Apparatus and method for washing and drying of semiconductor wafer

A technology of semiconductors and wafers, applied in chemical instruments and methods, cleaning methods and utensils, semiconductor/solid-state device manufacturing, etc., to achieve good watermark effects, improved cleaning and drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

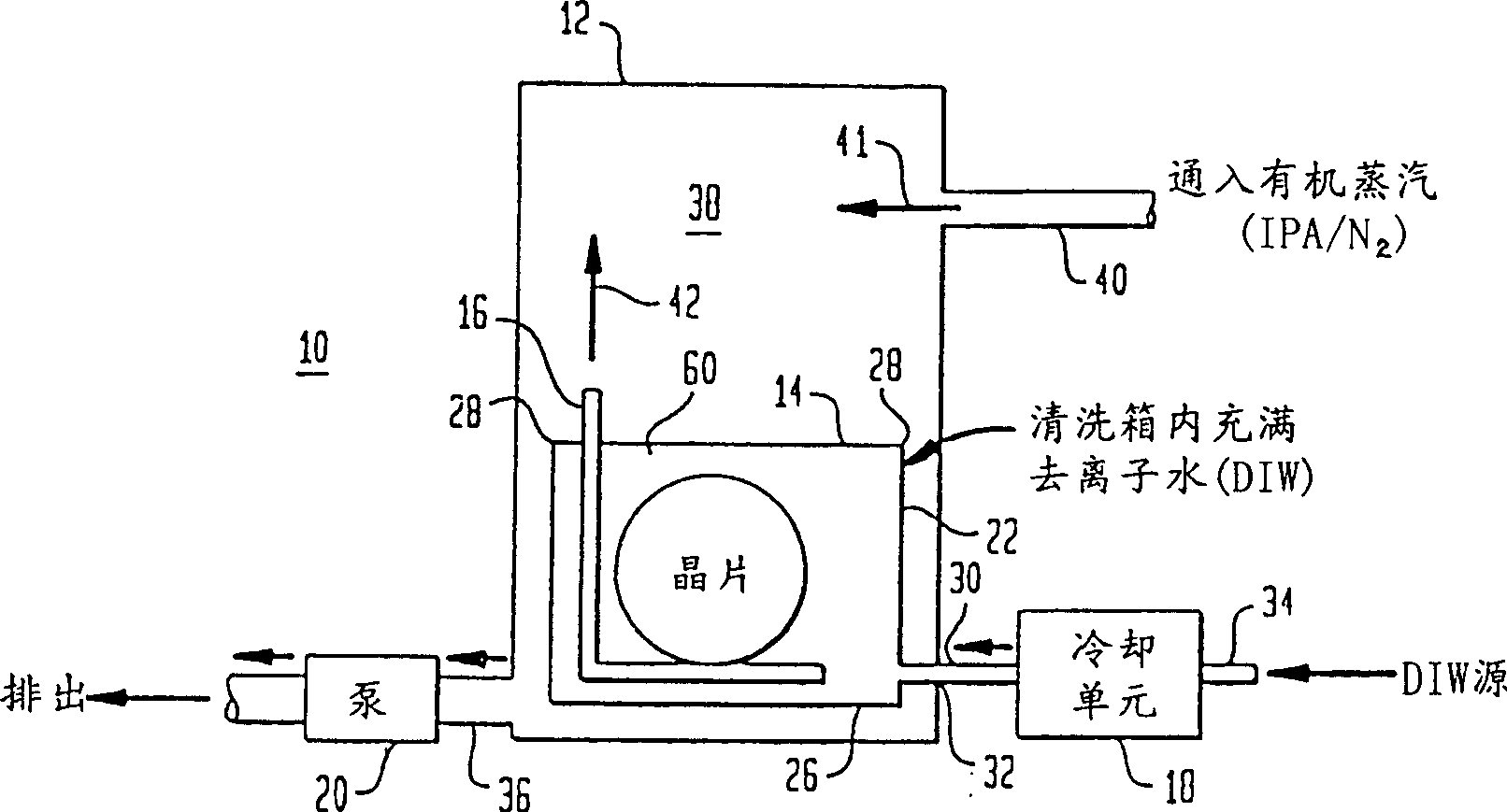

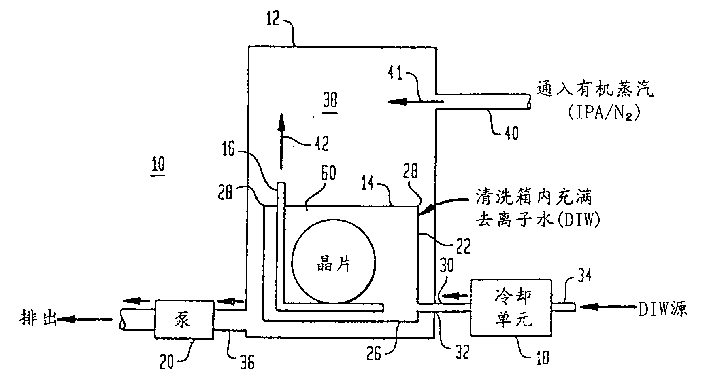

[0016] figure 1 A cross section of the device 10 of the present invention is schematically shown. The apparatus 10 can easily wash and dry one or more semiconductor wafers W substantially free of water marks (water spots) after drying. Apparatus 10 includes airtight enclosure 12 , wash tank 14 , water support and lift 16 , water cooling unit 18 , and pump 20 . Other elements within device 10 or housing 12 are not shown, but may be similar to commercially available devices. Such equipment is commercially available from Dai Nippon Screen (DAS) of Japan.

[0017] As shown, the cleaning tank 14 has a three-dimensional shape, with four vertical walls 22, a lower portion 26, and a toplip 28, without a top. Tank 14 is continuously filled with deionized water (DIW) 60 through supply pipe 30 through one tank wall 22 near bottom 26 of tank 14 . There is a sealing ring 32 around the pipe 30 passing through the wall of the airtight enclosure 12 to the tank 14 . Pipe 30 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com