Processing method for laminated composite cutting die plate

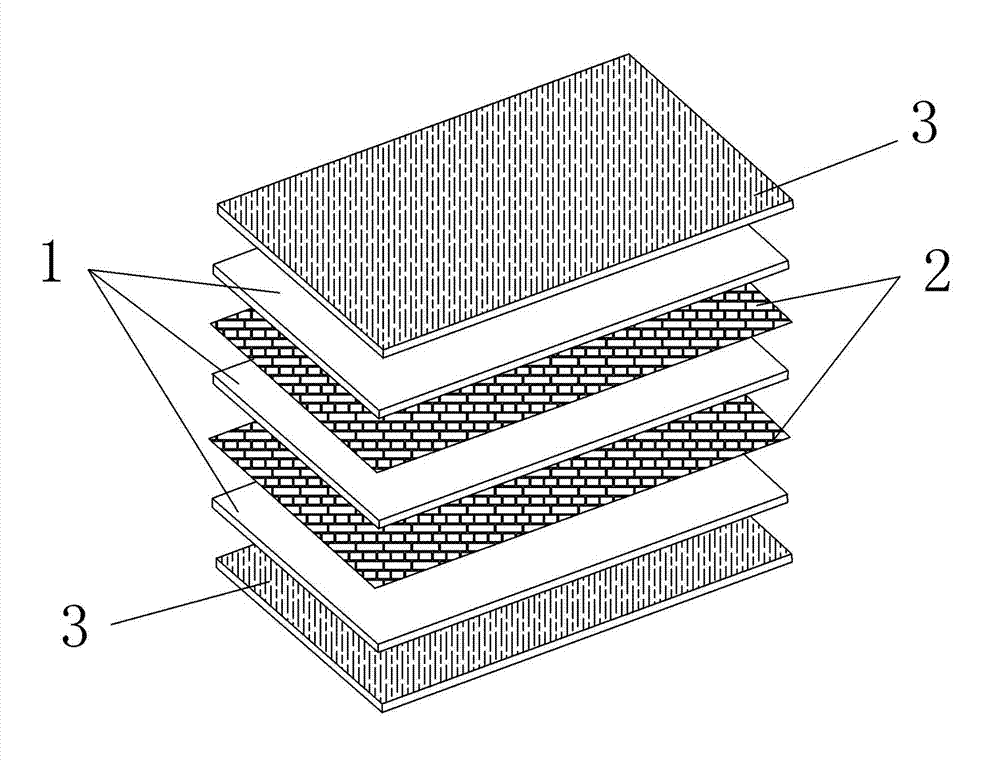

A processing method and composite knife technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of poor weather resistance, easy deformation at high temperature, poor corrosion resistance, etc., and achieve good water resistance, blocking corrosion and The effect of tide-induced deformation and physical strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A processing method for a composite layer cutter template, comprising the following steps:

[0025] (1) Rotate the log to obtain 1mm veneer, cut it into corresponding size and format; then obliquely grind the butt edge of the veneer, the angle formed between the inclined surface and the surface of the veneer is 40°; then glue the inclined surface and splice it. Partial heating at 200-220°C at the miter joint for 30 seconds to obtain the entire miter joint veneer;

[0026] (2) Immerse the mitered veneer in phenolic resin glue with a solid content of 20% for 3 hours, and the immersion temperature is 35-40°C;

[0027] (3) Arrange the glass fibers in phenolic resin with a solid content of 20% and impregnate for 0.5 hours, and the impregnation temperature is 35-40°C;

[0028] (4) Veneer drying: Dry the impregnated mitered veneer and glass fiber cloth at 50-60°C until the moisture content is 8-10%, and repair the holes on the dried veneer;

[0029] (5) Apply glue on one sid...

Embodiment 2

[0032] A method for processing a laminated composite knife template, comprising the following steps:

[0033] (1) Rotate the logs to obtain 5mm veneers, cut them into corresponding sizes and formats; then obliquely grind the butt edges of the veneers, and the angle formed between the bevel and the surface of the veneer is 20°; Carry out local heating at 220-230°C at the miter joint for 25 seconds to obtain the entire miter joint veneer;

[0034] (2) Immerse the mitered veneer in phenolic resin glue with a solid content of 30% for 4 hours, and the immersion temperature is 35-40°C;

[0035] (3) Arrange the glass fibers in phenolic resin with a solid content of 30% and impregnate for 0.8 hours, and the impregnation temperature is 35-40°C;

[0036] (4) Veneer drying: Dry the impregnated mitered veneer and glass fiber cloth at 50-60°C until the moisture content is 8-10%, and repair the holes on the dried veneer;

[0037] (5) Apply glue on one side of the 0.3mm PVC thin layer, and...

Embodiment 3

[0040] A method for processing a laminated composite knife template, comprising the following steps:

[0041] (1) Rotate the log to obtain 10mm veneer, cut it into corresponding size and format; then obliquely grind the butt edge of the veneer, the angle formed between the inclined surface and the surface of the veneer is 5°; then apply glue to the inclined surface, and Partial heating at 220-250°C at the miter joint for 20 seconds to obtain the entire miter joint veneer;

[0042] (2) Immerse the mitered veneer in phenolic resin glue with a solid content of 35% for 6 hours, and the immersion temperature is 35-40°C;

[0043] (3) Arrange the glass fibers in phenolic resin with a solid content of 35% and impregnate for 1 hour, and the impregnation temperature is 35-40°C;

[0044] (4) Veneer drying: Dry the impregnated mitered veneer and glass fiber cloth at 50-60°C until the moisture content is 8-10%, and repair the holes on the dried veneer;

[0045] (5) Apply glue on one side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com