Method for preparing micro-concave and micro-convex structures on amorphous alloy through nanosecond laser irradiation

An amorphous alloy, laser irradiation technology, applied in laser welding equipment, welding equipment, manufacturing tools and other directions, can solve the problem of unrealized micro-convex structure, and achieve the effects of low cost, simple method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

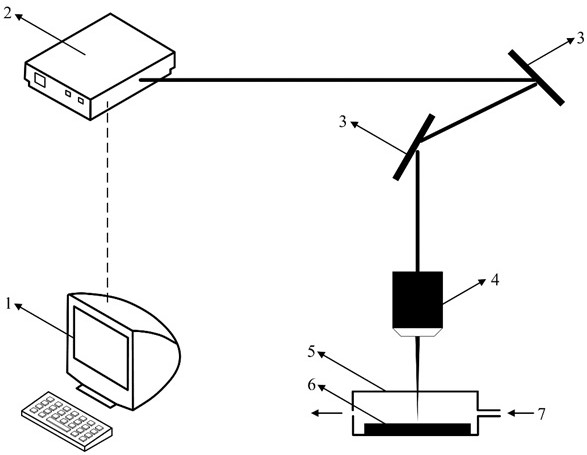

Method used

Image

Examples

Embodiment 1

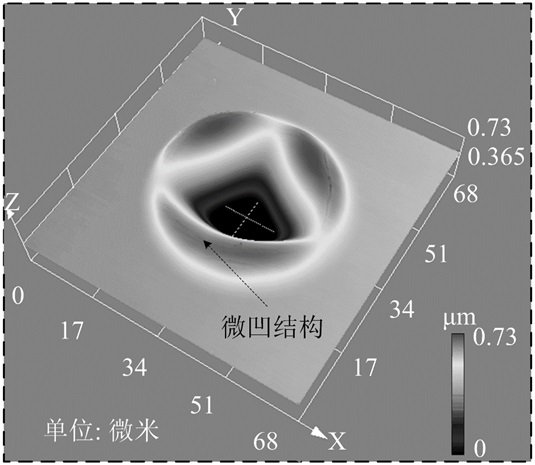

[0038] see Figure 4 and Figure 5 Shown is the three-dimensional morphology and cross-sectional profile of the surface microstructure of the amorphous alloy prepared by nanosecond laser irradiation in this embodiment. The selected laser peak power intensity is 2.4 × 10 11 W / m 2 , the number of laser pulses is 1000 times, and the argon pressure is 0.01MPa. It can be seen from the figure that under the irradiation parameters of this embodiment, a dimple structure is formed on the surface of the amorphous alloy. Wherein, the diameter of the dimple structure is about 50 μm, and the pit depth is about 640 nm.

Embodiment 2

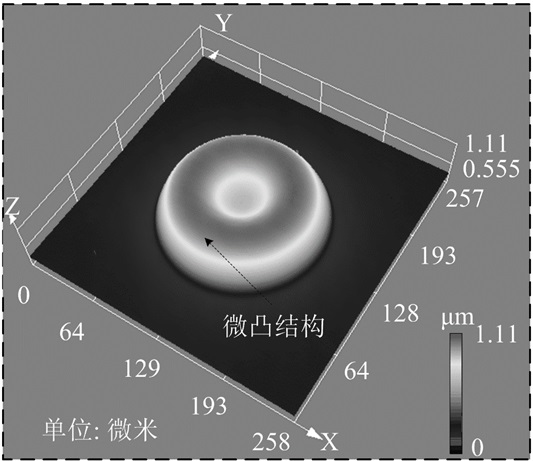

[0040] see Image 6 and Figure 7 Shown is the three-dimensional morphology and cross-sectional profile of the surface microstructure of the amorphous alloy prepared by nanosecond laser irradiation in this embodiment. The selected laser peak power intensity is 2 × 10 12 W / m 2 , the number of laser pulses is 1000 times, and the argon pressure is 0.01MPa. It can be found that by increasing the peak laser power intensity while keeping the number of laser pulses constant, a regular micro-convex structure is obtained on the surface of the amorphous alloy. Wherein, the diameter of the micro-protrusion structure is about 165 μm, and the height of the protrusion is about 820 nm.

Embodiment 3

[0042] see Figure 8 and Figure 9 Shown is the three-dimensional morphology and cross-sectional profile of the surface microstructure of the amorphous alloy prepared by nanosecond laser irradiation in this embodiment. The selected laser peak power intensity is 1 × 10 12 W / m 2 , the number of laser pulses is 50, and the argon pressure is 0.01MPa. It can be seen from the figure that under the irradiation parameters of this embodiment, a dimple structure is formed on the surface of the amorphous alloy. Wherein, the diameter of the dimple structure is about 53 μm, and the pit depth is about 115 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com