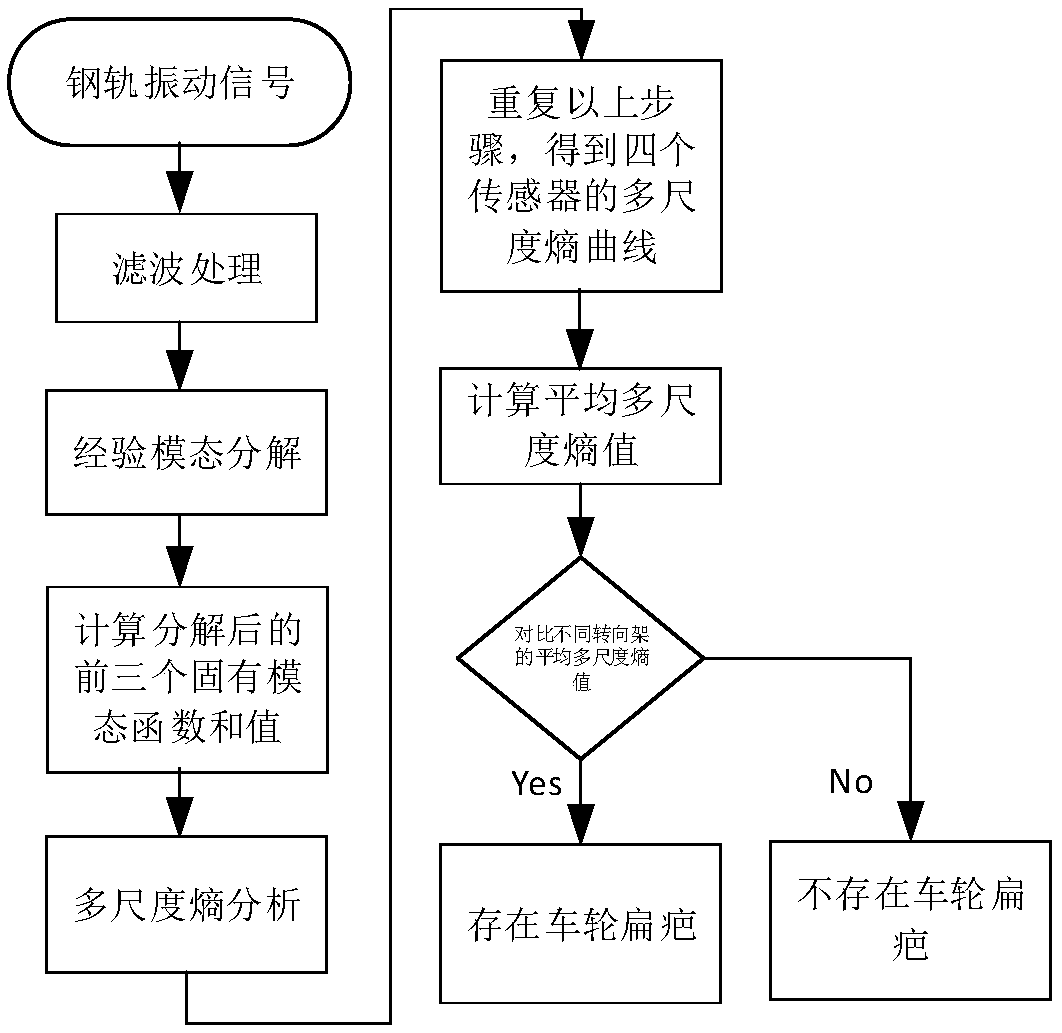

Method for detecting wheel flat damage fault based on EMD (Empirical Mode Decomposition) and multiscale entropy

A technology of empirical mode decomposition and multi-scale entropy, applied in railway vehicle testing, wheel rim measurement/measurement, etc., can solve problems such as failure to detect wheel flat scars in time, inconvenient for information management, and inability to track in real time, etc. Achieve the effect of fast detection speed, good real-time performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

