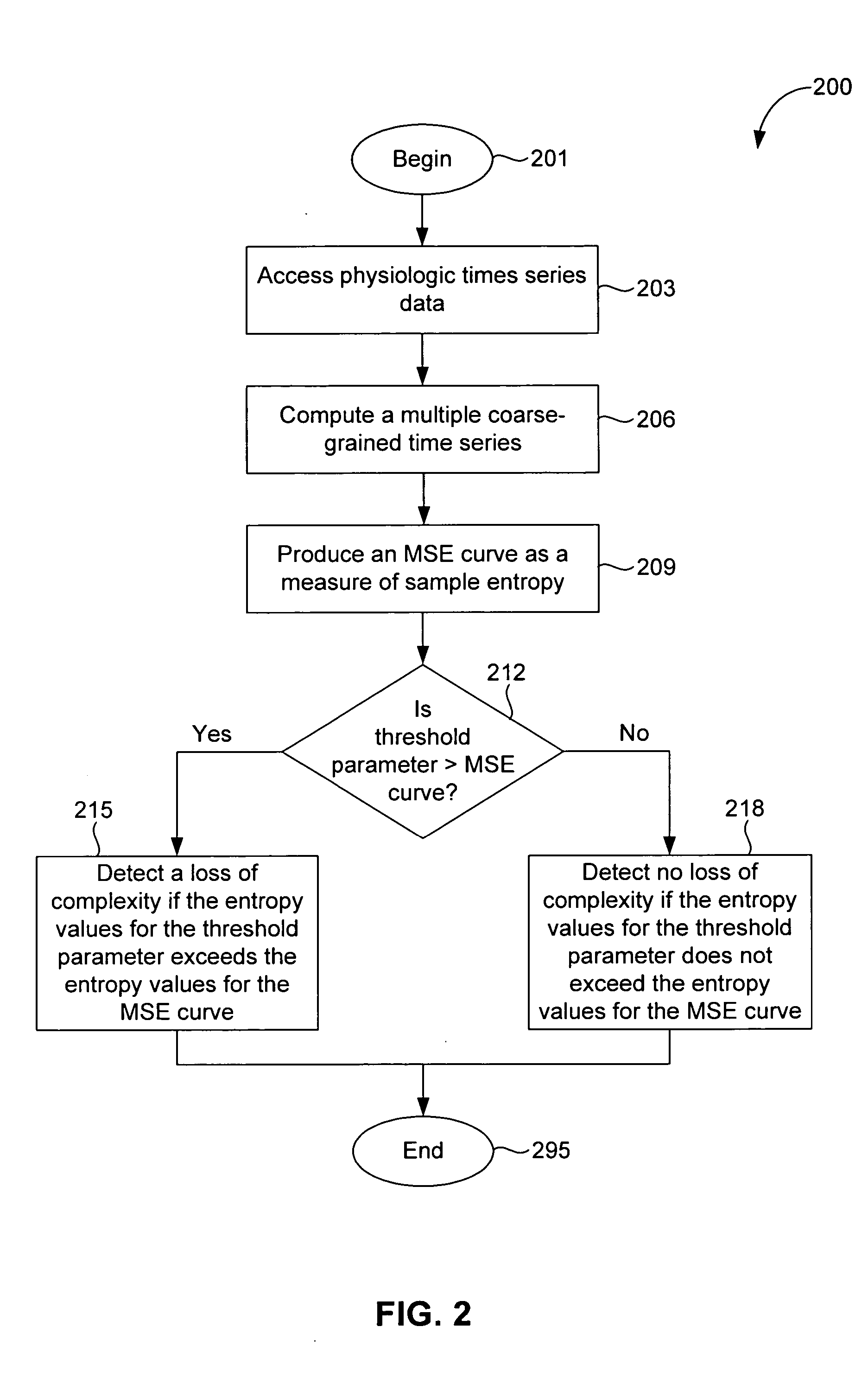

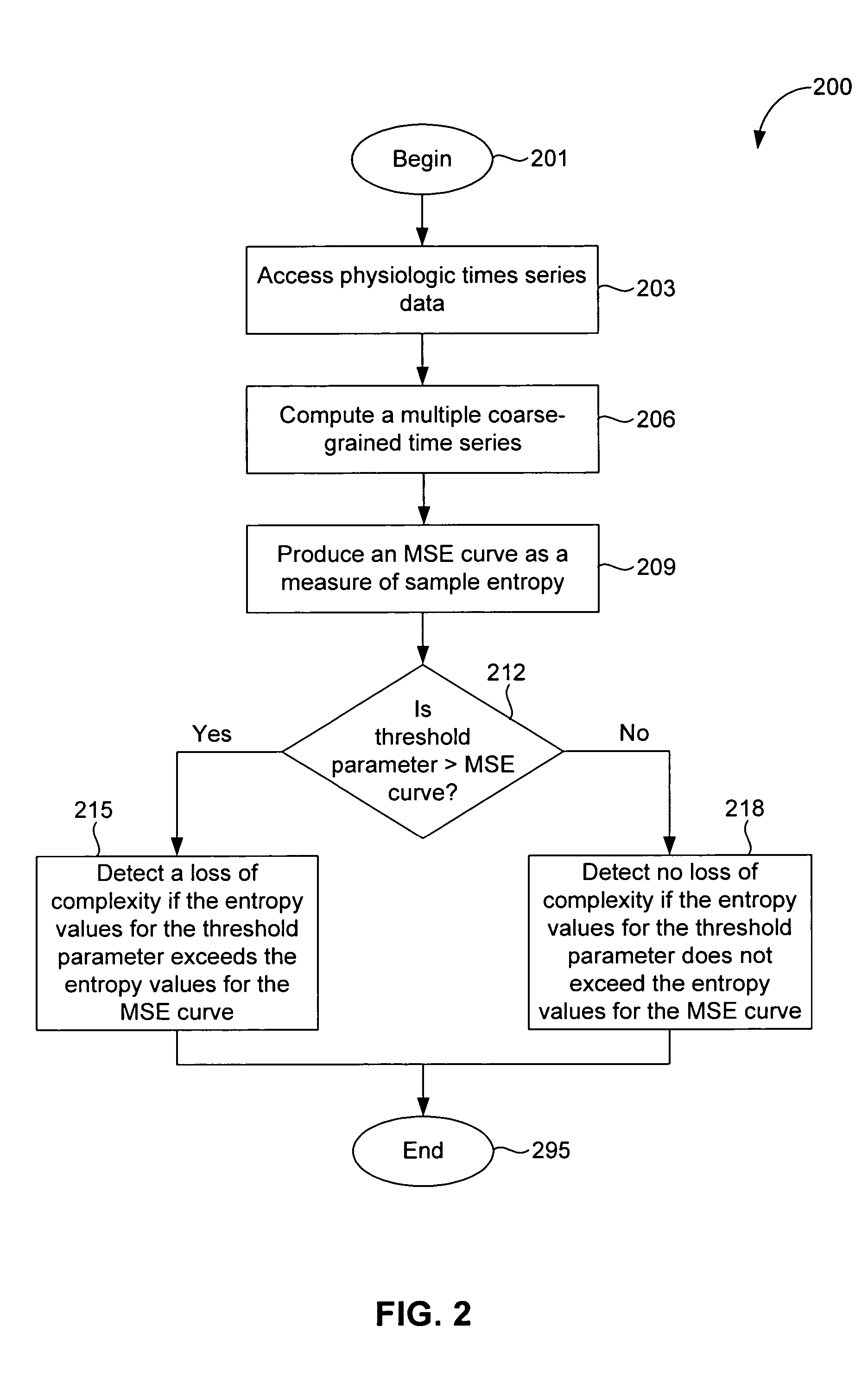

Complexity-based dynamical assay for assessing the toxicity and efficacy of pharmaceutical and other therapeutic interventions

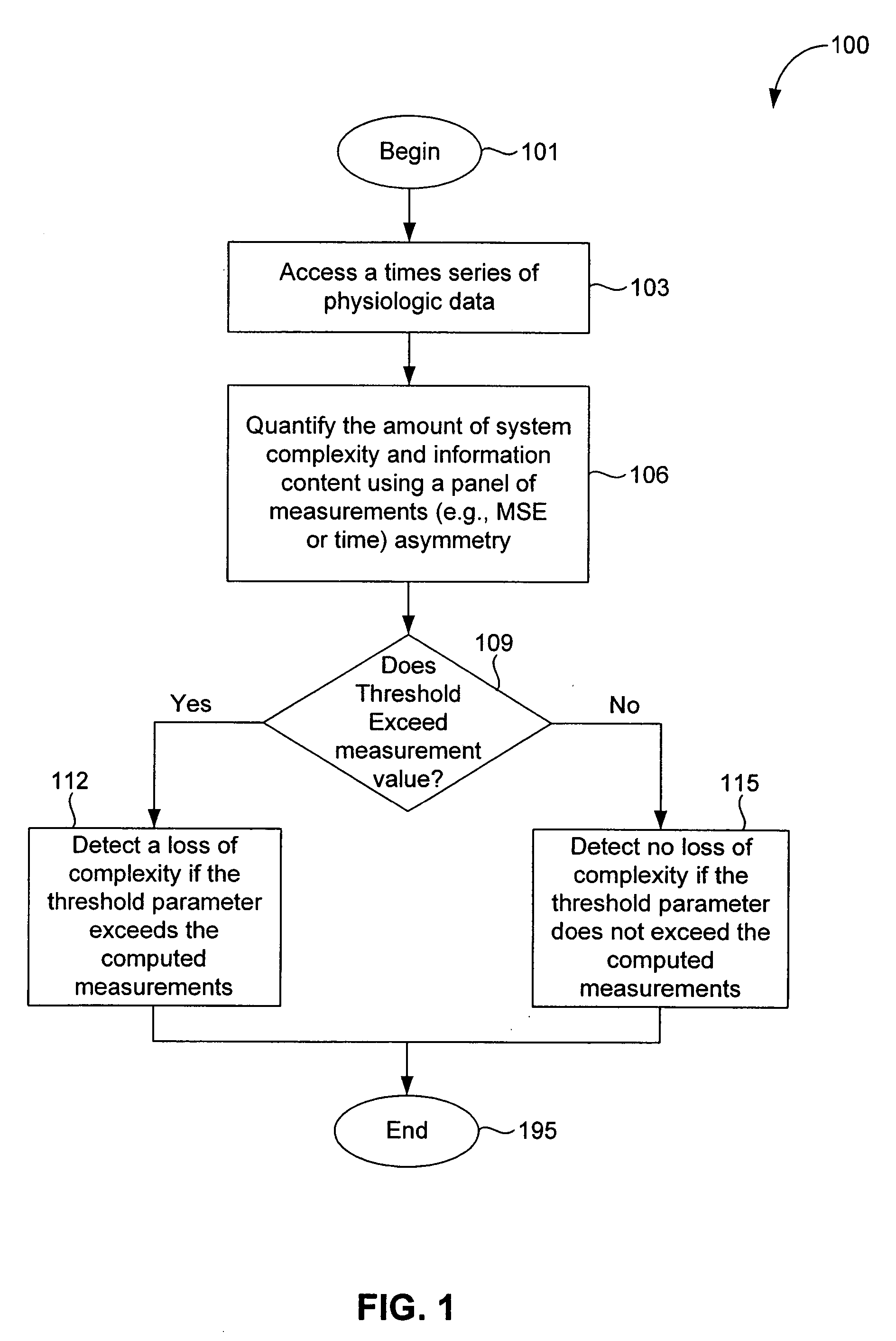

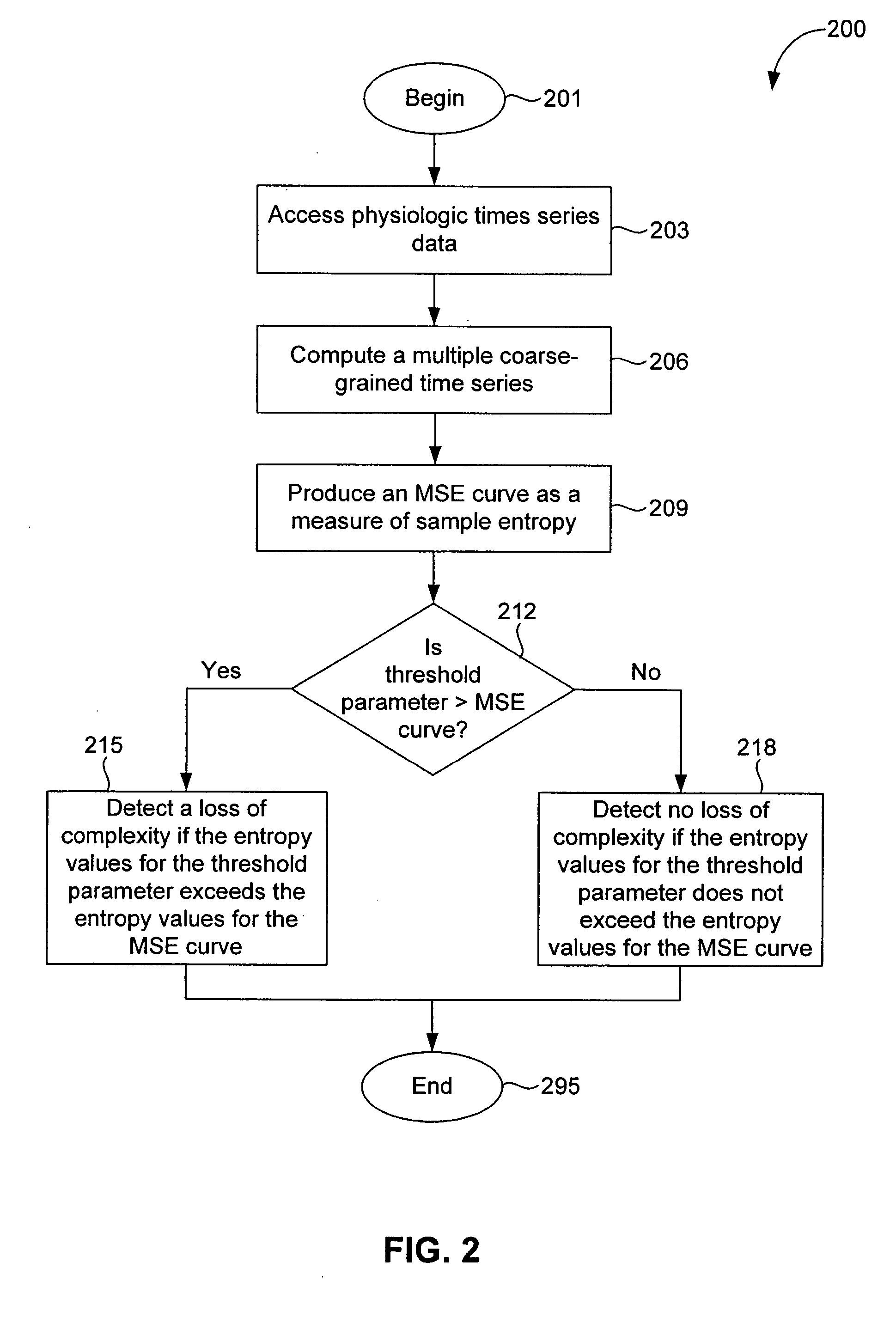

InactiveUS20060189875A1Quantify physiologic complexityReduce system complexityElectroencephalographyMedical data miningAssayEfficacy

In a subject undergoing therapeutic intervention, efficacy of the therapeutic intervention is assessed based on a series of physiologic data associated with the subject. The series of physiologic data is analyzed to produce a measure of complexity. The complexity measure is then compared to a control. The efficacy of the therapeutic intervention is assessed based on the comparison of the complexity measure to the control. The control may be, for example, a complexity measure taken prior to initiation of the therapeutic intervention, a complexity measure taken from a different subject, or a predetermined threshold value. The measure of complexity is generated using, for example, a multiscale entropy measurement (MSE), a time asymmetry measurement, and / or an information-based similarity measurement. An increase in complexity indicates a positive effect of the therapeutic intervention, while a decrease in complexity indicates a negative effect of the therapeutic intervention.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

