Patents

Literature

45 results about "Marangoni effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

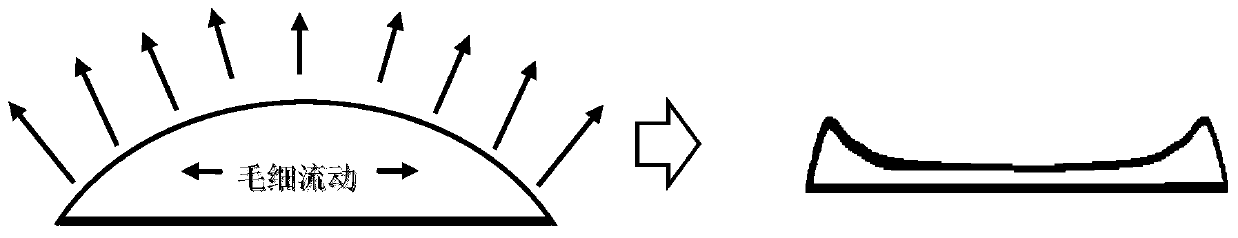

The Marangoni effect (also called the Gibbs–Marangoni effect) is the mass transfer along an interface between two fluids due to a gradient of the surface tension. In the case of temperature dependence, this phenomenon may be called thermo-capillary convection (or Bénard–Marangoni convection).

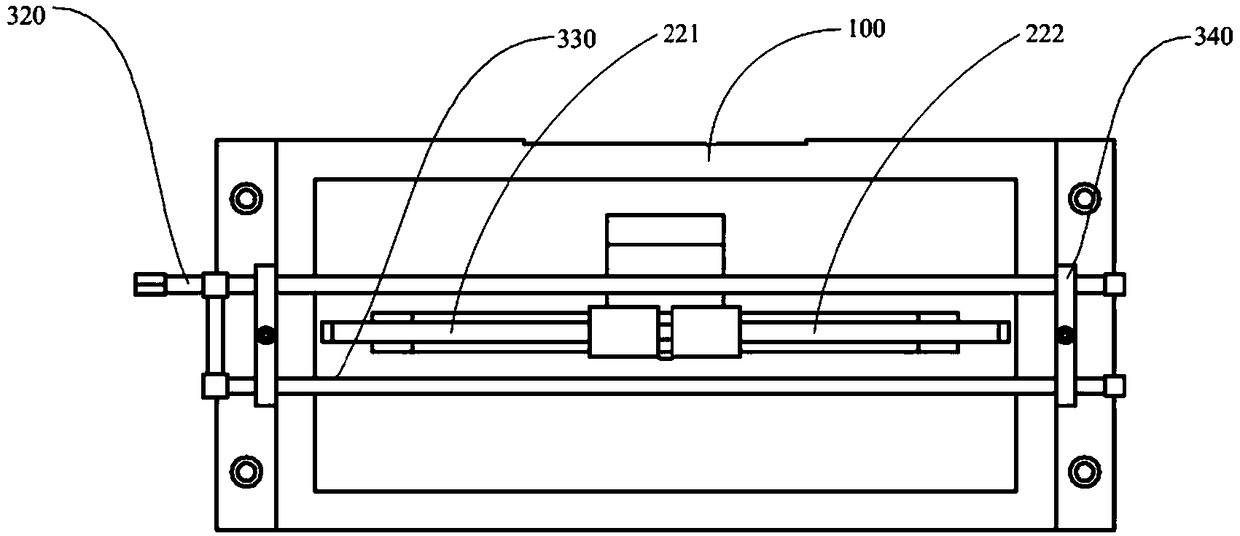

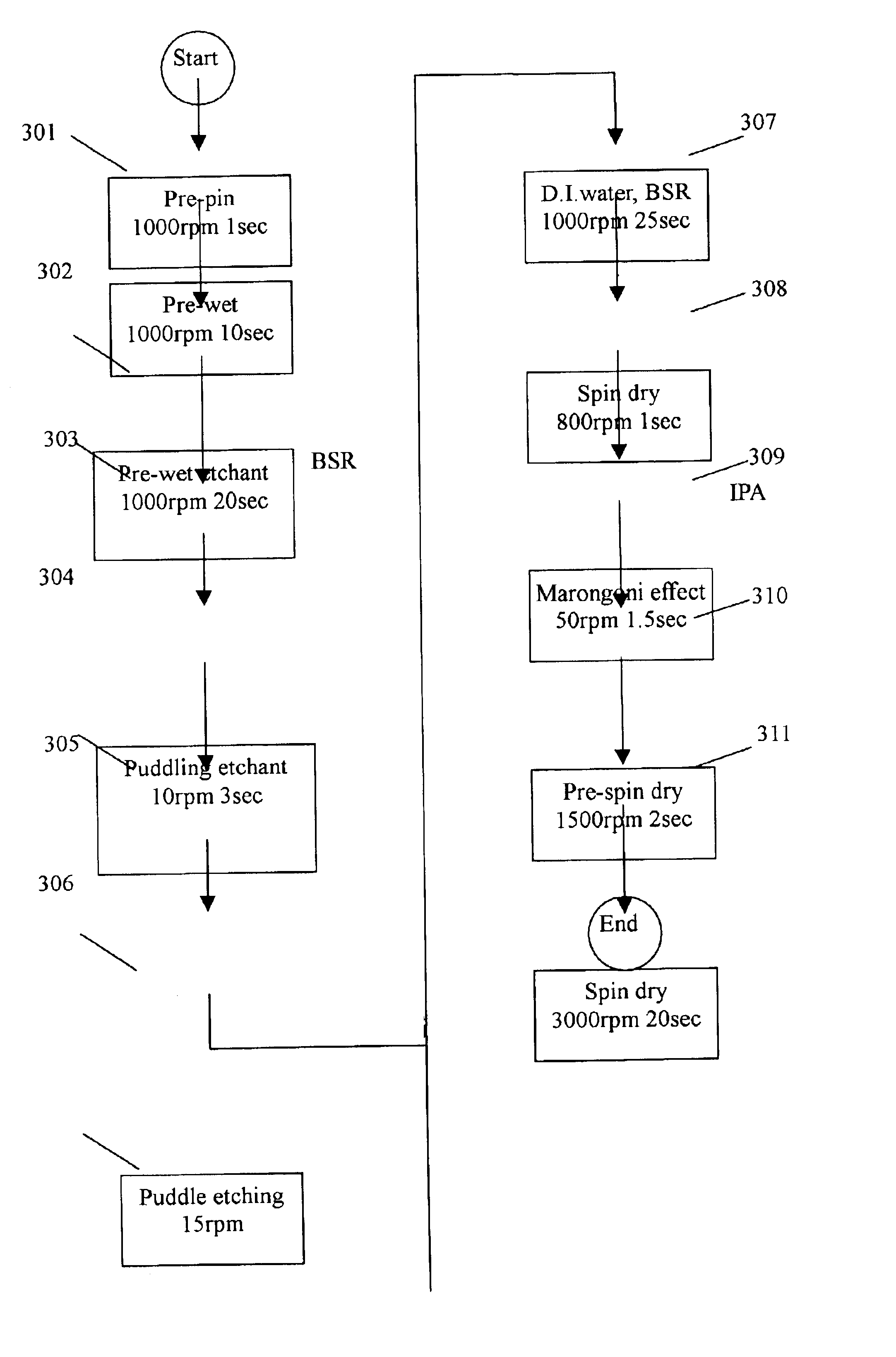

Puddle etching method of thin film by using spin-processor

The present invention discloses a puddle etching method of thin film. In a spin etching equipment, pre-wet the wafer by D.I. water and etch solution to remove the contamination and the upper layer of the film on the wafer. Then spin slowly (about 0-50 rpm) and inject etching solution to form a puddle of etching solution which will stay on the wafer, the wafer then keep spin slowly (about 0-50 rpm) such that the puddle of etching solution stay on the wafer and etching is going on by puddle etching. After the thin film is etched, the wafer is spin at higher speed, and D.I. water is injected to rinse. Then, IPA is used to remove the D.I. water by Marangoni effect. Finally raise the speed to dry the wafer.

Owner:GRAND PLASTIC TECH

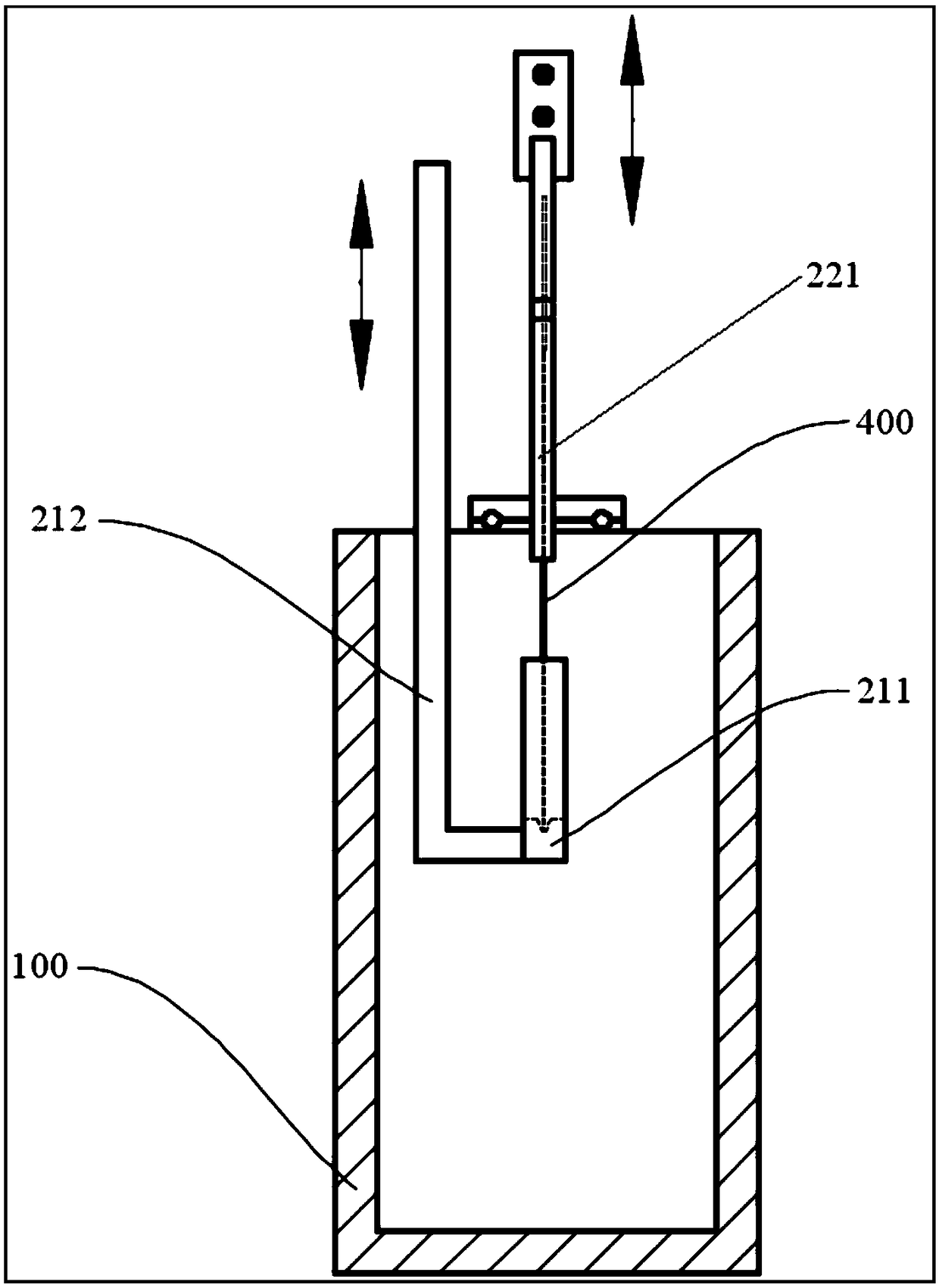

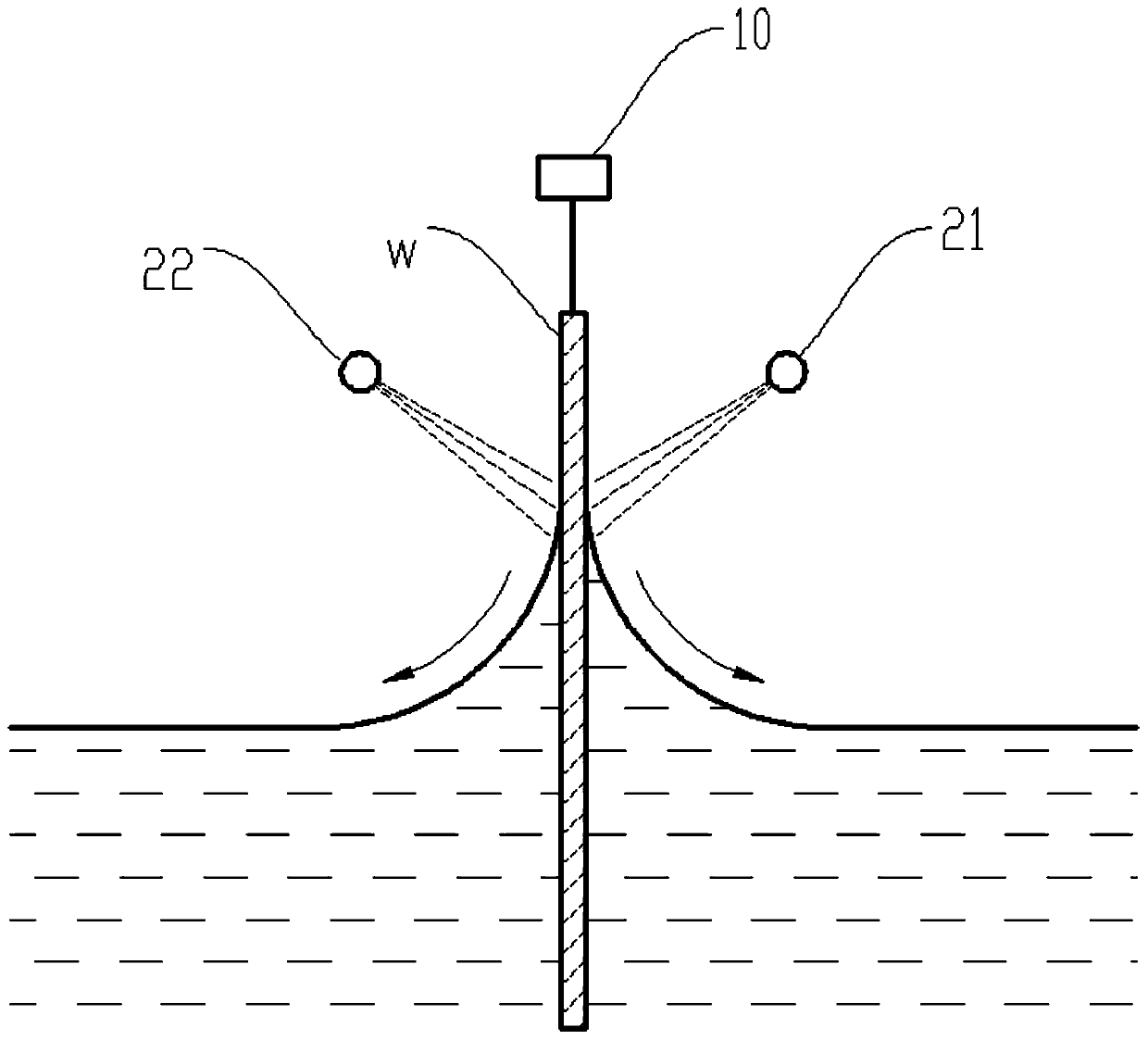

Wafer drying device and method based on Marangoni effect

InactiveCN108831849AKeep dryImprove securitySemiconductor/solid-state device manufacturingGreen environmentWafer

The invention discloses a wafer drying device and method based on a Marangoni effect, wherein the wafer drying device comprises: a water tank for containing deionized water; a wafer lifting device forlifting a wafer from the deionized water; a nitrogen gas source; a nitrogen gas spraying system for spraying a hot nitrogen gas onto the meniscus area of the wafer and deionized water when the waferis lifted in order to induce a temperature gradient in the meniscus area to generate a Marangoni flow downward from the meniscus area, so as to peel off a water absorbing film and achieve ultra-cleandrying of the wafer; and a controller for controlling the wafer lifting device, the nitrogen gas source and the nitrogen gas spraying system. The device and method perform Marangoni drying by using the green environment-friendly hot nitrogen gas instead of a combustible explosive and toxic organic steam, avoids the use of a protection device, simplifies a supply system and improves safety. The wafer lifting device is fixed at two positions and lifts the wafer step by step in order to prevent inability to dry a clamp-wafer contact area and to achieve complete wafer drying.

Owner:TSINGHUA UNIV +1

Production method of ultralow density high-tenacity high-elasticity melamine foams

The invention discloses a production method of ultralow density high-tenacity high-elasticity melamine foams, which comprises the following steps: using melamine formaldehyde resin or modified melamine formaldehyde resin as a base material, and adding an emulsifier, a foaming agent, a curing agent and molecules with an enhanced Marangoni effect; and after uniform emulsification, heating in a microwave oven, curing for a while, and molding. During the microwave foaming process, the addition of the molecules with an enhanced Marangoni effect not only can reduce the use amount of the foaming agent to a large extent, but also can regulate the aperture and the length-diameter ratio of edges of the foams in a large range, so as to greatly improve the various properties of melamine foams.

Owner:QILU UNIV OF TECH

Puddle etching method of thin film by using spin-processor

The present invention discloses a puddle etching method of thin film. In a spin etching equipment, pre-wet the wafer by D.I. water and etch solution to remove the contamination and the upper layer of the film on the wafer. Then spin slowly (about 0-50 rpm) and inject etching solution to form a puddle of etching solution which will stay on the wafer, the wafer then keep spin slowly (about 0-50 rpm) such that the puddle of etching solution stay on the wafer and etching is going on by puddle etching. After the thin film is etched, the wafer is spin at higher speed, and D.I. water is injected to rinse. Then, IPA is used to remove the D.I. water by Marangoni effect. Finally raise the speed to dry the wafer.

