Positioning die for arranging elbow pipe on powder concentrator shell

A technology for positioning molds and powder separators, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as difficult and accurate positioning, and achieve the effects of improving work efficiency, simple operation, and ensuring production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

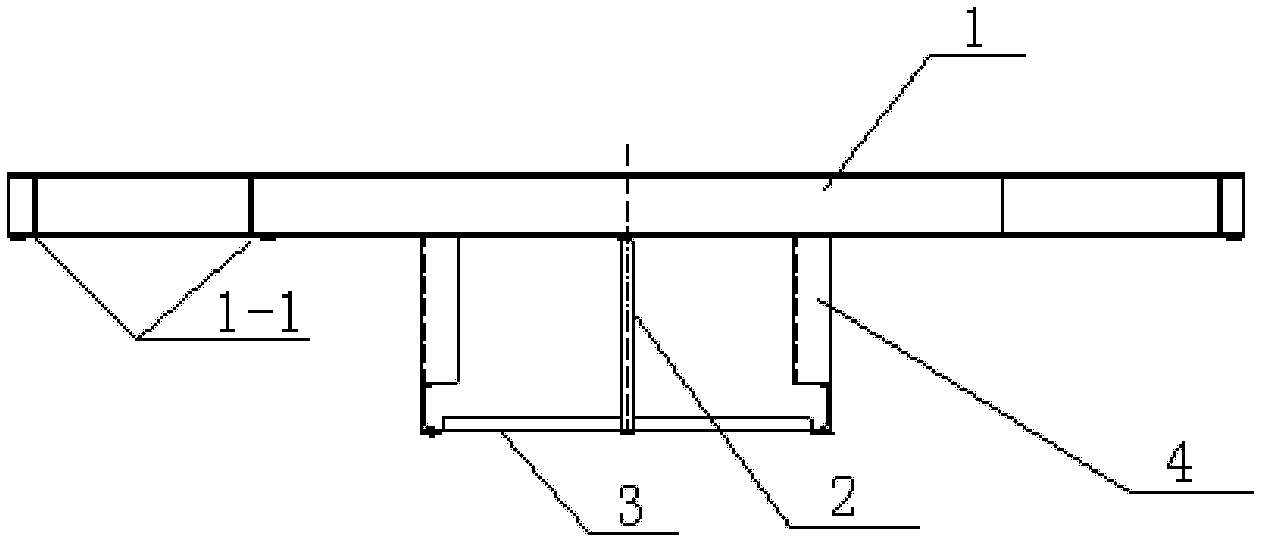

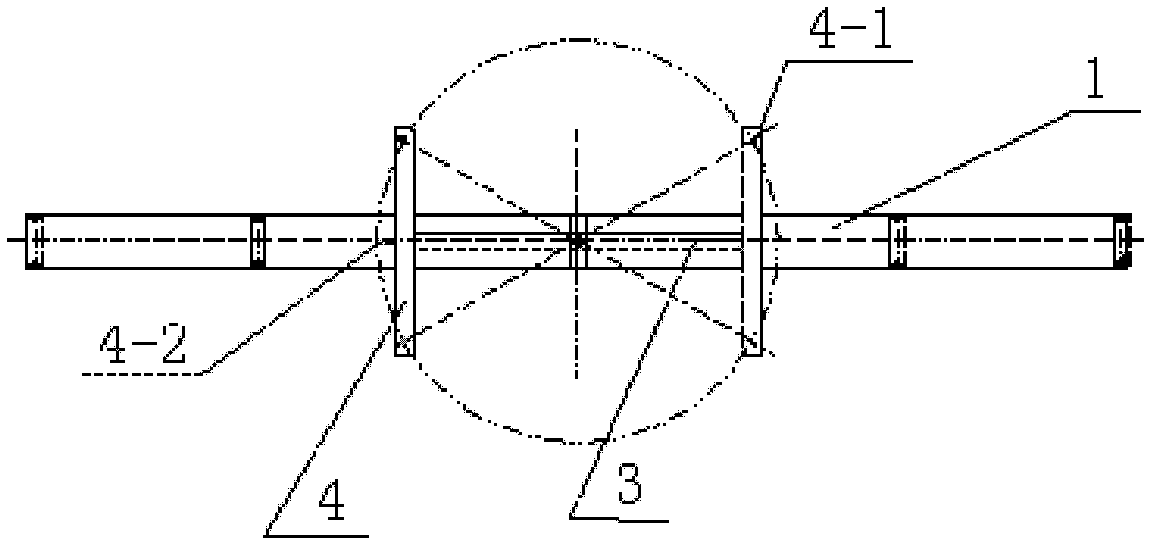

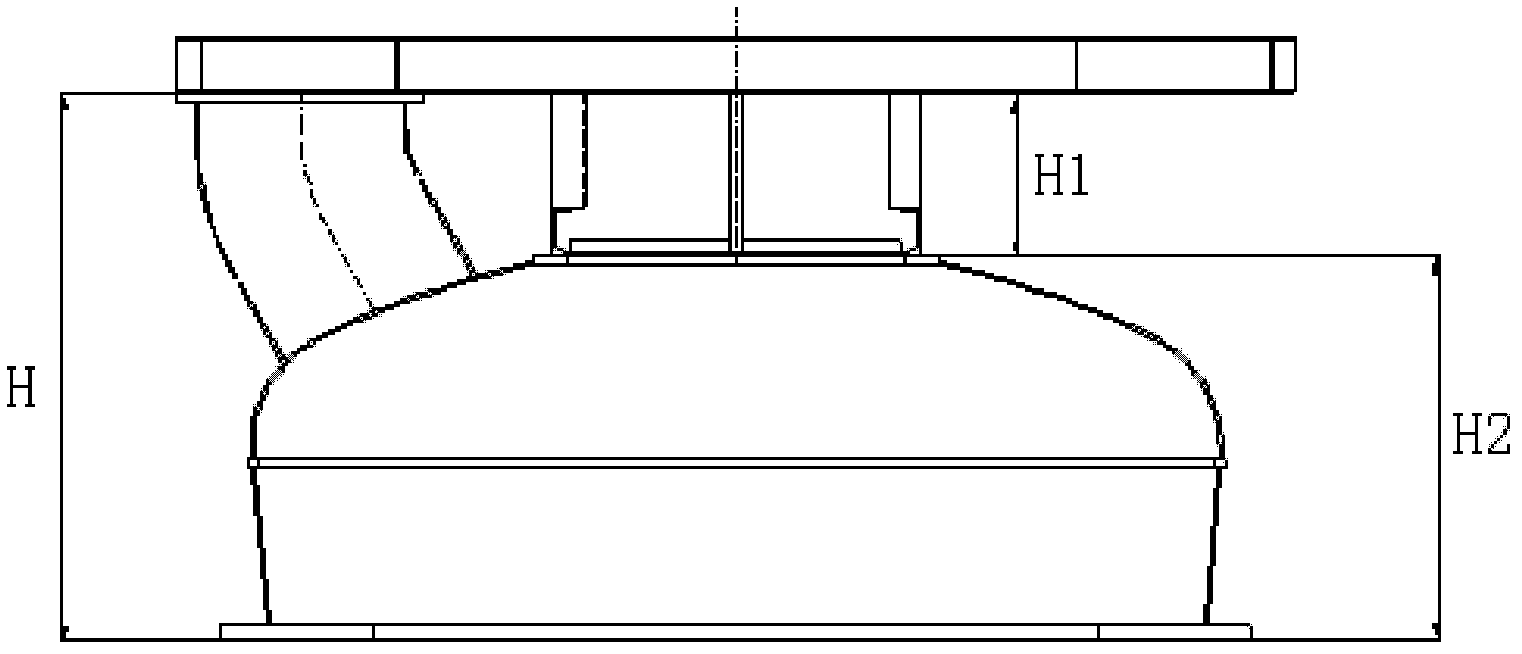

[0018] like figure 1 and figure 2 The positioning mold shown includes an upper formwork 1, a mandrel 2, a lower formwork 3 and two support plates 4, one end of the mandrel 2 is vertically connected to the center of the upper formwork 1, and the other end is vertically connected to the center of the lower formwork 3 In terms of position, each support plate 4 is vertically connected to the upper template 1 and the lower template 3, and two positioning modules 4-1 and a positioning pointer 4-2 are arranged on it, and the two positioning modules 4-1 are connected horizontally. The included angle with the mandrel 2 is 90°, the positioning pointer 4-2 points to the middle position of the two positioning modules 4-1, and the two support plates are symmetrically arranged at both ends of the mandrel 2 . The upper template 1 is provided with two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com