3D light thin breathable athletic undergarment manufacturing method

A manufacturing method and underwear technology, applied to bras, clothing, brassieres, etc., can solve problems such as unfavorable assembly line production, unfavorable competition level, unfavorable ventilation, etc., and achieve the effects of facilitating assembly line production, reducing production costs, and reducing dead zone areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

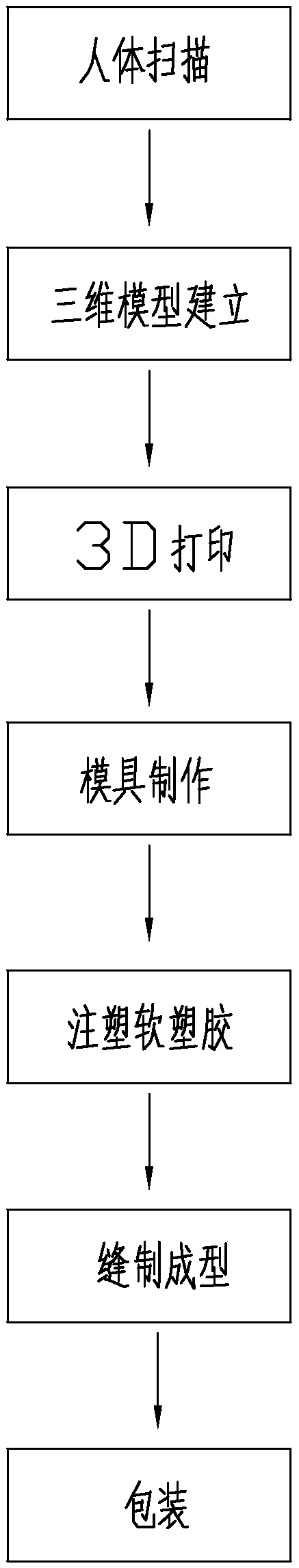

[0055] Custom production process:

[0056] 1) Body scan

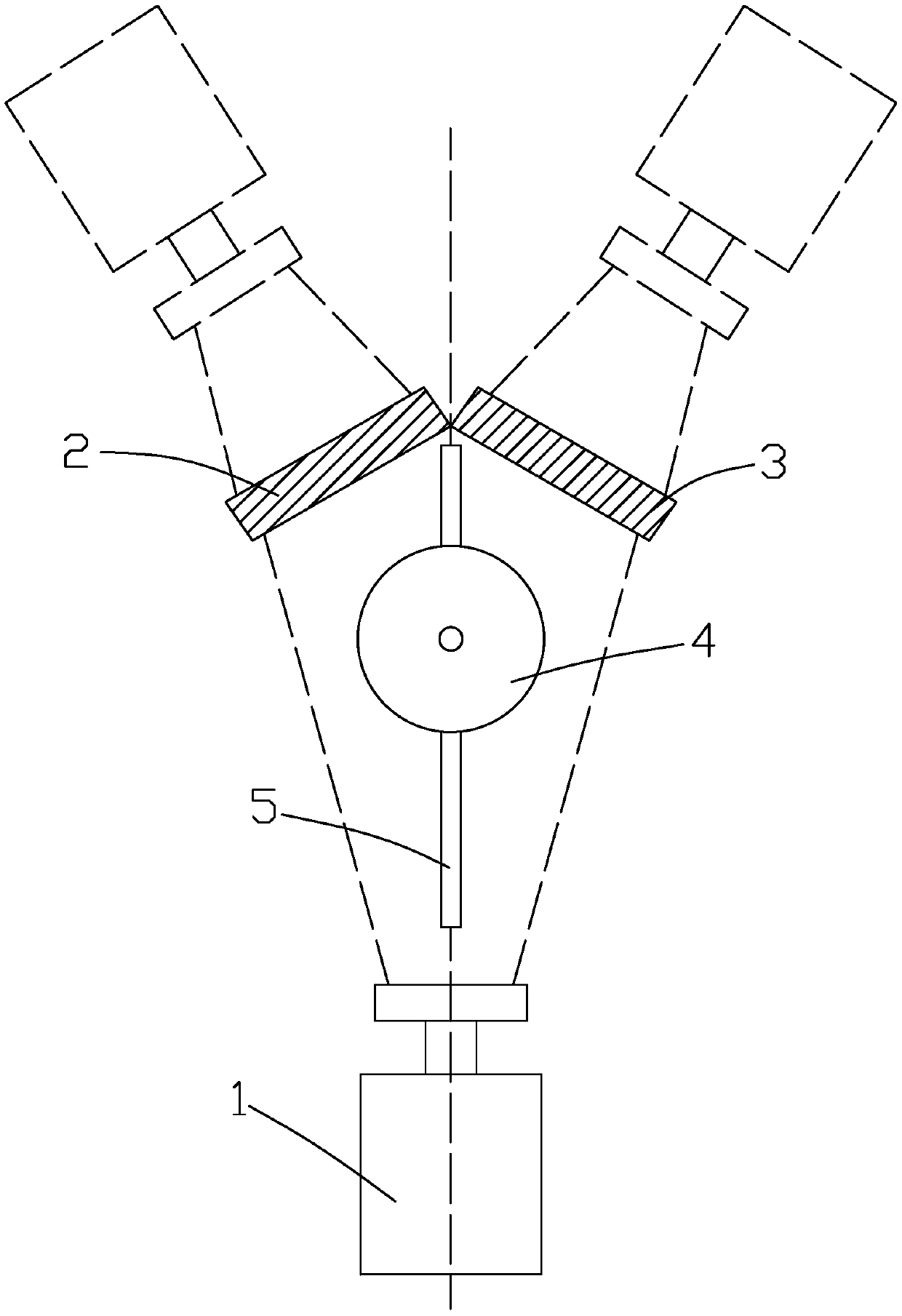

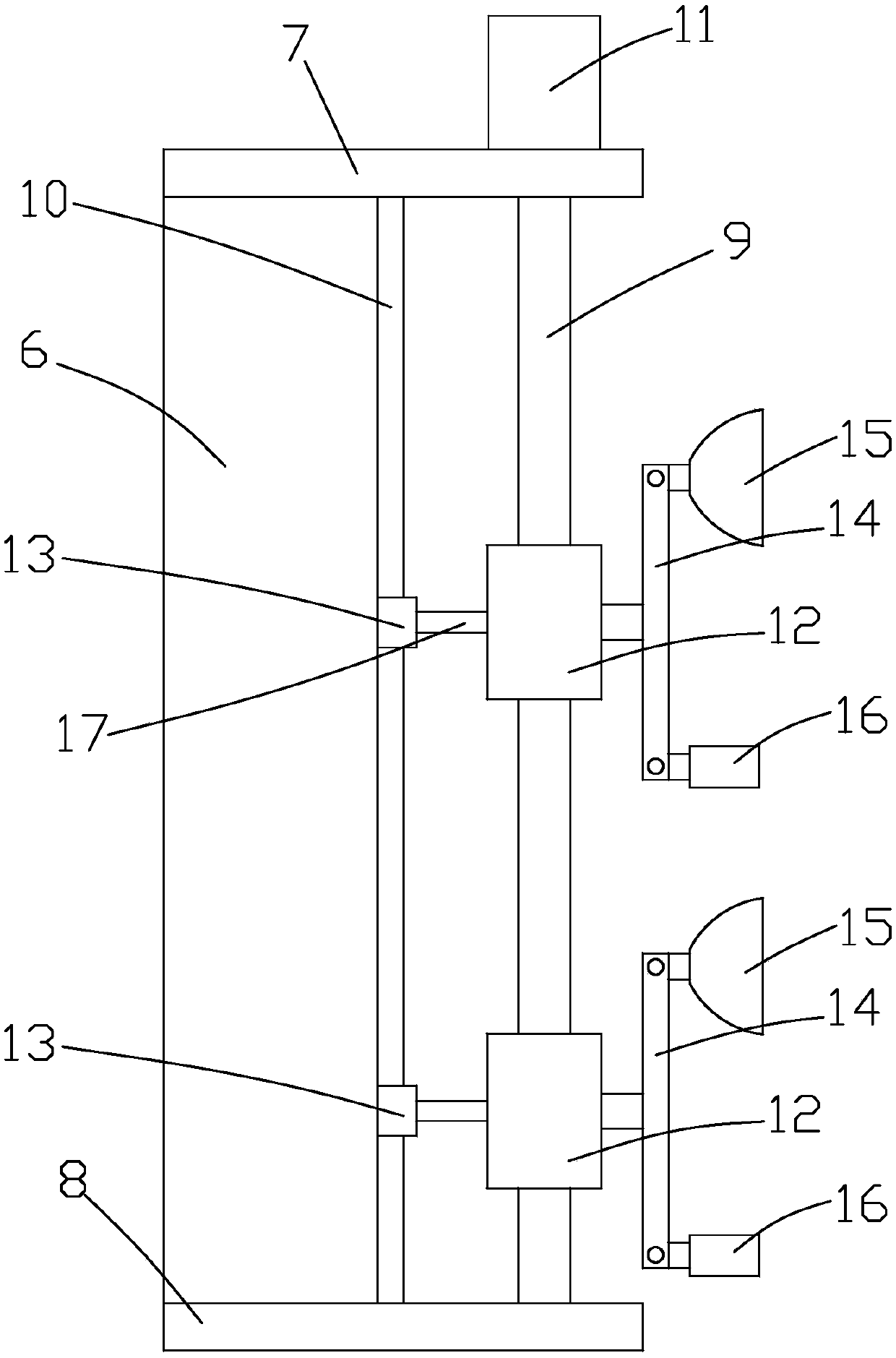

[0057] The human body is scanned by a three-dimensional digital human body scanning system. The scanned object stands on the turntable between the scanning device and two plane mirrors, and the position of the turntable is adjusted through the guide rail according to the height of the human body to control the distance between the scanned object and the scanning device. During the scanning process, the left and right halves of the front of the human body are mapped to the camera behind the human body through two mirrors, and the turntable is rotated at the same time, so that the two virtual cameras can be scanned continuously from three different visual directions at the same time as the real camera at the virtual image position object information;

[0058] 2) 3D model establishment

[0059] After the human body scanning is completed, the information scanned by the 3D digital human body scanning system is read, and th...

Embodiment 2

[0071] Mass production process:

[0072] 1) Body scan

[0073] The human body is scanned by a three-dimensional digital human body scanning system. The scanned object stands on the turntable between the scanning device and two plane mirrors, and the position of the turntable is adjusted through the guide rail according to the height of the human body to control the distance between the scanned object and the scanning device. During the scanning process, the left and right halves of the front of the human body are mapped to the camera behind the human body through two mirrors, and the turntable is rotated at the same time, so that the two virtual cameras can be scanned continuously from three different visual directions at the same time as the real camera at the virtual image position object information;

[0074] 2) 3D model establishment

[0075] After the human body scanning is completed, the information scanned by the 3D digital human body scanning system is read, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com