Owner:GRAND PLASTIC TECH

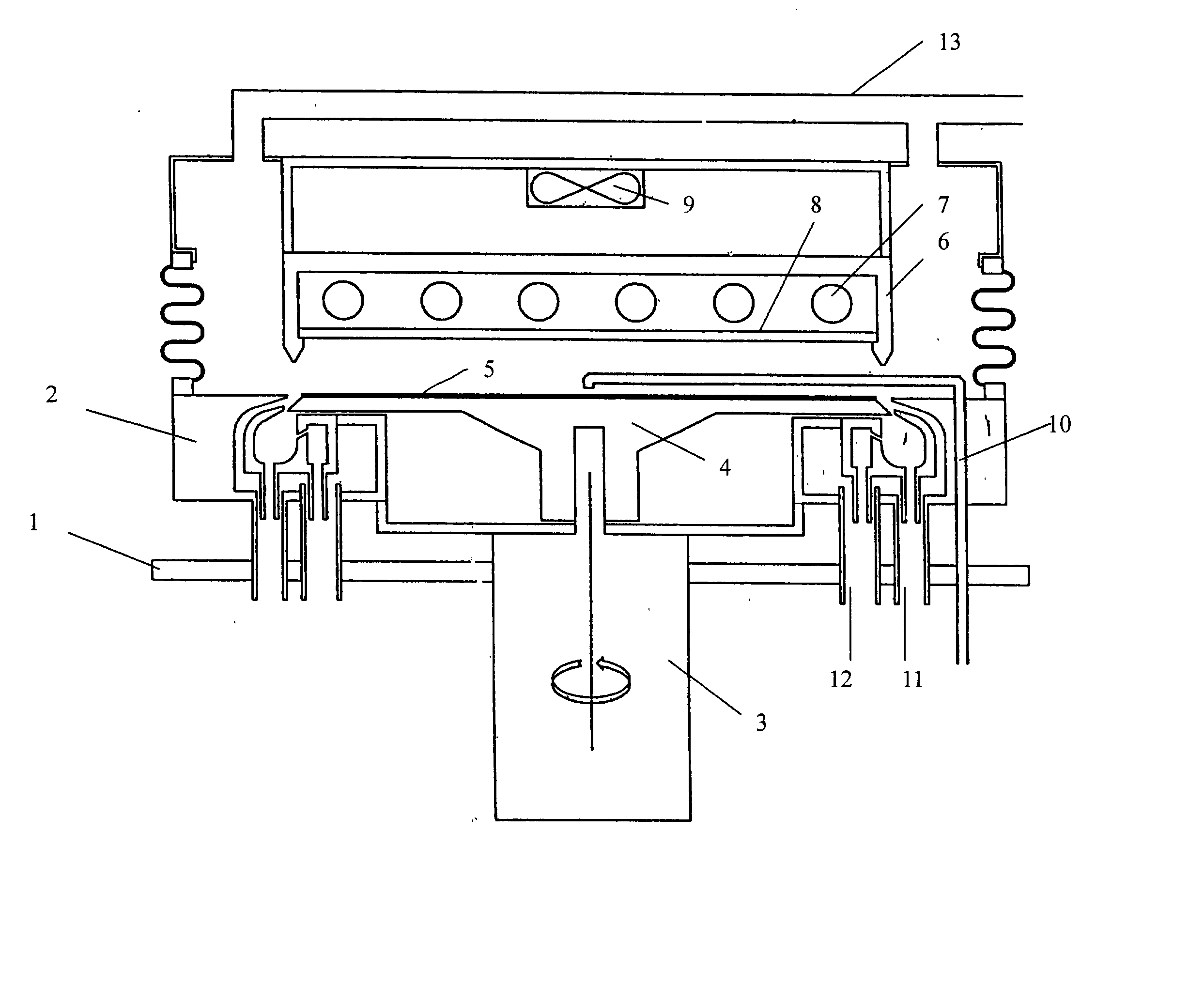

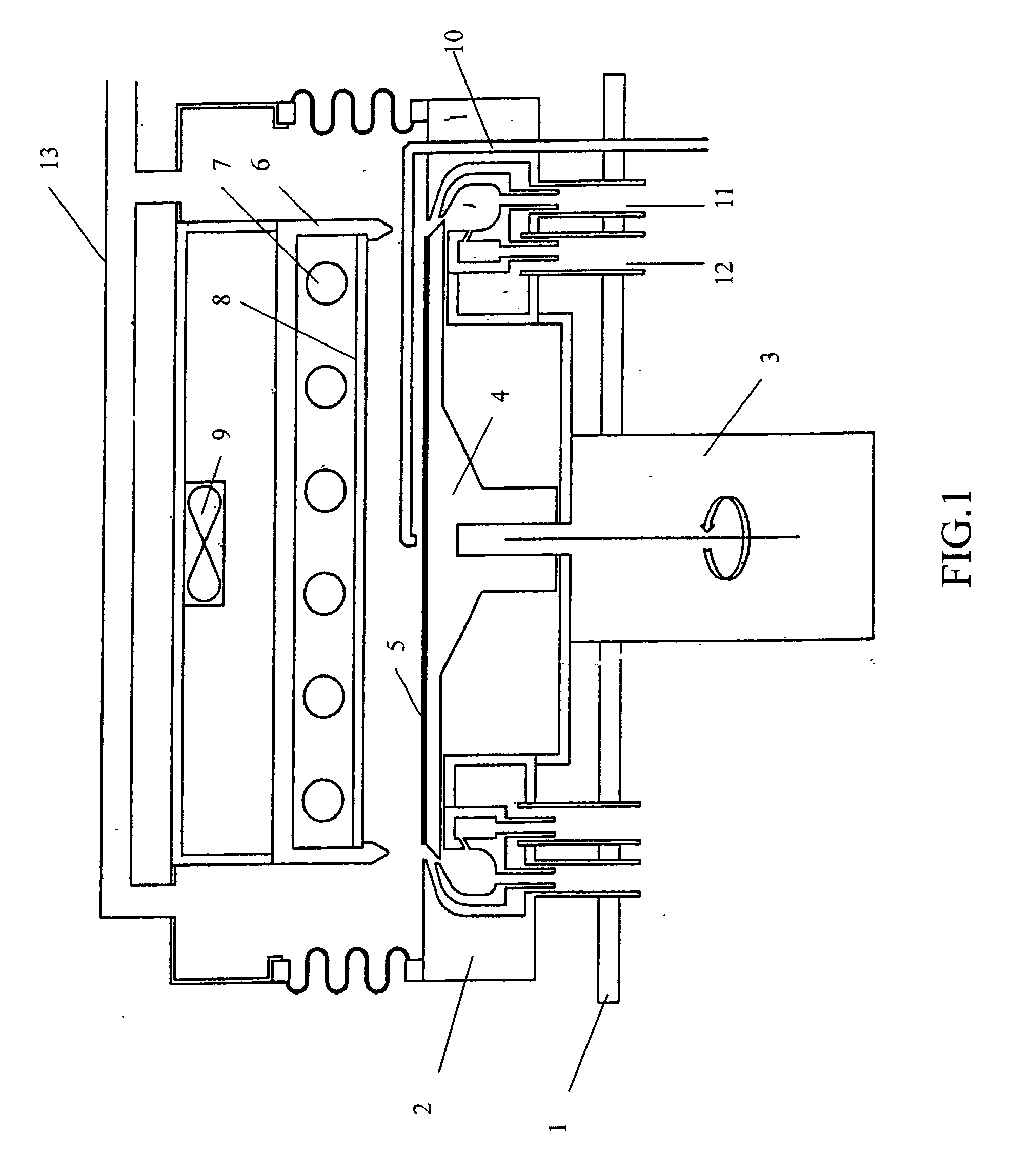

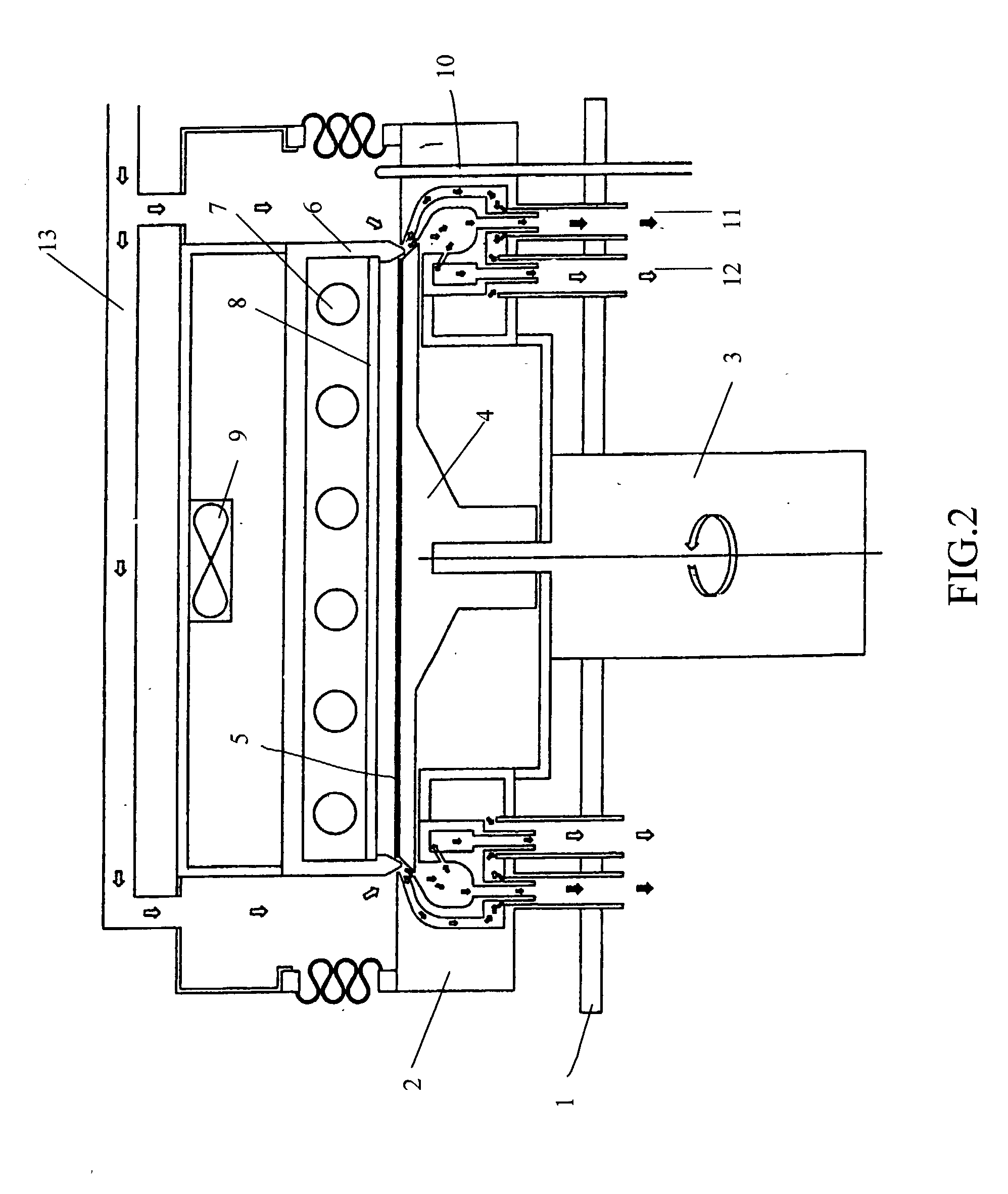

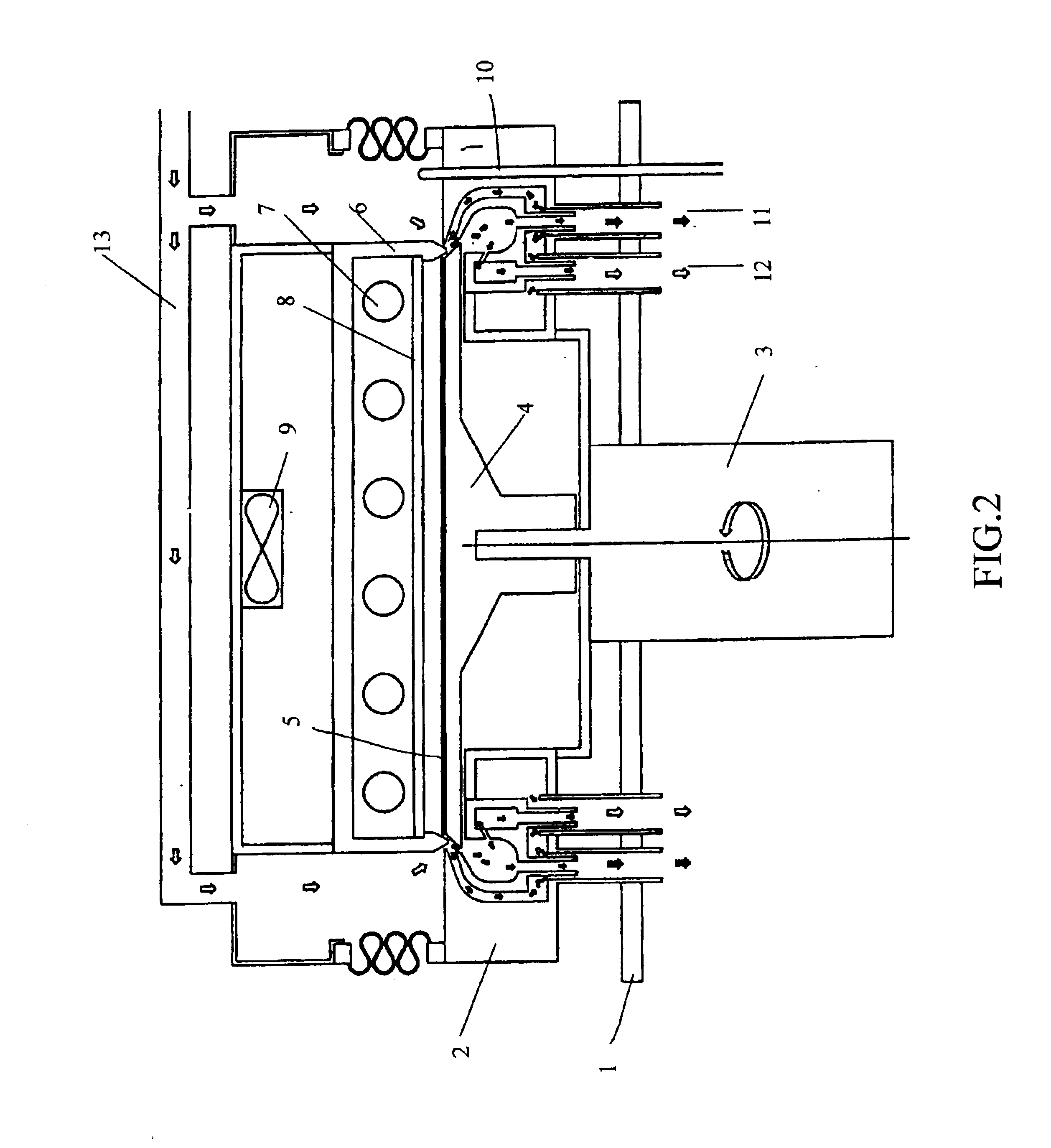

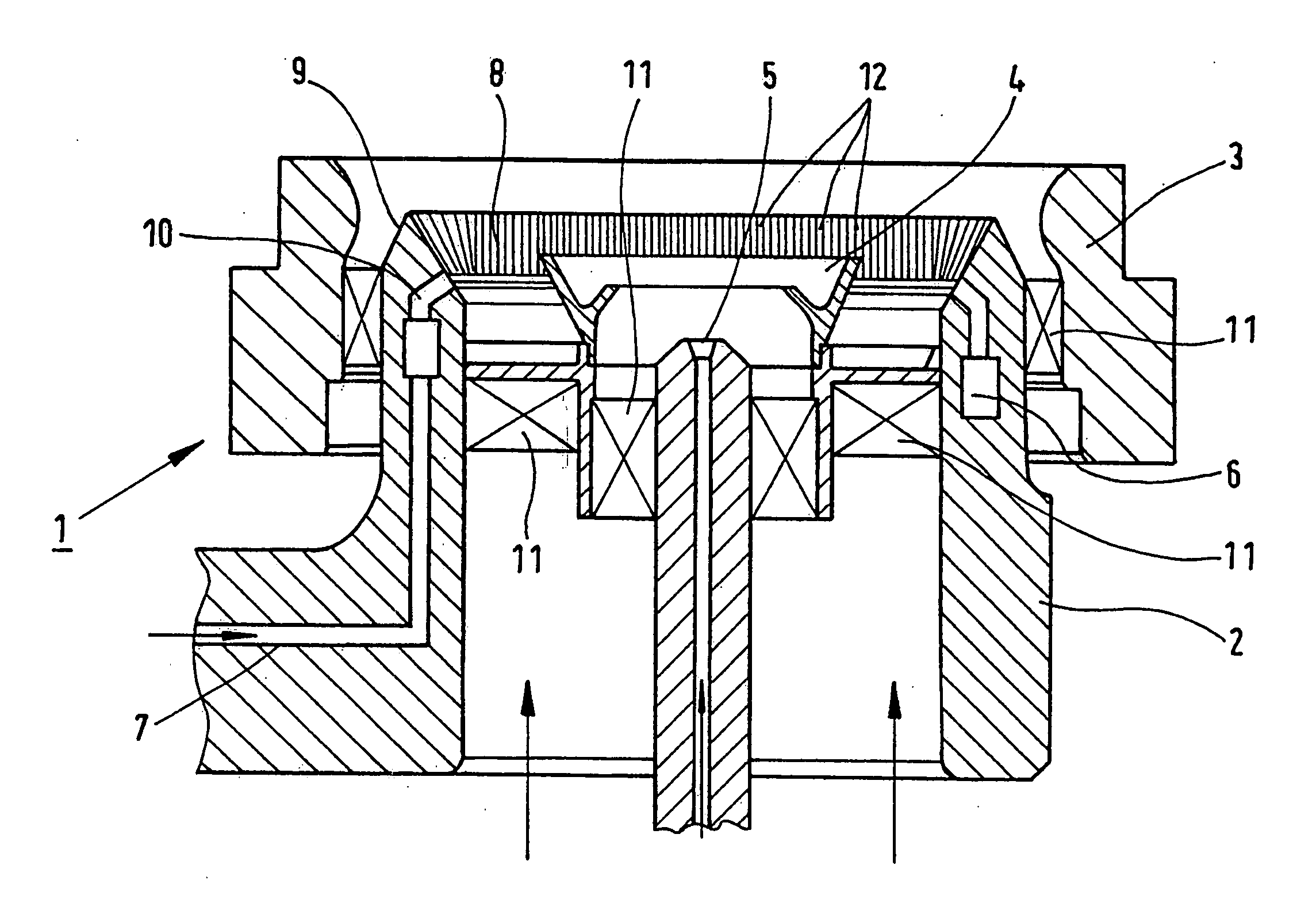

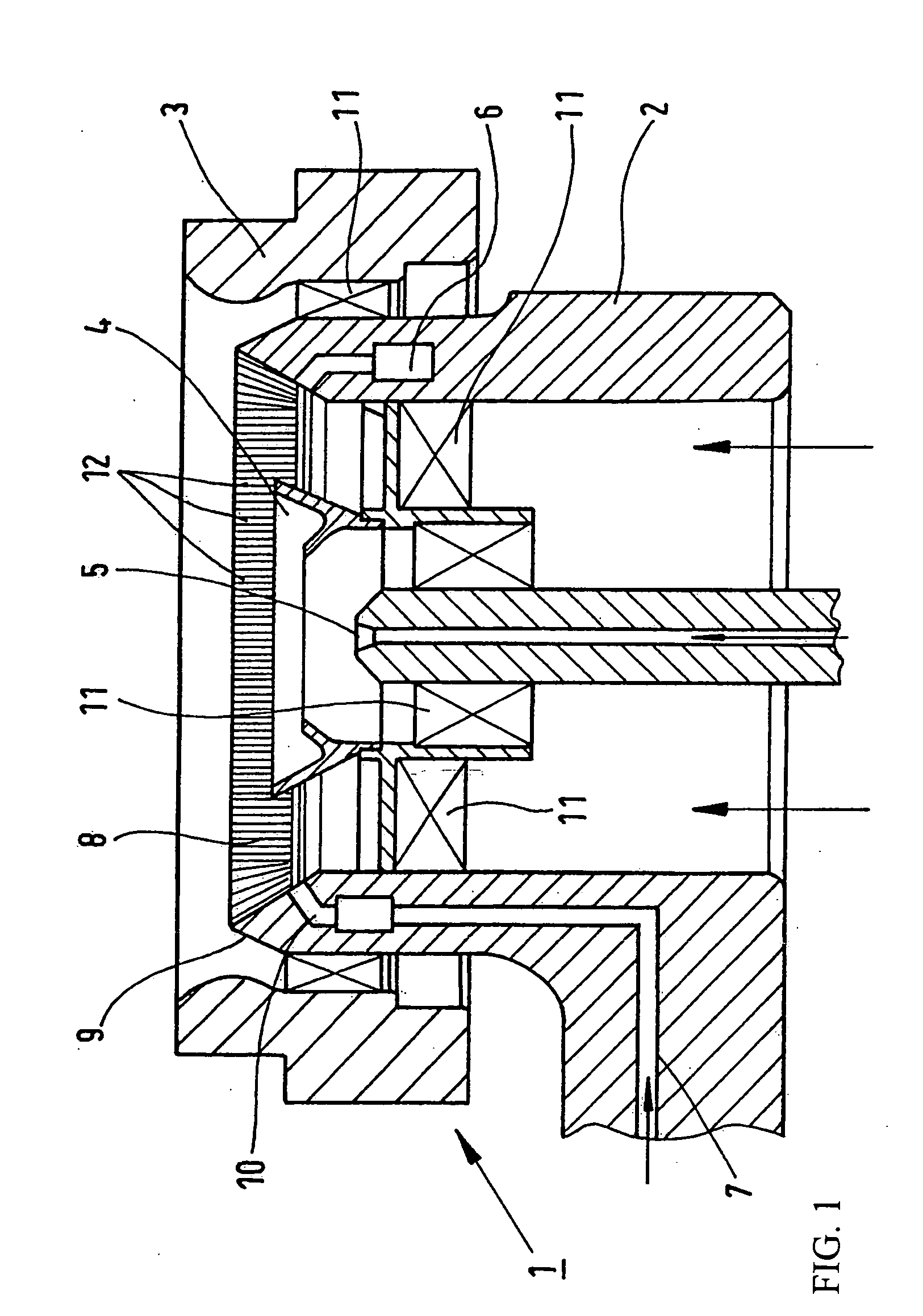

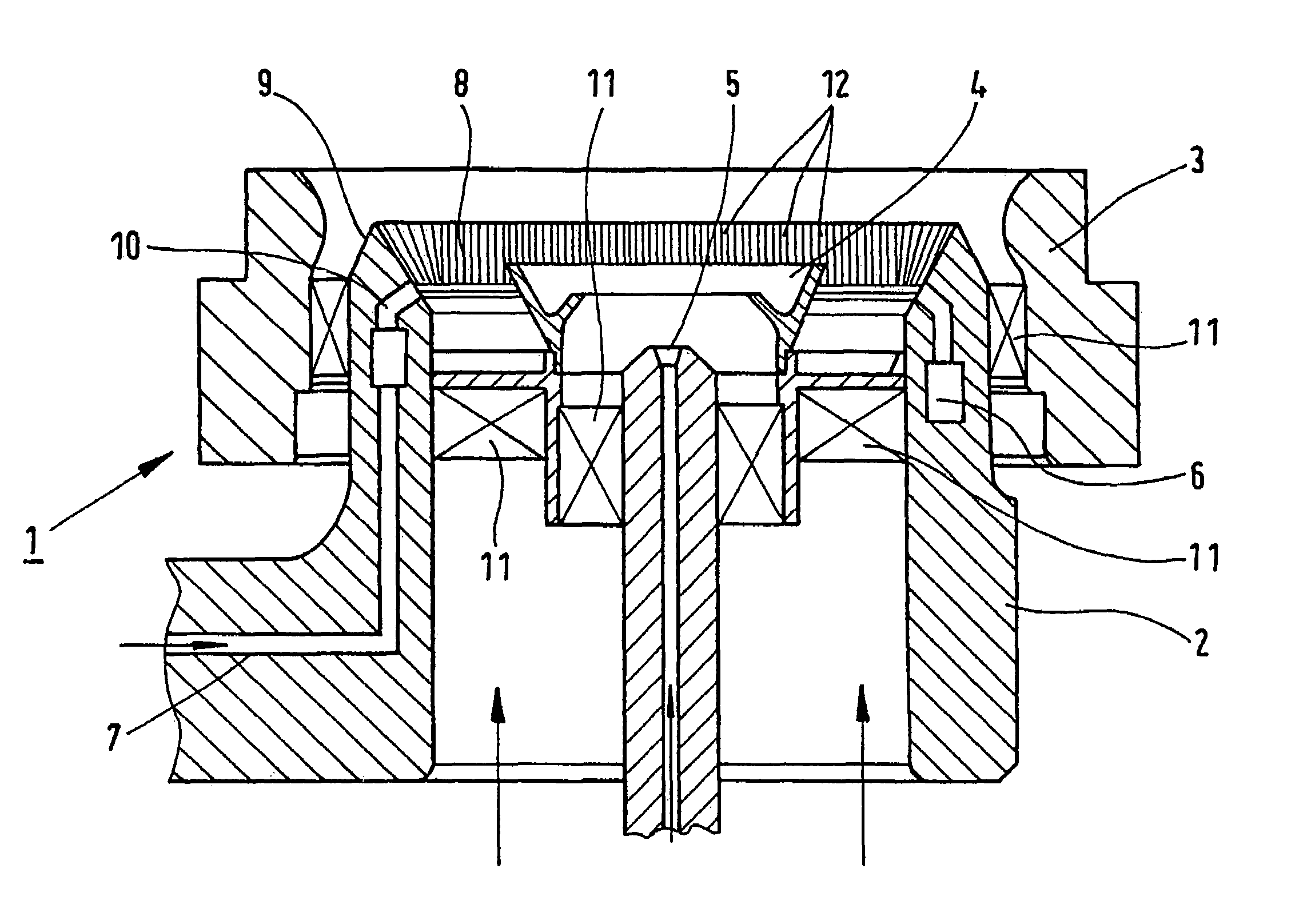

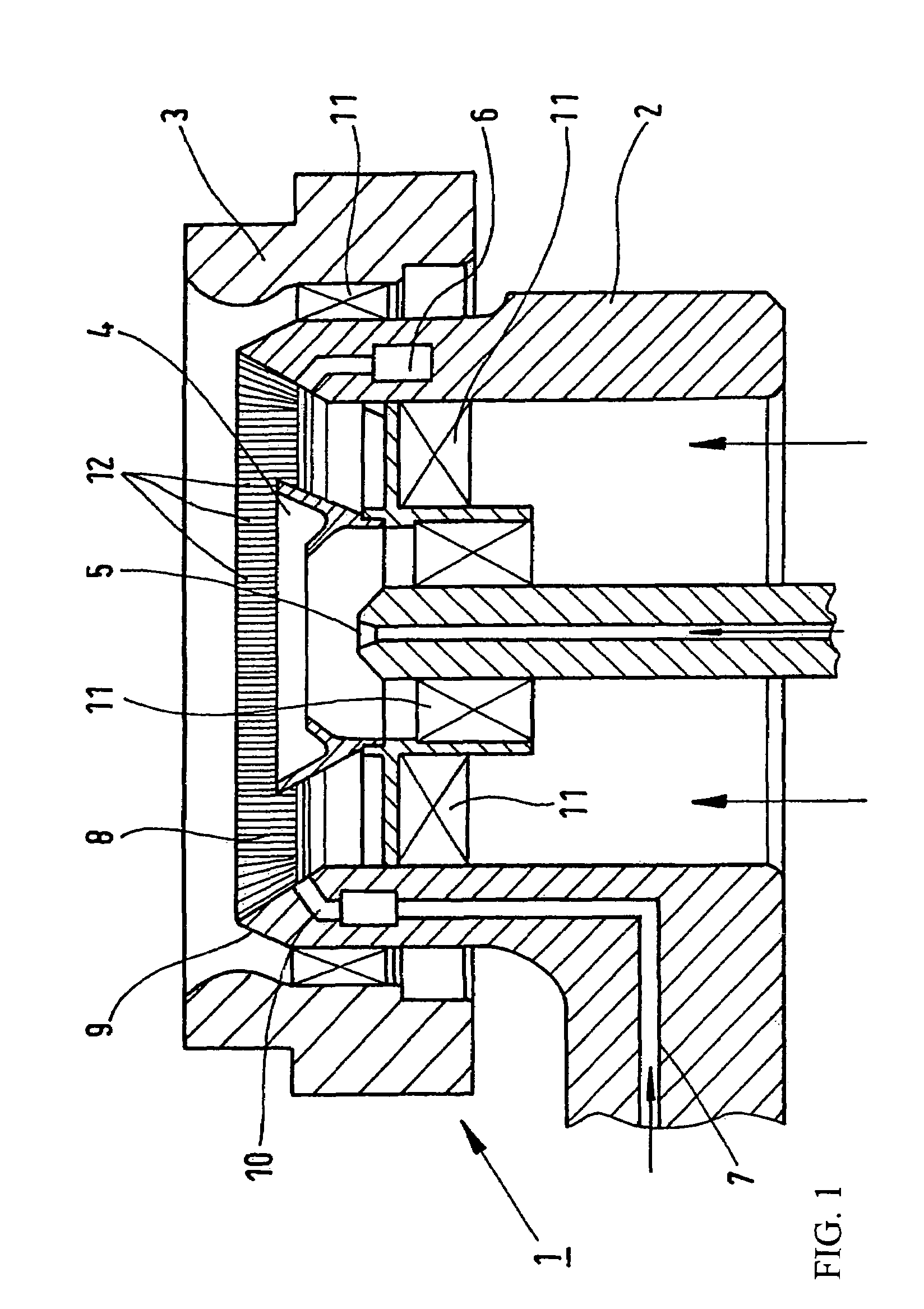

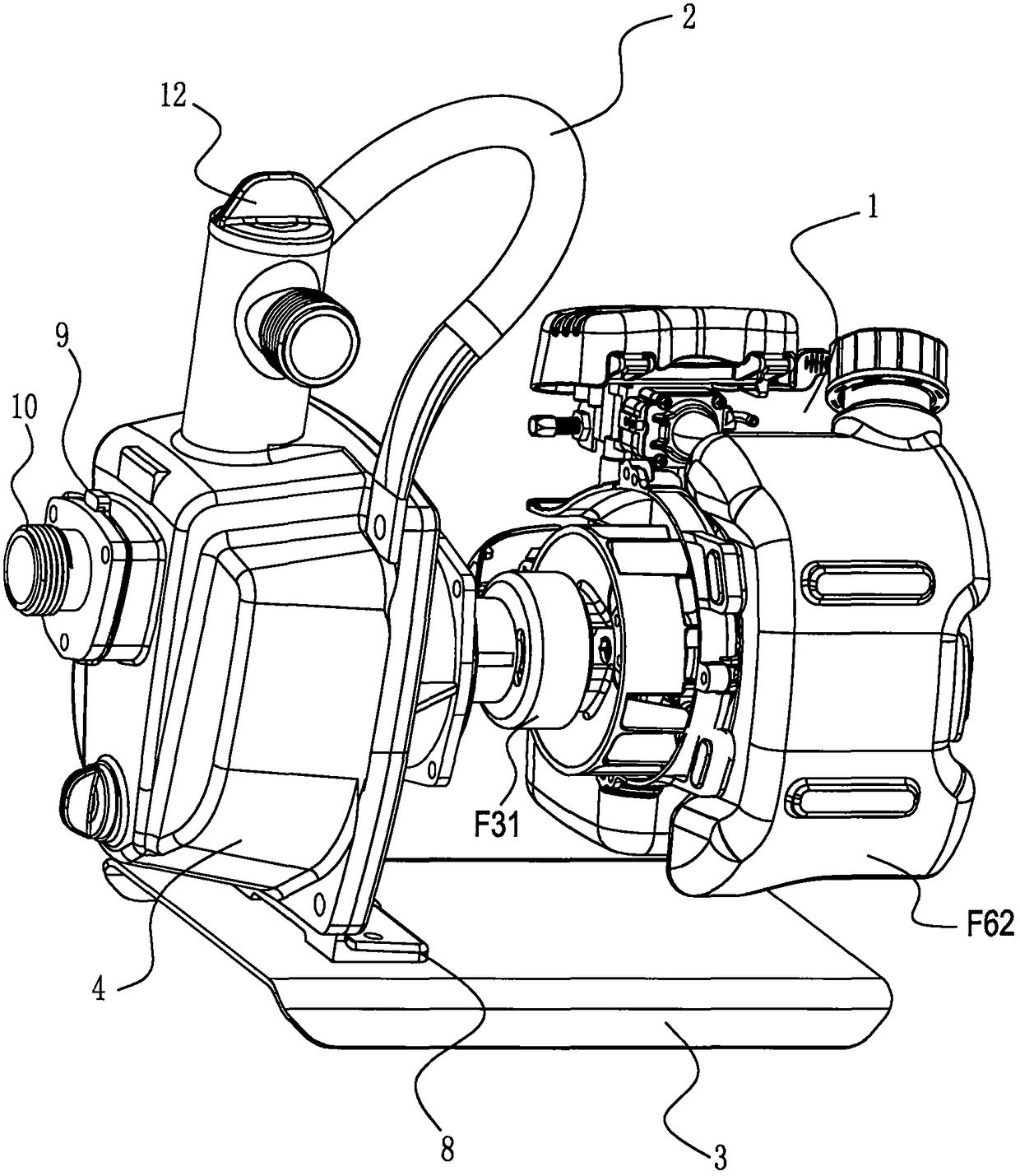

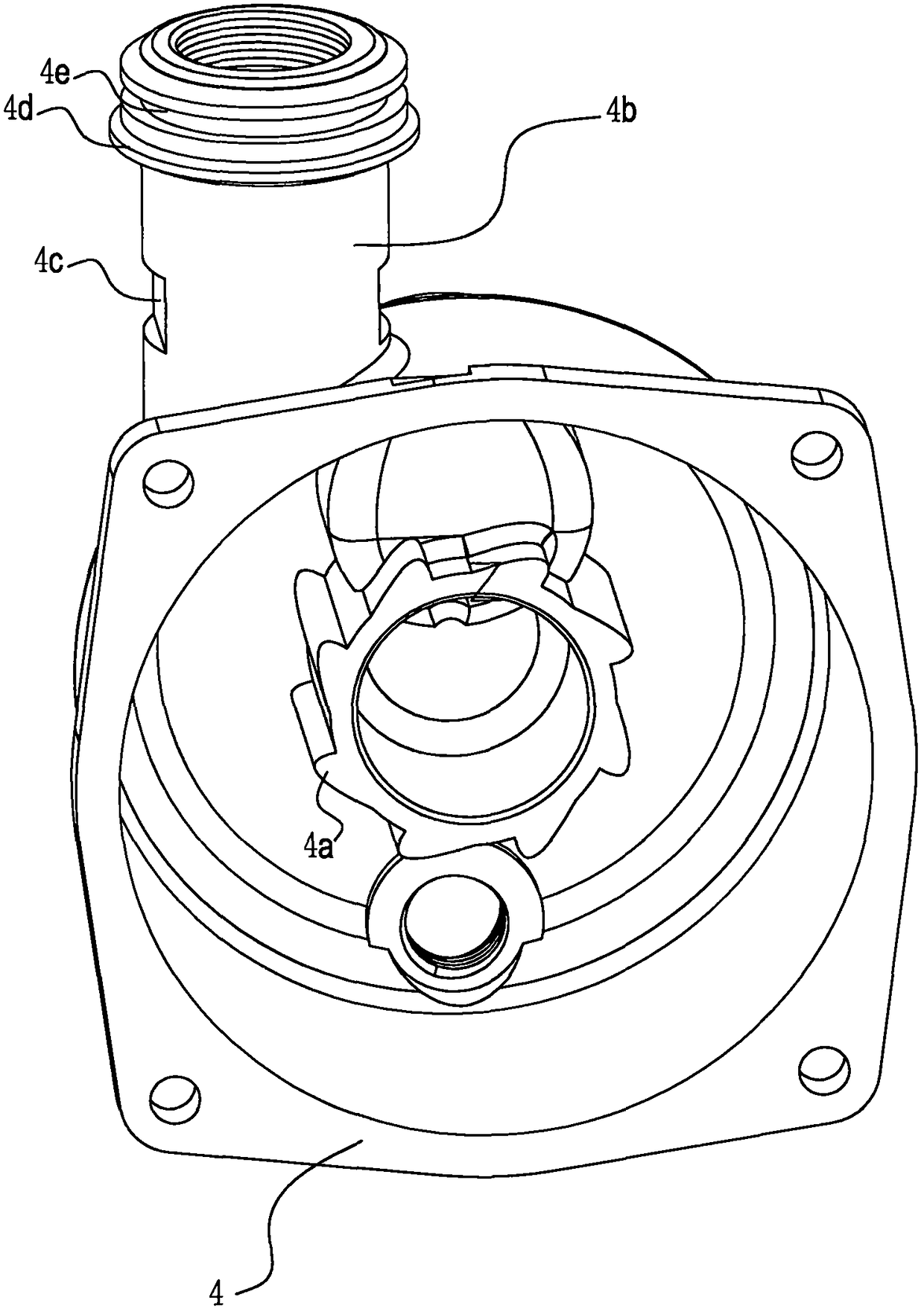

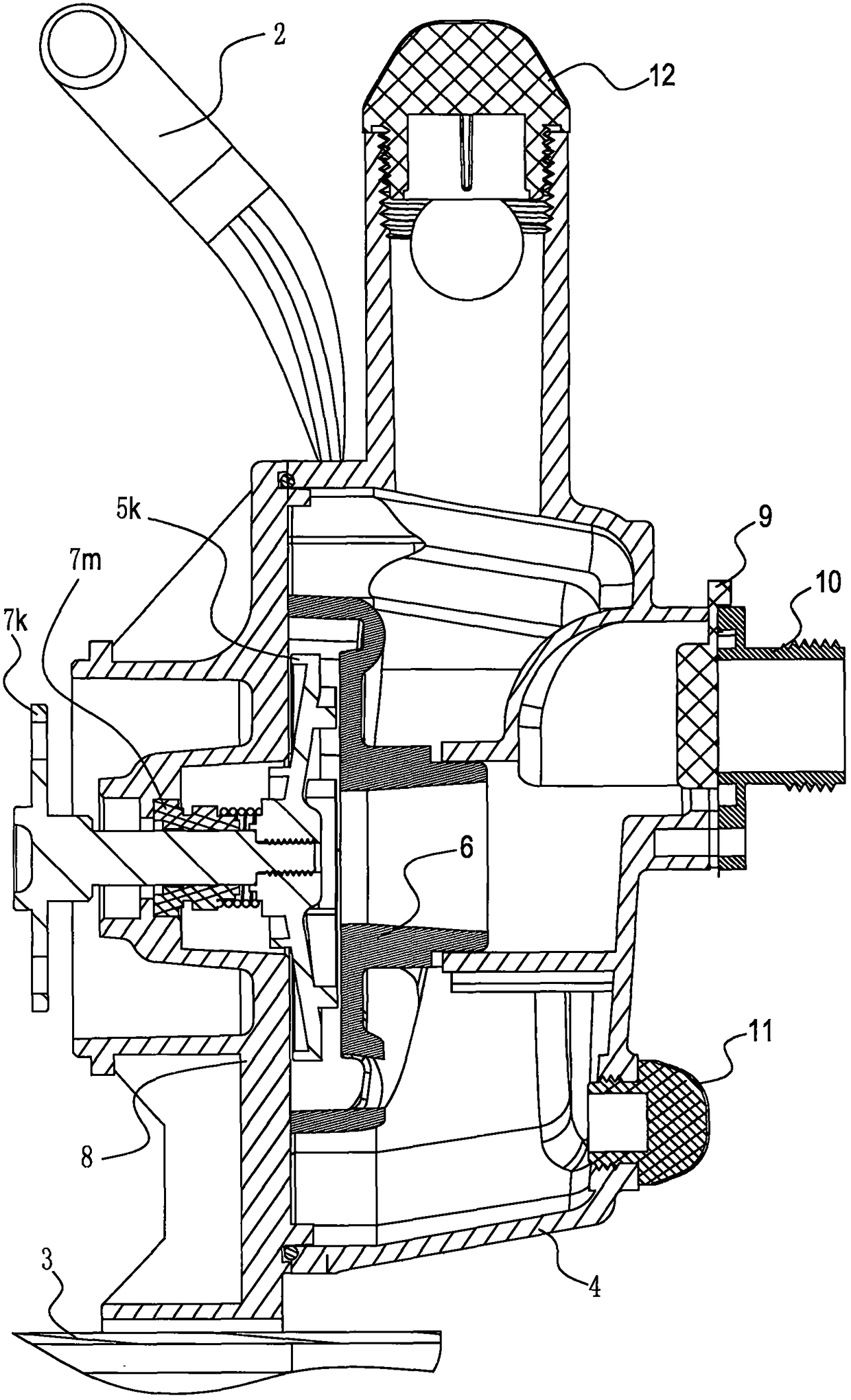

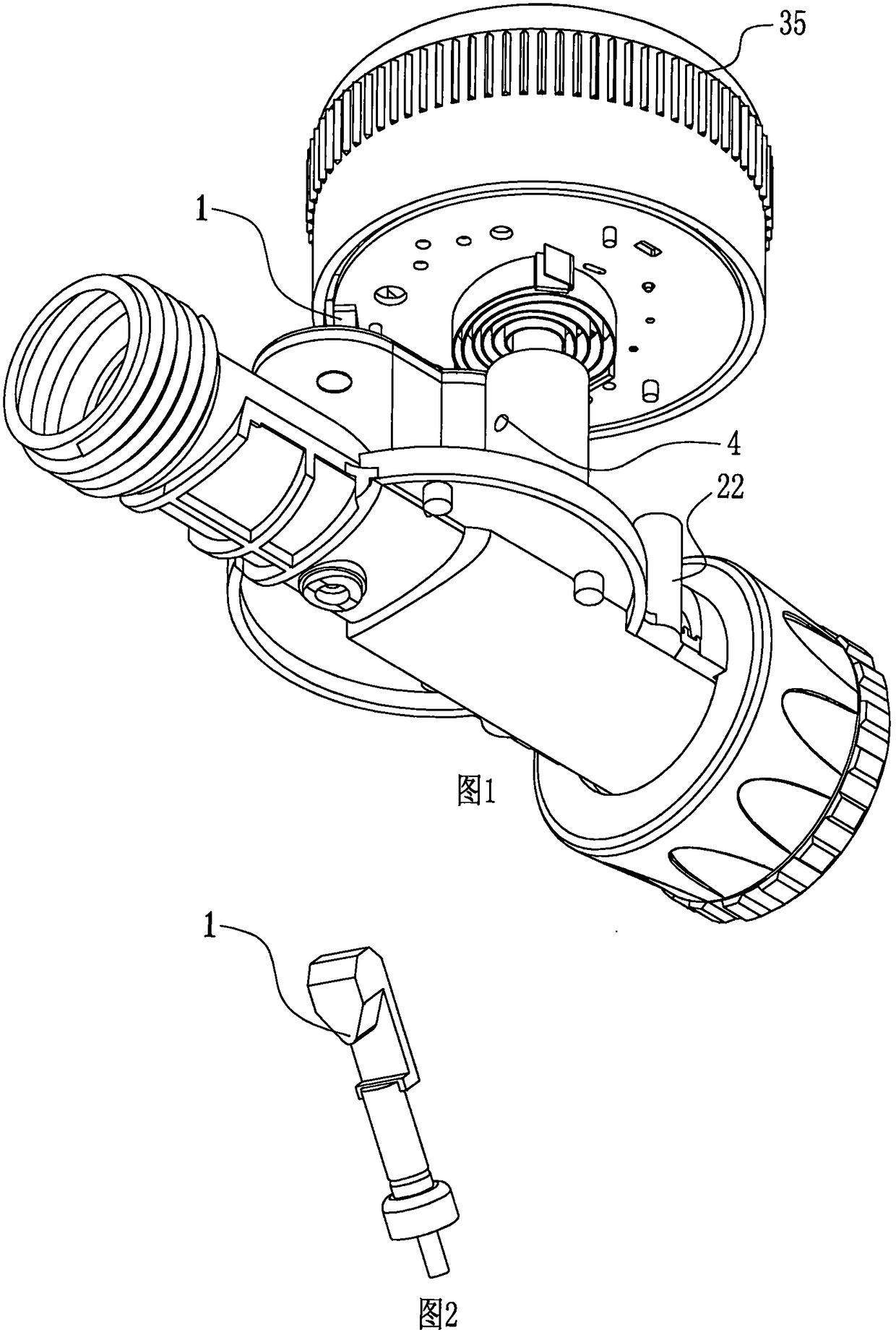

Lean premix burner with circumferential atomizer lip

With a lean premix burner (1), a plurality of preferably V-shaped, closely spaced fuel channels (12) is formed into the circumferential fuel-supplied film application surface (8) of the atomizer lip (9) in the direction of flow, in order to achieve a better heat transfer to the fuel due to the uniform fuel distribution and a transverse flux in the plurality of small fuel flows caused by the Marangoni effect, to completely converse the fuel by early vaporization and improved spraying, to reduce nitrogen oxide emission and to suppress combustion-driven pressure oscillations.

