Three-dimensional numerical control method for bridge section precasting technology

A technology for segments and bridges, applied in the field of bridge short-line method segment prefabrication, can solve the problems of not setting measurement data judgment and alarm mechanism, not setting remote database access function, difficult to judge and control human errors, and to achieve easy separation. The effect of management and maintenance, reducing manufacturing errors, and ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

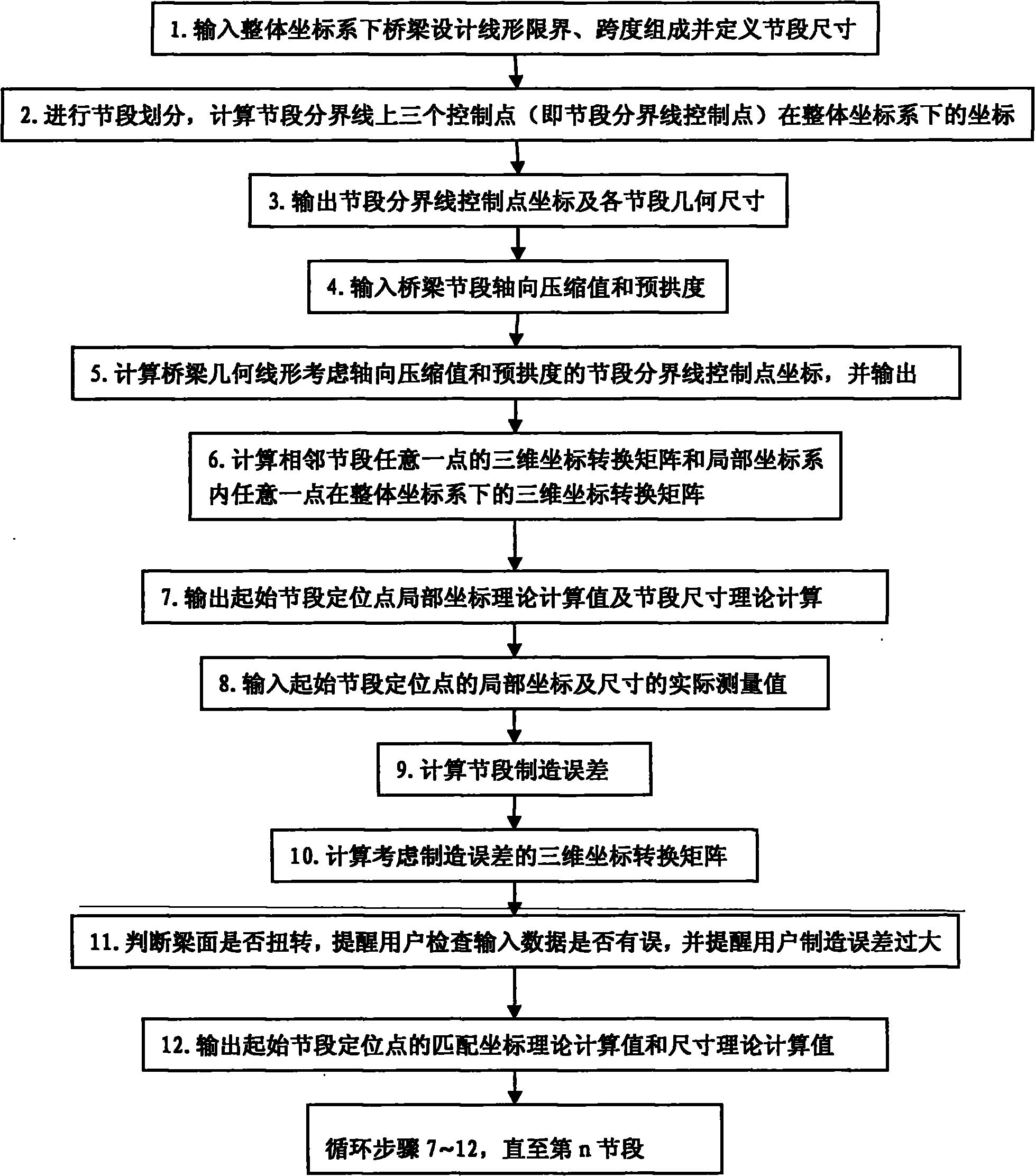

[0031] The present invention is a three-dimensional numerical control method for bridge segment prefabrication technology, and its algorithm flow is as follows: figure 1 shown, including the following steps:

[0032] 1. The user inputs the alignment and span of the bridge in the global coordinate system, and sets the geometric dimensions of the bridge segments. Among them, the bridge alignment refers to the outline of the beam surface, and the span refers to the plane distance between the centerlines of adjacent piers.