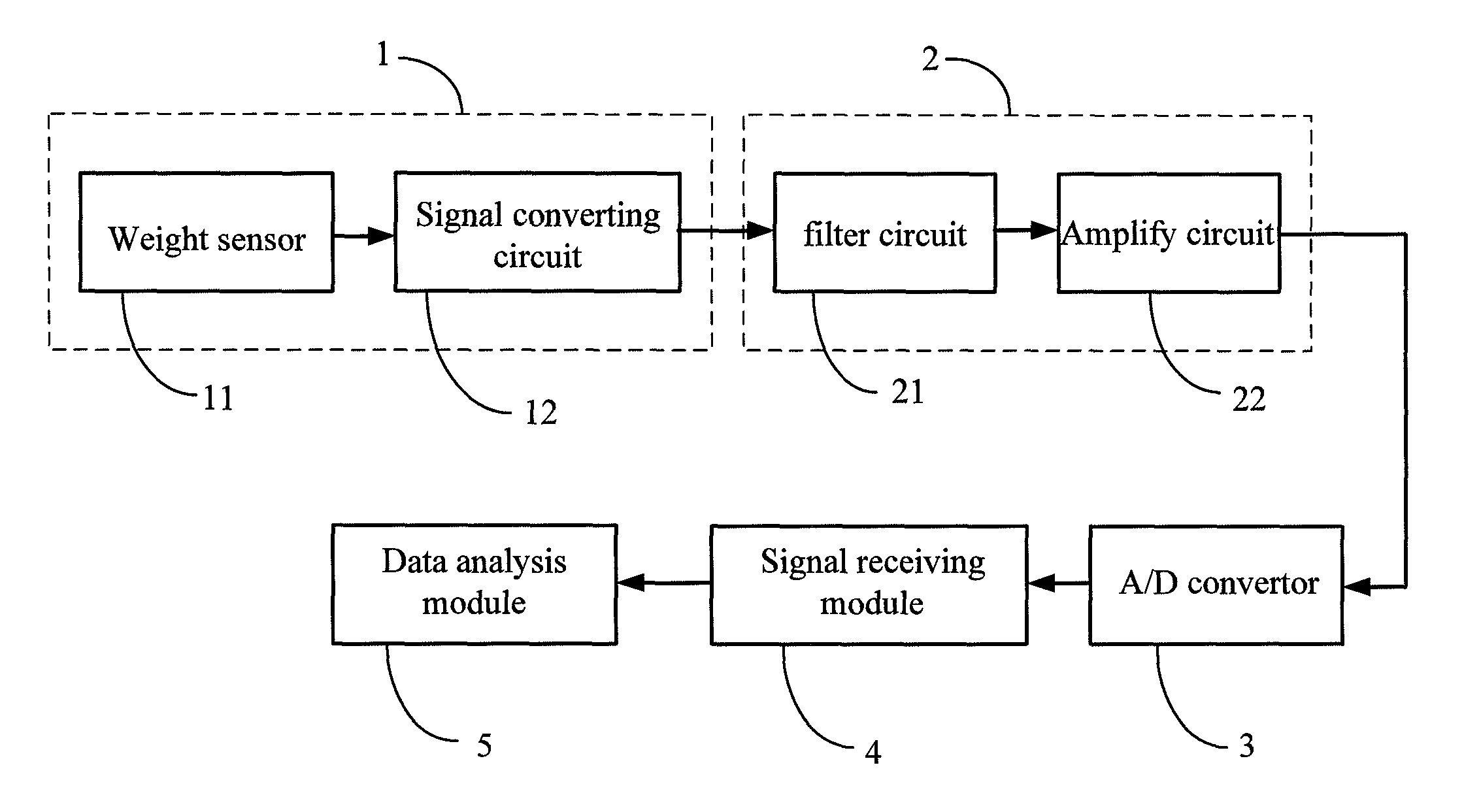

System for measuring body balance signals and a method for analyzing the same

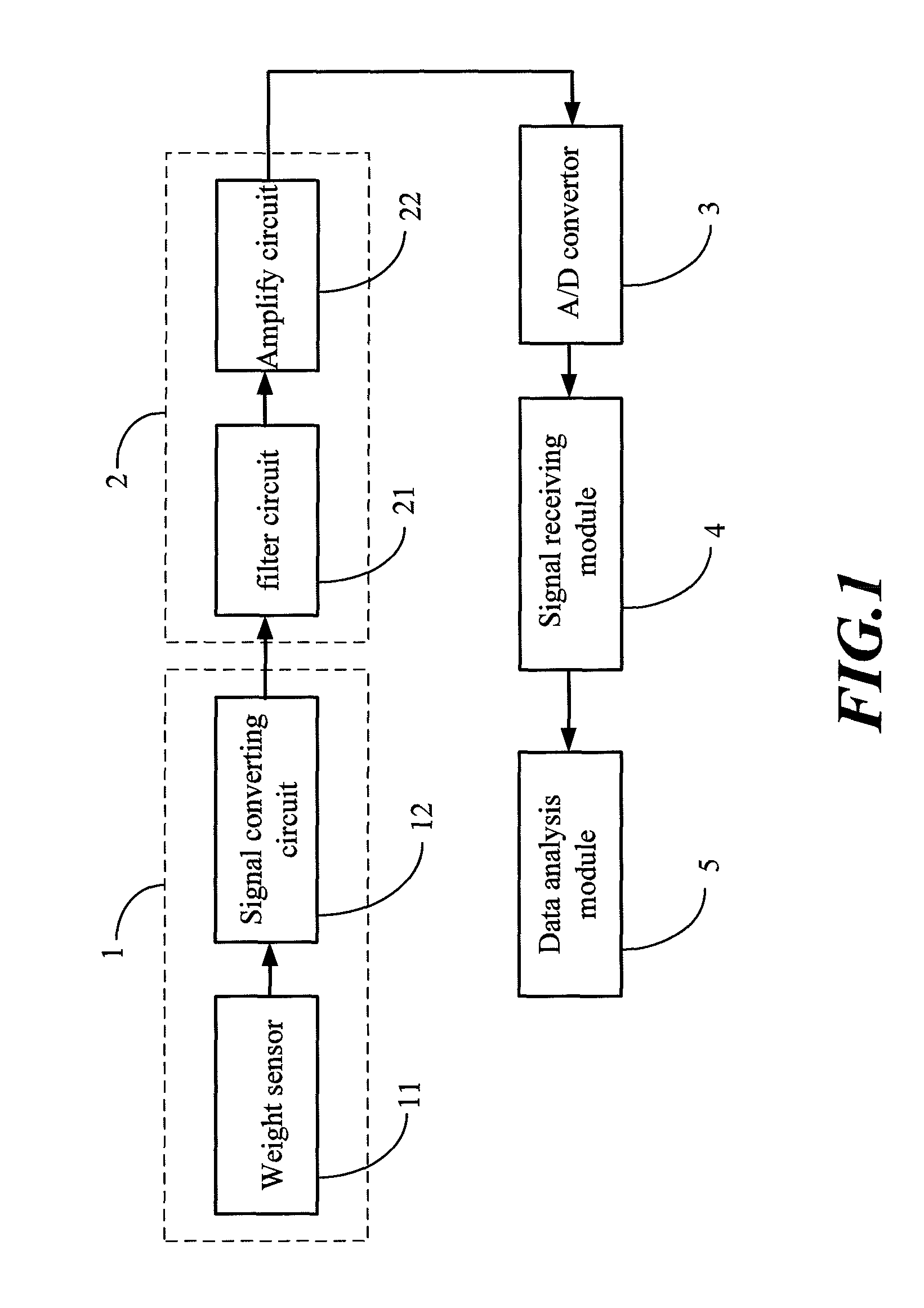

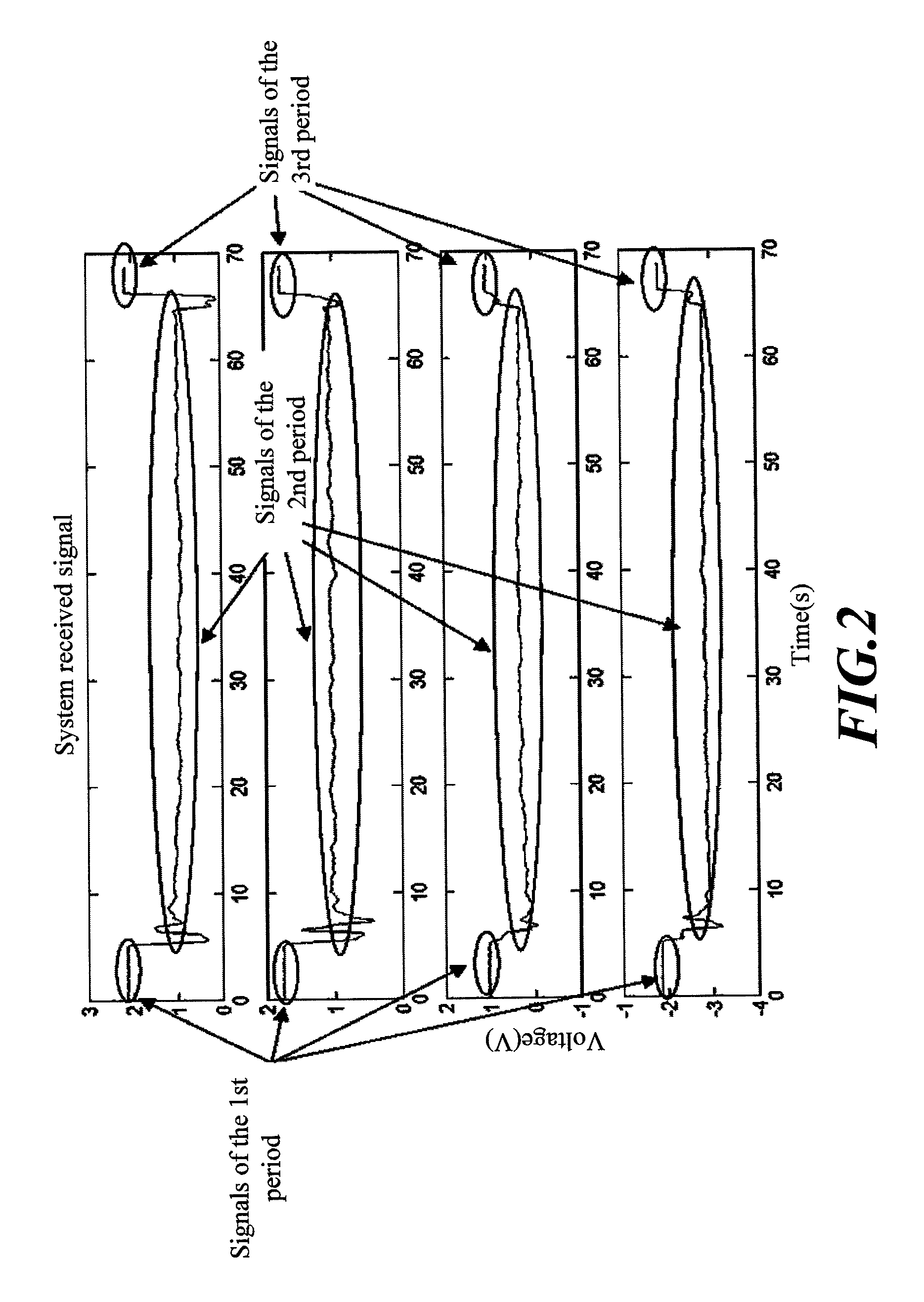

InactiveUS8405510B2Resolution problemPerson identificationRepeater circuitsBody balanceMeasurement device

A human body balance signals measuring system and the method of analysis thereof that has a measuring device, a filter amplifier, an A / D convertor (analog to digital convertor), a signal receiving module, and a data analyze module. The measuring device is linked with the filter amplifier. The filter amplifier can detect and collect the voltage signals caused by pressure change and then filter and amplify the signals. The signals are send to the A / D convertor to convert the analog circuit signals into digital signals for the receiving module to use these voltage change values for human body center of gravity offset evaluation to obtain the COP (center of pressure) offset and COP offset velocity. The data analyze module uses the measured body center of gravity offset for MSE (multiscale entropy) to quantitative the dynamic of human body center of gravity and verify the accuracy of this measuring system.

Owner:YUAN ZE UNIV +1

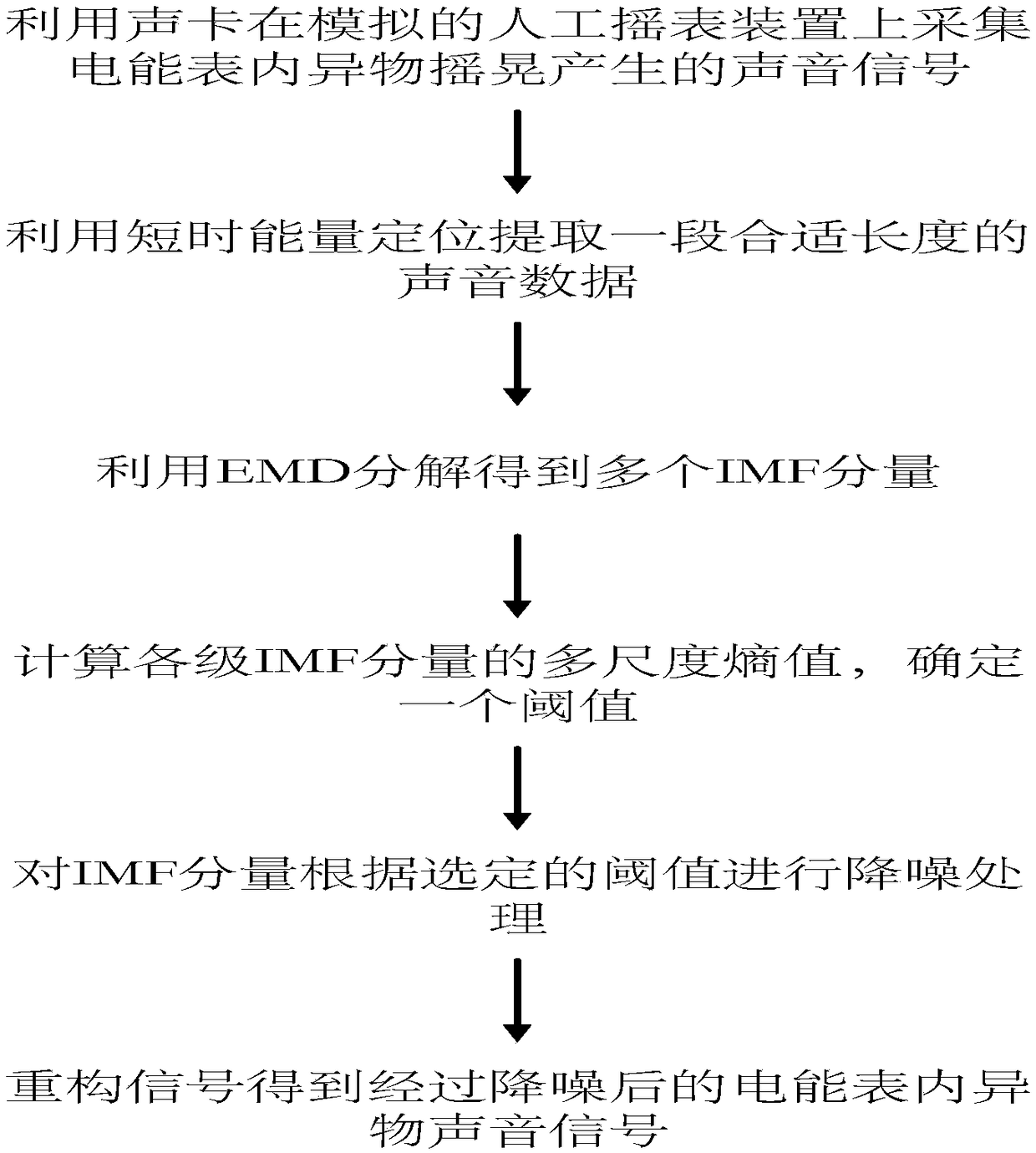

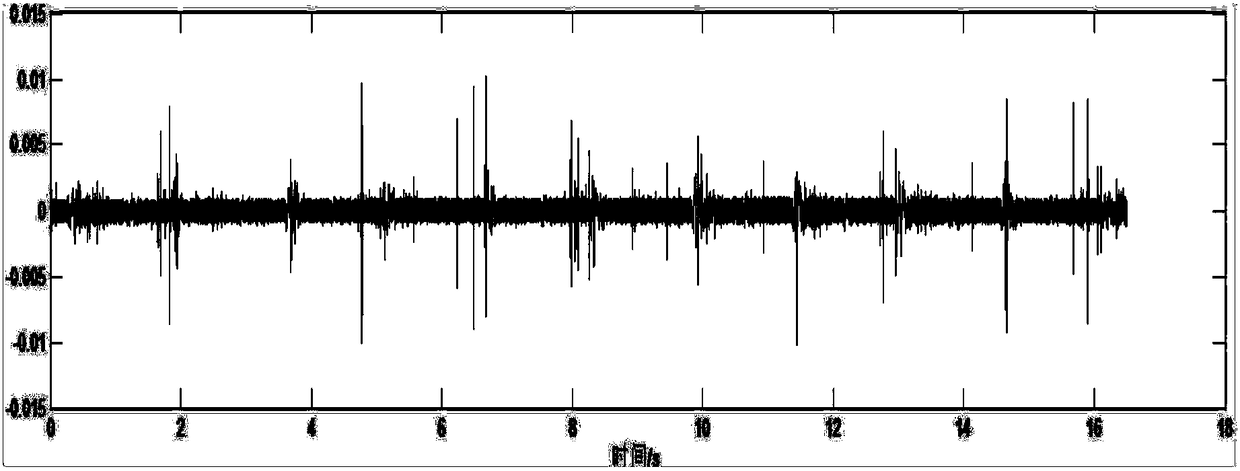

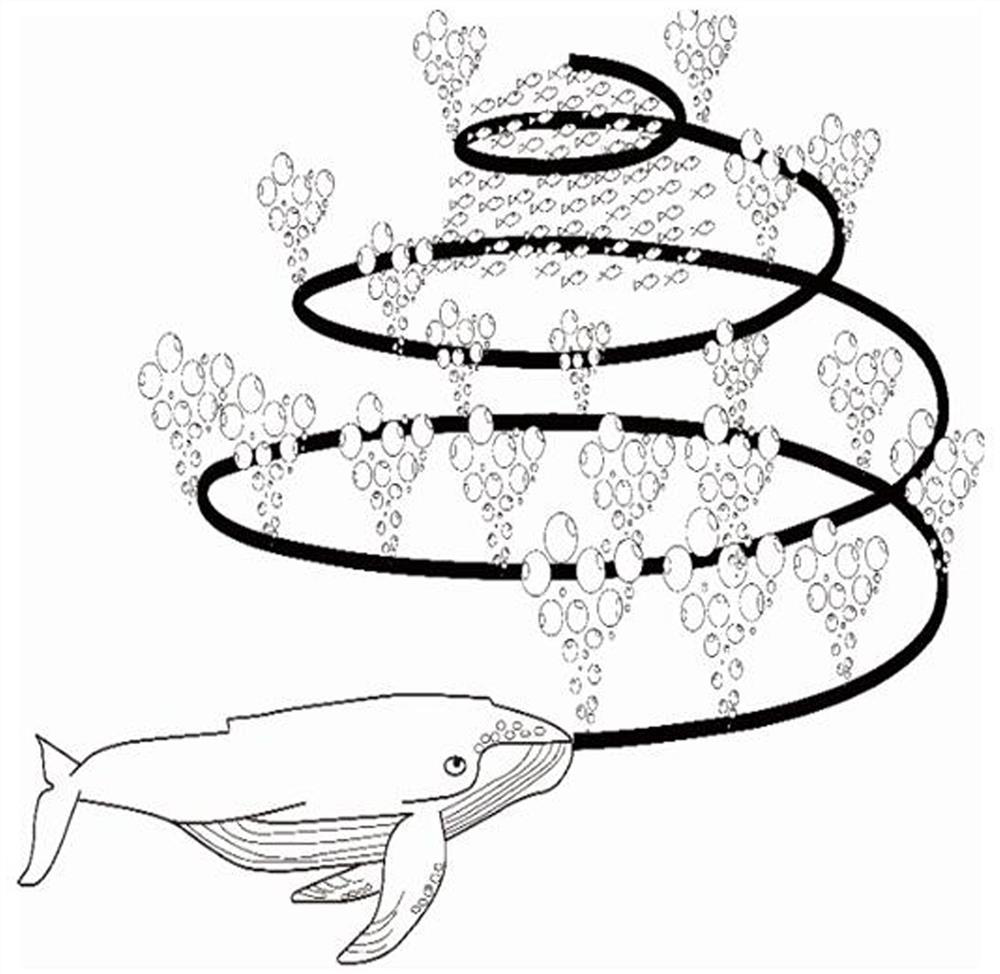

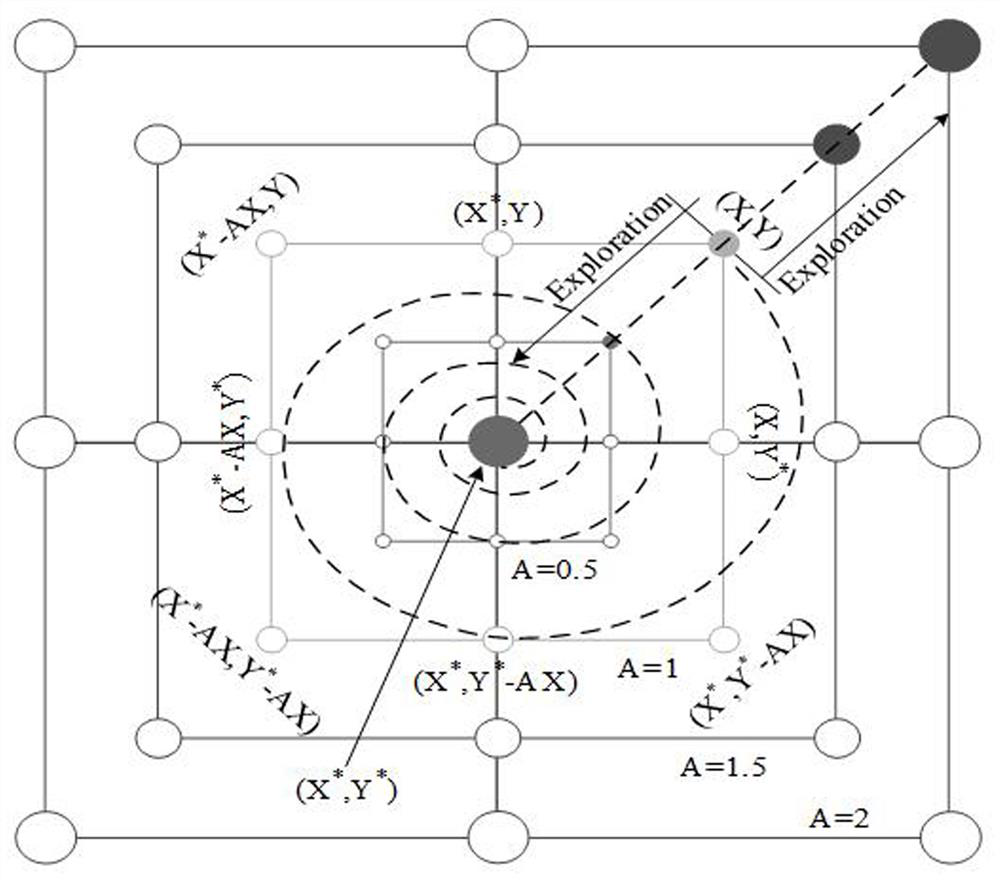

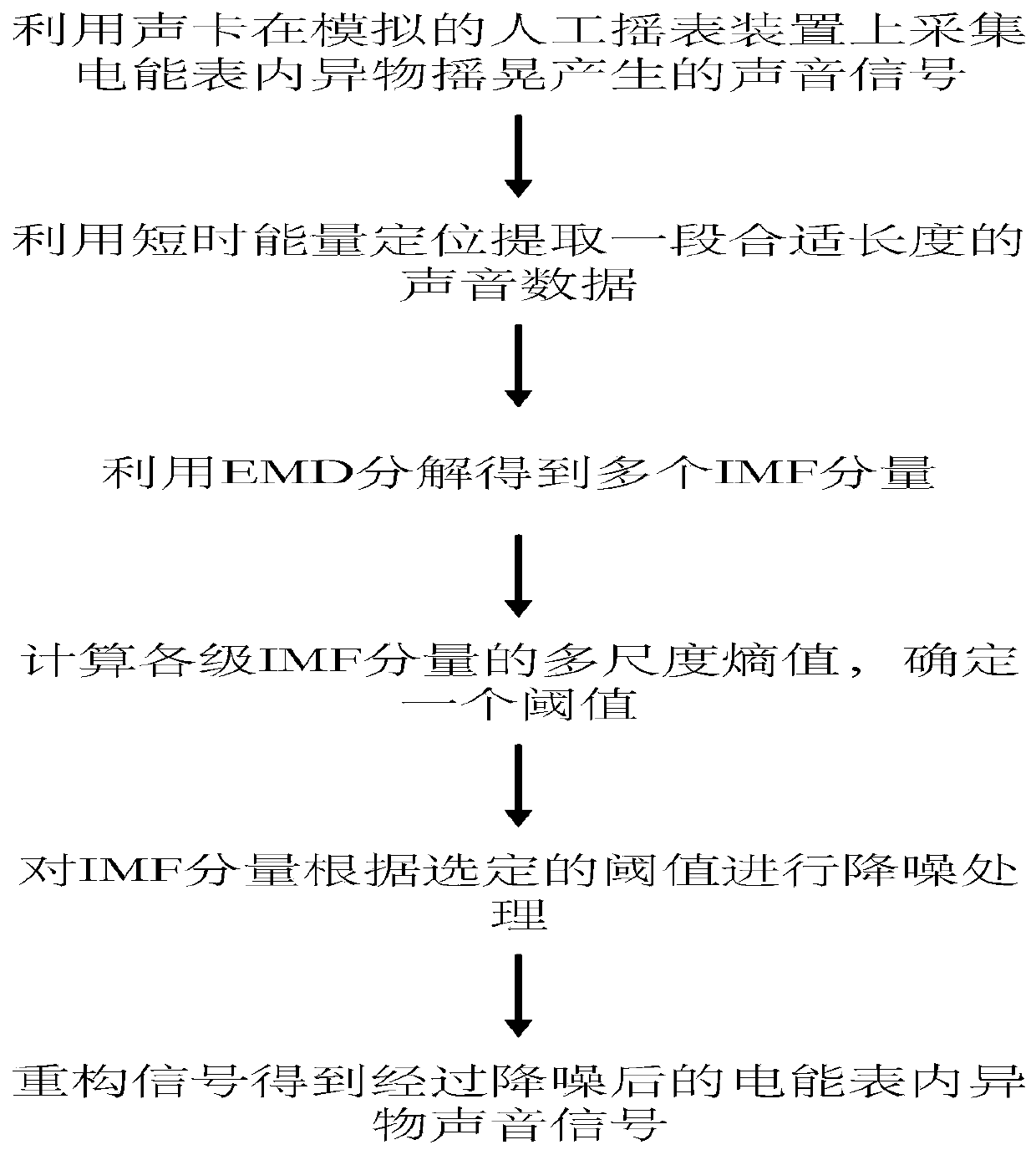

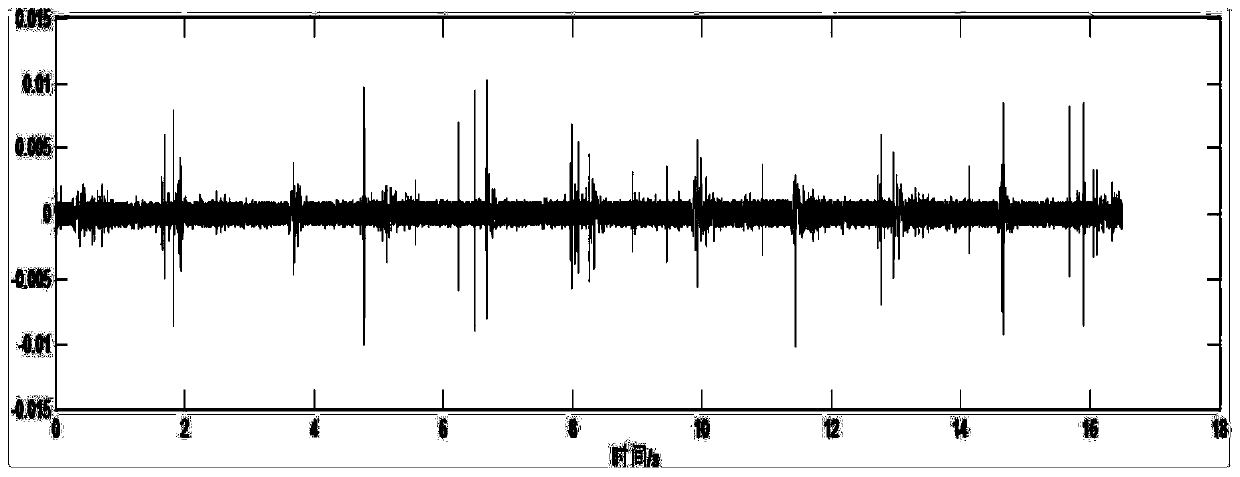

Sound signal noise reduction method and system of foreign matter in electric energy meter

ActiveCN108594161AShorten the lengthAvoid redundancySubsonic/sonic/ultrasonic wave measurementElectrical measurementsForeign matterDecomposition

The invention discloses a sound signal noise reduction method and system of foreign matter in an electric energy meter on the basis of short-time energy, multi-scale entropy and EMD. The method includes the steps that noise data generated by shaking of the foreign matter in the electric energy meter is collected; foreign matter sound signal data is extracted through short-time energy positioning;the extracted foreign matter sound signal data is subjected to empirical mode decomposition (EMD), and the multi-scale entropy of each stage of intrinsic mode function (IMF) component obtained throughEMD is calculated; the multi-scale entropy of the IMF components is subjected to noise reduction and filtering to obtain sound signals, obtained after noise reduction and filtering, of the foreign matter in the electric energy meter. The method has the advantages that short-time energy positioning can be used for data extraction to increase the processing speed; the sound signals of the foreign matter in the electric energy meter are processed through multi-scale entropy and empirical mode decomposition, which is a self-adaptive process, and the defect that traditional spectrum subtraction noise reduction estimation is not accurate is overcome; meanwhile, introduction of new noise is avoided to the maximum degree, and the foreign matter in the electric energy meter can be accurately detected.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +3