Owner:ROLLS ROYCE DEUT LTD & CO KG

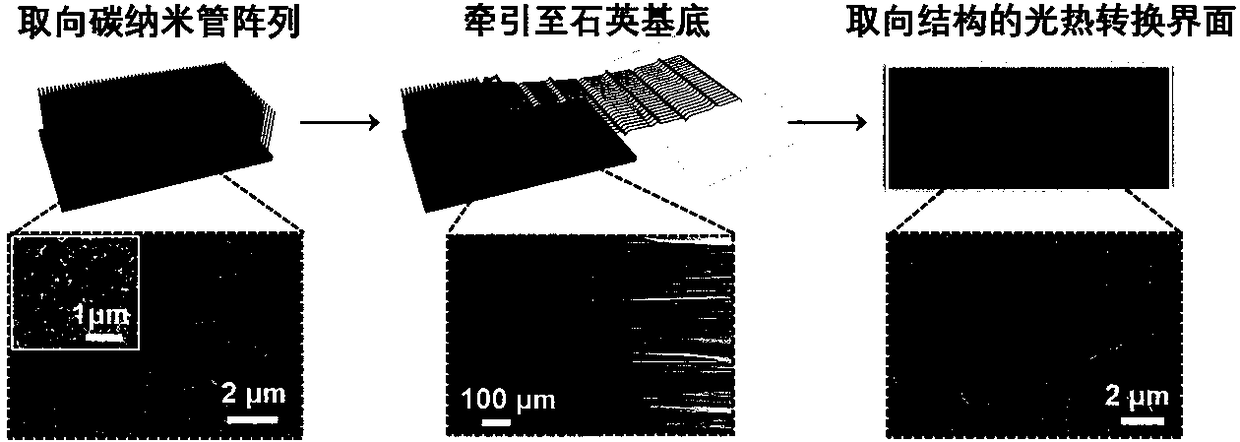

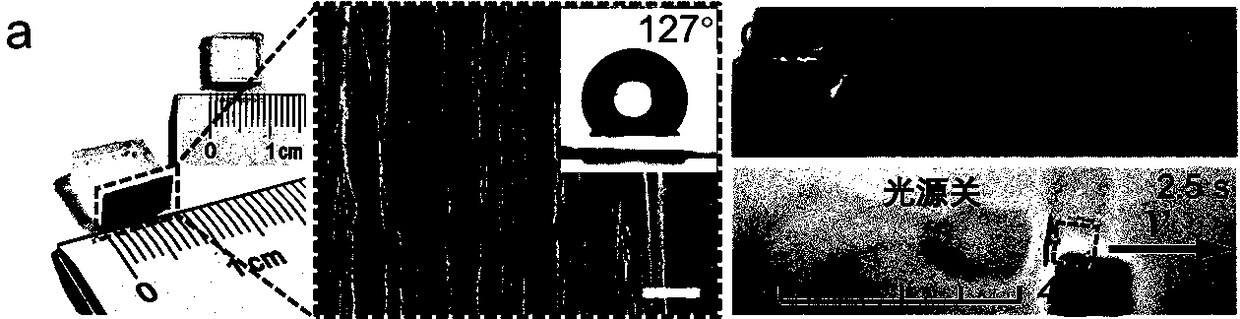

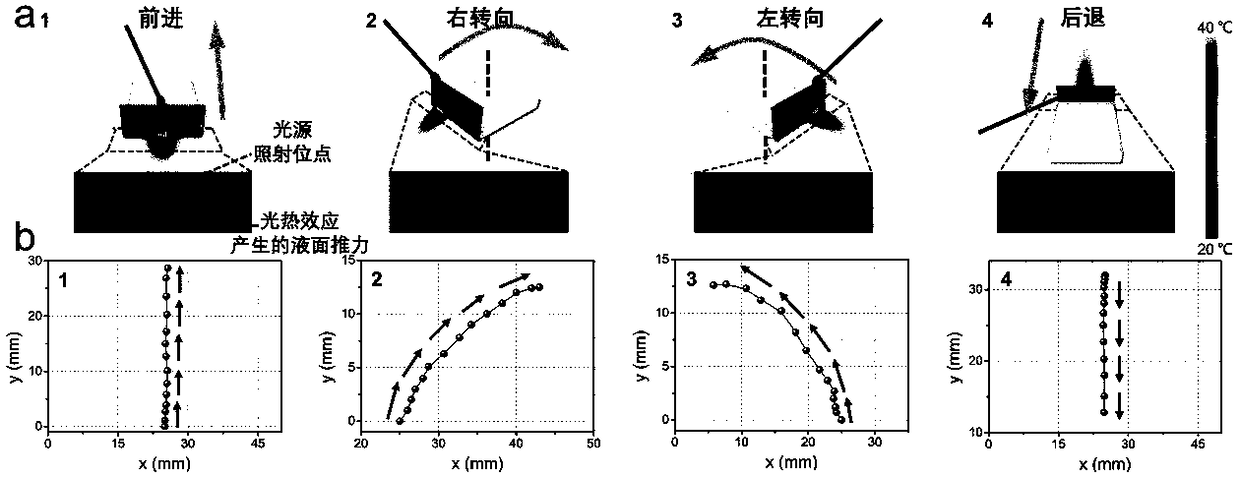

Micro robot driven by point light source and preparation method thereof

ActiveCN108527315AGood compatibilityHigh photothermal conversion efficiencyMicromanipulatorOther chemical processesLight spotMicro robotics

The invention belongs to the technical field of micro robots, and particularly relates to a micro robot driven by a point light source. The micro robot is formed by assembling a photo-thermal conversion interface which is an oriented carbon nanotube and a flexible and transparent base prepared from polydimethylsiloxane; when a light spot is controlled to irradiate on the photo-thermal conversion interface, photo-thermal conversion is generated in the structure of the carbon nanotube, and the generated heat is conducted to a floating liquid surface where the whole micro robot floats along a vertical oriented structure of the carbon nanotube; according to the Marangoni effect, the surface tension of the heated liquid surface adjacent to the photo-thermal conversion interface is sharply reduced, and the surface tension difference is formed between the heated liquid surface and the surrounding non-heated liquid surface, so that asymmetric pushing force is generated on the whole micro robot, and the micro robot is driven to move on the liquid surface. The micro robot has relatively high environmental adaptability and high controllability, and by setting different light-driven response interface distribution and point light source movement tracks, micro wireless remote driving systems with different motion modes can be obtained according to actual application scenes.

Owner:FUDAN UNIV

Lean premix burner with circumferential atomizer lip

InactiveUS7658075B2Improves mixtureReduce generationBurnersContinuous combustion chamberTransverse fluxCombustor

With a lean premix burner (1), a plurality of preferably V-shaped, closely spaced fuel channels (12) is formed into the circumferential fuel-supplied film application surface (8) of the atomizer lip (9) in the direction of flow, in order to achieve a better heat transfer to the fuel due to the uniform fuel distribution and a transverse flux in the plurality of small fuel flows caused by the Marangoni effect, to completely converse the fuel by early vaporization and improved spraying, to reduce nitrogen oxide emission and to suppress combustion-driven pressure oscillations.

Owner:ROLLS ROYCE DEUT LTD & CO KG

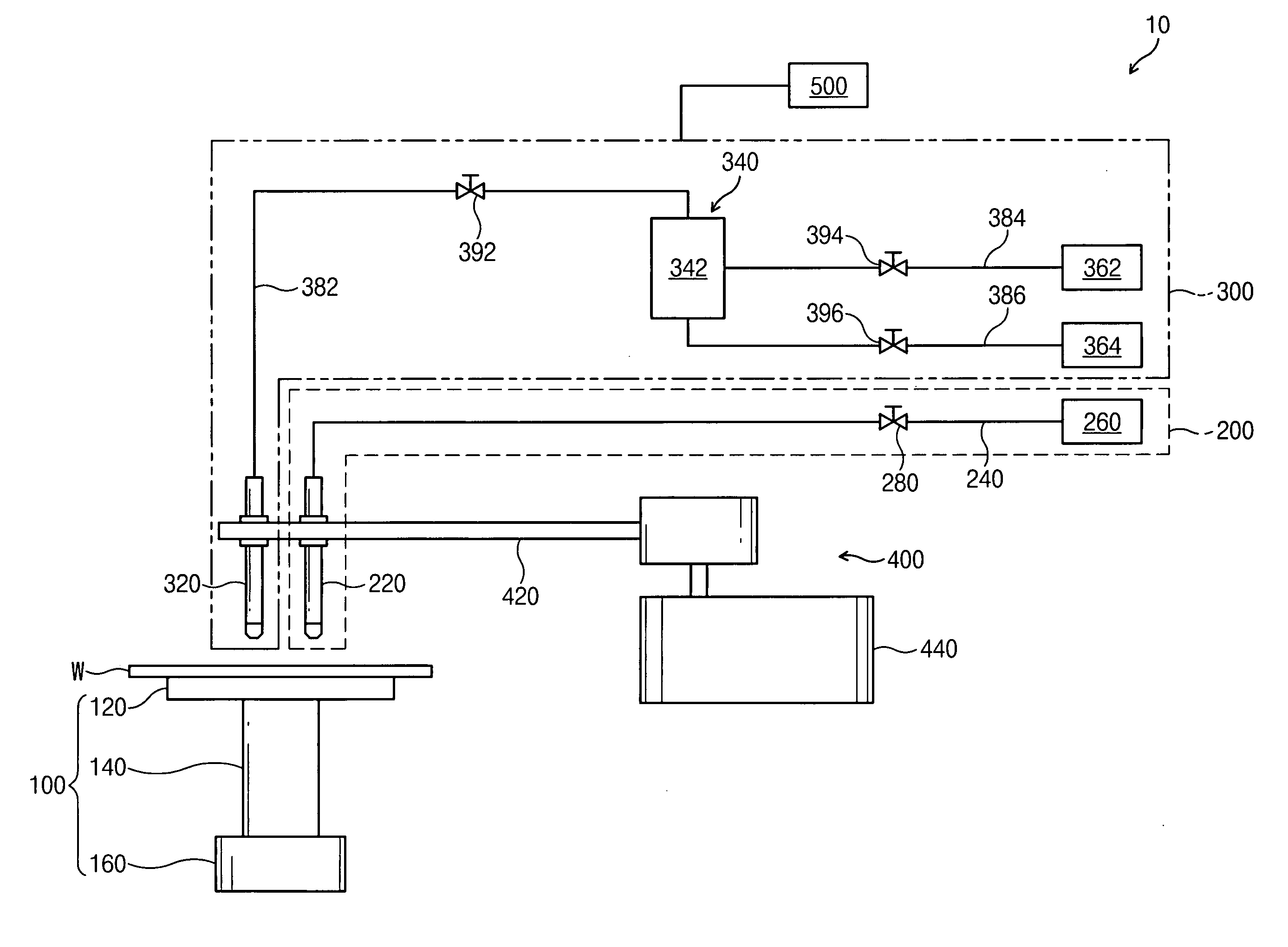

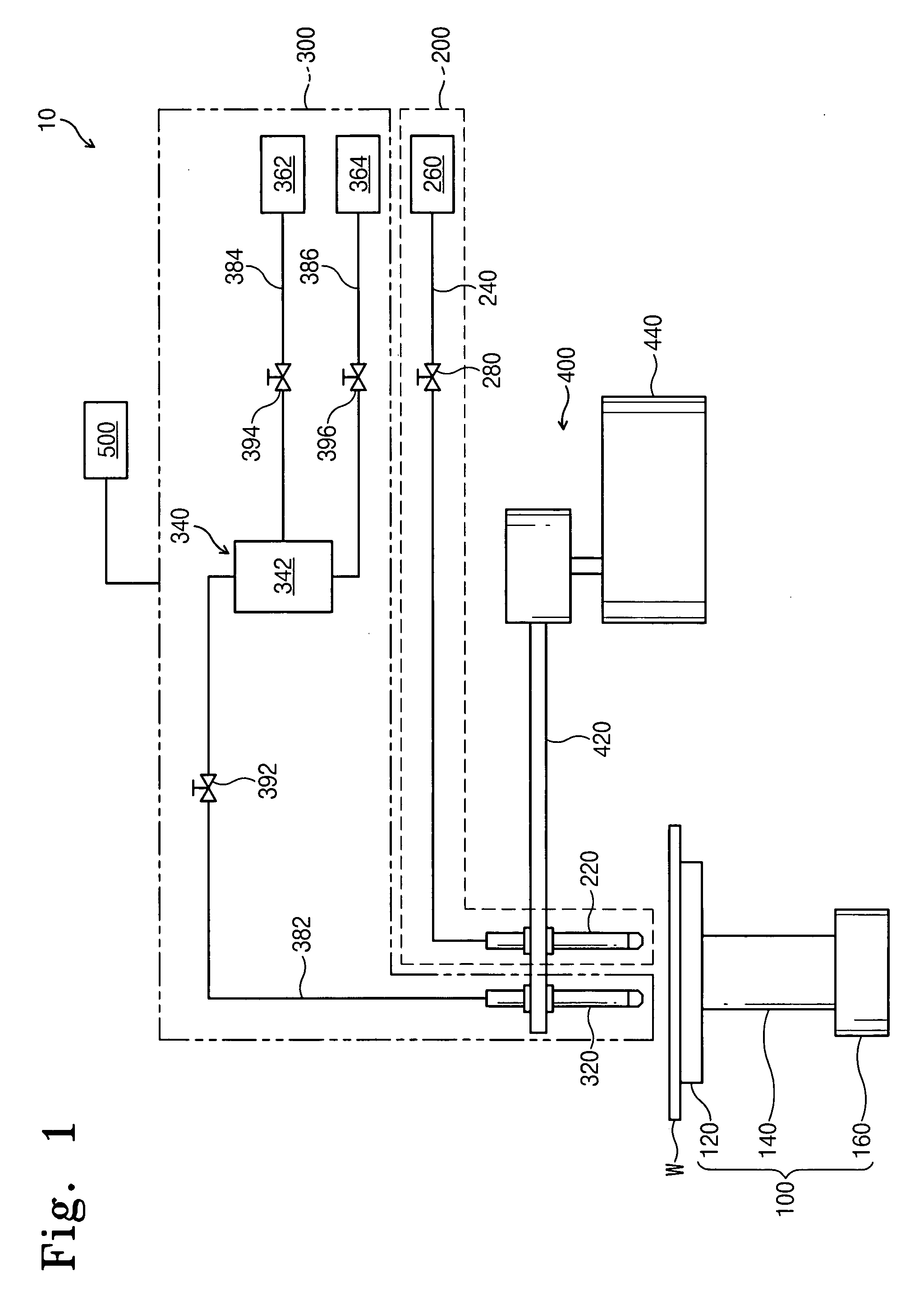

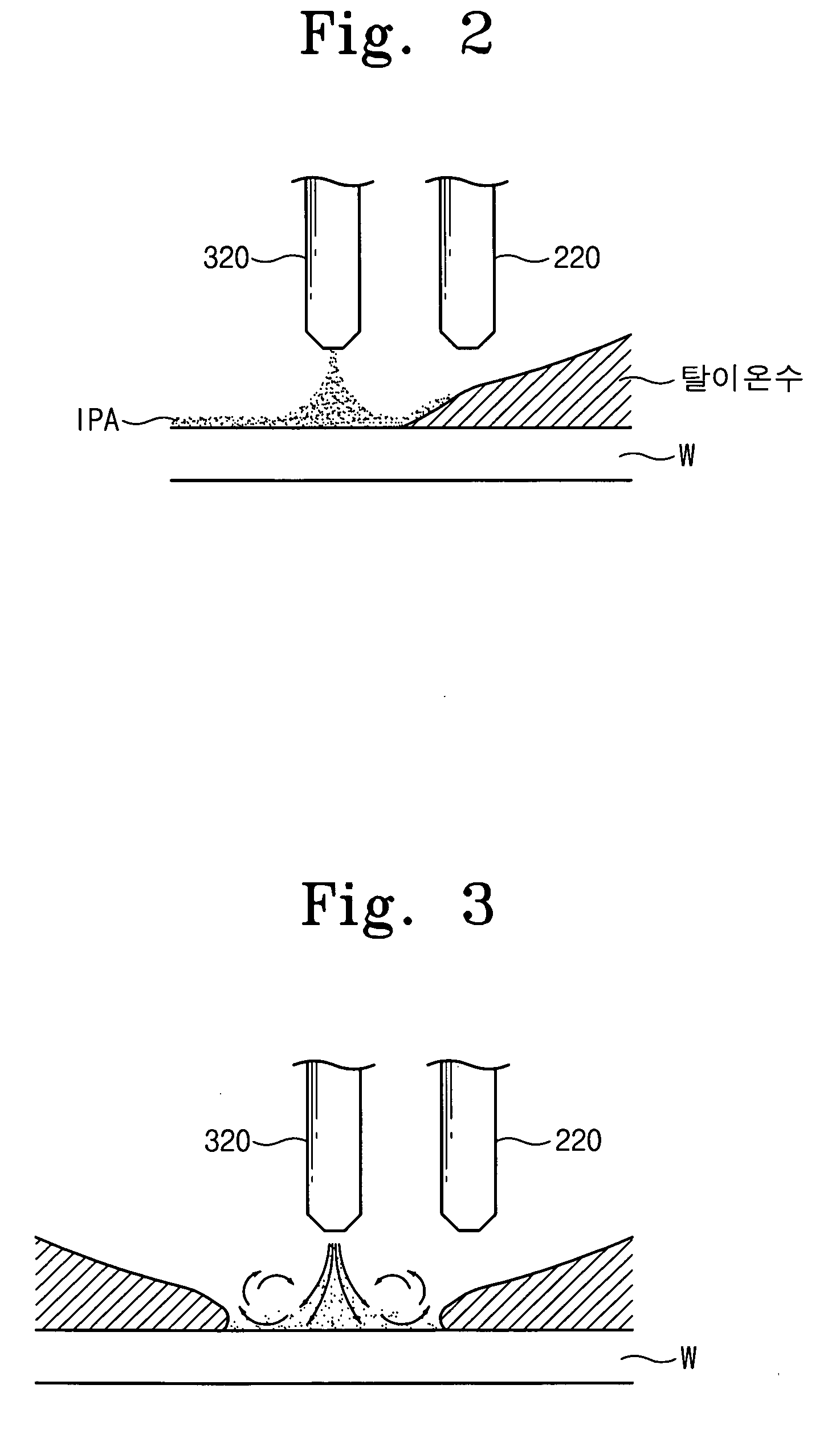

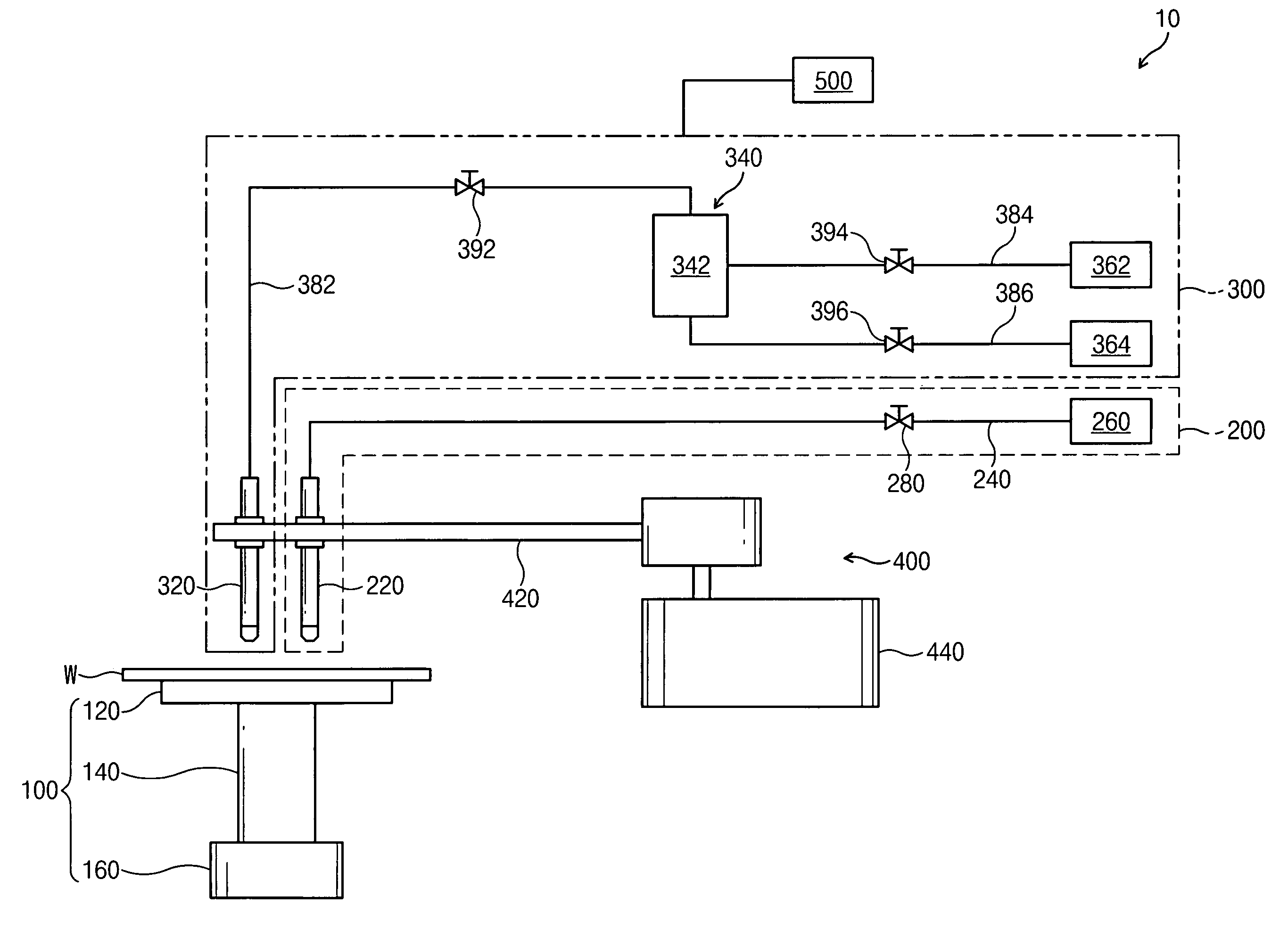

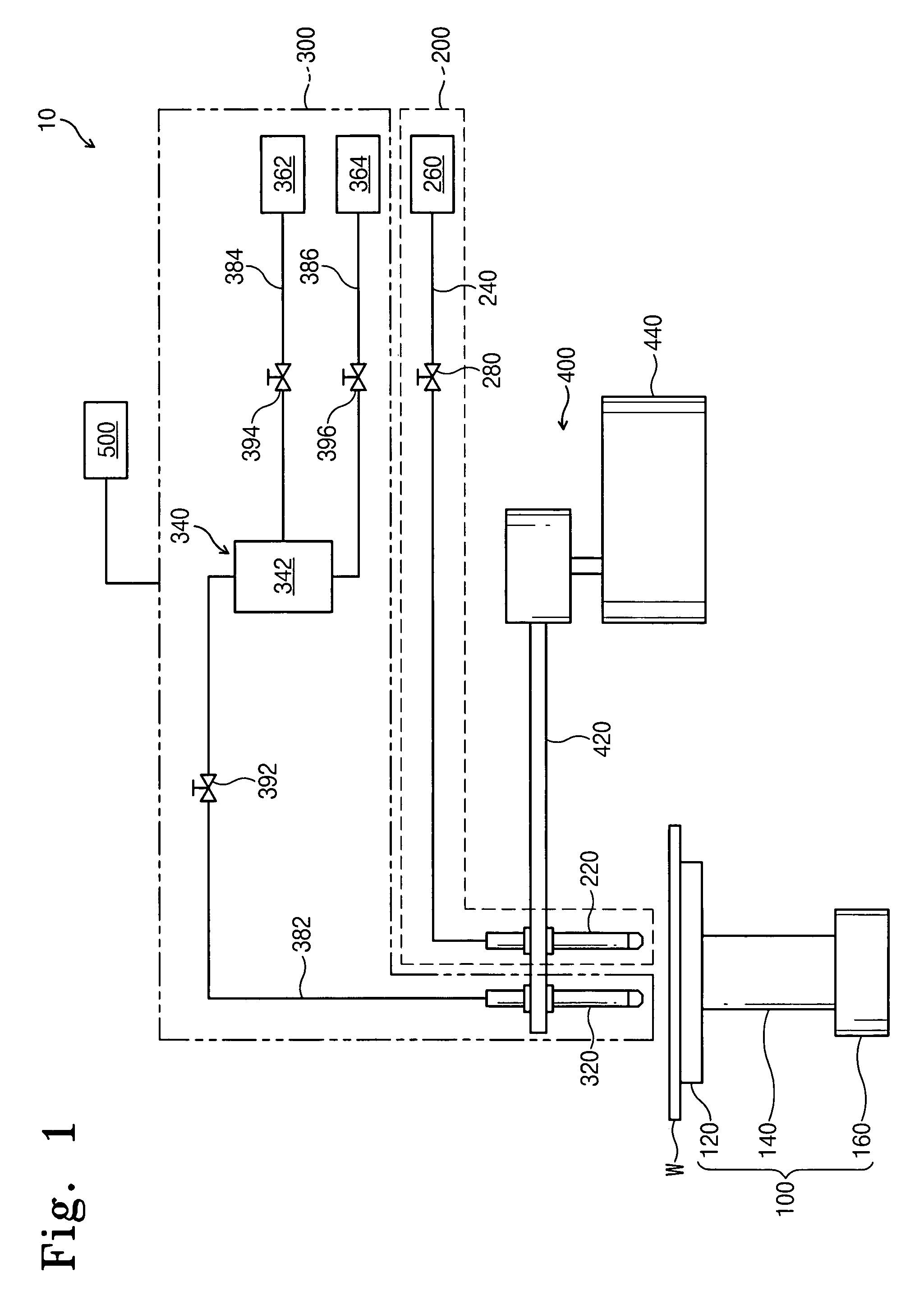

Apparatus for drying substrate and method thereof

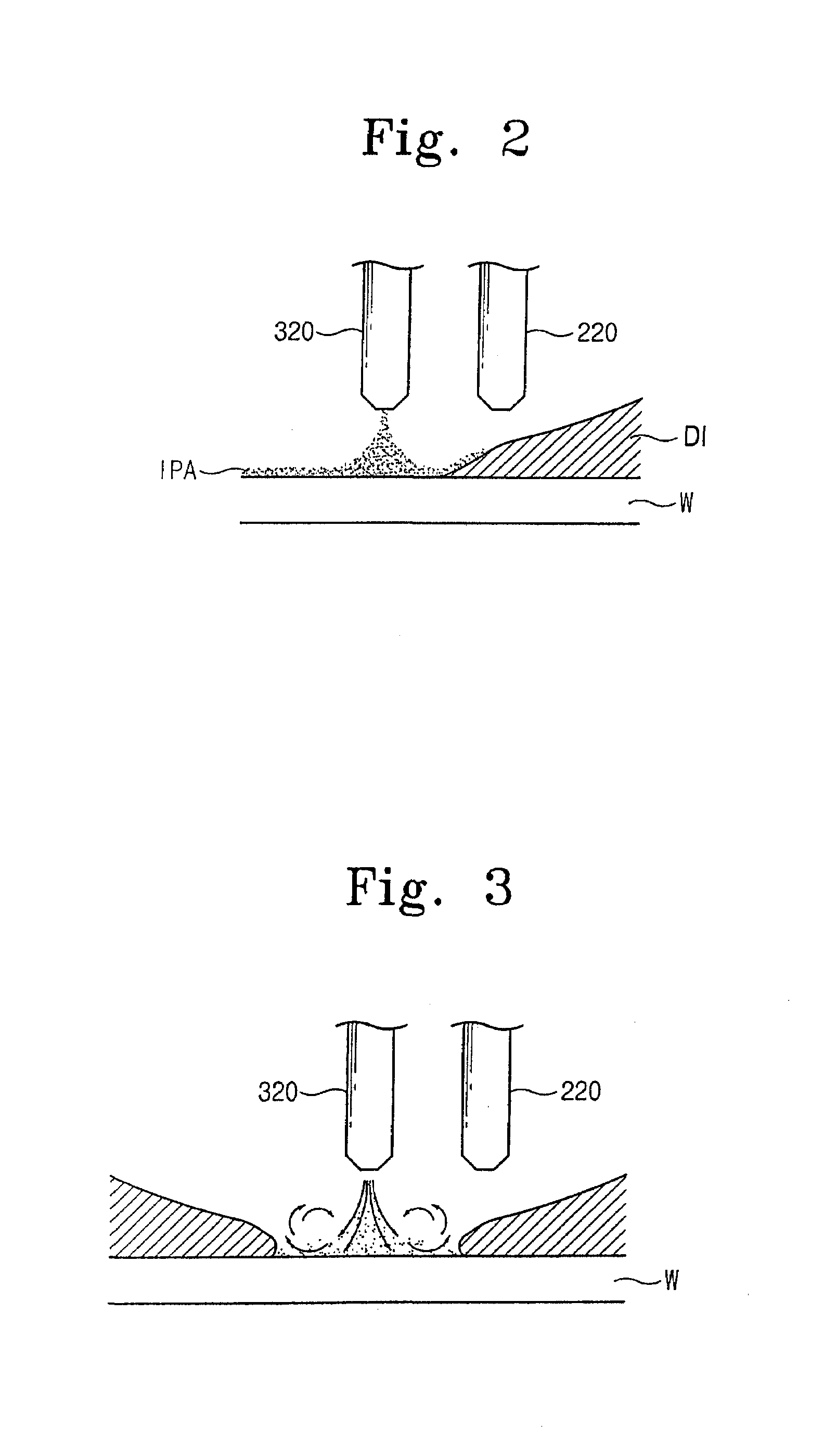

InactiveUS20060042722A1DistanceReduce distanceLiquid surface applicatorsLiquid fillingEngineeringIsopropyl alcohol

An apparatus for drying a substrate using the Marangoni effect is disclosed. The apparatus includes a rotatable supporting portion on which a substrate is placed. A first nozzle for supplying de-ionized water and a second nozzle for supplying isopropyl alcohol vapor are provided on the supporting portion. When the isopropyl alcohol vapor is supplied to the center of the substrate at the initial stage, the amount of alcohol that reaches the substrate is controlled by a controlling portion such that the amount of the second liquid gradually increases.

