Cave type prefabricated assembly comprehensive pipe rack and method for mounting same

A comprehensive pipe gallery and prefabricated assembly technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as poor integrity and stability, and easy collapse of the waterproof system, so as to achieve improved efficiency, controllable construction quality, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

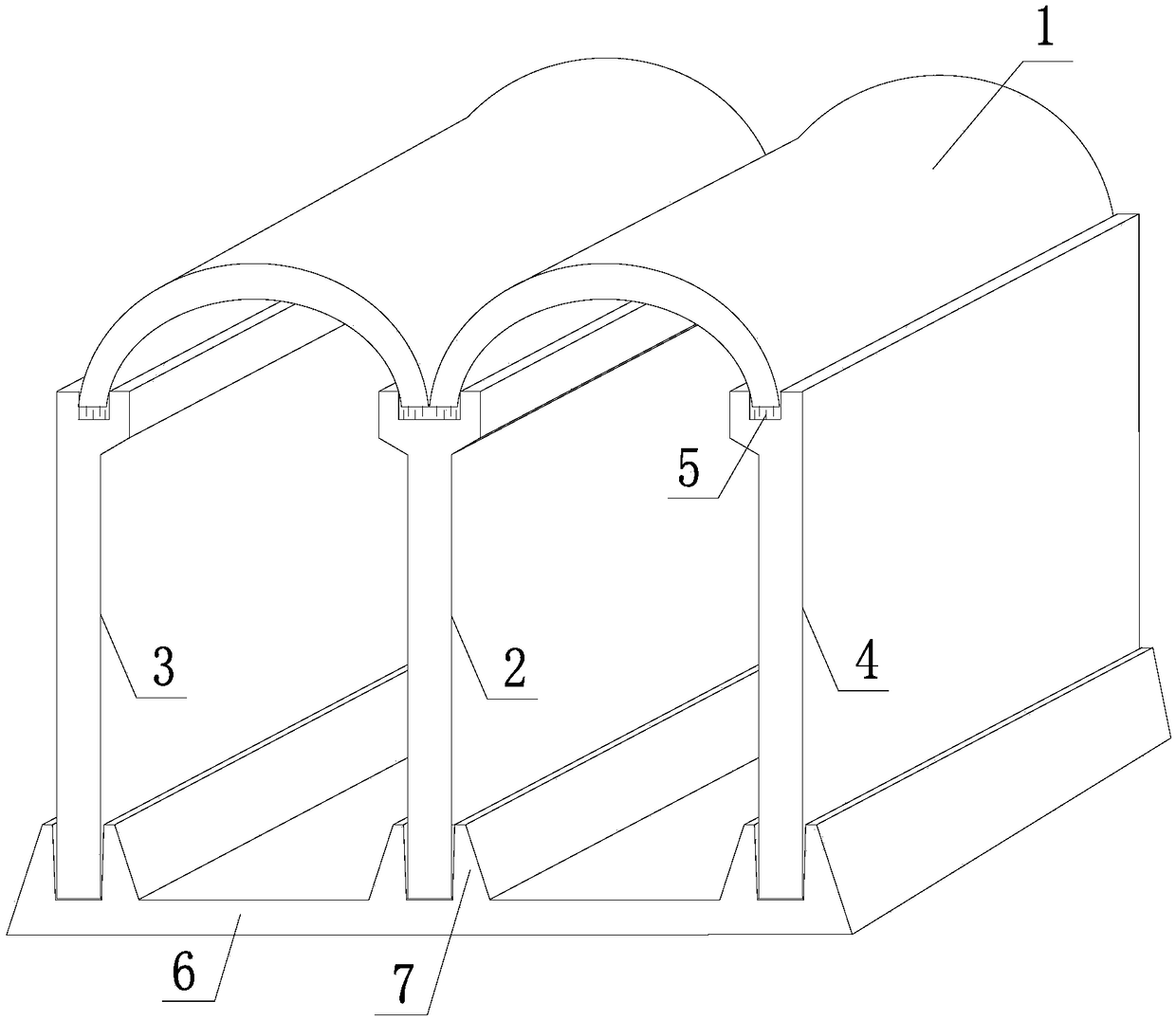

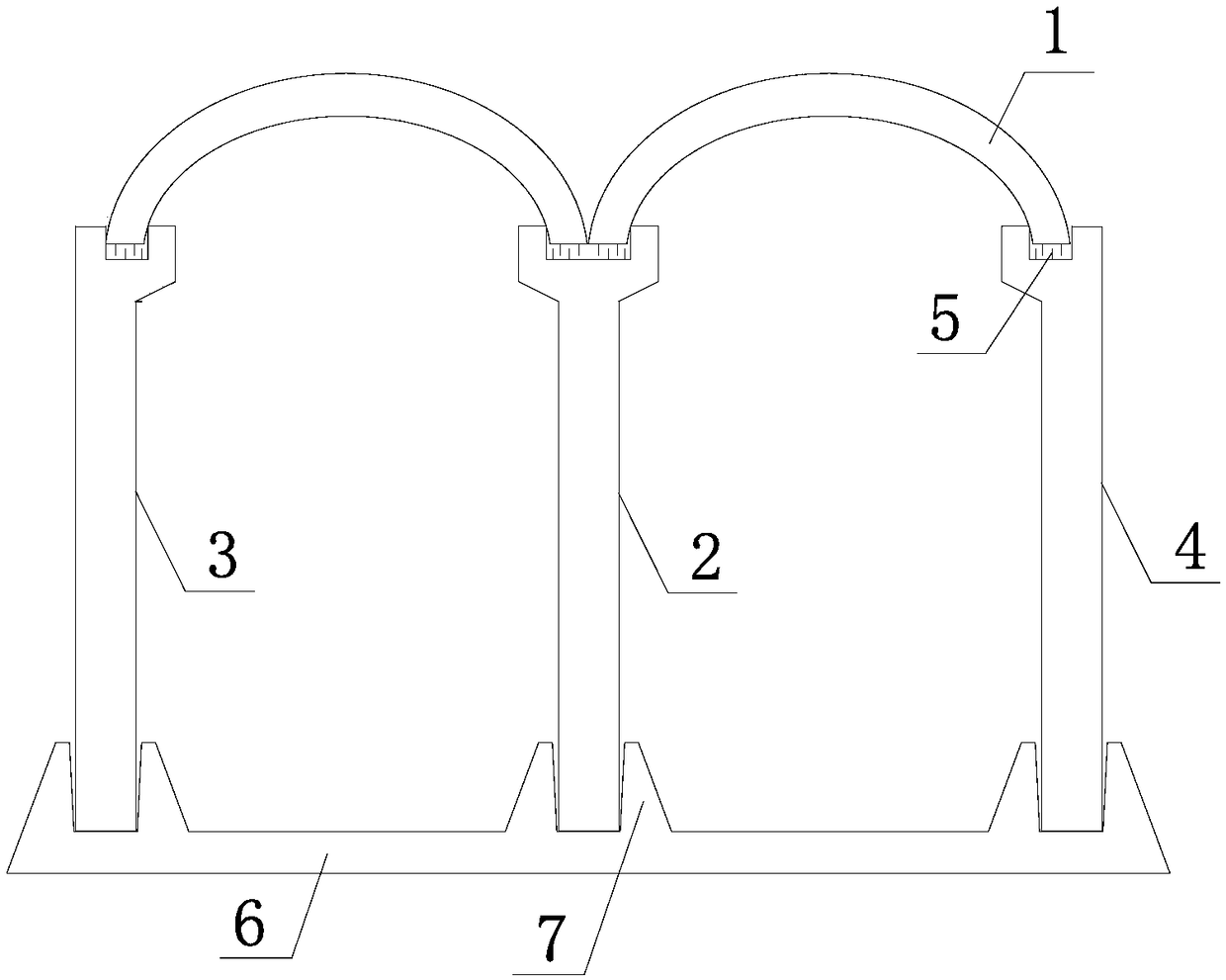

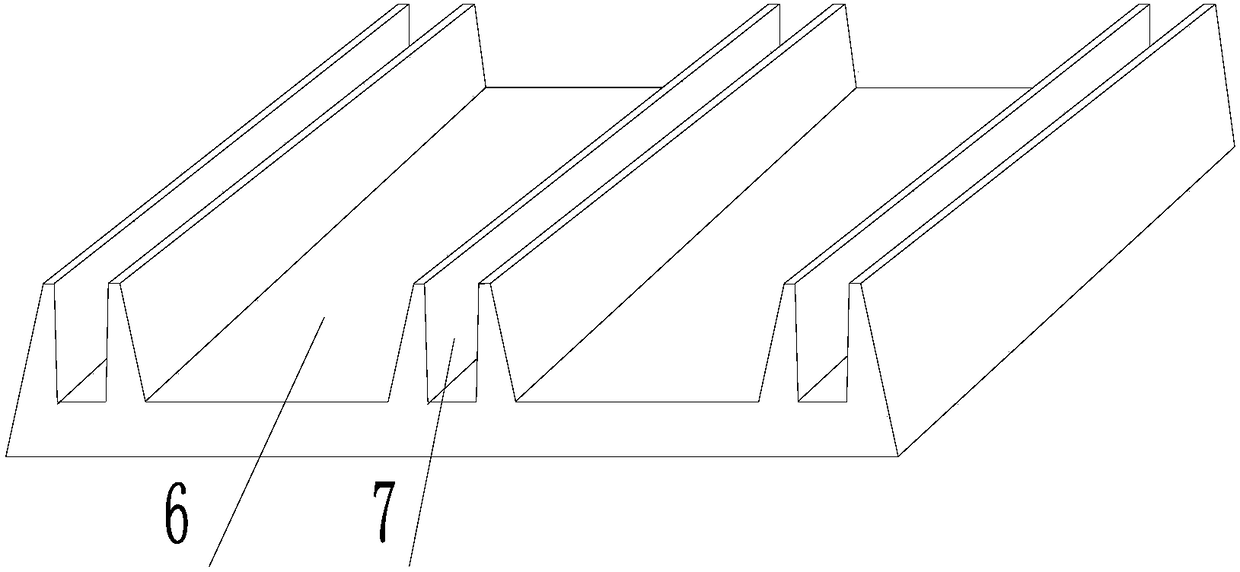

[0040] The present invention is a kind of cave-dwelling prefabricated integrated pipe gallery, such as figure 1 As shown, taking the double-compartment pipe gallery as an example, it is an integral component composed of a curved roof 1, a middle partition 2, a left partition 3, a right partition 4, a trough support 7 and a bottom plate 6. It is composed of these components A pipe joint is formed, and the pipe joints are connected in pairs to form a pipe gallery. The concrete used in the prefabrication of these components is waterproof concrete. Among them, double-layer steel mesh sheets are arranged inside the arc-shaped roof 1, which is prefabricated by the factory; the top of the middle partition 2 extends to both sides, and a groove is formed on the top for lapping and fixing of the arc-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com