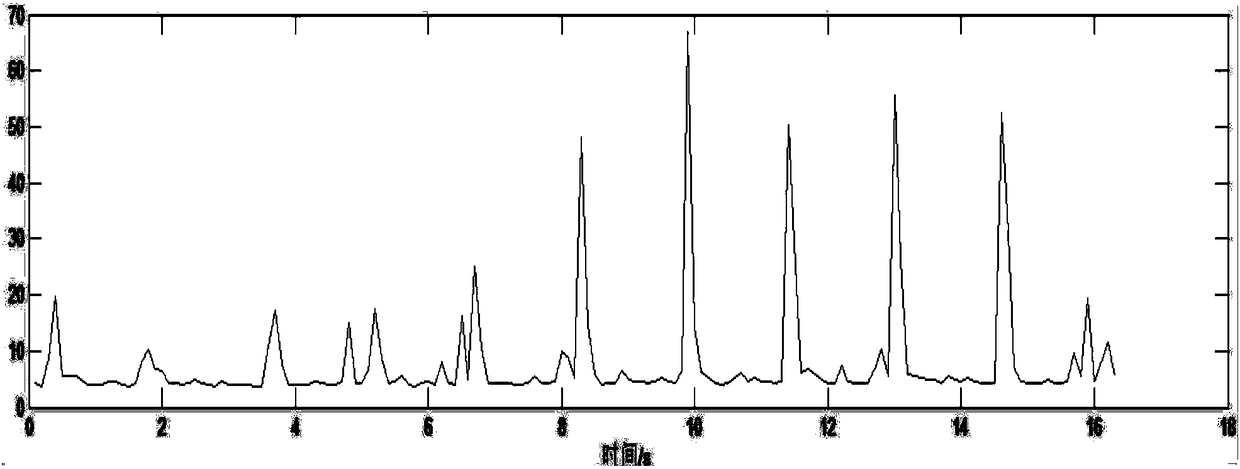

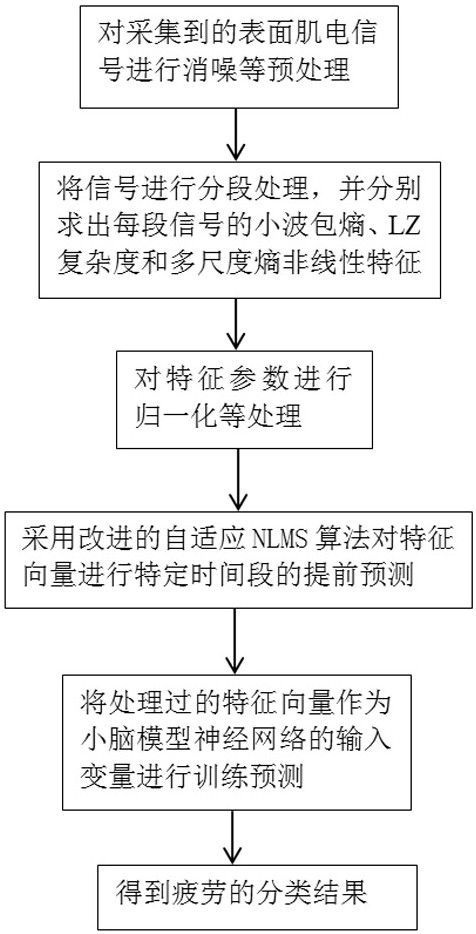

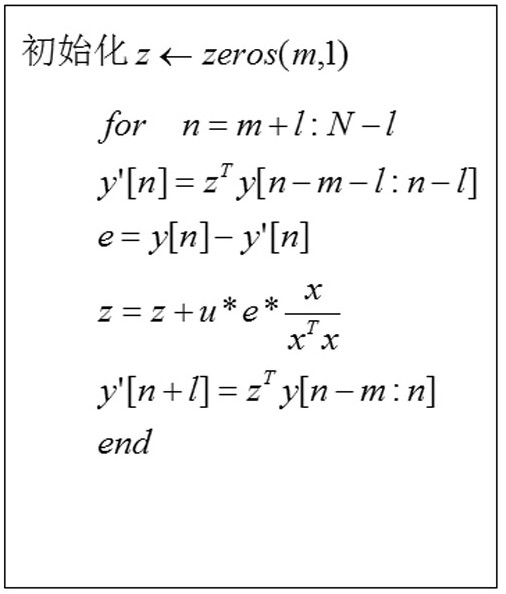

Muscle fatigue advanced prediction and classification method based on surface electromyographic signals

InactiveCN112120697ADiagnostic recording/measuringSensorsLeast mean squares filterClassification methods

The invention relates to a muscle fatigue advanced prediction and classification method based on surface electromyographic signals. The method comprises the following steps of: (1) selecting the surface electromyographic signals of muscles related to joint movement; (2) preprocessing the acquired surface electromyographic signals, then carrying out segment handling on the signals, and extracting nonlinear characteristic parameters from each segment of signals to serve as fatigue characteristic vectors, the nonlinear characteristic parameters including a wavelet packet entropy, LZ complexity and a multi-scale entropy; (3) respectively carrying out characteristic parameter prediction on each characteristic parameter by adopting an improved adaptive normalized least mean square filter (NLMS)algorithm, and by the improved adaptive NLMS algorithm, performing advanced prediction on the characteristic parameters according to a set advanced prediction time period through utilizing the characteristic of adaptive update of an NLMS in each time step; and (4) carrying out fatigue classification identification on the predicted characteristic parameters by adopting an improved cerebellum modelneural network. The method can predict muscle fatigue in advance.

Owner:FUZHOU UNIV

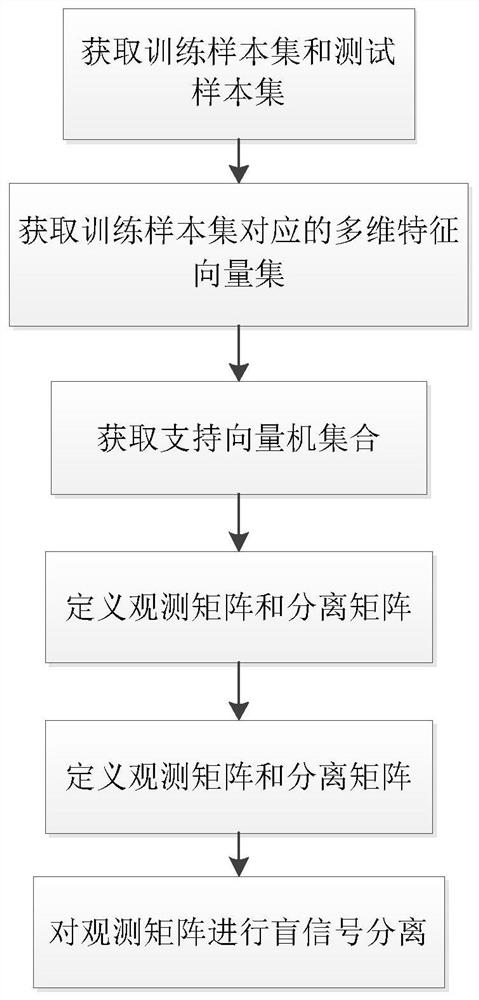

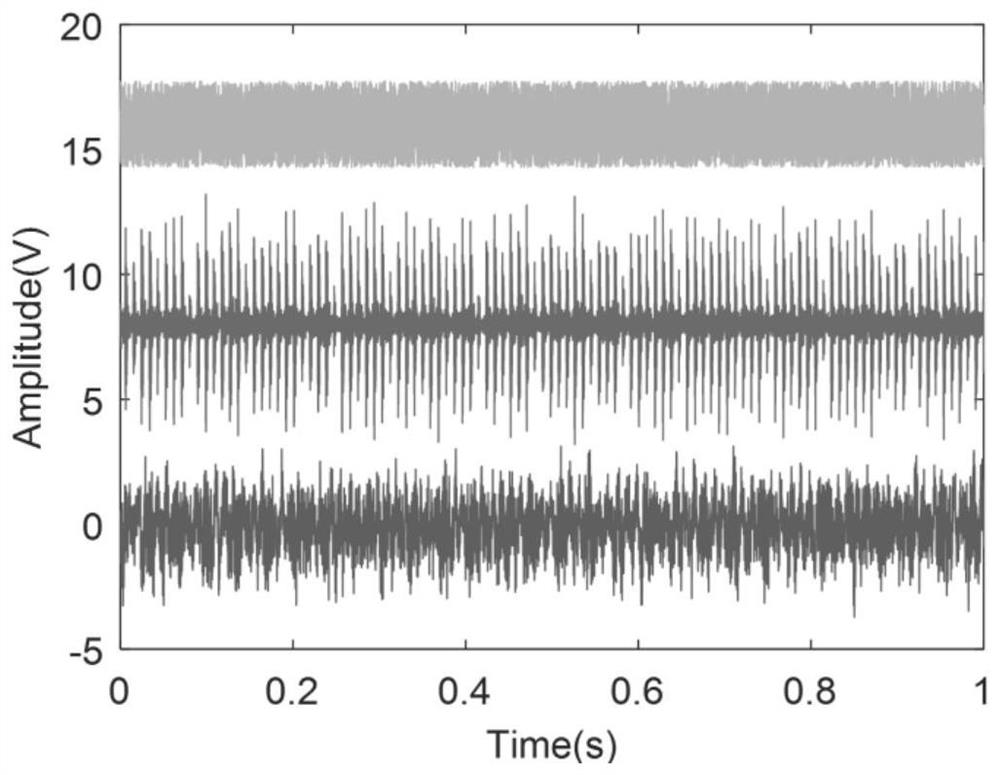

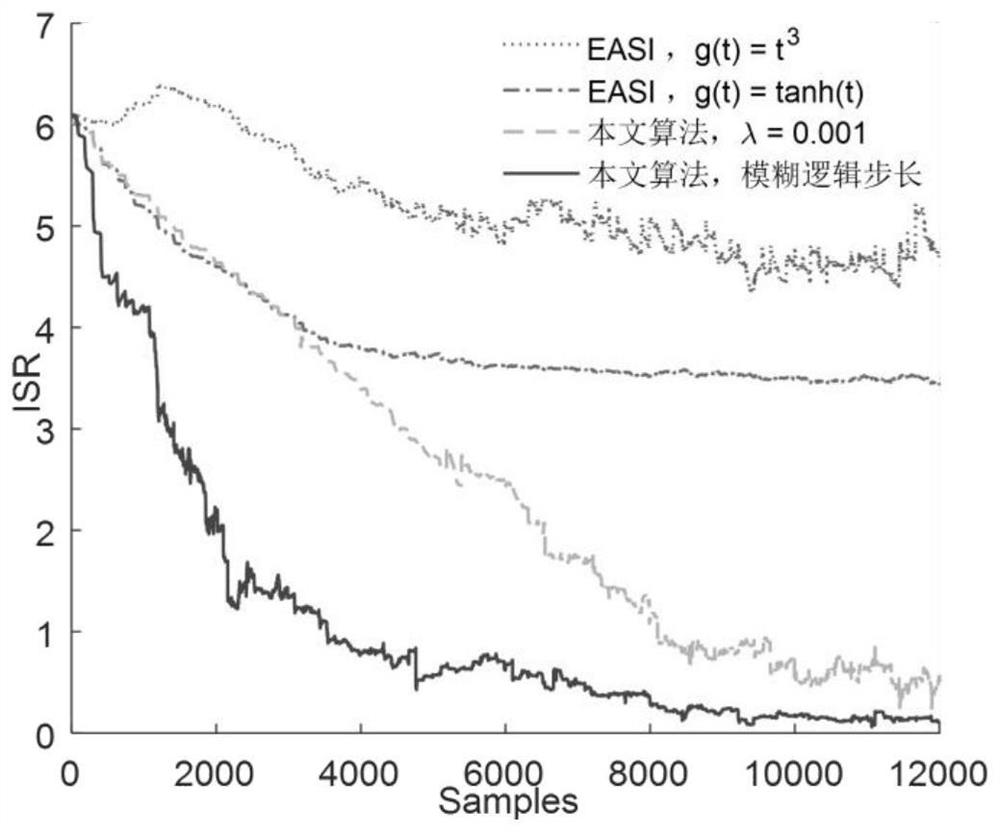

Rolling bearing fault diagnosis method based on blind signal separation and support vector machine

PendingCN112257530AImprove diagnostic accuracyImprove robustnessMachine part testingCharacter and pattern recognitionFeature vectorTest sample

The invention provides a rolling bearing fault diagnosis method based on blind signal separation and a support vector machine, belongs to the technical field of intelligent fault diagnosis of rotatingmachinery, and aims to improve the precision, efficiency and robustness of rolling bearing fault diagnosis, and the implementation steps are as follows: obtaining a training sample set and a test sample set; obtaining a multi-dimensional feature vector set corresponding to the training sample set; obtaining a support vector machine set; performing iterative training on the support vector machineset; defining an observation matrix and a separation matrix; performing blind signal separation on the observation matrix; and obtaining a fault diagnosis result of the rolling bearing. According to the invention, the self-adaptive selection nonlinear function and the iteration step length are introduced into the iteration of the separation matrix, the multi-dimensional feature vector composed ofthe amplitude domain parameter, the frequency domain index and the multi-scale entropy is adopted when the feature vector of the vibration signal is extracted, and the diagnosis precision, efficiencyand robustness are effectively improved in combination with the support vector machine.

Owner:XIDIAN UNIV

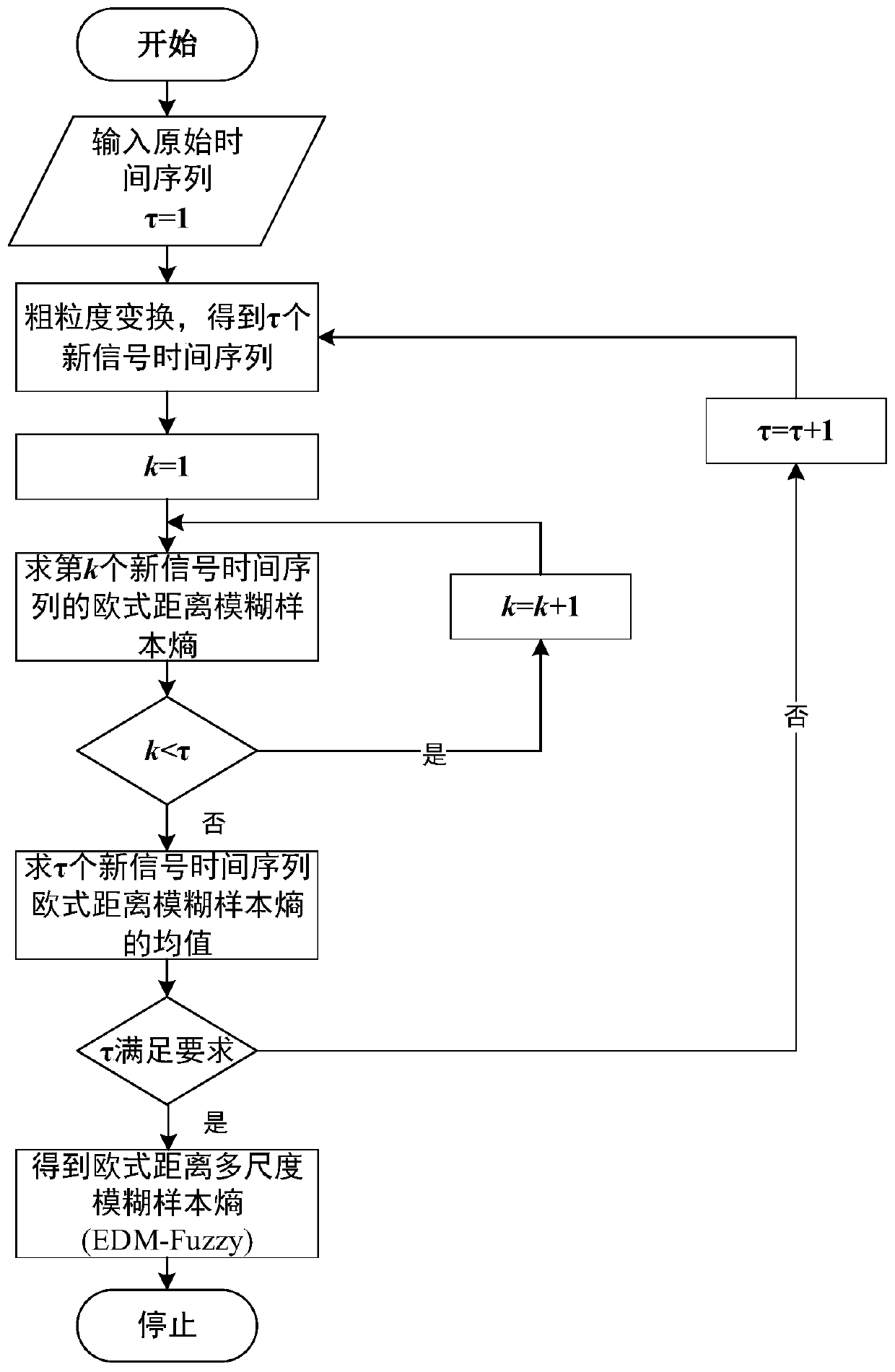

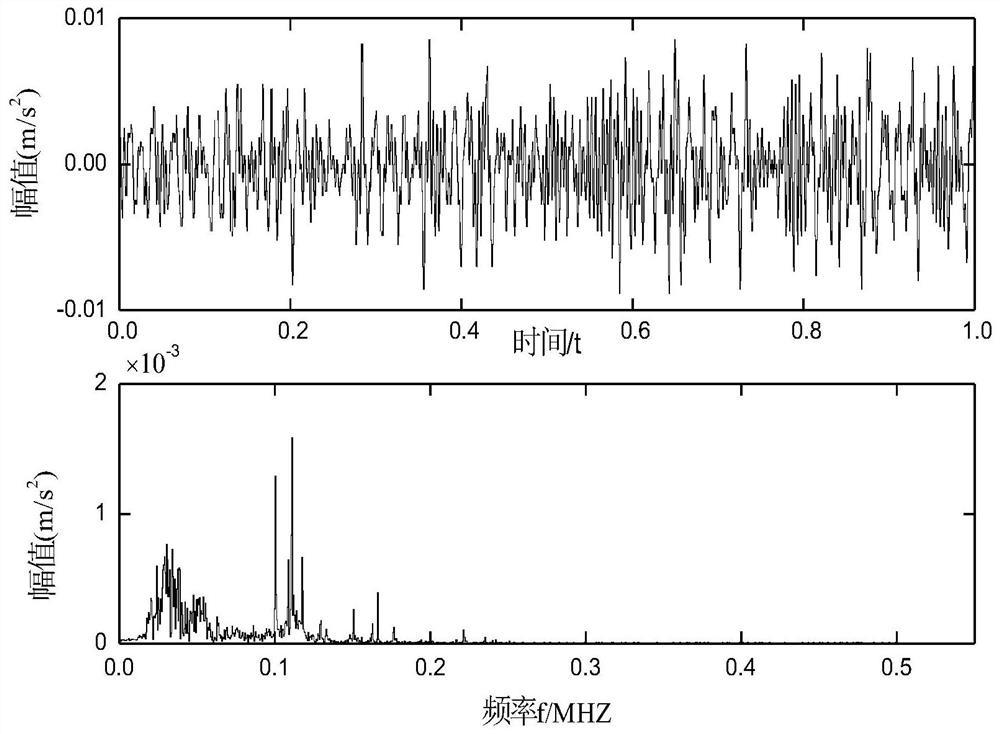

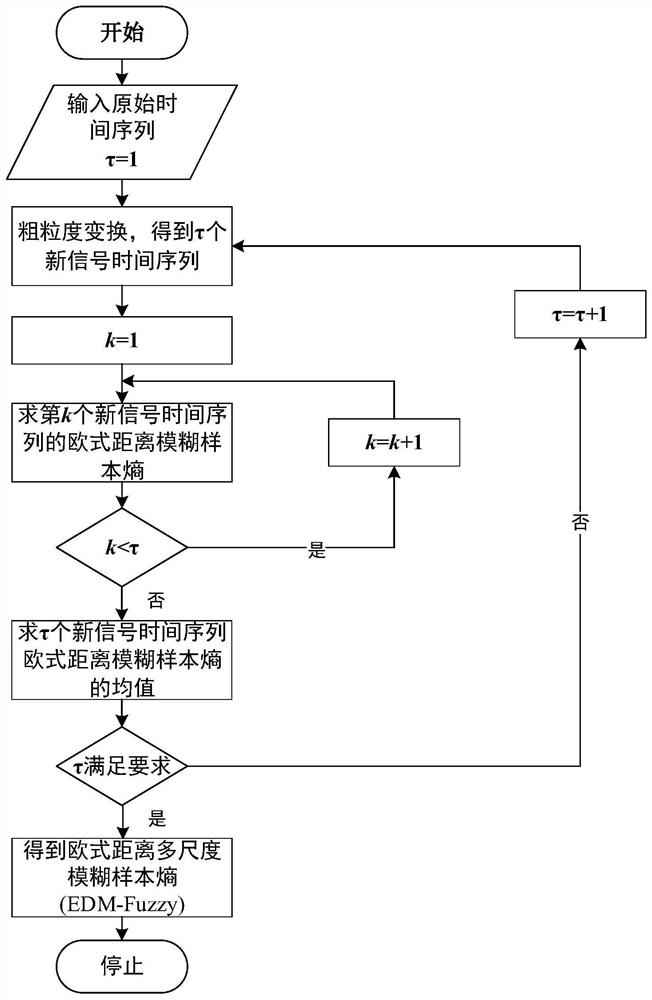

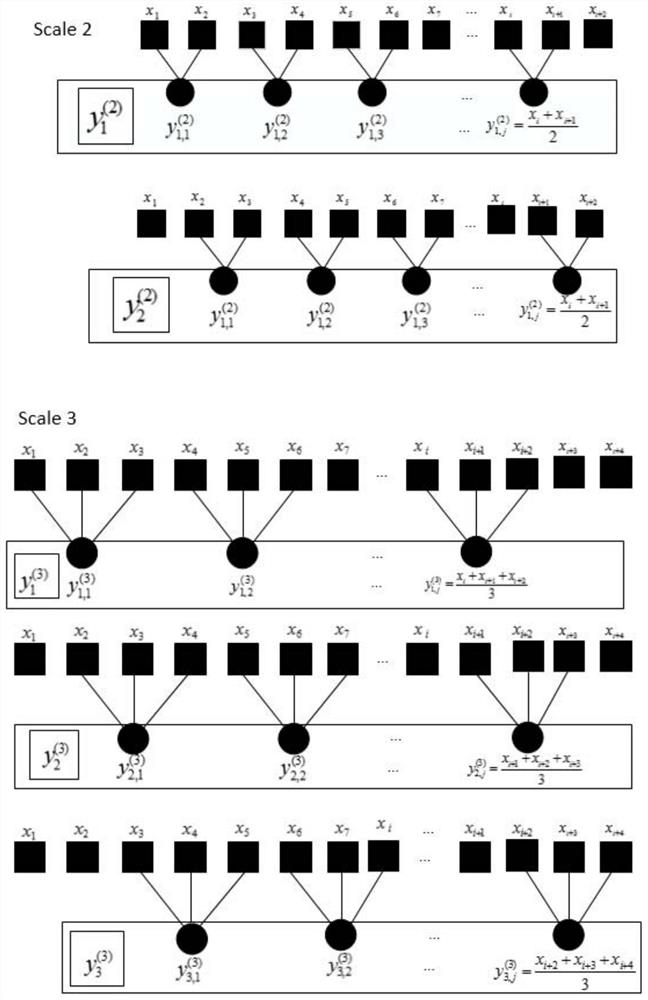

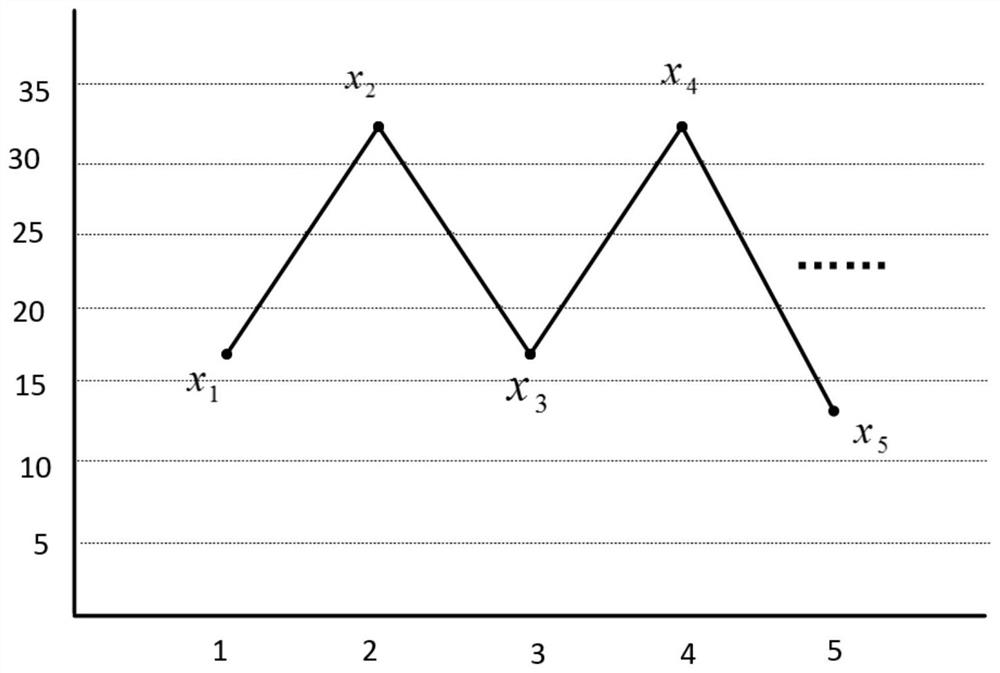

Industrial system fault detection method based on Euclidean distance multiscale fuzzy sample entropy

ActiveCN111122162AHigh precisionImprove stabilityMachine part testingNeural architecturesAlgorithmIndustrial systems

The invention discloses an industrial system fault detection method based on Euclidean distance multiscale fuzzy sample entropy. According to the method provided by the invention, the complexity of atime sequence can be described from a plurality of time scales; meanwhile, compared with an existing multiscale entropy method and an existing composite multiscale entropy (FME) method, the method hasthe advantages that the stability and the accuracy of the calculation of multi-scale fuzzy sample entropy (FME) are remarkably improved. The method can be used for judging and detecting the fault type of an industrial system and analyzing the complexity of the time sequence.