Owner:SAMSUNG ELECTRONICS CO LTD

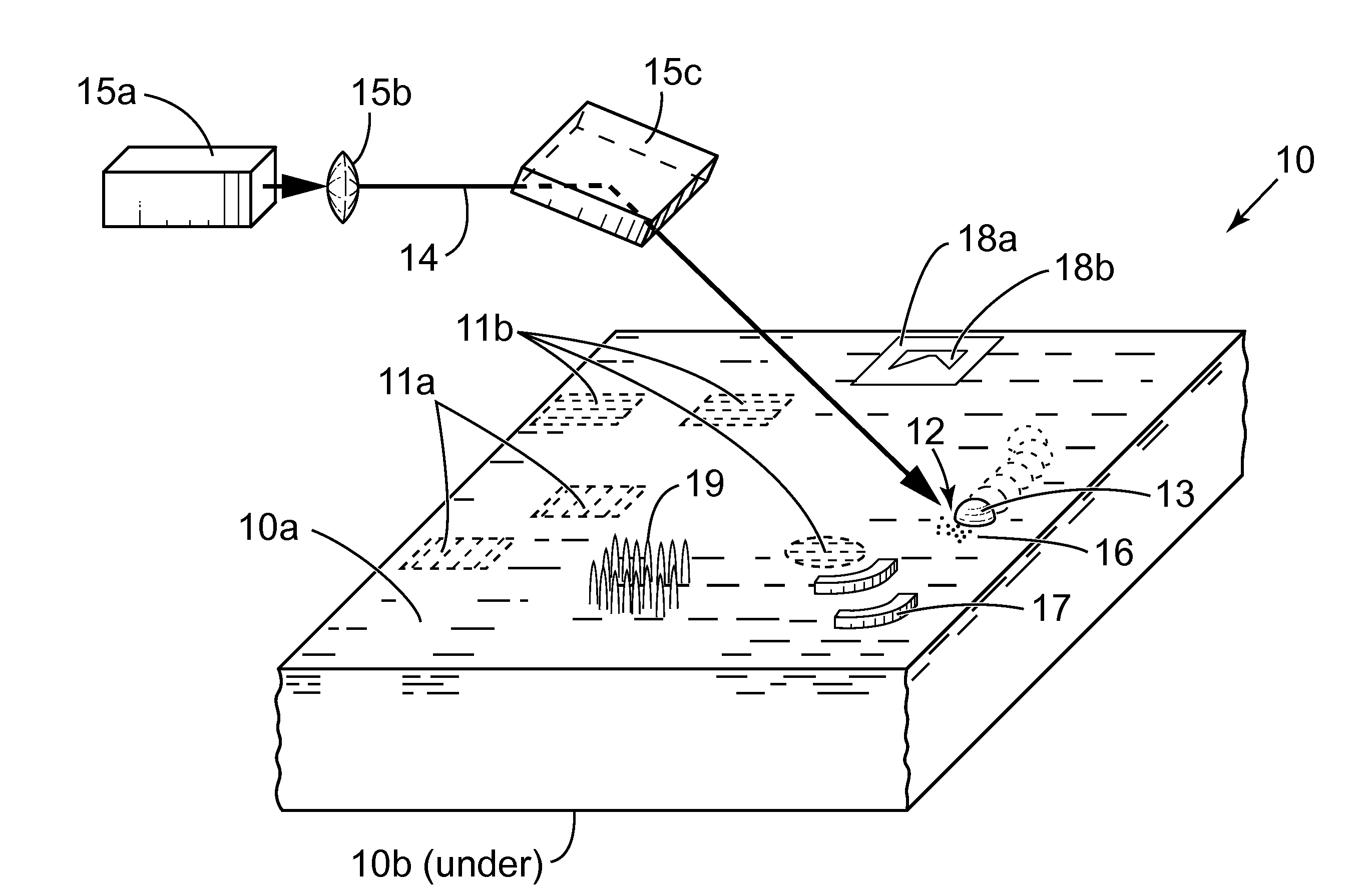

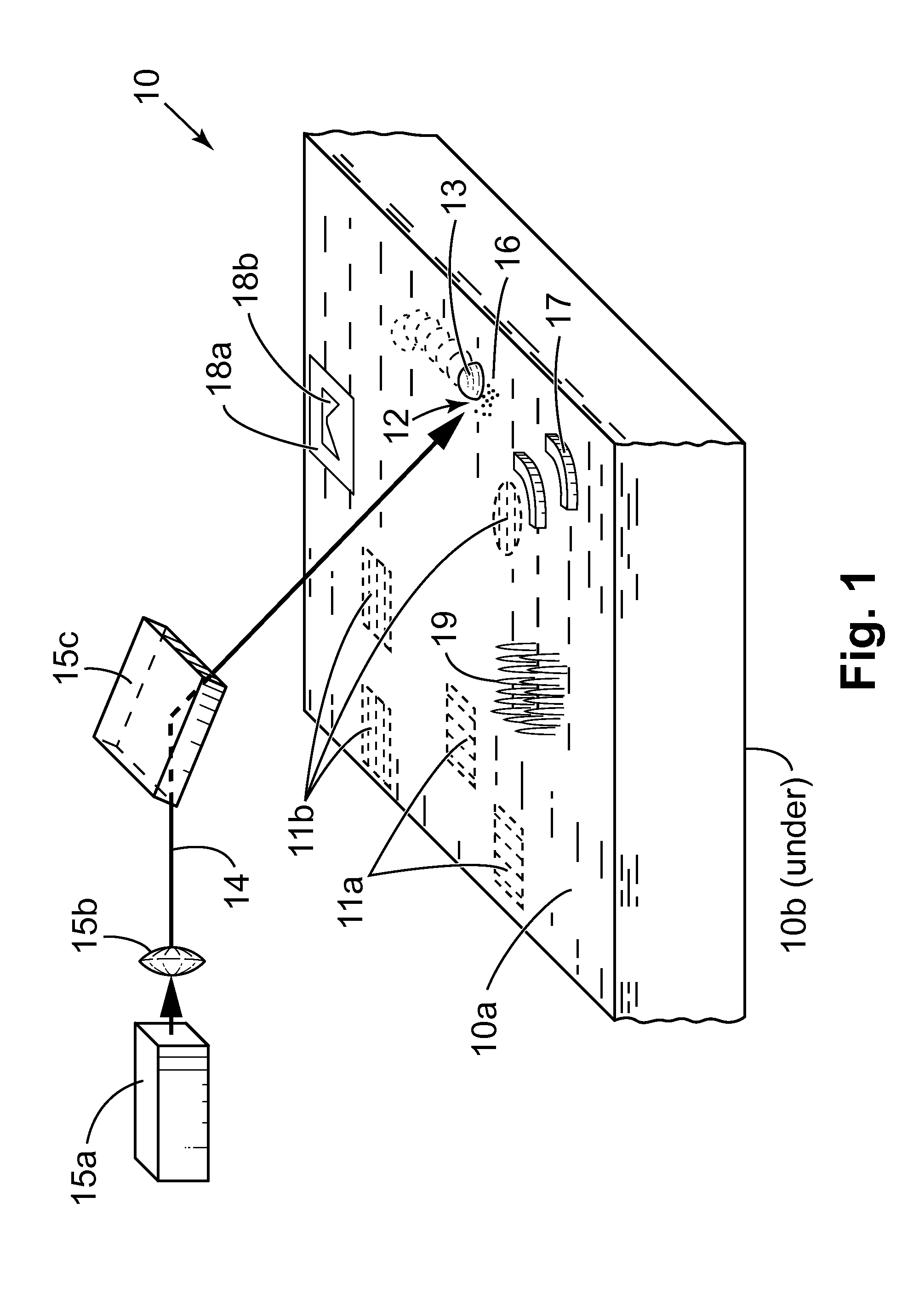

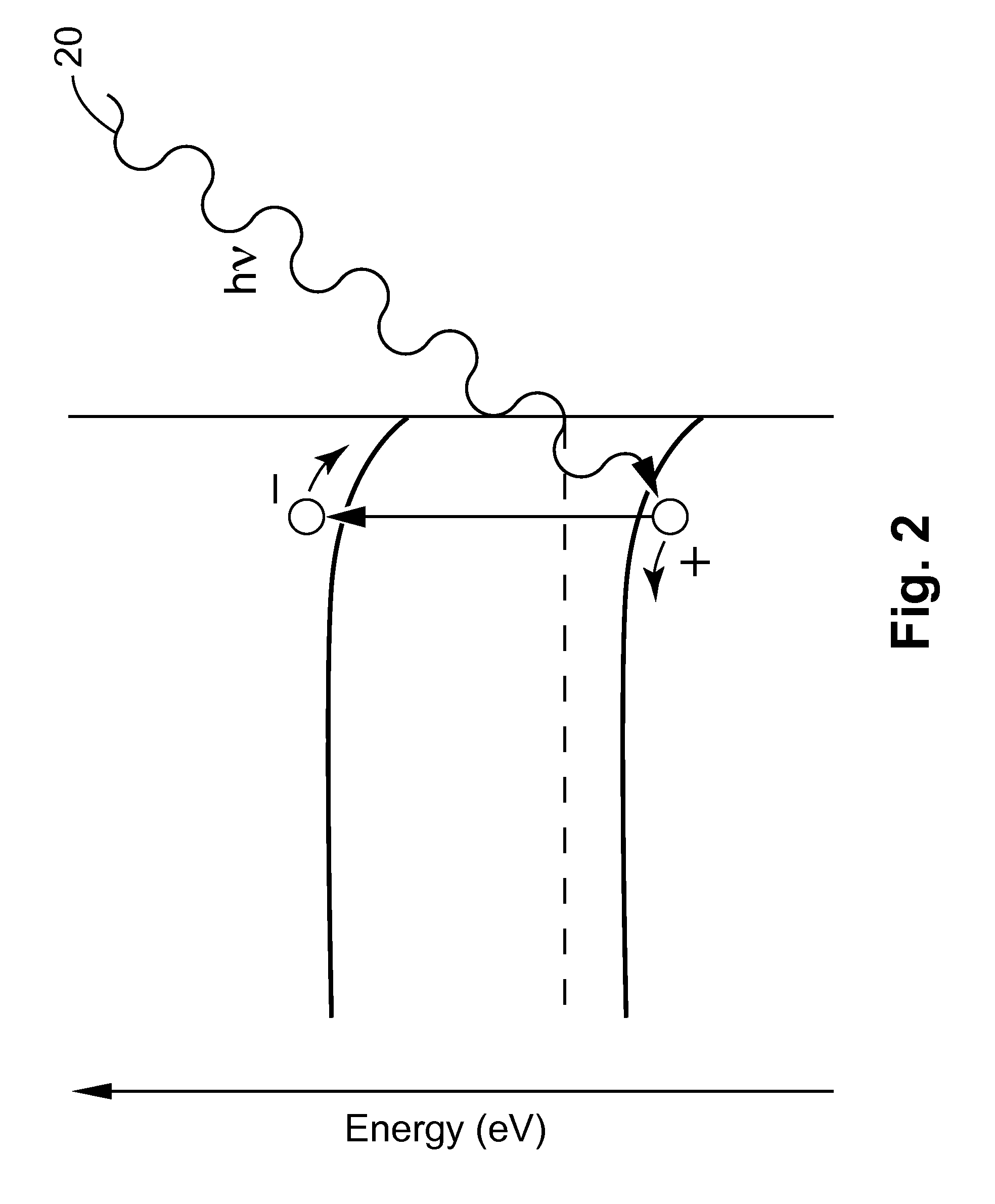

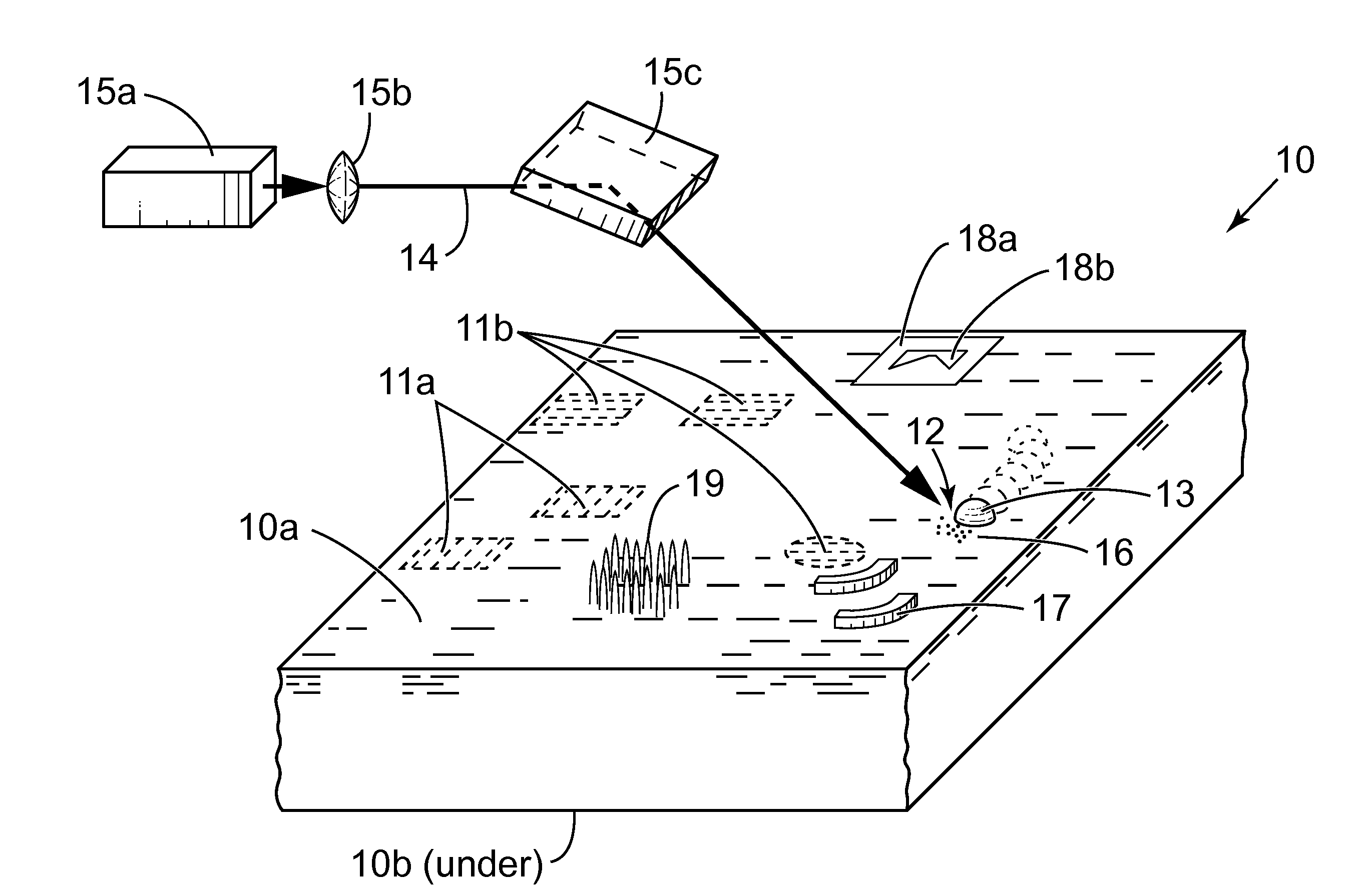

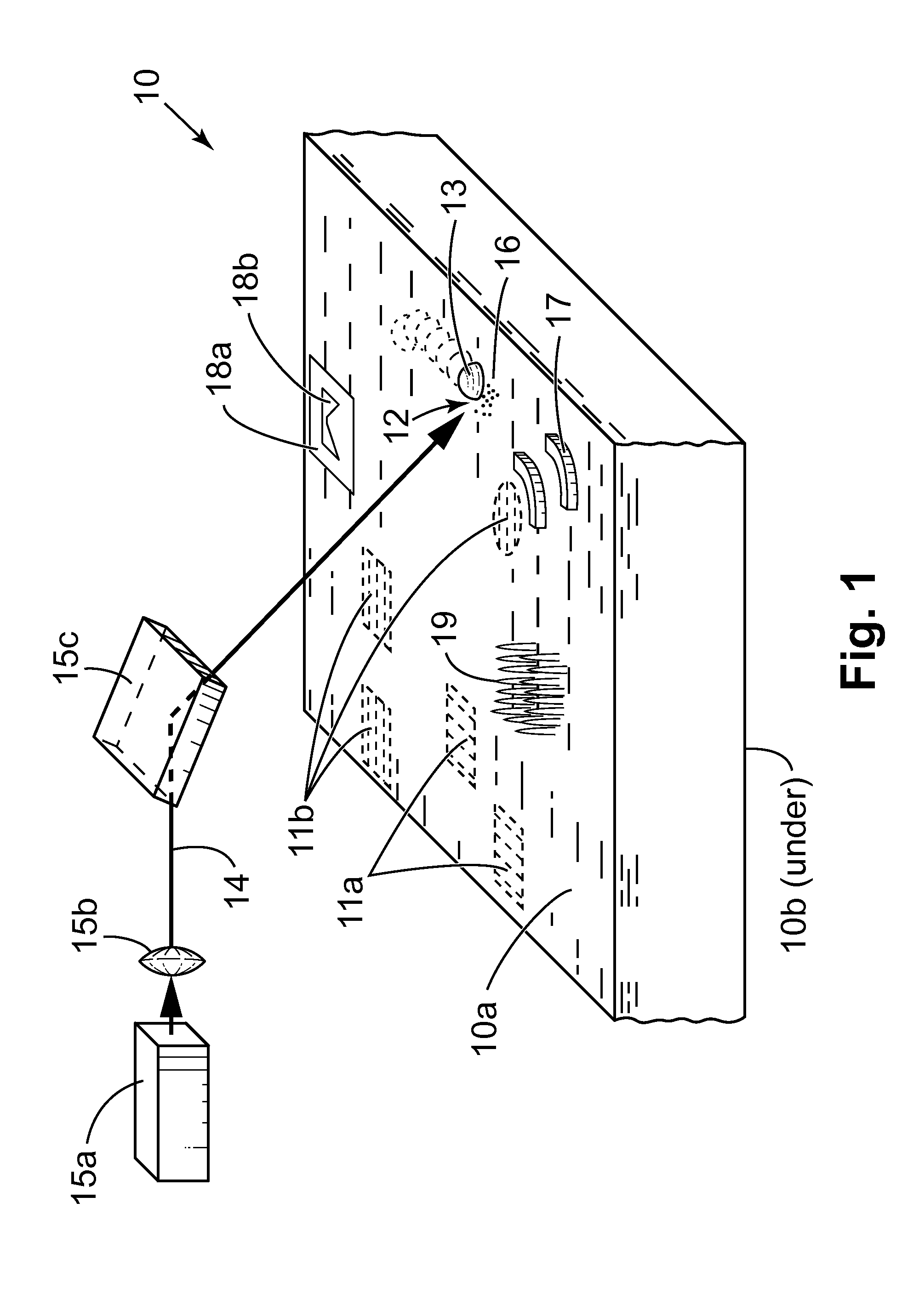

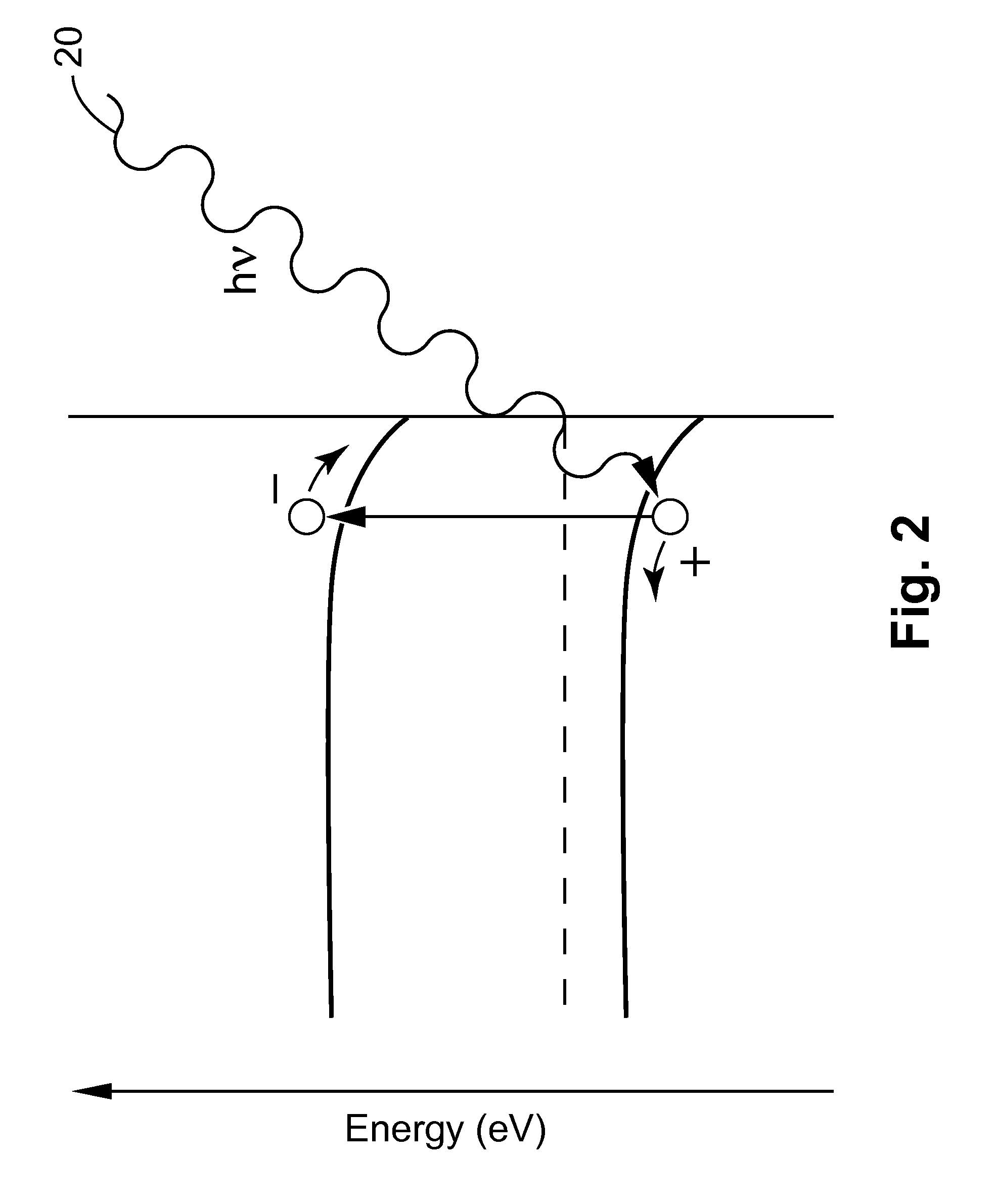

Microscale Fluid Transport Using Optically Controlled Marangoni Effect

Low energy light illumination and either a doped semiconductor surface or a surface-plasmon supporting surface are used in combination for manipulating a fluid on the surface in the absence of any applied electric fields or flow channels. Precise control of fluid flow is achieved by applying focused or tightly collimated low energy light to the surface-fluid interface. In the first embodiment, with an appropriate dopant level in the semiconductor substrate, optically excited charge carriers are made to move to the surface when illuminated. In a second embodiment, with a thin-film noble metal surface on a dispersive substrate, optically excited surface plasmons are created for fluid manipulation. This electrode-less optical control of the Marangoni effect provides re-configurable manipulations of fluid flow, thereby paving the way for reprogrammable microfluidic devices.

Owner:UT BATTELLE LLC

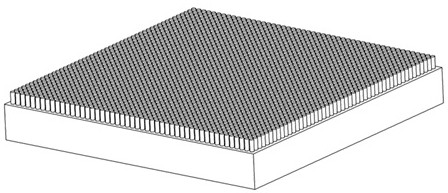

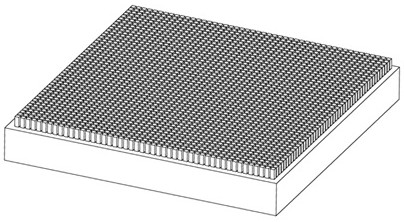

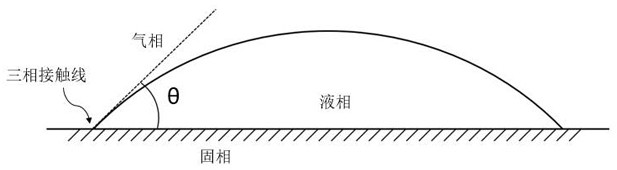

Bionic gradient super-hydrophobic structure design method based on Marangoni effect

ActiveCN112487635AEliminate the effects ofFunctionalMaterial nanotechnologyDesign optimisation/simulationSuperhydrophobeSurface tension force

The invention relates to a bionic gradient super-hydrophobic structure design method based on the Marangoni effect, and belongs to the technical field of micro-nano structure functional surface designand preparation. The method includes: single surface array structure is firstly constructed according to the characteristics of the hydrophobic surface structure, and the contact angle of the surfacestructure is calculated in combination with a Wenzel and Cassie model; different single array structures with the same parameters are constructed, the contact angles of all the structure models are compared, a structure sequence is constructed according to the contact angles, the structure parameters are finely adjusted, and then the structure sequence is constructed to form a continuous gradientcomposite array structure; a nanometer heating sheet is installed on a single structure, different temperature values are set to form a temperature gradient, and under the coupling of the structure gradient and the temperature gradient, due to the change of surface tension, liquid drops spontaneously move from a surface with a large contact angle to a surface with a small contact angle. Therefore, the surface tension difference caused by the Marangoni effect promotes directional movement and automatic rolling of the liquid drops, so that the self-cleaning characteristic is realized.

Owner:JILIN UNIV

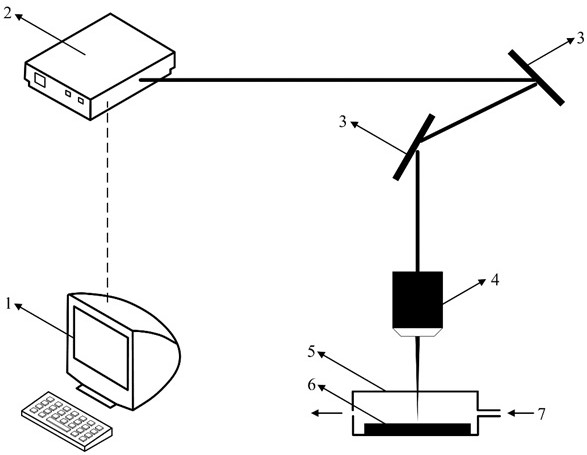

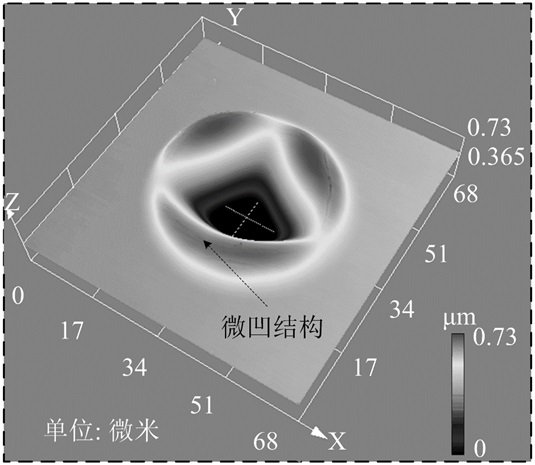

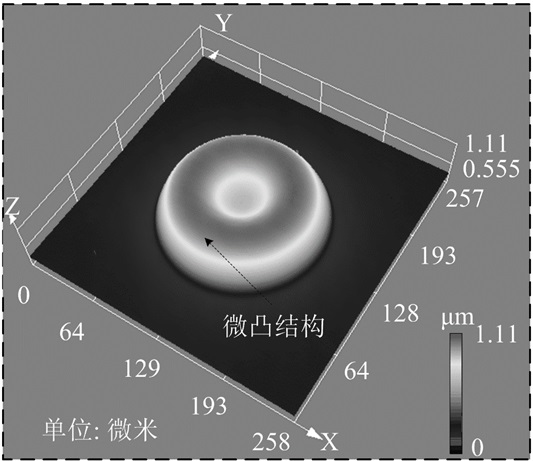

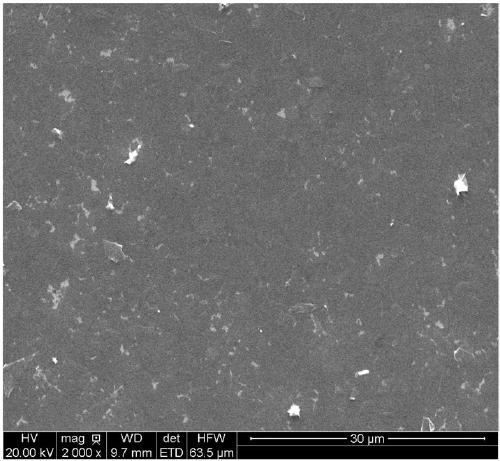

Method for preparing micro-concave and micro-convex structures on amorphous alloy through nanosecond laser irradiation

ActiveCN112692434ASimple methodFlexible approachLaser beam welding apparatusConvex structureNanosecond laser

The invention relates to a method for preparing micro-concave and micro-convex structures on amorphous alloy through nanosecond laser irradiation, and belongs to the field of processing of micro-nano structures on the surface of amorphous alloy. The method comprises the steps that the surface of a amorphous alloy material is ground and polished, and then the surface is cleaned and dried; and nanosecond laser point irradiation is conducted on the surface of the amorphous alloy by taking argon as a protective gas, a coupling action relationship between the recoil pressure of an irradiation point and a Marangoni effect is regulated and controlled by controlling peak laser power intensity and the number of laser pulses, and then, the micro-concave structure or the micro-convex structure is formed in an irradiation point region through inducing. According to the method, based on the amorphous alloy melt flow effect induced by nanosecond laser irradiation, the regular micro-concave or micro-convex structure can be prepared on the surface of the amorphous alloy by simply changing laser irradiation parameters, and the method has the advantages of simplicity, convenience, flexibility, quickness, controllability, low cost and the like, and has wide application prospects in the fields of biomedicine, micro-optical systems, micro-fluidic control and the like.