[0033] 2. Divide the bridge into segments, and divide the bridge into n segments.

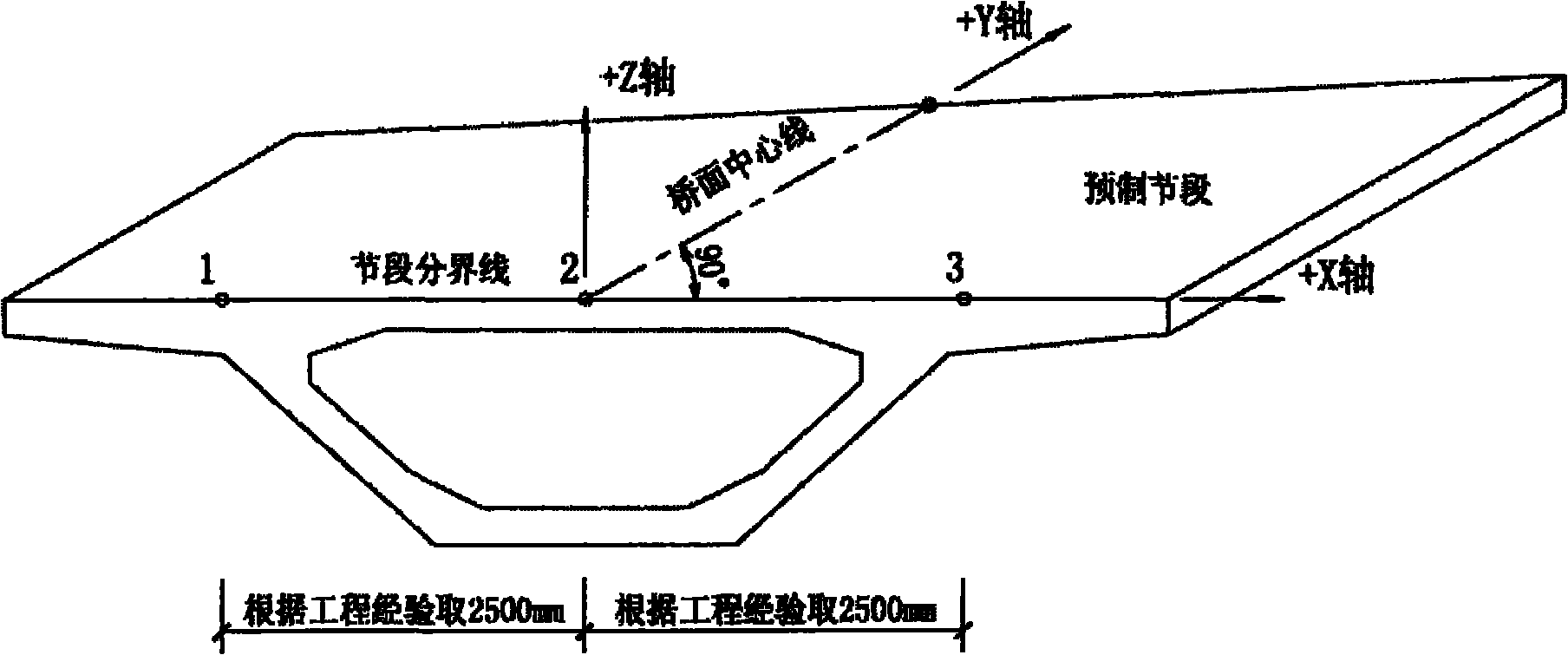

[0034] 3. Calculate the coordinates of the three segment boundary control points on the bridge segment boundary line in the global coordinate system (referred to as the global coordinate for short) and the geometric dimensions of each segment. Such as figure 2 As shown, the three segment boundary control points on the bridge segment boundary refer to the intersection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com