Owner:HANGZHOU DIANZI UNIV

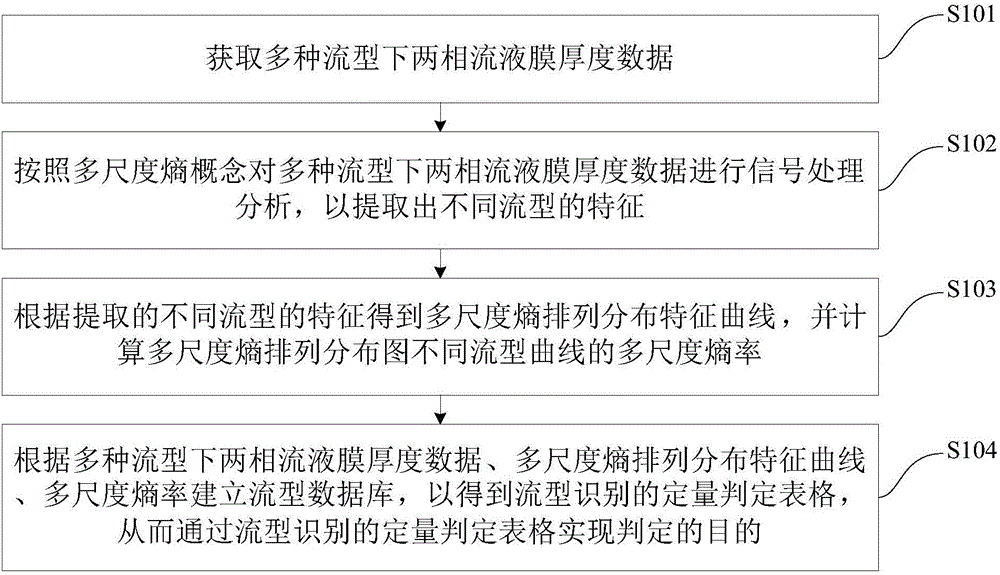

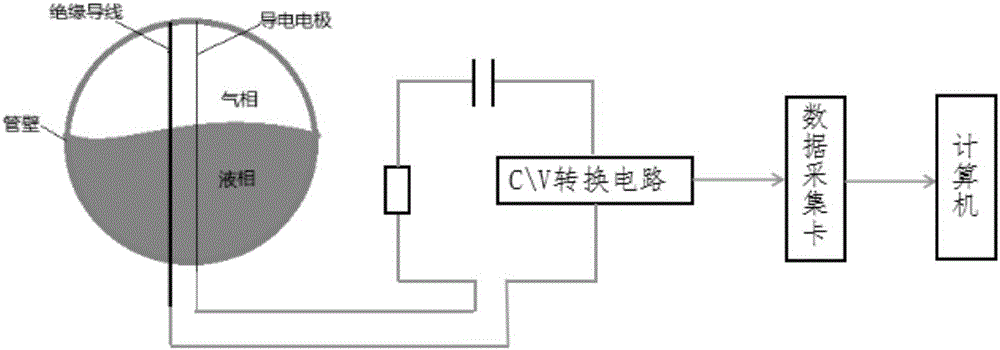

Quantitative determination method and device for flow pattern of horizontal gas-liquid two-phase flow

ActiveCN106247917AImprove applicabilityImprove reliabilityElectrical/magnetic thickness measurementsEntropy rateQuantitative determination

The invention discloses a quantitative determination method and a quantitative determination device for flow patterns of horizontal gas-liquid two-phase flows. The quantitative determination method comprises the steps of: acquiring two-phase flow liquid film thickness data in various flow patterns; carrying out signal processing analysis on the two-phase flow liquid film thickness data in various flow patterns according to a multiscale entropy (MSE) concept, so as to extract characteristics of different flow patterns; acquiring MSE arrangement distribution characteristic curves according to the extracted characteristics of different flow patterns, and calculating rates of MSE of different flow pattern curves of MSE arrangement distribution diagrams; and establishing a flow pattern database according to the two-phase flow liquid film thickness data in various flow patterns, the MSE arrangement distribution characteristic curves and the rates of MSE, so as to obtain a flow pattern identification quantitative determination form, and achieving the purpose of determination by means of the flow pattern identification quantitative determination form. The quantitative determination method can process two-phase flow liquid film thickness signals by adopting the MSE algorithm, achieve the purpose of flow pattern identification through extracting characteristic quantities, improve the applicability and reliability of determination, and improve the accuracy of determination.

Owner:TSINGHUA UNIV

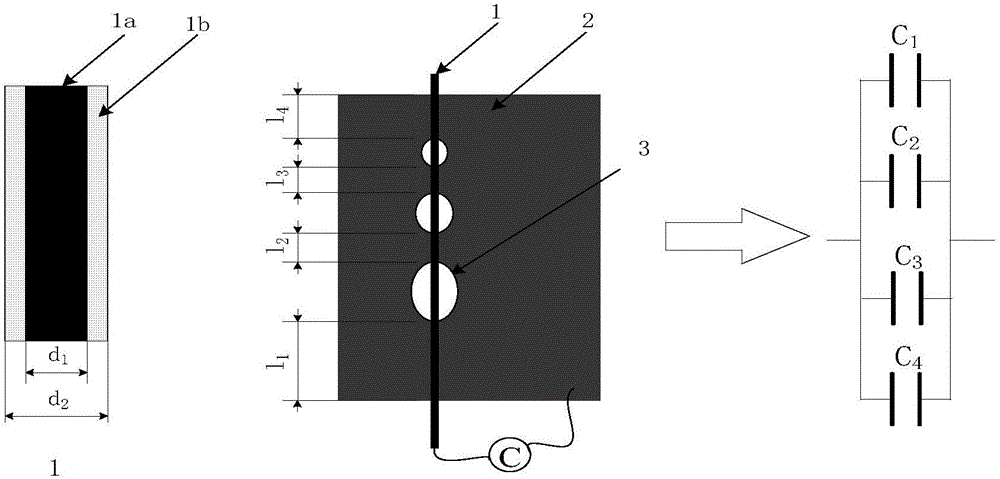

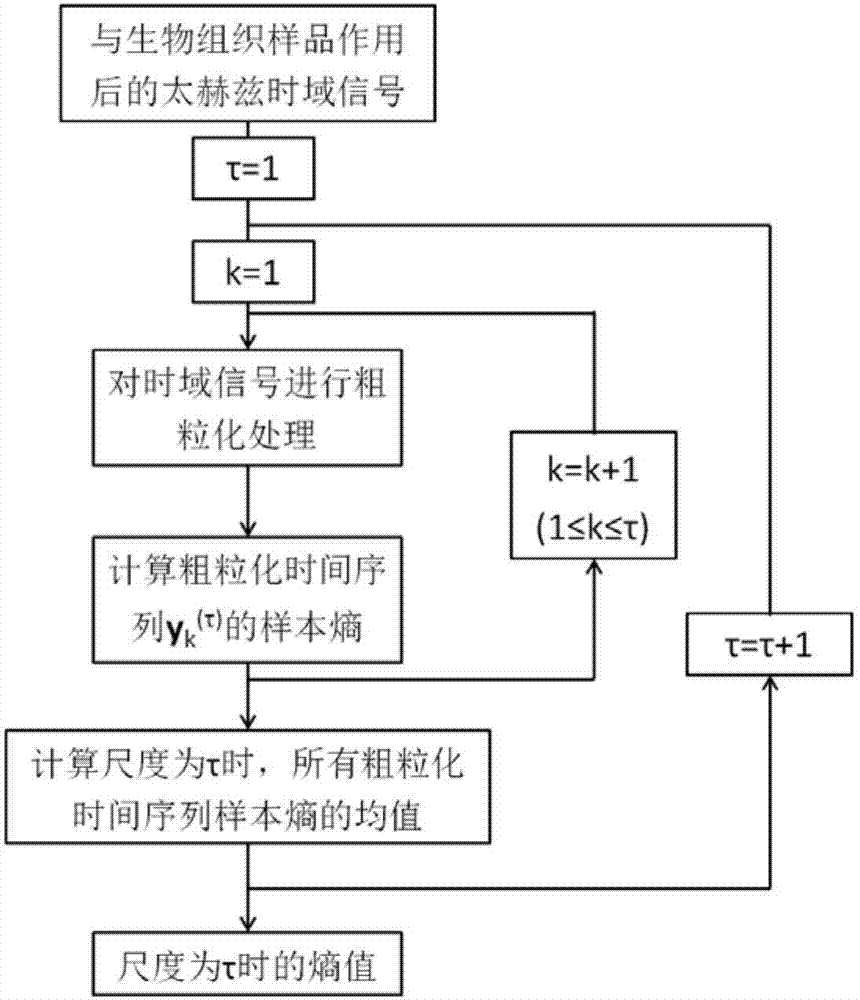

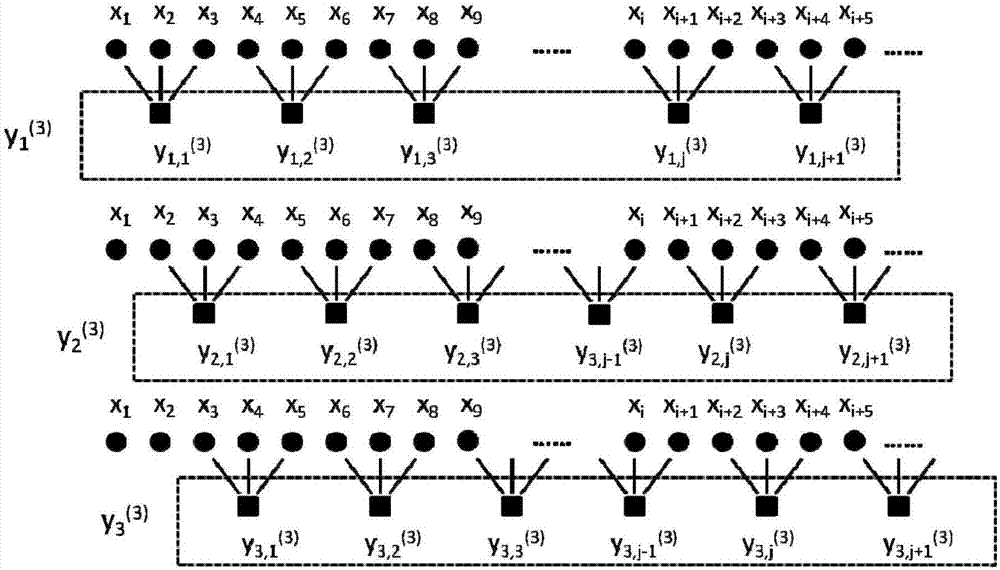

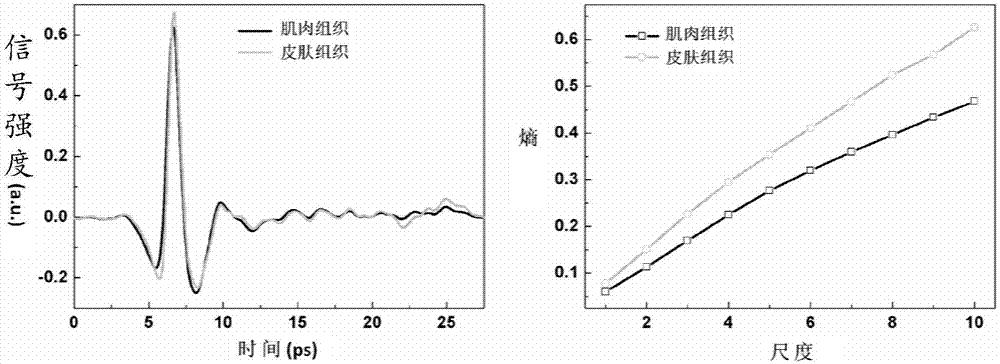

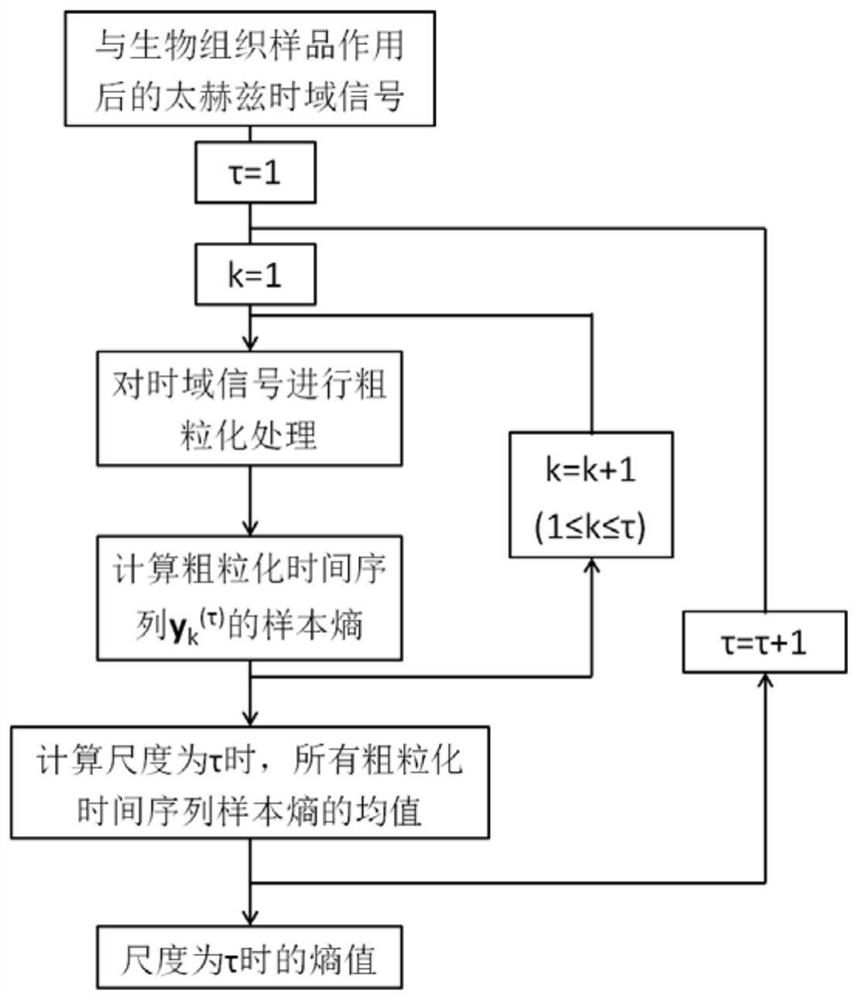

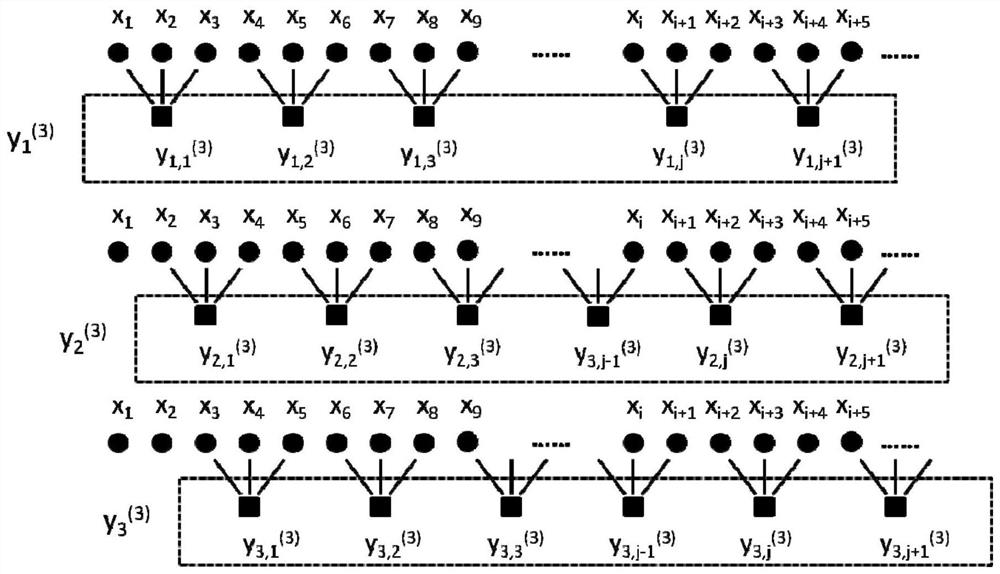

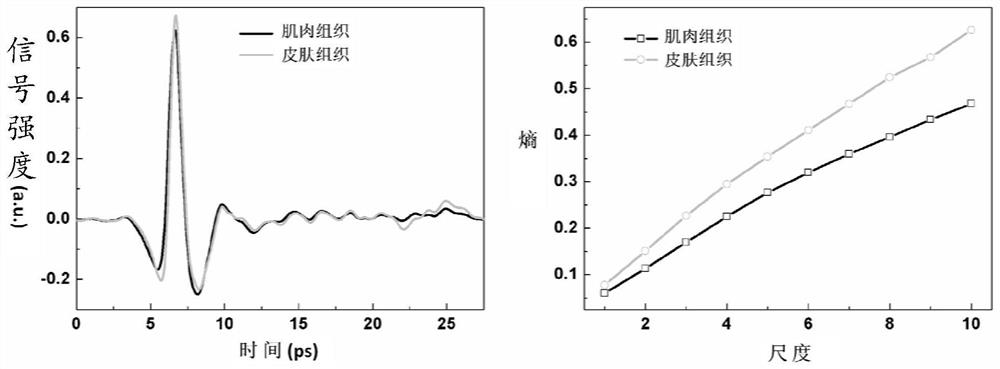

Biological tissue terahertz imaging method, system and equipment based on multiscale entropy

ActiveCN107468250AOvercoming utilizationTo overcome the problem of corresponding low imaging discriminationMaterial analysis by optical meansDiagnostic recording/measuringTime domainImage contrast

The invention discloses a biological tissue terahertz imaging method, system and equipment based on multiscale entropy. According to the method, the information of whole terahertz time-domain spectroscopy signals is utilized, and the entropy value of each point on the detected biological tissue sample on different time scales is obtained; the entropy value on a certain scale is selected, or the entropy values on multiple scales are added together, so that a terahertz image of the detected biological tissue sample is reconstructed. By means of the method, the limitations that a traditional biological tissue terahertz imaging method only uses the spectroscopy information of a certain time or frequency point are overcome, and imaging contrast among different samples is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Complexity-based dynamical analysis of a network

In a subject undergoing therapeutic intervention, efficacy of the therapeutic intervention is assessed based on a series of physiologic data associated with the subject. The series of physiologic data is analyzed to produce a measure of complexity. The complexity measure is then compared to a control. The efficacy of the therapeutic intervention is assessed based on the comparison of the complexity measure to the control. The control may be, for example, a complexity measure taken prior to initiation of the therapeutic intervention, a complexity measure taken from a different subject, or a predetermined threshold value. The measure of complexity is generated using, for example, a multiscale entropy measurement (MSE), a time asymmetry measurement, and / or an information-based similarity measurement. An increase in complexity indicates a positive effect of the therapeutic intervention, while a decrease in complexity indicates a negative effect of the therapeutic intervention. Stability of a non-biologic network, such as a computer network, communications network or transportation network can also be assessed.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

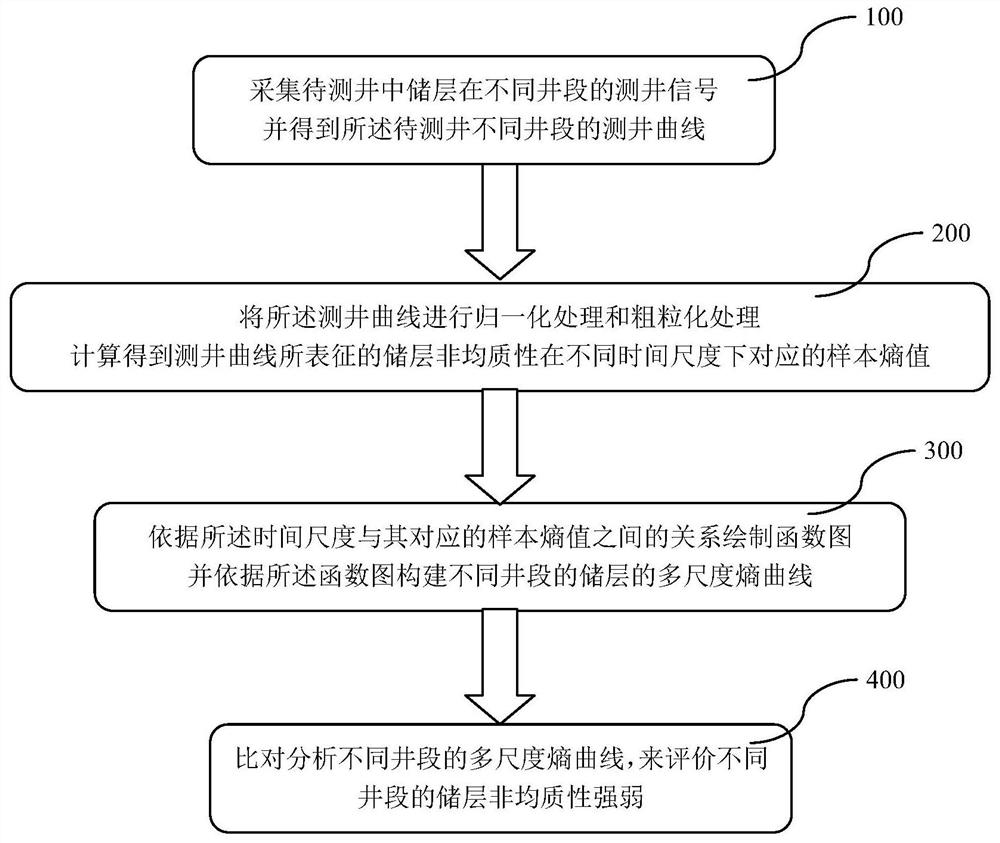

Method for analyzing reservoir heterogeneity based on multi-scale entropy

ActiveCN112836393AIncrease the amount of informationImprove accuracy and reliabilityDesign optimisation/simulationComplex mathematical operationsInformation analysisWell logging

