Micro robot driven by point light source and preparation method thereof

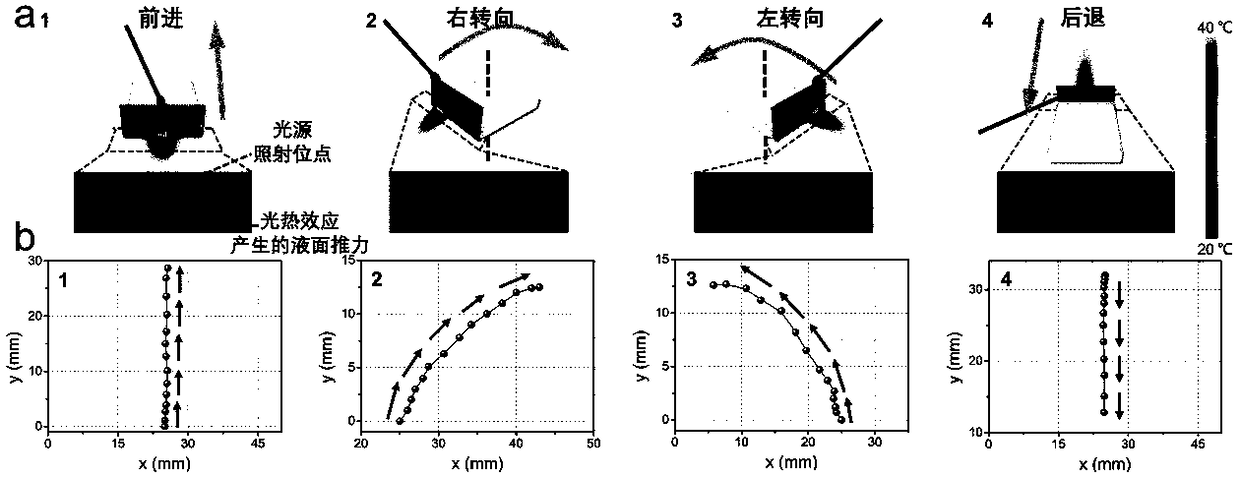

A micro-robot, point light source technology, applied in micro-manipulators, chemical instruments and methods, manipulators, etc., can solve the problems of limited material microstructure, low controllability, limited control accuracy of light-driven microrobots, etc. Effects of heat conversion efficiency, high environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

