Electric connector for flat conductor

An electrical connector, a flat type technology, applied in the field of electrical connectors for flat conductors, can solve the problems of reduced reliability of the connection state between terminals and flat conductors, achieve stable contact, and reduce manufacturing and assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

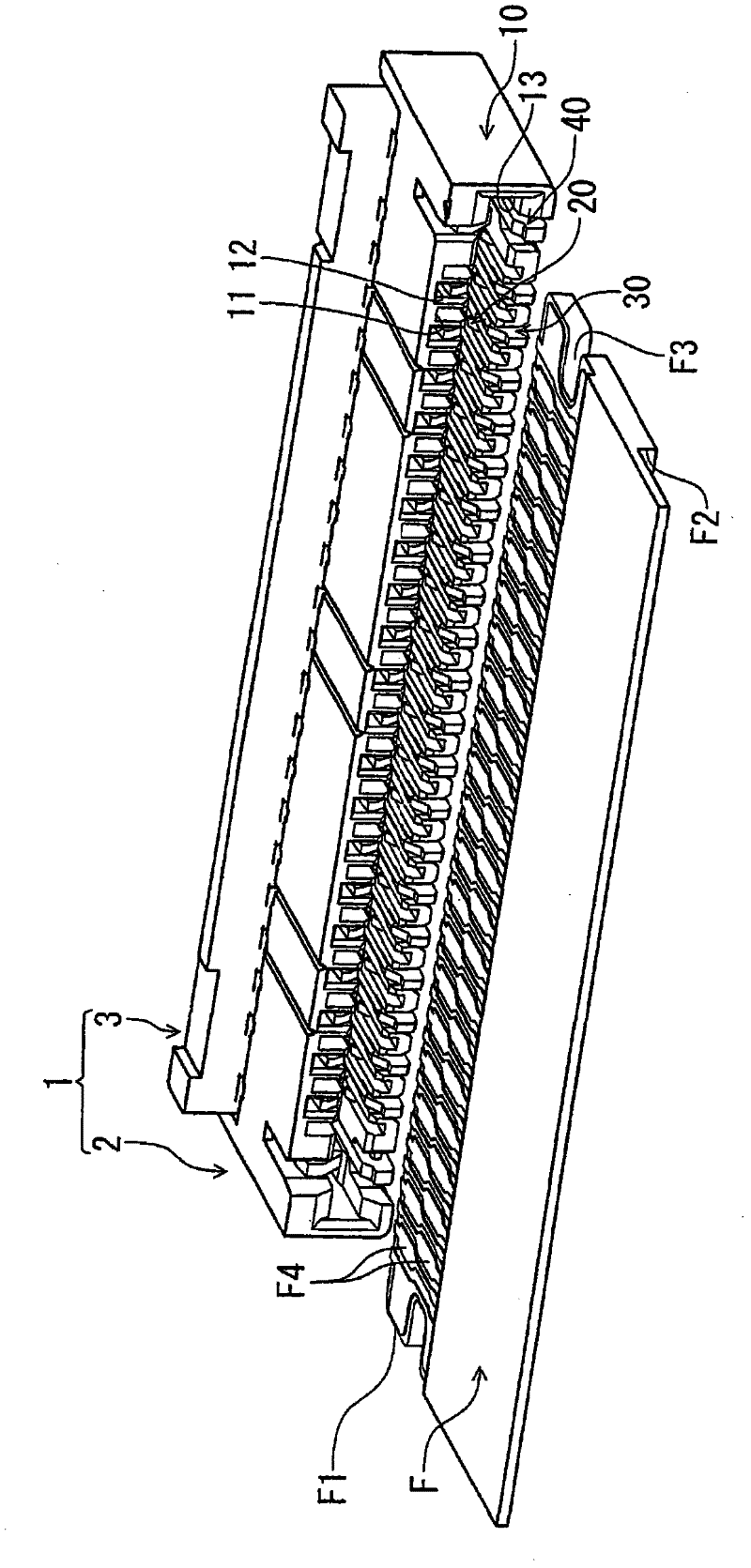

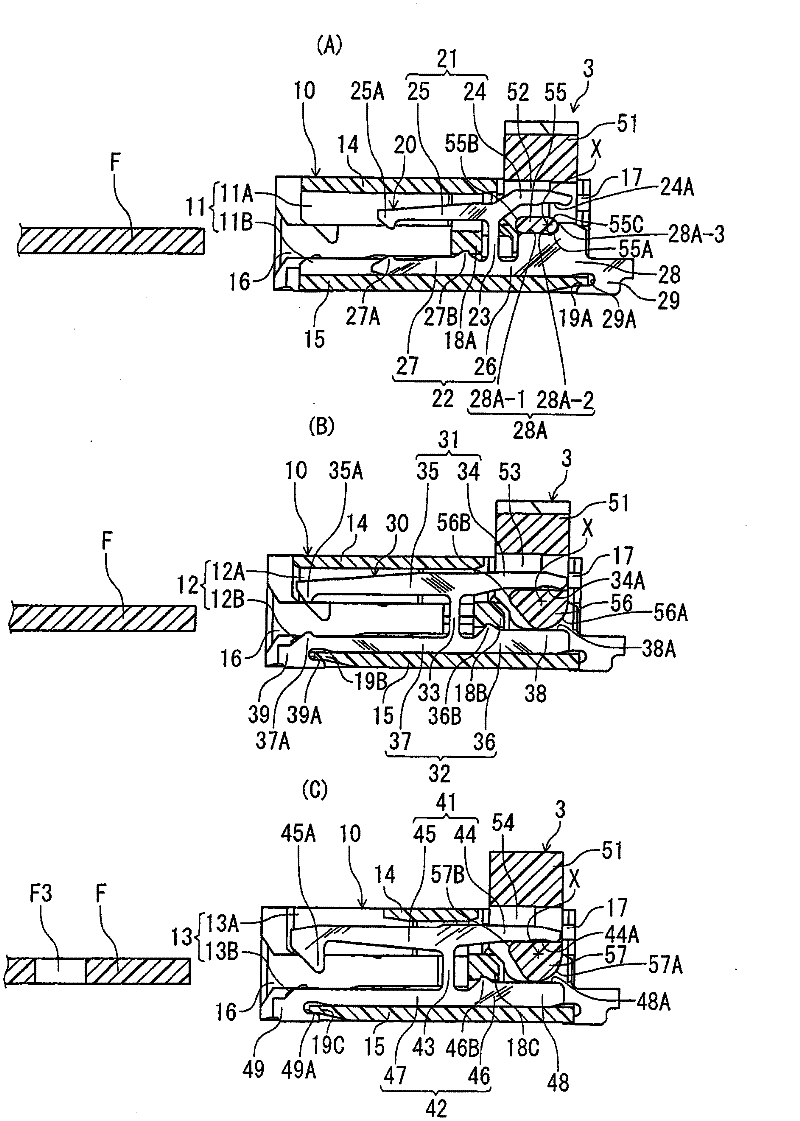

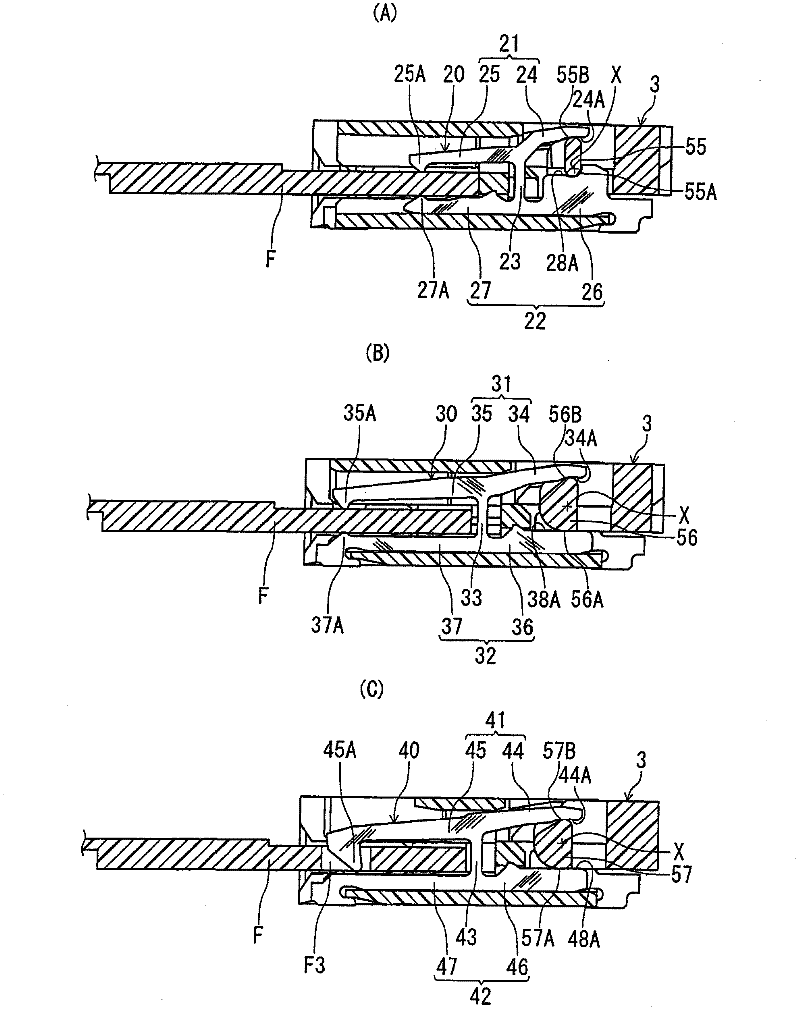

[0042] One embodiment of the present invention will be described below with reference to the drawings.

[0043] exist figure 1 Among them, symbol 1 is the connector of this embodiment, and symbol F is a flat conductor connected to the connector 1 .

[0044] The flat conductor F has a connecting portion connected to the above-mentioned connector 1 at its front end (the upper right edge in the figure), and extends longly toward the rear. Illustration omitted. In the present embodiment, the above-mentioned flat conductor F removes the covering portion on the upper surface of the tip portion to expose the connection circuit portion F1 to form a connection portion. In order to improve the strength when connecting with the connector, a reinforcing sheet F2 is provided on the lower surface of the connecting part.

[0045] At the connection portion of the above-mentioned flat conductor F, engaged portions F3 are formed by notches on both side edges in the width direction. Letting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com