The invention discloses a method for analyzing reservoir heterogeneity based on multi-scale entropy, and the method comprises the steps: collecting logging signals of a to-be-logged reservoir in different well sections, and obtaining logging curves of the to-be-logged reservoir in different well sections; performing normalization processing and coarse graining processing on the logging curve, and calculating corresponding sample entropy values of reservoir heterogeneity represented by the logging curve under different time scales; drawing a function diagram according to the relationship between the time scale and the corresponding sample entropy value, and constructing a multi-scale entropy curve of the reservoir of different well sections according to the function diagram; and comparing and analyzing the multi-scale entropy curves of different well sections to evaluate the reservoir heterogeneity strength of different well sections. A plurality of pieces of different information is obtained from logging signals according to different scales in a normalization and coarse graining processing mode, the information amount of to-be-processed data is increased in a multi-azimuth and multi-angle mode, meanwhile, a multi-scale entropy curve is constructed, all-directional comparison is achieved, and the accuracy and reliability of information analysis are improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

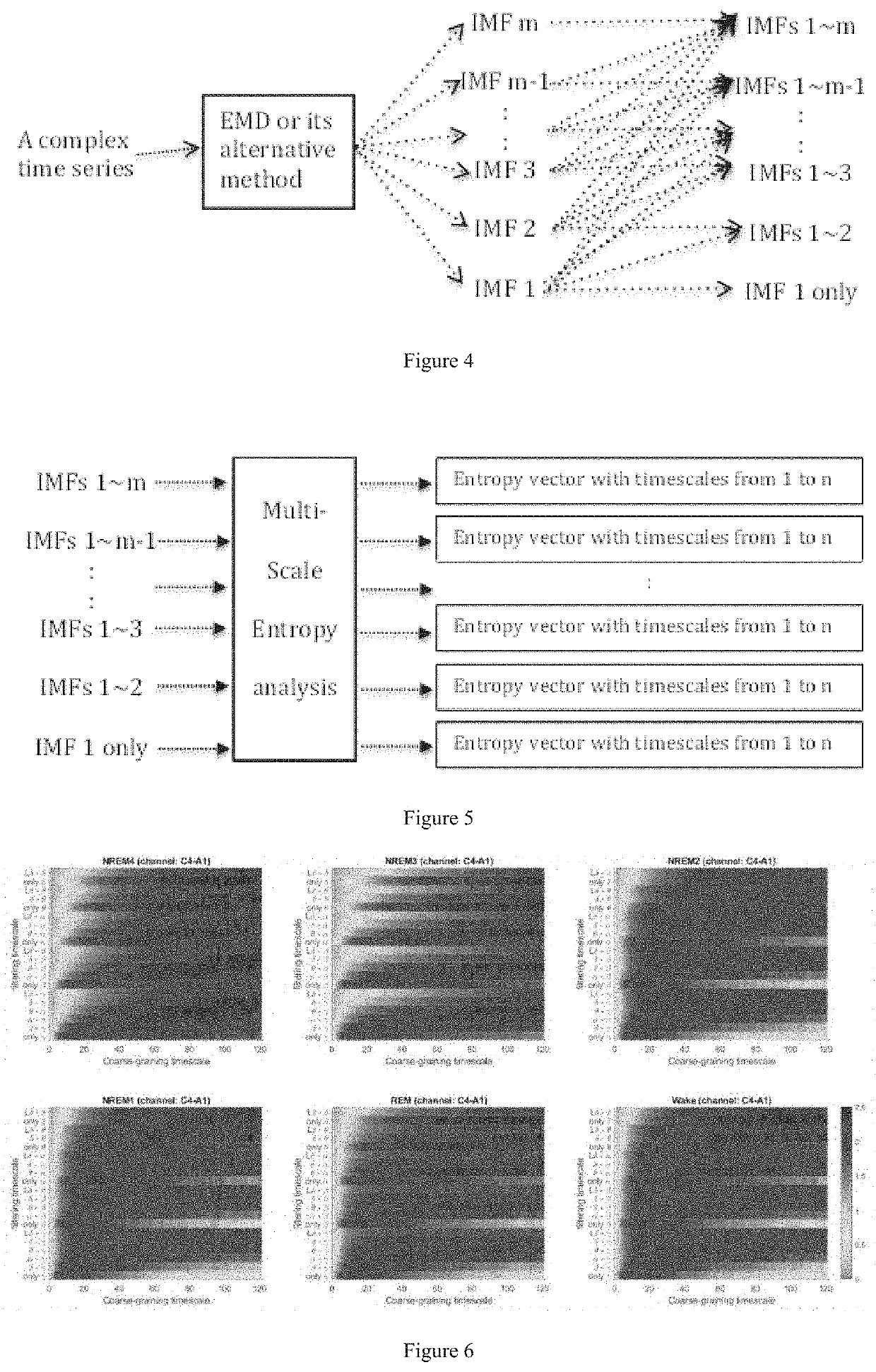

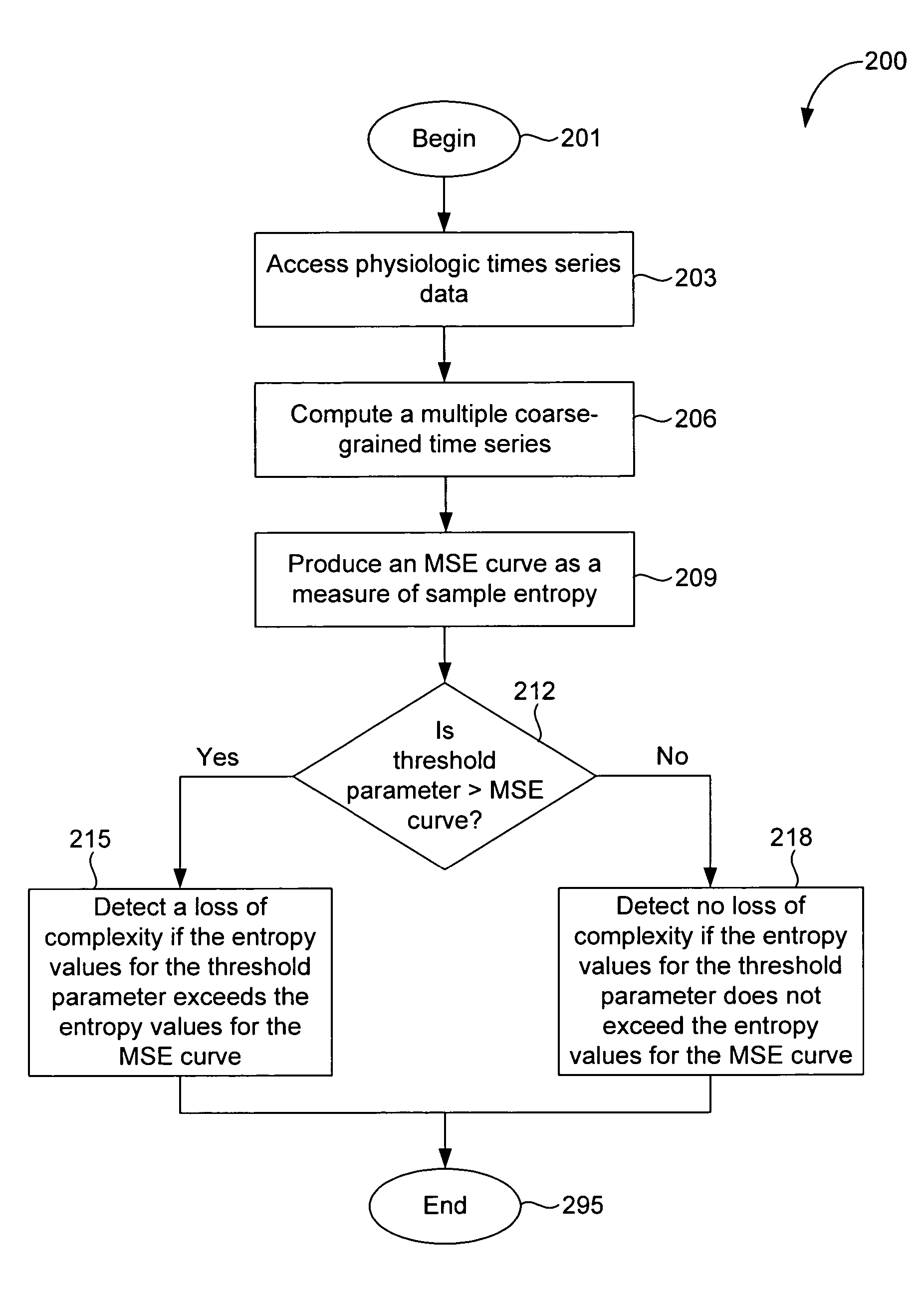

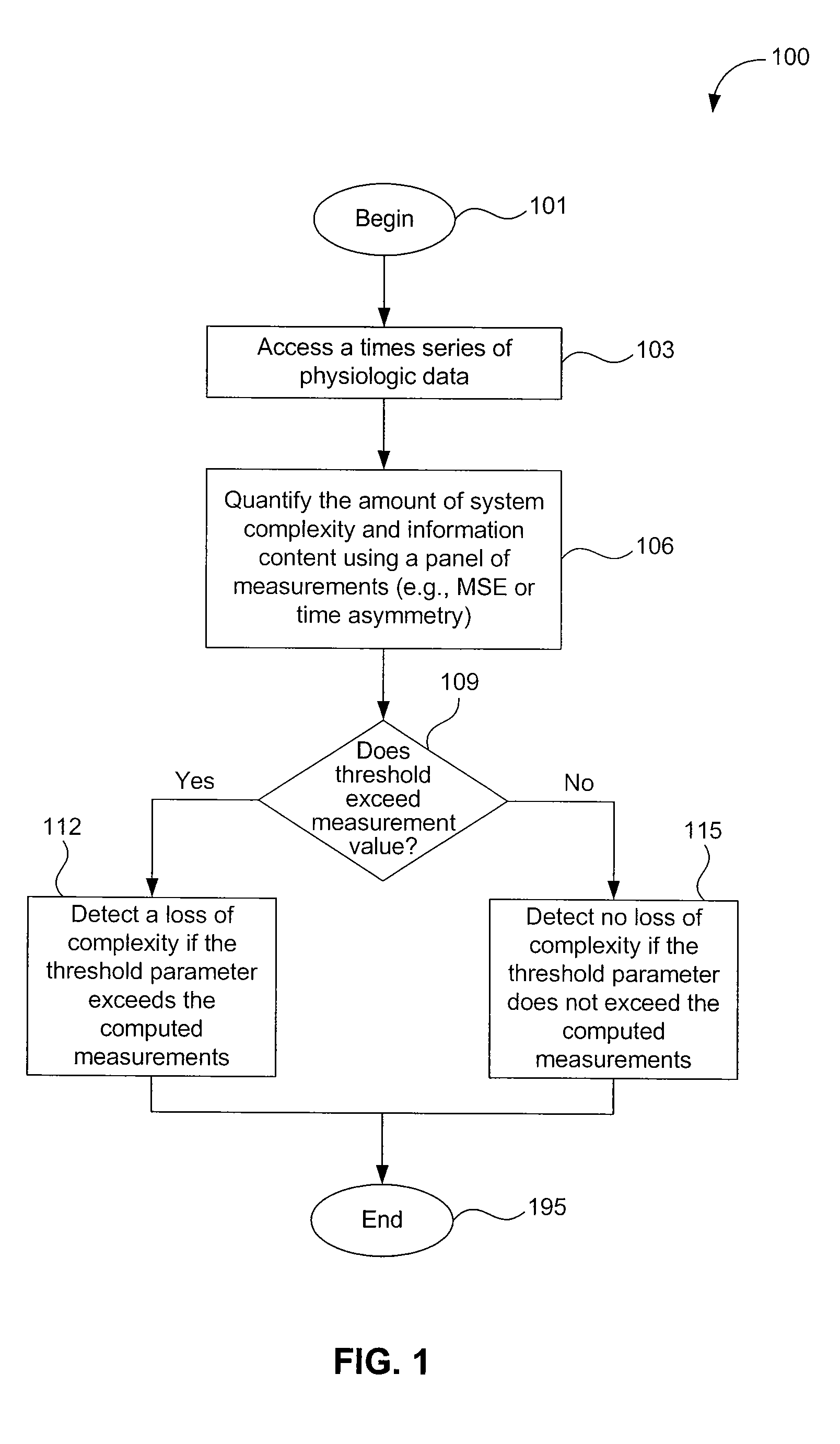

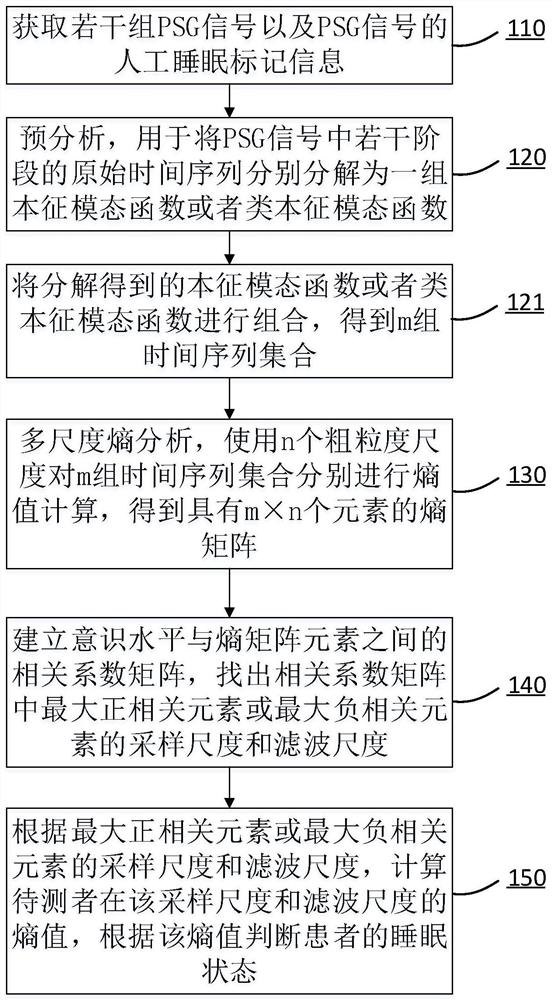

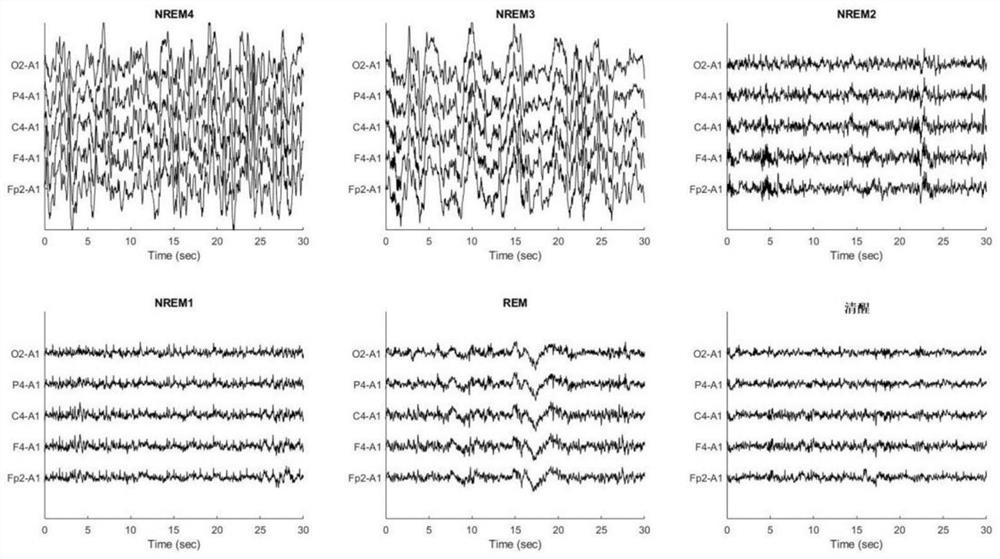

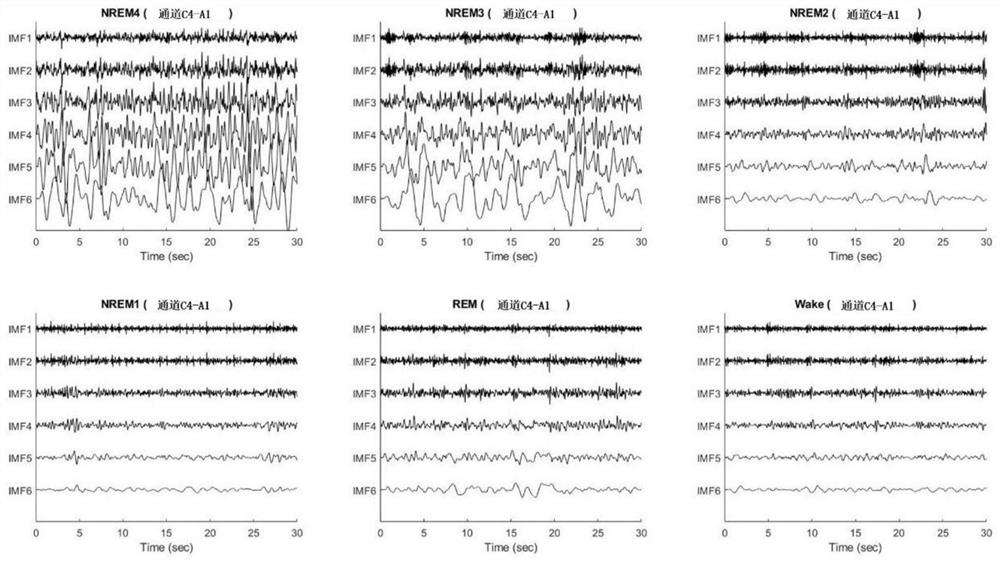

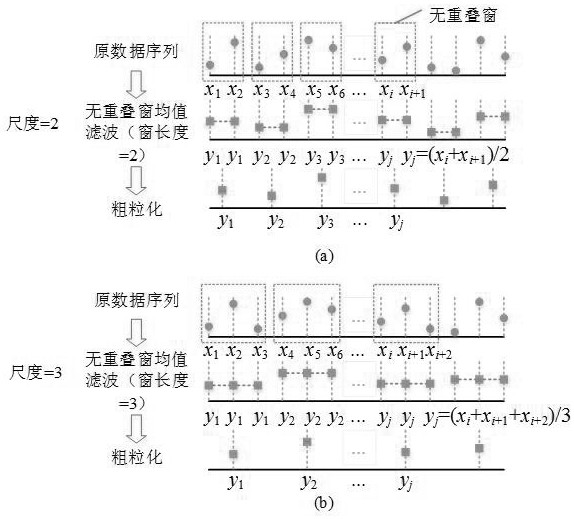

A Construction Method for Automatic Sleep Staging and Use Thereof

PendingUS20220323000A1Improve abilitiesReduce the amount of calculationDiagnostic recording/measuringSensorsSleep stagingCorrelation coefficient