Owner:JILIN UNIV

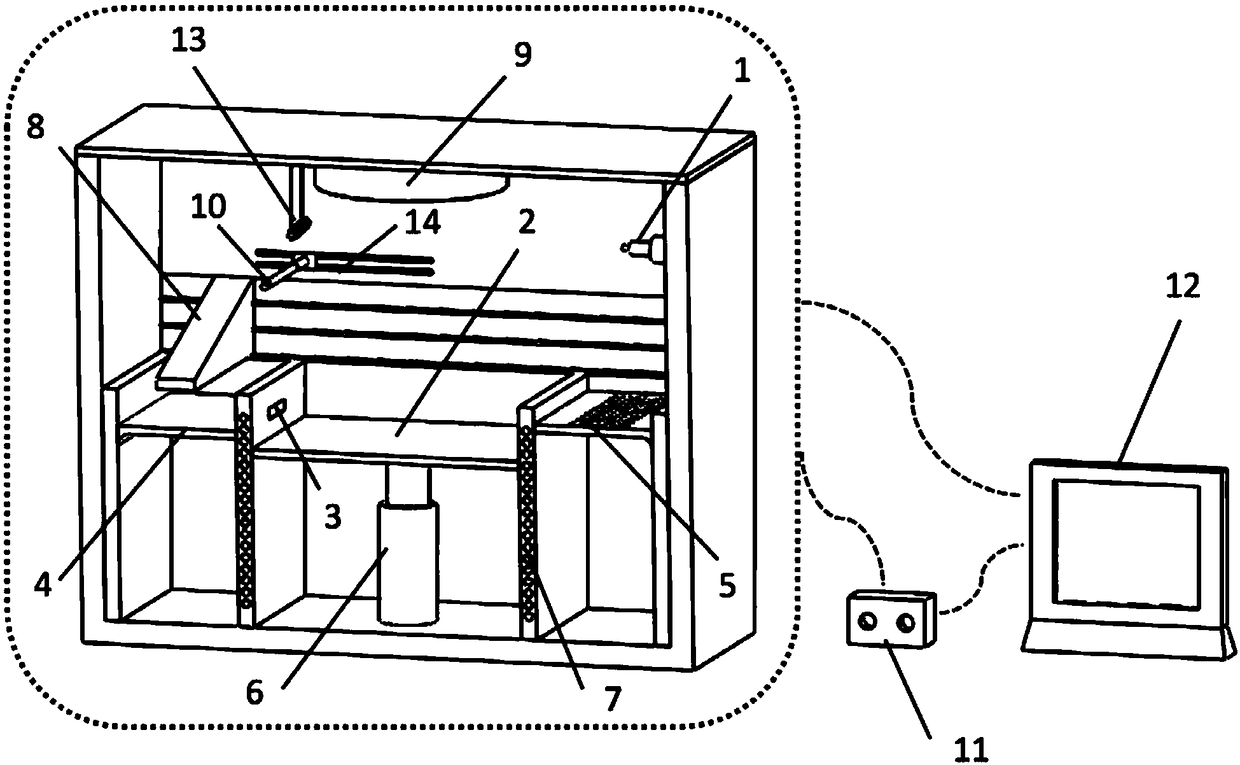

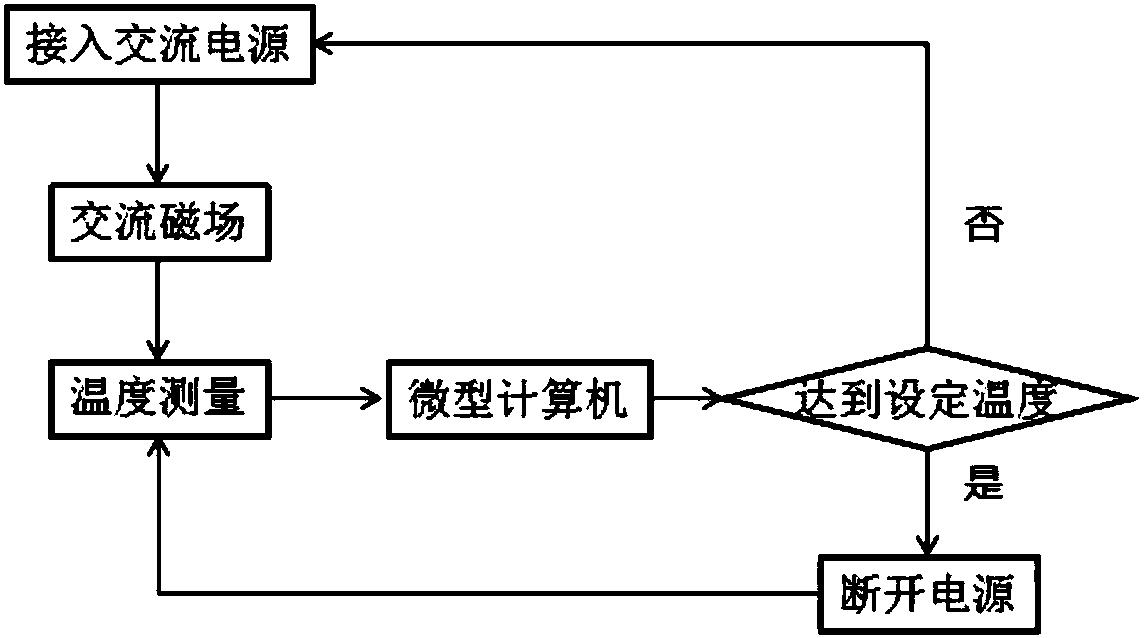

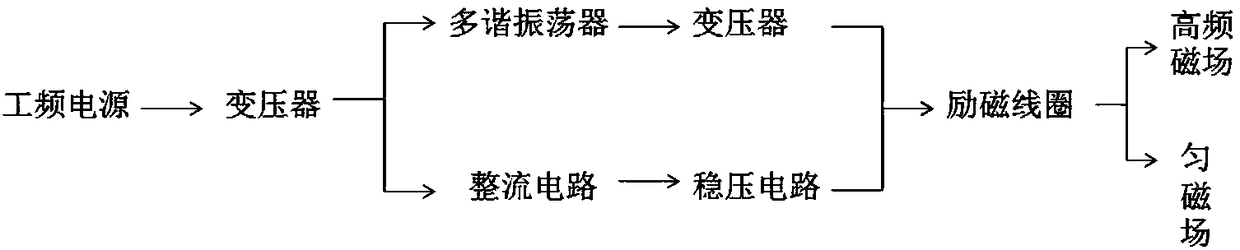

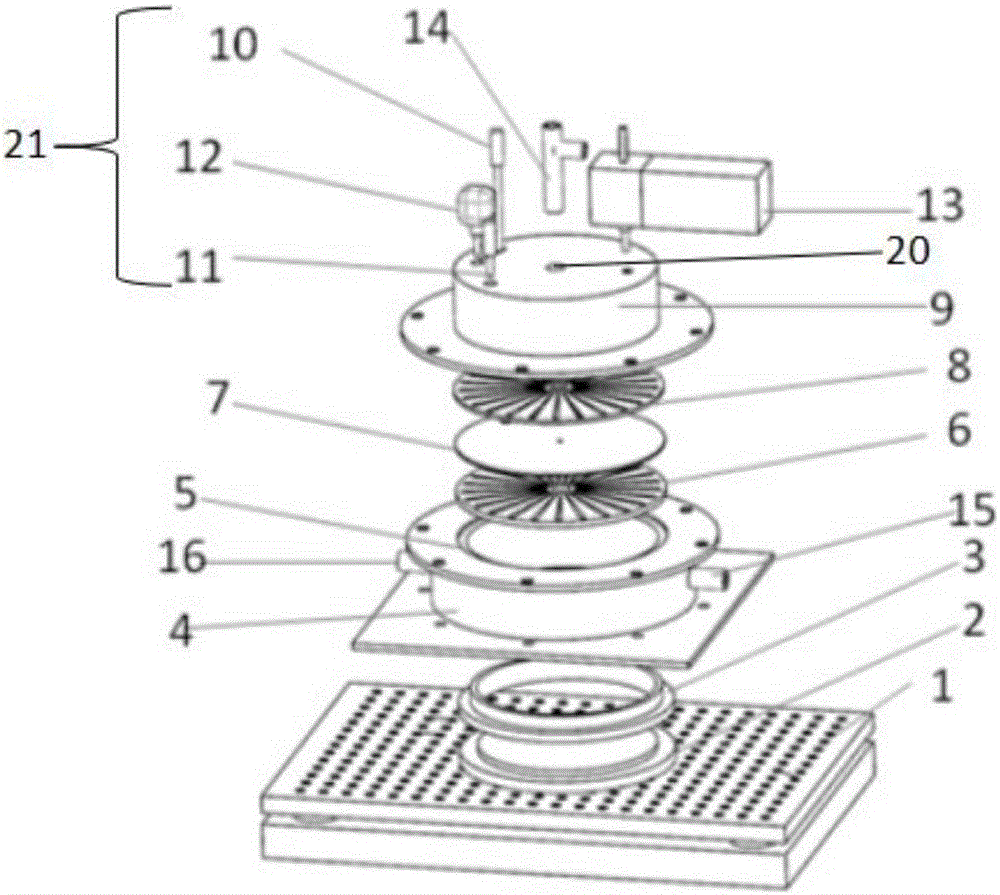

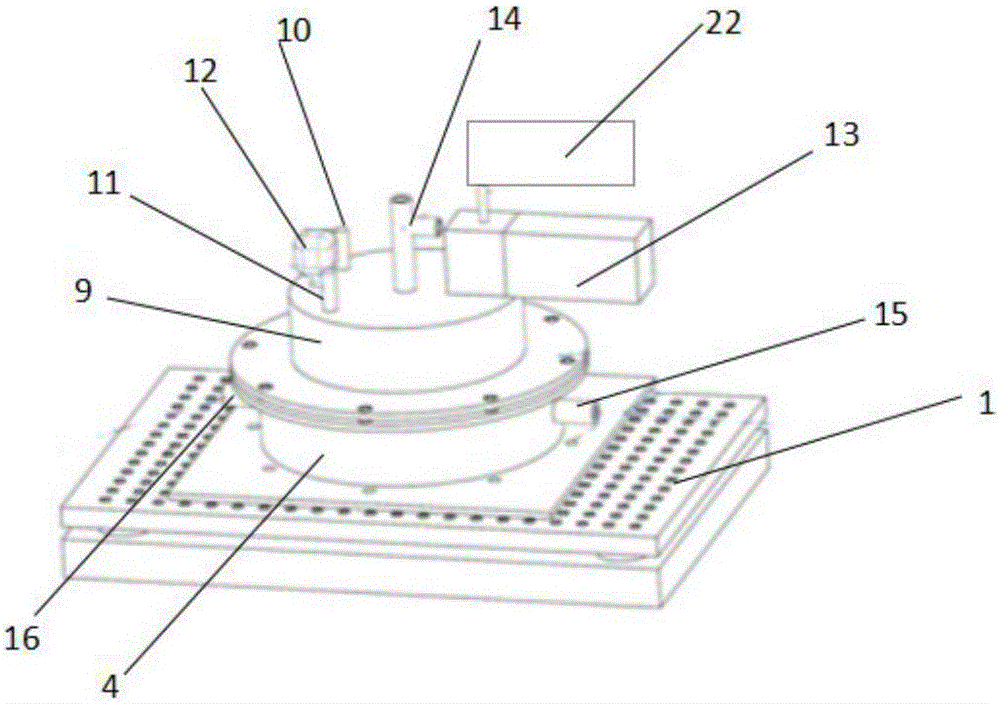

Thermo-magnetic coupling field cooperated selective laser-melting device and heating method thereof

ActiveCN108421976AImprovement is difficult to control, and there are defects such as coarse dendritesImprove the mechanical properties of defectsAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a thermo-magnetic coupling field cooperated selective laser-melting device and a heating method thereof. The thermo-magnetic coupling field cooperated selective laser-melting device is characterized in that a magnetic field generator is introduced on the basis of conventional laser selective sintering and heating; during normal printing, a control system controls the magnetic field generator to generate stable static magnetic fields; the static magnetic fields provide lorentz force to change flow field distribution, in a workpiece printing process, of a molten pool; when a workpiece is printed and accumulated to certain thickness, the magnetic field generator is controlled to generate alternating magnetic fields for heating, tempering and thermally treating the workpiece, and then naturally cooling the workpiece to the room temperature; and workpiece printing is continued according to the method until workpiece printing is ended. In a printing process, an unevenworkpiece effect generated by the Marangoni effect can be reduced, various defects caused by the printing process further can be eliminated, crystalline grains are refined, segregation is eliminated,and internal stress is reduced, so that the structure and the performance of the workpiece are more uniform, and therefore, growth of a metallographic structure of a printing material is promoted, and hardness and strength of the workpiece are improved.

Owner:湖南珞佳智能科技有限公司

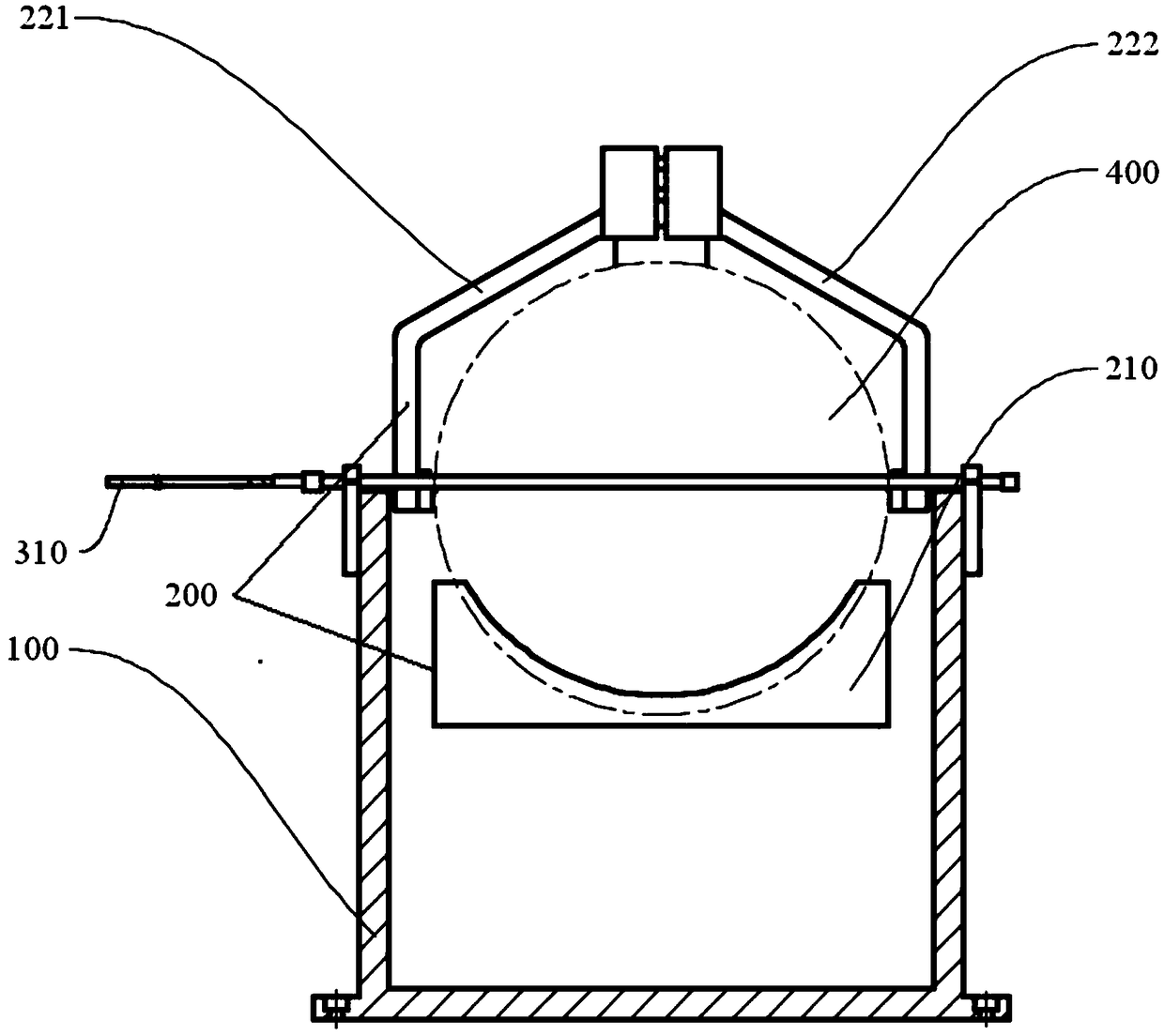

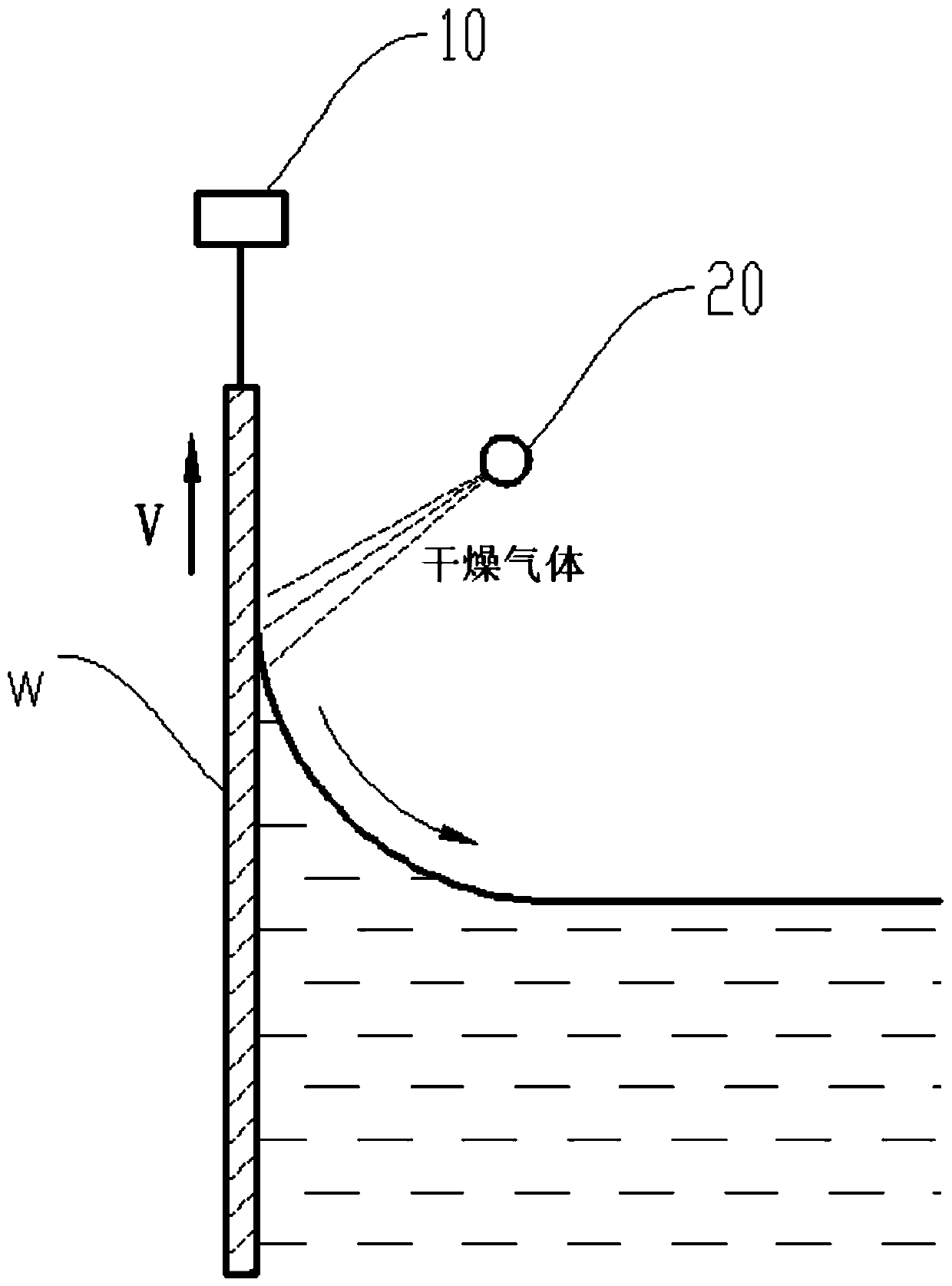

Marangoni effect-based wafer post-treatment system and method

PendingCN110265327AAchieve cleaningAchieve dryingSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to the technical field of chemical mechanical polishing post-treatment, and discloses a Marangoni effect-based wafer post-treatment system and method. The system comprises a wafer lifting device and a gas spraying device, wherein the wafer lifting device is used for pulling a wafer immersed in a cleaning liquid from the cleaning liquid, the gas spraying device is used for spraying a dried gas at a first temperature to a bent liquid surface region of the cleaning liquid attached onto a surface of the wafer during the process of lifting the wafer from the cleaning liquid, so that an attachment substance on the surface of the wafer is stripped from the surface of the wafer according to a direction opposite to a lifting direction.

Owner:TSINGHUA UNIV

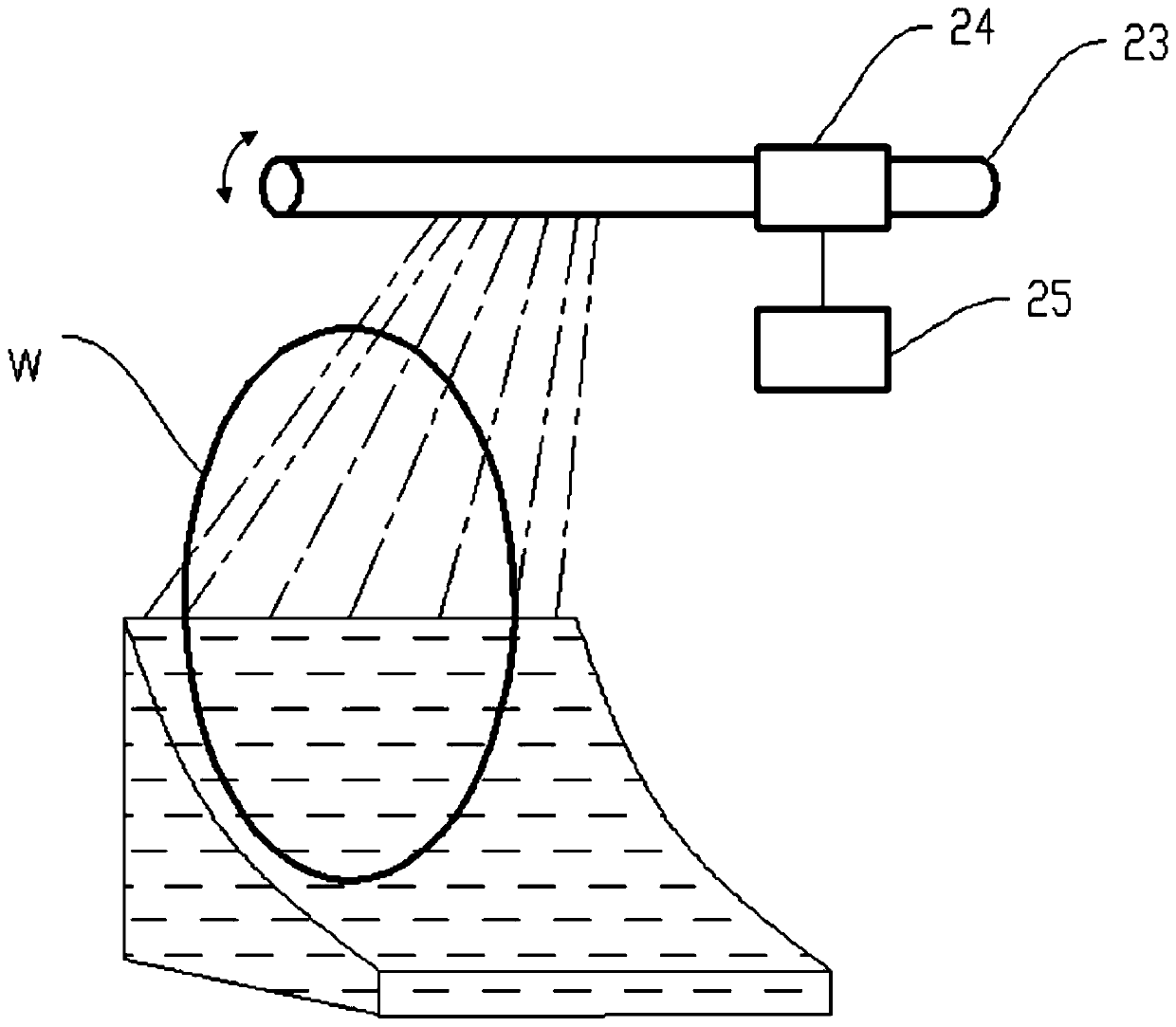

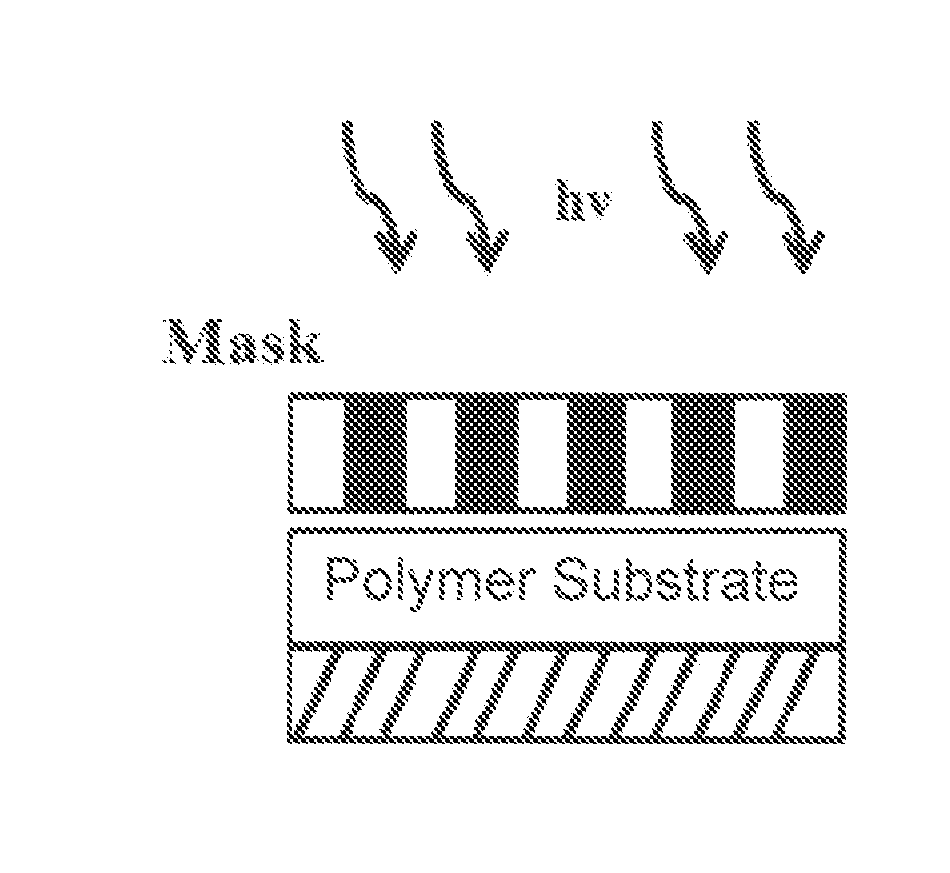

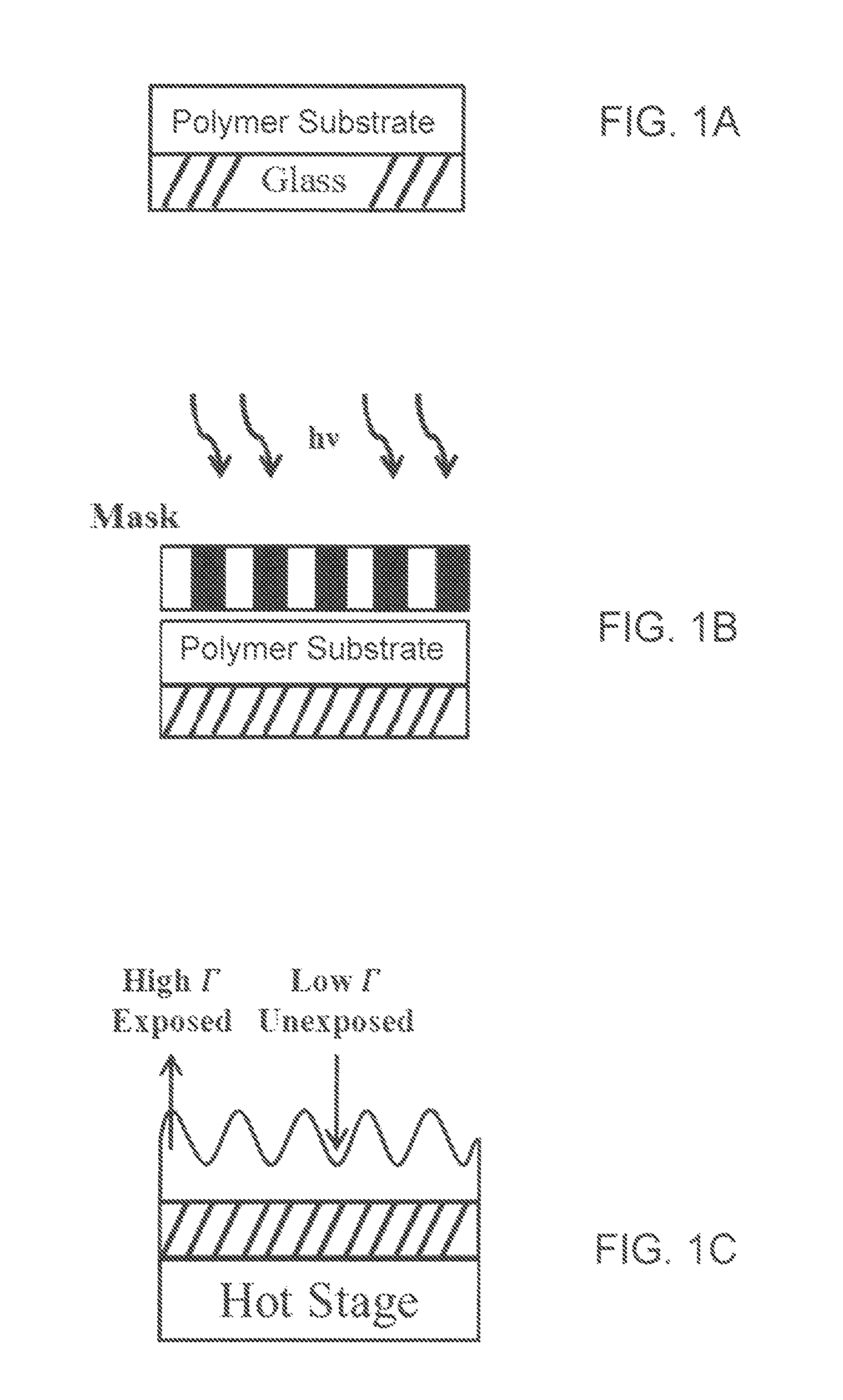

Method for creating topographical patterns in polymers via surface energy patterned films and the marangoni effect

ActiveUS20140054822A1Decorative surface effectsDuplicating/marking methodsBroadband light sourceBroadband

Using a broadband light source and a photomask, surface energy gradients can be directly transferred into polymer films. The Marangoni effect causes high surface energy regions to rise upon heating the film. This leads to the formation of three-dimensional topography that can be locked in by quenching the polymer by cooling.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

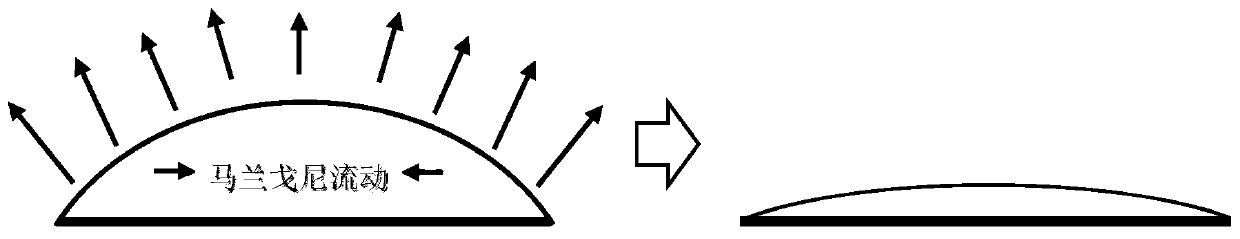

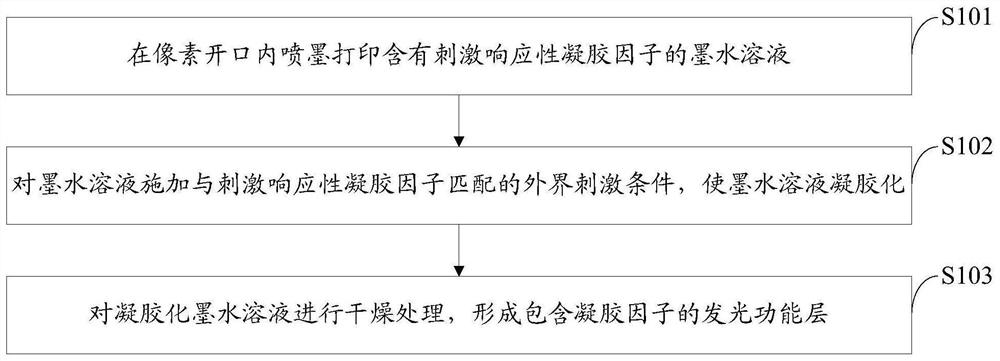

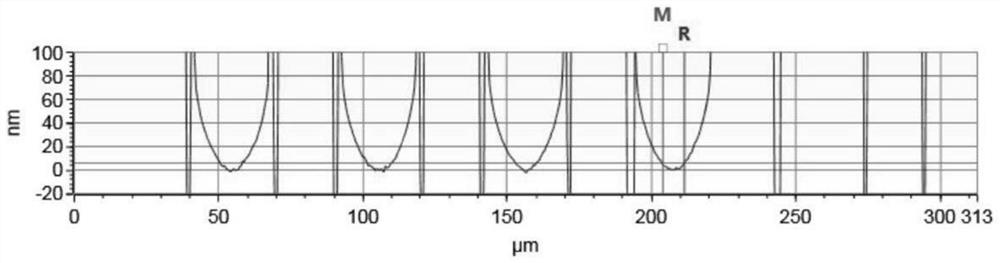

Ink-jet printing method, ink-jet printing device, ink-jet printing equipment and computer-readable storage medium

ActiveCN111137013AAffect performancePrevent the problem of uneven thickness of the film surfacePrintingDigital output to print unitsOrganic light emitting deviceComputer printing

The invention discloses an ink-jet printing method, an ink-jet printing device, ink-jet printing equipment and a computer-readable storage medium. The method is applied to an organic light-emitting device thin film, and comprises the following steps of acquiring a current position of a printing head of an ink-jet printer; and adjusting the moving distance of the printing head of the ink-jet printer according to the current position. The ink jet printing method is capable of controlling the thickness of the film surface by adjusting the moving distance of the printing head of the ink jet printer so that the problem of uneven thickness of the film surface caused by capillary flow and a Marangoni effect can be solved. Compared with the prior art in which the thickness of the film surface is controlled by adjusting the type and proportion of solvents, the ink jet printing method is low in cost, and can avoid the situation that an additive influences the performance of a device.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Spray area adjustable swing sprinkler

InactiveCN108713476AImproved Moment of InertiaImprove environmental qualityPump componentsExhaust apparatusRemote controlEngineering

The invention discloses a spray area adjustable swing sprinkler. A plurality of sharp foaming membranes are formed on a first noise reduction filter tube in a spray tube (19), and the sharp foaming membranes are foaming membranes with filter nets arranged on tips of pentagonal tapers; the second noise reduction filter tube is provided with a plurality of triangular taper tips; a steering chamber (18) is provided with a swinging steering device (23), and the spray tube and a spray head are provided with a plurality of sections of steerable joints and telescopic arms to be the spray area adjustable swing sprinkler; a walking wheel (g18) is a single wheel supporting the ground surface, and is provided with a power device and remote control; the ridges of the pyramids of the tips of the pentagonal tapers of the sharp foaming membranes form an angle of 45 degrees with the surface of a bearing bottom to obtain a contact angle approximating the MARANGONI EFFECT.