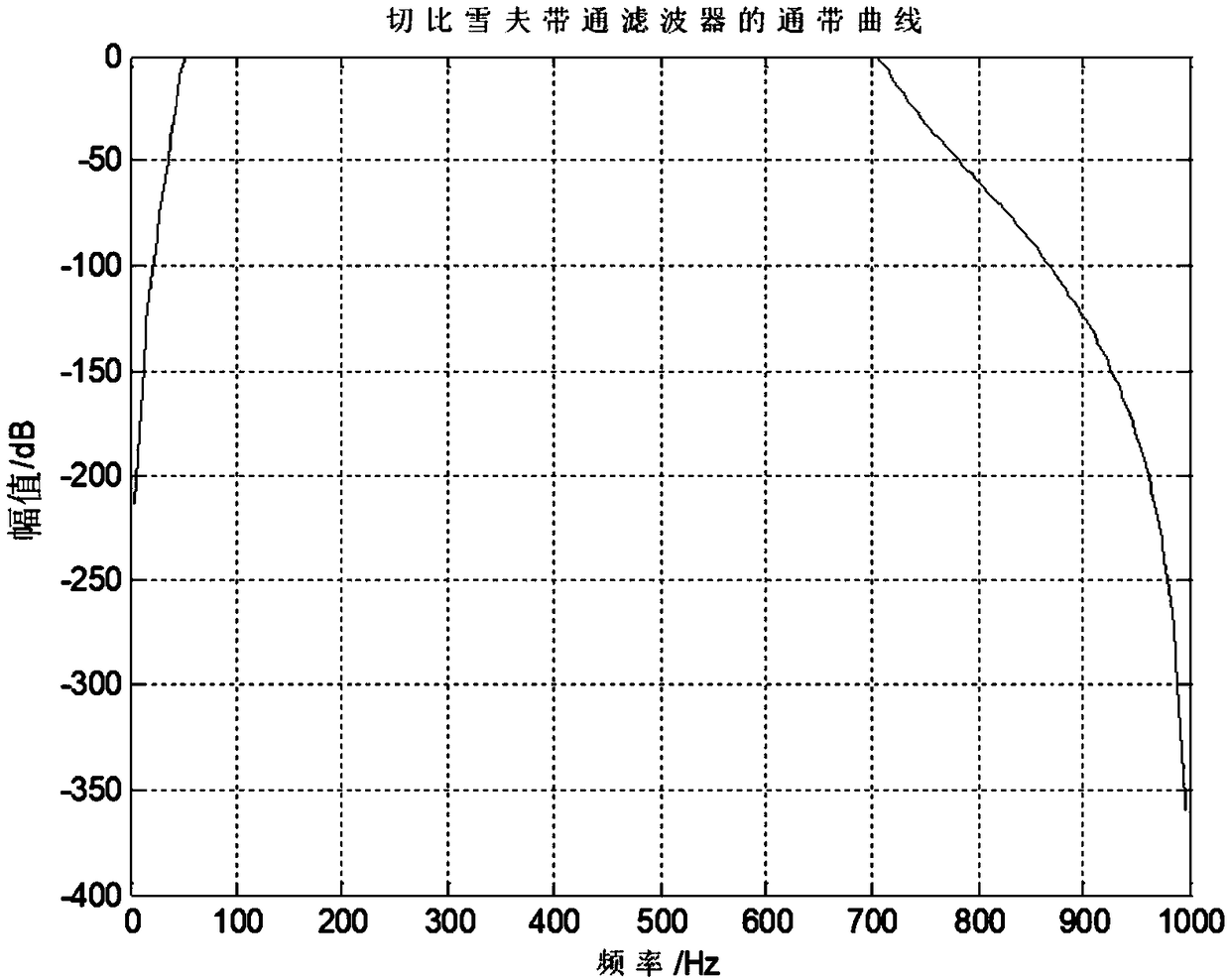

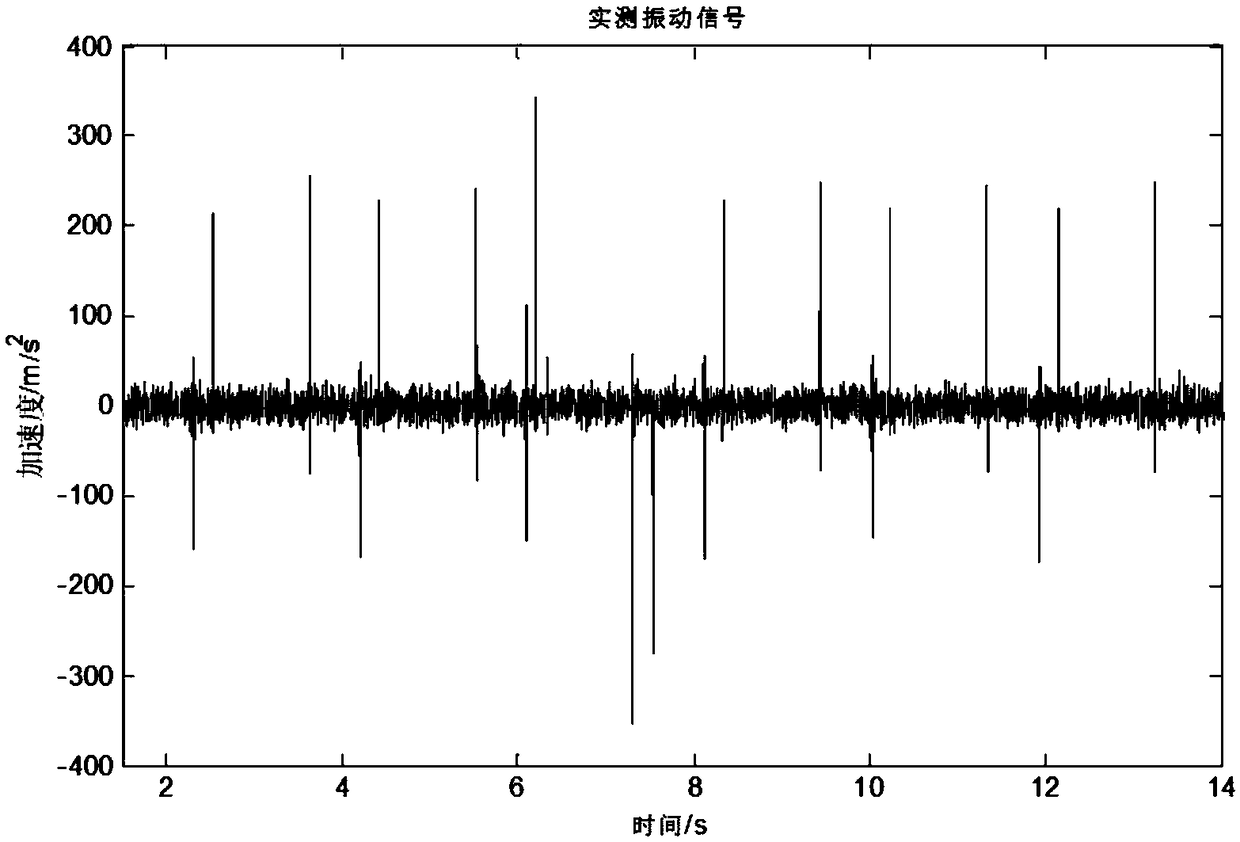

[0041] This embodiment adopts the rail vibration signal collected when a certain type of train of a certain subway company passes through a certain line, and the running speed is 40km / h, wherein the vibration signal collected by No. 1 sensor is as follows: image 3 shown. For the convenience of description, the data of one of the sensors is used for calculation description. First, the Chebyshev low-pass filter is used to filter the vibration signal to filter out useless clutter information. The vibration signal after filtering is as follows: Figure 4 shown. Since the car is composed of 6 sections, there are 12 bogies in total. The measured signals collected by the sensor are divided into compartments. Depend on Figure 4 It can be seen that there is a relatively obvious amplitude jump in the vibration acceleration value at the position of 4-8s, so the flat scar fault is most likely to occur at this position.

[0042] Name the front end of the vehicle as end 1, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com