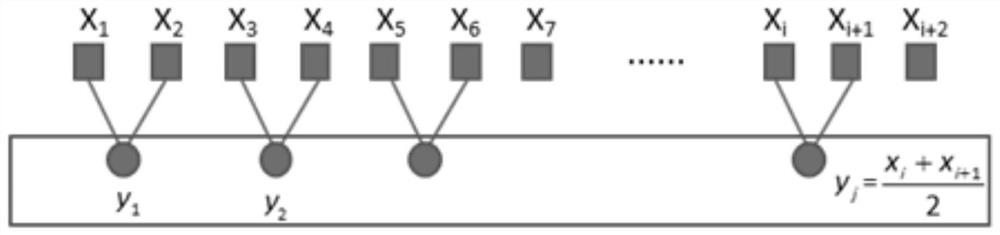

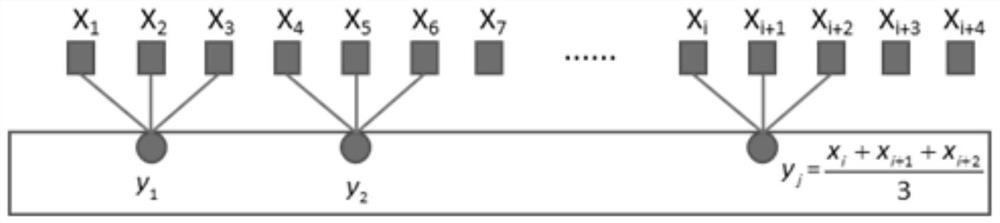

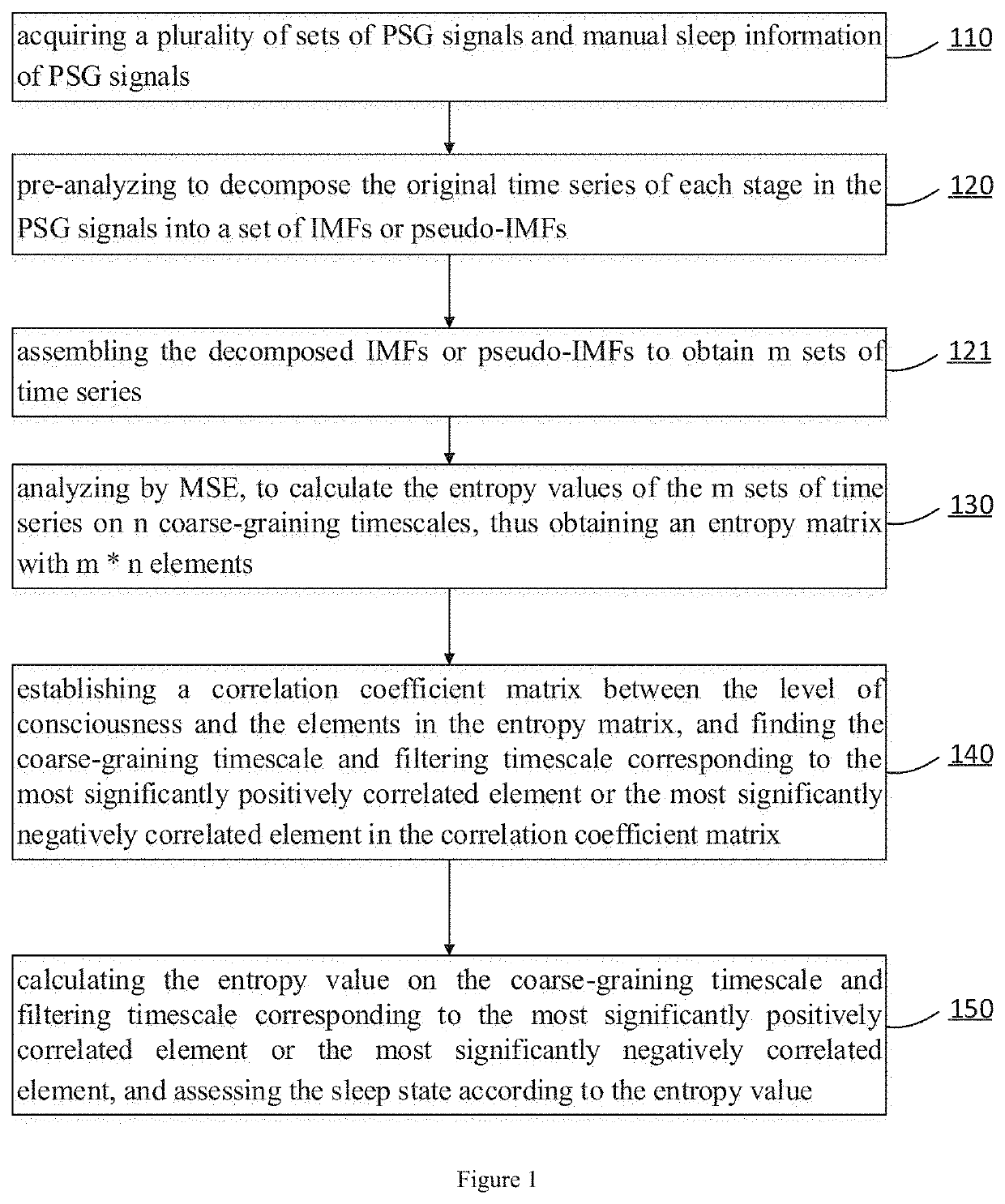

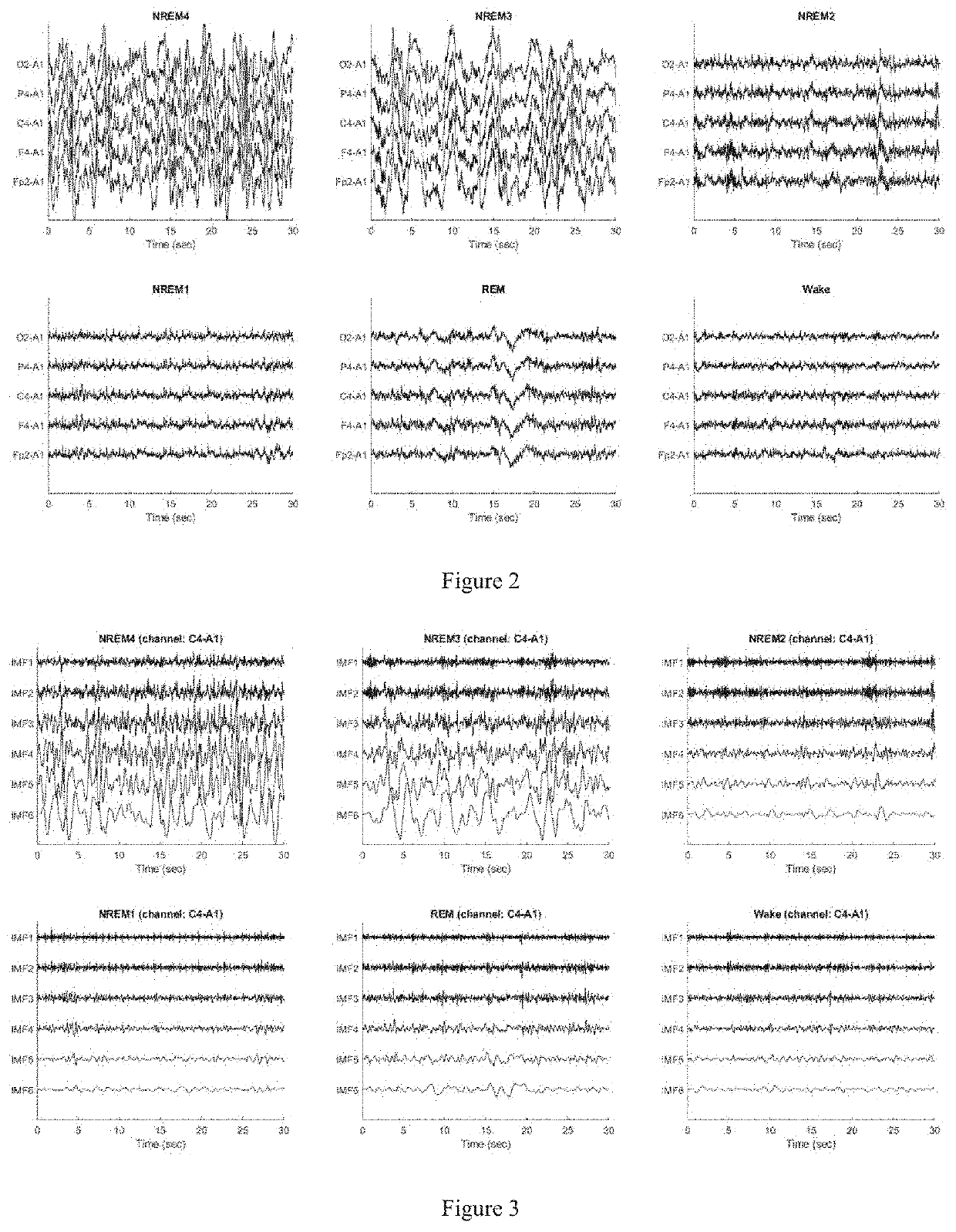

The present invention provides a construction method for automatic sleep staging and use thereof. The construction method for automatic sleep staging comprises: acquiring a plurality of sets of PSG signals and manual sleep information of PSG signals; pre-analyzing to decompose the original time series in the PSG signals into a set of pseudo-intrinsic mode functions (pseudo-IMFs); assembling the pseudo-IMFs to obtain m sets of time series; analyzing by multiscale entropy (MSE), to calculate the entropy values of the m sets of time series on n coarse-graining timescales, thus obtaining an entropy matrix with m*n elements; establishing a correlation coefficient matrix between the levels of consciousness and the elements in the entropy matrix, and finding the coarse-graining timescale and filtering timescale corresponding to the most significantly positively correlated element or the most significantly negatively correlated element in the correlation coefficient matrix; and calculating the entropy value on the coarse-graining timescale and filtering timescale corresponding to the most significantly positively correlated element or the most significantly negatively correlated element, and assessing the sleep state according to the entropy value.

Owner:JIANGSU AIDISCITECH RES INST CO LTD

Complexity-based dynamical assay for assessing the toxicity and efficacy of pharmaceutical and other therapeutic interventions

In a subject undergoing therapeutic intervention, efficacy of the therapeutic intervention is assessed based on a series of physiologic data associated with the subject. The series of physiologic data is analyzed to produce a measure of complexity. The complexity measure is then compared to a control. The efficacy of the therapeutic intervention is assessed based on the comparison of the complexity measure to the control. The control may be, for example, a complexity measure taken prior to initiation of the therapeutic intervention, a complexity measure taken from a different subject, or a predetermined threshold value. The measure of complexity is generated using, for example, a multiscale entropy measurement (MSE), a time asymmetry measurement, and / or an information-based similarity measurement. An increase in complexity indicates a positive effect of the therapeutic intervention, while a decrease in complexity indicates a negative effect of the therapeutic intervention.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

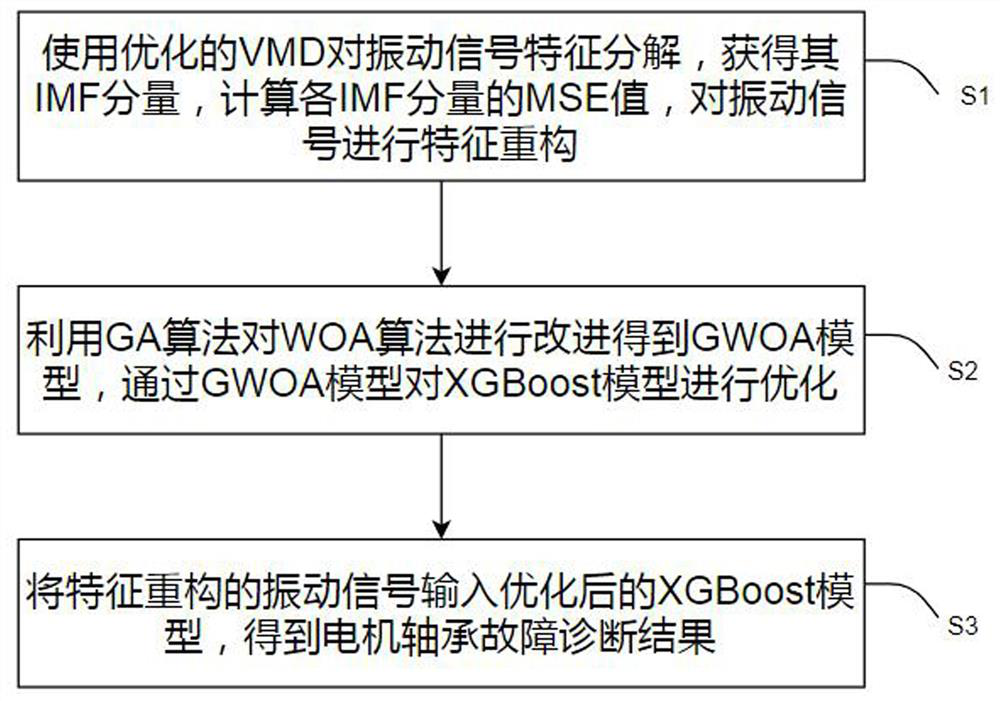

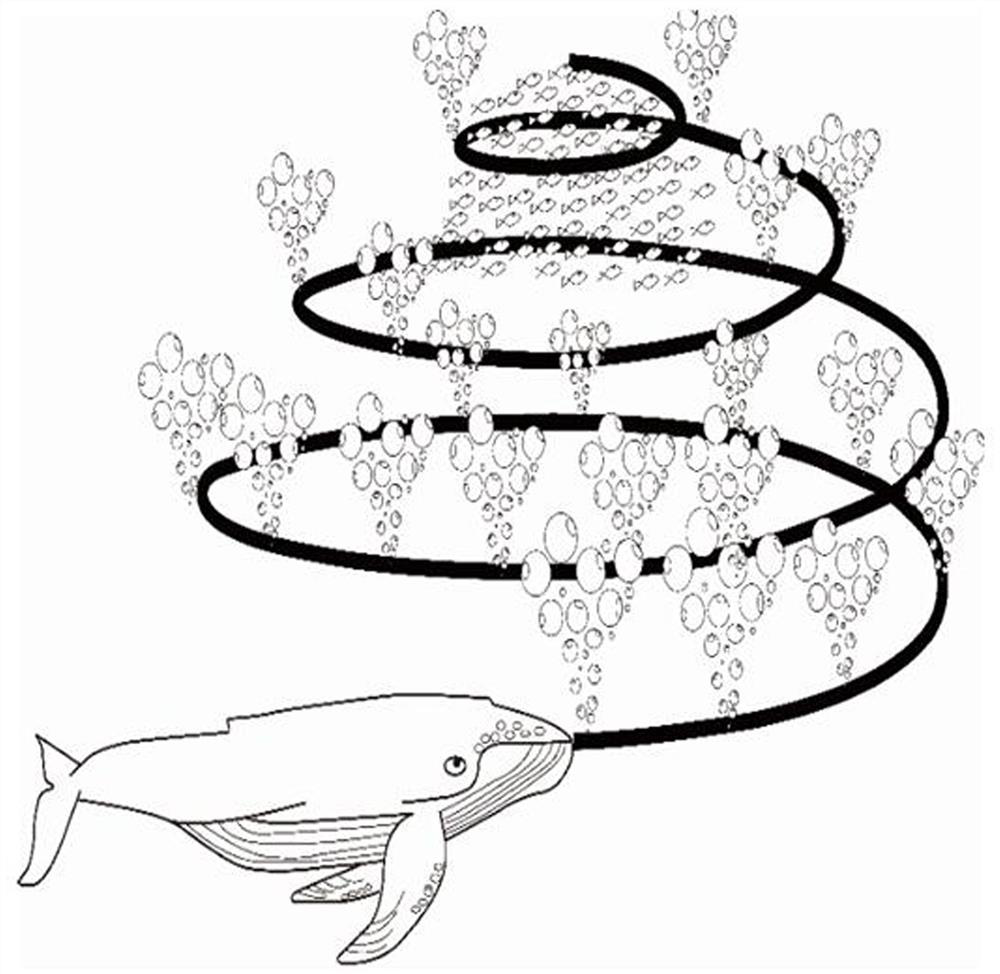

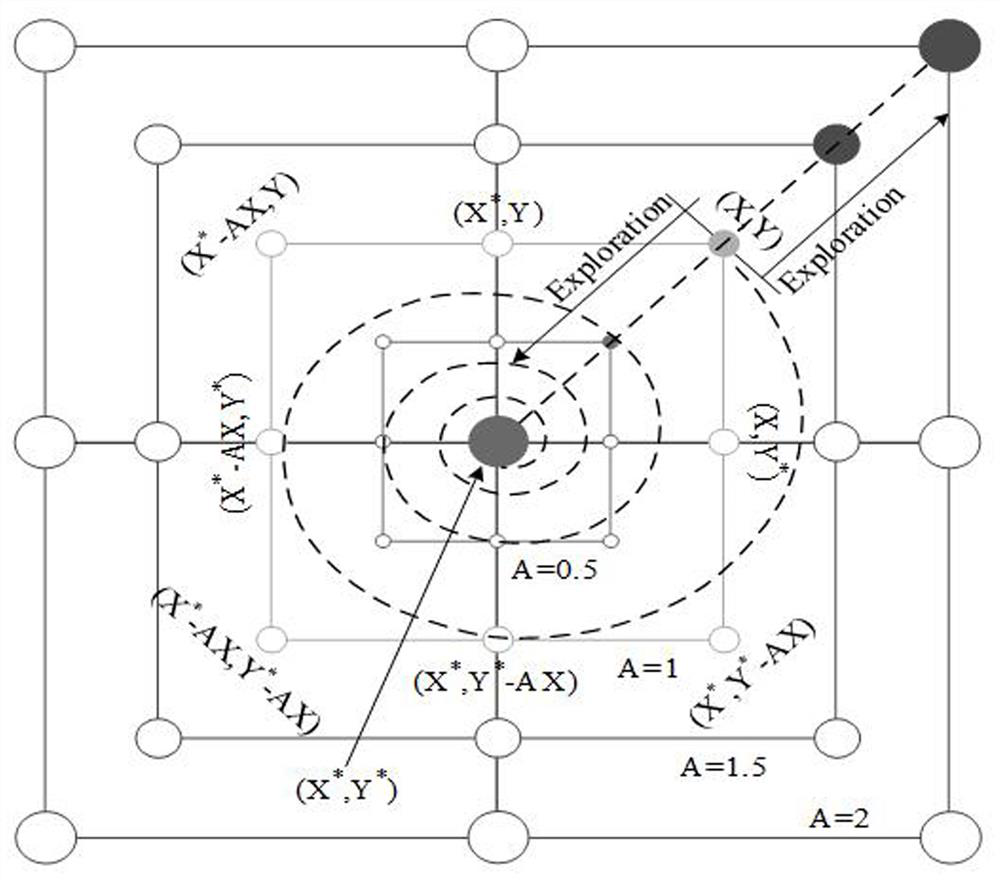

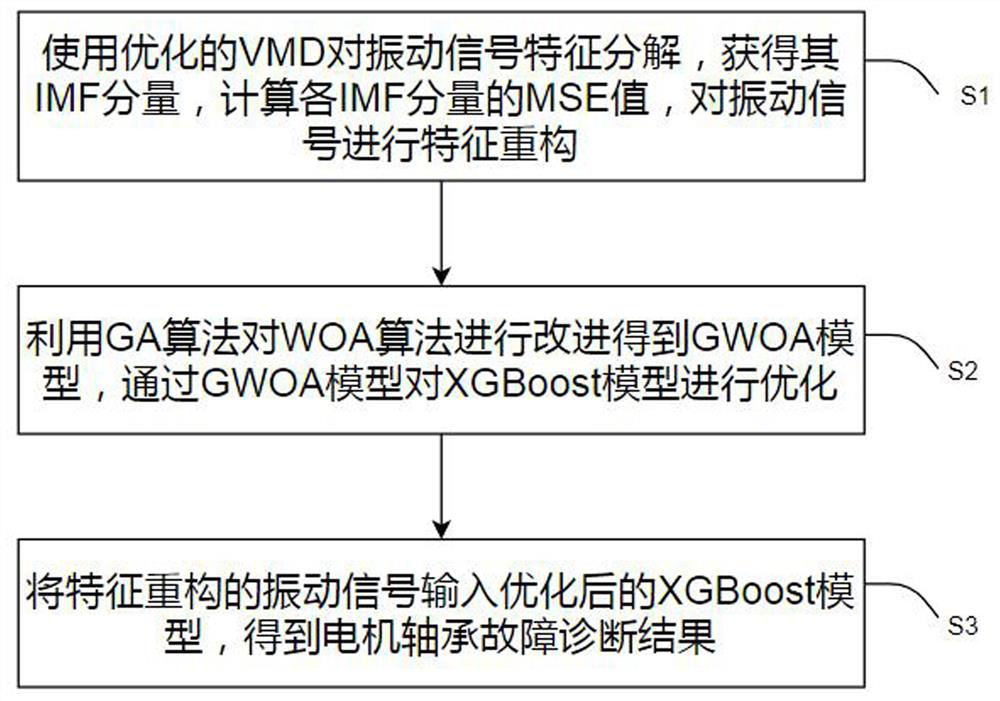

Motor bearing fault diagnosis method based on feature optimization and GWOA-XGBoost

ActiveCN114169110ASolve the problem of low diagnostic accuracyImprove the ability of signal feature extractionGeometric CADMachine part testingAlgorithmElectric machine

The invention relates to a motor bearing fault diagnosis method based on feature optimization and GWOA-XGBoost, and the method comprises the following steps: carrying out the feature decomposition of a vibration signal of a motor bearing through employing an optimized VMD, obtaining IMF components, calculating the MSE value of each IMF component based on a multi-scale entropy theory, and carrying out the feature reconstruction of the vibration signal through the MSE values; a WOA algorithm is improved by using a GA algorithm to obtain a GWOA model, and the XGBoost model is optimized through the GWOA model; and inputting the vibration signal subjected to feature reconstruction into the optimized XGBoost model to obtain a motor bearing fault diagnosis result. According to the motor bearing fault diagnosis method, the motor bearing fault diagnosis precision can be improved.

Owner:NAVAL UNIV OF ENG PLA

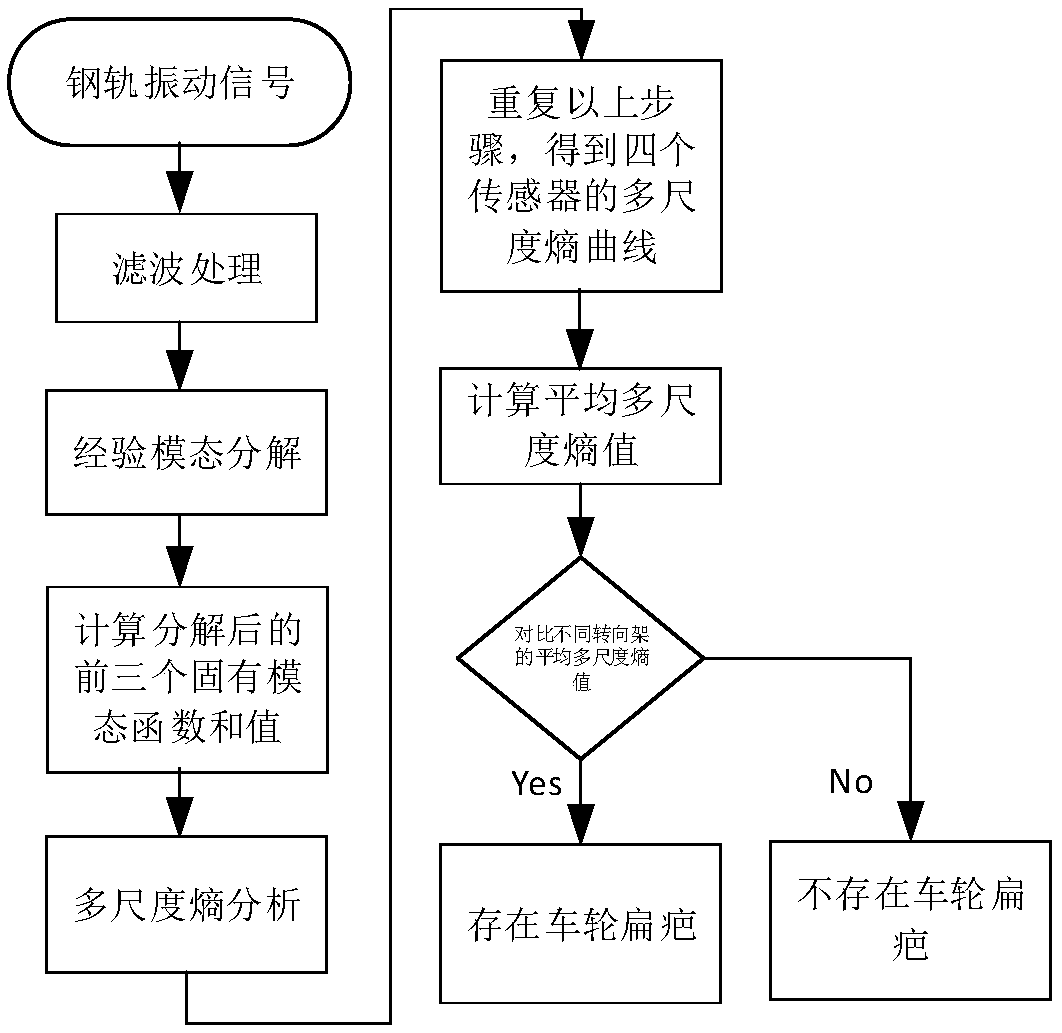

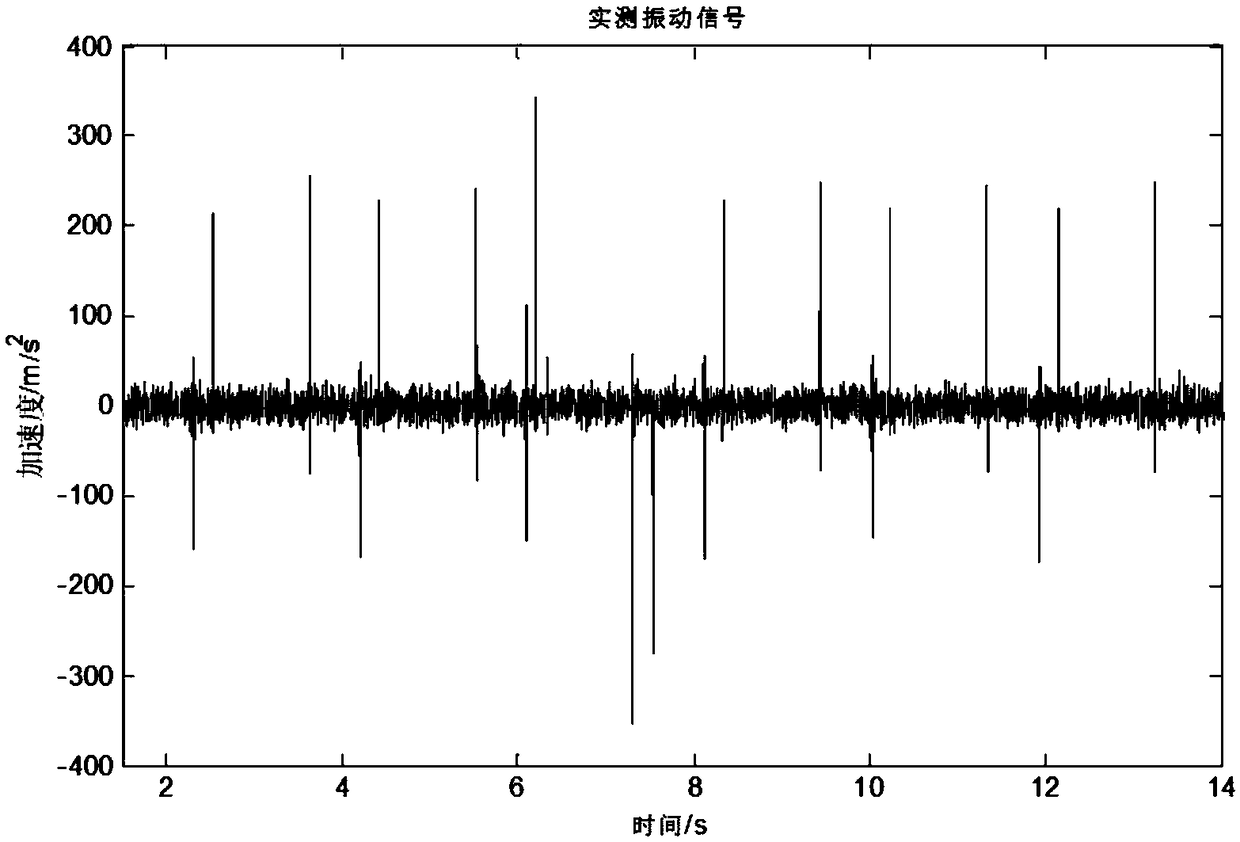

Method for detecting wheel flat damage fault based on EMD (Empirical Mode Decomposition) and multiscale entropy