Owner:NINGBO DAYE GARDEN IND

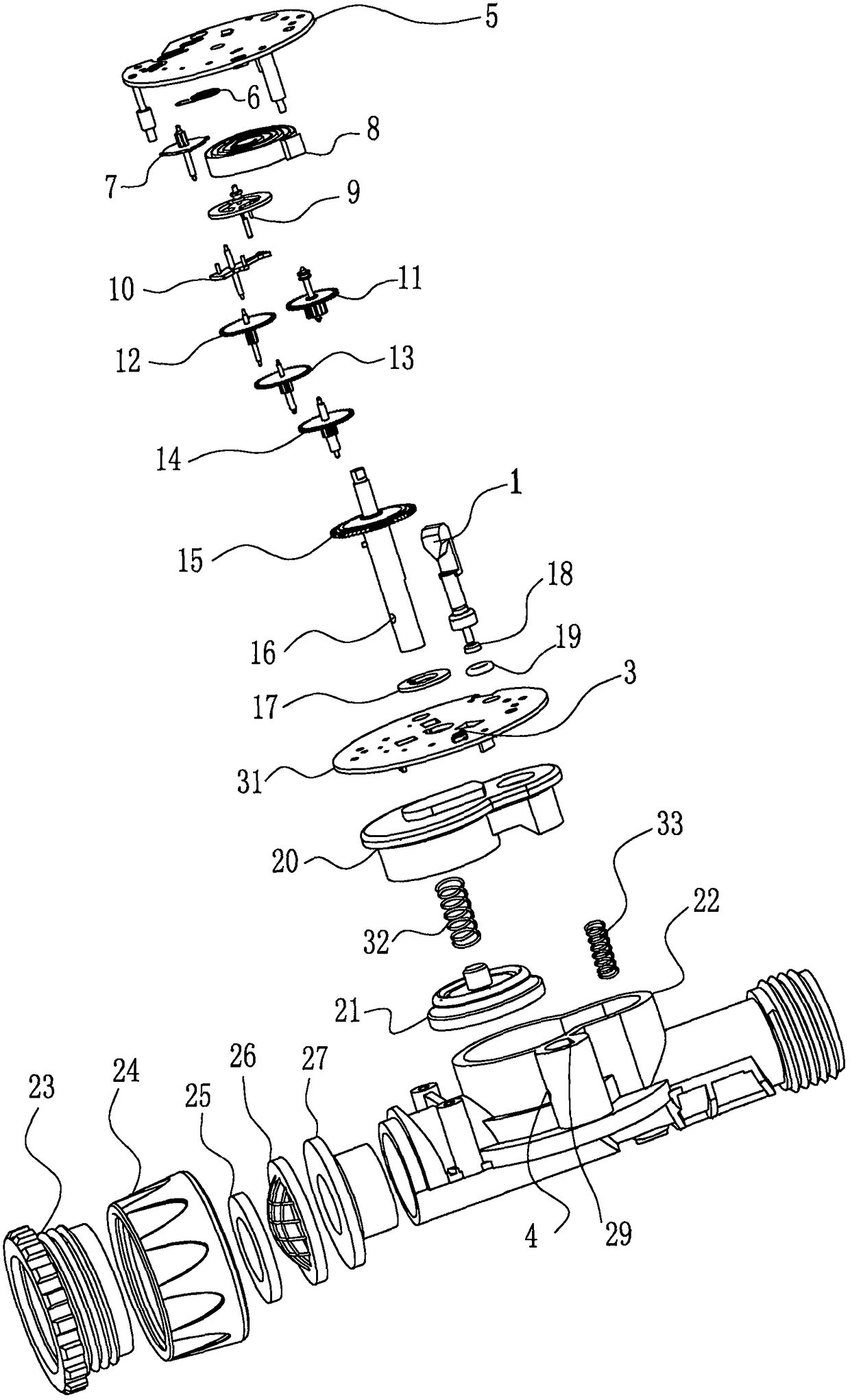

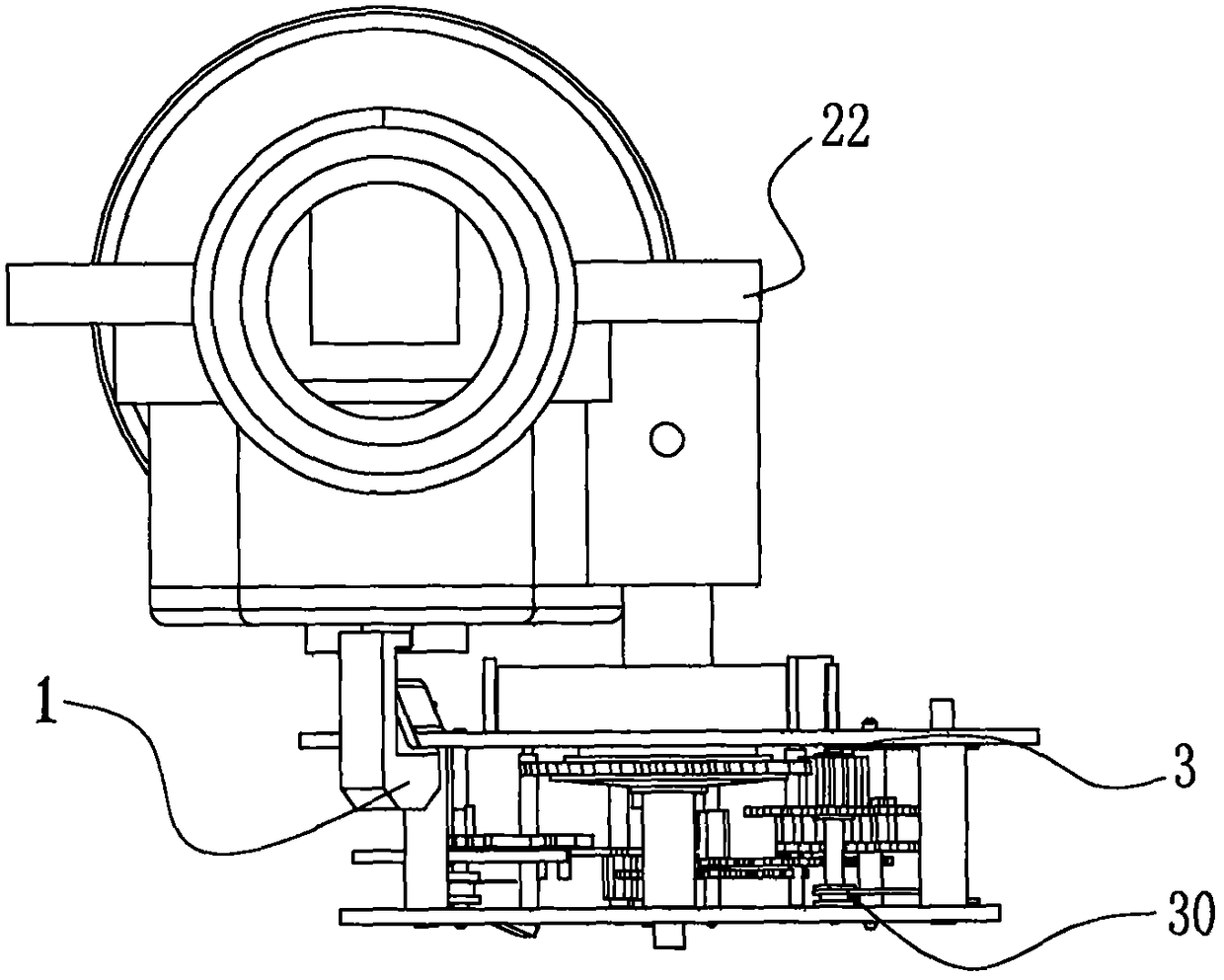

Flow adjustable type timer

InactiveCN108591589AImprove batch export qualityIncrease lossOperating means/releasing devices for valvesWatering devicesEngineeringAlloy coating

A flow adjustable type timer is formed by connecting a mechanical timer and an electromagnetic pump in series. The flow adjustable type timer is characterized in that a roller of a triggering bump 21eof an adjusting controlling rod 21d is a magnetic rolling column body; a gear bump 21g arranged on an adjusting controlling handle of the adjusting controlling rod is a protruded body containing a cubic curve with impact resisting property; in case of adjusting flow, a potentiometer can be simply rotated, and an electromagnetic pump coil connected to a potentiometer Rw and a diode can be changed;the voltage and the current in absorbing of a soft magnetic valve element change through coils of the potentiometer and the diode, thus the flow changes, and as a result, the flow adjustable timer isformed; a valve overflowing hole in a flexible main control valve element (21) is pentagonal; a wedge filtering sheet forms a 45-degree contact angle in order to be close to Marangoni effect; a microthrough hole is drilled through laser; a fatigue-free alloy coating is plated by a vacuum coating technology; and a micro laminated composite material is manufactured by electronic printing.

Owner:NINGBO DAYE GARDEN IND

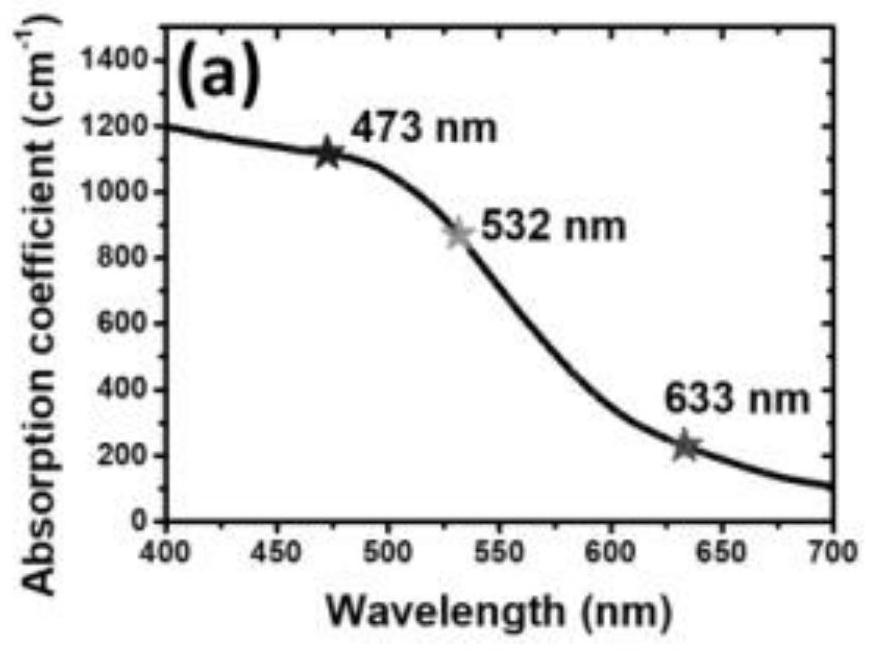

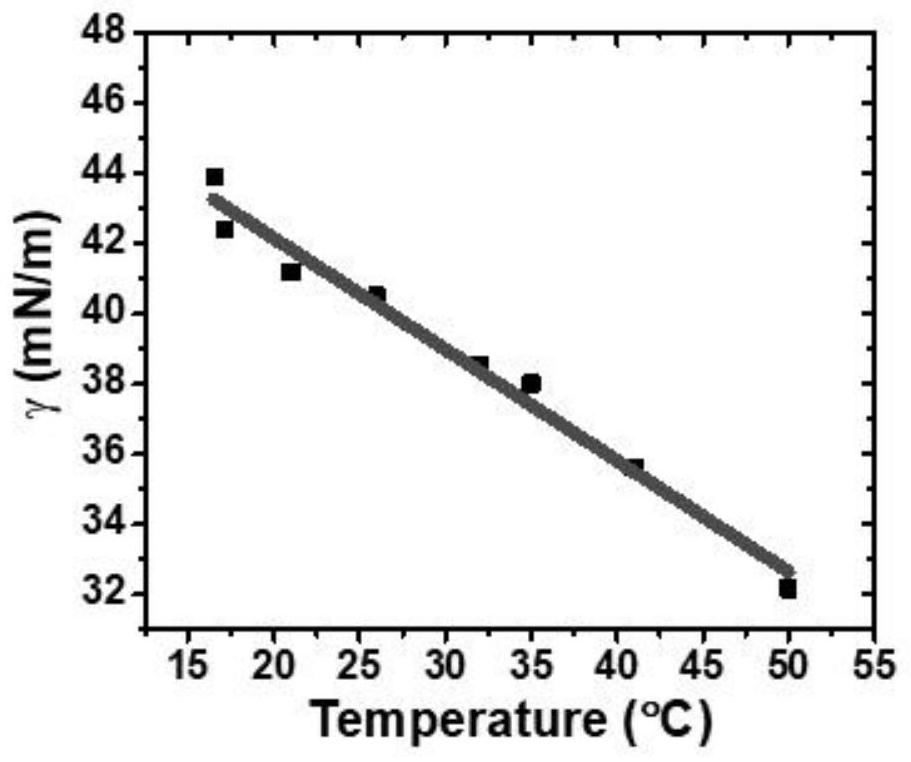

Method for generating Marangoni effect

ActiveCN112683737AOriginals for photomechanical treatmentSurface tension analysisAbsorbed energySurface tension force

The invention discloses a method for generating a Marangoni effect, a method for achieving engraving based on the Marangoni effect and a method for driving liquid to move. The method for generating the Marangoni effect comprises the steps that a light source is used for irradiating or a heat source is close to a solution A, the solution A absorbs energy to generate a local temperature difference, and the Marangoni effect is generated; the solution A is a solution which is strong in photo-thermal absorption and large in surface tension change coefficient along with temperature. Through holes and / or pits in various shapes can be carved, the movement direction of driving liquid can be controlled, vertical, horizontal and inclined movement can be achieved, repeatability is achieved, the application range is wide, the application potential is large, and energy efficiency conversion is high.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

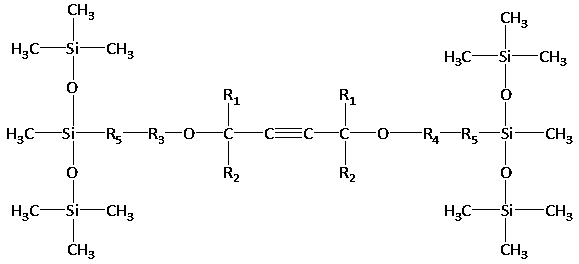

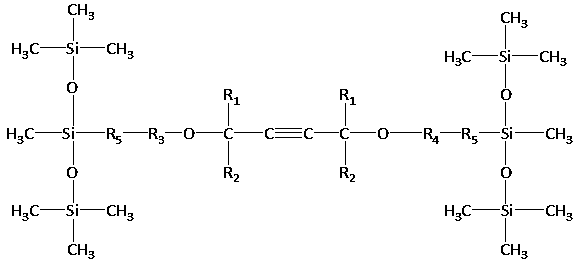

Superspreading wetting agent and preparation method thereof

InactiveCN110818890AImprove wettabilityReduce solubilityMacromolecular adhesive additivesCoatingsCritical micelle concentrationActive agent

The invention discloses a superspreading wetting agent. The superspreading wetting agent is silane-modified acetylenic diol polyether. The critical micelle concentration of the superspreading wettingagent in water is low; the superspreading wetting agent shows a superspreading phenomenon on the surface of a substrate and has an excellent wetting effect on the substrate; the superspreading wettingagent is short in balance time in a water-based system, and the tension difference between the inner surfaces and the outer surfaces of bubbles is large, so the Gibbs-Marangoni effect is counteractedand the bubbles are rapidly broken; and the superspreading wetting agent is a surfactant with unstable bubbles.

Owner:福建华夏蓝新材料科技有限公司

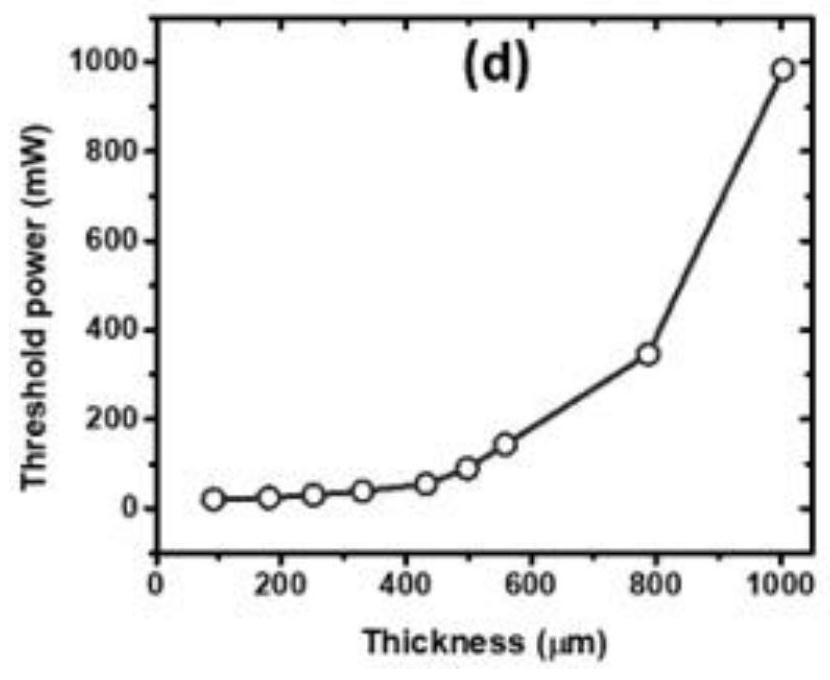

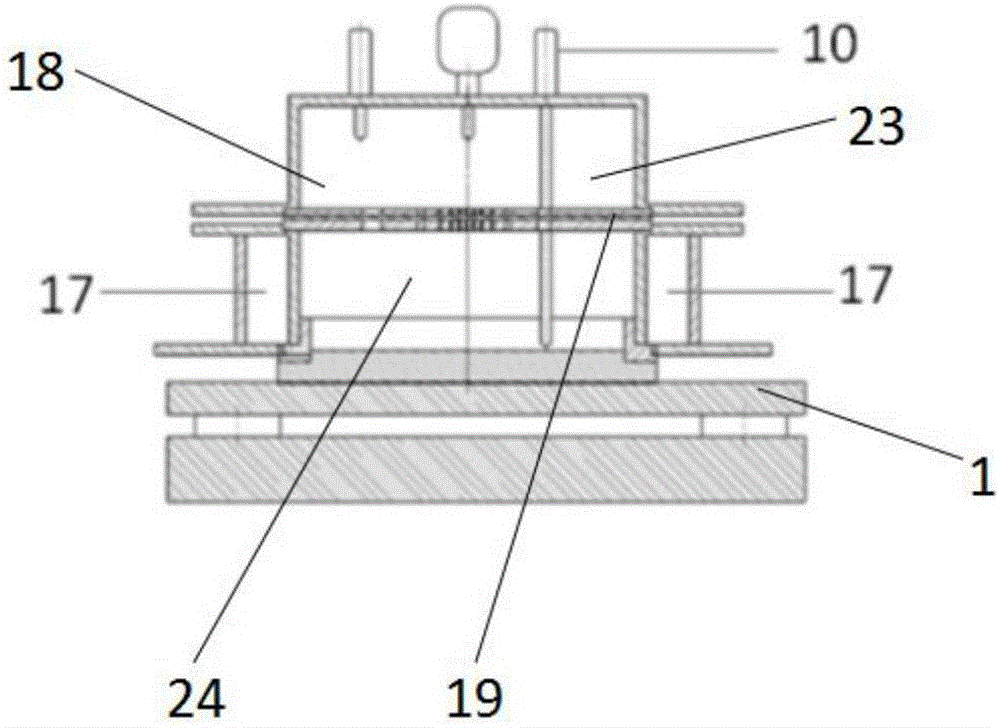

Polymer film casting method preparation device

ActiveCN106832362AReduce the impact of vibrationVapor discharge rate monitoring and controlSustainable biological treatmentLiquid statePorous membrane

The invention discloses a polymer film casting method preparation device which comprises a damping base, a casting mold, an upper cover, a monitoring unit and a mass flow controller, wherein the casting mold is connected with the damping base through a middle cylinder; the upper cover is connected with the middle cylinder to enable the casting mold to form a sealed casting cavity; a sealing ring and a porous membrane component are arranged at the connecting part of the upper cover and the middle cylinder; an interface for charging air and feeding a polymer solution is formed in the upper cover; the monitoring unit is connected with the upper cover and is communicated with the sealed casting cavity; the mass flow controller is communicated with the sealed casting cavity through the upper cover; and the mass flow controller is connected with a vacuum pump. As significant parameters such as the temperature, the pressure, the volatilization or diffusion velocities of polymers and solvents in a gas state, a liquid state and a solid state are monitored and controlled, the casting process procedures can be well handled, optimal process parameters which can eliminate or reduce the Marangoni effect can be found, film quality problems can be reduced, the repeatability and reliability of the process can be improved, and the quality and qualification rate of the film can be finally improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

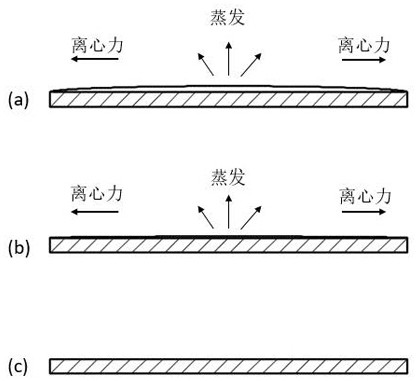

Wafer drying method and system

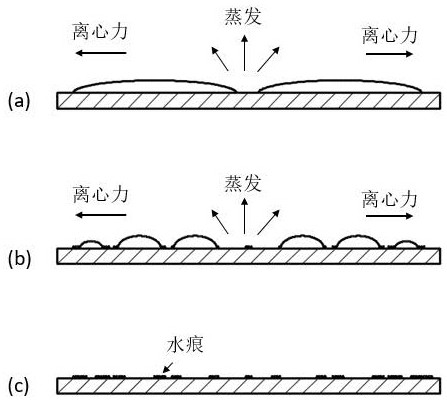

ActiveCN111739829AKeep dryAvoid it happening againSemiconductor/solid-state device manufacturingWaferComposite material

The invention discloses a wafer drying method and system. The wafer drying method comprises the steps that a wafer is made to rotate around a center shaft perpendicular to the surface of the wafer; amixed liquid is supplied to the surface of the wafer to form a liquid film of the mixed liquid on the surface of the wafer, wherein the mixed liquid is formed by dissolving a certain concentration ofa surface active material into a cleaning liquid, and the surface tension of the mixed liquid is lower than the surface tension of water; and dry gas is sprayed to the surface of the wafer to generatea Marangoni effect to enable the liquid film to be stripped from the surface of the wafer so as to realize wafer drying. The wafer drying system comprises a rotating unit, a liquid supply unit and adrying unit.

Owner:华海清科(北京)科技有限公司

Range dynamic jump adjusting type water bird sprayer

InactiveCN108636640AWide range of usesLiquid spraying apparatusInsect catchers and killersRemote controlSprayer

The invention discloses a range dynamic jump adjusting type water bird sprayer. Multiple wedge bubble films are arranged on a first noise reduction filter pipe in a spraying pipe, the wedge bubble films are formed by arranging bubble films with filter nets on pentagonal-pyramid-shaped wedges, a second noise reduction filter pipe is provided with multiple triangle-cone-shaped wedges, a swing steering gear (23) is arranged on a steering cavity (18), the spraying pipe and a spraying head are provided with multiple steering joints and a telescopic arm, and therefore a spraying area adjustable typeswing water sprayer is formed. A walking wheel (g18) is a single wheel supported on the earth surface, and is provided with a power device with a remote control function. The included angle between the bearing bottom and ridges of pyramids of the pentagonal-pyramid-shaped wedges of the wedge bubble films is 45 degrees to be approximate to the contact angle of MARANGONI EFFECT, the range dynamic jump adjusting type water bird sprayer is comprehensively prepared, and the using range is wide.

