Layout planing method for positioning unit of precise clamp

A fixture and layout technology, applied in the field of precision fixture positioning element layout planning, can solve the problems of lack of rigor, large amount of calculation, difficult to handle transition, etc., to reduce manufacturing and assembly errors, reduce precision requirements, and save manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand the technical solution of the present invention, the implementation steps of the precision fixture positioning element layout planning method are described in detail below.

[0010] (1) Define the positioning error measurement index and derive the positioning error control objective function: due to the influence of manufacturing errors, the actual pose of the workpiece fixed by the fixture will deviate from the ideal pose, and the deviation can be calculated by the differential motion vector relative to the workpiece coordinate system said, among them and are the differential translation and differential rotation vectors, respectively. Select a set of feature points on the workpiece according to the manufacturing task and determine a set of direction vectors , define two positioning error metrics:

[0011] e 1 = ξ T m 1 ξ

[0012] e 2 = ξ T m 2 ξ

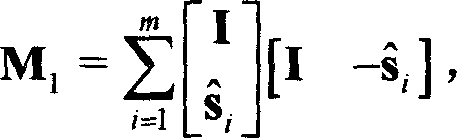

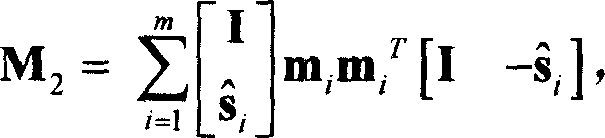

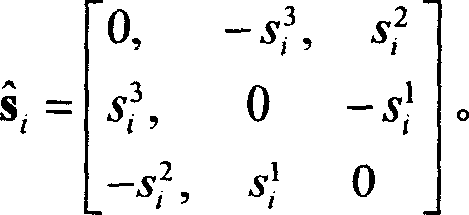

[0013] in M 1 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com