InactiveCN108827665AEasy to operateConvenient online detection of operating vehiclesWheel-rims surveying/measuringRailway vehicle testingVibration accelerationWave shape

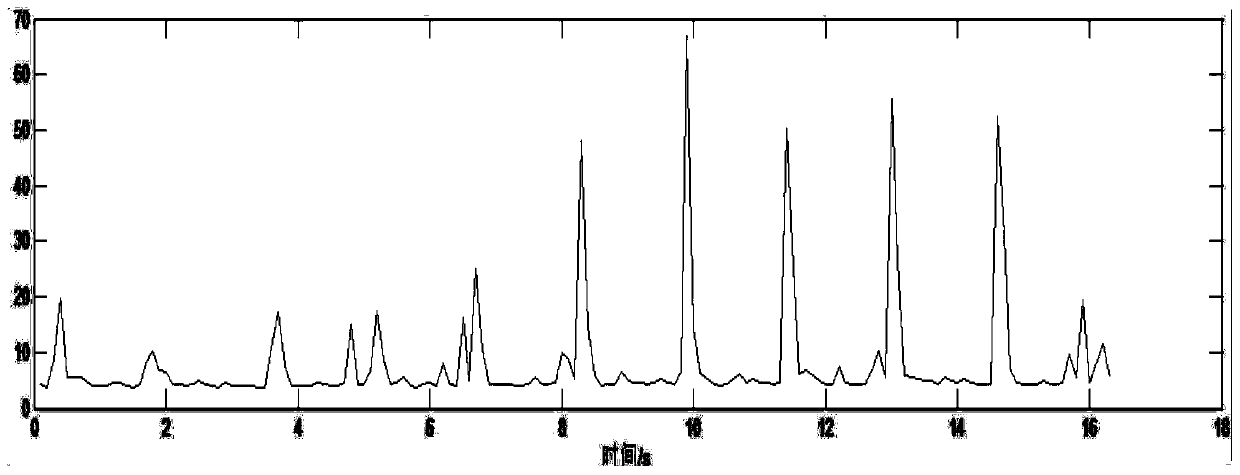

The invention discloses a method for detecting a wheel flat damage fault based on EMD (Empirical Mode Decomposition) and a multiscale entropy. The method comprises the steps: installing four vibrationacceleration sensors on one side of a rail to collect the vibration signals of the rail when a train passes; filtering the collected rail vibration signals to retain the signal related with the vibration of a wheel; carrying out the EMD of the filtered signal, and extracting the first three natural modal components of the signal; calculating the multi-scale entropy of the sum of the first three natural modal components to obtain the multi-scale entropies of each sensor; calculating the average multi-scale entropy of each sensor; determining whether the wheel has the flat damage fault or not through the comparing of the multi-scale entropy curves of the normal wheel of the same train. According to the invention, the method employs the rail vibration signals collected by the vibration acceleration sensors, achieves the detection of the wave-shaped wear of the rail through the wavelet packet energy entropy analysis of the vibration signals, is good in real-time performance, is convenientfor detection, is high in speed, and is wide in application range.

Owner:NANJING UNIV OF SCI & TECH

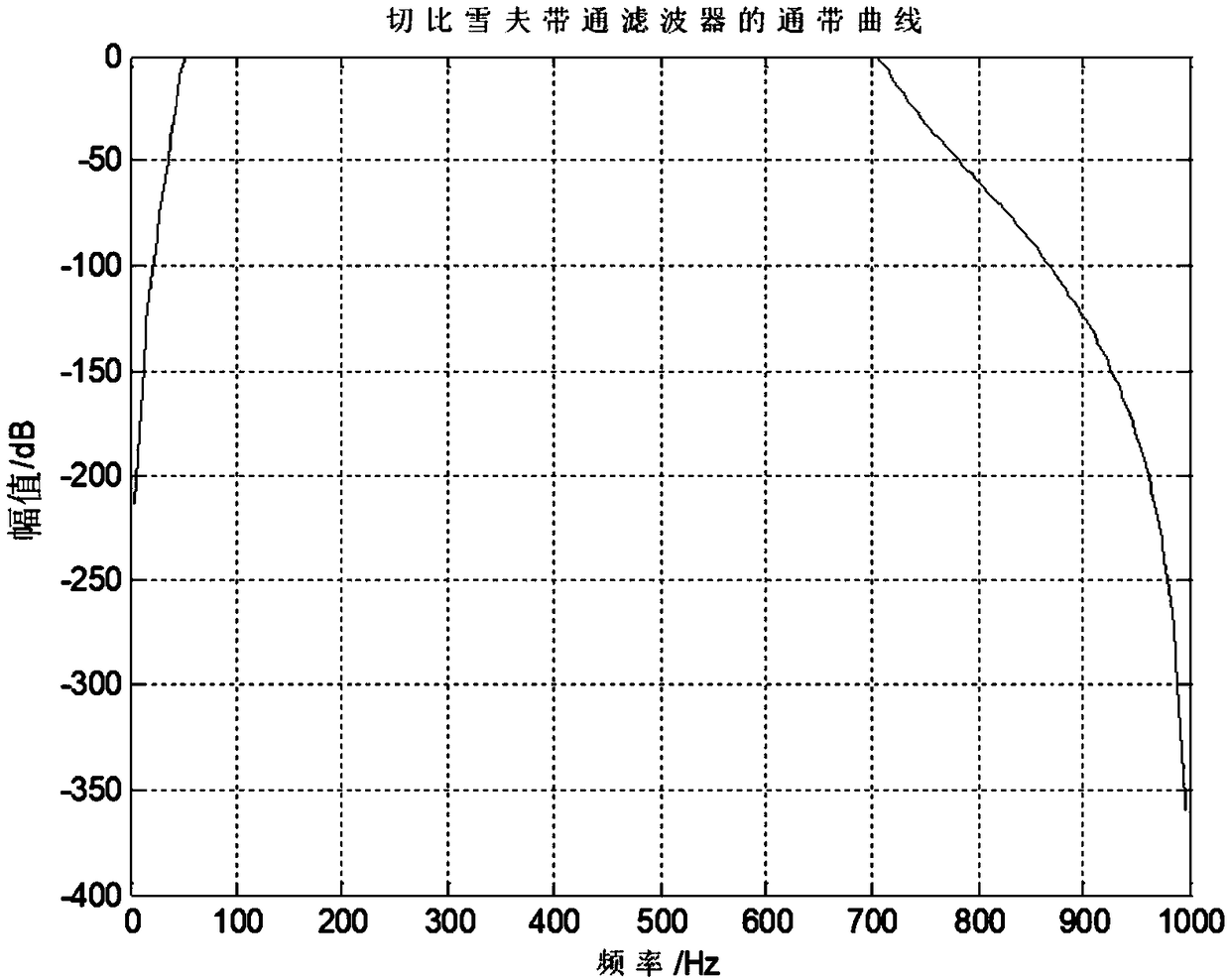

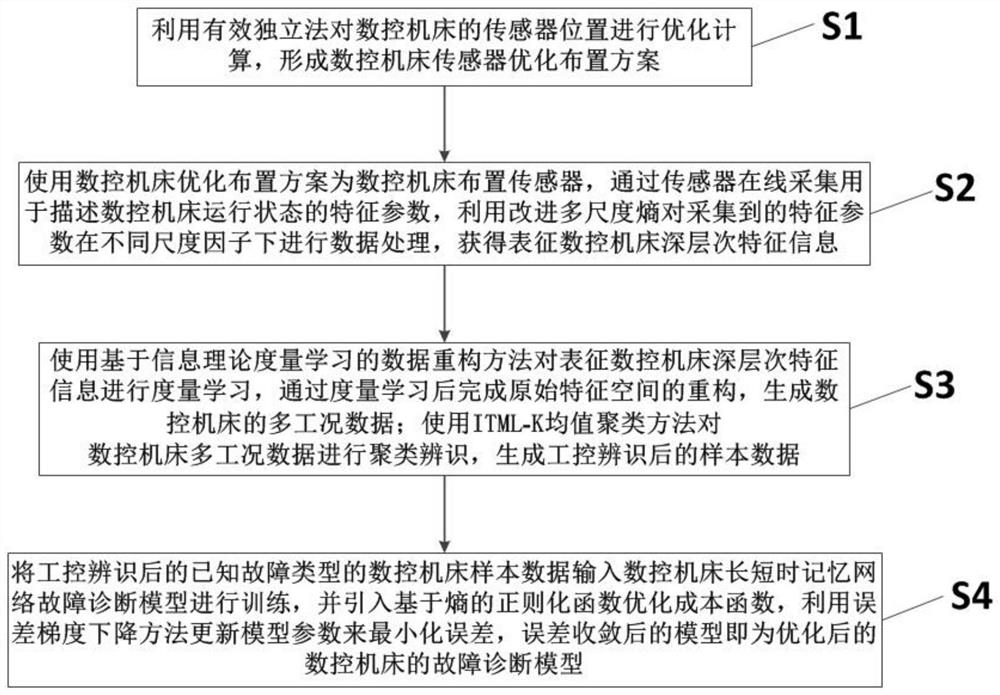

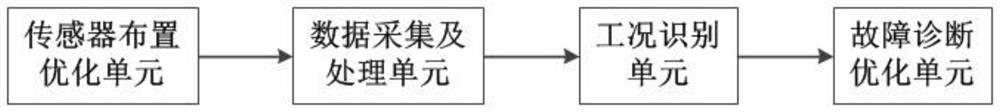

Fault diagnosis optimization method, system and device for numerical control machine tool under multiple working conditions

ActiveCN112650146AImprove operational safetyImprove operational reliabilityProgramme controlComputer controlNumerical controlData acquisition

The invention provides a fault diagnosis optimization method, system and device for a numerical control machine tool under multiple working conditions. Through arrangement optimization of numerical control machine tool sensors, effectiveness of data acquisition and utilization is improved, an improved multi-scale entropy algorithm is utilized to extract characteristic information of different states represented by the numerical control machine tools of different time scales, deep-level characteristic information is mined, and differentiation of characteristics among different states is improved; on the basis, ITML-K mean value clustering is used for identifying the working condition of the numerical control machine tool so that a problem of a poor identification effect of a traditional clustering method under the condition of multi-working-condition boundary fuzziness is solved; and finally, an entropy-based regularization function is utilized to solve an overfitting problem occurring when a data-driven numerical control machine tool fault diagnosis model is constructed so that the generalization and accuracy of the numerical control machine tool fault diagnosis model are improved, and the optimization of the numerical control machine tool fault diagnosis model is realized. The method, the system and the device have important help for improving the operation safety and reliability of the numerical control machine tool and improving the fault diagnosis rate of the numerical control machine tool.

Owner:CHINA NAT MASCH TOOL QUALITY SUPERVISION TESTING CENT

Automatic sleep staging establishing method and application thereof

ActiveCN112690759AHigh speedSmall amount of calculationDiagnostic recording/measuringSensorsPattern recognitionSleep staging

The invention provides an automatic sleep staging establishing method and application thereof. The automatic sleep staging establishing method comprises the following steps: acquiring a plurality of groups of PSG signals and artificial sleep marking information of the PSG signals; conducting pre-analysis: decomposing an original time sequence in the PSG signal into a group of similar intrinsic mode functions; combining the similar intrinsic mode functions to obtain m groups of time sequence sets; conducting multi-scale entropy analysis: performing entropy calculation on the m groups of time sequence sets by using n sampling scales to obtain an entropy matrix with m*n elements; establishing a correlation coefficient matrix between the consciousness level and the elements of the entropy matrix, and finding out a sampling scale and a filtering scale corresponding to the maximum positive correlation element or the maximum negative correlation element in the correlation coefficient matrix; sampling with coarse granularity scale; and according to the sampling scale and the filtering scale of the maximum positive correlation element or the maximum negative correlation element, calculating entropy values of the to-be-tested person in the sampling scale and the filtering scale, and judging the sleep state of the patient according to the entropy values.

Owner:南京生物医药谷建设发展有限公司

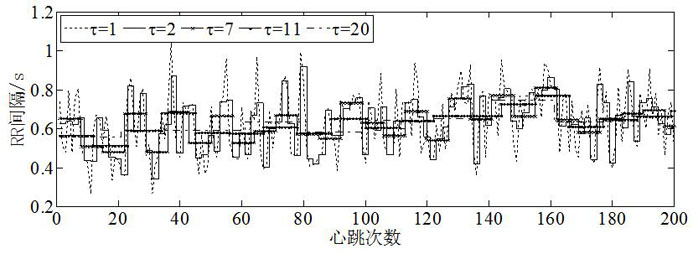

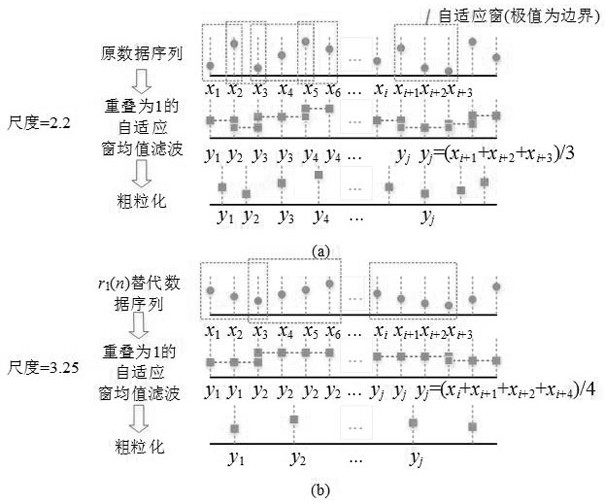

A method for analyzing heart rate variability data based on adaptive multiscale entropy

ActiveCN113499049BPracticalFully and accurately reflect complexityDiagnostic signal processingSensorsData setRR interval

The invention belongs to the field of medical technology, and relates to a method for analyzing heart rate variability data based on self-adaptive multi-scale entropy; the invention overcomes the shortcomings of MSE quantifying HRV complexity in a fixed scale, and quantifies HRV complexity comprehensively and accurately; The HRV is adaptively decomposed by state decomposition, and a series of multi-scale mean substitution data sets of the original data are obtained; secondly, each element in the mean substitution data set is coarse-grained and the corresponding adaptive scale is obtained; finally, the coarse-grained calculation is carried out. The averaged value replaces the SampEn value of each element in the data set, and the adaptive multi-scale entropy is obtained; the adaptive multi-scale entropy can comprehensively and accurately evaluate the HRV complexity.

Owner:CHANGZHI MEDICAL COLLEGE

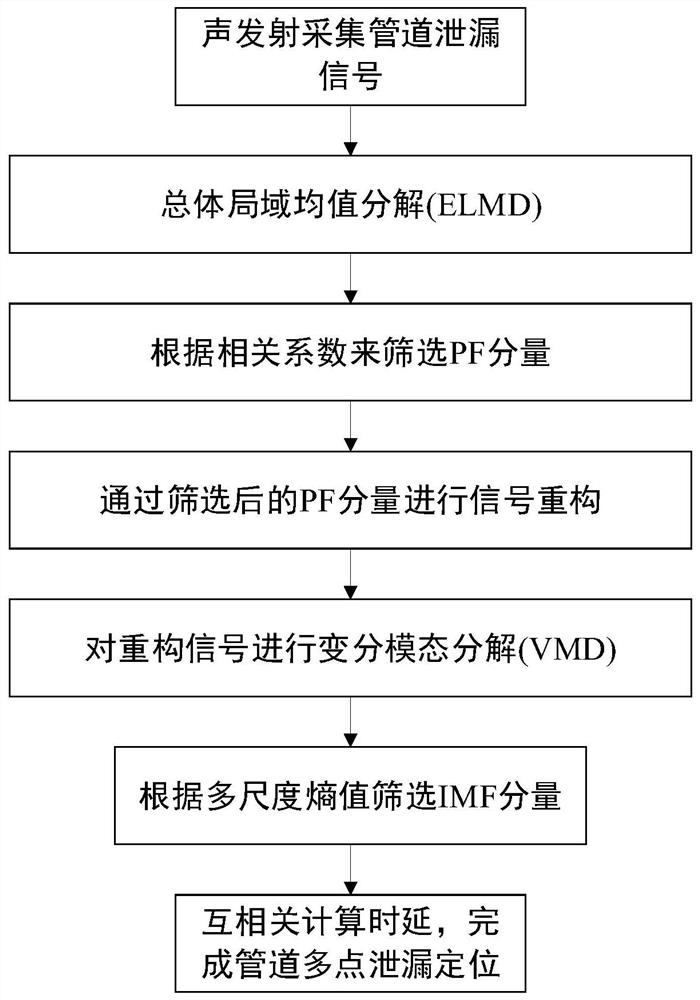

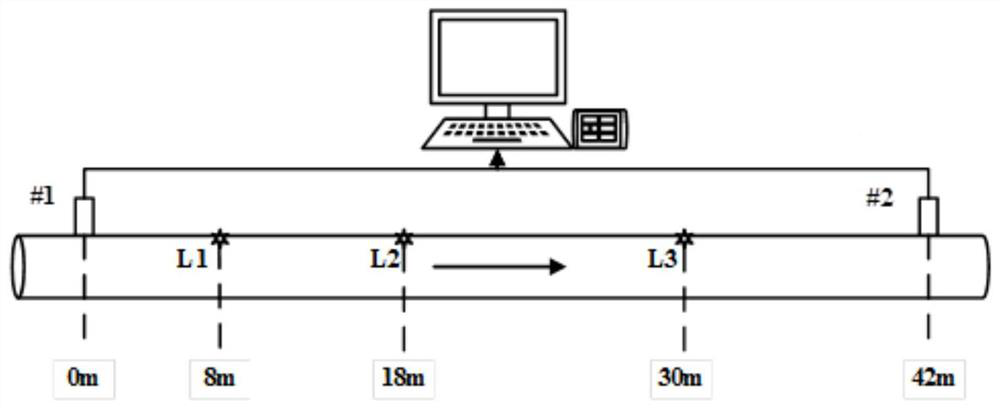

A method for locating multi-point leaks in pipelines based on improved vmd

ActiveCN110454687BOptimize the number of decomposition layersCancel noiseDetection of fluid at leakage pointMaterial analysis using acoustic emission techniquesCorrelation coefficientEngineering

The invention relates to a method for locating pipeline multi-point leaks based on improved VMD, comprising: collecting original pipeline leakage signals; performing overall local mean value decomposition on the original leakage signals to obtain several PF components; calculating the correlation coefficient of each PF component, Screen out the required PF component according to the correlation coefficient, and carry out signal reconstruction according to the screened out PF component, determine the k value of the variational mode decomposition; carry out the variational mode decomposition to the reconstructed signal, obtain several IMF components, Calculate the multi-scale entropy value of each IMF component, and screen the IMF component according to the multi-scale entropy value of each IMF component; perform signal reconstruction on the screened IMF component, and perform cross-correlation positioning calculation on each leakage signal after blind source separation Complete pipeline leak location. The invention can effectively extract pipeline leakage signals, eliminate the influence of low correlation components and noise in the original leakage signals, and make the final positioning result more accurate.

Owner:CHANGZHOU UNIV

Fault detection method for industrial system based on Euclidean distance multi-scale fuzzy sample entropy

ActiveCN111122162BAccurate portrayalHigh precisionMachine part testingNeural architecturesAlgorithmIndustrial systems

The invention discloses an industrial system fault detection method based on Euclidean distance multiscale fuzzy sample entropy. According to the method provided by the invention, the complexity of atime sequence can be described from a plurality of time scales; meanwhile, compared with an existing multiscale entropy method and an existing composite multiscale entropy (FME) method, the method hasthe advantages that the stability and the accuracy of the calculation of multi-scale fuzzy sample entropy (FME) are remarkably improved. The method can be used for judging and detecting the fault type of an industrial system and analyzing the complexity of the time sequence.

Owner:HANGZHOU DIANZI UNIV

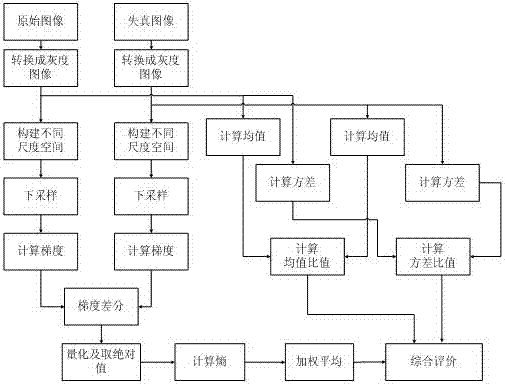

An image quality assessment method based on multi-scale gradient differential entropy

InactiveCN104881878BImprove consistencyImage enhancementImage analysisEvaluation resultPattern recognition

The invention discloses an image quality evaluation method based on multi-scale gradient difference entropies, and the method comprises the following steps: 1, converting an original image and a distorted image into gray-scale images; 2, calculating gradient difference entropies in different scale spaces based on the results obtained at step 1, and enabling the gradient difference entropies in different scale spaces to be averaged in a weighted manner; 3, calculating the ration of mean values of the gray-scale images corresponding to the original image and the distorted image; 4, calculating the ratio of variances of the gray-scale images corresponding to the original image and the distorted image; 5, carrying out comprehensive evaluation based on the results obtained at step 2, 3, and 4. The method introduces a basic concept of scale space, is based on a forming process of a target on a retina of a person at different distances, and is better in consistency with subjective evaluation results through the extraction of contour characteristics in the scale space and the reflecting of the difference between contour characteristics of the original image and the distorted image in the scale space through the entropies.