Owner:NINGBO DAYE GARDEN IND

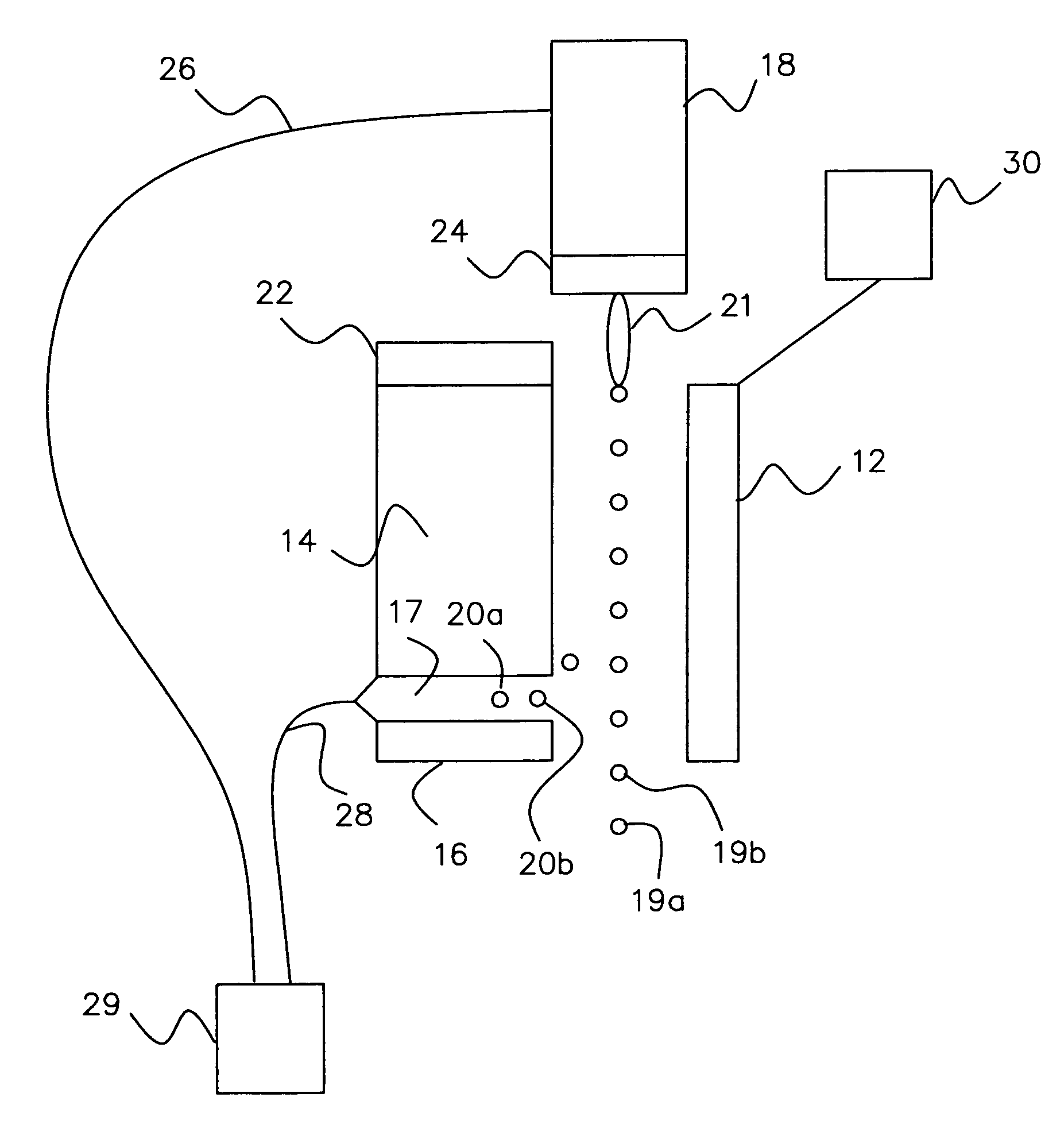

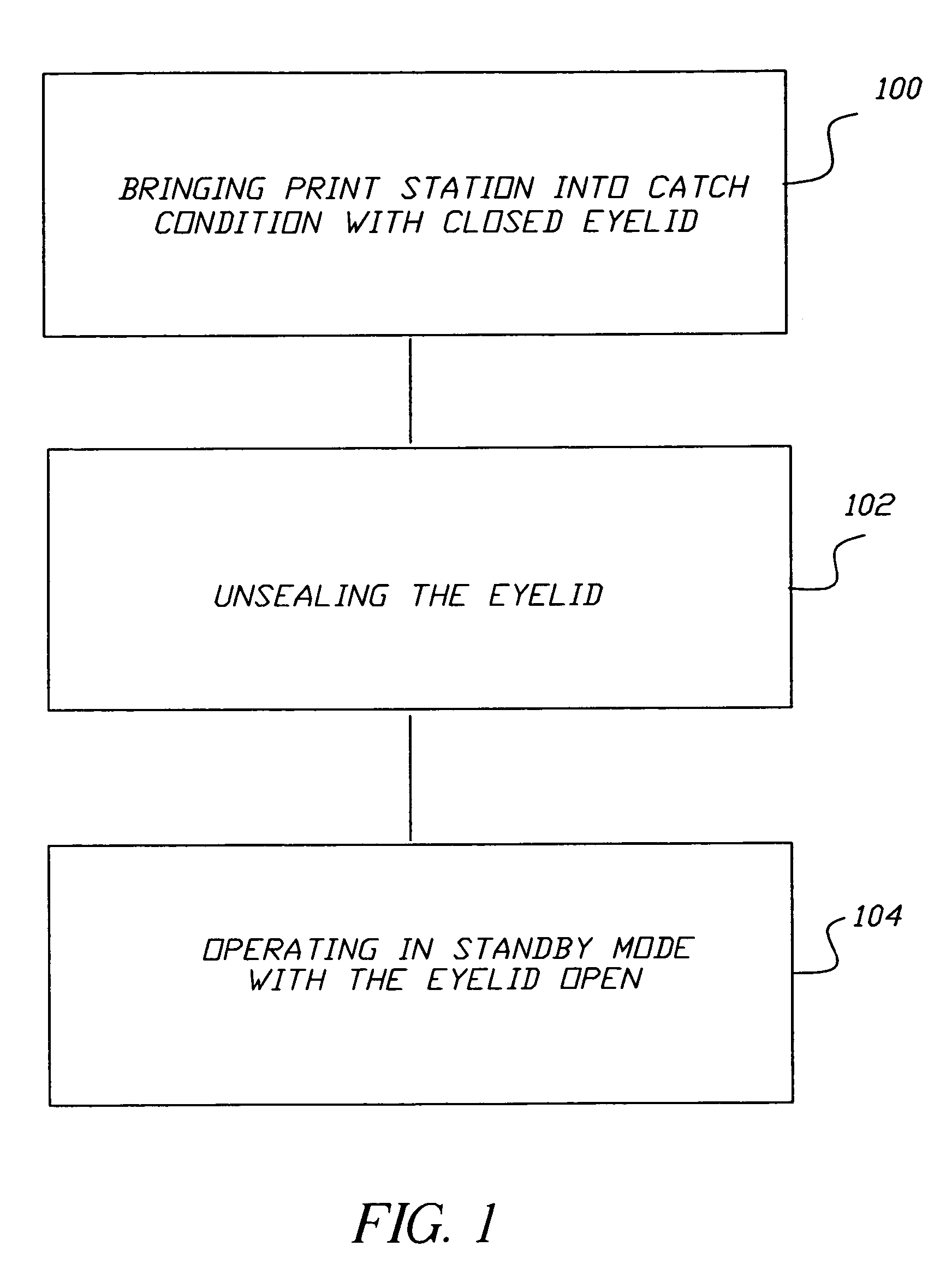

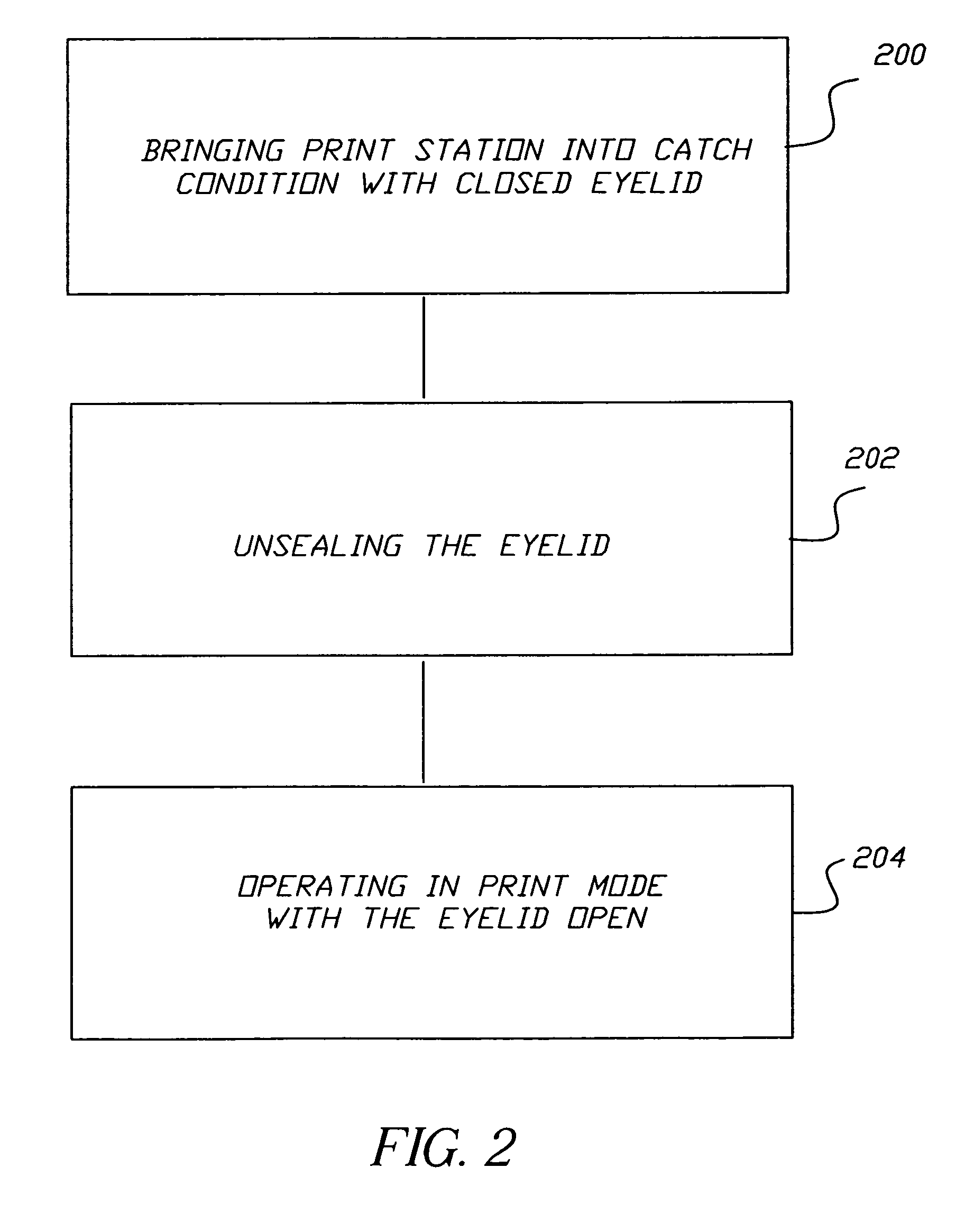

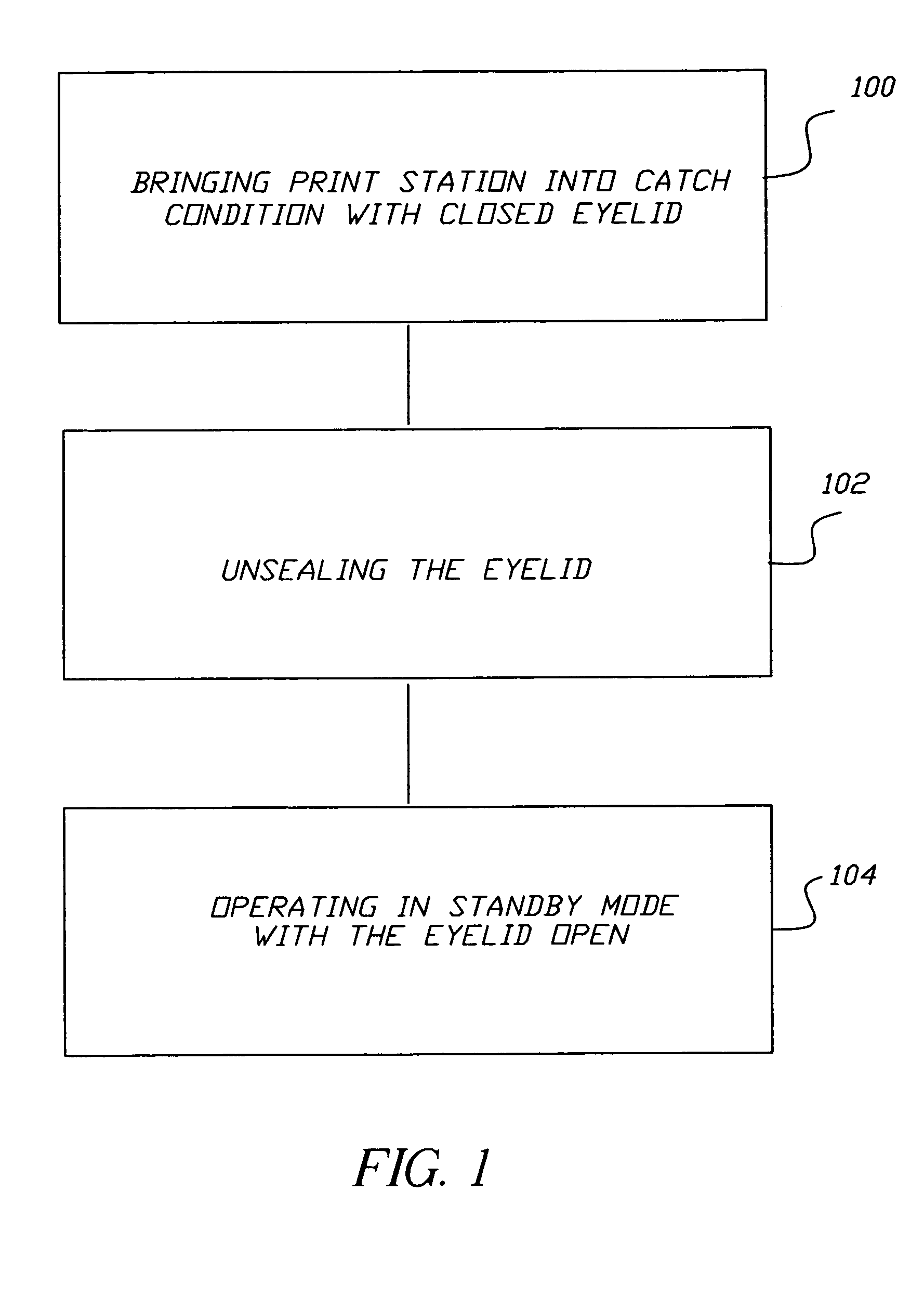

Supression of Marangoni Effect on the catcher face

Owner:EASTMAN KODAK CO

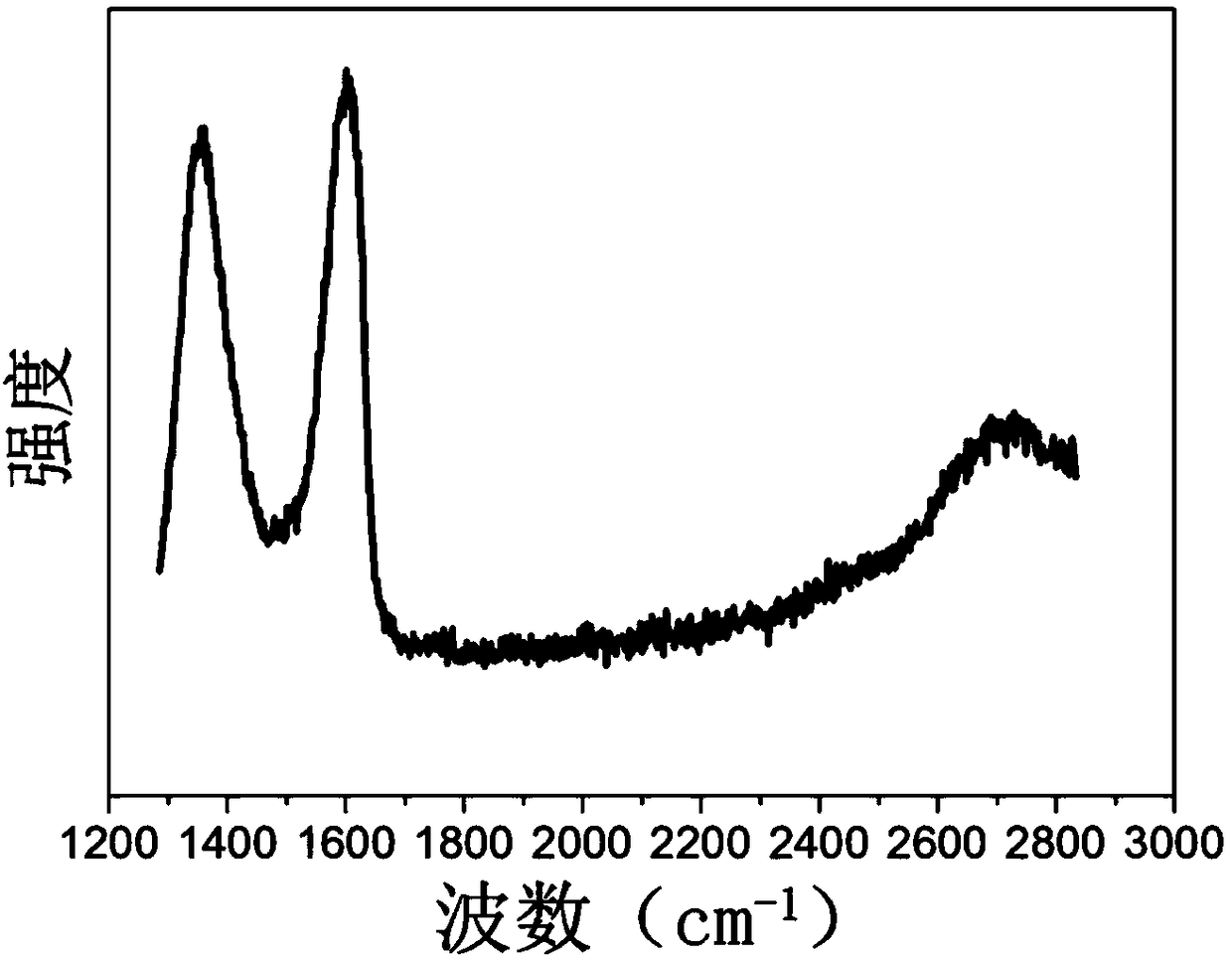

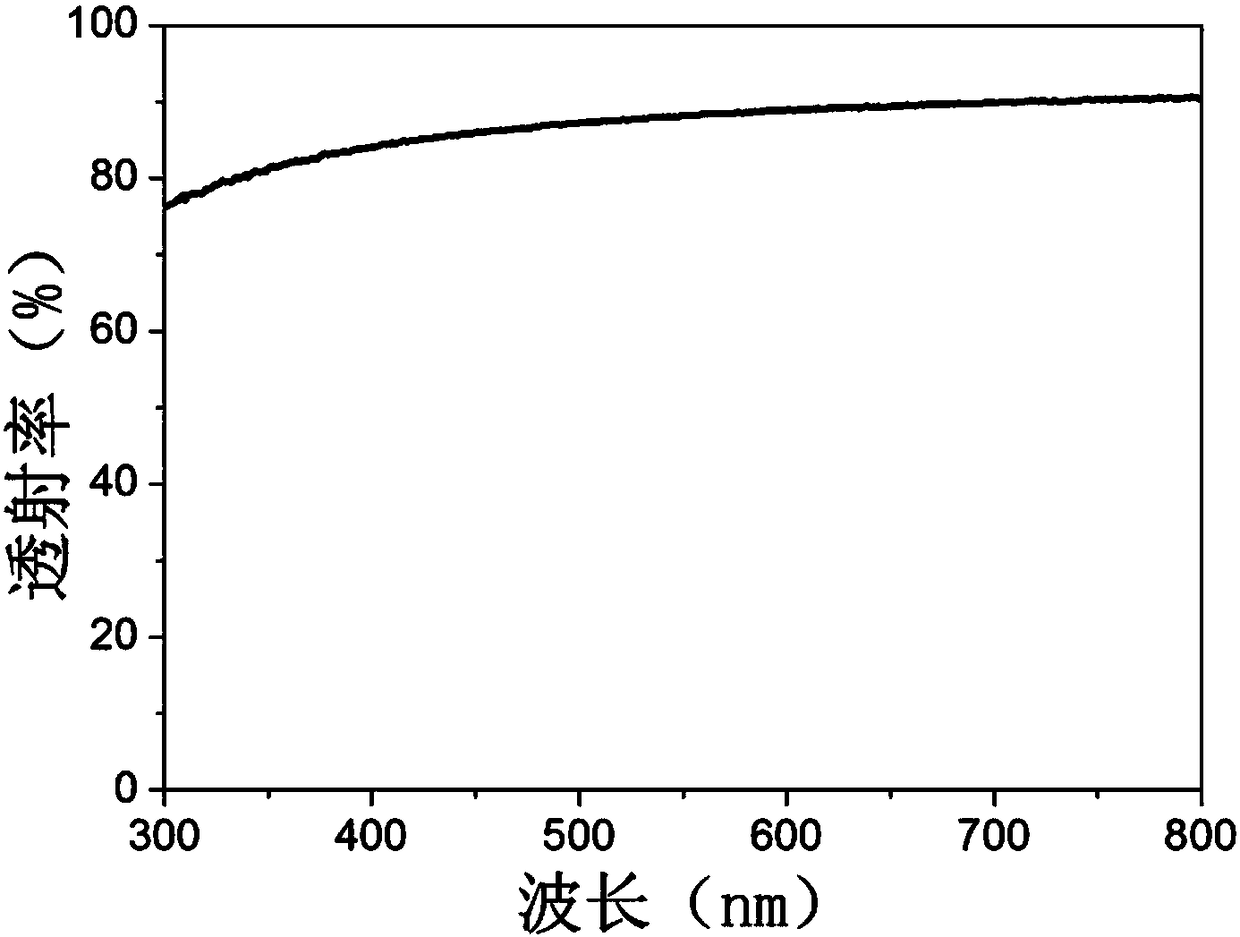

Self-assembly graphene nanometer thin film and preparing method and application thereof

PendingCN109133039AHigh light transmittanceImprove uniformityConductive layers on insulating-supportsMagnetic/electric field screeningTransmittanceThin layer

The invention relates to self-assembly graphene nanometer thin film and a preparing method and application thereof. The method specifically comprises the following steps of 1, providing first dispersing liquid, a second solvent and a substrate, wherein the first dispersing liquid comprises a first solvent and a graphene material dispersed in the first solvent; 2, dropwise adding the first dispersing liquid into the second solvent at a first speed, and based on the Marangoni effect, obtaining a thin layer of the graphene material on the liquid level of the obtained mixed liquid; 3, transferringthe obtained thin layer of the graphene material in step 2 into the substrate, and drying the obtained product to obtain the self-assembly graphene nanometer thin film. The invention further discloses the self-assembly graphene nanometer thin film prepared by means of the method and the application of the self-assembly graphene nanometer thin film. The method is quick, efficient, low in cost, safe, environmentally friendly, free of limitation on the substrate and capable of preparing the graphene nanometer thin film on a large scale. The graphene nanometer thin film is good in uniformity, high in light transmittance and excellent in electric conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Apparatus for drying substrate and method thereof

InactiveUS7322385B2Increase volumeSubstrate and the second nozzle is gradually reducedLiquid surface applicatorsLiquid fillingAlcoholEngineering

An apparatus for drying a substrate using the Marangoni effect is disclosed. The apparatus includes a rotatable supporting portion on which a substrate is placed. A first nozzle for supplying de-ionized water and a second nozzle for supplying isopropyl alcohol vapor are provided on the supporting portion. When the isopropyl alcohol vapor is supplied to the center of the substrate at the initial stage, the amount of alcohol that reaches the substrate is controlled by a controlling portion such that the amount of the second liquid gradually increases.

