Making method of edentulous jaw precise tooth transfer model

A technology for transferring models and manufacturing methods, applied in teaching models, dentistry, dental implants, etc., can solve problems such as uneven stress, large errors in tooth plaster models, and deformation of trays, so as to reduce rework rate, reduce manufacturing errors, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] A method for making a precise tooth transfer model of an edentulous jaw, comprising the following steps:

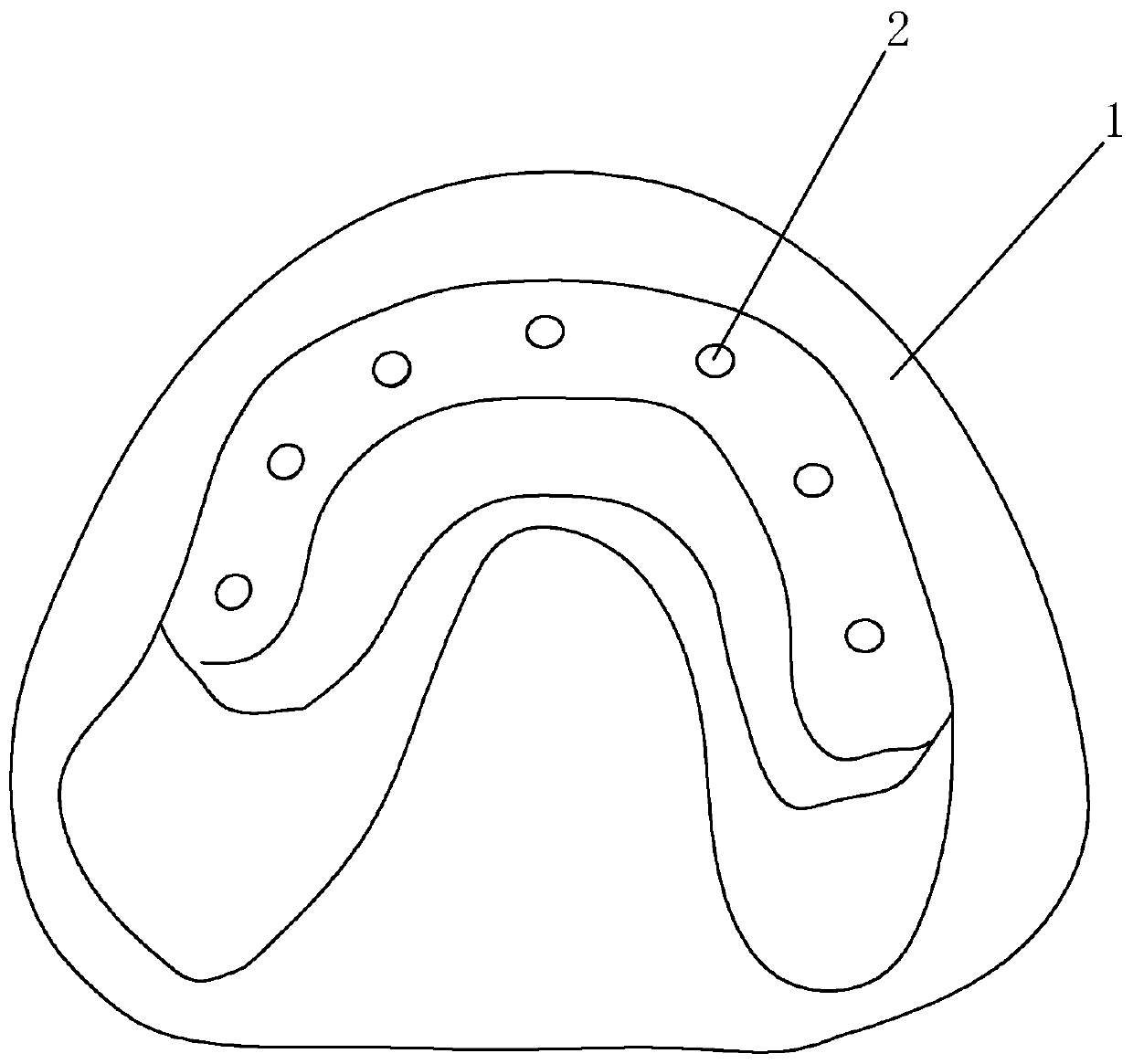

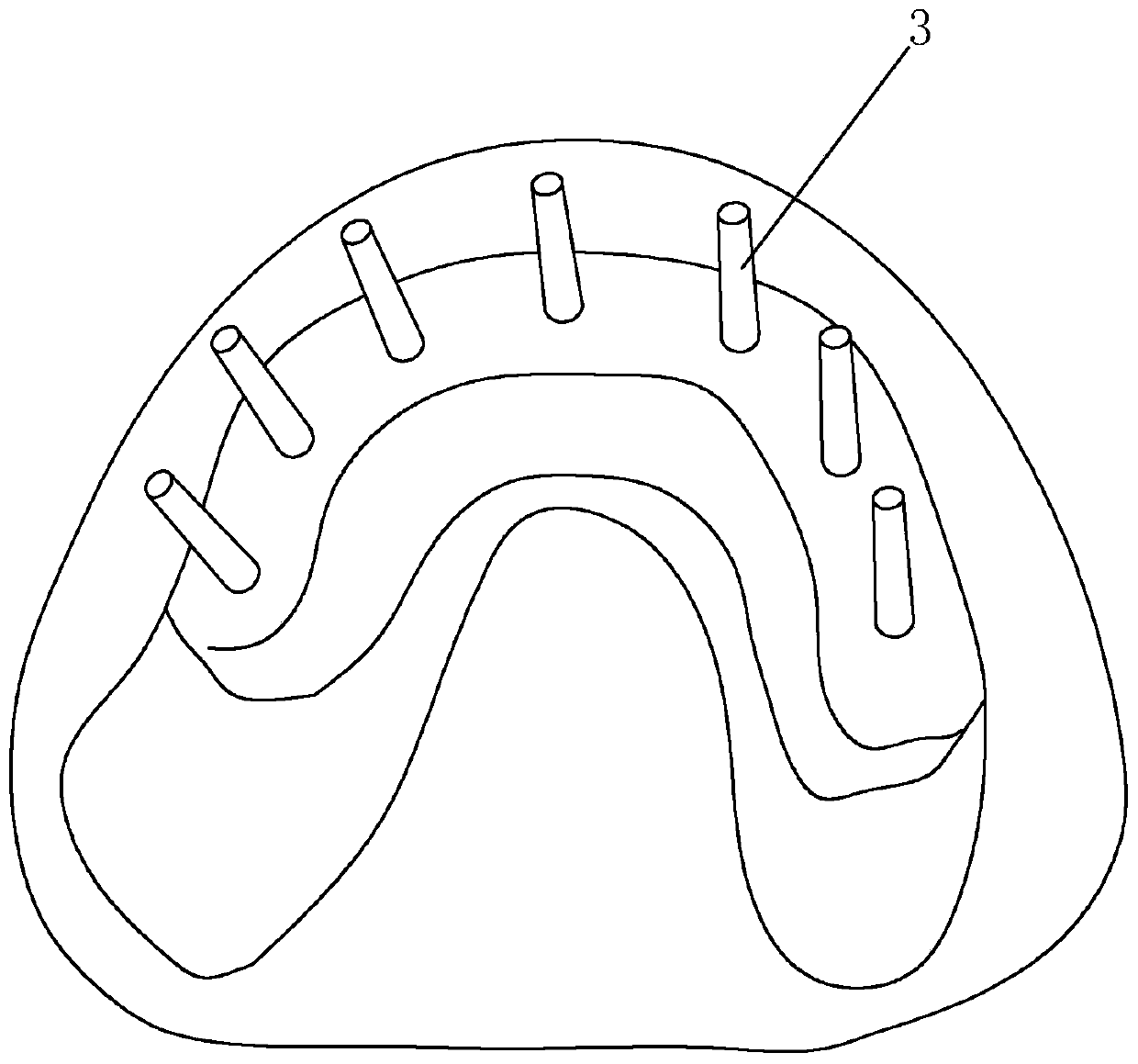

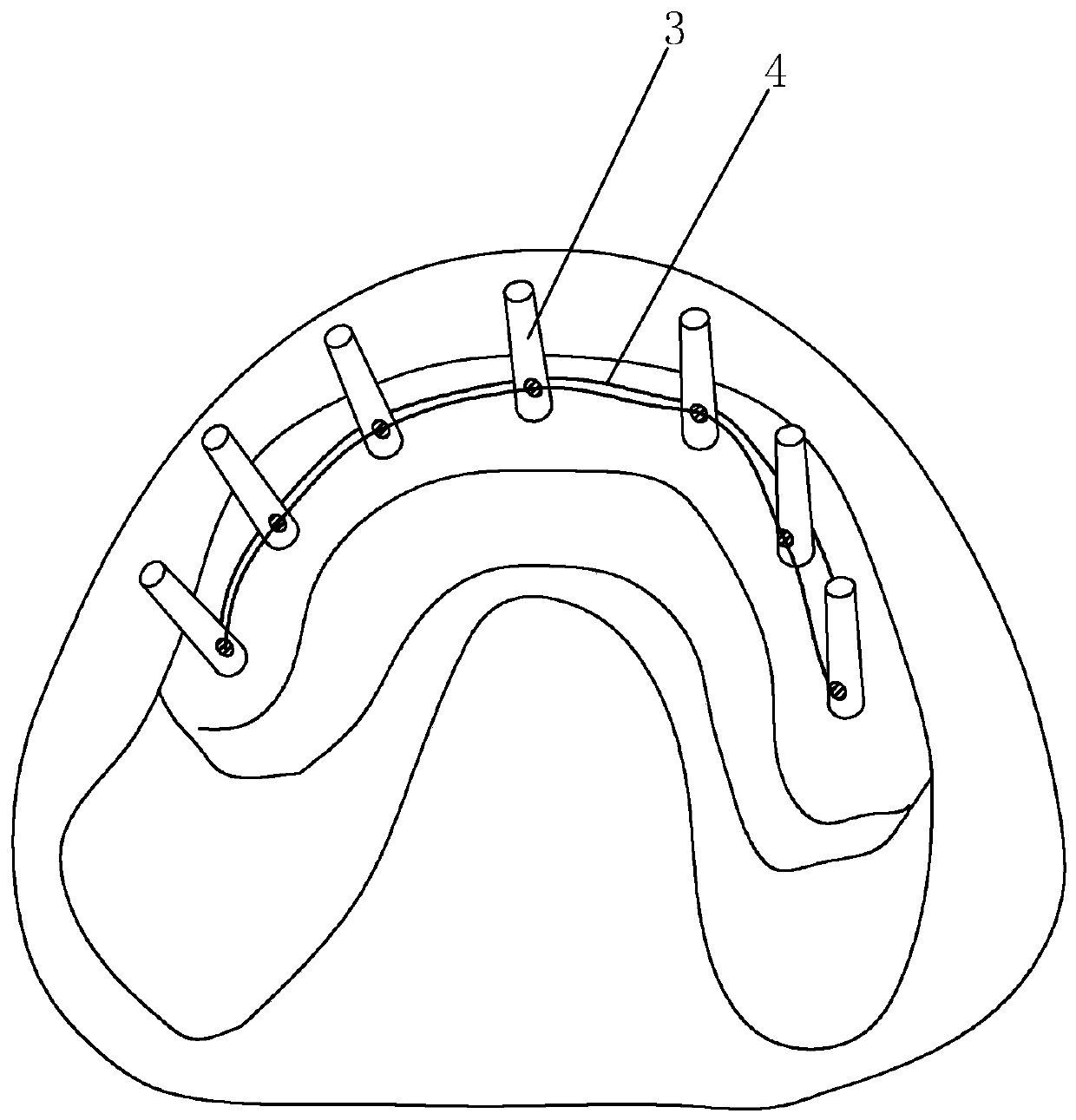

[0044] Step 1: Taking impressions for the first time, adopting the method of window-opening type impression-taking, specifically including, first fixing the transfer rod 3 on the implant with fixing screws, mixing the silicone rubber on the window-opening tray, and then placing the silicone rubber impression With the tray of wood in place in the mouth, make sure that the setscrew can pass through the fenestration. About 4-5 minutes after the impression material is solidified, loosen the fixing screw from the opening to completely dislocate the transfer rod 3, and then take the tray out of the oral cavity. At this time, the transfer rod 3 together with the fixing screw is taken out of the oral cavity together with the silicone rubber impression, and then the implant substitute 2 is installed in the silicone rubber impression, and the substitute 2 is fixed on the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com