Owner:WUHAN UNIV

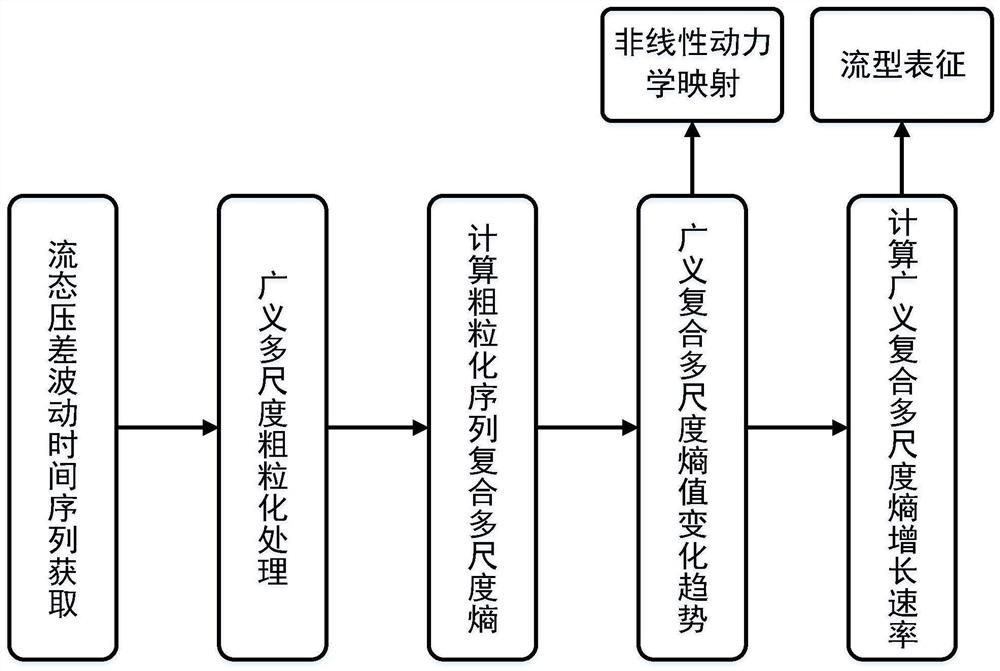

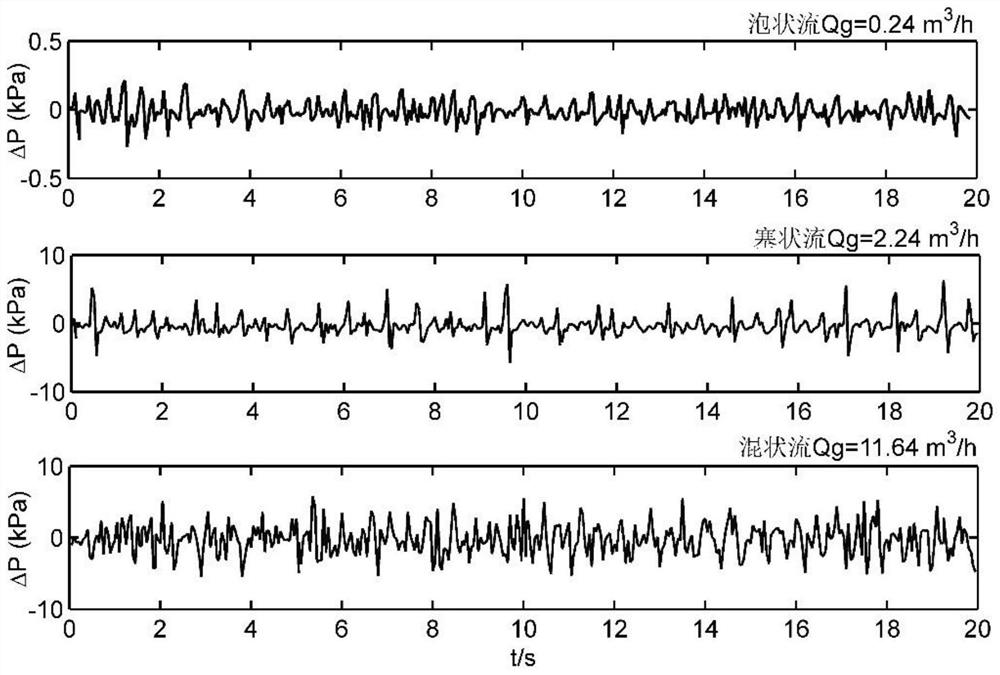

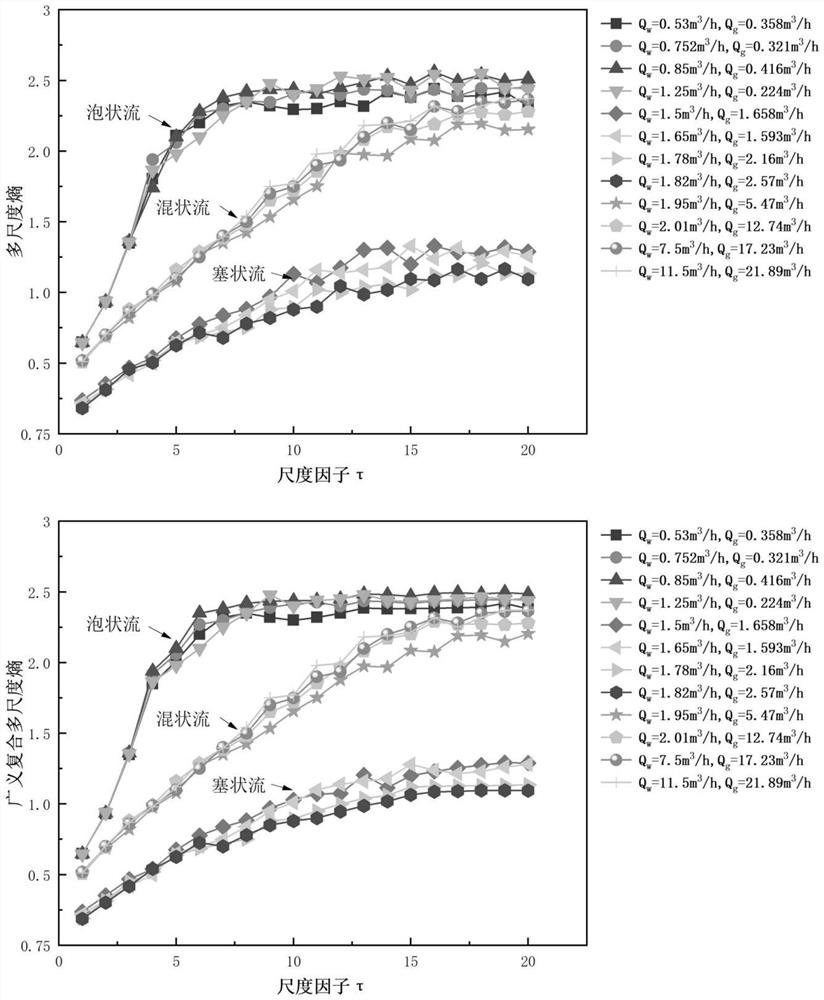

Gas-liquid two-phase flow pattern nonlinear kinetic analysis method based on generalized composite multi-scale entropy

InactiveCN113092062ASimple calculationImprove robustnessHydrodynamic testingComputational physicsStatistical physics

The invention provides a gas-liquid two-phase flow pattern nonlinear kinetic analysis method based on generalized composite multi-scale entropy. The method comprises the following steps: firstly, carrying out an air-water-gas-liquid two-phase flow experiment, and collecting pressure difference fluctuation time sequences of three flow patterns; then performing generalized coarse graining processing according to the flow type differential pressure fluctuation time sequence, calculating entropy values of all coarse graining time sequences of different scale factors, averaging the entropy values under the same scale factor, obtaining generalized composite multi-scale entropy under different scales, and drawing an entropy value change trend chart of the generalized composite multi-scale entropy; and finally, according to the generalized composite multi-scale entropy change trend charts of different flow patterns, calculating the generalized composite multi-scale entropy growth rate, and obtaining generalized composite multi-scale entropy growth rate distribution of the three flow pattern pressure difference fluctuation time sequences, thereby realizing representation and identification of the flow patterns. The generalized composite multi-scale entropy in the invention can map the complexity of the gas-liquid two-phase flow, and has the characteristics of strong robustness, simple calculation and easy realization.

Owner:QIQIHAR UNIVERSITY

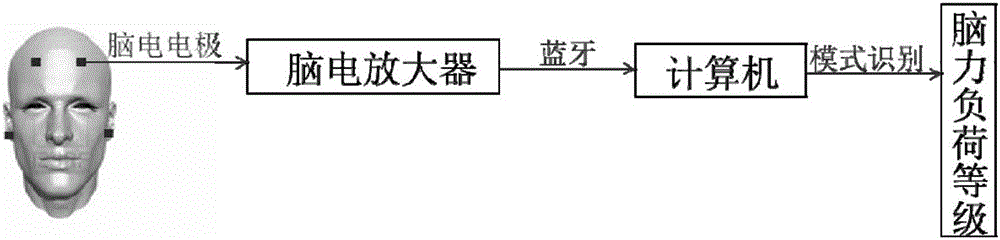

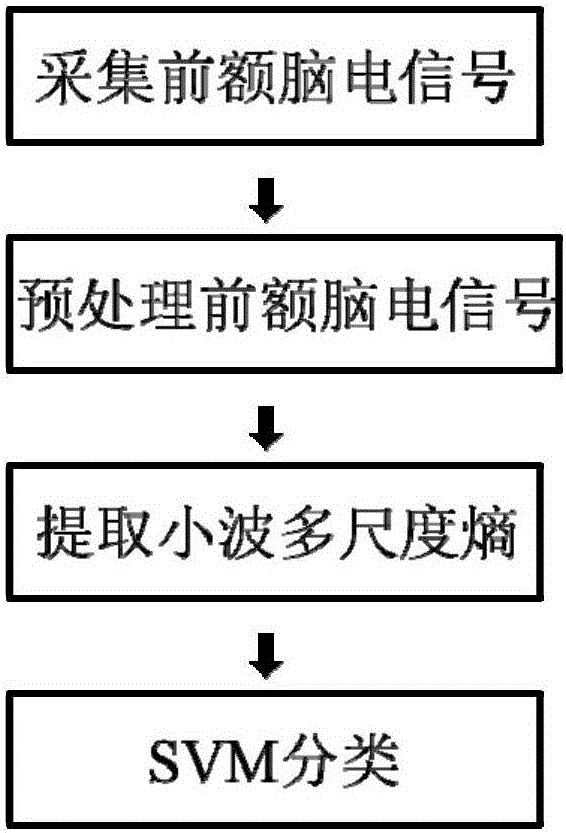

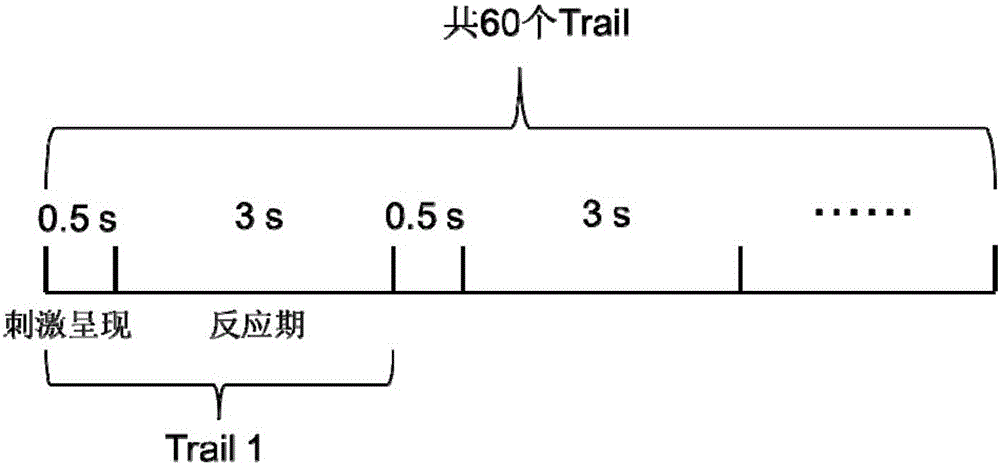

An online detection method of mental load based on forehead EEG signal

ActiveCN103610447BDoes not affect normal operationImprove accuracySensorsPsychotechnic devicesData pre-processingWavelet

The invention discloses a mental workload online detection method based on forehead electroencephalogram signals. The method comprises the following steps that the forehead electroencephalogram signals are collected with a silver / silver chloride electrode as a sensor; an electroencephalogram amplifier is used for carrying out amplification and filtering on the forehead electroencephalogram signals, then data preprocessing is carried out, and the processed forehead electroencephalogram signals are acquired; a stimulation task is compiled as n-back; wavelet multiscale entropy features are extracted from the processed forehead electroencephalogram signals; model recognition is carried out on the wavelet multiscale entropy features through a support vector machine, and an obtained result is the mental workload level and recognition accuracy of data. The experiment process of the method is carried out on the forehead, the need for washing the head before and after the process is avoided, the operation is facilitated, and meanwhile the influence on signal collection by the hair and the scalp is avoided. The method can effectively improve the accuracy and convenience of a mental workload detection system and obtain considerable social benefits and economic benefits.

Owner:禹锡科技(天津)有限公司

Method, system and device for terahertz imaging of biological tissue based on multi-scale entropy

ActiveCN107468250BIncrease contrastMaterial analysis by optical meansDiagnostic recording/measuringTime domainImage contrast

The invention discloses a biological tissue terahertz imaging method, system and equipment based on multiscale entropy. According to the method, the information of whole terahertz time-domain spectroscopy signals is utilized, and the entropy value of each point on the detected biological tissue sample on different time scales is obtained; the entropy value on a certain scale is selected, or the entropy values on multiple scales are added together, so that a terahertz image of the detected biological tissue sample is reconstructed. By means of the method, the limitations that a traditional biological tissue terahertz imaging method only uses the spectroscopy information of a certain time or frequency point are overcome, and imaging contrast among different samples is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

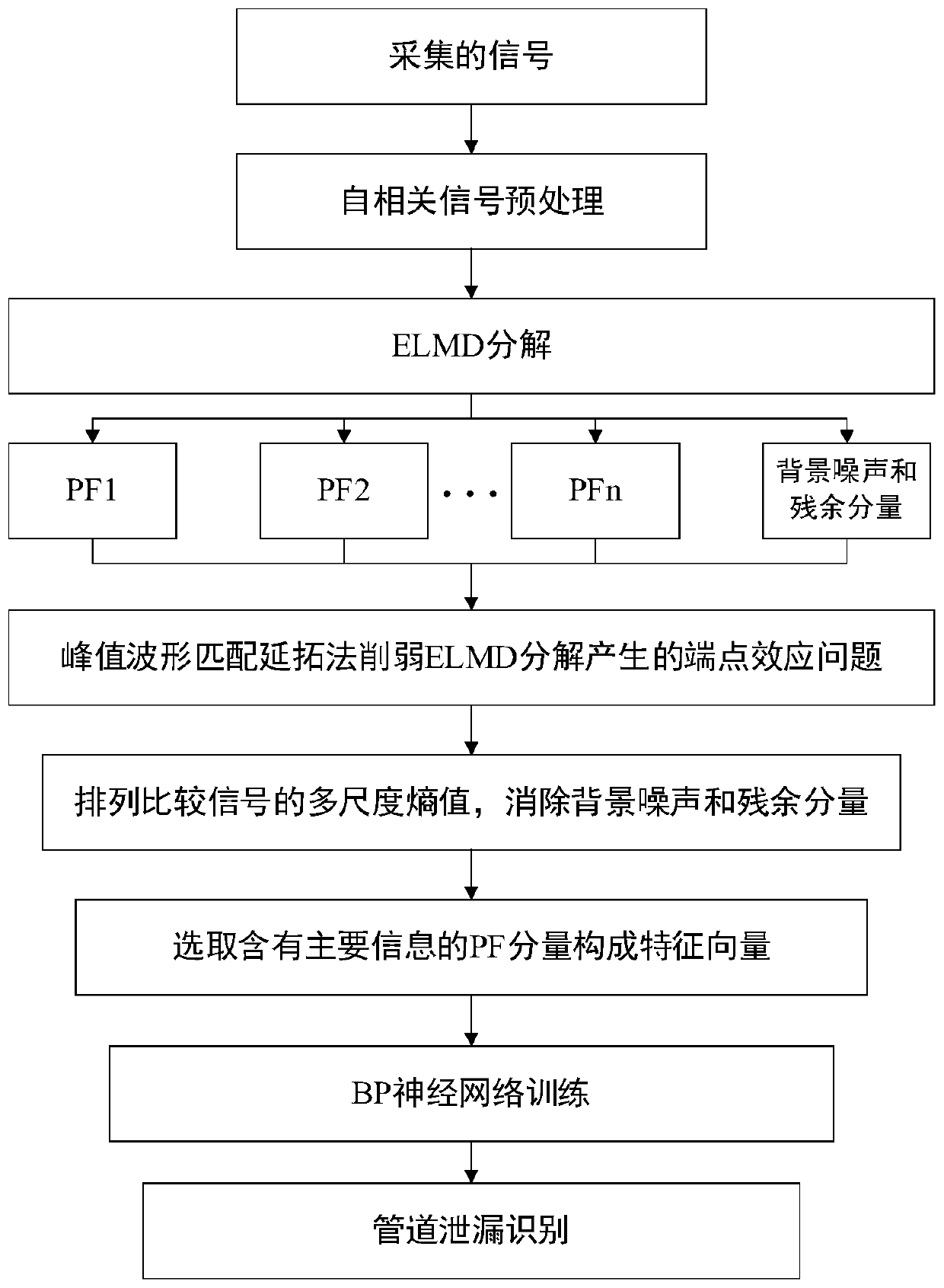

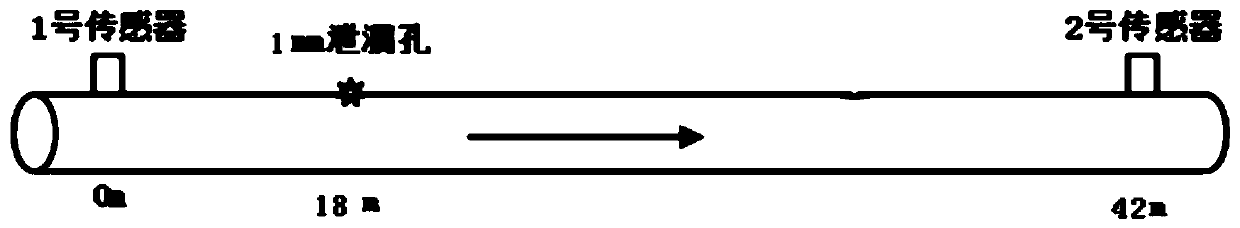

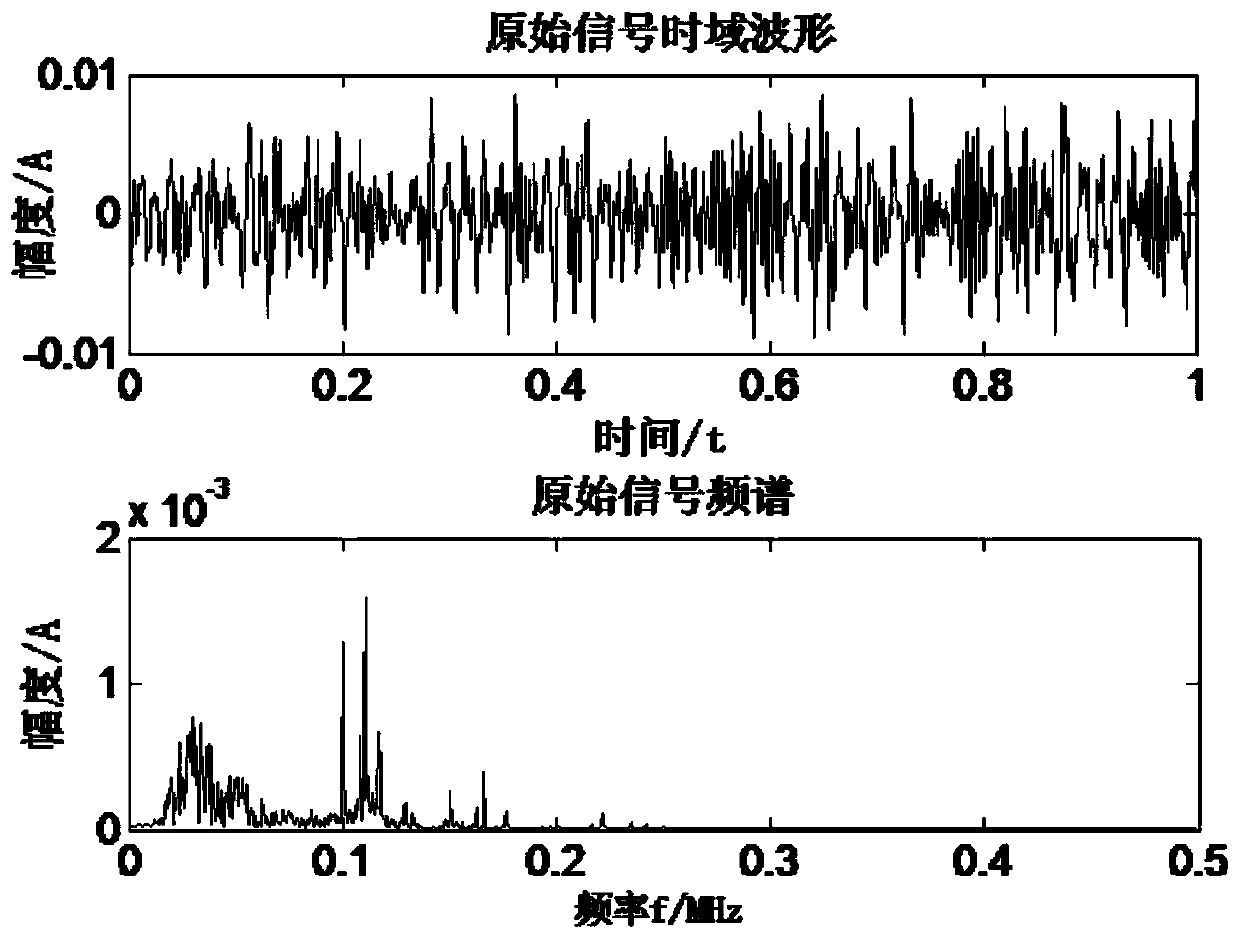

Pipeline Leakage Signal Recognition Method Based on Improved Elmd Multiscale Entropy

ActiveCN109084186BRemove background noiseAccurate identificationDetection of fluid at leakage pointPipeline systemsFeature vectorAlgorithm

The invention provides a pipeline leakage signal identification method based on improved ELMD multi-scale entropy. The pipeline leakage signal identification method includes the steps that firstly, acquired experimental data are subjected to noise pre-processing to eliminate low-correlation components in signals; then pre-processed signals are subjected to ELMD processing to obtain PF components;an endpoint effect problem reserved by ELMD decomposition is weakened through a peak value waveform matching method; the multi-scale entropy of the PF components is calculated correspondingly, and multi-scale entropy values of leakage signals are arrayed and compared to eliminate background noise; a feature vector is constructed by selecting a principal PF component according to the multi-scale entropy values; the feature vector is used as an input vector of a BP neural network to train the network; and a to-be-tested sample is input into a trained BP neural network to obtain a pipeline leakage identification result. The pipeline leakage signal identification method based on the improved ELMD multi-scale entropy can adapt to various conditions of pipelines and has good testing accuracy.

Owner:CHANGZHOU UNIV

Motor bearing fault diagnosis method based on feature optimization and gwoa-xgboost

ActiveCN114169110BSolve the problem of low diagnostic accuracyImprove the ability of signal feature extractionGeometric CADMachine part testingAlgorithmElectric machine

Owner:NAVAL UNIV OF ENG PLA

A noise reduction method and system for foreign object sound signals in electric energy meters

ActiveCN108594161BShorten the lengthAvoid redundancySubsonic/sonic/ultrasonic wave measurementElectrical measurementsForeign matterNoise

The invention discloses a sound signal noise reduction method and system of foreign matter in an electric energy meter on the basis of short-time energy, multi-scale entropy and EMD. The method includes the steps that noise data generated by shaking of the foreign matter in the electric energy meter is collected; foreign matter sound signal data is extracted through short-time energy positioning;the extracted foreign matter sound signal data is subjected to empirical mode decomposition (EMD), and the multi-scale entropy of each stage of intrinsic mode function (IMF) component obtained throughEMD is calculated; the multi-scale entropy of the IMF components is subjected to noise reduction and filtering to obtain sound signals, obtained after noise reduction and filtering, of the foreign matter in the electric energy meter. The method has the advantages that short-time energy positioning can be used for data extraction to increase the processing speed; the sound signals of the foreign matter in the electric energy meter are processed through multi-scale entropy and empirical mode decomposition, which is a self-adaptive process, and the defect that traditional spectrum subtraction noise reduction estimation is not accurate is overcome; meanwhile, introduction of new noise is avoided to the maximum degree, and the foreign matter in the electric energy meter can be accurately detected.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com