Owner:SAMSUNG ELECTRONICS CO LTD

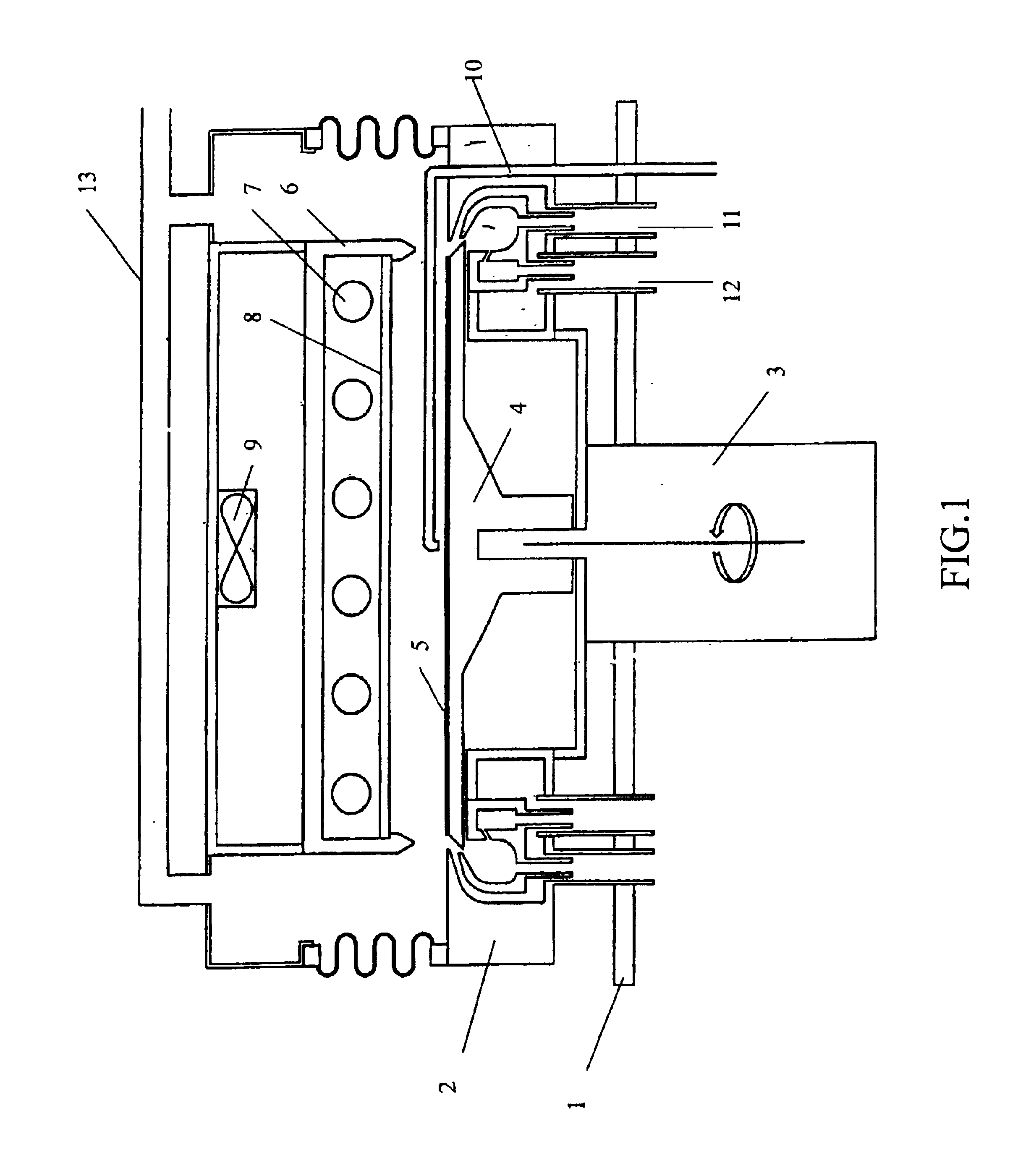

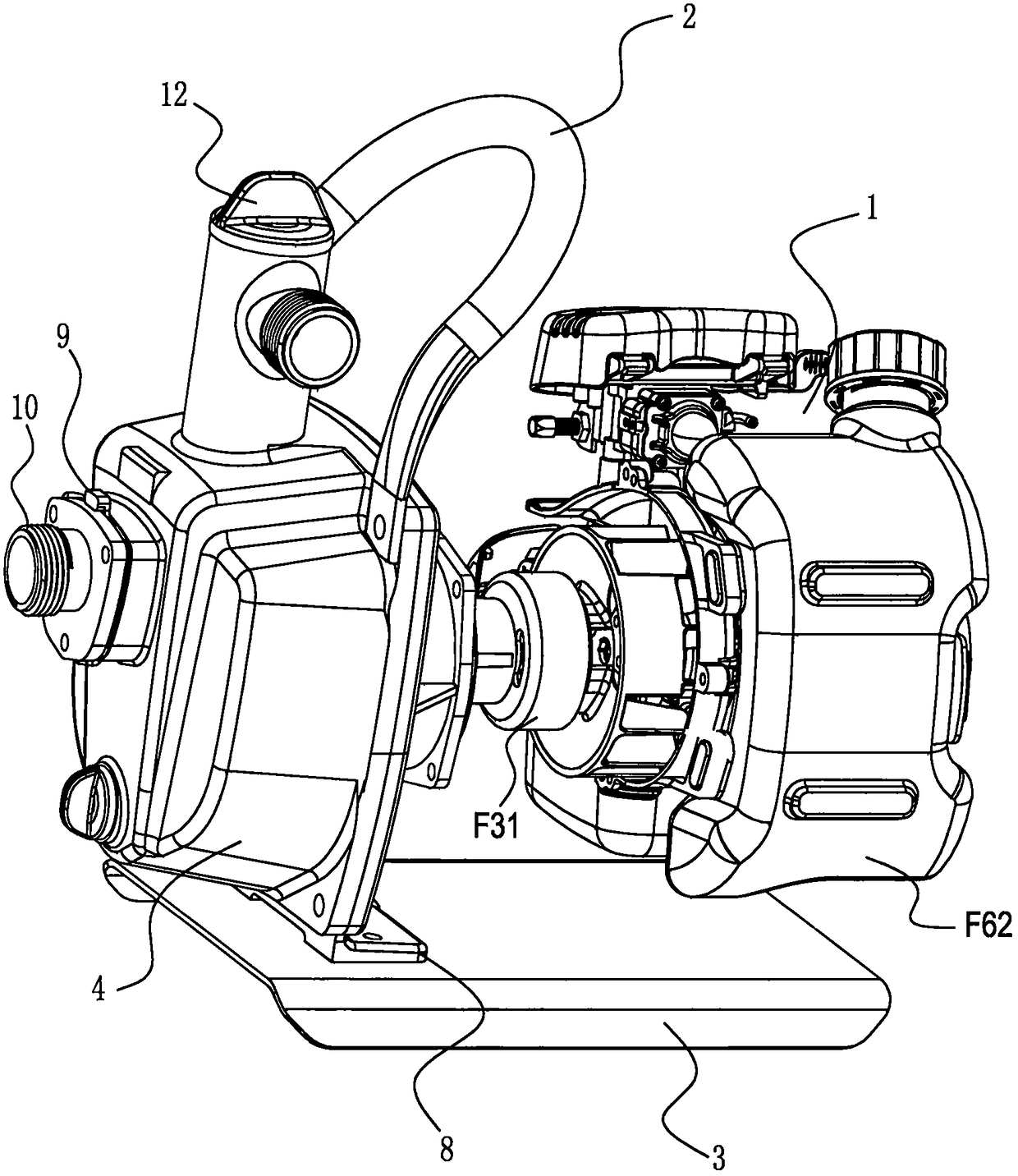

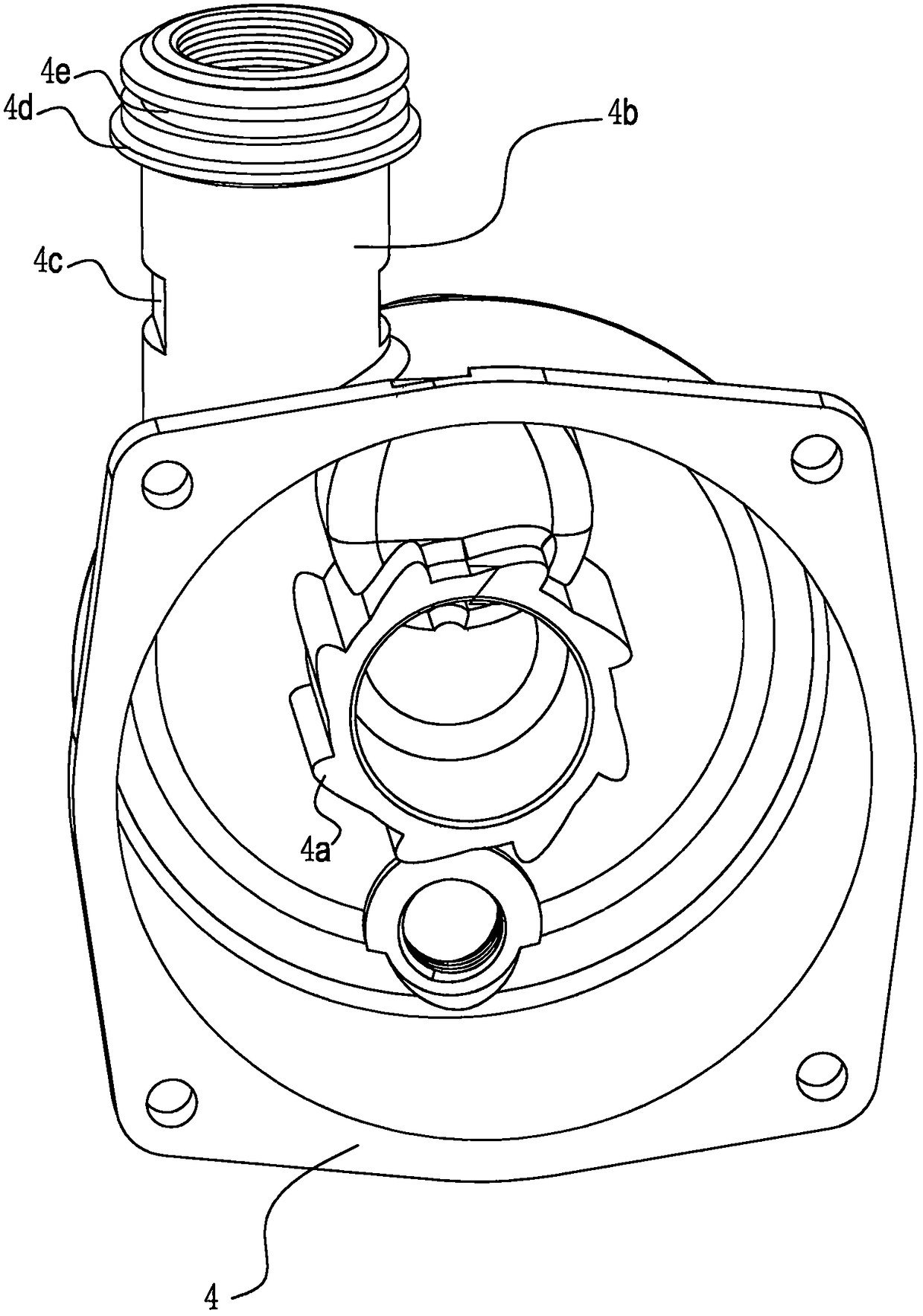

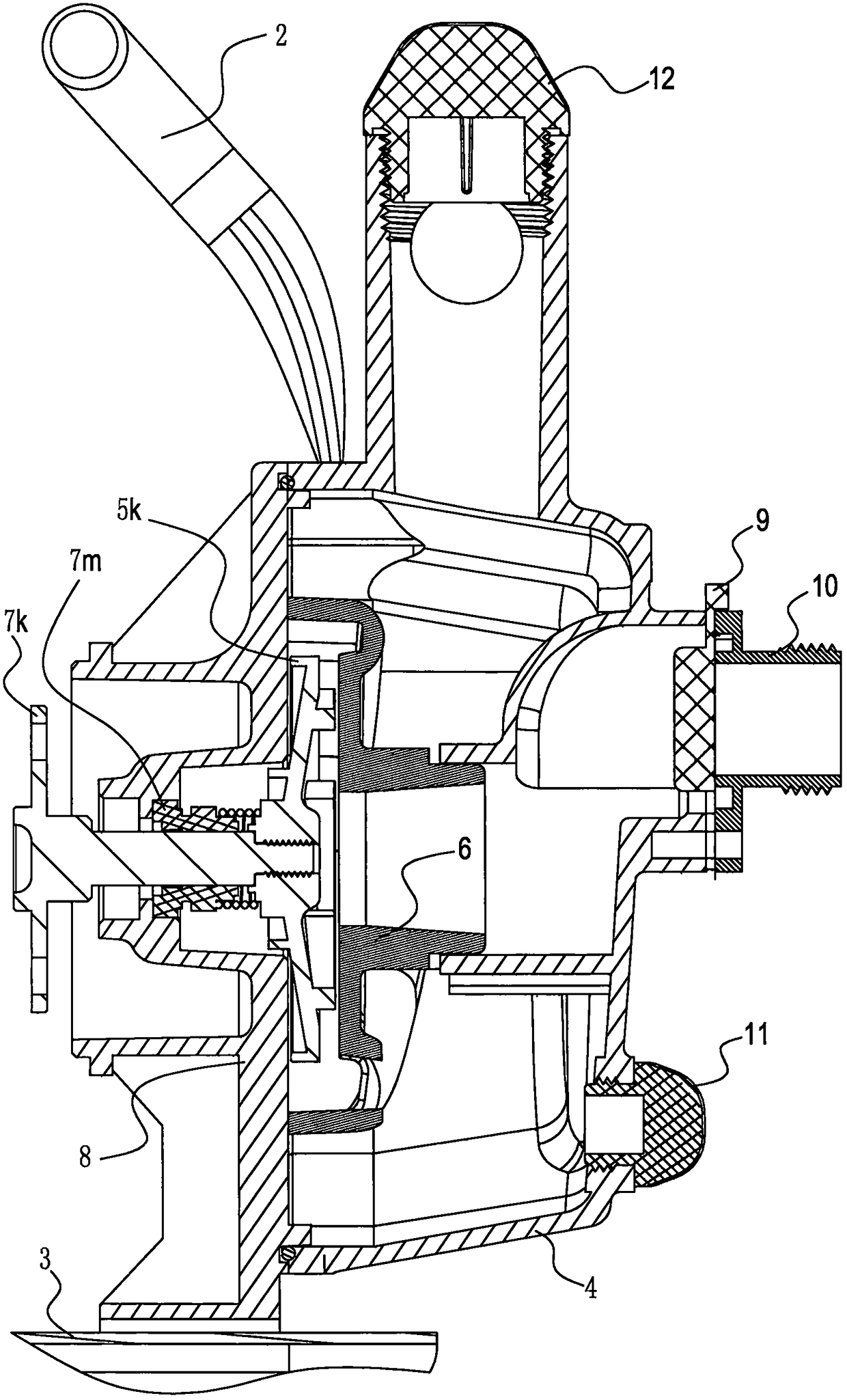

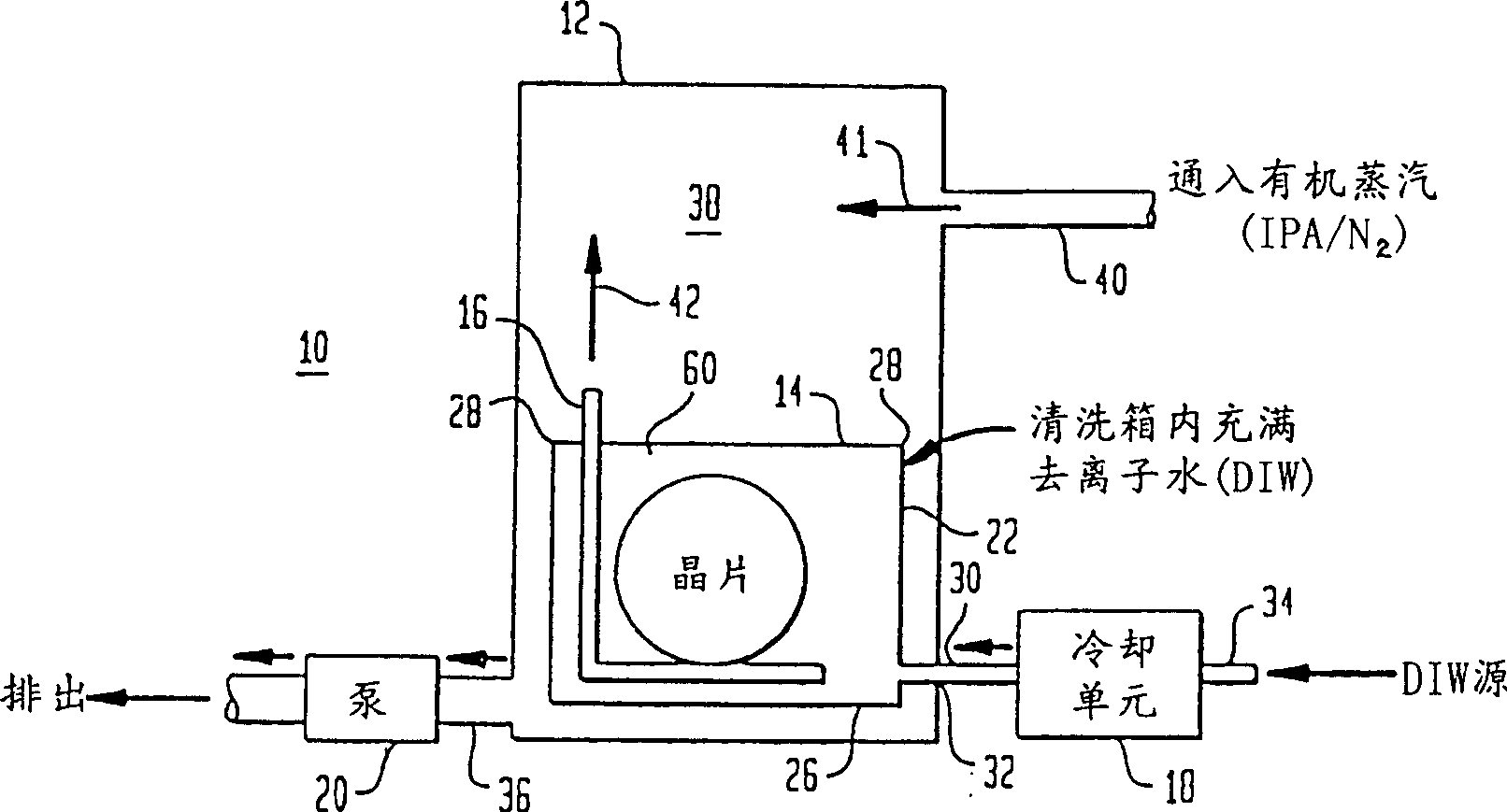

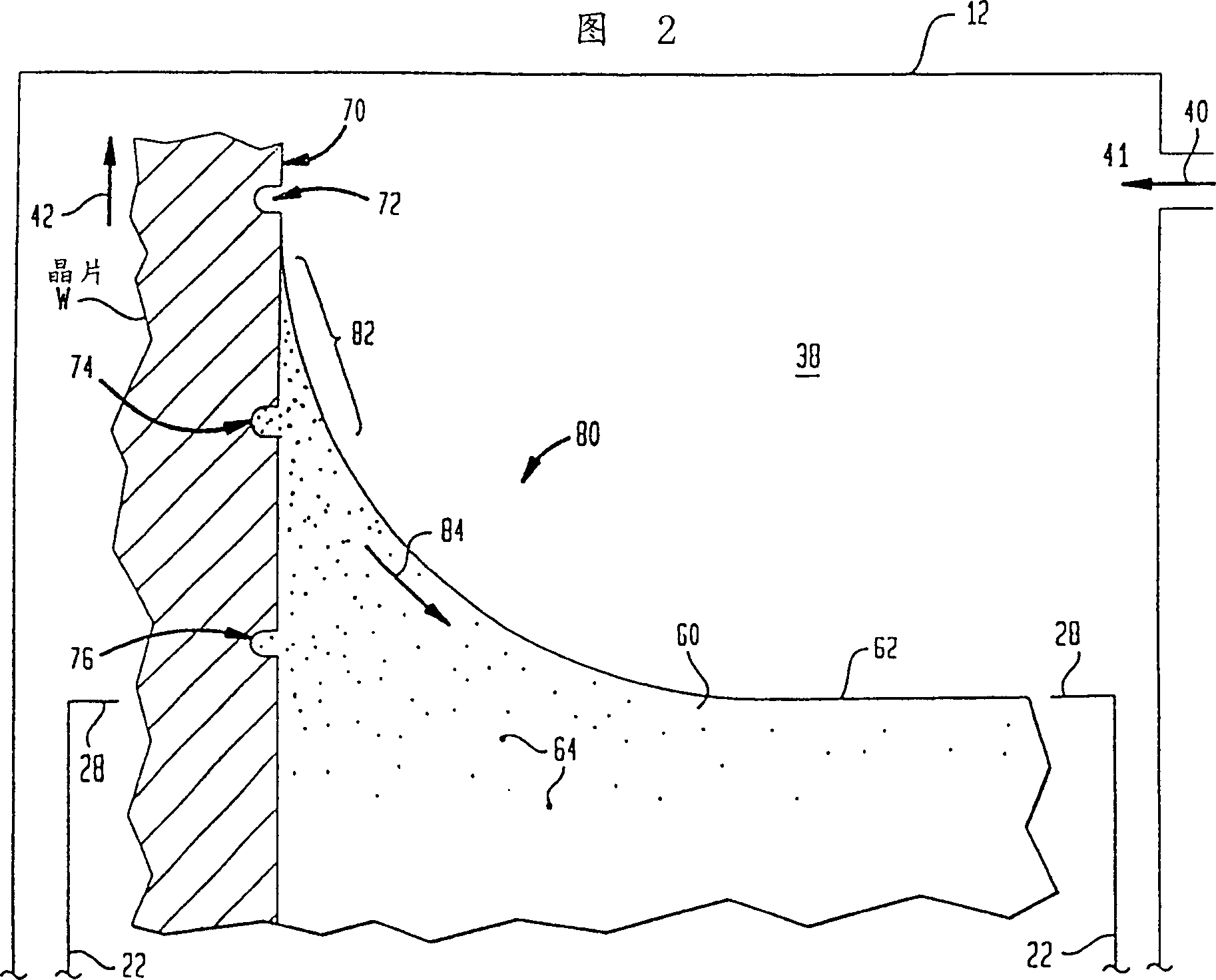

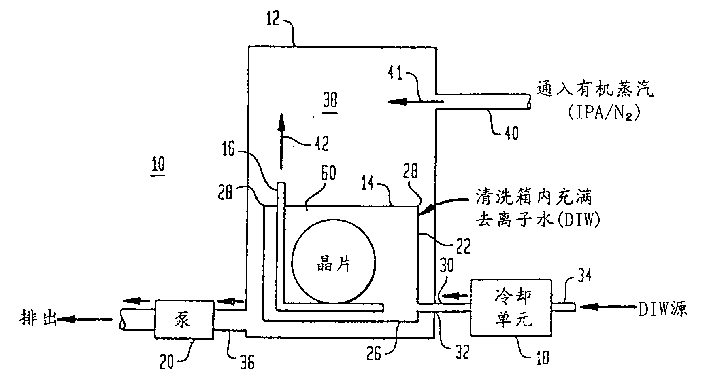

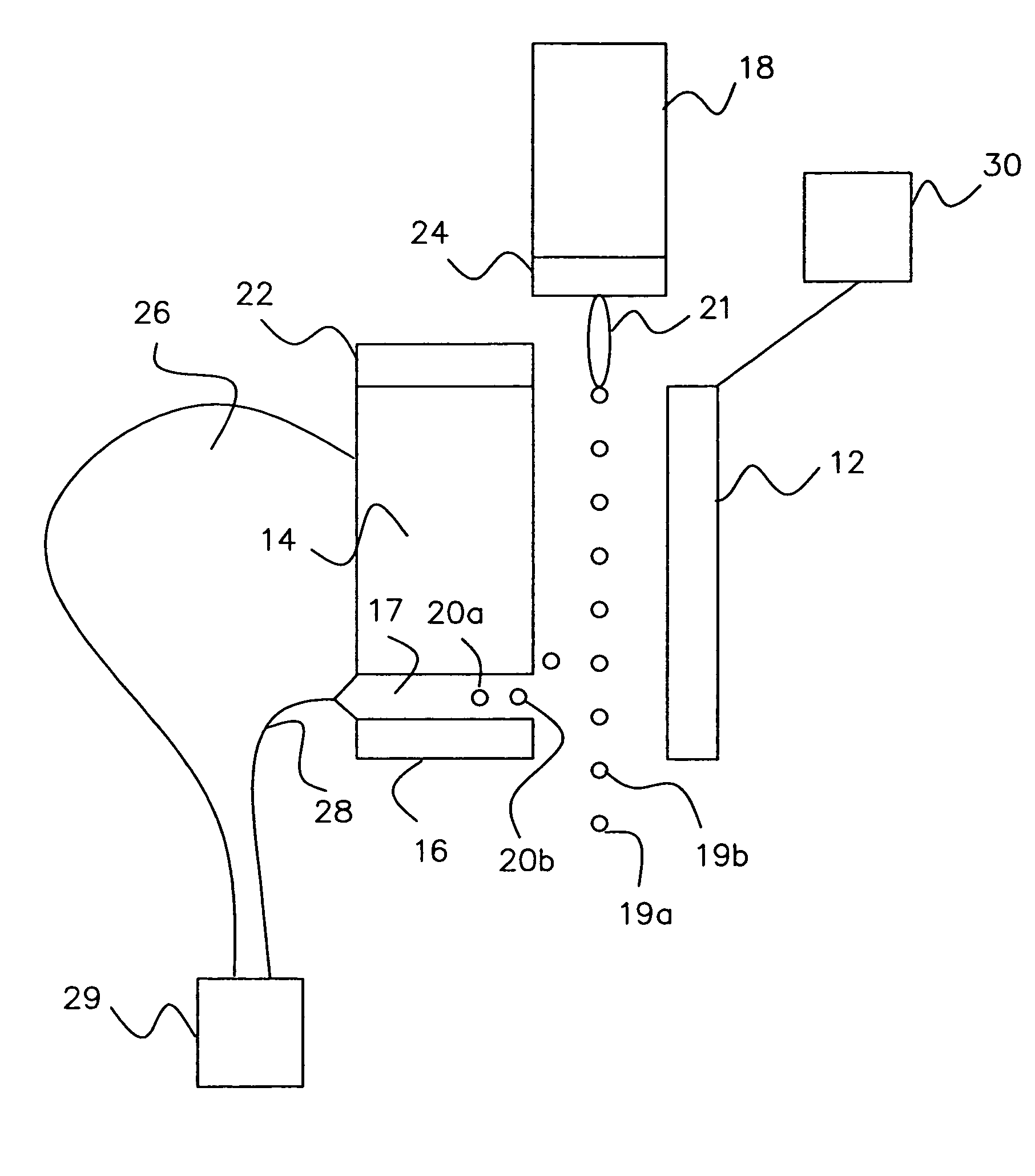

Apparatus and method for washing and drying of semiconductor wafer

InactiveCN1152417CGood waterproof effectSemiconductor/solid-state device manufacturingCleaning processes and apparatusNitrogen gasWater spot

Apparatus and method are provided for improved washing and drying of semiconductor wafers utilizing an enhanced "Marangoni effect" flow of liquid off of the wafers for superior prevention ofwatermarks (water spots) on integrated circuits (ICs) on the wafers. The apparatus includes a housing 12 which may be hermetically sealed, an open-top wash tank 60 within a lower part of the housing, a moveable rack 16 for holding the wafers either in the tank for washing or in an upper part of the housing for drying, apparatus 34 for supplying chilled (near freezing) de-ionized water (DIW) to a lower part of the tank, the DIW flowing within the tank and overflowing the top thereof, a pump 20 for draining overflowing DIW from the housing, and apparatus 40 for supplying to the housing organic vapor such as isopropyl alcohol (IPA) in a dry gas such as nitrogen. During wafer drying operation of the apparatus the pressure within the housing is kept at about one Torr or less.

Owner:SIEMENS AG +1

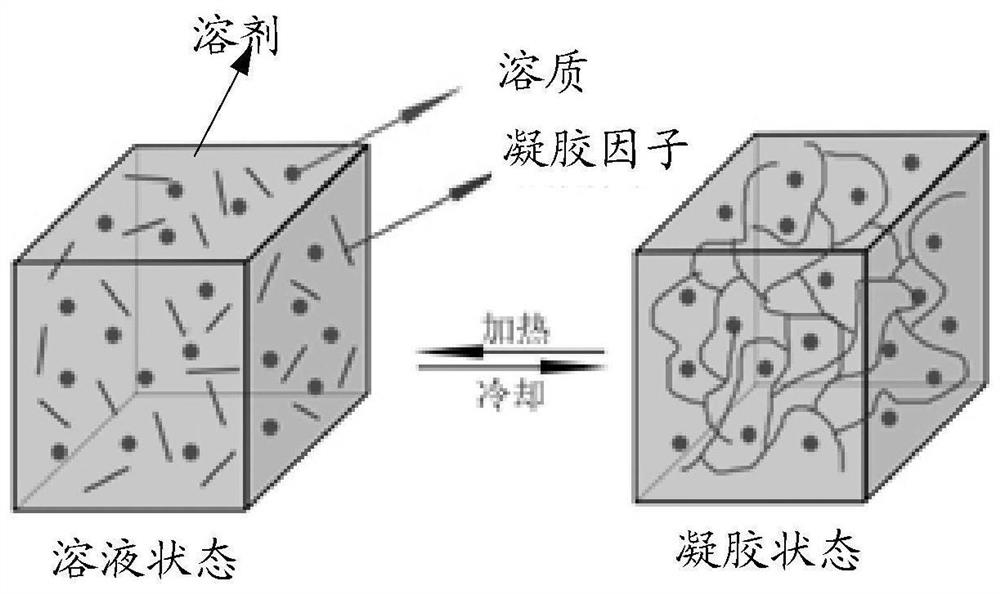

Organic electroluminescence display panel, manufacturing method thereof and display device

PendingCN112186127AReduce unevenness of light and shadePrevent premature volatilizationSolid-state devicesSemiconductor/solid-state device manufacturingPrinting inkOrganic electroluminescence

The invention discloses an organic electroluminescent display panel, a manufacturing method thereof and a display device, and the method comprises the steps of enabling an ink solution to be printed to a pixel opening through a nozzle in a mode of introducing a stimuli-responsive gelator into the printed ink solution; applying certain external stimulus to drive the gelator, so that the ink solution in the pixel opening is in a gelatinized state, the ink solvent is prevented from volatilizing in advance, and the uniformity of ink drops in the pixel opening before the underlayer substrate is dried to form a film is kept. In the drying treatment process after printing is completed, due to the fixing effect of the gelator on the solute and the solvent, the Marangoni effect can be effectively inhibited, coffee rings and climbing phenomena formed in the solute drying process are prevented, the solute can be uniformly spread in the pixel openings to form a film, and the overall film forming uniformity of the whole panel in the light-emitting functional layers in the pixel openings is effectively improved, the printing defects are reduced, the pixels emit light uniformly after being lightened, the electric leakage phenomenon is reduced, and then the device performance is improved.

Owner:BOE TECH GRP CO LTD

Microscale fluid transport using optically controlled marangoni effect

Low energy light illumination and either a doped semiconductor surface or a surface-plasmon supporting surface are used in combination for manipulating a fluid on the surface in the absence of any applied electric fields or flow channels. Precise control of fluid flow is achieved by applying focused or tightly collimated low energy light to the surface-fluid interface. In the first embodiment, with an appropriate dopant level in the semiconductor substrate, optically excited charge carriers are made to move to the surface when illuminated. In a second embodiment, with a thin-film noble metal surface on a dispersive substrate, optically excited surface plasmons are created for fluid manipulation. This electrode-less optical control of the Marangoni effect provides re-configurable manipulations of fluid flow, thereby paving the way for reprogrammable microfluidic devices.

Owner:UT BATTELLE LLC

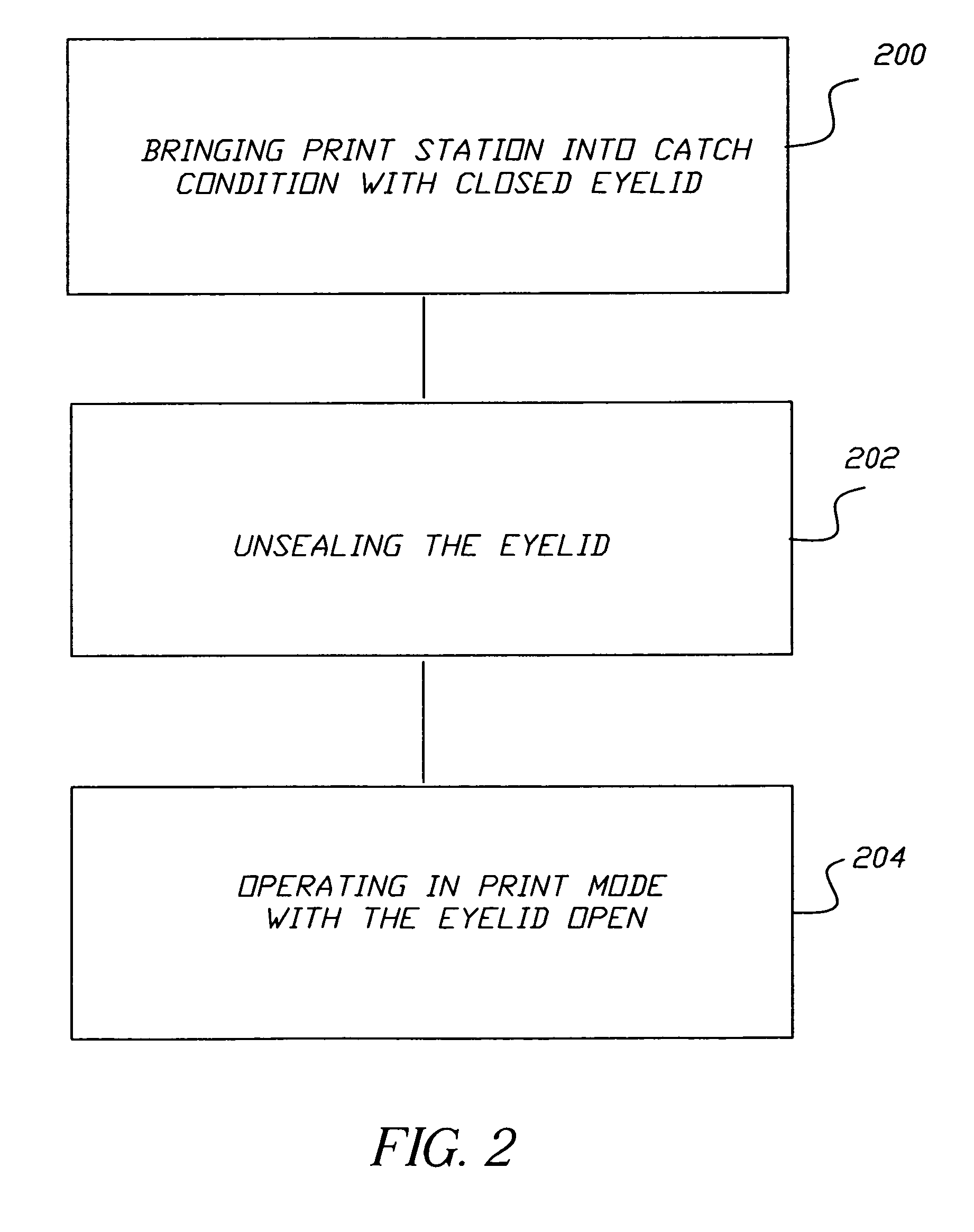

Supression of marangoni effect on the catcher face

The method for controlling ink migration onto a catcher of an ink jet print station from catch condition using a low surface tension ink entails bringing an ink jet print station using low surface tension ink into catch condition with the eyelid sealably engaging the catcher and the catcher flow pan, and using an eyelid actuator to unseal the eyelid forming a gap between the catcher flow pan, the catcher, and the eyelid. The method ends by operating the ink jet print station with the eyelid unsealed to suppress migration of the low surface tension ink onto the catcher during standby mode.

Owner:EASTMAN KODAK CO

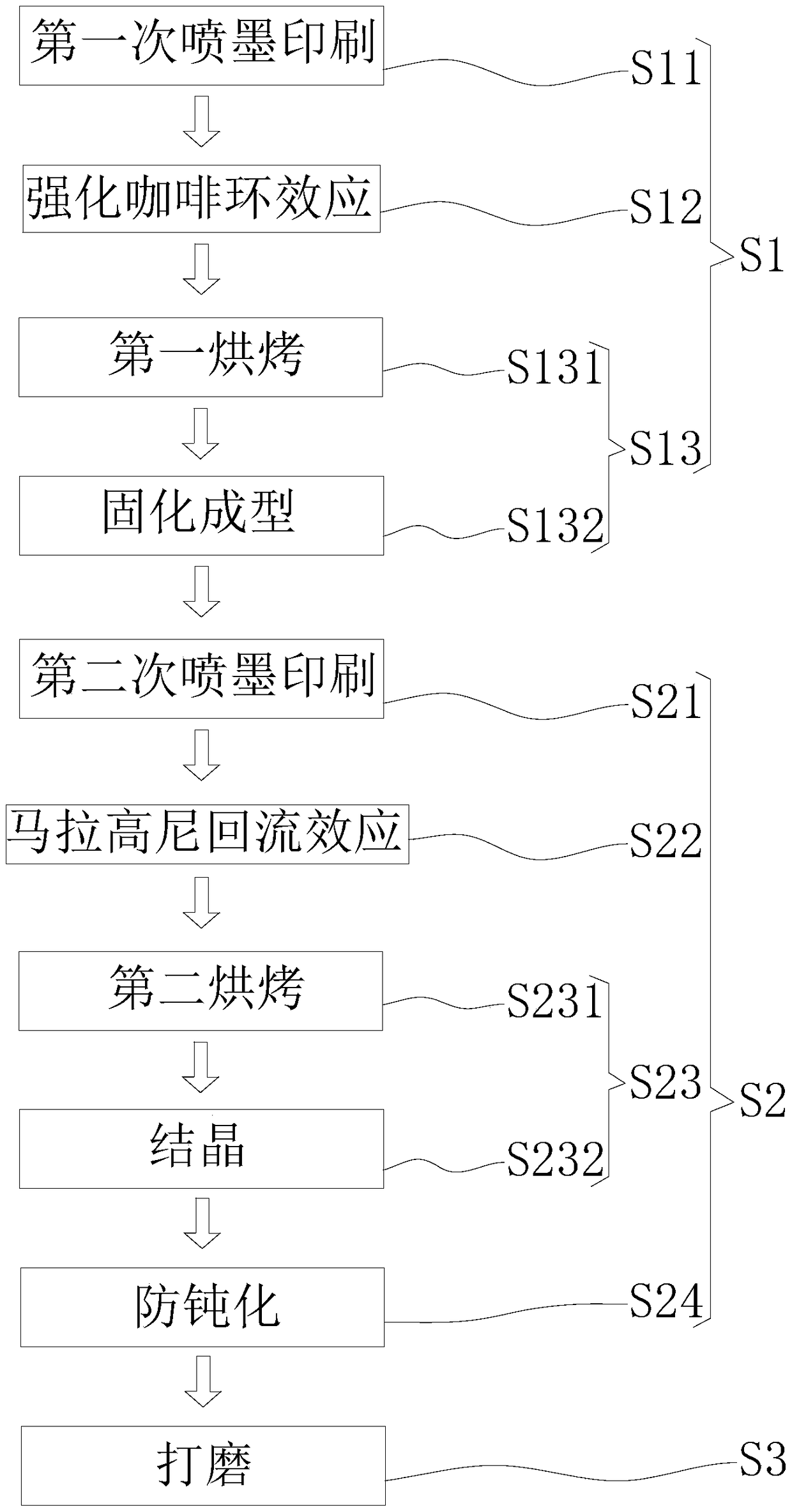

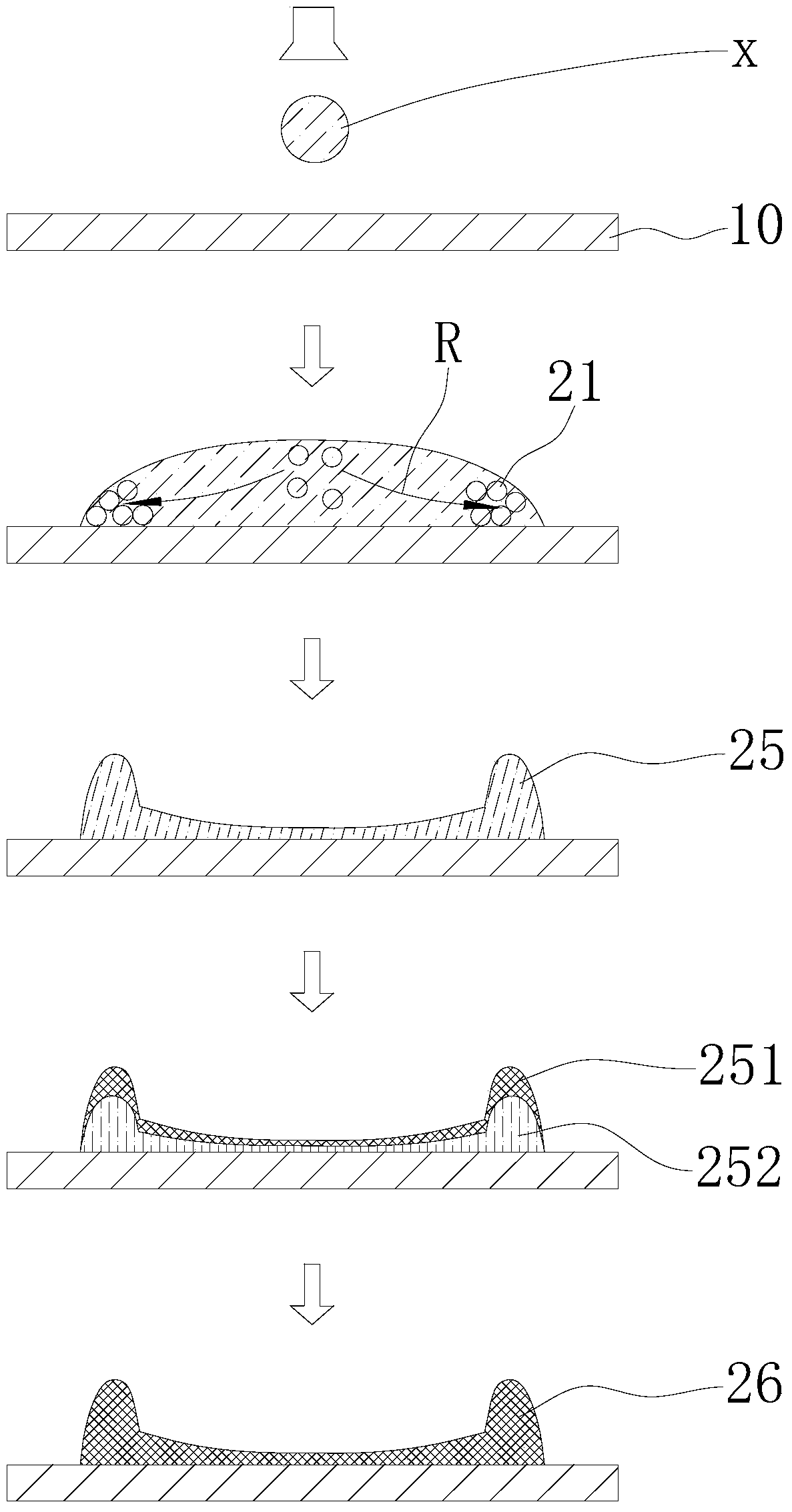

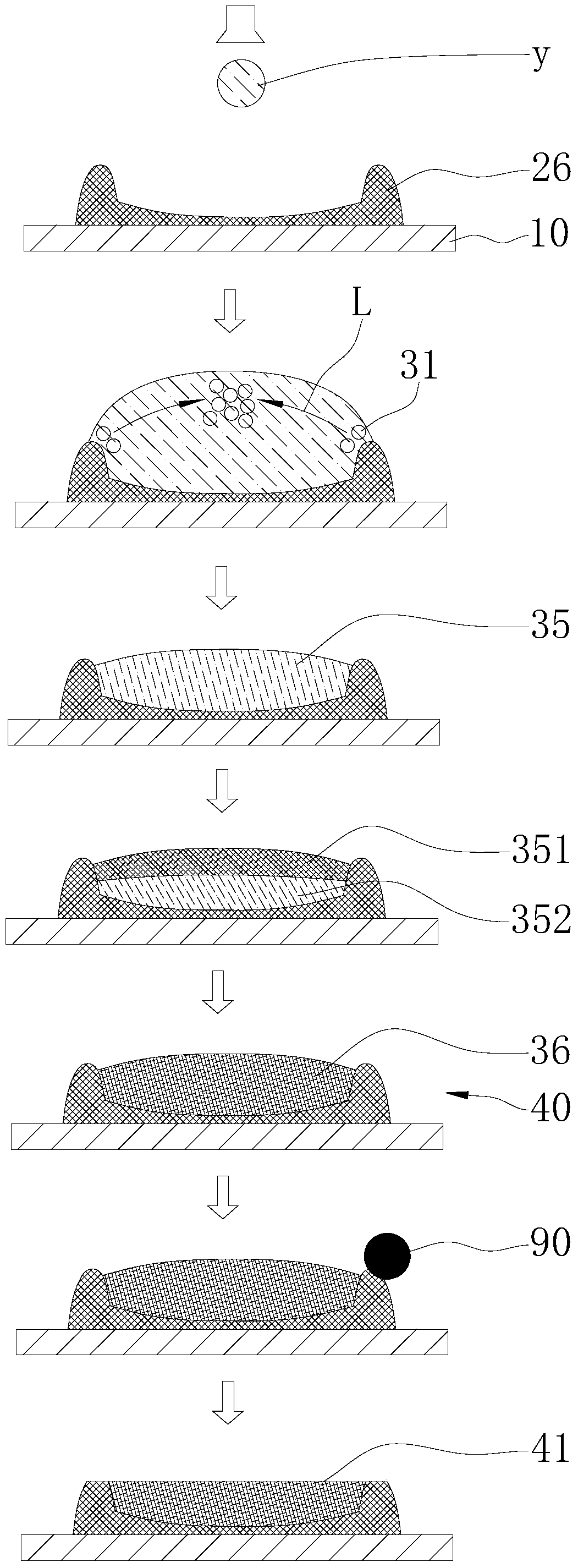

Inkjet printing metal pattern and preparation method thereof

ActiveCN106335298BUniform thicknessLow resistivityDuplicating/marking methodsCoffee ring effectEngineering

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com