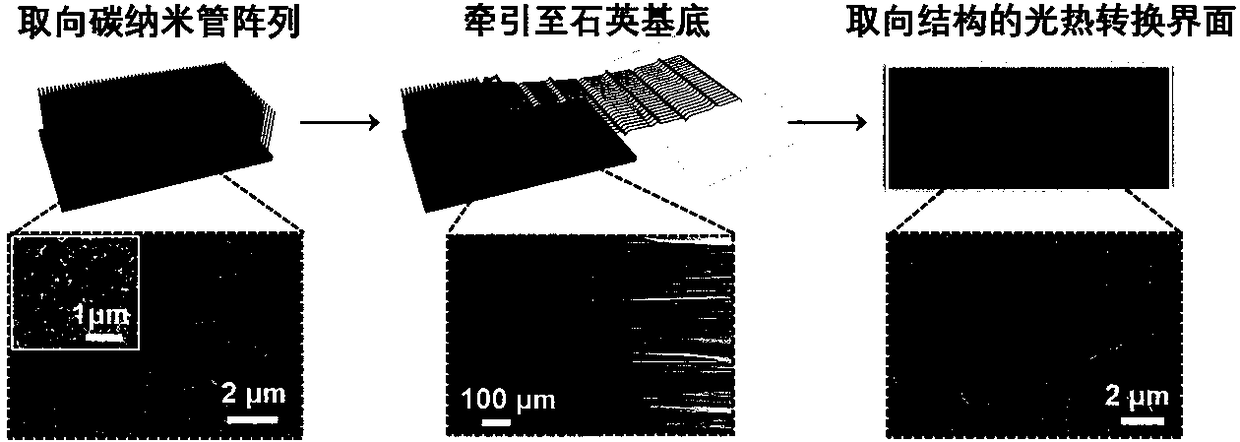

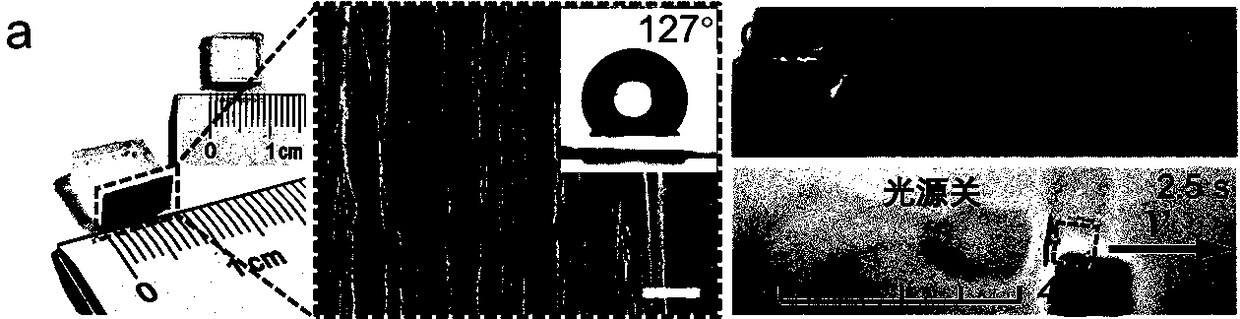

[0027] (1) Preparation of aligned carbon nanotube light-absorbing material: Prepare a transparent quartz plate with a length of 4 mm, a width of 8 mm, and a thickness of 0.05 mm as a substrate; prepare a spinnable carbon nanotube array by chemical vapor deposition, and use a blade to form a carbon nanotube Pull a carbon nanotube film with a width of 3 mm on one side of the array, and overlap 20 layers on the quartz plate to obtain an aligned carbon nanotube film with a thickness of 200 μm, whose orientation direction is consistent with the pulling direction and perpendicular to the long side of the quartz plate;

[0028] (2) Preparation of light-to-heat conversion interface based on aligned carbon nanotubes: Add 10 microliters of ethanol dropwise around the composite sheet of quartz sheet / aligned carbon nanotubes to make the aligned carbon nanotube film and the quartz sheet fit closely, and heat at 50°C For 1 minute, the ethanol was partially evaporated to dryness; cut off alon...

Embodiment 2

[0033] (1) Preparation of aligned carbon nanotube light-absorbing material: Prepare a transparent quartz plate with a length of 6 mm, a width of 9 mm, and a thickness of 0.1 mm as a substrate; prepare a spinnable carbon nanotube array by chemical vapor deposition, and use a blade to form a carbon nanotube Pull a carbon nanotube film with a width of 5 mm on one side of the array, and overlap 30 layers on the quartz plate to obtain an aligned carbon nanotube film with a thickness of 500 μm, whose orientation direction is consistent with the pulling direction and perpendicular to the long side of the quartz plate;

[0034] (2) Preparation of a light-to-heat conversion interface based on aligned carbon nanotubes: Add 50 microliters of ethanol dropwise around the composite sheet of quartz sheet / aligned carbon nanotubes to make the aligned carbon nanotube film and the quartz sheet fit closely, and heat at 60°C After 3 minutes, the ethanol was partially evaporated to dryness; the quar...

Embodiment 3

[0040] (1) Preparation of aligned carbon nanotube light-absorbing material: Prepare a transparent quartz plate with a length of 8 mm, a width of 10 mm, and a thickness of 0.2 mm as the substrate; prepare a spinnable carbon nanotube array by chemical vapor deposition, and use a blade to form a carbon nanotube Pull a carbon nanotube film with a width of 7 mm on one side of the array, and overlap 50 layers on the quartz plate to obtain an aligned carbon nanotube film with a thickness of 1000 μm, whose orientation direction is consistent with the pulling direction and perpendicular to the long side of the quartz plate;

[0041] (2) Preparation of a light-to-heat conversion interface based on aligned carbon nanotubes: Add 100 microliters of ethanol dropwise around the quartz sheet / aligned carbon nanotube composite sheet to make the aligned carbon nanotube film and the quartz sheet tightly bonded, and heat at 80°C After 5 minutes, the ethanol was partially evaporated to dryness; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com