Self-assembly graphene nanometer thin film and preparing method and application thereof

A nano-film and graphene technology, applied in the field of materials, can solve the problems of polluting the environment, complex processes and equipment, and difficulty in preparing nano-scale graphene films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] More specifically, the invention provides a kind of preparation method of self-assembled graphene nano film, comprises the steps:

[0049] 1) providing a first dispersion liquid, a second solvent and a substrate, wherein the first dispersion liquid comprises a first solvent and a graphene-like material dispersed in the first solvent;

[0050] 2) adding the first dispersion liquid dropwise to the second solvent at a first rate, and obtaining a thin layer of the graphene-based material at the liquid level of the resulting mixed liquid based on the Marangoni effect;

[0051] 3) transferring the thin layer of the graphene-based material obtained in step 2) onto the substrate, and drying the resulting product to obtain a self-assembled graphene nanofilm.

[0052] In the present invention, the mixing volume ratio of the first dispersion liquid and the second solvent is 1:200˜1:5.

[0053]It should be understood that, in the present invention, the ratio of the surface tension...

Embodiment 1

[0072] Embodiment 1 Graphene nano film 1

[0073] The electrochemically exfoliated graphene was mixed with ethanol to prepare a dispersion with a concentration of 0.5 mg / mL, and placed in an ultrasonic machine for 60 min. Take 20mL of the ultrasonically dispersed dispersion, slowly drop it into 200mL of water, and self-assemble on the water surface to form a uniform thin layer. The formed thin layer was transferred to a quartz substrate, and dried at 60° C. for 60 minutes to remove residual water and dispersant to obtain a self-assembled graphene nanofilm 1 .

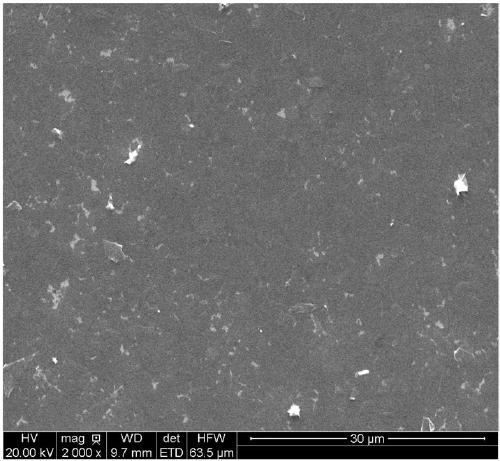

[0074] figure 1 It is the scanning electron micrograph of embodiment 1 gained self-assembled graphene nano film 1.

[0075] From figure 1 It can be seen that graphene is spliced into a relatively dense nanoscale film through self-assembly, and the coverage rate exceeds 99%.

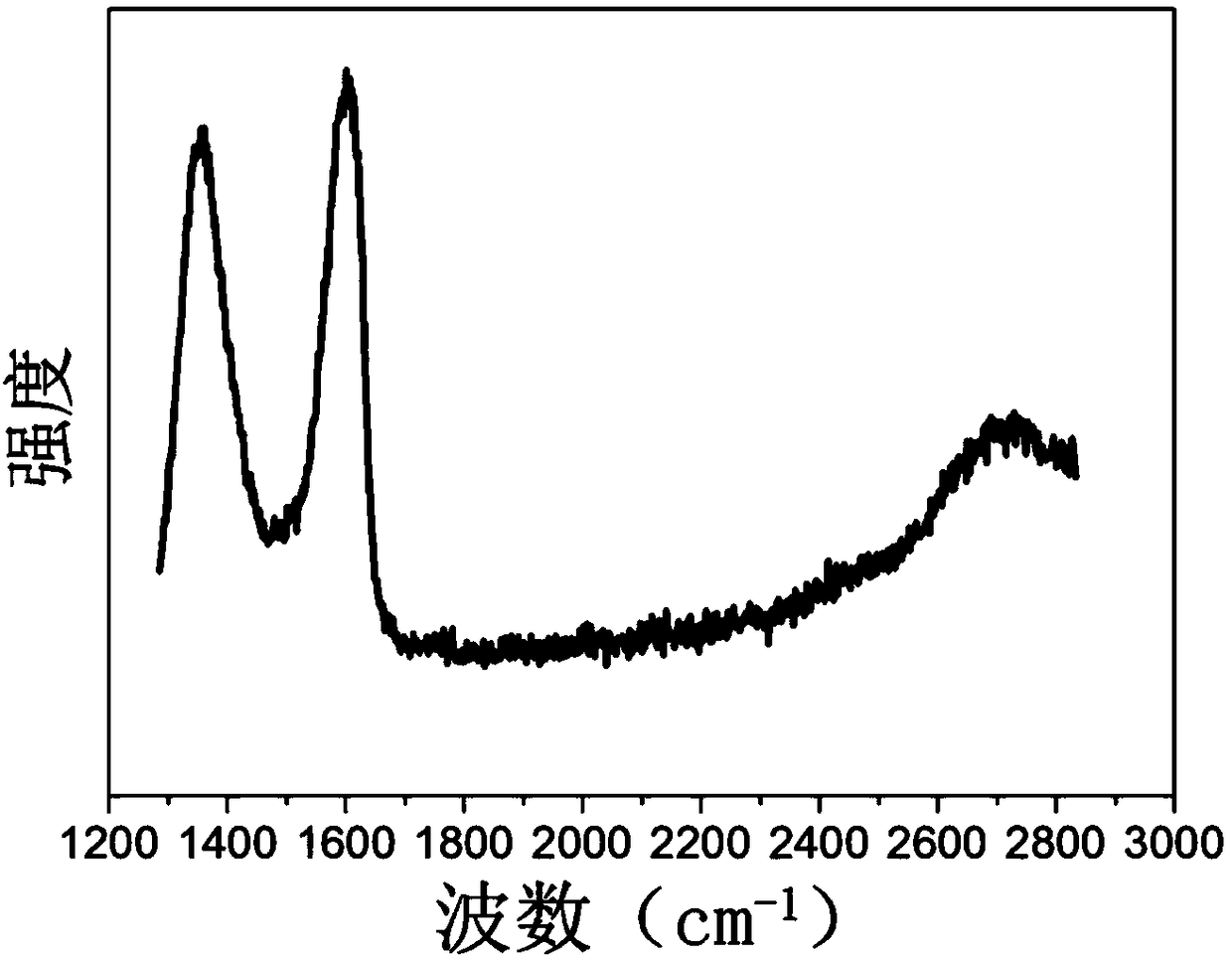

[0076] figure 2 It is the Raman graph of the self-assembled graphene nanofilm 1 obtained in embodiment 1.

[0077] From figure 2 It can...

Embodiment 2

[0081] Embodiment 2 graphene nano film 2

[0082] The electrochemically exfoliated graphene was mixed with methanol to form a dispersion with a concentration of 1 mg / mL, and placed in an ultrasonic machine for 60 min. Take 10mL of the ultrasonically dispersed dispersion and slowly add it dropwise (for example, at a rate of 20mL / min) into 200mL of water, and self-assemble on the water surface to form a uniform thin layer. The formed thin layer was transferred to a glass substrate, and dried at 60° C. for 60 minutes to remove residual water and dispersant to obtain a self-assembled graphene nanofilm 2 .

[0083] The performance of the graphene nano-film 2 obtained in embodiment 2 is similar to that of the graphene nano-film 1 obtained in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com