Superspreading wetting agent and preparation method thereof

A wetting agent and super-spreading technology, applied in the direction of adhesive additives, polymer adhesive additives, coatings, etc. High tension problems, to achieve the effect of low dynamic surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

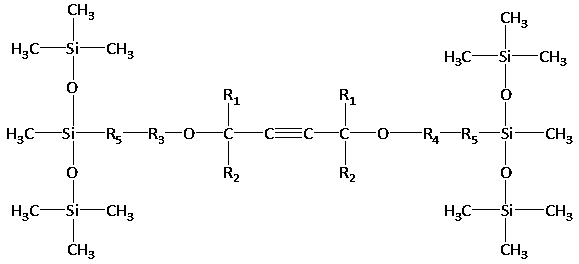

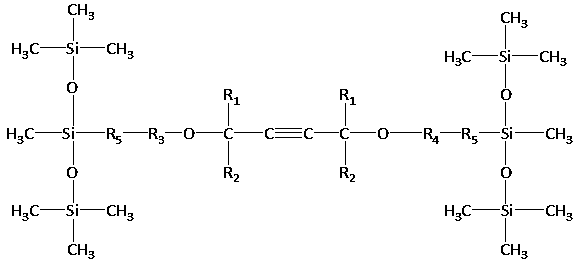

Image

Examples

Embodiment 1

[0025] The preparation method of super-spreading wetting agent of the present invention is:

[0026] (1) Add 0.001 mol of catalyst lithium hydroxide to 1 mol of 5,8-dimethyl-6-dodeyn-5,8-diol after dehydration by molecular sieve, and pass through 8 mol of epoxy Ethane, heat up to 90°C, keep the temperature for 3 hours, then cool down to 40°C; pass the reaction product into an ethanol-activated mixed-bed ion exchange column to remove the catalyst, and obtain acetylene glycol polyoxyethylene ether-0400;

[0027] (2) Add the methanol solution containing 2 mol of potassium methylate into the acetylenic glycol polyoxyethylene ether-0400, raise the temperature to 65°C and maintain a slight boiling state, slowly distill out the methanol, keep it for 2 hours, and then distill off the residual methanol under reduced pressure; Cool to 25°C to obtain acetylenic glycol polyoxyethylene ether-0400 potassium salt;

[0028] (3) Add 2.2 mol of sulfonyl chloride dropwise into 2 mol of 3-(3-hyd...

Embodiment 2

[0031] The preparation method of super-spreading wetting agent of the present invention is:

[0032] (1) Add 0.004 mol of catalyst potassium hydroxide to 1 mol of 3-hexyne-2,5-diol after molecular sieve dehydration, and add 12 mol of propylene oxide under the protection of nitrogen. hour, lower the temperature to 35°C; pass the reaction product into an ethanol-activated mixed-bed ion-exchange column to remove the catalyst, and obtain acetylene glycol polyoxypropylene ether-0006;

[0033] (2) Add the ethanol solution containing 2 mol sodium ethoxide into the acetylene glycol polyoxypropylene ether-0006, raise the temperature to 80°C and keep it in a slightly boiling state, and slowly distill the ethanol out, keep it for 4 hours and then distill it off under reduced pressure to remove the residual ethanol ; Cool to 25°C to obtain acetylene glycol polyoxypropylene ether-0006 sodium salt;

[0034] (3) Add 2.8 mol of thionyl chloride dropwise into 2 mol of 3-(3-hydroxymethyl)hepta...

Embodiment 3

[0037] The preparation method of super-spreading wetting agent of the present invention is:

[0038] (1) Add 0.005 mol catalyst zinc hexacyanocobaltate to 1 mol of 2,5-dimethyl-3-hexyne-2,5-diol after dehydration by molecular sieve, and pass it into 22 mol ring Ethylene oxide and 8 mol propylene oxide are heated up to 120°C, kept at a constant temperature for 9 hours, and cooled to 35°C; the reaction product is passed into an ethanol-activated mixed-bed ion exchange column to remove the catalyst, and the acetylene glycol polyoxyethylene poly Oxypropylene ether-1104;

[0039] (2) Add 1 mol potassium ethoxide ethanol solution and 1 mol potassium methoxide ethanol solution into acetylene glycol polyoxyethylene polyoxypropylene ether-1104, raise the temperature to 65°C and keep it in a slightly boiling state for 2 hours, and slowly distill out Methanol, after the methanol is basically evaporated, the temperature is raised to 78°C to slowly distill ethanol out, and the residual et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com