Motor bearing fault diagnosis method based on feature optimization and gwoa-xgboost

A technology for motor bearing and fault diagnosis, which is applied in the field of motor fault diagnosis to achieve high diagnostic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

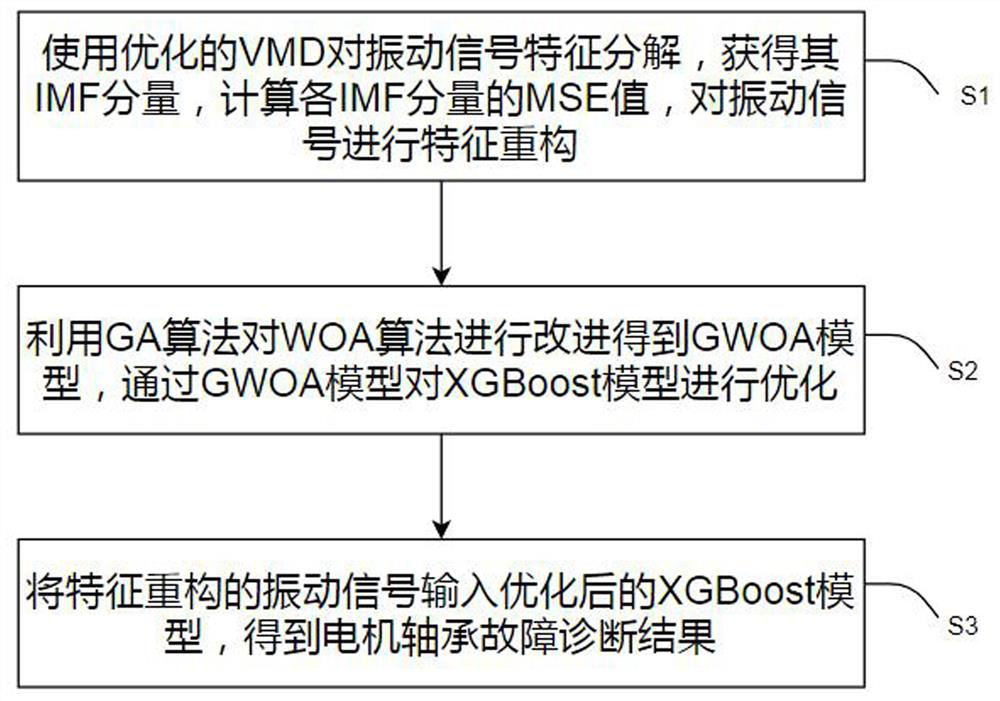

[0055] like figure 1 Shown is the flow chart of the motor bearing fault diagnosis method based on feature optimization and GWOA-XGBoost provided in this embodiment, such as figure 1 As shown, the motor bearing fault diagnosis method based on feature optimization and GWOA-XGBoost provided in this embodiment includes the following steps:

[0056] S1, use the optimized VMD (Variational Modal Decomposition, Variational Modal Decomposition) algorithm to decompose the vibration signal of the motor bearing to obtain its IMF (Intrinsic Mode Function, Intrinsic Mode Function) component, which is calculated based on multi-scale entropy theory The MSE (Multi Scale Entropy, multi-scale entropy) value of each IMF component, and the vibration signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com